Patents

Literature

323 results about "Tripropyleneglycol diacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet light curing transparent priming paint and preparation method and use method thereof

ActiveCN102952455AReduce lossImprove product qualityPolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycolPolyester

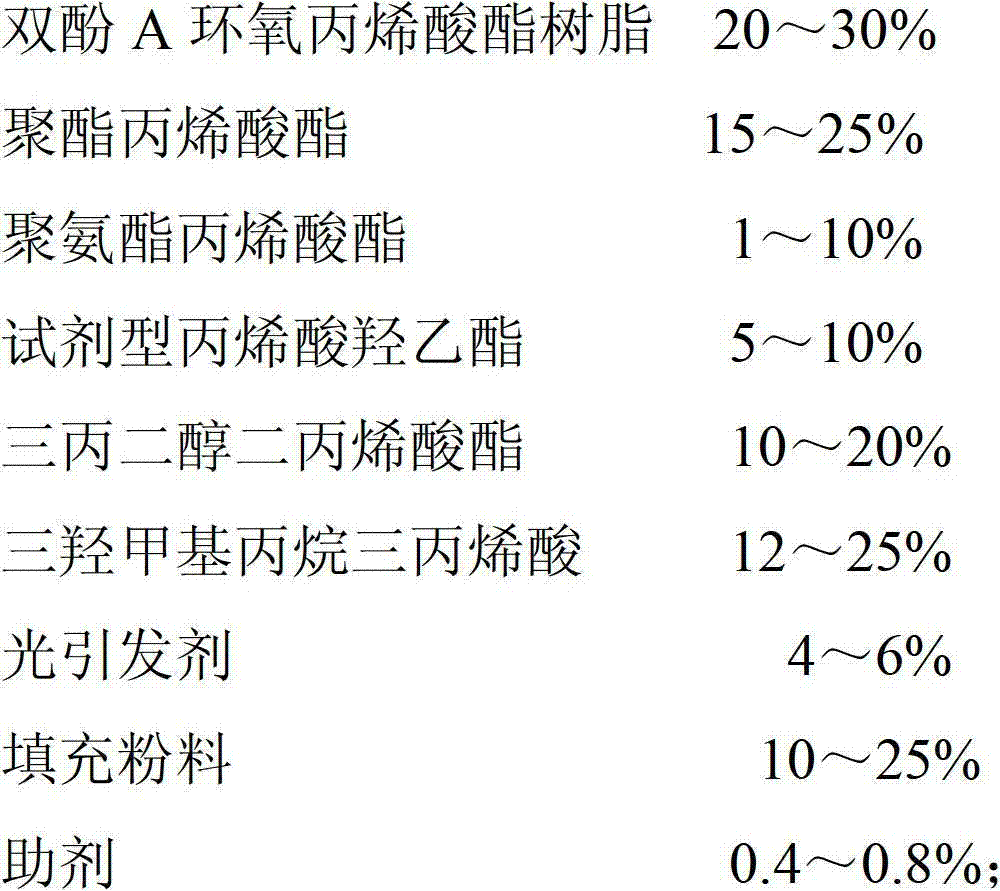

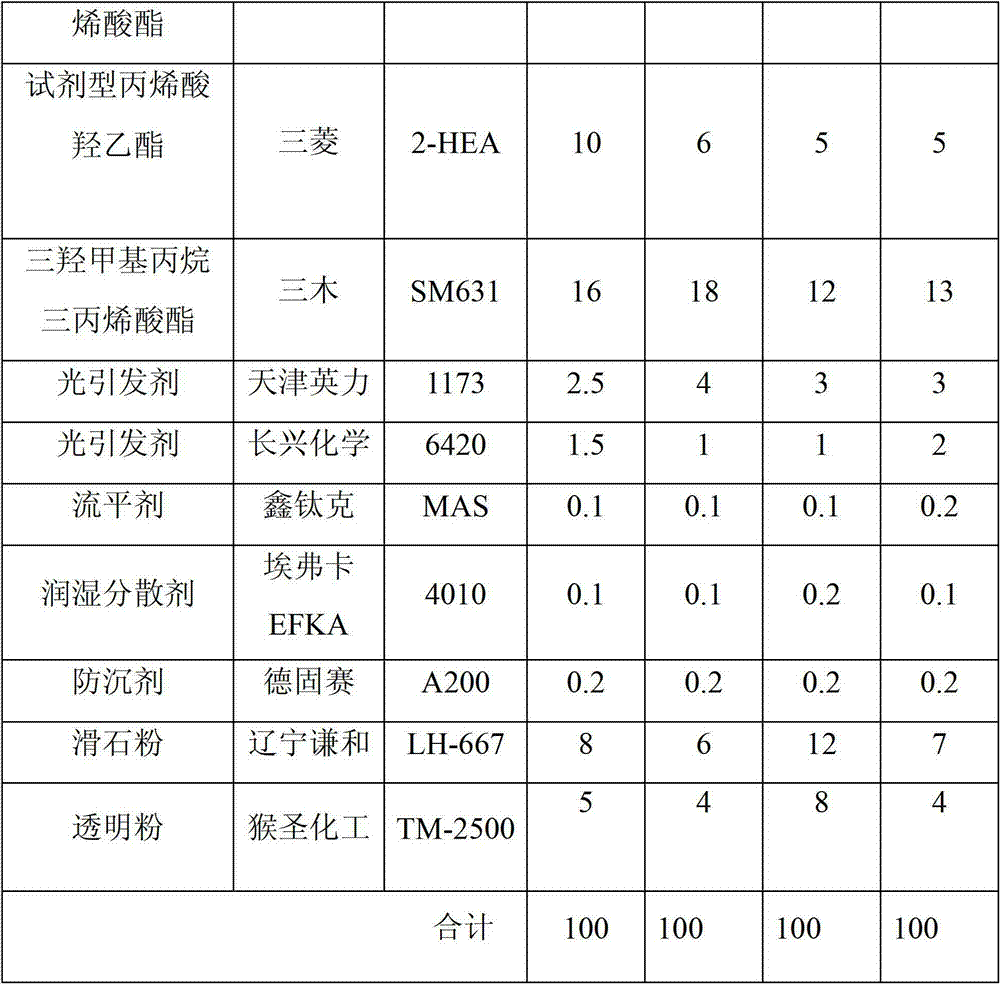

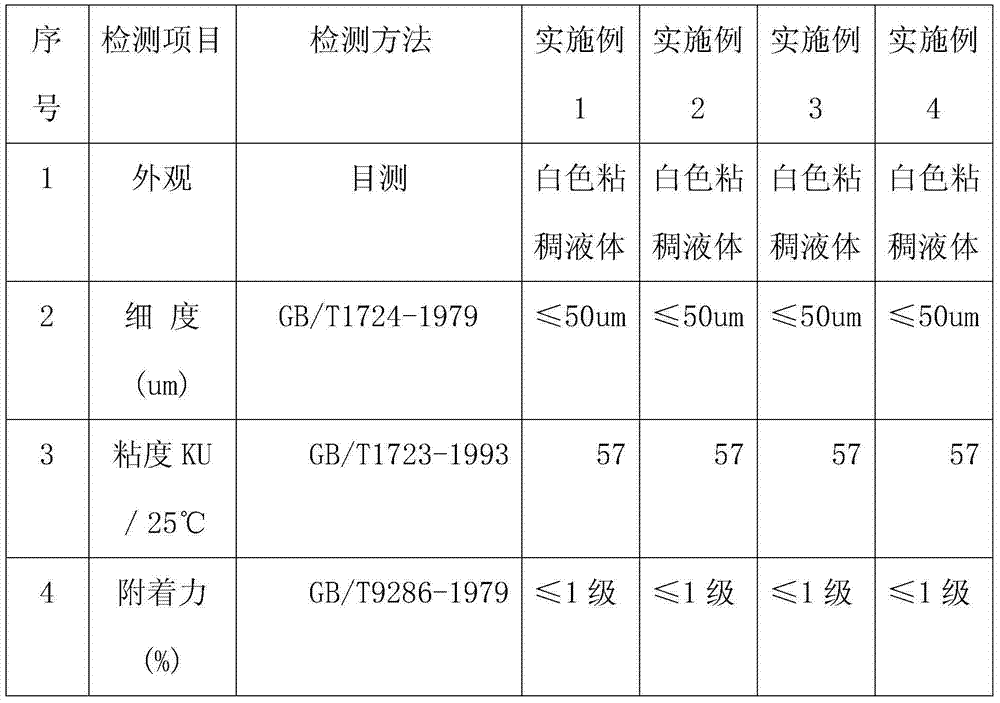

The invention discloses an ultraviolet light curing transparent priming paint and a preparation method and a use method thereof. The ultraviolet light curing transparent priming paint comprises the following components in percentage by weight: 20-30% of bisphenol A epoxy acrylate resin, 15-25% of polyester acrylate, 1-10% of urethane acrylate, 5-10% of reagent type hydroxyethyl acrylate, 10-20% of tripropylene glycol diacrylate, 12-25% of trimethylolpropane triacrylate, 4-6% of photoinitiator, 10-25% of filling powder and 0.4-0.8% of promotor. The ultraviolet light curing transparent priming paint is suitable for laser roller construction, has good grittiness and transparency, has the characteristics that sanding is not needed for semi-curing recoating between film layers and the like, and has thick coating performance and the performance that the surface is similar to a mirror surface, and compared with conventional roller coating, the coating weight is greatly increased, roller coating processes are saved, the priming paint is sanded by a sanding machine without large pressure and with a small number of sanded films, a workpiece has no bright spots, the fullness of a product is guaranteed, the product quality is improved, the loss of the machine is smallreduced, and the use amount of sanding belts is greatly reduced.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

