Patents

Literature

52 results about "Neopentylglycol diacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

UV curing luminous plate and its preparing process

ActiveCN101397495ANo emissionsNo pollutionSynthetic resin layered productsLuminescent compositionsNon toxicityAcrylic resin

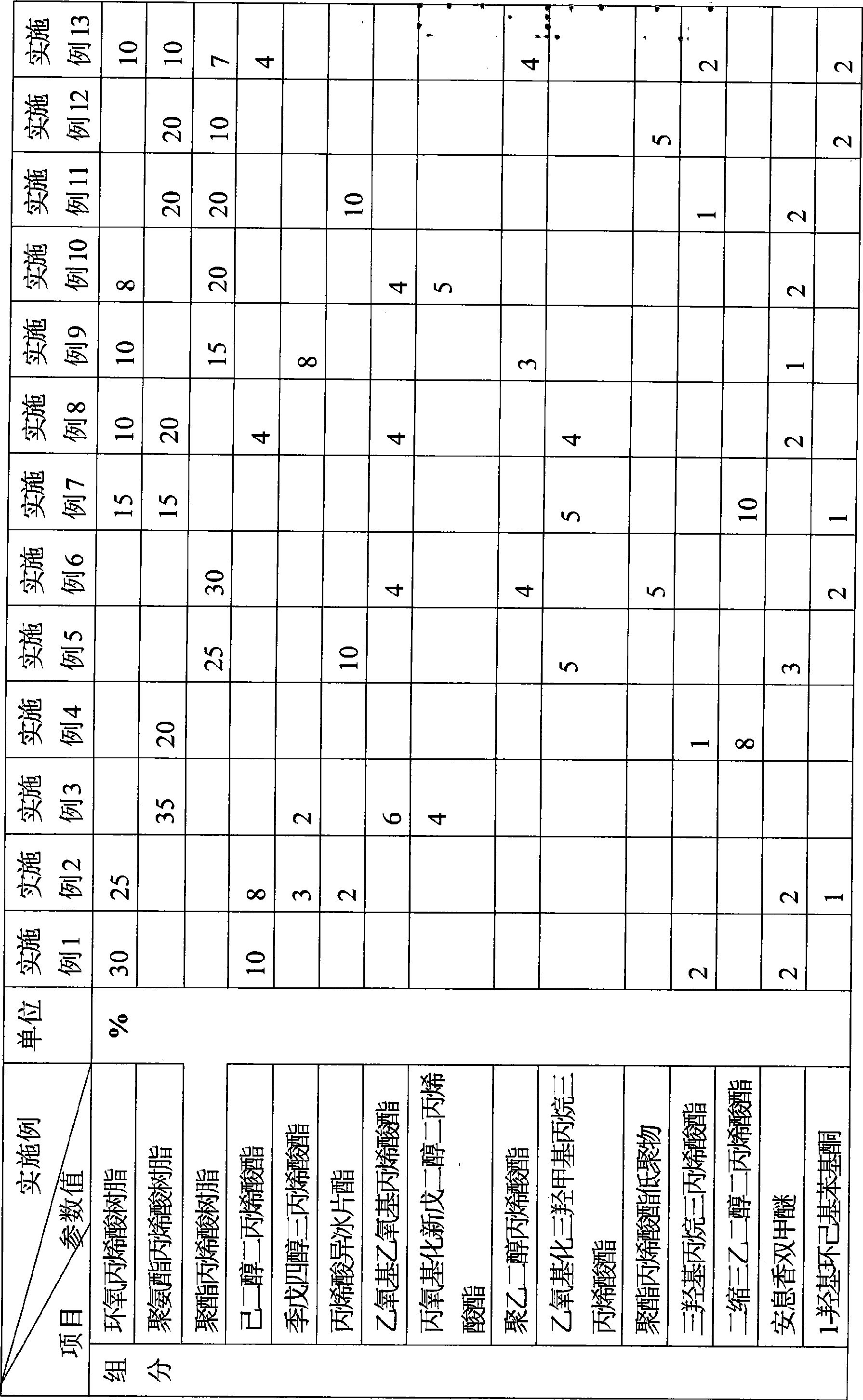

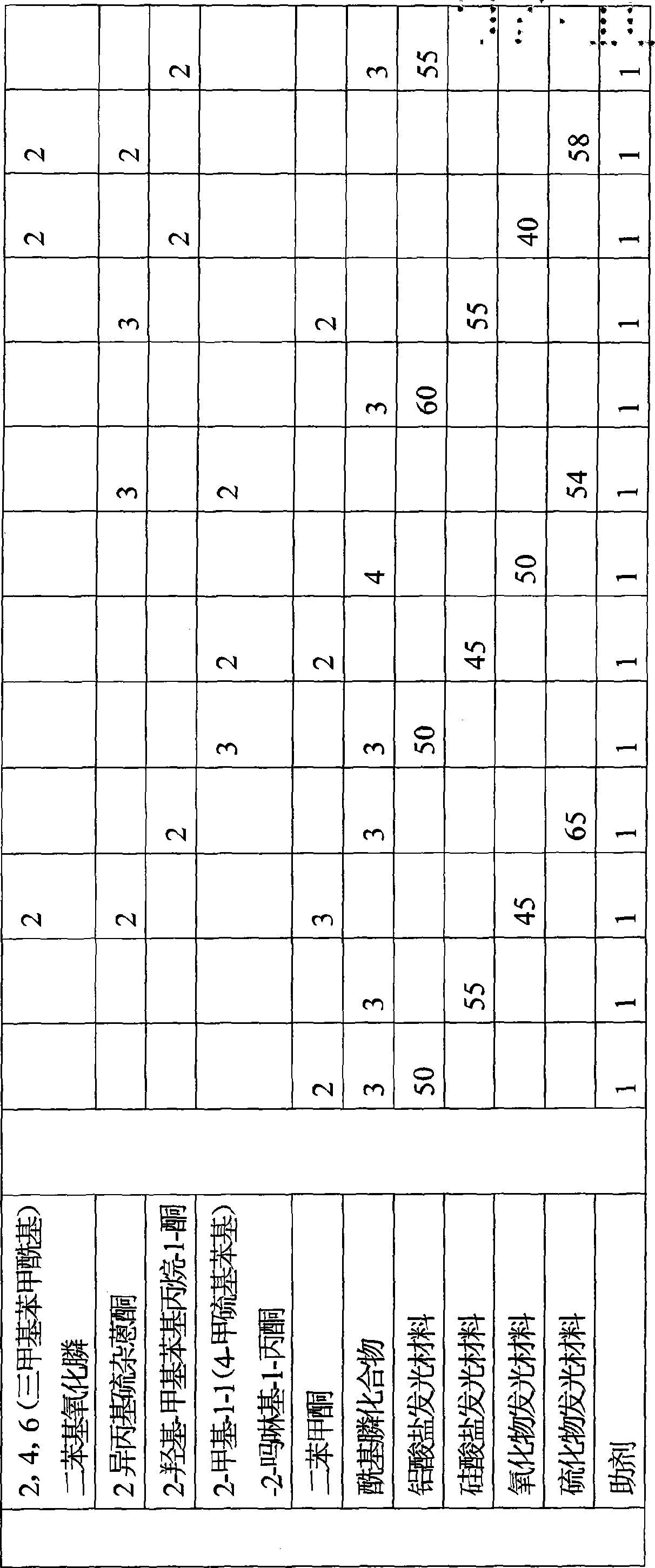

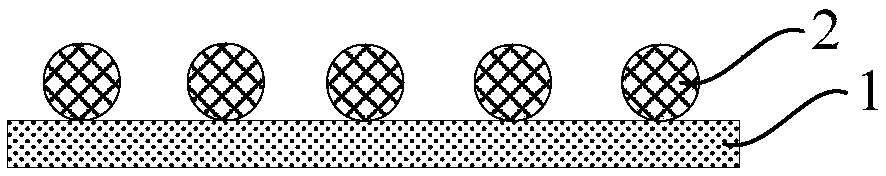

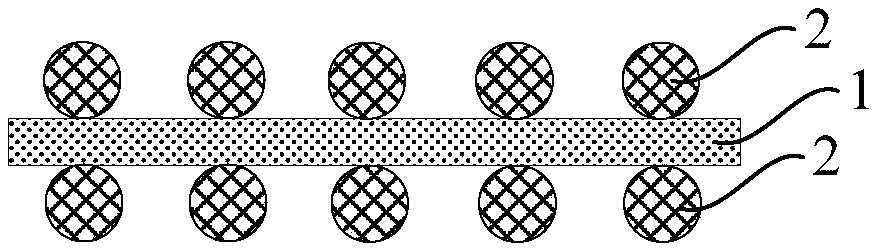

An UV curing luminescent panel consists of a luminescent layer and a reflective layer. The luminescent layer with the thickness of 0.02-5.0mm consists of light-cured resin (10-40 percent of resins such as epoxy acrylic resin, polyurethane acrylic resin, polyester acrylic resin and the like), photosensitive diluent (photosensitive diluent is 10-20 percent of resins of ethoxylated acrylic ester, propoxylated neopentyl glycol diacrylate, TMPTA and the like), photoinitiator (2-10 percent of beans development kit BDK and the like), luminescent materials (10-65 percent) and additive (0-5 percent). The UV curing luminescent panel has the advantages of no solvent emission, saving energy due to instant drying of UV curing, high production efficiency due to on-line processing, and being applicable to base materials sensitive to heat; furthermore, the prepared luminescent panel is characterized by high brightness, long luminescent time, excellent acid and alkali resistance and weatherability, good printing performance, non-toxicity, no radiation and stable physicochemical performance.

Owner:DALIAN LUMINGLIGHT SCIENCE & TECHNOLOGY CO LTD

UV metal printing ink and preparation method thereof

The present invention relates to a UV metal printing ink and a preparation method thereof. The UV metal printing ink contains, by weight, 22.6% of chlorinated modified polyester acrylate, 15-25% of an adhesive force promoter, 5-10% of an active monomer, 7% of a composite photoinitiator, 35-50% of a metal pigment, 0.2% of a scratch-resistant auxiliary agent, and 0.2% of a polymerization inhibitor, wherein the active monomer is one selected from tri(propylene glycol) diacrylate, trimethylolpropane triacrylate and neopentyl glycol diacrylate or a composition comprising tri(propylene glycol) diacrylate, trimethylolpropane triacrylate and neopentyl glycol diacrylate. The present invention further provides a preparation method for the UV metal printing ink. With the UV metal printing ink, the direct adhesive force with the substrate can be enhanced.

Owner:SHENZHEN XINHUAYI PRINTING

A lithium ion battery isolation film and a preparation method thereof

InactiveCN109037555AImprove adhesionThe overall thickness is thinCell seperators/membranes/diaphragms/spacersPorous substratePolymer science

The invention provides a lithium ion battery isolation film, which includes a porous substrate and a polymer coating coated on at least one side surface of the porous substrate; and the material of the polymer includes at least one of polyacrylic acid, polymethacrylic acid, polymethyl acrylate, styrene copolymer, neopentyl glycol diacrylate, polytetrafluoroethylene, polyimide, polyamide, polyester, polysulfone and polyacrylonitrile. The polymer has good bonding performance, the prepared polymer coating prepared by the invention is thin in thickness, uniform and continuous in distribution, andthe adhesion among the porous substrate, the inorganic coating and the positive and negative electrode sheets can be improved, thereby improving the hardness of the battery cell. In addition, the polymer particles have a large number of micro-pores between them, and the polymer particles swelling in the electrolyte is small, which can ensure that the obtained isolation film has good air permeability and battery cyclicity.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

