Multi-point anchoring sectional reinforcement construction method for prestressed carbon fiber plate of variable cross-section beam

A carbon fiber plate and variable cross-section beam technology, which is applied in bridge reinforcement, bridge maintenance, bridges, etc., can solve problems such as difficulties in carbon fiber plate reinforcement, achieve the effects of shortening the construction period, reducing cost, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to further understand the content of the present invention, the present invention is described in detail in conjunction with examples, and the following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention.

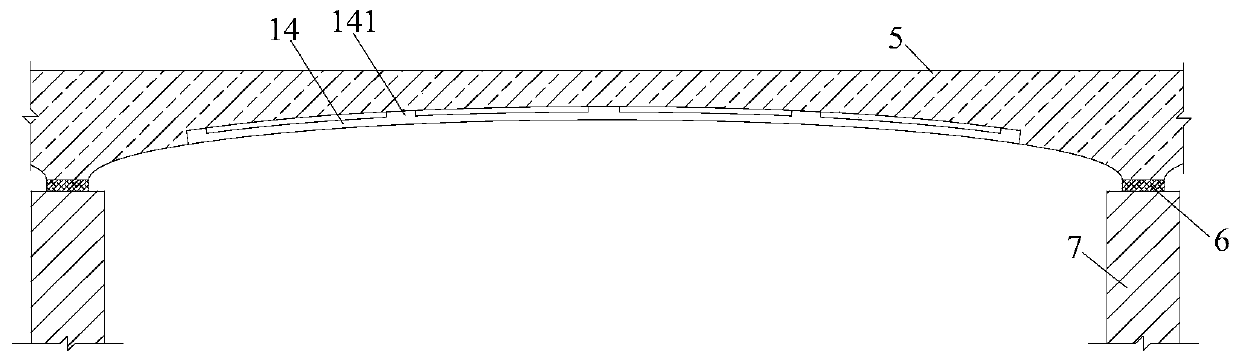

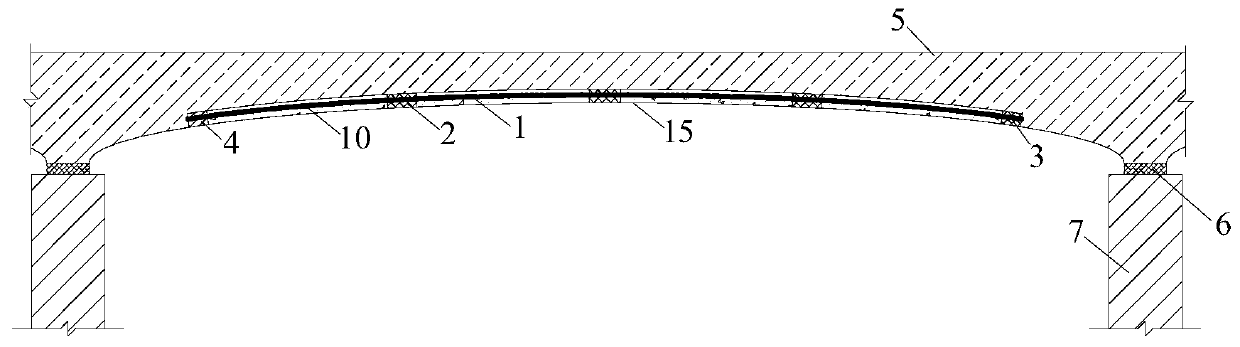

[0050] The multi-point anchoring segmental reinforcement construction method of prestressed carbon fiber plate of variable cross-section beam is used to strengthen the variable cross-section beam 5, which is erected on the pier column 7 through the support 6, and the thickness of the reinforcement protection layer at the bottom of the variable cross-section beam 5 is 5cm . The multi-point anchoring segmental strengthening construction method of the prestressed carbon fiber plate of the variable cross-section beam includes the following steps:

[0051] 1) combined with attached figure 1 As shown, the variable cross-section beam 5 is cut to form a groove 14 at the bottom of the beam:

[0052] 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com