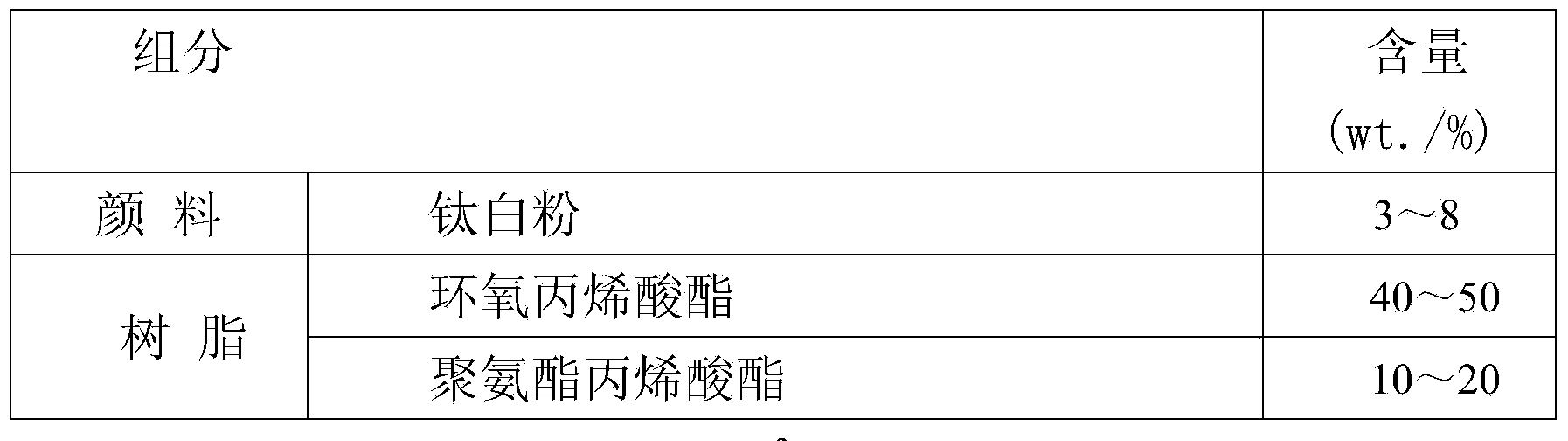

UV (Ultraviolet) curing white primer for laser roller painting of woodware and preparation and application methods thereof

InactiveCN103694862AReduce lossReduce usagePretreated surfacesPolyurea/polyurethane coatingsPolyesterUltraviolet

The invention discloses a UV (ultraviolet) curing white primer for laser roller painting of woodware, which has high coating quantity and flat and bright coated surface. The UV curing white primer comprises 15-25 percent of bisphenol A epoxy acrylate, 15-25 percent of polyester acrylate, 1-10 percent of polyurethane acrylate, 8-15 percent of tripropylene glycol diacrylate, 3-8 percent of reagent type hydroxyethyl acrylate, 10-25 percent of trimethylolpropane triacrylate, 5-8 percent of photoinitiator, 0.2-0.4 percent of wetting dispersant, 0.2-0.4 percent of anti-settling agent, 8-15 percent of talcum powder and 10-20 percent of titanium dioxide. The UV curing white primer has the characteristics that after laser roller painting construction is ended, the coating amount is capable of reaching 35-45g / m<2>, the coated surface is flat and bright, the covering power is stronger than that of a common roller painting UV white primer, and the semi-curing repainting between paint films is not required to be ground, and the like. When being used for performing coating, the UV curing white primer has the advantages of time and labor saving, high fullness of products, and less loss of a machine.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

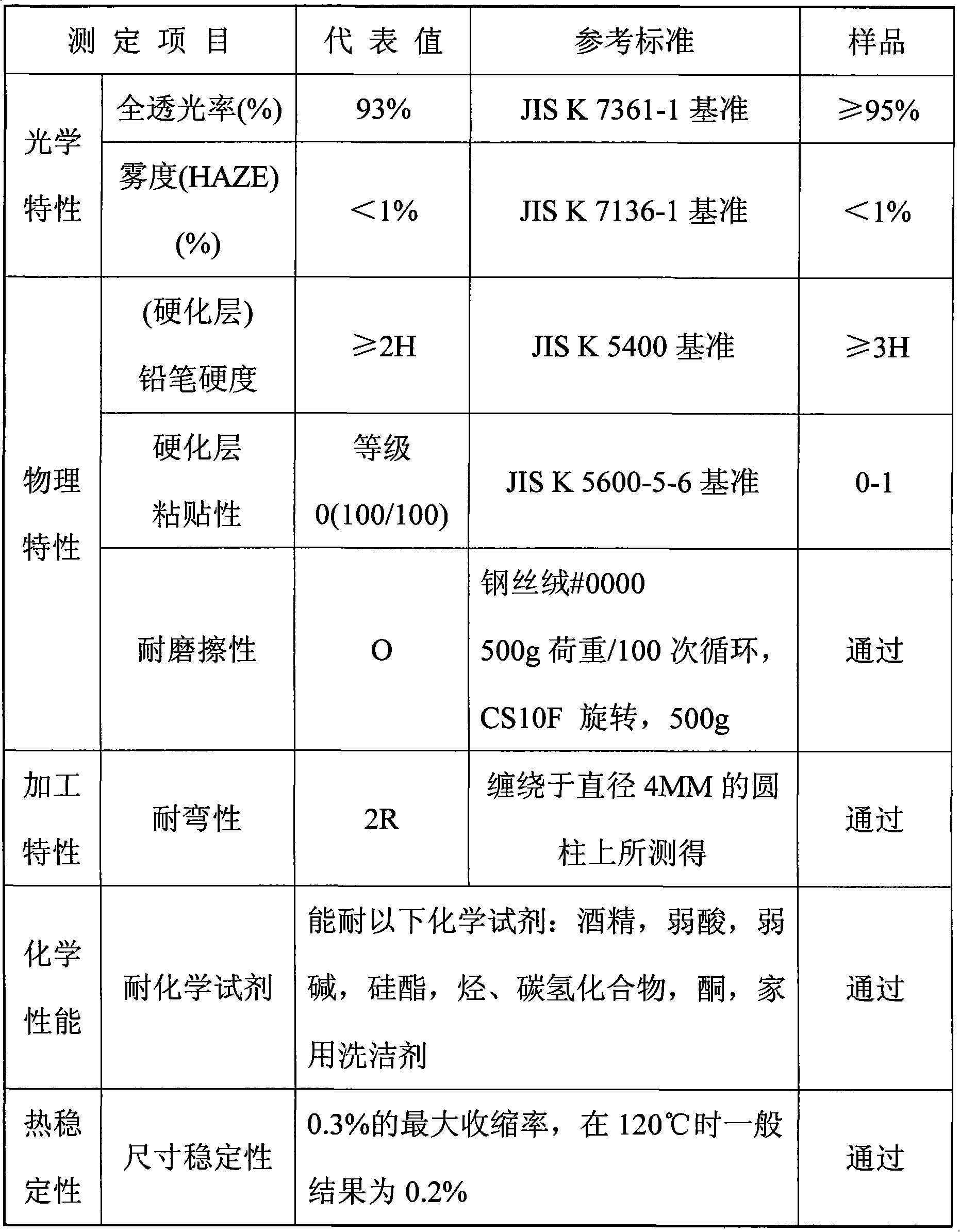

Preparation method of biaxially oriented polyester film surface wear-resistant scratch-resistant coating

InactiveCN101564720AImprove uniformitySolve pollutionPretreated surfacesPolyurea/polyurethane coatingsEpoxyWear resistant

A preparation method of biaxially oriented polyester (BOPET) film surface wear-resistant scratch-resistant coating relates to a preparation method of a BOPET film surface coating and solves the problems of high cost and poor wear resistance and scratch resistance of the coating when preparing the BOPET film surface wear-resistant scratch-resistant coating in the prior art. The preparation method of the invention includes the following steps of: uniformly mixing polyurethane hexa-acrylate, epoxy modified acrylate, dipentaerythritol monohydroxy hexa-acrylate, trimethylolpropane tri-acrylate, tripropylene glycol diacrylate, butyl titanate and compound cracking light trigger to obtain coating material; then coating the coating material on the BOPET film surface done with corona treatment, and finally obtaining the (BOPET) film surface wear-resistant scratch-resistant coating after ultraviolet curing. The BOPET film surface wear-resistant scratch-resistant coating has low cost and good wear resistance and scratch resistance, and the coating performance pencil hardness is over 3H.

Owner:HARBIN INST OF TECH

High gloss high abrasion resistance ultra-violet curing overprinting varnish of mobile phone and preparation method thereof

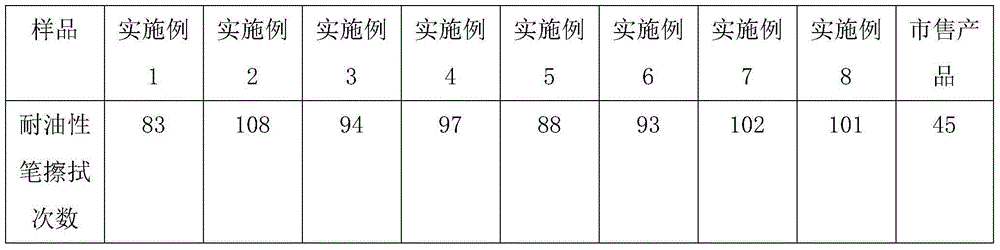

InactiveCN101967338AImprove wear resistanceHigh gloss and high wear resistancePolyurea/polyurethane coatingsPolyester coatingsIsooctyl acrylatePolyester

The invention discloses a high gloss high abrasion resistance ultra-violet (UV) curing overprinting varnish of mobile phone and a preparation method thereof. The method of the invention uses low-viscosity polyester acrylate and aliphatic polyurethane acrylate as base resin which combines with ethoxylated pentaerythritol tetraacrylate, Trimethylolpropane triacrylate, Tri(propylene glycol) diacrylate, 1,6-hexanediol diacrylate and 2-ethylhexyl acrylate which are used as active diluent, alcohol and ethyl acetate which are used as diluent, benzophenone and 1-hydroxycyclohexyl phenyl ketone which are used as photoinitiator, reactive amine coinitiator, defoaming agent, flatting agent, slip agent and other agents to mix evenly and prepare the UV overprinting varnish. The overprinting varnish of the invention adopts the special raw material formula and has good lustrousness, adhesive force and mechanical stability; as some polyfunctional resins and resins with special functional groups are added, the crosslink density of the UV varnish is increased in the curing process and the hardness of the product is up to 5-7H; and as solid wax powder used as the slip agent is added, the coefficients of friction can be reduced and the product can have extremely high wear resistance.