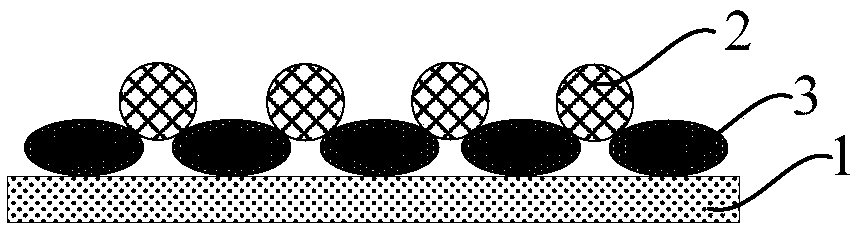

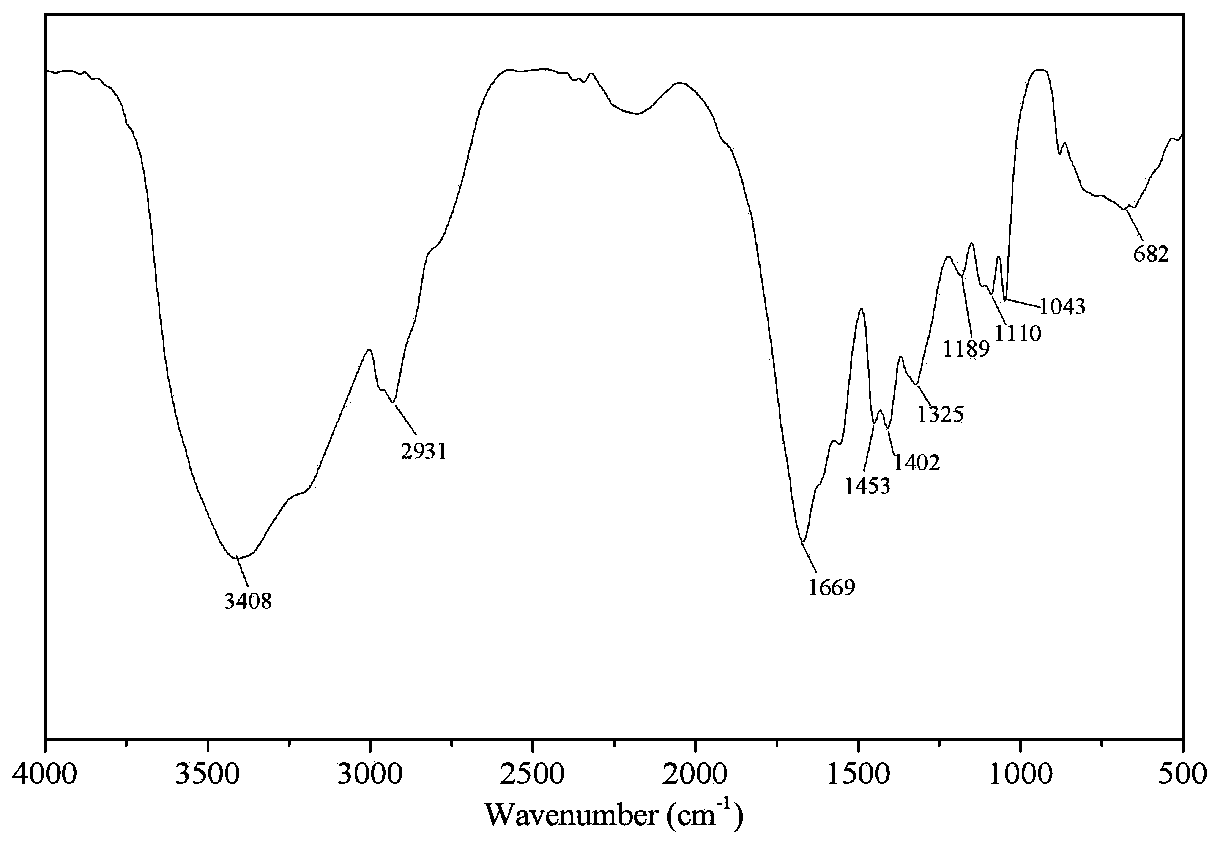

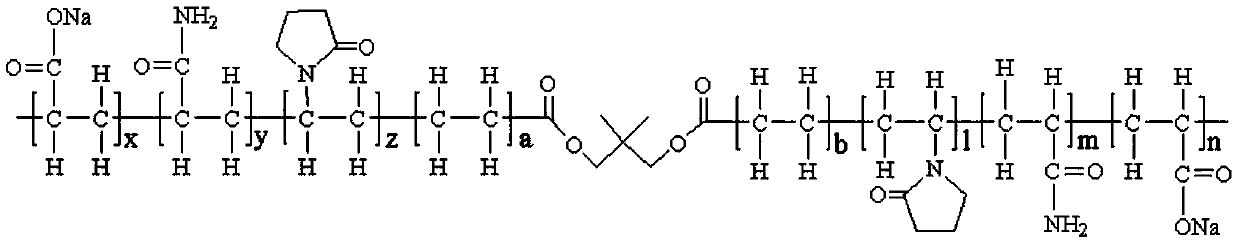

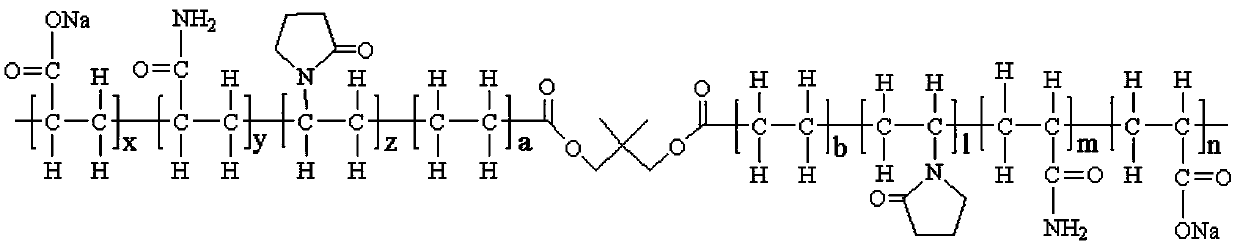

Water-soluble AA-AM-NVP-NGD quadripolymer temporary plugging agent for fracturing and synthesis method of water-soluble AA-AM-NVP-NGD quadripolymer temporary plugging agent

ActiveCN111484578AImprove temporary blocking strengthImprove rigidityDrilling compositionNeopentylglycol diacrylatePyrrolidinones

The invention relates to the technical field of oilfield chemistry. The invention discloses a water-soluble AA-AM-NVP-NGD quadripolymer temporary plugging agent for fracturing and a synthesis method of the water-soluble AA-AM-NVP-NGD quadripolymer temporary plugging agent. The temporary plugging agent is a quadripolymer mainly prepared from the following raw material monomers in percentage by mass: 30% to 40% of acrylic acid, 59.4% to 68.0% of acrylamide, 0.5% to 1.5% of N-vinyl pyrrolidone and 0.1% to 0.5% of neopentyl glycol diacrylate. According to the temporary plugging agent, the N-vinylpyrrolidone with a five-membered ring structure is introduced into a temporary plugging agent molecular chain, so that the rigidity and the stability of the temporary plugging agent molecular chain can be improved, and the temporary plugging strength of the temporary plugging agent is improved; the neopentyl glycol diacrylate with two carbon-carbon double bonds is used for synthesizing the temporary plugging agent, and plays a role of a cross-linking agent, so that the temporary plugging agent becomes a water-swelling body after absorbing water, and cracks can be plugged; the blocking removalmechanism of the temporary plugging agent is different from that of an existing water-soluble temporary plugging agent, no blocking removal agent needs to be additionally added in the blocking removalprocess, complete blocking removal only needs to be achieved under the action of temperature and water, and the blocking removal performance is good.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Water-based inkjet ink and preparation method thereof

The invention discloses water-based inkjet ink and a preparation method thereof. The ink is prepared from, deionized water, polyethylene glycol 200, a pigment, ethylene glycol dimethacrylate, ethyl methacrylate, neopentyl glycol diacrylate, lauryl alcohol polyoxyethylene, triethanolamine, polyoxyethylene polyoxypropylene pentaerythritol ether, ethylene bis stearamide, 4-[(4,6-bis(octylthio)-1,3,5-triazine-2-yl) amino]-2,6-ditert-butyl phenol, octyl methoxycinnamate, titanium dioxide and the like. The water-based inkjet ink has the advantages that the water-based inkjet ink meets the requirements of environmental protection, printing pollution is greatly reduced, the octyl methoxycinnamate and the titanium dioxide are added into the ink and are combined to form a protective film for ultraviolet light blocking on the dye surface layer of the ink, so that the ink does not fade under the outdoor light exposure, is resistant to scratching and is not easily oxidized, and output performed by using the ink does not need printing materials with special coatings.

Owner:北海市天硌打印耗材有限公司

Compound type ultraviolet light-cured anticorrosive paint and preparation method thereof

InactiveCN103013203AEmission reductionReduce consumptionAnti-corrosive paintsNeopentylglycol diacrylateUltraviolet lights

The invention discloses a compound type ultraviolet light-cured anticorrosive paint and a preparation method thereof, wherein the paint is prepared by the following ingredients by weight percent: 30%-50% of epoxy acrylate, 5%-25% of modified mica iron oxide, 10%-25% of dimethyltrimethylene glycol diacrylate, 5%-15% of tripropylene glycol diacrylate, 1%-2% of trimethylolpropane triacrylate, 5%-10% of methyl methacrylate hydroxyl ethyl ester, 2%-5% of 1173, 0.5%-1% of triethanolamine, 2%-5% of KH-570, 1%-5% of linseed oil, 2%-5% of organosilicone adhesion promoter and 0.5%-1% of defoaming agent. The preparation method includes the steps of modifying mica iron oxide by a sol-gel method, adding all the ingredients in the technical scheme into a vacuum mixer for mixing uniformly, and then adding the mixture into a sand mill for grinding to obtain the paint. The compound type ultraviolet light-cured anticorrosive paint has the advantages of environmental protection, good anticorrosion effect and excellent adhesion effect on metal base materials.

