Industrial protection non-woven material and manufacturing method thereof

A non-woven material and industrial protection technology, which is applied in the field of non-woven materials, can solve the problems of reducing tensile strength, affecting the protective effect, and low tensile strength, and achieves good air permeability, good flame retardant characteristics and environmental protection effects. Good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

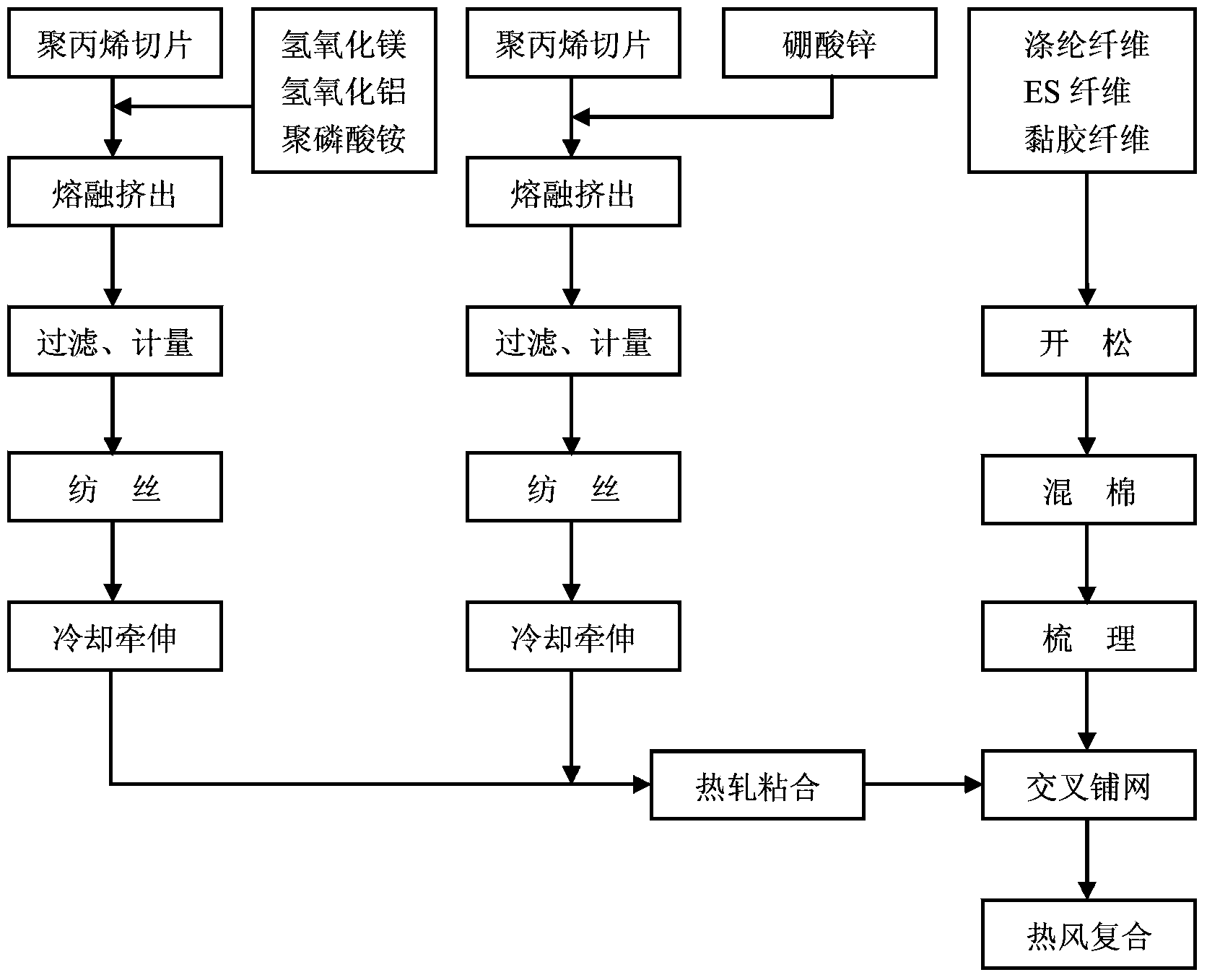

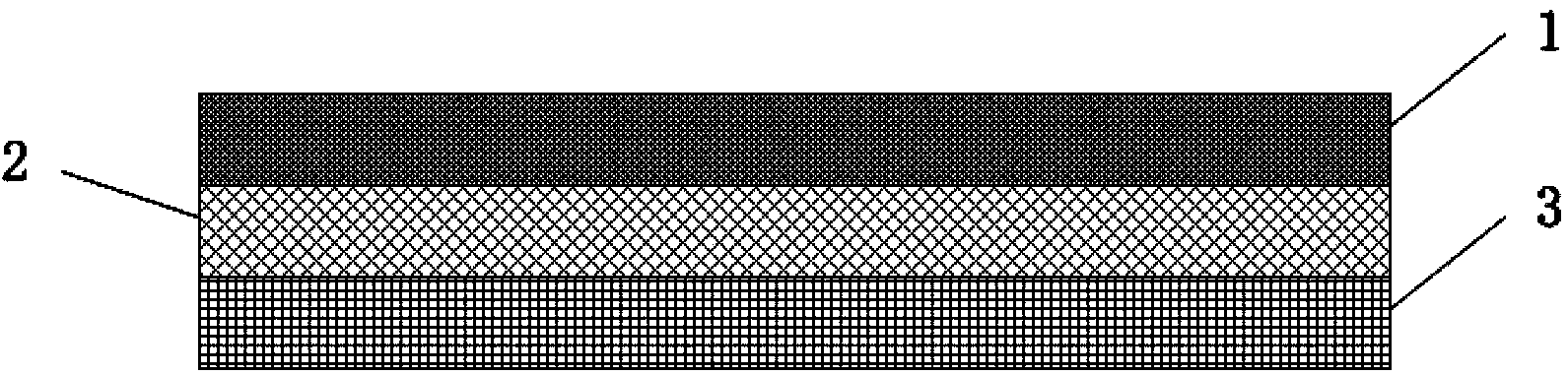

[0042] The process flow of this example, such as figure 1 As shown, first prepare PP spunbonded nonwoven fabric, and mix polypropylene, magnesium hydroxide, aluminum hydroxide, and melamine-wrapped ammonium polyphosphate with a melt index of 38g / 10min in a weight ratio of 60:10:10:20. Raw materials, produced according to the polypropylene spunbond process, the grammage is 20g / m 2 Spun-bonded nonwoven fabric; zinc borate and polypropylene chips with a melt index of 1500g / 10min are mixed in a weight ratio of 10:90, and the production weight is 10g / m 2 PP melt-blown nonwoven fabric; then produce and process according to the process of melt-blown non-woven fabric, lay the melt-blown fiber web on the pre-produced spun-bonded non-woven fabric, and bond the two layers of non-woven fabric through a rolling mill , to make a SM nonwoven fabric layer; the bonded SM nonwoven fabric layer and the carded ES doped nonwoven fabric layer are cross-laid, and after cross-lapping, they enter th...

Embodiment 2

[0045] The process flow of this example is the same as that of Example 1, wherein the melt index of polypropylene for preparing PP spunbonded nonwovens is 38g / 10min, and the weight of ammonium polyphosphate wrapped by polypropylene, magnesium hydroxide, aluminum hydroxide, and melamine The ratio is 65:10:10:15, and the production weight is 20g / m 2 PP spunbond nonwoven fabric; PP melt blown nonwoven composition and preparation method are the same as embodiment one; In the ES doped nonwoven fabric layer carded into the net, the fineness of polyester fiber and ES fiber are respectively 9D and 4D, the mixing ratio of the three fibers remains unchanged; the hot-air drying oven for hot-air bonding and composite consolidation after cross-lapping is set at a hot-air temperature of 105°C. Other unmentioned parts are the same as the first embodiment.

[0046] After testing, the nonwoven material for industrial protective clothing prepared in this example has good tensile strength, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com