Heat-resistant shielded power cable for nuclear power stations

A technology for power cables and nuclear power plants, applied in the field of heat-resistant shielded power cables for nuclear power plants, can solve problems such as difficulty in achieving heat-resistant shielding for nuclear power plants, no indication of which materials to use, hidden dangers of normal system operation, etc., and achieves high hardness and toughness. The effect of uniform dielectric constant and excellent electrical shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

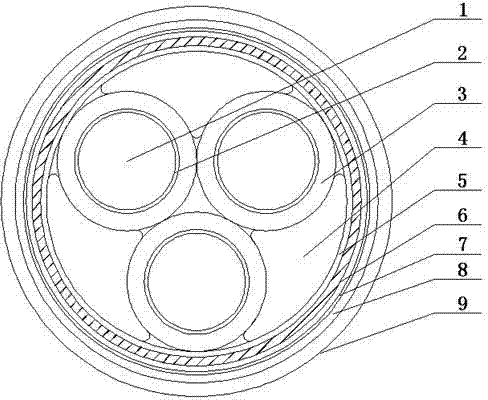

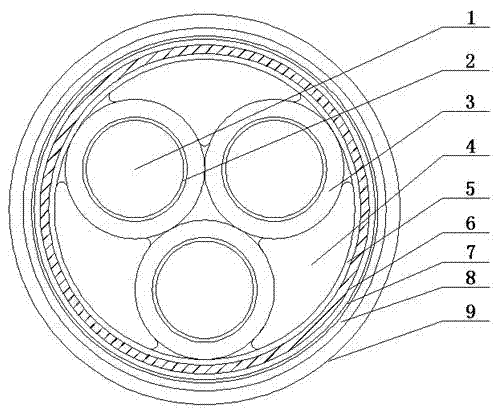

[0024] The present invention includes a composite cable core, the composite cable core is formed by twisting three power cables, a filler layer 4 is arranged on the composite cable core, and an isolation layer 5, Composite shielding layer 6, flame retardant tape 7, oxygen barrier layer 8 and outer sheath 9, the filler layer 4 is made of low-smoke halogen-free flame-retardant polyolefin material, the isolation layer 8 is made of polyester film wrapped, the composite shielding The inner layer of layer 6 (hatched part) is braided and wrapped with tinned copper wire, and the outer layer of composite shielding layer 6 (peripheral part of the hatched part) is wrapped with aluminum-plastic composite tape (aluminum-plastic composite tape is wrapped around make the aluminum foil facing outward), the flame-retardant tape 7 is made of glass fiber tape wrapping, the oxygen barrier layer 8 is made of irradiation cross-linked low-smoke halogen-free flame-retardant polyethylene extruded and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com