Owner:JIANGSU UNIV OF SCI & TECH

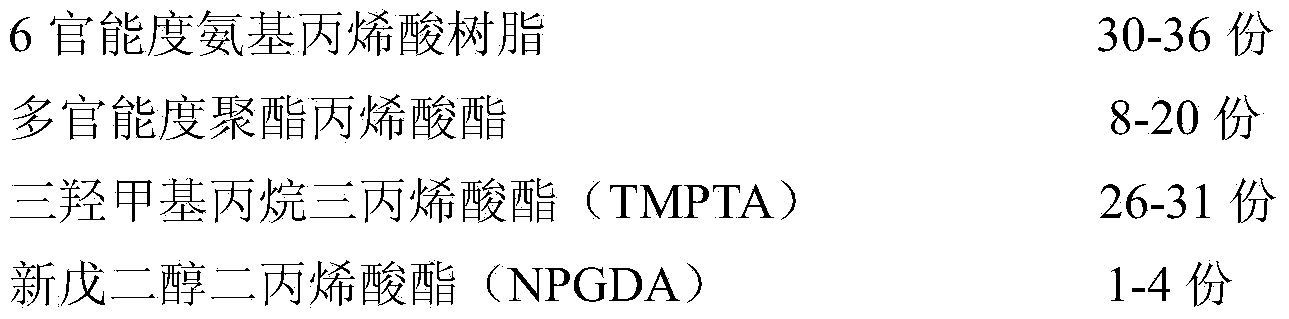

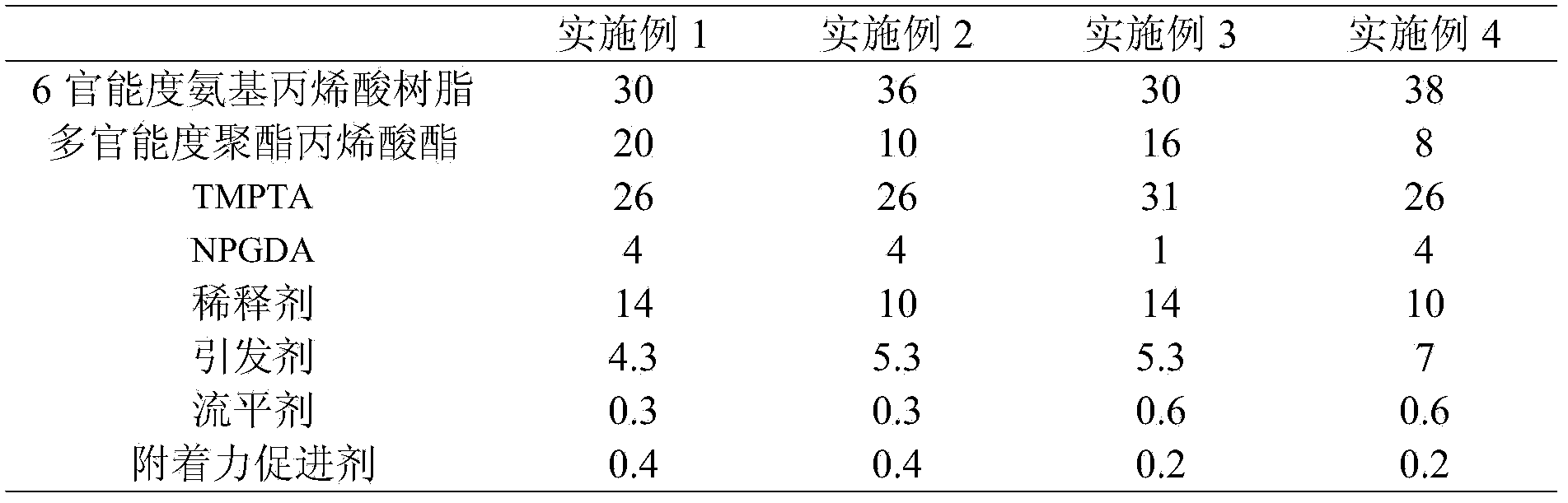

High-adhesion anti-yellowing gloss oil and preparation method thereof

InactiveCN103709892ALow viscosityInitiation efficiency is highPolyester coatingsEpoxyNeopentylglycol diacrylate

The invention discloses a kind of high-adhesion anti-yellowing gloss oil. Adopted matrix resin is 6-functionality amino acrylate resin, so that the curing speed is high, and the cost is lower than those of modified epoxy or polyurethane acrylate resins. Trimethylolpropane triacrylate (TMPTA) and neopentyl glycol diacrylate (NPGDA) are taken as active diluents, so that the system viscosity is lowered, the glossiness is increased, the shrinkage rate is controlled, and the adhesion is improved; an adhesion promoter enhances the mutual acting force with a substrate, so that the adhesion is better. An initiator is high in initiation efficiency, and has an excellent yellowing resistance.

Owner:ZHEJIANG RONGTAI TECH ENTERPRISE

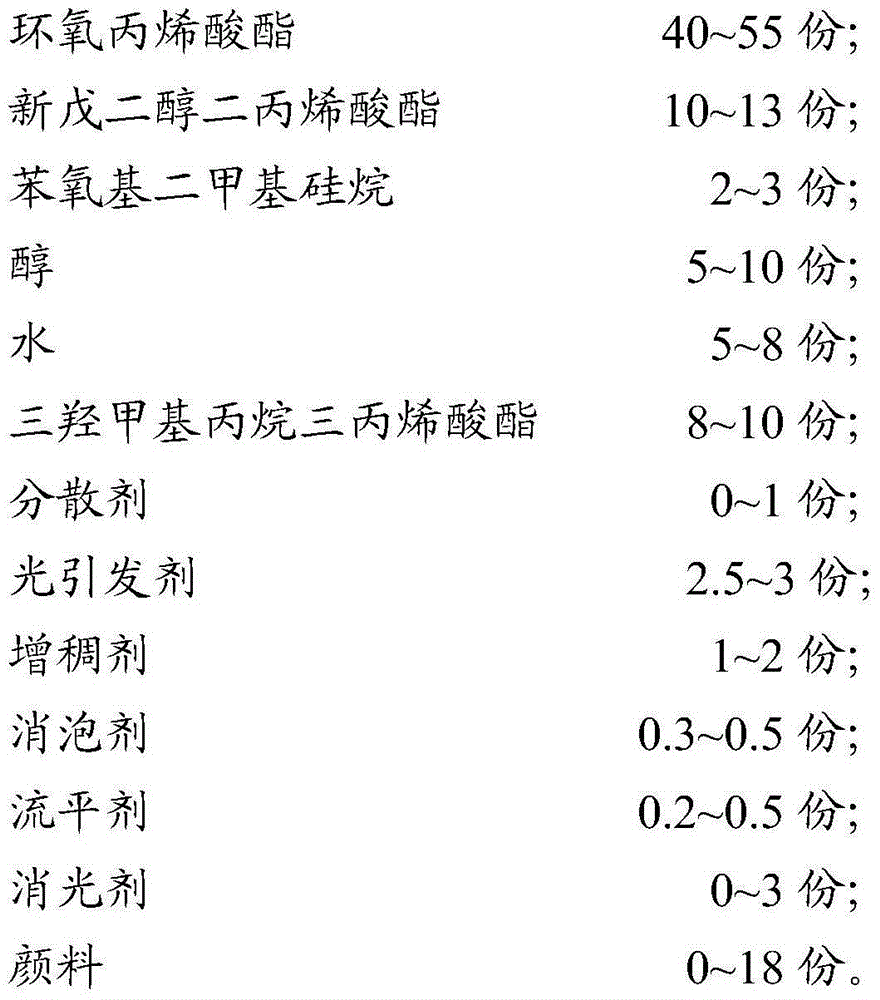

Water-based dotting paint

ActiveCN104830210AHigh hardnessImprove adhesionEpoxy resin coatingsWater basedNeopentylglycol diacrylate

The invention provides a water-based dotting paint which comprises the following components in parts by weight: 15-30 parts of epoxy acrylate, 5-15 parts of reactive diluent (comprising trimethylolpropane triacrylate and neopentyl glycol diacrylate), 0-2 parts of dispersing agent, 1-4 parts of diphenyl ketone photoinitiator, 0-3 parts of polyurea thickener, 5-10 parts of alcohol compound, 0-8 parts of matting powder, 5-10 parts of water, 0.1-1 part of defoaming agent, 0.2-1 part of leveling agent, 0-2 parts of organobentonite, 0-3 parts of silica white and 30-40 parts of powder (comprising talcum powder and calcium carbonate). The water-based dotting paint has high hardness and favorable adhesive force by comprehensively controlling various components. Besides, the water-based dotting paint has favorable dotting effect and is environment-friendly.

Owner:珠海展辰新材料股份有限公司

Method for manufacturing local grating by using UV (Ultraviolet) ink

The invention discloses UV (Ultraviolet) ink, which consists of 55-60 percent by mass of UV resin, 25-30 percent by mass of dimethyltrimethylene glycol diacrylate, 7-8 percent by mass of aluminum isocaprylate and 7-8 percent by mass of a photosencitizer. The invention further discloses a method for manufacturing a local grating by using the UV ink. The method comprises the following steps of: printing twice on a printed product based on the alignment of grating lines in a screen printing way; and curing two printing results respectively through a UV photo-curing reaction to obtain the local grating. In the method, screen printing is combined with the UV ink for printing directly on the printed product, so that a process is simple, convenient and rapid.

