Patents

Literature

280 results about "Silenes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silene, or silalkenes, are unsaturated hydrosilicons, which means that they consist only of hydrogen and silicon atoms and all bond, with the exception of one double bond, are either single or double bonds. By definition cycles are excluded, so that the silenes comprise homologous series of inorganic compounds with the general formula SiₙH₂ₙ ₋ ₂ₖ ₊ ₂, k > 0, where k is defined as the number of double bonds. There are no commercial sources.

Catalysts for making ethanol from acetic acid

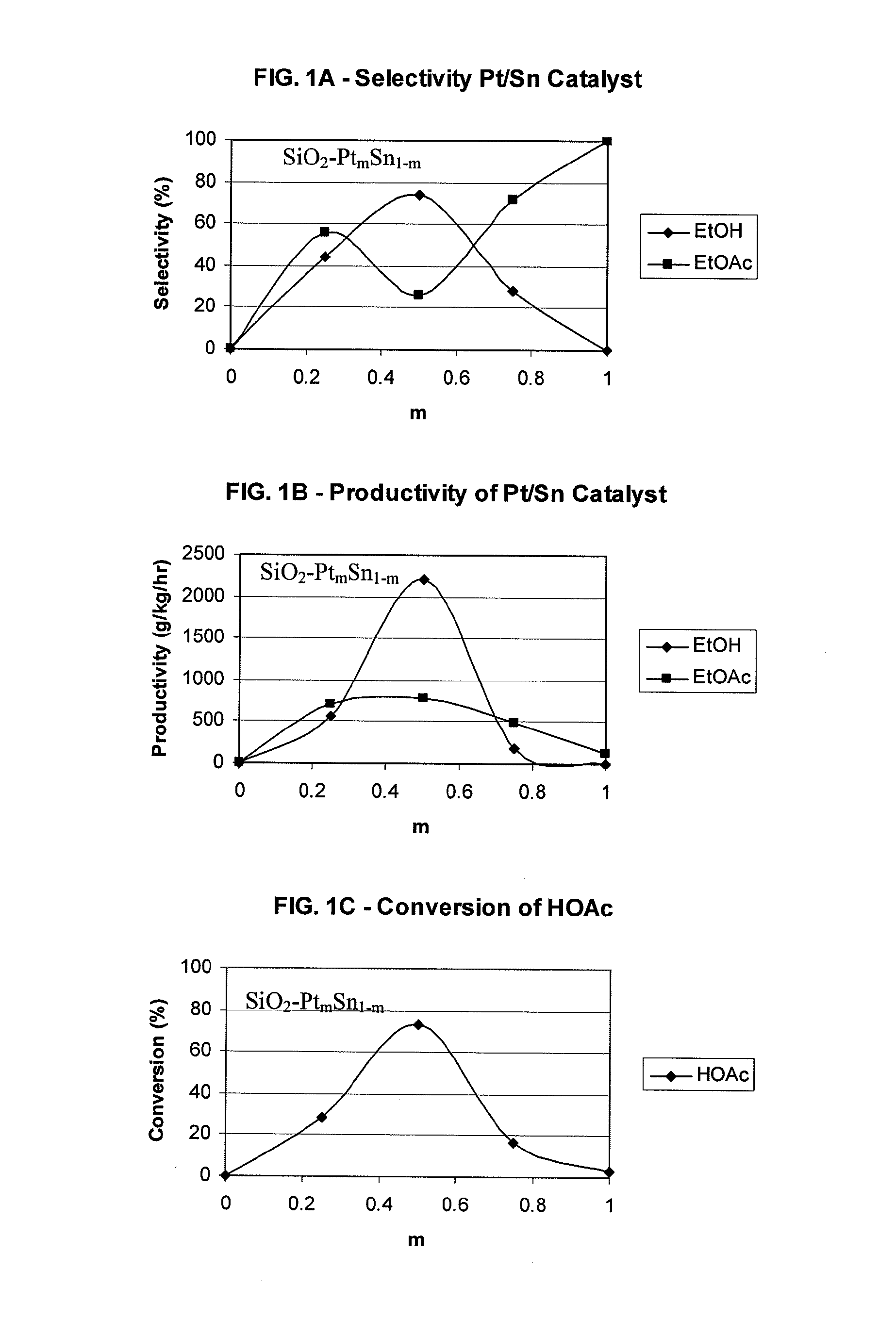

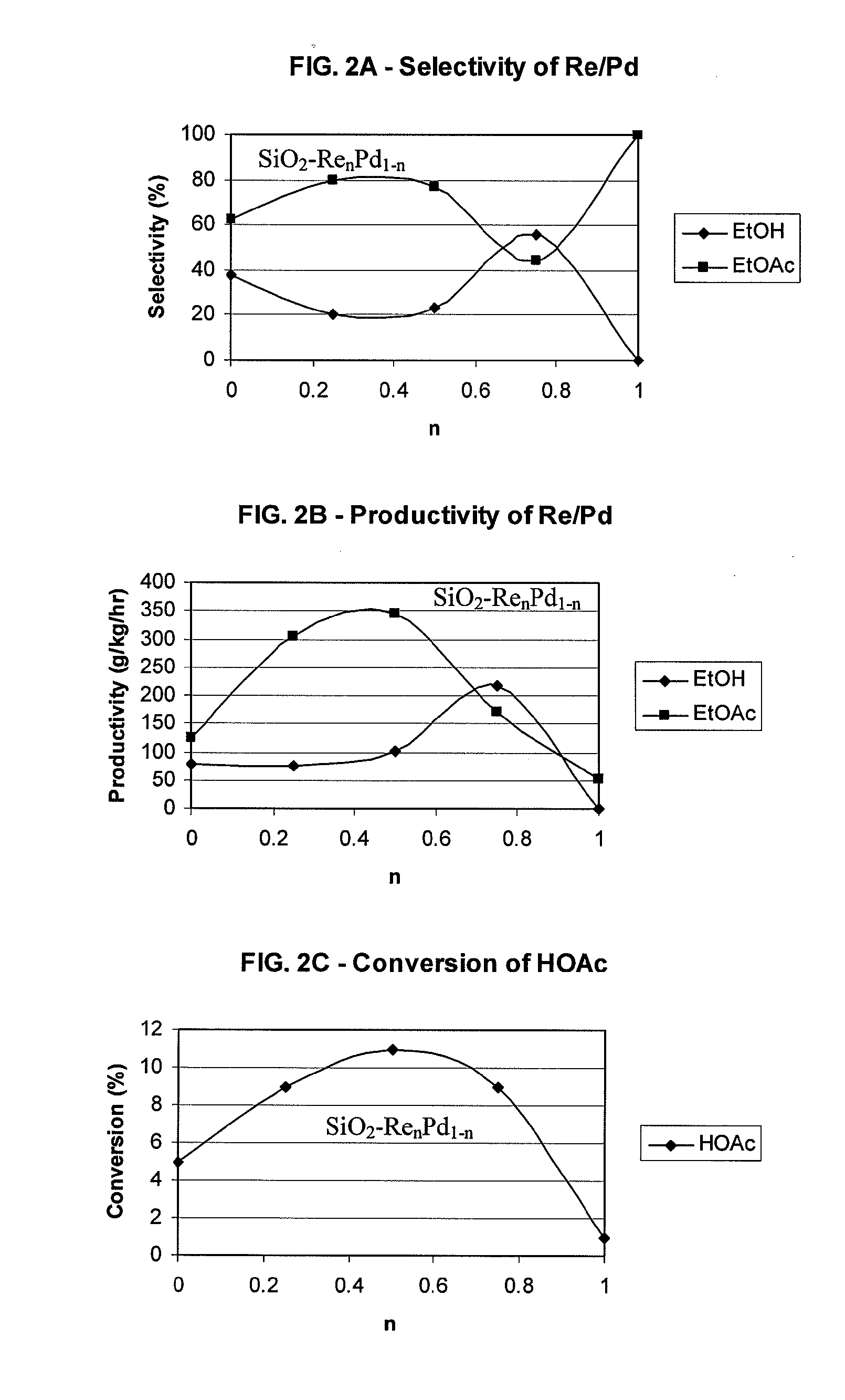

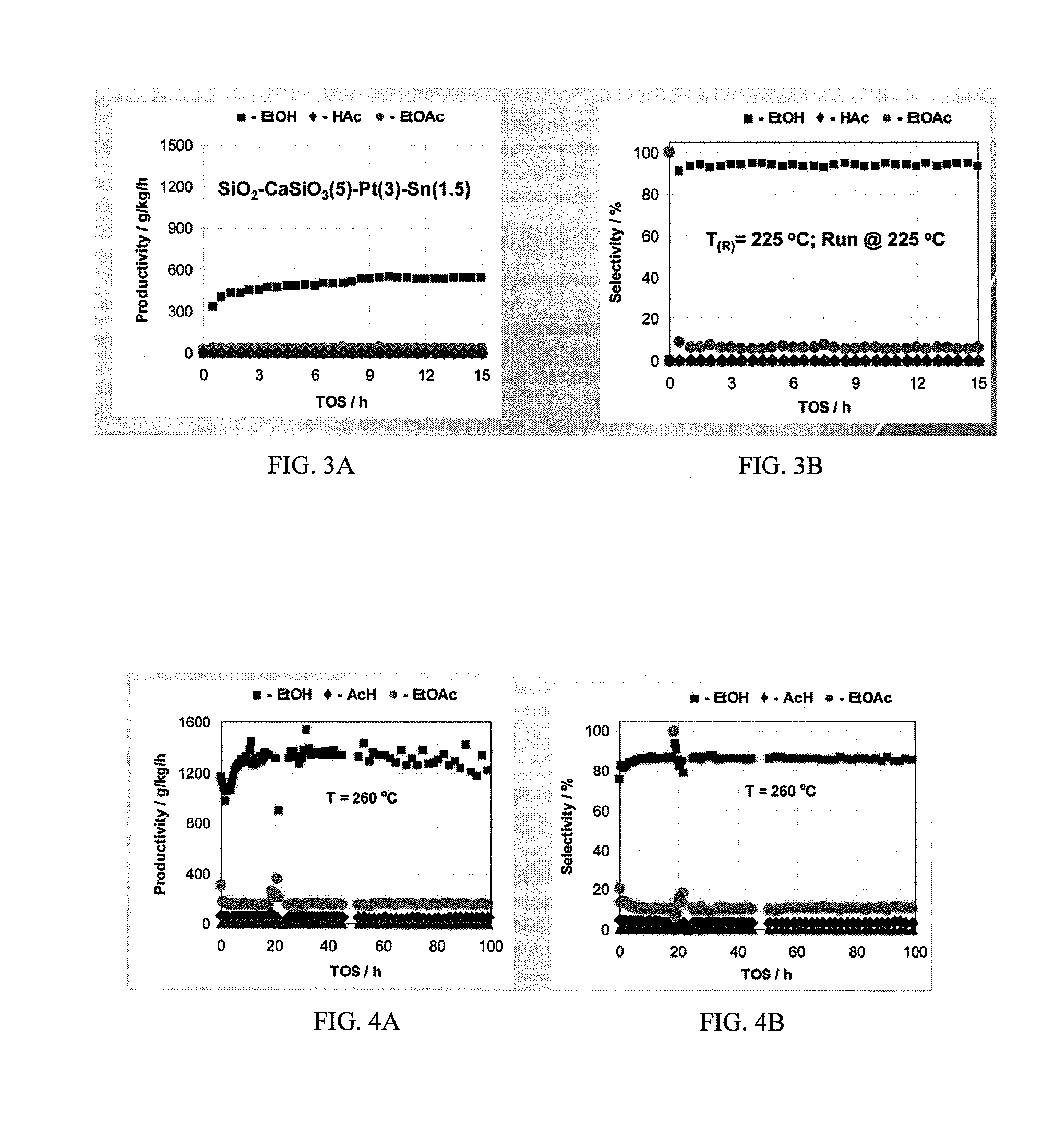

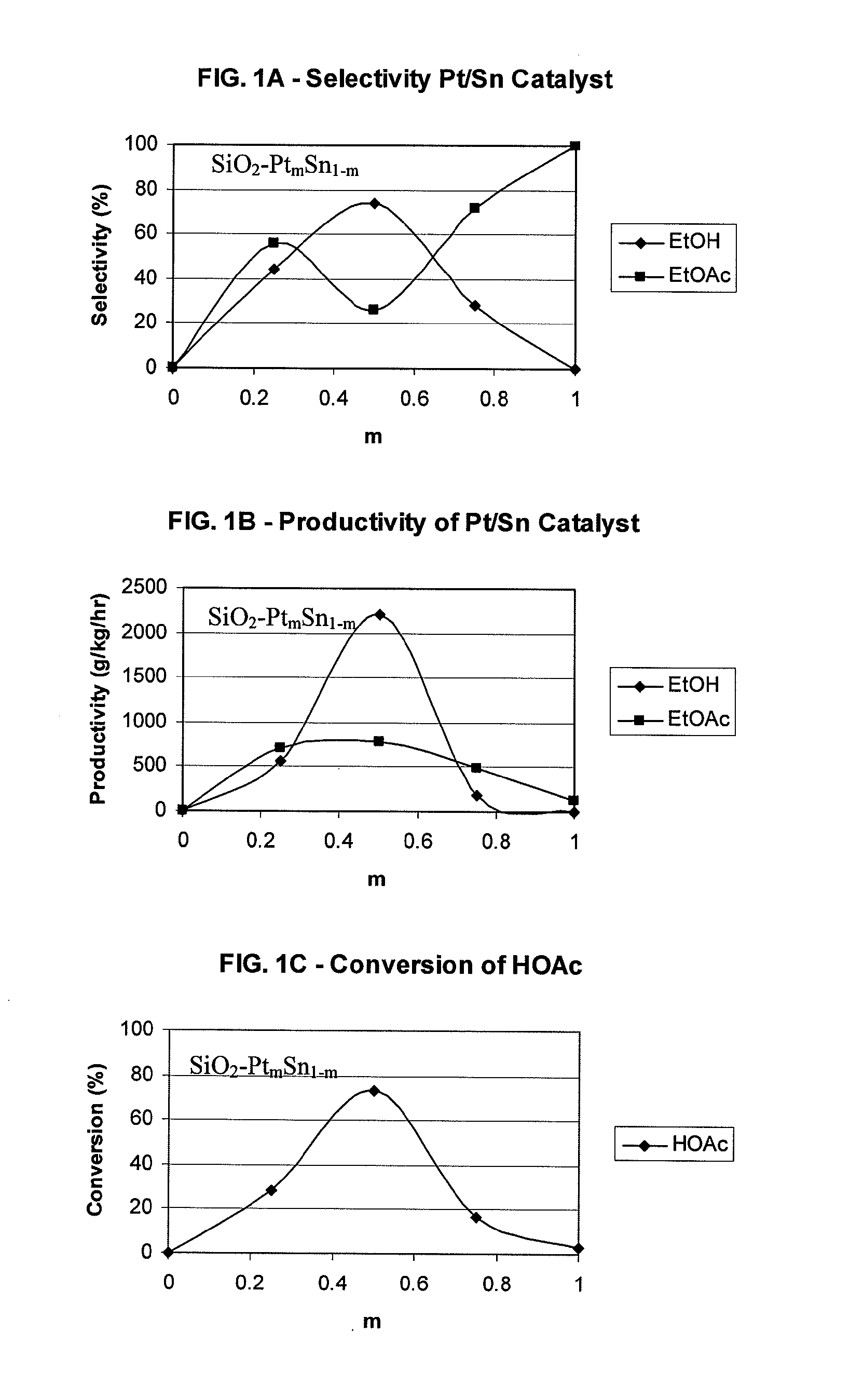

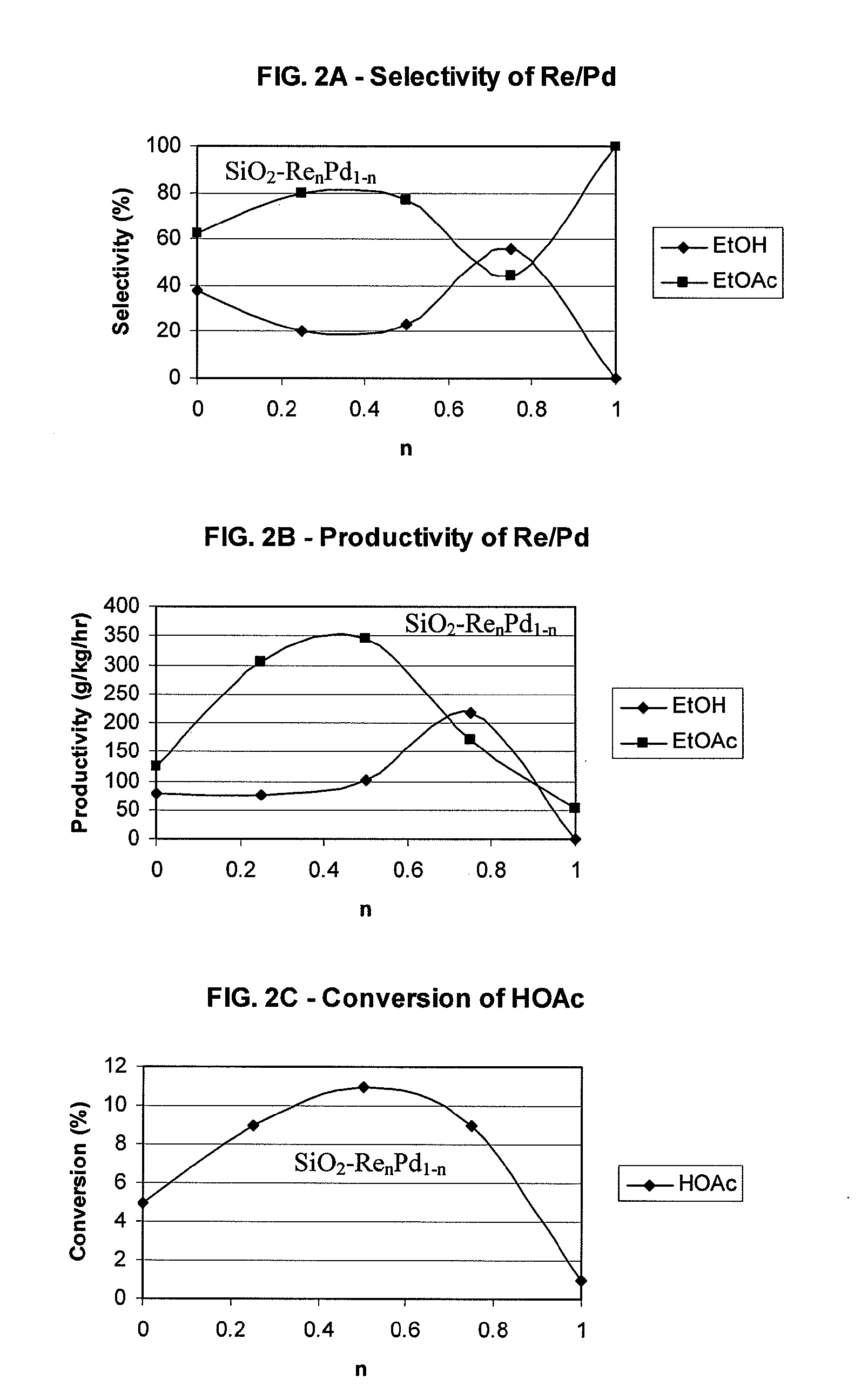

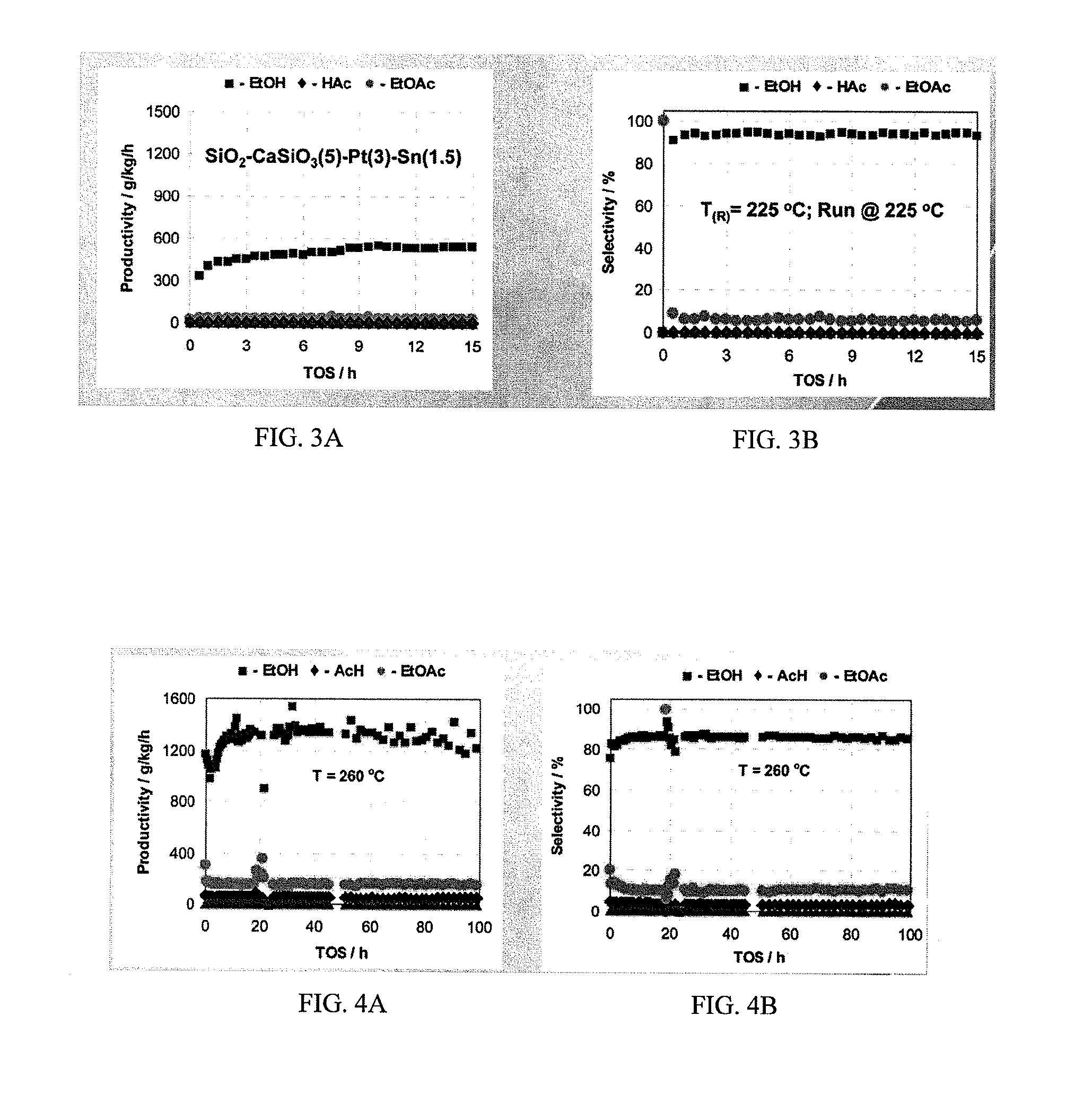

InactiveUS20100197485A1High selectivitySuitable for useMolecular sieve catalystsOrganic compound preparationTungstenIridium

