Low-carbon environment-friendly cellular light composite wallboard

A composite wallboard, low-carbon and environmentally friendly technology, applied in thermal insulation, building components, sound insulation, etc., can solve the problems of large unit proportion of formed board, large orange rod material unit, complex production process, etc., and achieves sound insulation and heat insulation performance. Good pressure bearing capacity, good durability, and the effect of reducing operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

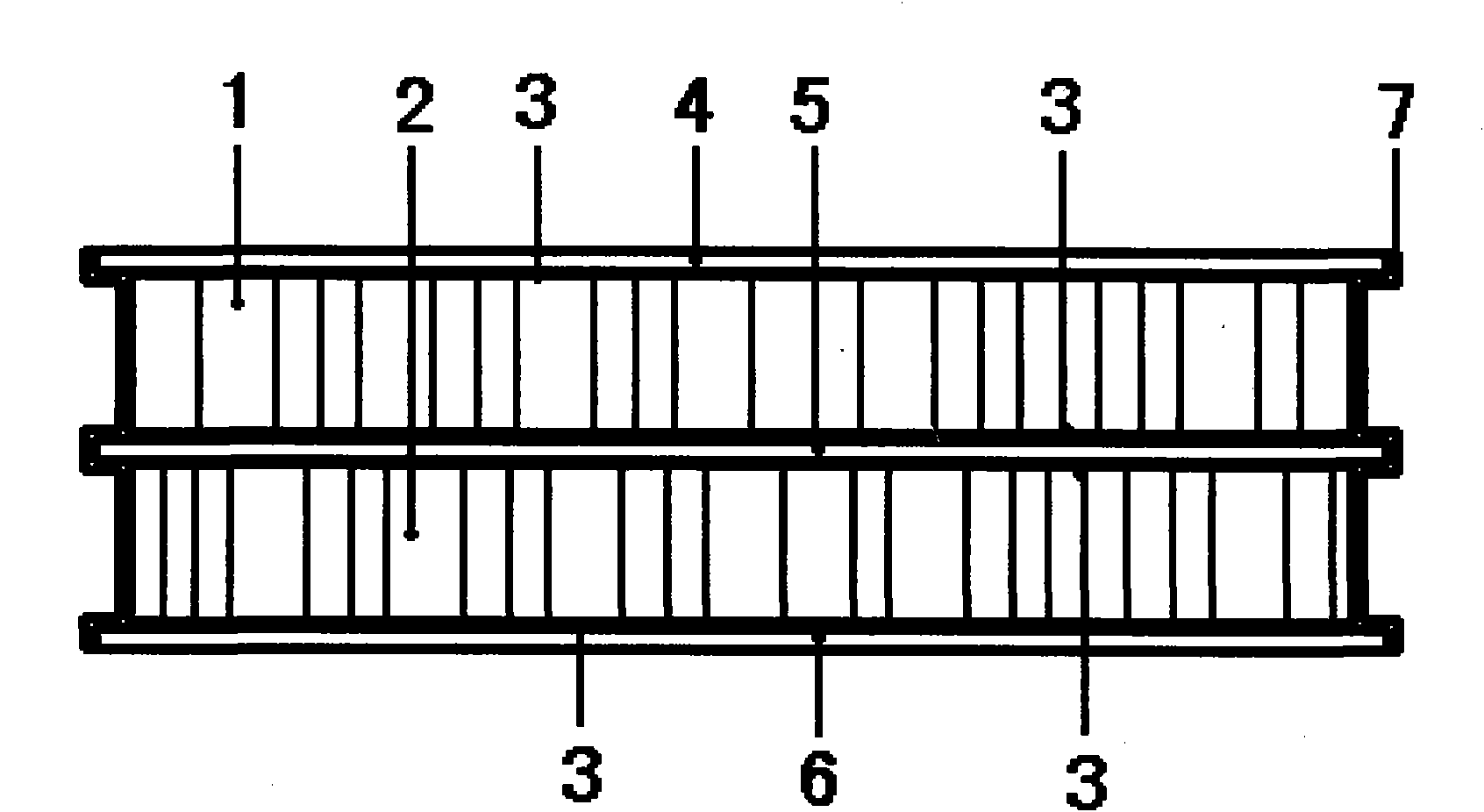

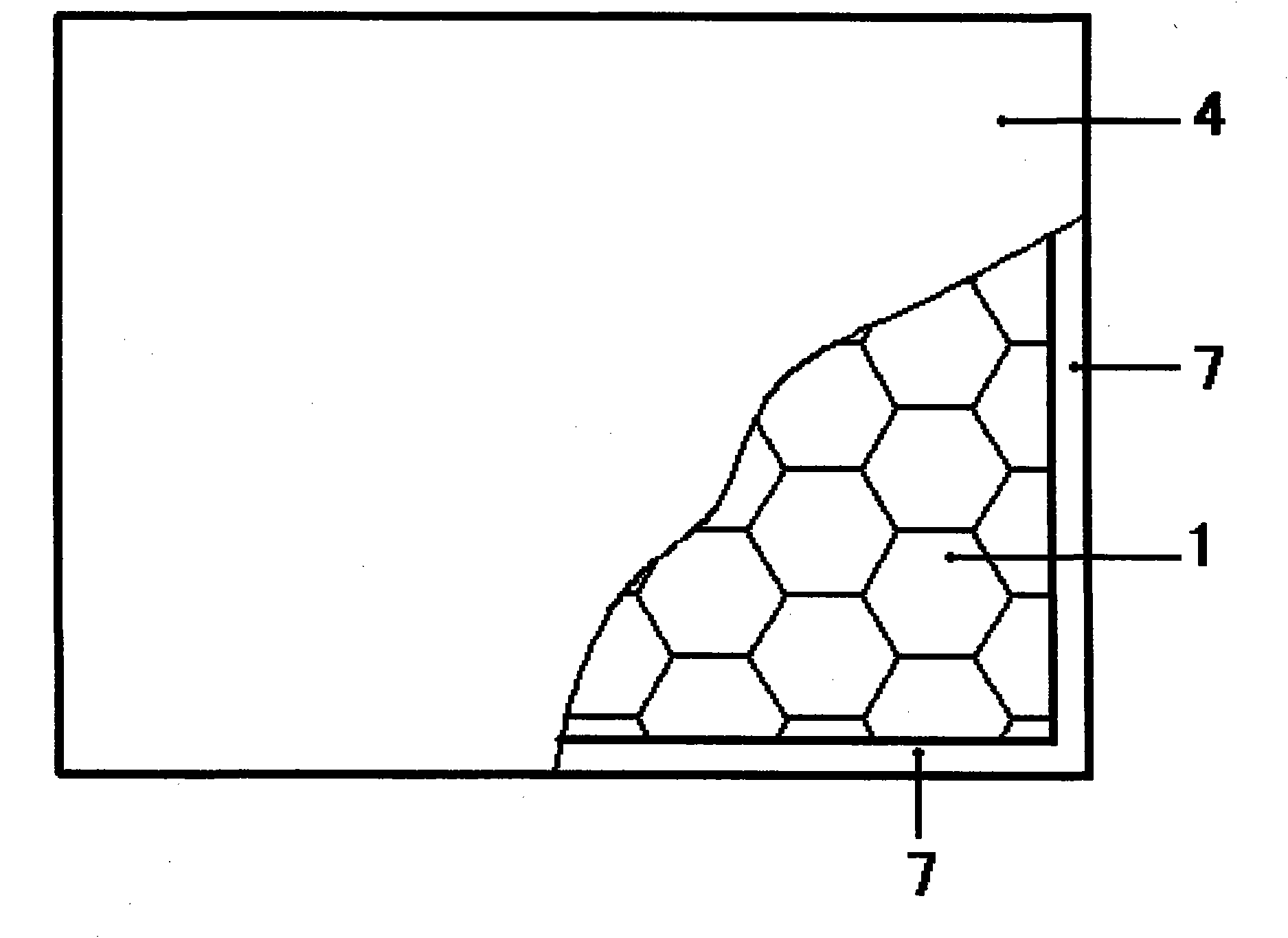

[0036] Example 1: Combining figure 1 The present invention will be specifically described.

[0037]The honeycomb lightweight composite wallboard includes: honeycomb cardboard inner layer core materials 1, 2, waterproof and heat-resistant adhesive layer 3, environment-friendly panels 4, 5, 6, and reinforced edge-sealing connection buckle 7. The core materials 1 and 2 of the inner layer of the honeycomb cardboard are respectively sandwiched between the upper environmental protection profile 4, the middle environmental protection profile 5, and the lower environmental protection profile 6. The waterproof and heat-resistant adhesive layer 3 connects the honeycomb cardboard The layer core material and the three environmental protection panels are firmly pasted together, and the reinforced edge sealing connection buckle 7 is embedded in the composite plate along the four sides of the composite plate to make a honeycomb lightweight composite wallboard.