Owner:WUHAN UNIV

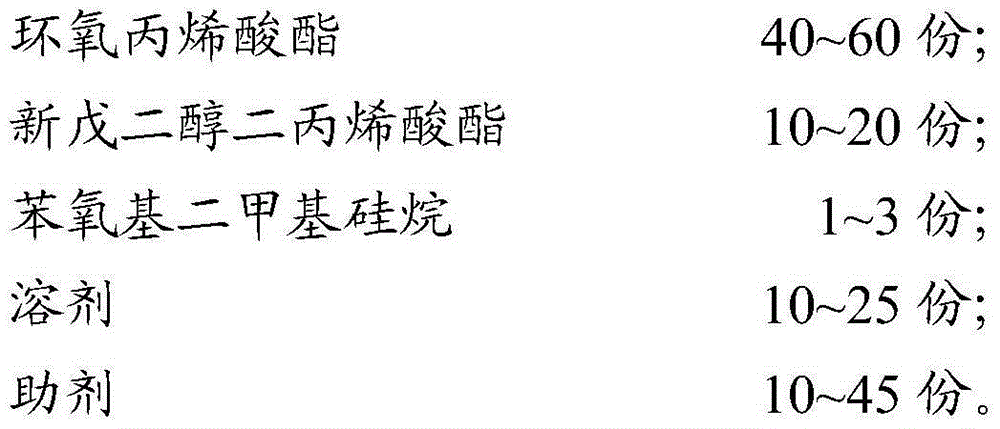

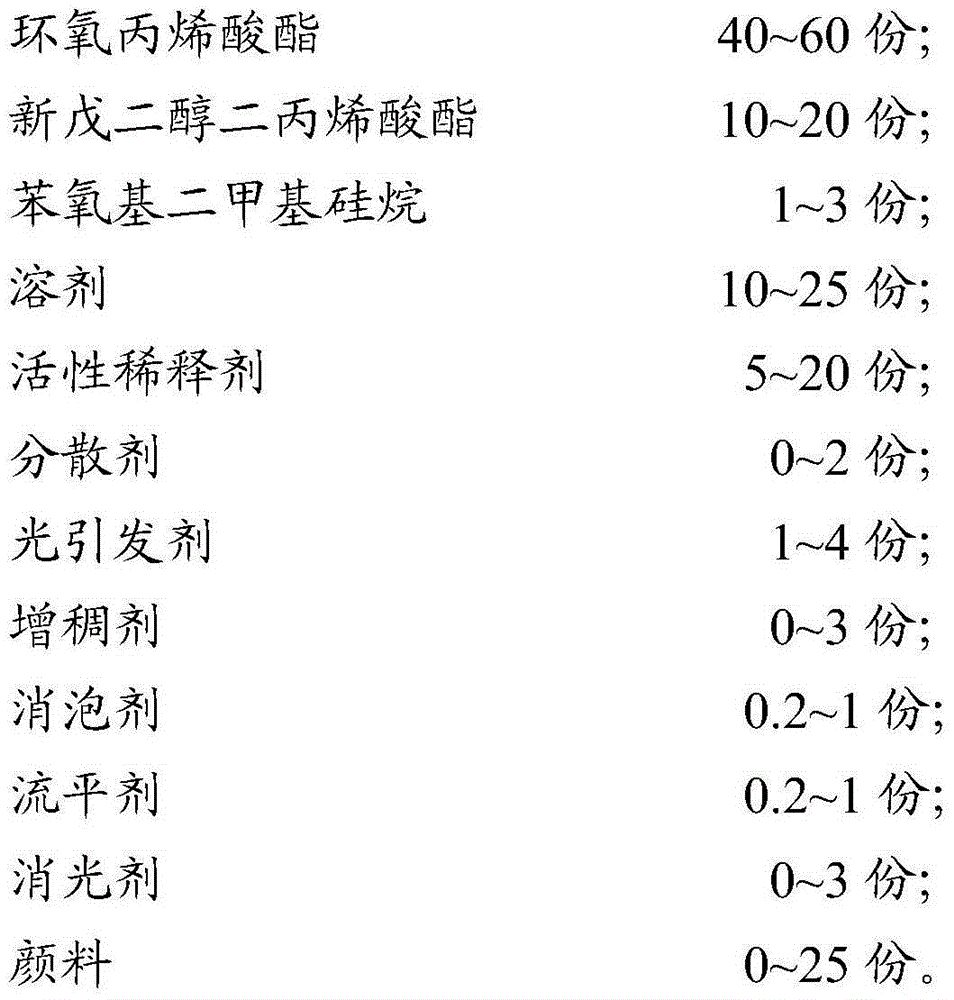

Water-based UV (ultraviolet) coating material

The invention belongs to the field of a coating material, and particularly relates to a water-based UV (ultraviolet) coating material. The water-based UV coating material comprises the following components in parts by weight: 40 to 60 parts of epoxy acrylate; 10 to 20 parts of neopentyl glycol diacrylate (NPGDA); 1 to 3 parts of phenoxyl dimethylsilane; 10 to 25 parts of solvent; and 10 to 45 parts of additives. The epoxy-modified acrylate is used as a main body to be matched with NPGDA and phenoxyl dimethylsilane, so that the adhesive force of the coating material on the plastic surface can be remarkably improved. An experimental result shows that after the water-based UV coating material is cured on the plastic surface, the adhesive force reaches level I.

Owner:展辰新材料集团股份有限公司 +4

Preparation method of 3-hydroxypivalic acid neopentylglycol diacrylate

ActiveCN101723831AEmission reductionPromote environmental protectionOrganic compound preparationCarboxylic acid esters preparationNeopentylglycol diacrylateAcid value

The invention relates to an improvement of a preparation method of 3-hydroxypivalic acid neopentylglycol diacrylate, which is characterized by comprising the following steps of: absorbing reaction products of esterification reaction by macroporous resin and / or ion exchange resin till an acid value accords with requirements; and depriving a solvent. Compared with the prior art, the invention deprives (reduces) unreacted reactants (the acid value) of the reaction products through resin exchange absorption without washing, neutralizing by alkali and generating waste washing water basically in the production process, reduces the waste water discharge in the production process, recovers the exchange resin and reuse by activating the exchange resin after the exchange resin is absorbed to be saturated, is an energy-saving consumption-reducing environmental-friendly new process, has good environmental protection without washing and waste products generated due to the washing, also increases the yield of products and enhances the yield coefficient by 5 percent.

Owner:江苏三木化工股份有限公司

Method for preparing neopentylglycol diacrylate

InactiveCN101462952ALow costImprove product qualityOrganic compound preparationCarboxylic acid esters preparationNeopentylglycol diacrylateColor intensity

The invention belongs to a method for preparing neopentyl glycol diacrylate ester, comprising the steps as follows: (1) neopentyl glycol, acrylic acid, catalyst, solvent and polymerization inhibitor are put into a reaction kettle to be fully mixed and stirred, so as to form a mixture; (2) a steam valve of the reaction kettle is opened to slowly heat the mixture, within 1h the temperature is controlled and maintained at 50-80 DEG C for a 20-40min reaction; (3) when the temperature is increased to 70-120 DEG C, reflow is carried out for 3-5h and then the reaction is finished; (4) soda water solution and sodium chloride water solution are added into the mixture and after washing the upper organic phase is extracted; (5) the upper organic phase is separated from the solvent; (6) then cooling and filter pressing are carried out to obtain the end product. The method has simple process, high yield coefficient, low color intensity, good activity and flexibility, low shrinking percentage and good quality and produces few by-products or little waste water.

Owner:TIANJIN CHEM REAGENT RES INST

Light-cured polyurethane coating and preparation method thereof

The invention relates to a light-cured polyurethane coating and a preparation method thereof. The coating consists of two parts: light-cured isocyanuric ring polyurethane resin A and light-cured polyurethane coating B, wherein the light-cured isocyanuric ring polyurethane resin A comprises 369 parts of (2-hydroxyethyl) isocyanurate, 0.5 part of hydroquinone, 84 parts of hexamethylene diisocyanate and 0.1 part of triethylamine; and the light-cured polyurethane coating B comprises 50 parts of compound A, 50 parts of noepentyl glycol diacrylate and 2 parts of Sgacuse 184. The components are irradiated by energy rays (such as ultraviolet rays and ionizing radiation) and can be cured fast, and a coating film has good flexibility, high hardness and good processability, acid resistance, alkali resistance, solvent resistance and the like. The coating is coated with a bar material painting device or in the method of brushing, spraying and the like. The coating is coated on an ABS resin board by a No.5 bar material coating device and is irradiated by an 80W / cm medium-voltage mercury lamp for 3s, and then a high-hardness coating film is obtained. The coating is suitable for furniture made of plastics, optical instruments, stationery, auto parts, aircraft glass, various plastic or glass products with metal films, glass containers and the like.

Owner:李岳

Radiation curable ink composition

ActiveUS20120264845A1Improve dehumidification effectImprove printing qualityOptical articlesInksVinyl etherNeopentylglycol diacrylate

A radiation curable ink composition has improved adhesion towards rigid recording media, good jetting behaviour and no or minimal health and safety risks. The radiation curable ink has a viscosity of 30 mPa·s, or less, at 50° C., has at least two monofunctional monomers, the two monofunctional monomers including a first monomer selected from an N-vinyl amide and a second monofunctional monomer being isobornyl acrylate, a difunctional acrylate monomer being propoxylated (or ethoxylated) neopentyl glycol di acrylate (SR 9003), at least one multifunctional monomer selected from the group consisting of a trifunctional acrylate monomer, a tetrafunctional acrylate monomer, a pentafunctional acrylate monomer, a trifunctional epoxide monomer, a tetrafunctional epoxide monomer, a pentafunctional epoxide monomer, a trifunctional oxetane monomer, a tetrafunctional oxetane monomer, a pentafunctional oxetane monomer, a trifunctional vinylether monomer, a tetrafunctional vinylether monomer and a pentafunctional vinylether monomer, the ink further includes at least one photoinitiator and a colorant.