Catalysts and processes for forming catalysts for use in hydrogenating acetic acid to form ethanol. In one embodiment, the catalyst comprises a first metal, a silicaceous support, and at least one metasilicate support modifier. Preferably, the first metal is selected from the group consisting of copper, iron, cobalt, nickel, ruthenium, rhodium, palladium, osmium, iridium, platinum, titanium, zinc, chromium, rhenium, molybdenum, and tungsten. In addition the catalyst may comprise a second metal preferably selected from the group consisting of copper, molybdenum, tin, chromium, iron, cobalt, vanadium, tungsten, palladium, platinum, lanthanum, cerium, manganese, ruthenium, rhenium, gold, and nickel.

Owner:CELANESE INT CORP

Processes for making ethanol from acetic acid

InactiveUS20100197985A1High selectivityPreparation by oxo-reaction and reductionEthylene productionCeriumCobalt

A process for selective formation of ethanol from acetic acid by hydrogenating acetic acid in the presence of first metal, a silicaceous support, and at least one support modifier. Preferably, the first metal is selected from the group consisting of copper, iron, cobalt, nickel, ruthenium, rhodium, palladium, osmium, iridium, platinum, titanium, zinc, chromium, rhenium, molybdenum, and tungsten. In addition the catalyst may comprise a second metal preferably selected from the group consisting of copper, molybdenum, tin, chromium, iron, cobalt, vanadium, tungsten, palladium, platinum, lanthanum, cerium, manganese, ruthenium, rhenium, gold, and nickel.

Owner:CELANESE INT CORP

Method for producing flexographic printing plates by means of laser engraving

InactiveUS6935236B2High resolutionAvoid it happening againDuplicating/marking methodsSemiconductor/solid-state device manufacturingCross-linkLaser engraving

The invention relates to a method for producing flexographic printing forms by engraving a printing relief on a flexographic printing element that can be laser engraved, said element having a photochemically cross-linked relief layer. The relief layer is transparent and comprises oxidic, siliceous or zeolitic solid matter with a particle size between 1 and 400 nm in a quantity of between 0.1 and 8 wt. % in relation to the quantity of all components in the relief layer.

Owner:XSYS PRINT SOLUTIONS DEUT GMBH

Silane-modified oxidic or siliceous filler, process for its production and its use

Silane-modified oxidic or siliceous filler with a bead fraction below 75 μm of less than 15 wt. % and a median particle size distribution between of 150 to 500 μm, which is produced by the reaction of at least one microbeaded or microgranular, oxidic or siliceous filler in a compressed gas with at least one silane. The silane-modified oxidic or siliceous fillers are used in rubber compounds.