Owner:苏州凯康化工科技有限公司

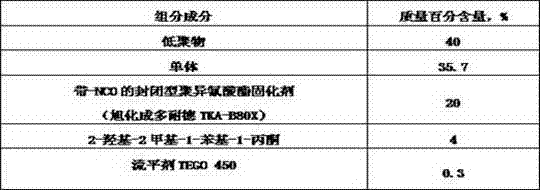

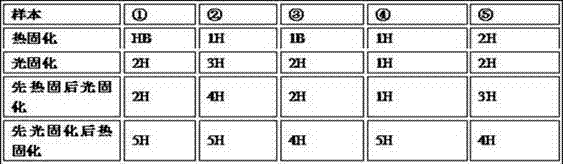

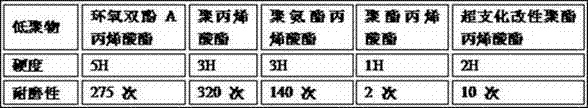

High-strength coating formed by virtue of photo-thermal dual-curing and preparation method thereof

InactiveCN104745055AUniform and dense spatially cross-linked network structureDense unimolecular space structurePolyurea/polyurethane coatingsPolymer scienceMeth-

The invention provides a coating which is formed under the condition of photo-thermal dual-curing and is good in hardness and high in wear resistance. The coating is obtained by performing UV (ultraviolet) curing at first and then performing thermal curing on the following materials in percentage by weight: 30-60% of a low polymer with -OH, 15-36% of a monomer with -OH, 19-30% of a closed type polyisocyanate curing agent with -NCO, 2-5% of a photoinitiator and 0.2-0.8% of an auxiliary agent, wherein the low polymer with -OH is bisphenol A epoxy acrylate, polyacrylate or polyurethane acrylate, and the monomer is one, two or three types of ethyl metrhacrylate, tri(propylene glycol) diacrylate or trimethylolpropane triacrylate. The polyurethane polymer and the polyacrylate polymer in the coating provided by the invention are crosslinked by virtue of chemical bonds, and a formed single-molecule space structure is more compact in structure, and is obviously improved on hardness and wear resistance. The invention also provides a preparation method of the coating.

Owner:汕头市大千高新科技研究中心有限公司

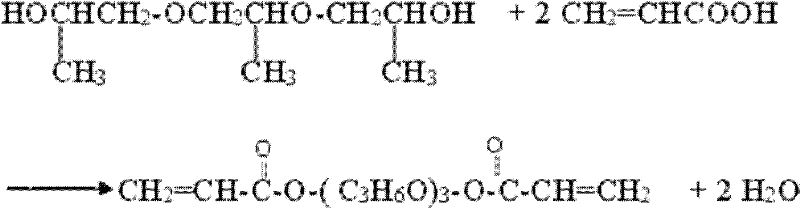

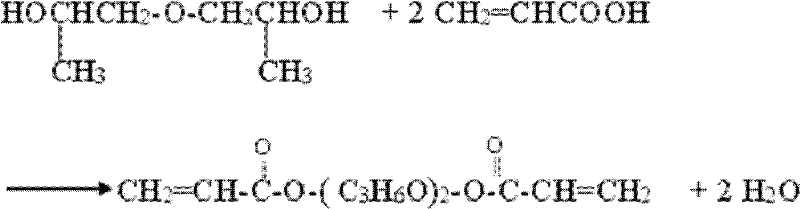

Clean production method of dipropylene glycol diacrylate (DPGDA) or tripropylene glycol diacrylate (TPGDA)

ActiveCN102491896ANo processing costsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters preparationTripropylene glycolDipropylene glycol diacrylate

The invention which belongs to the light-cured material field relates to a clean production method of DPGDA or TPGDA. The method concretely comprises the following steps: 1, carrying out esterification reflux dehydration on dipropylene glycol / tripropylene glycol, acrylic acid, a catalyst, a solvent, a polymerization inhibitor and an antioxidant; 2, adding sodium hydroxide and a small amount of water to neutralize; 3, adding a magnesium polysilicate adsorbent to adsorb a salt generated through neutralization; 4, carrying out reduced pressure dehydration and desolventization; 5, press-filtering to filter out magnesium polysilicate and the salt absorbed thereby; 6, adding alkaline calcium bentonit and calcium oxide to decolor, remove trace water and remove trace acids; 7, press-filtering; and 8, carrying out product index detection. The clean production method of the DPGDA or the TPGDA of the invention, which has the advantages of high yield, economic benefit possessing and environmental benefit possessing, fundamentally solves an organic wastewater pollution problem in the production process of the DPGDA or the TPGDA.

Owner:JIANGSU LITIAN TECH

Ceramic pulp for photo-curable 3D printing and preparation method and application of ceramic pulp

ActiveCN110627501AHigh viscosityAdditive manufacturing apparatusCeramic shaping apparatusTripropylene glycolMeth-

The invention discloses ceramic pulp for photo-curable 3D printing and a preparation method and application of the ceramic pulp. The ceramic pulp includes ceramic powder, photo-curable resin, a photoinitiator and a dispersant, wherein the photo-curable resin comprises the components: in percent by mass, 10-60% of bisphenol A epoxy acrylate, 10-60% of trimethylolpropane triacrylate, 10-60% of tripropylene glycol diacrylate and 10-60% of isobornyl methacrylate. The rheological performance of the slurry can be adjusted through selection of reactive diluents with different functionalities and adjustment of the ratio of the diluents, needs of light curing molding can be met by the slurry, and degreasing and sintering are performed on a molded sample so as to obtain a high-density zirconia ceramic product with a relative density of up to 98.8%.

Owner:SHENZHEN RES INST CENT SOUTH UNIV +1

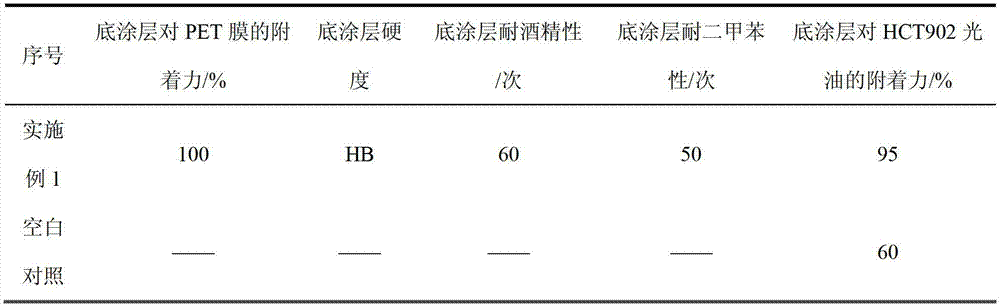

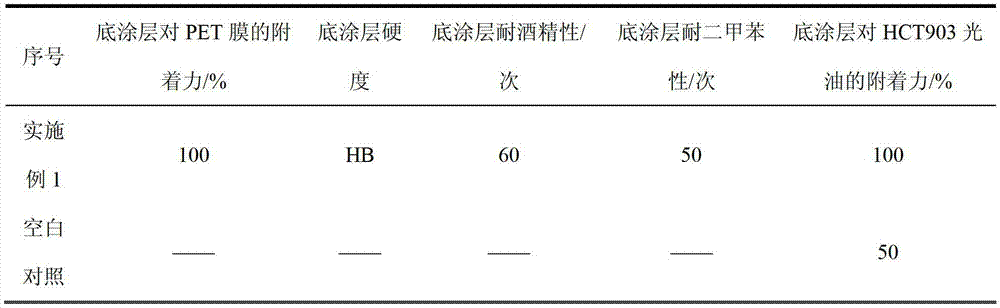

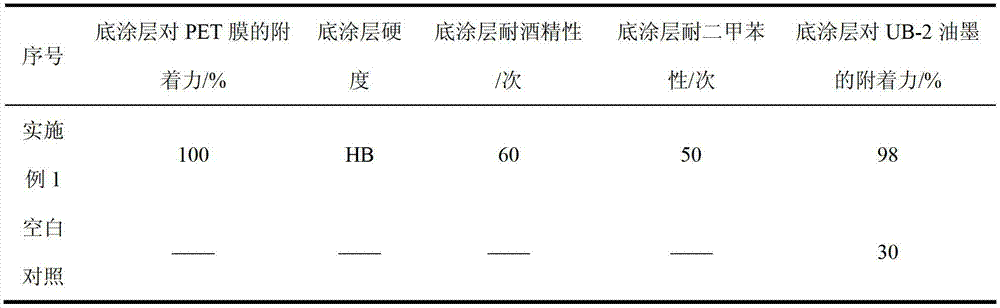

Ultraviolet-curable PET film surface treatment bottom sizing agent and preparing method and application thereof

The present invention discloses an ultraviolet-curable PET film surface treatment bottom sizing agent and a preparing method and an application thereof. The ultraviolet-curable PET film surface treatment bottom sizing agent is characterized by comprising, based on the mass percentage of 100%, 45% -55% of difunctional aliphatic carbamate-acrylate oligomers; 15% -20% of a trifunctional reactive diluent of trihydroxymethylpropyl trimethylacrylate; 15% -20% of a bifunctional reactive diluent of tripropylene glycol diacrylate; 1.5%-2.5% of a photo initiator of 2-hydroxy-2-methyl -1-phenyl acetone; 1.5% -2.5% of a photo initiator of 1-hydroxy cyclohexyl phenyl ketone and 5% -15% of ethyl acetate. The ultraviolet-curable PET film surface treatment bottom sizing agent of the invention can be applied to PET decoration materials, label materials and PET protective film surface treatment, and can improve adhesive force of UV ink and coatings.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Weather-resistant leather finishing agent

InactiveCN102977764AImprove wear resistanceSolve the defect of easy yellowingPolyurea/polyurethane coatingsLeather surface finishingTripropylene glycolPolymer science