Owner:OCE TECH

Radiation curable ink composition

ActiveUS8524795B2Good jetting behaviourImprove adhesionOptical articlesInksNeopentylglycol diacrylateNeopentyl glycol

A radiation curable ink composition has improved adhesion towards rigid recording media, good jetting behavior and no or minimal health and safety risks. The radiation curable ink has a viscosity of 30 mPa·s, or less, at 50° C., has at least two monofunctional monomers, the two monofunctional monomers including a first monomer selected from an N-vinyl amide and a second monofunctional monomer being isobornyl acrylate, a difunctional acrylate monomer being propoxylated (or ethoxylated) neopentyl glycol di acrylate (SR 9003), at least one multifunctional monomer selected from the group consisting of a trifunctional acrylate monomer, a tetrafunctional acrylate monomer, a pentafunctional acrylate monomer, a trifunctional epoxide monomer, a tetrafunctional epoxide monomer, a pentafunctional epoxide monomer, a trifunctional oxetane monomer, a tetrafunctional oxetane monomer, a pentafunctional oxetane monomer, a trifunctional vinylether monomer, a tetrafunctional vinylether monomer and a pentafunctional vinylether monomer, the ink further includes at least one photoinitiator and a colorant.

Owner:OCE TECH

Melamine panel protection layer

InactiveCN105482652AImprove adhesionImprove protectionPolyurea/polyurethane coatingsEpoxy resin coatings(Hydroxyethyl)methacrylateNeopentylglycol diacrylate

The invention discloses a melamine panel protection layer. The melamine panel protection layer comprises, by weight, 25-35 parts of epoxy acrylate, 25-30 parts of polyurethane acrylate, 20-30 parts of hydroxyethyl methacrylate, 13-20 parts of neopentylglycol diacrylate, 5-10 parts of benzophenone, 3-5 parts of diatomite, 3-5 parts of ammonium sulfate, 1-3 parts of tourmalinite and 1-5 parts of nanometer zinc oxide. The melamine panel protection layer can improve the adhesion of a protection layer coating to a melamine panel, and has the advantages of high glossiness, good wear resistance and high hardness.

Owner:QINGDAO DAFANG WISDOM NETWORK TECH CO LTD

Method for preparing organic glass with high-wearing feature and high punching resistance by film transfer method

InactiveCN101104701ASufficient surface hardnessSufficient surface resistanceCoatingsNeopentylglycol diacrylatePolyethylene glycol

Disclosed is a method of producing organic glass with high wear resistance and high impact resistance by film transferring. Methyl methacrylate prepolymer, pentaerythritol tris-acrylate, dipentaerythritol acrylate, trimethylolpropane tris-acrylate, noepentyl glycol diacrylate, polyethylene glycol (200, 400, 600) diacrylate, hexanediol diacrylate, photosensitizer, flow agent and defoaming agent are sprayed on a toughened glass template to be uv-cured to functional film. The toughened glass with the functional film is used as a template to make the organic glass with wear resistance and impact resistance according to the conventional preparation process with polymethyl methacrylate being injected into the template. The organic glass sheet has the advantages of enough surface hardness and surface resistance, fine impact resistance, antistatic effect and light transmittance, and obvious wear absorption and low moisture resistance compared with the common organic glass.

