Multifunctional power maintenance protective glove material

A protective glove and multi-functional technology, applied in the field of electric power, can solve problems such as poor effect and short service life of gloves, achieve superior flame retardancy and improve product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

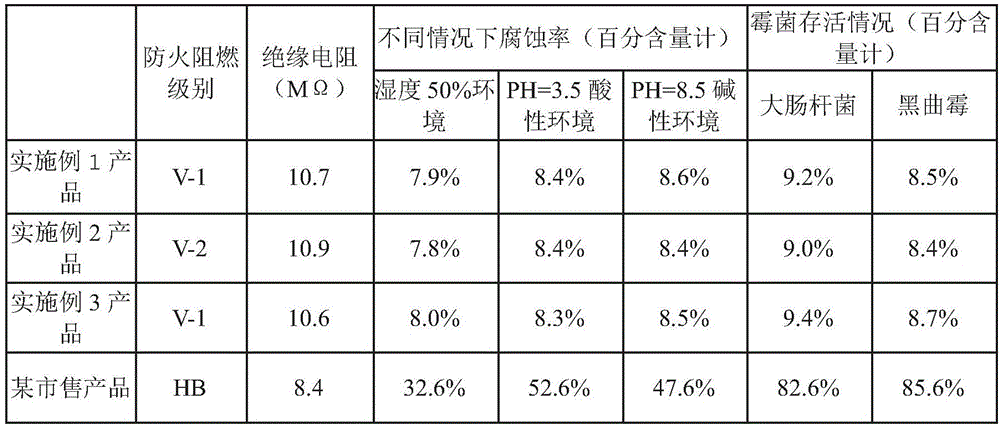

Examples

Embodiment 1

[0016] The multifunctional power maintenance protective glove material in this embodiment is composed of the following components in parts by mass: 16 parts of polymethyl methacrylate, 14 parts of halogenated butyl rubber, 14 parts of ketone aldehyde resin, tallow dihydroxyethyl 12 parts of amine oxide, 14 parts of grape seed oil, 14 parts of cooked tung oil, 12 parts of diethyl carbonate, 14 parts of Turkish oil, 14 parts of allylthiourea, 12 parts of berberine, 12 parts of oxymatrine, 12 parts of silver ion antibacterial agent, 14 parts of lithium chromate powder, 12 parts of silicon powder, 10 parts of sodium aluminosilicate powder, 14 parts of zirconium silicate powder, 12 parts of aluminum silicate powder, 10 parts of magnesium silicate powder, silicic acid 12 parts of salt, 10 parts of diatom powder, 10 parts of pyromellitic dianhydride, 12 parts of hexamethylene diisocyanate, 12 parts of hexabromocyclododecane, 12 parts of decabromodiphenyl ether, 12 parts of butyl ricin...

Embodiment 2

[0022] The multifunctional power maintenance protective glove material in this embodiment is composed of the following components in parts by mass: 18 parts of polymethyl methacrylate, 16 parts of halogenated butyl rubber, 16 parts of ketone aldehyde resin, tallow dihydroxyethyl 14 parts of amine oxide, 16 parts of grape seed oil, 16 parts of cooked tung oil, 14 parts of diethyl carbonate, 16 parts of Turkish oil, 16 parts of allylthiourea, 14 parts of berberine, 14 parts of oxymatrine, 14 parts of silver ion antibacterial agent, 16 parts of lithium chromate powder, 14 parts of silicon powder, 12 parts of sodium aluminosilicate powder, 16 parts of zirconium silicate powder, 14 parts of aluminum silicate powder, 12 parts of magnesium silicate powder, silicic acid 14 parts of salt, 12 parts of diatom powder, 12 parts of pyromellitic dianhydride, 14 parts of hexamethylene diisocyanate, 14 parts of hexabromocyclododecane, 14 parts of decabromodiphenyl ether, 14 parts of butyl ricin...

Embodiment 3

[0028] The multifunctional power maintenance protective glove material in this embodiment is composed of the following components in parts by mass: 20 parts of polymethyl methacrylate, 18 parts of halogenated butyl rubber, 18 parts of ketone aldehyde resin, tallow dihydroxyethyl 16 parts of amine oxide, 18 parts of grape seed oil, 18 parts of cooked tung oil, 16 parts of diethyl carbonate, 18 parts of Turkish oil, 18 parts of allyl thiourea, 16 parts of berberine, 16 parts of oxymatrine, 16 parts of silver ion antibacterial agent, 18 parts of lithium chromate powder, 16 parts of silicon powder, 14 parts of sodium aluminosilicate powder, 18 parts of zirconium silicate powder, 16 parts of aluminum silicate powder, 14 parts of magnesium silicate powder, silicic acid 16 parts of salt, 14 parts of diatom powder, 14 parts of pyromellitic dianhydride, 16 parts of hexamethylene diisocyanate, 16 parts of hexabromocyclododecane, 16 parts of decabromodiphenyl ether, 16 parts of butyl rici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com