Owner:QINGDAO WINCHANCE TECH

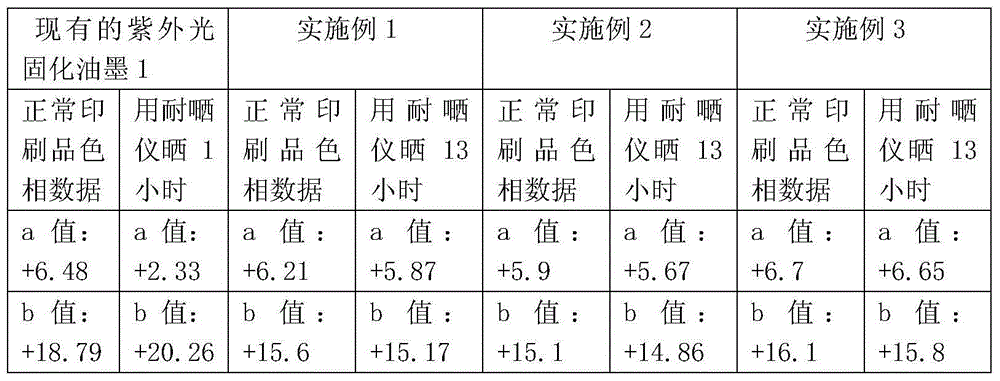

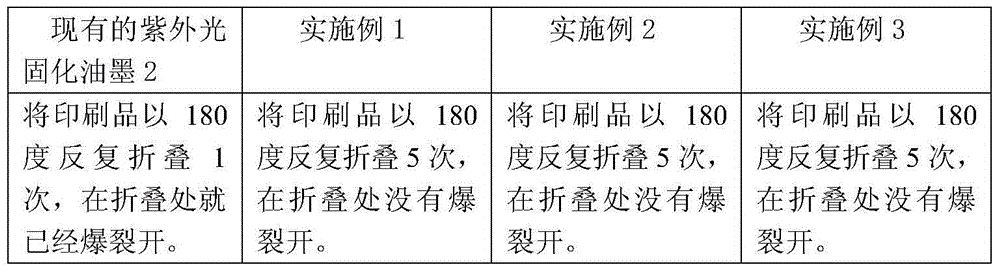

Ultraviolet curing ink and preparation method thereof

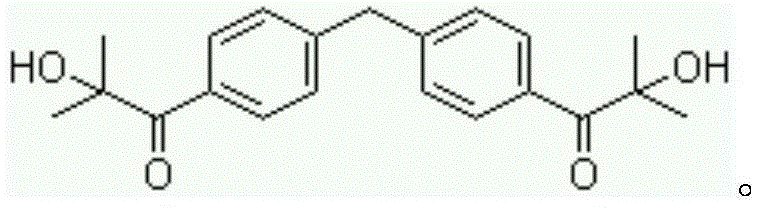

ActiveCN104804527AGood yellowing resistanceNot easy to yellowInksTripropylene glycolFolding endurance

Ultraviolet curing ink comprises the following components in weight proportion: 24-35% of polyurethane acrylate, 14-25% of epoxy acrylate, 15-25% of tripropylene glycol diacrylate, 15-25% of 1,1,1-trimethylol propane triacrylate, 0.5-2.5% of 1,1'-(methylenedi-4,1-phenylene)bis[2-hydroxyl-2-methyl-1-acetone],0.5-1.5% of Oligo[2-hydroxy-2-methyl-1-[4-(1-methylvinyl)phenyl]propanone], 0.1-1% of polydimethylsiloxane, 0.1-1% of polyether modified polysiloxane and 1-5% of polyethylene wax. The invention further provides the preparation method of the ultraviolet curing ink. According to the ultraviolet curing ink, an ink printing layer with a wrinkle effect is formed after the ultraviolet curing ink is cured after printing, and the ink printing layer has good anti-yellowing performance and good folding endurance.

Owner:SHANTOU DONGFENG PRINTING CO LTD

UV paint

InactiveCN101294011AImprove adhesionAccelerated corrosionPretreated surfacesPolyurea/polyurethane coatingsPhosphateAcrylic resin

The invention provides a UV coating used for stamped magnesium alloy. The UV coating mainly contains the following components: 43-62 weight parts of monomers, 3-7 weight parts of acrylate phosphate, 30-50 weight parts of polyurethane acrylic resin, 5-12 weight parts of aliphatic polyurethane acrylate, 6-10 weight parts of photoinitiator and 0.3-0.5 weight parts of levelling agents. The monomers include tripropylene glycol diacrylate and dipentaerythritol hexaacrylate. The photoinitiator is composed of 2-hydroxy-methoxyphenyl propane-1-one, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 1-hydroxyl cyclohexylphenyl ketone and Ciba initiator. The levelling agent is an organic silicon or organic silane levelling agent. The UV coating has good adhesion on an oxide layer and a passivation layer of the stamped magnesium alloy and has good corrosion resistance.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Medical antibacterial hydrogel dressing and preparation method thereof

InactiveCN106237374AImprove antibacterial propertiesShort hemostatic timeSurgical adhesivesBandagesArginineArginine ethylester

The invention discloses a medical antibacterial hydrogel dressing and a preparation method thereof. The hydrogel dressing is prepared from the following raw materials: thiolated chitosan, sodium glycerophosphate hydrate, carbomer, oxidized sodium alginate, L-arginine ethyl ester dihydrochloride, theophylline, glycine fumarate, L-carnitine powder, stachyose, hydroxyethyl methylacrylate, tri(propylene glycol) diacrylate, ginkgo flavonol, polyhexamethylene biguanidine, povidone iodine, alcoholic extract of herba andrographitis, triethanolamine and de-ionized water. The hydrogel dressing prepared by the invention can achieve inhibitory rates 91% and 94% or above on pseudomonas aeruginosa and staphylococcus aureus separately, and the hydrogel dressing has a broad-spectrum antibacterial property and a durable antibacterial effect; and in addition, the hemostasis time of the dressing is just 9-18s and healing time is shorter than 10d, and healed regenerated skin has a smooth and delicate surface; therefore, the hydrogel dressing is excellent in wound healing capacity and quite good in healing effect.

Owner:林春梅

Fingerprint resisting ultraviolet curing paint and operating method thereof

InactiveCN101570653ASolve the problem of not easy to remove and poor pollution resistanceEasy to removeAntifouling/underwater paintsPretreated surfacesPolymer modifiedUltraviolet

The invention discloses a fingerprint resisting ultraviolet curing paint which mainly comprises the following components according to the mass percent: 25-28 of stain resisting low polymer, 4-6 of multifunctional-group aliphatic urethane acrylate, 5-6 of urethane acrylate, 22-25 of polymer modified acrylate, 25-30 of tri(propylene glycol) diacrylate, 15-18 trimethylolpropane methylacrylate, 4-5 of 1-hydroxycyclohexy phenyl ketone, 0.4-0.5 of stain resisting photo-curing assistant, 0.1-0.3 of flatting agent and 120-130 of diluting agent. The invention develops the fingerprint ultraviolet curing paint which has fingerprint resisting effect, easy cleaning of permanent pen marks and better oil stain resistance and is used for a PC board by adopting stain resisting low polymer as main resin and adding the stain resisting photo-curing assistant in the formulation, and solves the problems that common ultraviolet curing paint is easily stained by fingerprints, the permanent pen marks are not easy to remove and the stain resistance is poor.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

High-fire-retardant ultraviolet curing coating

InactiveCN105038569AImprove wear resistanceStrong adhesionFireproof paintsPolyurea/polyurethane coatingsPolyethylene glycolDefoaming Agents

The invention discloses a high-fire-retardant ultraviolet curing coating. The high-fire-retardant ultraviolet curing coating comprises the following raw materials: urethane acrylate, epoxy acrylate, epoxidized soybean oil acrylate, phosphorus-containing acrylate, N-vinyl pyrrolidone, polyethylene glycol acrylate, tri(propylene glycol) diacrylate, pentaerythritol triacrylate, trimethylolpropane triacrylate, benzophenone, 2-methyl-2-hydroxyl-1-phenylacetone, coumarone, nano-silica, nano aluminum hydroxide, ammonium polyphosphate, silica powder, expanded graphite, a flattening agent, a defoaming agent, a wetting agent, a dispersant and a coupling agent. The high-fire-retardant ultraviolet curing coating disclosed by the invention is good in flame retardance property, high in adhesion force, excellent in comprehensive performance and long in service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

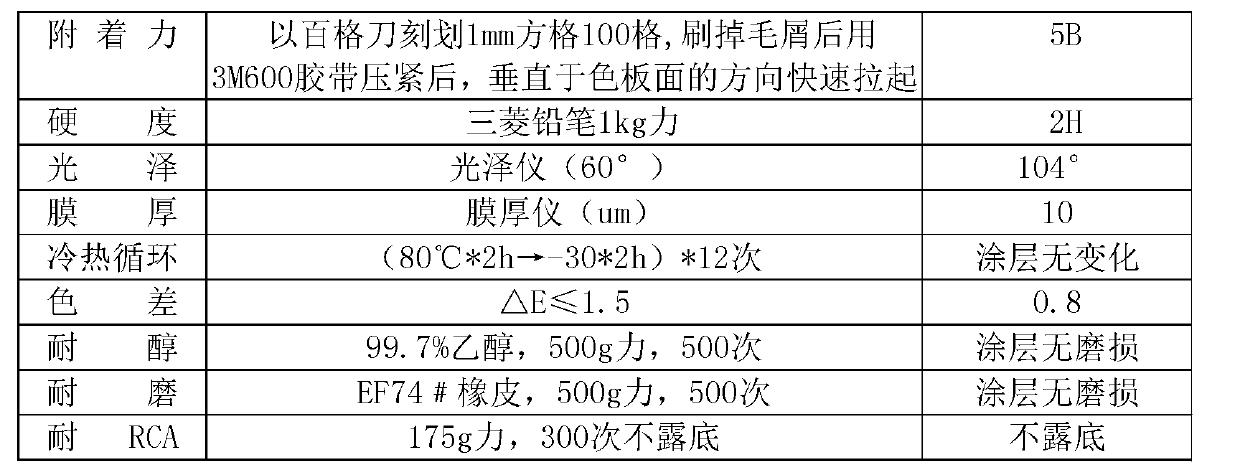

UV (Ultraviolet) varnish and preparation method thereof

ActiveCN103087626AStrong adhesionHigh hardnessPolyurea/polyurethane coatingsEpoxy resin coatingsSilanesEthyl acetate

The invention discloses a UV (ultraviolet) varnish and a preparation method thereof. The UV varnish is composed of the following raw materials in parts by weight: 50-60 parts of polyurethane acrylate, 10-20 parts of epoxy acrylate, 10-15 parts of ethyl acetate, 8-10 parts of toluene, 2-4 parts of 1,6-hexandiol diacrylate, 2-3 parts of tripropylene glycol diacrylate, 2-4 parts of 1-hydroxy-cyclohexy-phenyl ketone, 1-2 parts of 2,4,6-trimethyl benzoyl ethyl phenyl phosphoinate, 1-2 parts of zinc dialkyl dithiophosphate, 0.8-1 part of poly(butyl acrylate), 0.8-1 part of ehtanediamine, 0.8-1 part of N-2-(aimno ethyl)-3-aminopropyl trimethoxy silane, 0.8-1 part of ehtanediamine tetramethylene phosphornic acid sodium salt, 0.3-0.5 part of plant ash, 3-5 parts of modified complexing agent, and 2-4 parts of light calcium carbonate. The paint produced by the method disclosed by the invention is strong in adhesive force, good in paint film hardness and gloss, and strong in cold-heat circulating resistance, alcohol resistance and wear resistance; and the physical property of the paint film is further enhanced by the added modified complexing agent and light calcium carbonate.