Owner:张少华

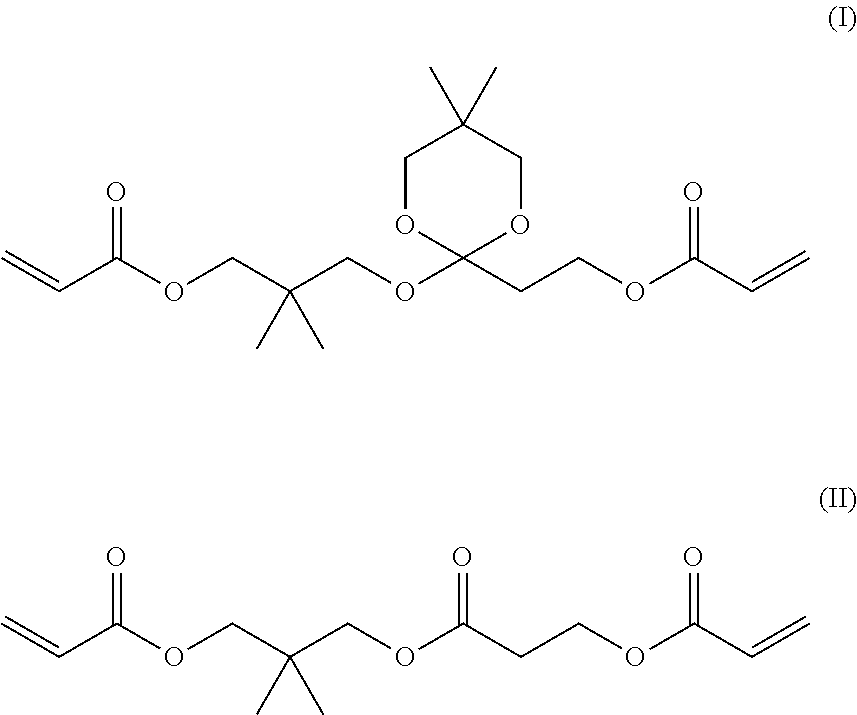

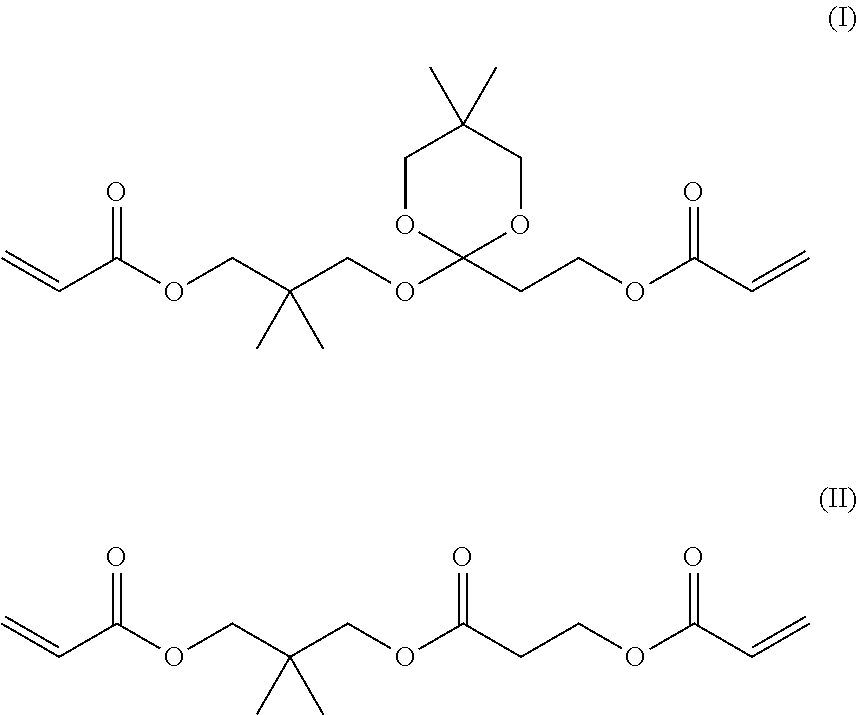

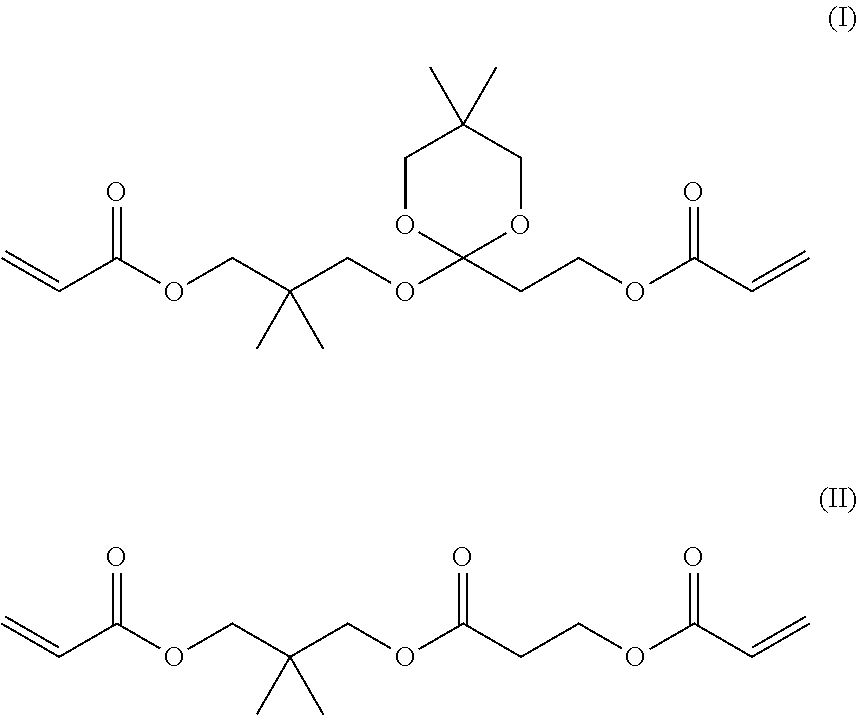

Curable composition, pattern forming method, pattern, and method for manufacturing device

ActiveUS20170190820A1Excellent releasabilityExcellent ink jet dischargePhotomechanical apparatusSemiconductor/solid-state device manufacturingNeopentylglycol diacrylateCompound (substance)

Provided are a curable composition having excellent releasability and ink jet discharge accuracy, a pattern forming method, a pattern, and a method for manufacturing a device.The curable composition includes a polymerizable compound and a photopolymerization initiator, in which neopentyl glycol diacrylate accounts for 10% by mass or more of the polymerizable compound, and the total content of a compound represented by the following Formula (I) and a compound represented by the following Formula (II) is 5% by mass or less with respect to the content of neopentyl glycol diacrylate.

Owner:FUJIFILM CORP

Ultraviolet curing coating capable of being used on surfaces of plastic and stone and preparation method thereof

ActiveCN103834279AImprove aging resistanceEvenly dispersedEpoxy resin coatingsPolyester coatingsNeopentylglycol diacrylateKetone

The invention discloses an ultraviolet curing coating capable of being used on surfaces of plastic and stone. The ultraviolet curing coating capable of being used on the surfaces of plastic and stone is characterized by being prepared from the following raw materials in parts by weight: 20-25 parts of bisphenol A epoxy acrylate, 30-35 parts of polyester acrylate, 10-12 parts of hydroxyethyl acrylate, 6-9 parts of hydroxyethyl methylacrylate, 3-5 parts of photoinitator 2959, 10-13 parts of neopentyl glycol dicarylate, 9-11 parts of cresyl glycidyl ether, 1-2 parts of sodium hexametaphosphate, 1-2 parts of methyl ethyl ketone, 3-5 parts of titanium dioxide, 1-2 parts of grape seed oil, 4-6 parts of barite powder and 4-5 parts of auxiliary agent. The ultraviolet curing coating capable of being used on the surfaces of the plastic and stone is added with a natural antioxidant ingredient of grape seed oil, the anti-aging property of the ultraviolet curing coating can be enhanced, and the ultraviolet curing coating is safe and non-toxic; an auxiliary agent is added, so that the ultraviolet curing coating is uniformly dispersed, the curing speed is high, a film can be rapidly formed, the surface hardness of the film is high, the glossiness is good, the hiding power is high, the film is uniform, and the ultraviolet curing coating has good adhesion property and can be rapidly adhered on the surfaces of plastic and stone.

Owner:佛山市海而斯涂料有限公司

Method for preparing ethoxylated neopentylglycol diacrylate

InactiveCN101462960ALow costWide variety of sourcesOrganic compound preparationCarboxylic acid esters preparationEpoxyNeopentylglycol diacrylate

The invention belongs to a method for preparing propoxylation neopentylglycol diacrylate ester, comprising the steps as follows: (1) epoxy propane, neopentylglycol, acrylic acid, catalyst, solvent and polymerization inhibitor are put into a reaction kettle to form a mixture; (2) a valve is opened to slowly heat the mixture, and the temperature is controlled and maintained at 60-90 DEG C for a 20-40min reaction; (3) the mixture is continued to be heated to the temperature of 80-120 DEG C to react for 3-4h, then reflow is carried out for 5-7h, and then the reaction is finished; (4) soda water solution and sodium chloride water solution are added into the mixture, and after washing, quiescence and demixing the upper organic phase is extracted; (5) the upper organic phase is separated from the solvent; (6) and then cooling and pressing are carried out to obtain the end product. The method has simple process, high yield coefficient, good activity and flexibility, low color intensity, shrinking percentage and irritation, and good quality, and produces few by-products or little waste water.