Embodiment 2

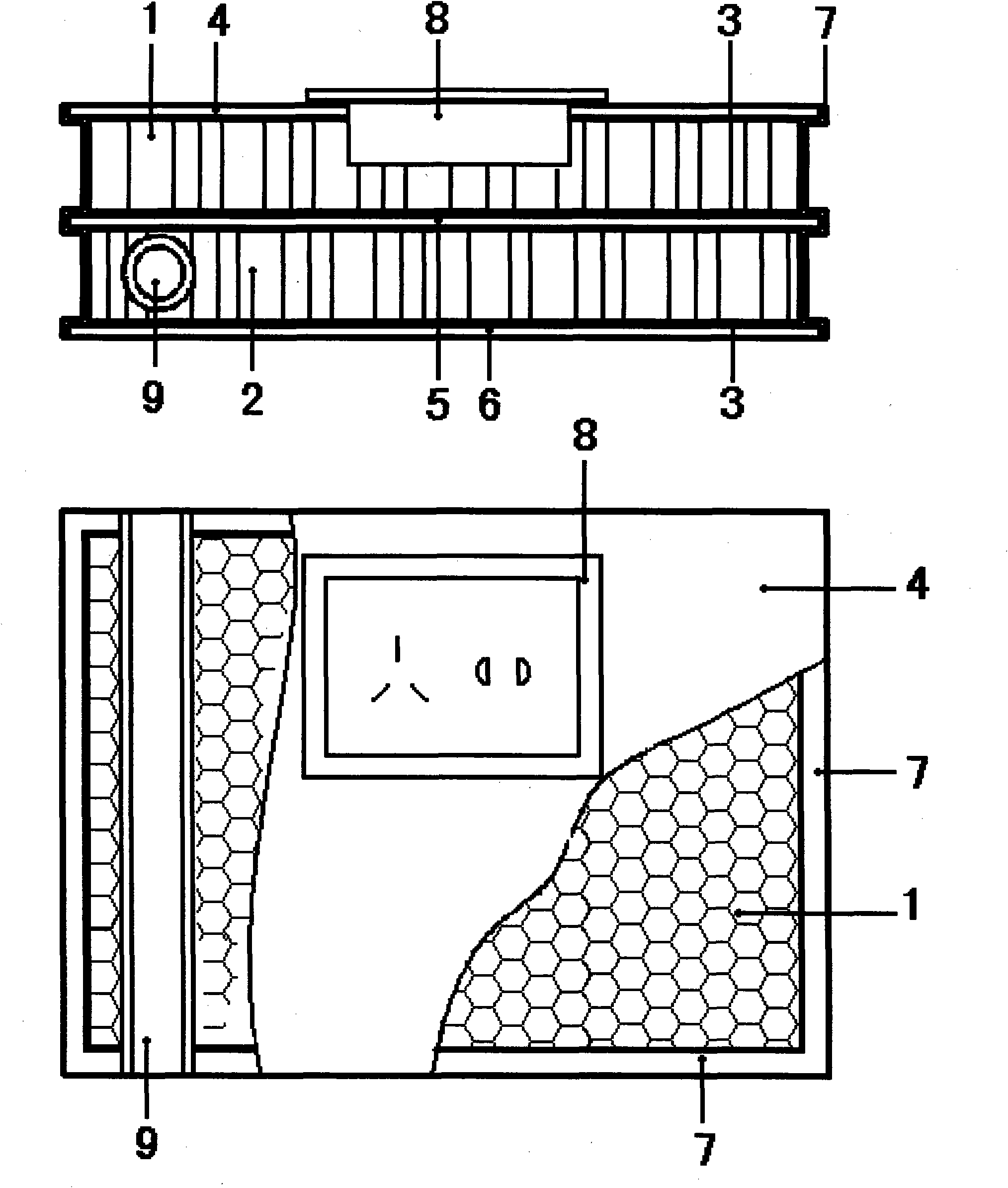

[0038] Example 2: Combining image 3 The present invention will be specifically described.

[0039] Honeycomb lightweight composite wallboard includes: honeycomb cardboard inner layer core material 1, 2, waterproof and heat-resistant adhesive layer 3, environment-friendly panels 4, 5, 6, reinforced edge sealing connection buckle 7, embedded electrical junction box 8 , wire protective tube 9.

[0040] The core materials 1 and 2 of the inner layer of the honeycomb cardboard are sandwiched between the upper environmental protection panel 4, the middle environmental protection panel 5 and the lower environmental protection panel 6 respectively, and the waterproof and heat-resistant adhesive layer 3 connects the inner layer of the honeycomb cardboard. The core material is firmly pasted together with the three environmental-friendly panels. The embedded electrical junction box 8 passes through one side panel and embeds the inner core material of the honeycomb cardboard on the same ...

Embodiment 3

[0041] Example 3: Binding Figure 5 The present invention will be specifically described.

[0042] The honeycomb lightweight composite wallboard can adopt the structural form of Example 1 or Example 2, but the reinforced edge-sealing connecting buckle 7 of the honeycomb lightweight composite wallboard adopts the inserted male and female joint form shown in this figure.

[0043] In the figure, there are two honeycomb lightweight composite wall panels on the left and right, and the edge banding buckle 7a of the left composite wall panel is embedded in the inner layer of the composite wall panel to the left along the lower side of the upper panel 4 and the upper side of the lower panel 6 of the left composite wall panel. Inside the core material, self-tapping screws 11 securely connect the edge banding strip to the upper panel 4 and lower panel 6 of the left composite wallboard; the edge banding buckle 7b of the right composite wallboard is embedded in the inner core of the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com