Owner:惠州市汇流实业有限公司

UV film-pressed yellowing-resistant topcoat gloss paint

ActiveCN103289456ADry fastImprove the decorative effectPolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycolPolymer science

The invention provides an UV (Ultra Violet) film-pressed yellowing-resistant topcoat gloss paint, comprising the following components by weight percent: 35%-45% of functional monomer, 17%-23% of polyurethane acrylate, 26%-40% of epoxy acrylic resin, 0.2-0.3% of defoamer, 0.4%-0.6% of flatting agent and 5%-7% of photoinitiator. The functional monomer is a mixture of hydroxyethyl methacrylate, dipropylene glycol diacrylate, tripropylene glycol diacrylate and trimethylolpropane triacrylate. The UV film-pressed yellowing-resistant topcoat gloss paint provided by the invention is good in adhesive force, excellent in resistance to yellowing, low cost, simple and flexible to operate, high in drying speed, free of waste and high in production efficiency.

Owner:上海展辰涂料有限公司 +1

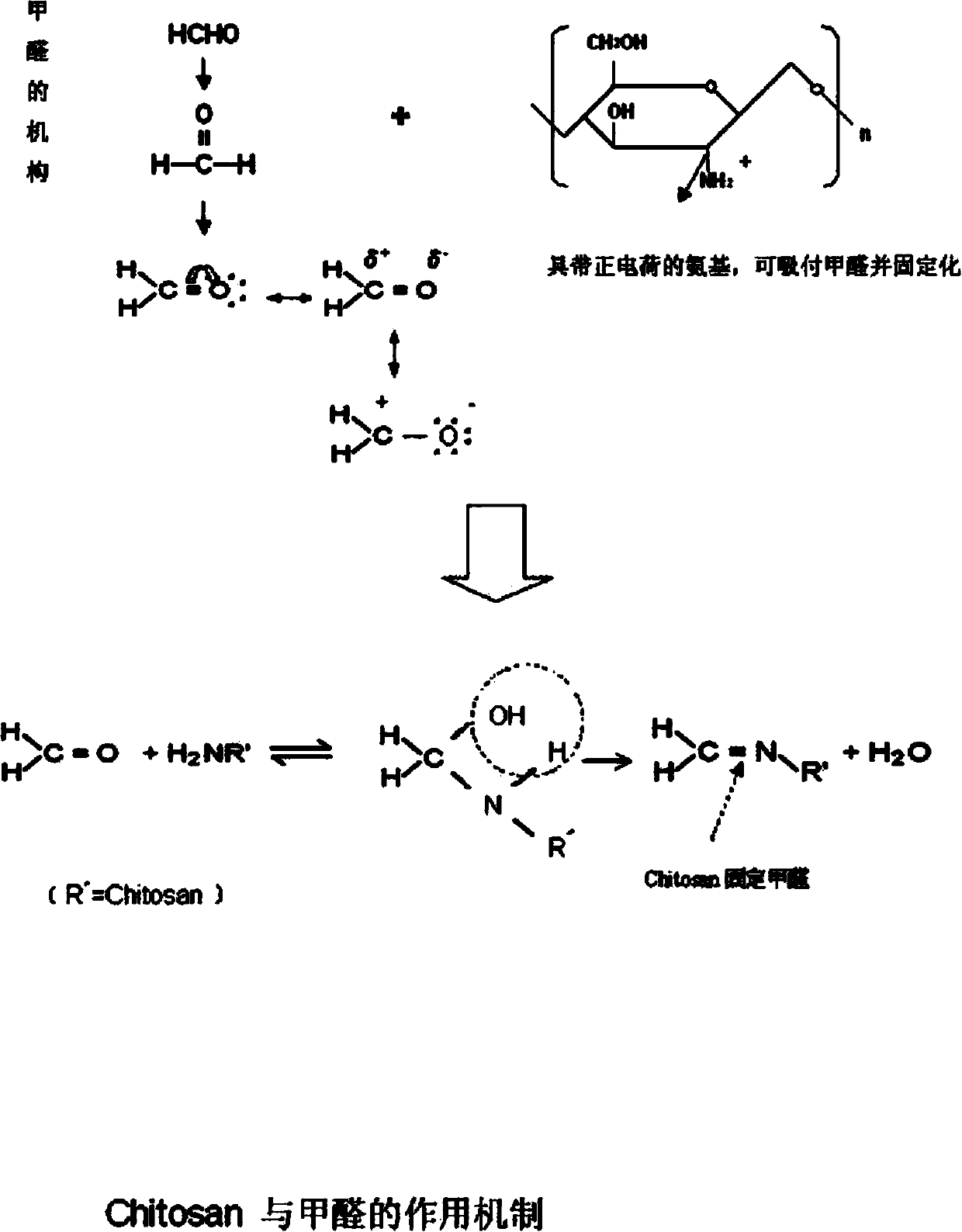

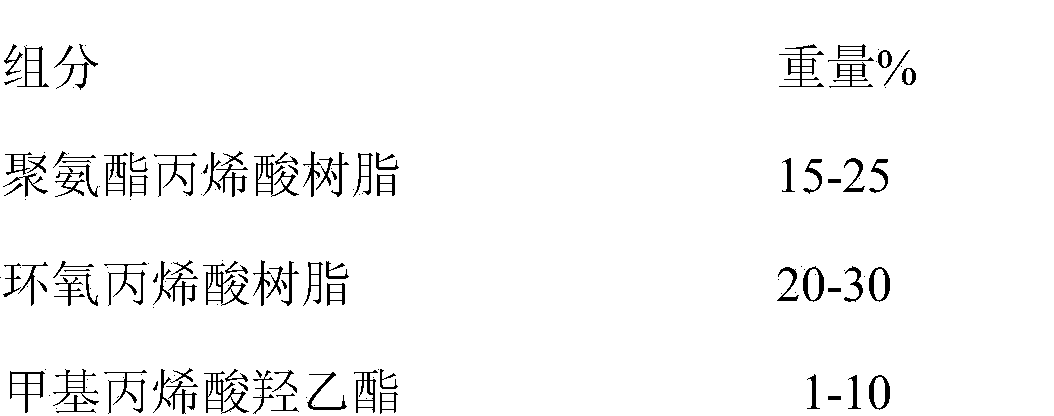

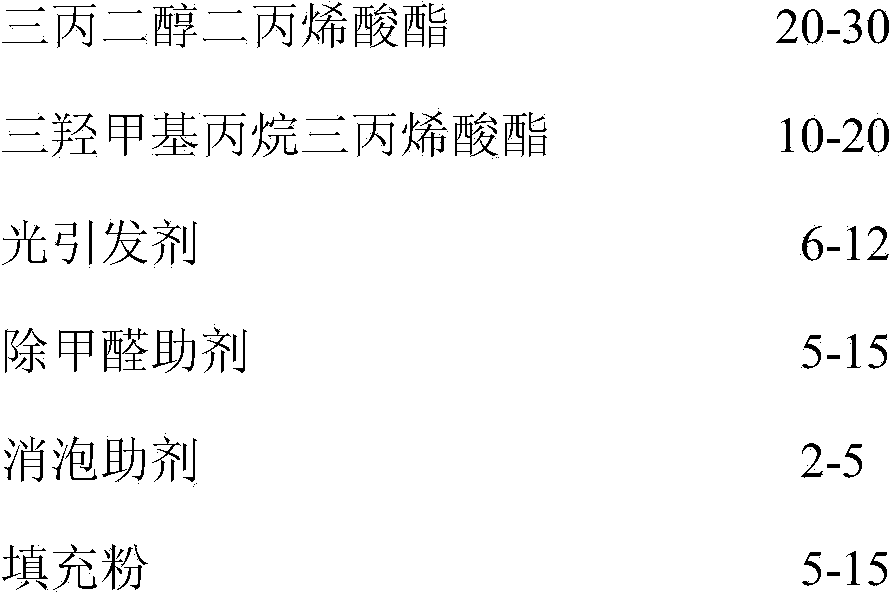

Novel photo-curing formaldehyde removing environment-friendly coating and preparation method of novel photo-curing formaldehyde removing environment-friendly coating

ActiveCN103589327AImprove toughnessImprove wear resistancePolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycol(Hydroxyethyl)methacrylate

The invention discloses a novel photo-curing formaldehyde removing environment-friendly coating and a preparation method of the novel photo-curing formaldehyde removing environment-friendly coating. The novel photo-curing formaldehyde removing environment-friendly coating comprises, by weight, 15-25% of polyurethane acrylic resin, 20-30% of epoxy acrylic resin, 1-10% of hydroxyethyl methylacrylate, 20-30% of tripropylene glycol diacrylate, 10-20% of trimethylolpropane trimethylolpropane triacrylate, 6-12% of photoinitiator, 5-15% of formaldehyde removing assistant, 2-5% of defoaming assistant and 5-15% of filling powder. The novel photo-curing formaldehyde removing environment-friendly coating prepared with the formula and the preparation method has the good formaldehyde purification performance and the good formaldehyde purification effect durability.

Owner:东周化学工业(昆山)有限公司

High-strength impact resistance oil paint

InactiveCN105255353AOvercoming impact resistanceOvercome the problem of large shrinkage during curingFireproof paintsPolyurea/polyurethane coatingsAcrylic resinPolyethylene glycol

The invention discloses high-strength impact resistance oil paint. The high-strength impact resistance oil paint is prepared from polyurethane acrylic resin, epoxy-acrylic resin, bisphenol A epoxy resin, ethylene diglycidyl ether, polyethylene glycol, 2-propenoic acid,1,1'-[(1-methyl-1,2-ethanediyl)bis[oxy(methyl-2,1-ethanediyl)]]ester, pentaerythritol triacrylate, azodiisobutyronitrile, 1-hydroxycyclohexylphenylketone, triarylsulfonium hexafluoroantimonate salt, carbon black, graphene oxide, carbon nanotubes, cresyl diphenyl phosphate, a flatting agent, an antifoaming agent, a thickening agent, a silane coupling agent, phenolic epoxy acrylate, solvent and corrosion inhibitor. The high-strength impact resistance oil paint is good in impact resistance, excellent in anti-static property, high in strength, high in adhesive force with a base material and not prone to be disengaged in the using process.