Owner:TIANJIN CHEM REAGENT RES INST

Impact modifier applied to PVC bellow

InactiveCN101418065AGood weather resistanceImprove impact resistanceNeopentylglycol diacrylateEthyl acrylate

The invention provides an impact modifier for PVC bellows. The impact modifier is characterized in that the impact modifier is a core-shell structure copolymer; a core shell of the impact modifier is formed through the emulsion polymerization of butyl acrylate and neopentylglycol diacrylate, which is initiated by an initiator in the presence of surfactant and nitrogen; methyl methacrylate and ethyl acrylate are used for proceeding with emulsion polymerization grafting reaction on the core layer, so as to form a shell layer of the impact modifier, wherein the total weight of polymeric monomer is counted as 100 percent, the butyl acrylate accounts for 40 to 50 percent; the neopentylglycol diacrylate accounts for 1 to 5 percent; the ethyl acrylate accounts for 40 to 45 percent; and the methyl methacrylate accounts for 4 to 15 percent. The impact modifier grafts the neopentylglycol diacrylate in the core layer, so as to ensure that the obtained PVC bellows can have better weather resistance and impact resistance, excellent adjustable processability and powder fluidity, and reduces production cost at the same time, thereby having excellent economical efficiency.

Owner:SHANDONG RUIFENG CHEM

Environmental-friendly protection coating of art design printed wrapping paper

InactiveCN106192567AExcellent flame retardantGood acid and alkali resistanceFlexible coversWrappersSandalwood oilDiphenylsilanediol

The invention relates to an environmental-friendly protection coating of art design printed wrapping paper, which is prepared from the following components: trioctyl trimellitate, hydrogenated rosin, heat-vulcanized silicone rubber, triethylene glycol di-2-ethylhexoate, cellulose acetate butyrate, dibasic lead stearate, ammonium polyphosphate, calcium hypochlorite, methyl 4-hydroxybenzoate, carbendazim, didecyl dimethyl ammonium chloride, sodium dichloroisocyanurate, sodium hydrosulfide, calcium acetate, sodium hydrogen phosphate, sodium carbonate, praseodymium oxide powder, dolomite powder, honey, lavender essential oil, cottonseed oil, sandalwood oil, styrene-acrylic emulsion, propoxy neopentyl glycol diacrylate, glycerin monostearate, butyl hydroxy anisd, terephthalyl alcohol, p-chlorophenol, p-nitrobenzoic acid and diphenyl silandiol. The product disclosed by the invention has relatively superior flame retardance, acid and alkali resistance, mildew prevention and mold resistance, and the performance of the product is improved.

Owner:余志娟

Temporary plugging agent capable of realizing well zone seepage and preparation method thereof

ActiveCN114044851AUnblocking time is adjustableAutomatic adjustment of unblocking timeProductsReagentsMeth-Neopentylglycol diacrylate

The invention provides a temporary plugging agent capable of realizing well zone seepage and a preparation method thereof. The temporary plugging agent is prepared by the following steps: dissolving an acrylamide monomer and a glyceryl allyl ether monomer in a solvent, adding N,N-methylene acrylamide, an acrylate compound, and an initiator, continuously reacting for 5-12 hours, and after reaction, drying to obtain thetemporary plugging agent, wherein the acrylate compound is one of butanediol diacrylate, dipropylene glycol acrylate and neopentyl glycol diacrylate, the mass ratio of N,N-methylene acrylamide to the acrylate compound is 1: (5-12), and the mass of N,N-methylene acrylamide accounts for 0.08%-0.15% of the total mass of the monomer. According to the temporary plugging agent, the plugging rate is high and can reach 95% or above, the plug removal rate is high and can reach 82% or above, residual gel obtained after plug removal is conducted finally is little, the influence on the stratum is small, and the temporary plugging agent can be used for well zone seepage volume fracturing.

