UV (Ultraviolet) curing white primer for laser roller painting of woodware and preparation and application methods thereof

A laser roller, white technology, applied in the direction of coating, polyester paint, epoxy resin paint, etc., can solve the problem that the laser roller thick coating surface is flat and close to the mirror surface, the sanding process cannot be carried out, and the laser roller cannot be applied Coating machine and other problems, to achieve the effect of increasing the amount of coating at one time, reducing the amount of abrasive belt used, and ensuring the fullness of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

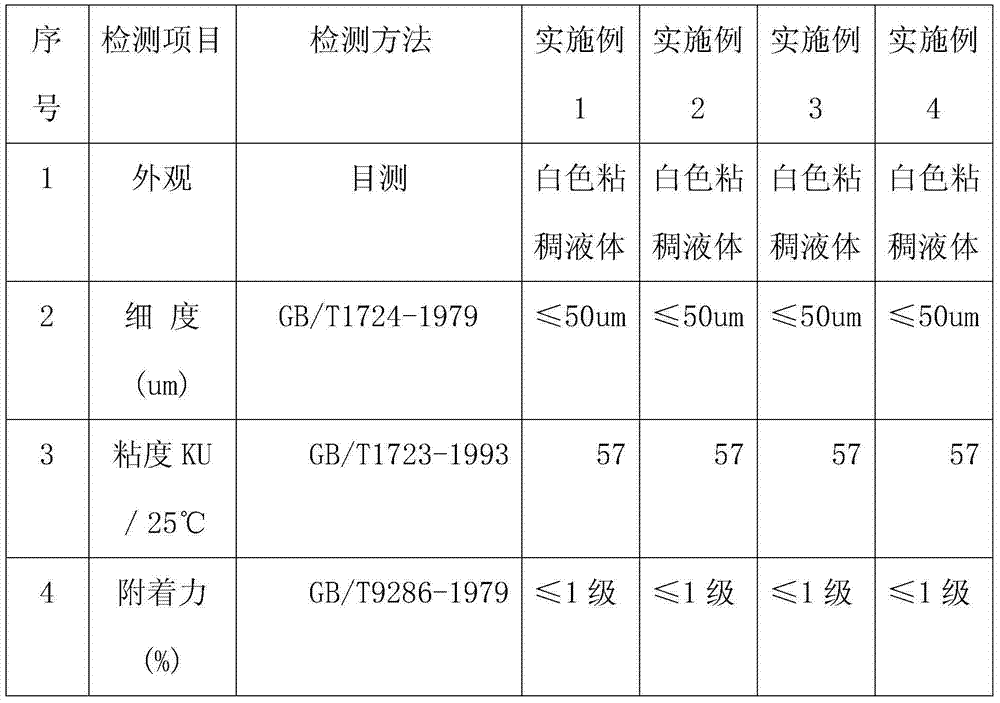

[0110] Get each component according to the weight listed in "Example 1" in Table 1, and the preparation method is as follows:

[0111] Step 1: Bisphenol A epoxy acrylate, polyester acrylate, polyurethane acrylate, reagent type hydroxyethyl acrylate (2-HEA), tripropylene glycol diacrylate (TPGDA), trimethylolpropane triacrylic acid ( TMPTA), photoinitiator TPO (Yingli), 184 (Yingli), wetting and dispersing agent EFKA4010 (Efka) were added to the container in sequence, and dispersed at 500PRM for 3-5 minutes until uniform;

[0112] Step 2: Add fumed silica A200 (Degussa), talcum powder LH-667 (Liaoning Qianhe) and titanium dioxide R902 (DuPont) sequentially while stirring. After adding, disperse at 1200RPM for 15-20 minutes until the fineness is ≤ 60 μm, 100 mesh filter to obtain the white primer of the present invention.

[0113] The using method of present embodiment white primer

[0114] Wooden veneer substrate - roll coating transparent putty 15-20g / ㎡ (semi-cured) - roll c...

Embodiment 2

[0117] With the weight of each component listed in "Example 2" in Table 1, repeat the method described in Example 1 (only the weight of each component changes), and make the special UV-curable white for wood laser roller coating of Example 2 Primer, carry out construction according to the usage method of example 1.

[0118] The routine performance test results are shown in the corresponding data of "Example 2" in Table 2.

Embodiment 3

[0120] With the weight of each component listed in "Example 3" in Table 1, repeat the method described in Example 1 (only the weight of each component changes), and make the special UV-curable white for wood laser roller coating of Example 3 Primer, carry out construction according to the usage method of example 1.

[0121] The routine performance testing results are shown in the corresponding data of "Example 3" in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com