Owner:安徽嘉年华漆业有限公司

UV metal printing ink and preparation method thereof

The present invention relates to a UV metal printing ink and a preparation method thereof. The UV metal printing ink contains, by weight, 22.6% of chlorinated modified polyester acrylate, 15-25% of an adhesive force promoter, 5-10% of an active monomer, 7% of a composite photoinitiator, 35-50% of a metal pigment, 0.2% of a scratch-resistant auxiliary agent, and 0.2% of a polymerization inhibitor, wherein the active monomer is one selected from tri(propylene glycol) diacrylate, trimethylolpropane triacrylate and neopentyl glycol diacrylate or a composition comprising tri(propylene glycol) diacrylate, trimethylolpropane triacrylate and neopentyl glycol diacrylate. The present invention further provides a preparation method for the UV metal printing ink. With the UV metal printing ink, the direct adhesive force with the substrate can be enhanced.

Owner:SHENZHEN XINHUAYI PRINTING

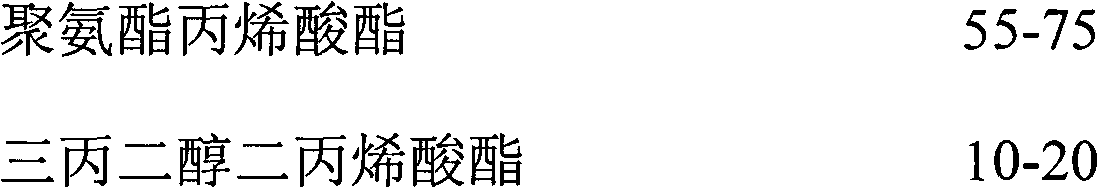

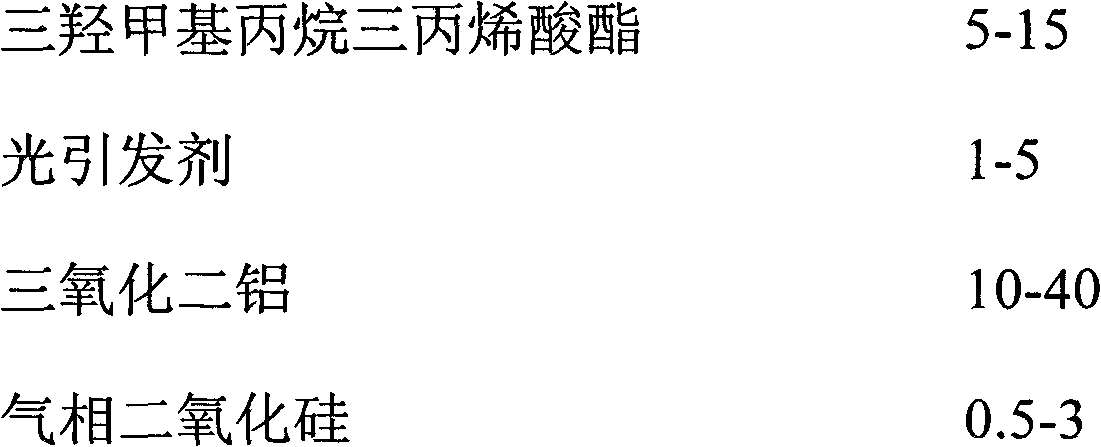

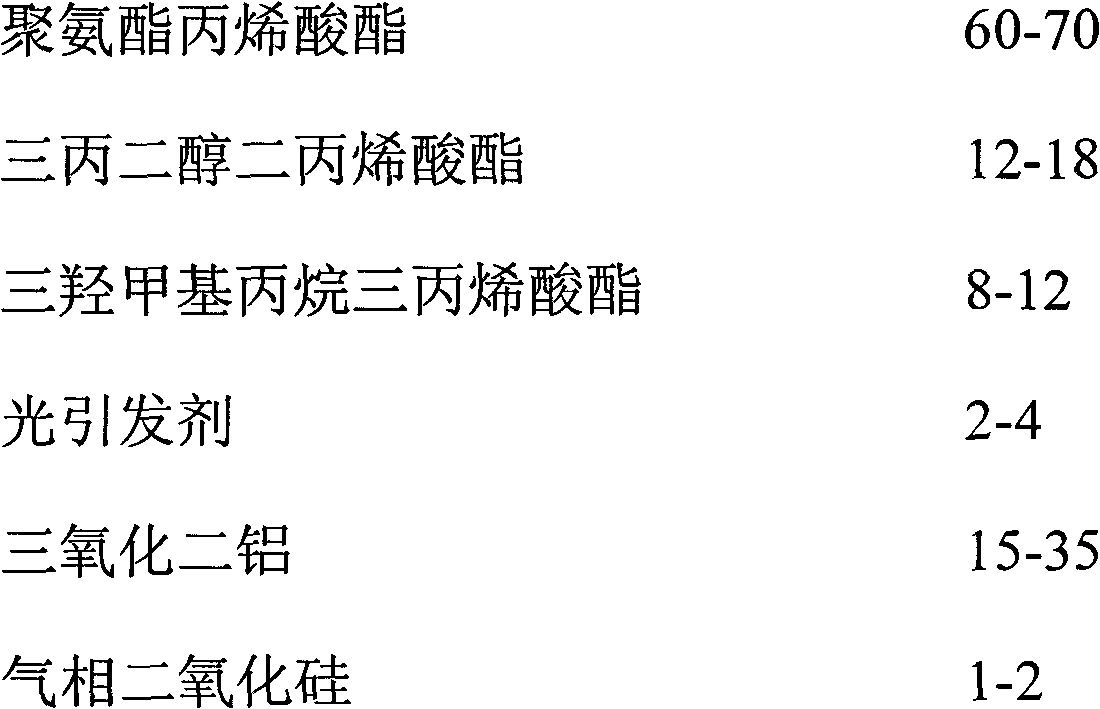

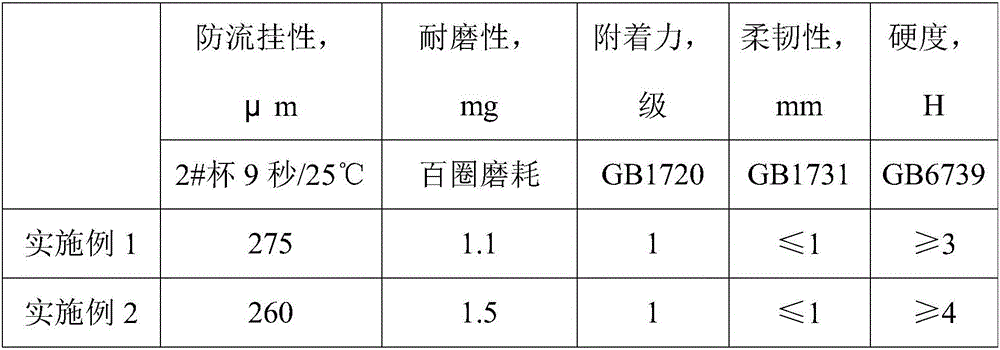

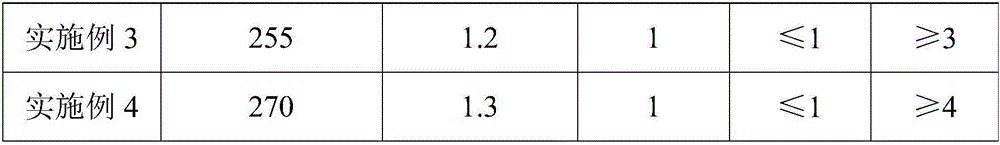

Ultraviolet wear resistant primer and preparation method thereof

ActiveCN102618163AImprove clarityImprove wear resistancePolyurea/polyurethane coatingsTripropylene glycolWear resistant

The invention discloses an ultraviolet wear resistant primer and a preparation method thereof. The ultraviolet wear resistant primer comprises the following components in parts by weight: 55-75 of urethane acrylate, 10-20 of tripropylene glycol diacrylate, 5-15 of trimethylolpropane triacrylate, 1-5 of photoinitiator, 10-40 of aluminum oxide and 0.5-3 of fumed silica. The preparation method provided by the invention comprises the following steps of: firstly mixing, dissolving and stirring the tripropylene glycol diacrylate and the trimethylolpropane triacrylate, then adding the photoinitiator and stirring, adding the urethane acrylate for blending and stirring, adding the fumed silica and the aluminum oxide while stirring, stirring for 10-20 minutes after addition, resting for 1-2h, and filtering by using a filter screen to obtain the ultraviolet wear resistant primer. The ultraviolet wear resistant primer provided by the invention has good wear-resistant performance and high hardness; after wood floors are coated by the ultraviolet wear resistant primer, and the wood floors have good whole definition; and the formula is simple and reasonable. The preparation method provided by the invention has the advantages that the technology is simple and the processing is convenient.

Owner:上海蓝宝涂料有限公司

High abrasion-resistant UV (ultraviolet) white primer for electrostatic spraying

InactiveCN106833295AGuaranteed mechanical strengthModerate molecular weightFireproof paintsEpoxy resin coatingsAcrylic resinPolyamide

The invention relates to a high abrasion-resistant UV (ultraviolet) white primer for electrostatic spraying. The high abrasion-resistant UV white primer is prepared from the following raw materials in parts by weight: 40 to 70 parts of epoxy acrylic resin, 15 to 35 parts of hydroxy acrylic resin, 10 to 20 parts of thermoplastic acrylic resin, 15 to 30 parts of tripropylene glycol diacrylate, 5 to 25 parts of modified graphene, 2 to 6 parts of nanometer silicon dioxide, 1 to 5 parts of nanometer titanium dioxide, 1 to 5 parts of heavy calcium carbonate, 5 to 15 parts of montmorillonite, 10 to 20 parts of white pigment, 2 to 5 parts of zinc stearate, 2 to 6 parts of carboxymethyl cellulose sodium, 1 to 5 parts of polyamide wax, 0.5 to 2 parts of flatting agent, 0.1 to 0.5 part of defoaming agent, 2 to 6 parts of photoinitiator, and 5 to 15 parts of organic solvent. The high abrasion-resistant UV white primer for electrostatic spraying has the advantage that at the premise of ensuring the good electrostatic spraying effect, the anti-sagging property of the primer and the abrasion-resistant property of the primer film are greatly improved.