Owner:西安维克特睿油气技术有限公司

Power cable for solar photovoltaic power distribution cabinet

InactiveCN106009451ASoft textureExcellent flame retardantClimate change adaptationInsulated cablesTrichloroethyl PhosphateAntimony oxide

The invention relates to a power cable for a solar photovoltaic power distribution cabinet, which includes a plurality of copper alloy wires and protective sleeves. The copper alloy wires are placed parallel to each other, and the outer layer of each copper alloy wire is covered with a protective sleeve. Composition of the following components: acrylate rubber powder, SEBS thermoplastic elastomer, styrene-modified alkyd resin, waste oil, glyceryl tricaprylate, sandalwood oil, styrene-acrylic emulsion, transformer oil, benzalkonium chloride, dibenzofuran , zinc pyrithione, bis-imidazolidinyl urea, lead oxide powder, fly ash, antimony oxide powder, sodium iodoacetate, potassium fluotitanate, pearl powder, mica powder, potassium aluminum sulfate, trichloroethyl phosphate, poly Benzimidazole imide, nano-magnesium hydroxide, polyethylene wax, sodium lauryl sulfate, bis-tert-butyl peroxycumene, tert-butyl hydroperoxide, aluminum distearate, tetra-titanate Butyl ester, neopentyl glycol diacrylate. The invention improves the performance of the product.

Owner:权周越

Preparation method and application of pearl wool material for medical packaging

The invention discloses a preparation method and application of a pearl wool material for medical packaging. The preparation method comprises the following steps of: carrying out wet ball milling on attapulgite, aluminum hydroxide and absolute ethyl alcohol, then carrying out ultrasonic dispersion on ball-milled mixed slurry, natural bamboo fibers and polyvinyl acetate to obtain an initial mixture, meanwhile carrying out primary mixing on low density polyethylene, neopentyl glycol diacrylate and hexamethylenamine, and adding dibenzylidene sorbitol, sodium bicarbonate and an activating agent for secondary mixing to obtain a secondary mixture, finally, causing the initial mixture and the secondary mixture to react with an antistatic agent and a foaming agent at a high temperature and a highpressure, carrying out extrusion molding and cooling to obtain the finished material. The prepared pearl wool material has a good sealing property and a strong antibacterial property; and as a packaging material, the pearl wool material has good application prospect.

Owner:苏州国立塑料制品有限公司

Conductive photosensitive resin for photocuring 3D printing and preparation method thereof

InactiveCN110885491AFast curing efficiencyImprove conductivityAdditive manufacturing apparatus3d printPolymer science

The invention discloses a conductive photosensitive resin for photocuring 3D printing. The conductive photosensitive resin for photocuring 3D printing comprises the following components by mass: 25-40parts of an ethylene-vinyl acetate copolymer, 20-35 parts of urethane acrylate, 15-30 parts of conductive filler, 1-5 parts of a titanate coupling agent, 10-25 parts of neopentyl glycol diacrylate, 0.5-5 parts of dimethyl polysiloxane, 0.5-5 parts of a BYK-306 leveling agent and 2-10 parts of benzophenone. According to the invention, the conductive photosensitive resin for 3D printing adopts theethylene-vinyl acetate copolymer and urethane acrylate as the matrix, also is added with the conductive filler, and at the same time utilizes the interaction of the ethylene-vinyl acetate copolymer and the conductive filler to further enhance the conductivity, therefore the conductive photosensitive resin disclosed by the invention not only keeps high curing efficiency, but also has good conductivity.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

Multifunctional power maintenance protective glove material

InactiveCN106243597AExcellent flame retardantGood acid and alkali resistanceGlovesProtective garmentDecabromodiphenyl etherPolymethyl methacrylate

The invention relates to a multifunctional power maintenance protective glove material, which is composed of the following components: polymethyl methacrylate, halogenated butyl rubber, keto-aldehyde resin, tallow dihydroxyethyl amine oxide, grape seed oil, boiled tung oil, diethyl carbonate, sulfonated castor oil, allylthiourea, berberine, oxymatrine, a silver ion antibacterial agent, lithium chromate powder, silicon powder, silicon powder, sodium aluminosilicate powder, zirconium silicate powder, aluminium silicate powder, magnesium silicate powder, silicate, diatom powder, pyromellitic dianhydride, hexamethylene diisocyanate, hexabromocyclododecane, decabromodiphenyl ether, butyl ricinoleate, 2-ethylhexyl acrylate, Propoxy Late oneopentylglycol diacrylate, an aziridine cross-linking agent, butyl hydroxyanisole, and p-aminophenol. The product provided by the invention has superior flame retardance, acid and alkali resistance, anti-mildew and antibacterial properties, and the product performance is improved.

Owner:李云海

Preparation method for neopentylglycol diacrylate

InactiveCN106854156AEmission reductionHigh yieldOrganic compound preparationCarboxylic acid esters preparationState of artNeopentylglycol diacrylate

Compared with the prior art, the method for preparing neopentyl glycol diacrylate of the present invention removes or reduces the unreacted substances in the reaction product through resin exchange adsorption, different neutralization, extraction, and water washing processes, and basically no washing wastewater is generated in the production process. It reduces the discharge of waste water in the production process, and the exchange resin can be recycled and reused after adsorption and saturation. It is a new energy-saving and environmentally friendly process. Secondly, there is no need to wash with water, and no product is wasted by washing with water, which improves the product yield, which can increase the yield by more than 5%.

Owner:HUIZHOU CHANGRUNFA PAINT

UV infiltration bottom for calcium silicon plate

InactiveCN109913116AImprove water resistanceImprove interlayer adhesionPolyurea/polyurethane coatingsNeopentylglycol diacrylateAcrylic resin

The invention provides a UV infiltration bottom for a calcium silicon plate, wherein the UV infiltration bottom comprises: an aromatic polyurethane acrylic resin, aliphatic polyurethane acrylate, propoxylated neopentyl glycol diacrylate, trimethylolpropane triacrylate, an organosilicon antifoaming agent and a photoinitiator. According to the present invention, by compounding aromatic polyurethaneacrylic resin, aliphatic polyurethane acrylate, propoxylated neopentyl glycol diacrylate and trimethylolpropane triacrylate, the obtained UV infiltration bottom has good water resistance, can providegood interlayer adhesion to substrates and paint films, further has advantages of excellent leveling property, excellent yellowing resistance and excellent outdoor weather resistance, and can well meet the applications of the UV infiltration bottom in outdoor wall surfaces, especially in calcium silicon plates.

Owner:HUIZHOU CHANGRUNFA PAINT +1

Impact modifier applied to PVC bellow

InactiveCN101418065BImprove impact resistanceGood weather resistanceNeopentylglycol diacrylateEthyl acrylate

The invention provides an impact modifier for PVC bellows. The impact modifier is characterized in that the impact modifier is a core-shell structure copolymer; a core shell of the impact modifier is formed through the emulsion polymerization of butyl acrylate and neopentylglycol diacrylate, which is initiated by an initiator in the presence of surfactant and nitrogen; methyl methacrylate and ethyl acrylate are used for proceeding with emulsion polymerization grafting reaction on the core layer, so as to form a shell layer of the impact modifier, wherein the total weight of polymeric monomer is counted as 100 percent, the butyl acrylate accounts for 40 to 50 percent; the neopentylglycol diacrylate accounts for 1 to 5 percent; the ethyl acrylate accounts for 40 to 45 percent; and the methyl methacrylate accounts for 4 to 15 percent. The impact modifier grafts the neopentylglycol diacrylate in the core layer, so as to ensure that the obtained PVC bellows can have better weather resistance and impact resistance, excellent adjustable processability and powder fluidity, and reduces production cost at the same time, thereby having excellent economical efficiency.

Owner:SHANDONG RUIFENG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com