High-adhesion anti-yellowing gloss oil and preparation method thereof

A technology of adhesion promoter and varnish, which is applied in coatings, polyester coatings, etc., can solve the problem that the yellowing resistance is difficult to meet the needs of practical applications, achieve excellent yellowing resistance, low product price, and improve adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

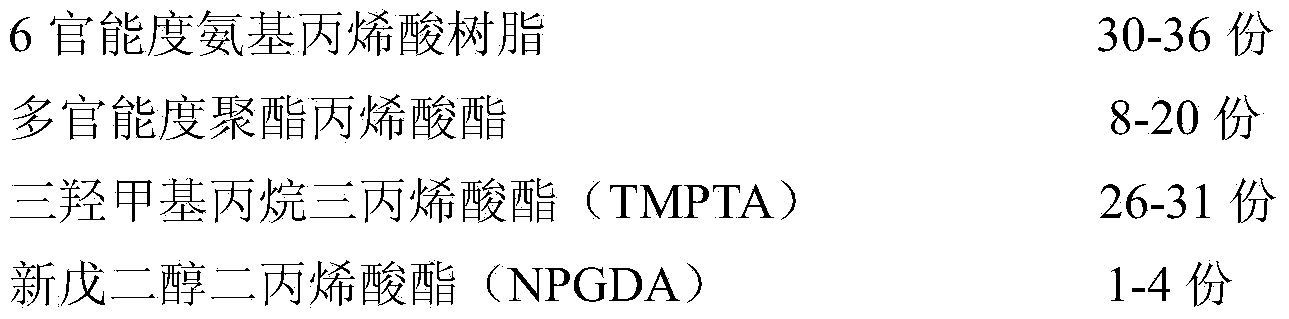

Method used

Image

Examples

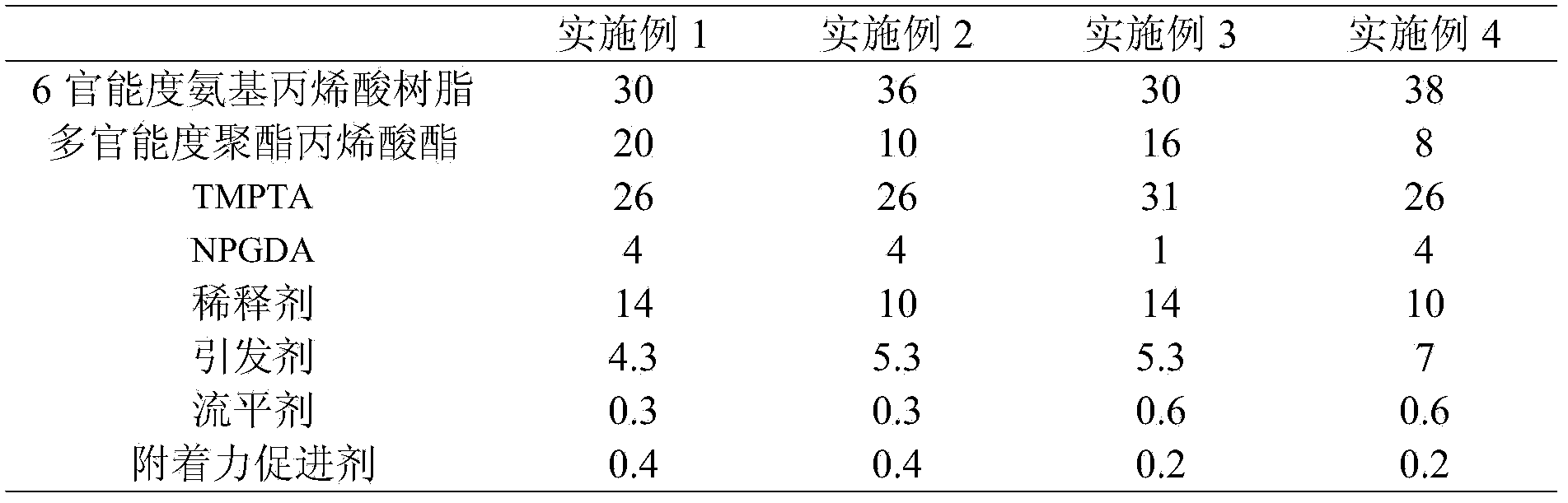

Embodiment 1

[0029] In this embodiment, the 6-functionality aminoacrylic resin used is Jiangyin Mole 1025, the 4-functionality polyester acrylate is AgiSyn730, the diluent used is a mixed solution of 5g toluene, 2g xylene and 7g ethyl acetate, and the initiator used is BASF LucirinTPO and AgiSyn1810, the leveling agent used is BYK333, and the adhesion promoter used is Ketian 7112.

Embodiment 2

[0031] In this example, the 6-functionality aminoacrylic resin used is Ketian, the 4-functionality polyester acrylate is NeoRadP-90, the diluent used is a mixture of 3g toluene and 7g ethyl acetate, and the initiator used is 4.3g BASF Irgacure184 and 1gAgiSyn1810, the leveling agent used is Silok8244, and the adhesion promoter used is Sartomer CN704.

Embodiment 3

[0033] In this example, the 6-functionality aminoacrylic resin used is Zhongshan Qianyou UN003, the 4-functionality polyester acrylate is Changxing Chemical 6323-100, and the diluent used is a mixture of 5g toluene, 2g xylene and 7g ethyl acetate , the initiator used is 4.3g BASF Irgacure184 and 1gAgiSyn1810, the leveling agent used is Digao Glide432, and the adhesion promoter used is Sartomer CN704.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com