Owner:TIANCHANG JINLING ELECTRONICS

UV photoluminescence ink

InactiveCN102977683ARaw materials are cheap and easy to getLow costInksPigment treatment with organosilicon compoundsPolyesterCredit card

The present invention discloses a UV photoluminescence ink, and belongs to the field of printing ink preparation. The UV photoluminescence ink is characterized in that modified ZnS:Cu is adopted as a luminescence material, a mixture of an epoxy acrylic acid resin and a polyester acrylate resin is adopted as a prepolymer, a mixture of trimethylolpropane triacrylate and tripropylene glycol diacrylate is adopted as a diluted monomer, a photoinitiator, an accelerator, an antifoaming agent and the like are matched, and uniform mixing is performed to obtain the finished product. The UV photoluminescence ink can be widely applicable for printing on securities, tax receipts, invoices, credit cards and other valuable bills.

Owner:HUNAN UNIV OF TECH +1

White ultraviolet curing finishing coat

ActiveCN103709906AFast curingIncrease productivityPolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycol(Hydroxyethyl)methacrylate

The invention discloses a white ultraviolet curing finishing coat which consists of the following components by weight percent: 50-70 percent of resin, 23-40 percent of an acrylate compound monomer, 4.5-9.5 percent of a photo-initiator and 0.3-3.0 percent of an aid, wherein the resin is a mixture consisting of epoxy acrylate and urethane acrylate; the acrylate compound monomer is one or a mixture of two of hydroxyethyl methylacrylate, tripropylene glycol diacrylate, 1,6-hexanediol diacrylate, dipropylene glycol diacrylate and trimethylolpropane triacrylate. The white ultraviolet curing finishing coat can be sprayed instead of the conventional solvent based coating, and has the advantages of high curing speed, high production efficiency, lower plate production cost, energy saving, carbon reduction and the like.

Owner:东周化学工业(昆山)有限公司

Ultraviolet-curable pollution-resistant coating

ActiveCN104152010AImprove featuresFast curingAntifouling/underwater paintsPaints with biocidesPolyesterPentaerythritol

The invention discloses an ultraviolet-curable pollution-resistant coating. The ultraviolet-curable pollution-resistant coating is prepared from the following components in parts by weight: 60-75 parts of modified epoxy acrylate, 58-68 parts of epoxy acrylate, 20-25 parts of urethane acrylate, 30-35 parts of polyester modified acrylate, 12-18 parts of pentaerythritol pentaacrylate, 13-23 parts of tripropylene glycol diacrylate, 7-8 parts of pollution-resistant photocuring auxiliary, 1-8 parts of photoinitiator, 32-39 parts of diluent and 2-4 parts of a flatting agent. The ultraviolet-curable pollution-resistant coating is an ultraviolet-curable coating which can be cured instantaneously under ultraviolet irradiation at a room temperature; besides, the ultraviolet-curable pollution-resistant coating has excellent pollution resistance and iodine resistance, and is capable of achieving the purposes of energy conservation, environmental protection and fast curing.

Owner:ZHANGJIAGANG DAWN CHEM

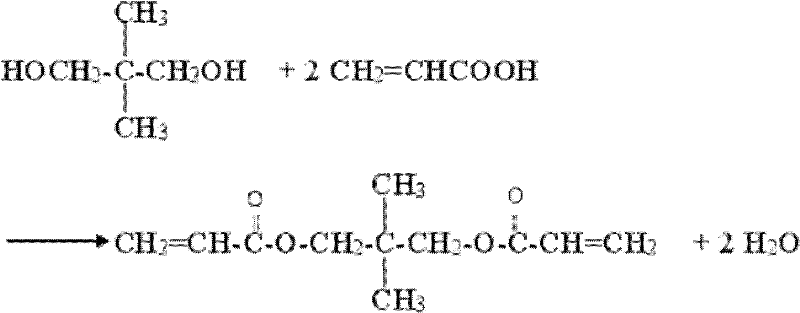

Method for preparing tri(propylene glycol) diacrylate

ActiveCN101462954AWide variety of sourcesEasy to getOrganic compound preparationCarboxylic acid esters preparationTripropylene glycolSolvent

The invention belongs to a method for preparing tripropylene glycol diacrylate ester, comprising the steps as follows: (1) tripropylene glycol, acrylic acid, catalyst, solvent and polymerization inhibitor are put into a reaction kettle to be fully mixed and stirred, so as to form a mixture; (2) a steam valve of the reaction kettle is opened to slowly heat the mixture to the temperature of 70-90 DEG C for a 20-40min reaction; (3) when the temperature is continued to be increased to 80-115 DEG C, reflow is carried out for 3-5h and then the reaction is finished; (4) soda water solution and sodium chloride water solution are added into the mixture and after washing the upper organic phase is extracted; (5) the upper organic phase is separated from the solvent; (6) and then cooling and filter pressing are carried out to obtain the end product. The method is simple in process, produces few by-products or little waste water, has good activity and flexibility, low color intensity, acidity, viscosity, and shrinking percentage, high yield coefficient and good quality.

Owner:TIANJIN CHEM REAGENT RES INST

Fingerprint resisting UV light oil and operating method thereof

ActiveCN101570652AEasy to removeSolve the problem of not easy to remove and poor pollution resistanceAntifouling/underwater paintsPaints with biocidesPolymer modifiedUrethane acrylate

The invention discloses fingerprint resisting UV light oil which mainly comprises the following components according to the weight portion: 30-35 of stain resisting low polymer, 5-6 of urethane acrylate, 15-18 of polymer modified acrylate, 15-18 of tri(propylene glycol) diacrylate, 25-30 trimethylolpropane methylacrylate, 4-5 of 1-hydroxycyclohexy phenyl ketone, 0.4-0.5 of stain resisting photo-curing assistant, 0.1-0.3 of flatting agent and 120-140 of diluting agent. The invention develops the fingerprint UV light oil which has fingerprint resisting effect, easy cleaning of permanent pen marks and better oil stain resistance and is used for an ABS+PC plastic piece by adopting stain resisting low polymer as main resin and adding the stain resisting photo-curing assistant in the formulation, and solves the problems that common UV light oil is easily stained by fingerprints, the permanent pen marks are not easy to remove and the stain resistance is poor.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

UV paint

The invention discloses a UV coating, which mainly includes the following components, the content of which is expressed in parts by weight: tripropylene glycol diacrylate 10-25; dipentaerythritol hexaacrylate 0-15; acrylate phosphate 3-7 Acrylic resin 10-20; Acrylic acid metal salt 5-15; Photoinitiator 2.0-3.0; Defoamer 0-0.3; Acrylic acid metal salt) as an adhesion promoter, has good adhesion and corrosion resistance on the magnesium alloy oxide layer and passivation layer.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

Environment-friendly light-curing electrostatic spraying primer

InactiveCN102732137ALow viscosityIncrease moisturePolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterAcrylic resin