Owner:EVONIK DEGUSSA GMBH

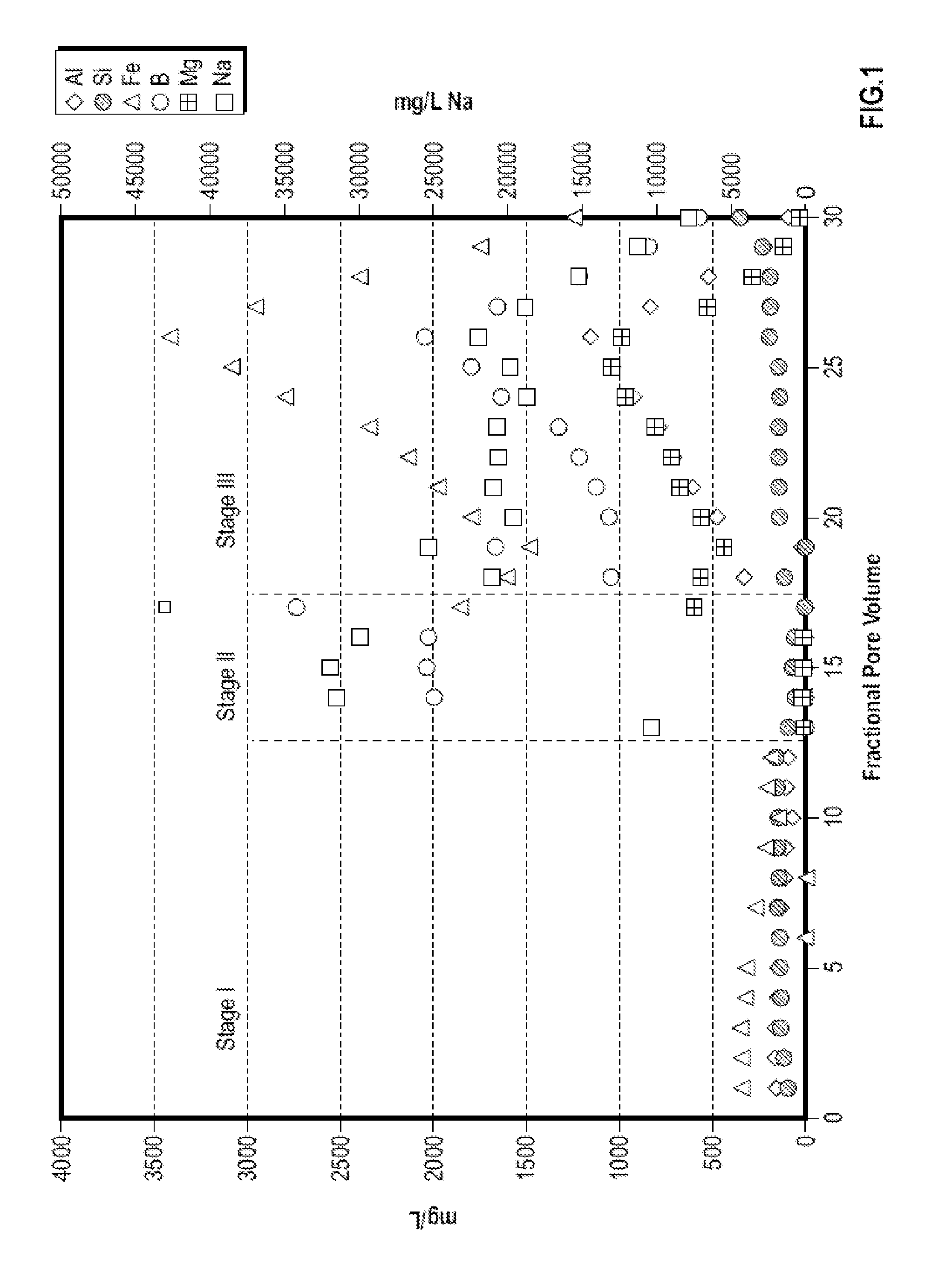

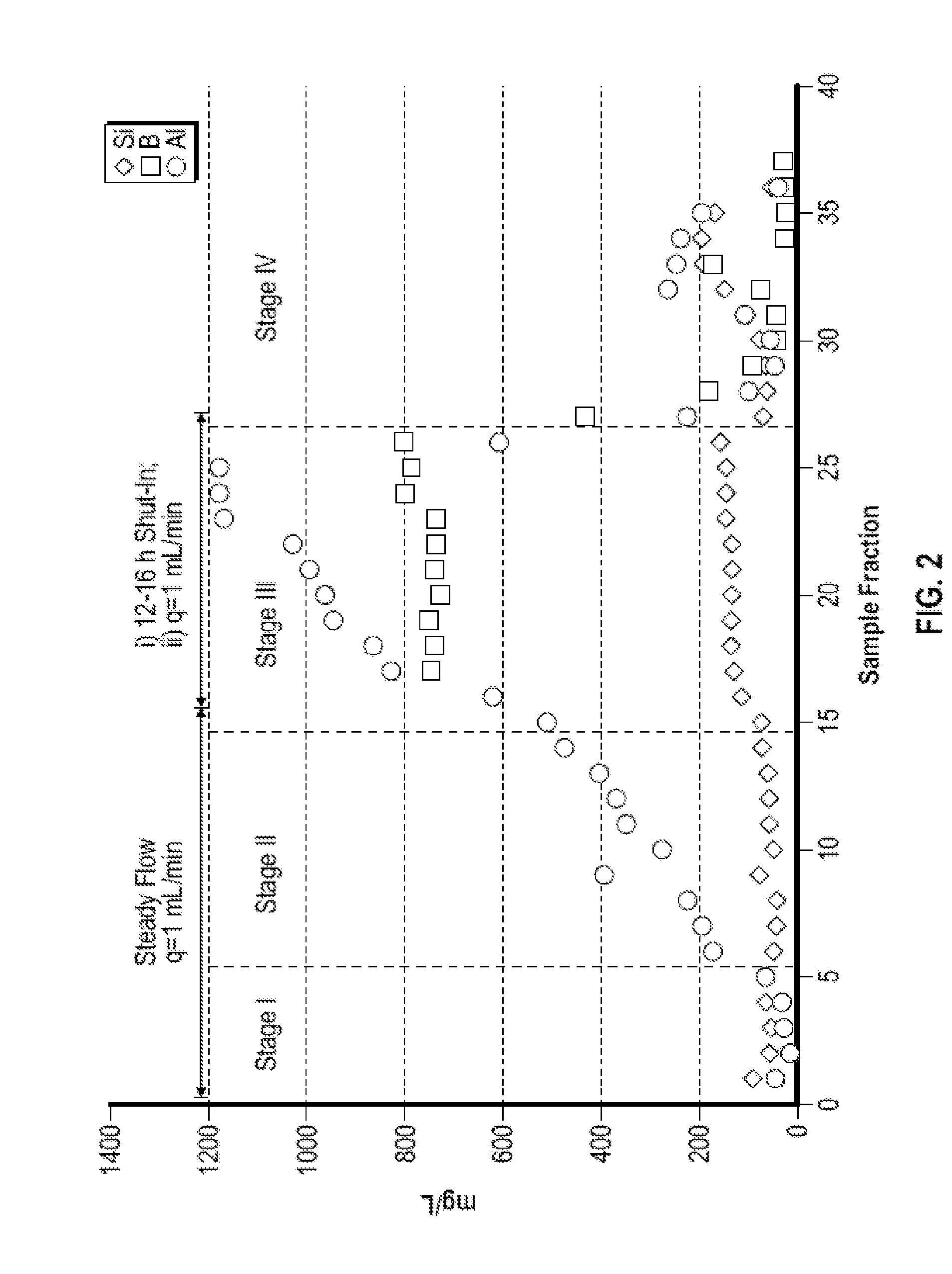

Treatment fluids containing a boron trifluoride complex and methods for use thereof

Treatment fluids for use in subterranean formations, particularly sandstone and other siliceous formations, may contain a source of fluoride ions to aid in mineral dissolution. In some cases, it may be desirable to generate the fluoride ions from a fluoride ion precursor, particularly a hydrofluoric acid precursor, such as a boron trifluoride complex. Methods described herein can comprise providing a treatment fluid that comprises an aqueous base fluid, a boron trifluoride complex, and a chelating agent composition, and introducing the treatment fluid into a subterranean formation,

Owner:HALLIBURTON ENERGY SERVICES INC

Cleaning and multifunctional coating composition containing an organosilane quaternary compound and methods of using

ActiveUS20050096250A1Improve adhesionIncreased durabilitySilicon organic compoundsCationic surface-active compoundsPolyesterSand granules

Cleaning and multifunctional coating compositions containing hydrogen peroxide and an organosilane quaternary compound in aqueous formulations are used to improve water and soil repellency and residual antimicrobial activity. Various surfaces may be treated including metal, glass, plastics, rubber, porcelain, ceramic, marble, granite, cement, tile, sand, silica, enameled appliances, polyurethane, polyester, polyacrylic, melamine / phenolic resins, polycarbonate, siliceous, painted surfaces, wood, and the like.

