Filler composition and application thereof

A technology of composition and resin composition, which is applied in the field of laminates, can solve the problems of high production cost, high cost of spherical silica powder, narrow application range, etc., and achieve the effect of increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

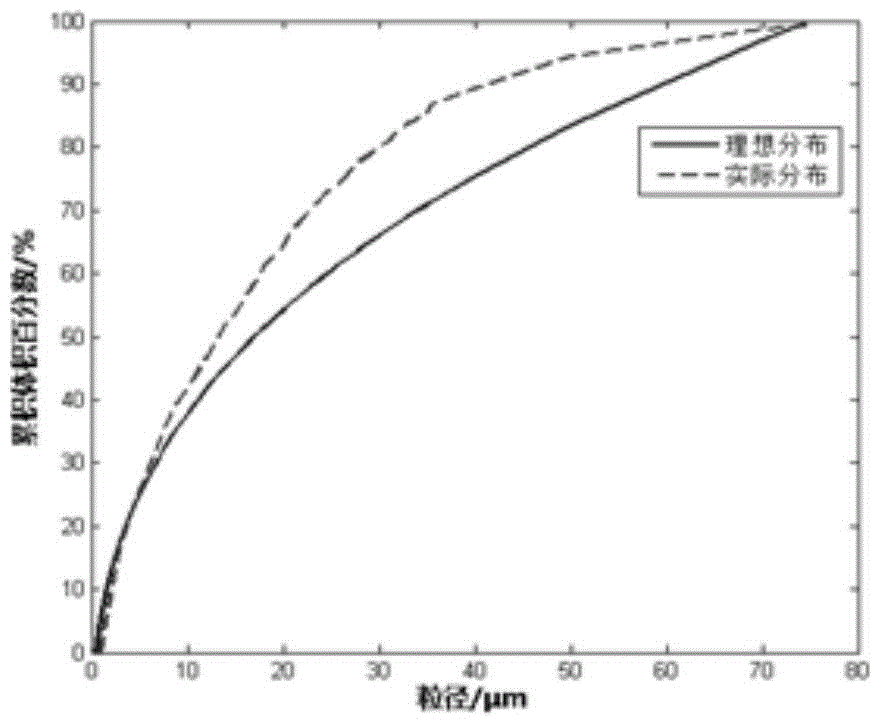

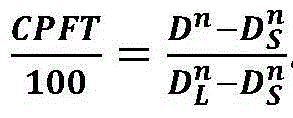

Method used

Image

Examples

Embodiment 1-6

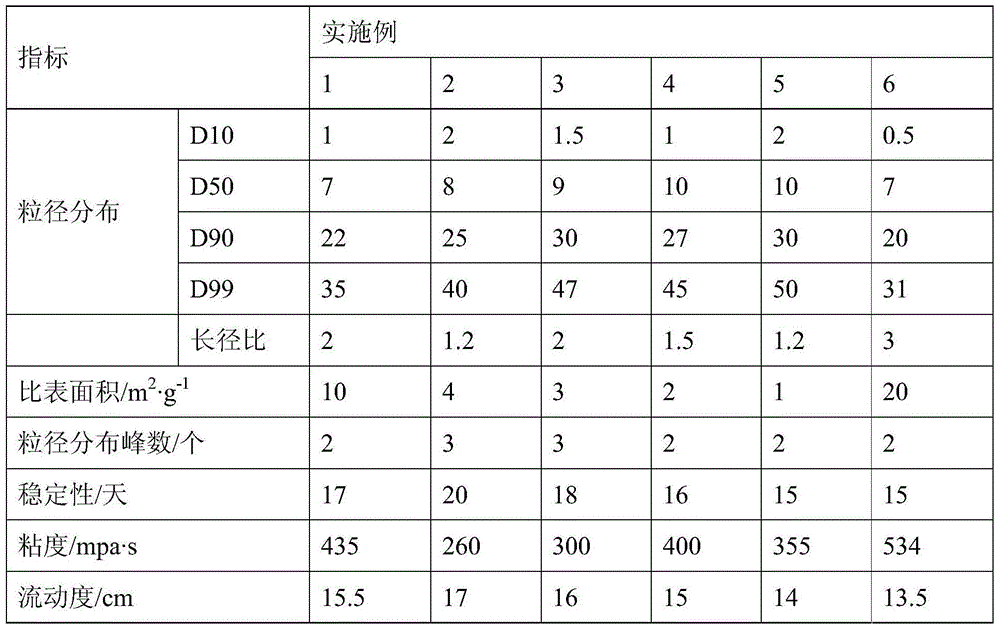

[0046] Angular silica with different particle size distributions was prepared, and the particle size distribution, specific surface area and peak number of particle size distribution are shown in Table 1. Use vinyl silane coupling agent (Shin-Etsu Chemical, product name KBM1003) to carry out surface treatment to angular silica (self-preparation) of different particle size distribution, the consumption of this surface treatment agent is 1% of siliceous micropowder filler weight , and then add butanone solution, and prepare a filler composition with a solid content of 70% after high-speed grinding.

[0047] The following test methods were used to test and evaluate the fluidity, viscosity and stability of the obtained filler composition, and the results are shown in Table 1.

Embodiment 7-12

[0058] With 100 parts by weight of brominated bisphenol A type epoxy resin (Dow Chemical, epoxy equivalent 435, bromine content 19%, product name DER530), 24 parts by weight of novolak resin (Japan Qunrong, hydroxyl equivalent 105, product name TD2090), 0.05 parts by weight of 2-methylimidazole, respectively added to the self-made filler composition in Examples 1-6, placed in a methyl ethyl ketone solvent, mechanically stirred, emulsified, and the filler content of Example 7-12 is 30wt % (based on resin), glue with a solid content of 65wt%, then impregnated with glass fiber cloth, heated and dried to form a prepreg, placed copper foil on both sides, pressurized and heated to form a copper clad laminate.

[0059] The following test methods were used to test and evaluate the coefficient of thermal expansion (CTE), interlayer adhesion and dispersion of the obtained copper-clad laminate, and the results are shown in Table 3.

Embodiment 13

[0061] With 100 parts by weight of brominated bisphenol A type epoxy resin (Dow Chemical, epoxy equivalent 435, bromine content 19%, product name DER530), 24 parts by weight of novolak resin (Japan Qunrong, hydroxyl equivalent 105, product name TD2090), 0.05 parts by weight of 2-methylimidazole, adding the self-made filler composition in Example 2, placing in a methyl ethyl ketone solvent, mechanical stirring, emulsification and being formulated so that the filler content is 50wt% (based on resin), and the solid content is 65wt% glue, impregnated with glass fiber cloth, heated and dried to form a prepreg, placed copper foil on both sides, pressurized and heated to form a copper clad laminate.

[0062] The following test methods were used to test and evaluate the coefficient of thermal expansion (CTE), interlayer adhesion and dispersion of the obtained copper-clad laminate, and the results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com