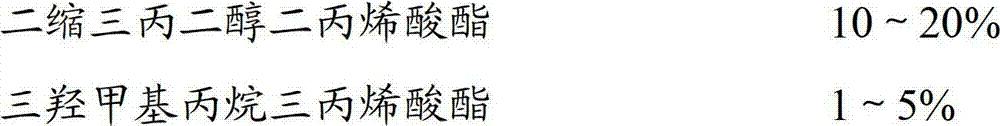

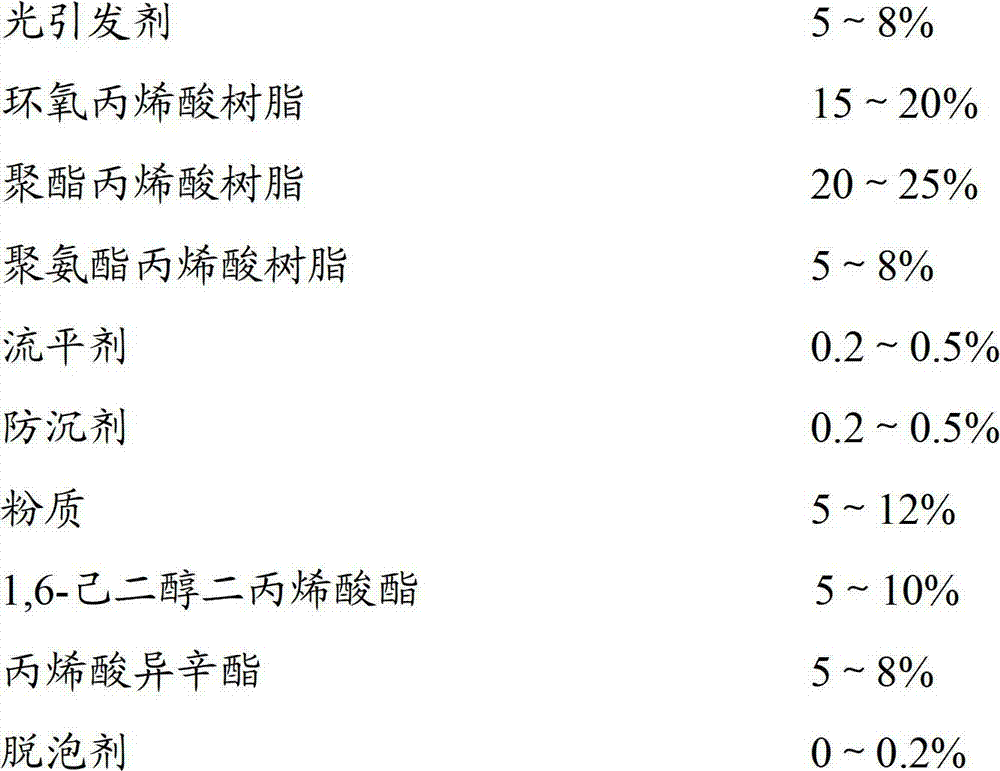

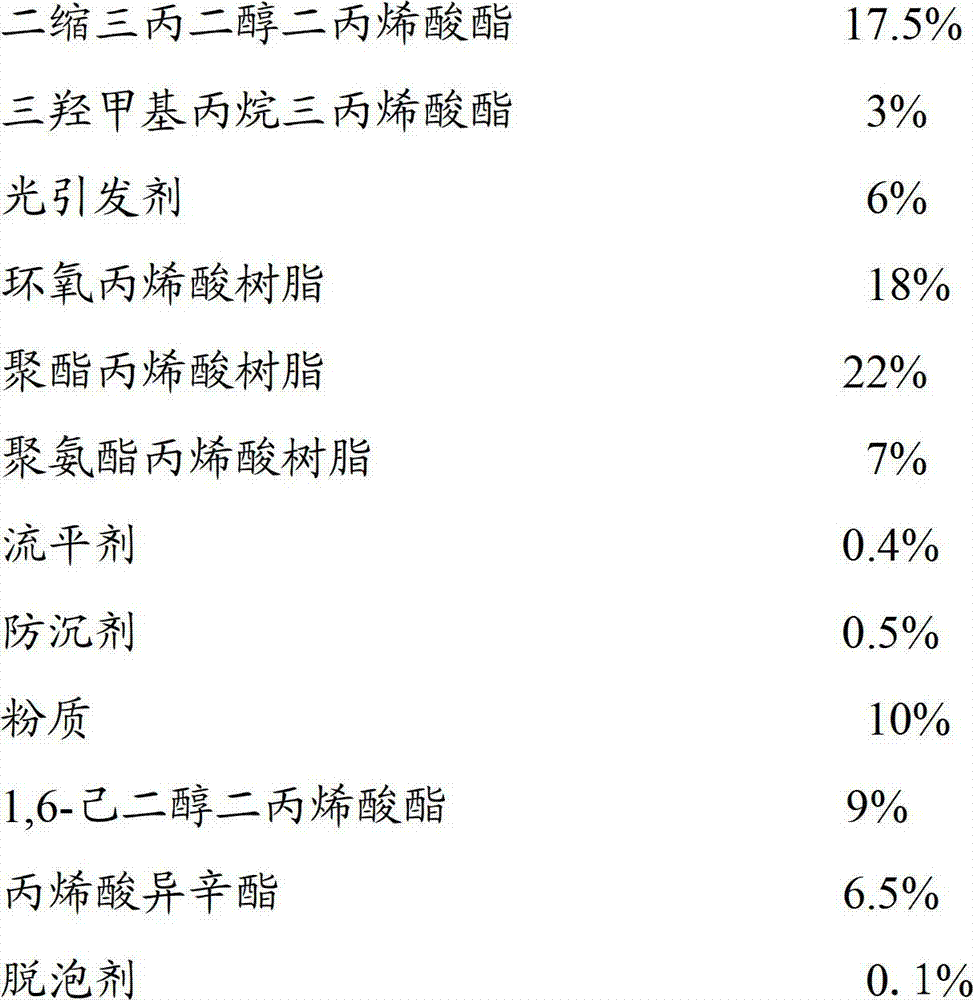

The invention provides an environment-friendly light-curing electrostatic spraying primer, comprising the following components in percentage by weight: 10-20% of 2-Propenoic acid,1,1'-[(1-methyl-1,2-ethanediyl)bis[oxy(methyl-2,1-ethanediyl)]] ester, 1-5% of trimethylolpropane triacrylate, 5-8% of a photo-initiator, 15-20% of epoxy acrylate, 20-25% of polyester acrylic resin, 5-8% of polyurethane acrylic resin, 0.2-0.5% of a flatting agent, 0.2-0.5% of an anti-settling agent, 5-12% of flour, 5-10% of 1,6-hexanediol diacrylate, 5-8% of 2-ethylhexyl acrylate and 0-0.2% of a defoaming agent. The light-curing electrostatic spraying primer adopts a UV monomer with low viscosity and strong dilution capacity to replace an original solvent, contains no VOC (Volatile Organic Compounds), can be recycled and belongs to green and environment-friendly paints; UV resin with low viscosity and good wettability is used as main resin so that the content of solid paint is high; and the light-curing electrostatic spraying primer can be directly applied to electrostatic spraying without being diluted by the organic solvent and has the advantages of good atomization effect, good package to devices, excellent adherence and good rubbing property.

Owner:东莞大宝化工制品有限公司 +1

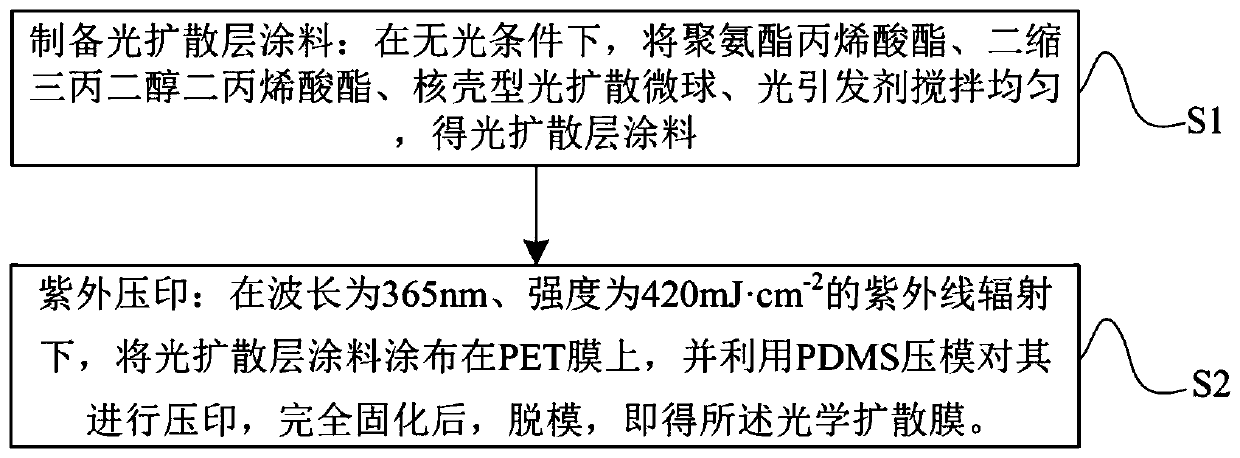

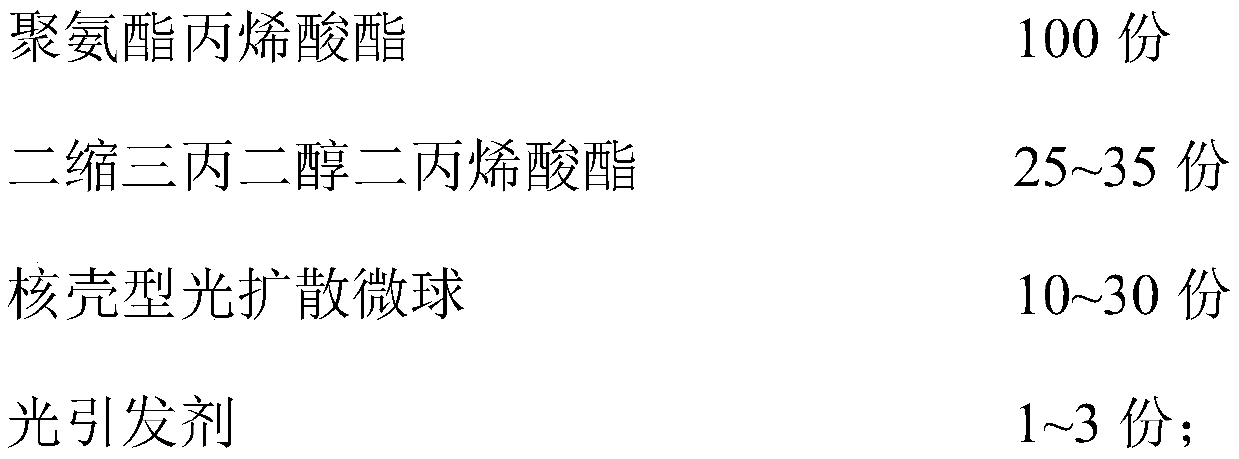

Optical diffusion film and manufacturing method thereof

ActiveCN111399096AImprove stabilityImprove diffusion abilityDiffusing elementsNon-linear opticsTripropylene glycolMicrosphere

The invention discloses an optical diffusion film and a manufacturing method thereof. According to the optical diffusion film, a PET film serves as a base material, and a light diffusion layer is cured on the surface. The light diffusion layer is prepared from the following raw materials in parts by mass: 100 parts of urethane acrylate, 25-35 parts of tripropylene glycol diacrylate, 10-30 parts ofcore-shell type light diffusion microspheres and 1-3 parts of a photoinitiator. The preparation method of the core-shell type photodiffusion microsphere comprises the following steps: adjusting the pH value of the 35-50% (v / v) ethanol solution to 3.0-5.0; adding APS, VTMS and phenyltriethoxysilane into the mixture; magnetically stirring at 25-40 DEG C to react for 2-6 hours; adjusting the pH value to 9-11, continuously reacting for 3-8 hours, adding Zn(NO3)2.6H2O, Ce(NO3)3.6H2O, Al(NO3)3.9H2O and HTM, magnetically stirring for 0.5-1 hour, refluxing at 80 DEG C for 3-5 hours, cooling to 40-50DEG C, dropwise adding glutaraldehyde for cross-linking modification for 1-2 hours, centrifugally washing and drying. The optical diffusion film is uniform, stable, good in weather resistance and durability, the visible light transmittance reaches 93% or above, the haze reaches 85% or above, the ultraviolet light transmittance is lower than 12%, and the 400 nm-480 nm short-wave blue light transmittance is lower than 15%.

Owner:合肥星宸新材料有限公司

Ultraviolet light cured nail polish and production method thereof

InactiveCN102423287ASimple preparation processEasy to operateCosmetic preparationsToilet preparationsTripropylene glycolUltraviolet lights

The invention relates to an ultraviolet light cured nail polish and a production method. The ultraviolet light cured nail polish comprises the components in percentage by weight: 42-50 percent of urethane acrylate, 20-28 percent of epoxy acrylate, 7-10 percent of 1,6-hexanediol diacrylate, 8-10 percent of tripropylene glycol diacrylate, 0.3-0.4 percent of flatting agent 468, 0.1-0.3 percent of flatting agent 3080, 0.1-0.3 percent of flatting agent 333, 4-6 percent of light trigger, 1-3 percent of amine resin 5603. The preparation method of the ultraviolet light cured nail polish comprises the following steps of: feeding various materials according to the proportion of a formula; uniformly stirring the fed materials; checking; filtering; and packaging. The raw materials in the formula of the ultraviolet light cured nail polish disclosed by the invention have low cost; the production process of the ultraviolet light cured nail polish is simple and easy to operate; and in addition, the ultraviolet light cured nail polish product disclosed by the invention meets the requirement of environment friendliness and a paint film has favorable flexibility.

Owner:TIANJIN MEIJIAMEI PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com