Owner:RESOURCE DEV LLC

Tamping plug for blast furnace spout and its preparation method

InactiveCN1718752ALow costImprove performanceBlast furnace componentsBlast furnace detailsAl powderTar

A stemming for the tap hole of blast furnace is proportionally prepared from industrial corundum particles, silicon carbide particles, medium-temp asphalt particles, Suzhou clay powder, coke powder, high-Al powdered coal ash and tar oil through proportional mixing, stirring and vacuum extruding. It features low cost and high stability.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Composition for treating substrate and process of treatment

InactiveUS20040060476A1Improve propertiesExcellent abrasion resistanceOther chemical processesCoatingsOrganic solventWater insoluble

The composition for treating a siliceous substrate comprises: substantially water insoluble fluoro silane; an organic solvent in an amount sufficient for solubilizing the fluoro silane, and at least one ammonium and / or phosphonium compound, the weight ratio (ammonium and / or phosphonium compound / water insoluble fluoro silane) being greater than 0.005

Owner:ICT COATINGS

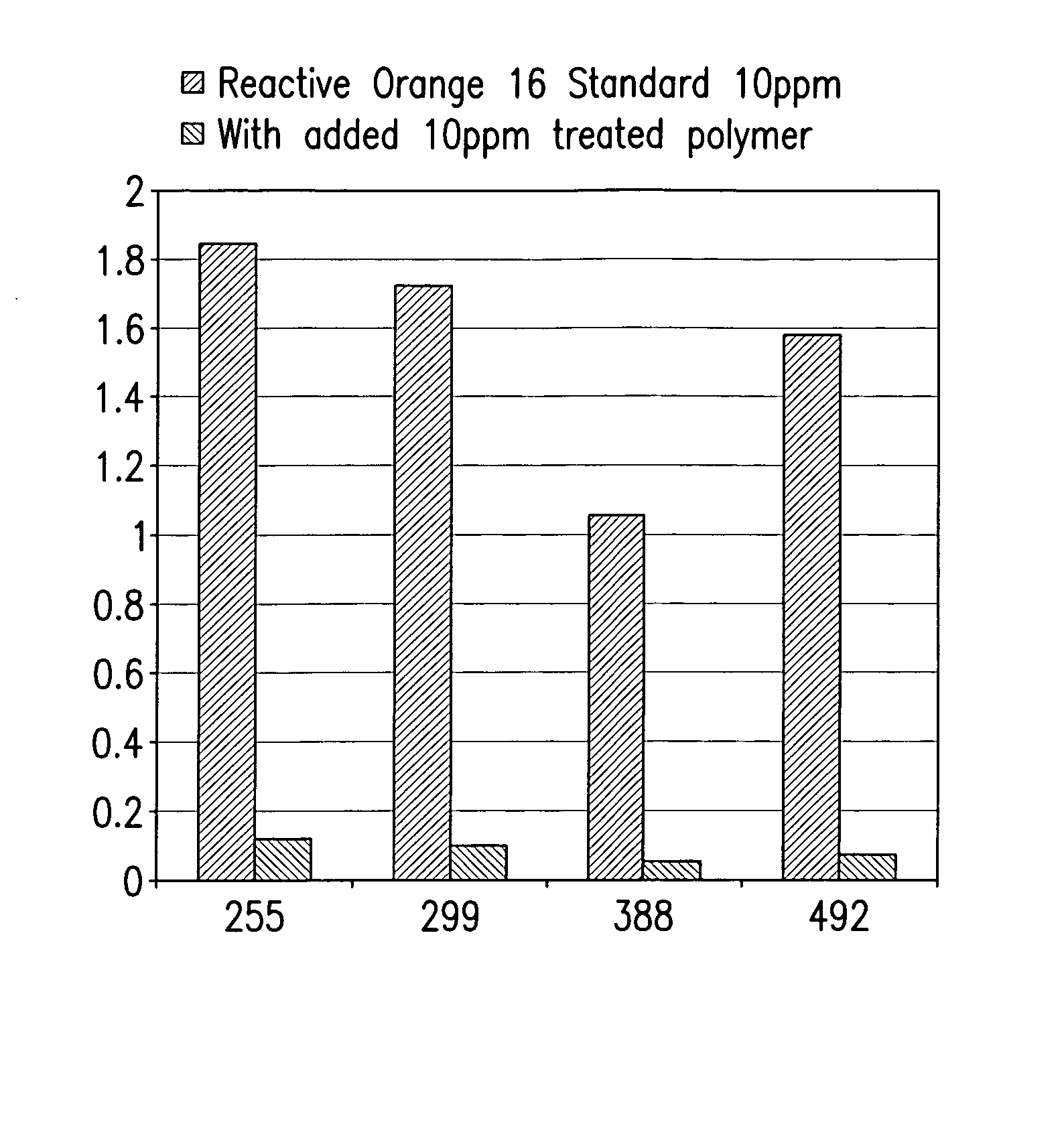

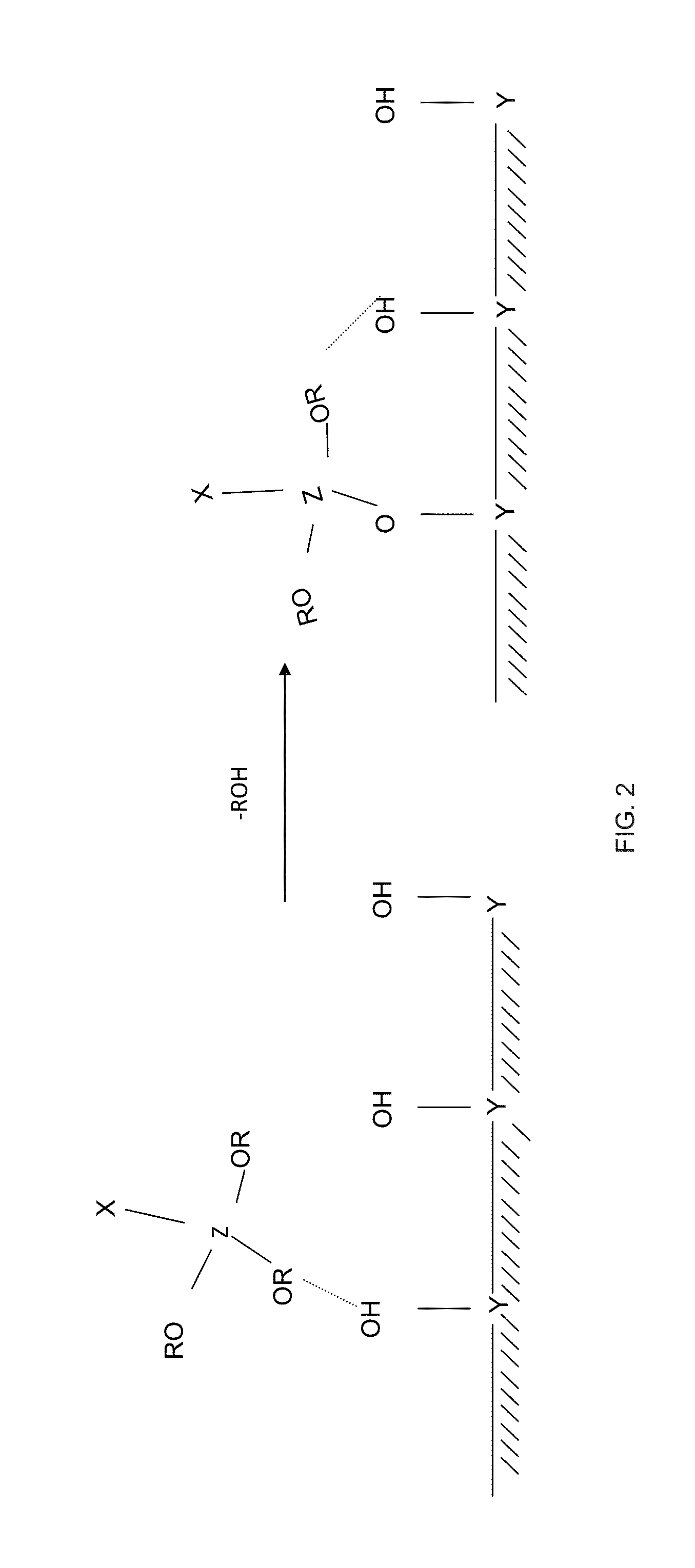

Novel crosslinked polymeric substrates methods of preparation and end use applications of the substrates

InactiveUS20090274634A1Peptide/protein ingredientsTreatment involving filtrationPolymer scienceSilenes

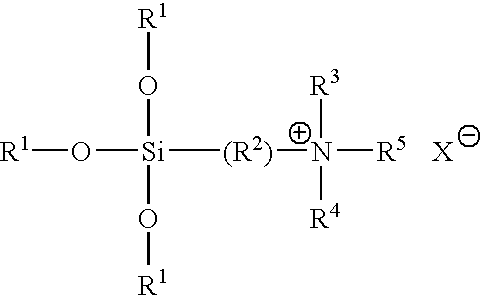

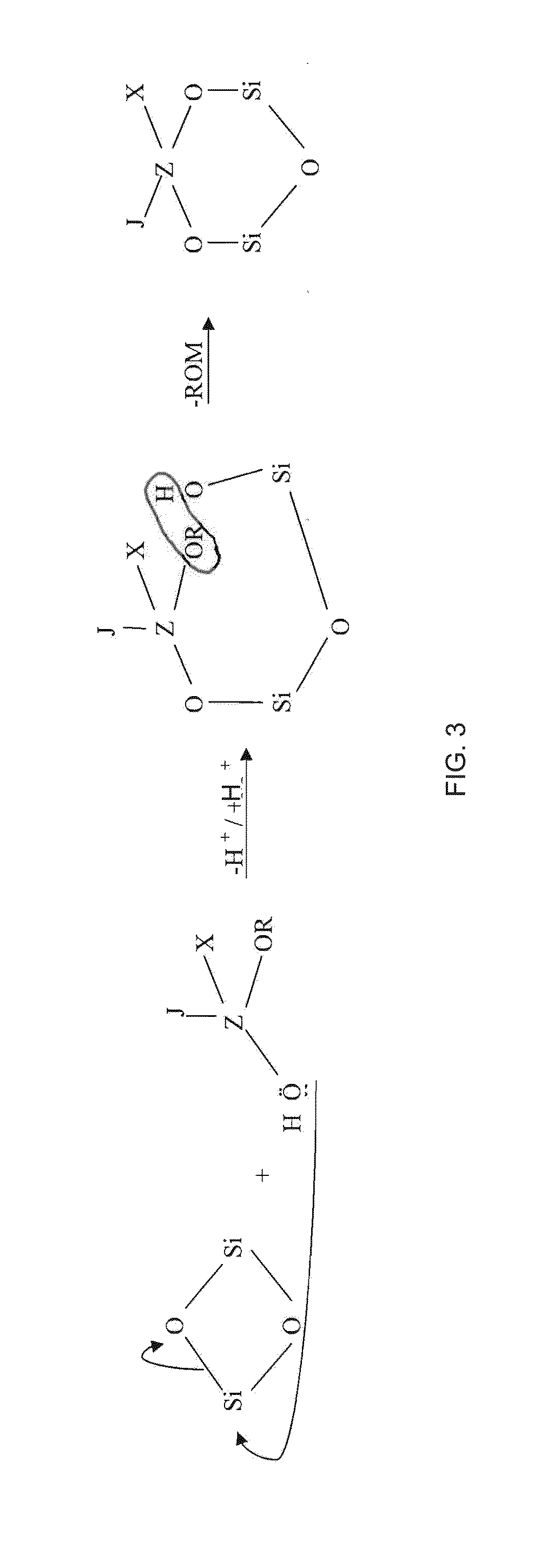

A composition of matter wherein the composition comprises a siliceous substrate having silanols on the surface and a polymer selected from the group consisting essentially of a water soluble polymer, a water soluble copolymer, an alcohol soluble polymer, an alcohol soluble copolymer, and combinations of such polymers, wherein the polymer is chemically bonded to the siliceous substrate by a silane linking material having the general formulaO3 / 2SiQYthat is derived from an alkoxy-functional silane having the general formula(RO)3SiQXand processes for preparing the crosslinked polymer that is chemically bonded to the surface of the siliceous substrate.

Owner:CAPTUR TECH +1

Aluminum-silicon light heat insulation brick and preparation method thereof

ActiveCN102167622ARaw materials are cheap and easy to getSimple production processCeramicwareInsulation layerBrick

The invention relates to an aluminum-silicon light heat insulation brick and a preparation method thereof. The preparation method comprises the following steps of: uniformly mixing 40-55 percent by weight of light alumina aggregate, 25-40 percent by weight of bauxite chamotte, 5-12 percent by weight of calcium aluminate cement, 8-13 percent by weight of organic polymer, 2-5 percent by weight of silicon powder, 0.05-0.15 percent by weight of water reducing agent and 15-25 percent by weight of water, calendering and molding by casting; curing under the condition of room temperature for 24-48 hours, demolding and drying at the temperature of 100-120 DEG C for 20-36 hours; and preserving heat at the temperature of 1,400-1,550 DEG C for 3-5 hours to obtain the aluminum-silicon light heat insulation brick. The preparation method has the advantages of wide raw materials, simple process and low production cost; the prepared aluminum-silicon light heat insulation brick has the advantages of high compressive strength, low volume density, low heat conductivity, high using temperature, low re-burning linear change rate, high thermal shock stability and the like; the product is applied to various industrial furnace heat insulation layers, has a wide application range and remarkably-reduced energy consumption and temperature outside a furnace, and can be safely and effectively produced.

Owner:WUHAN UNIV OF SCI & TECH

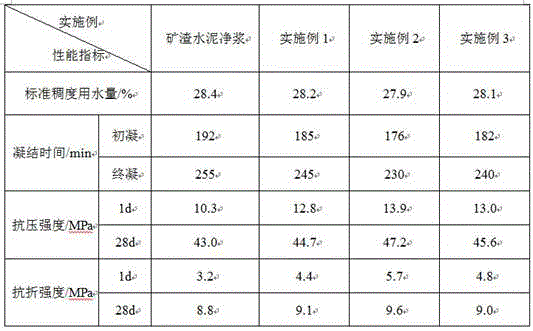

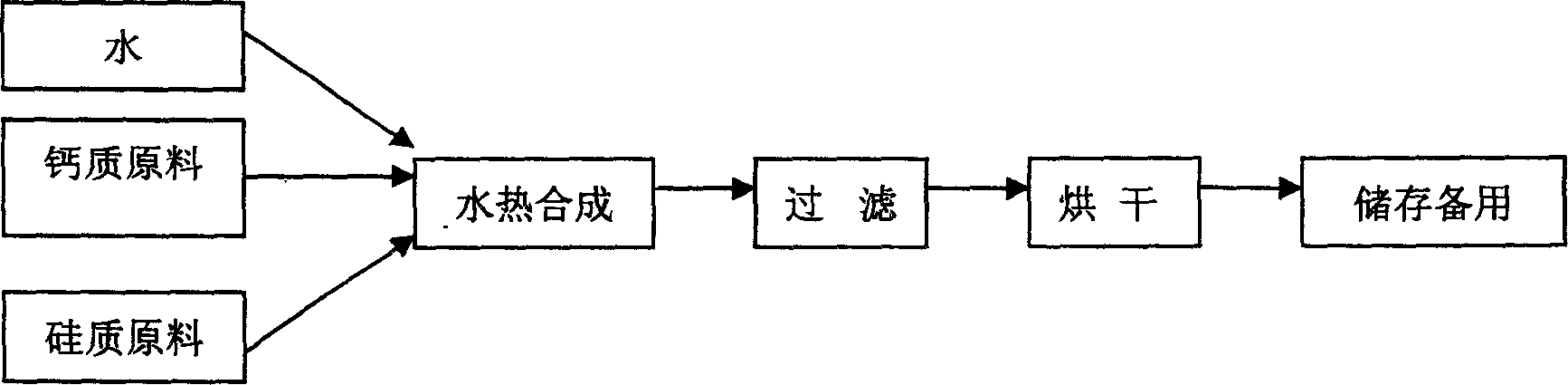

Preparation method and application method of hydrated calcium silicate seed crystal

InactiveCN105753000AGood dispersionGood early strengthAlkaline-earth metal silicatesCalcium silicateCarbonization

The invention relates to a preparation method and application method of a hydrated calcium silicate seed crystal. The materials for preparing the hydrated calcium silicate seed crystal comprise a calcium material, a silicon material, deionized water, a dispersant, anhydrous ethanol and sodium hydroxide. The adopted calcium material is calcium oxide, the adopted silicon material is one of sodium silicate and diatomite, and the adopted dispersant is a poly-carboxylic acid high molecular polymer. The controlled factors comprise the ratio of calcium to silicon, the ratio of water to solid, the dosage of the dispersant, the reaction temperature, the reaction pressure and the reaction time. The product prepared by the method provided by the invention is suitable for a construction engineering adopting mixed material cement as a cementitious system, and has an obvious effect of promoting the development of the early strength of a mixed material cement base material, so that the application scope of the mixed material cement is expanded, the dilemma of solid waste emission is relieved, the cement production cost is reduced, the emissions of wastes during cement production are reduced, and the product is beneficial to low-carbonization and greening development of cement, and has good environmental protection benefits and social and economic benefits.

Owner:TONGJI UNIV

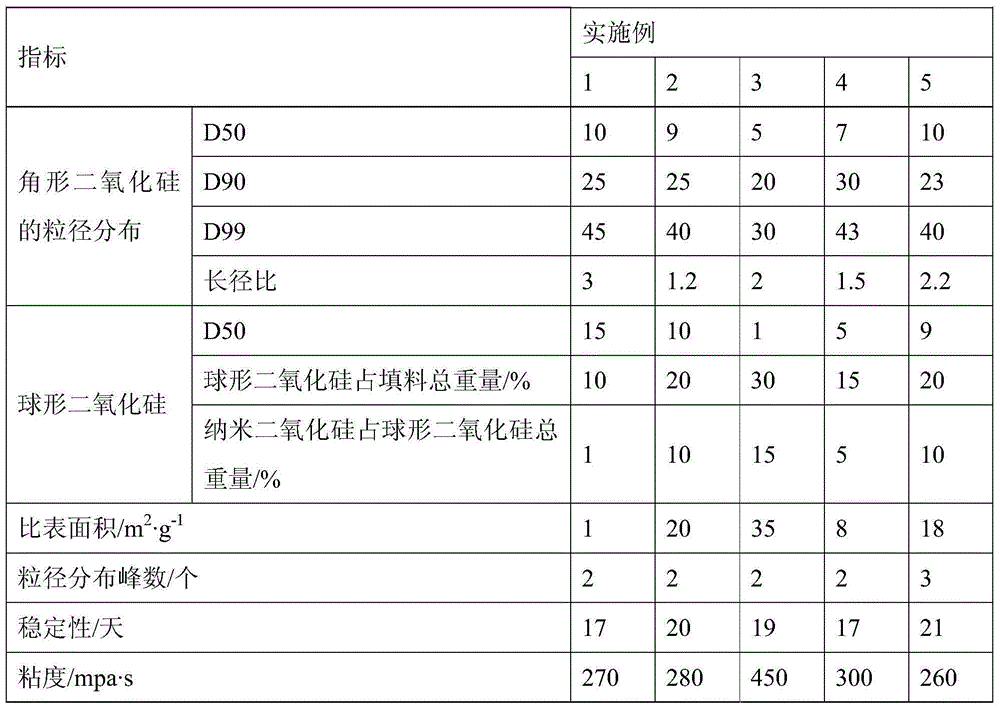

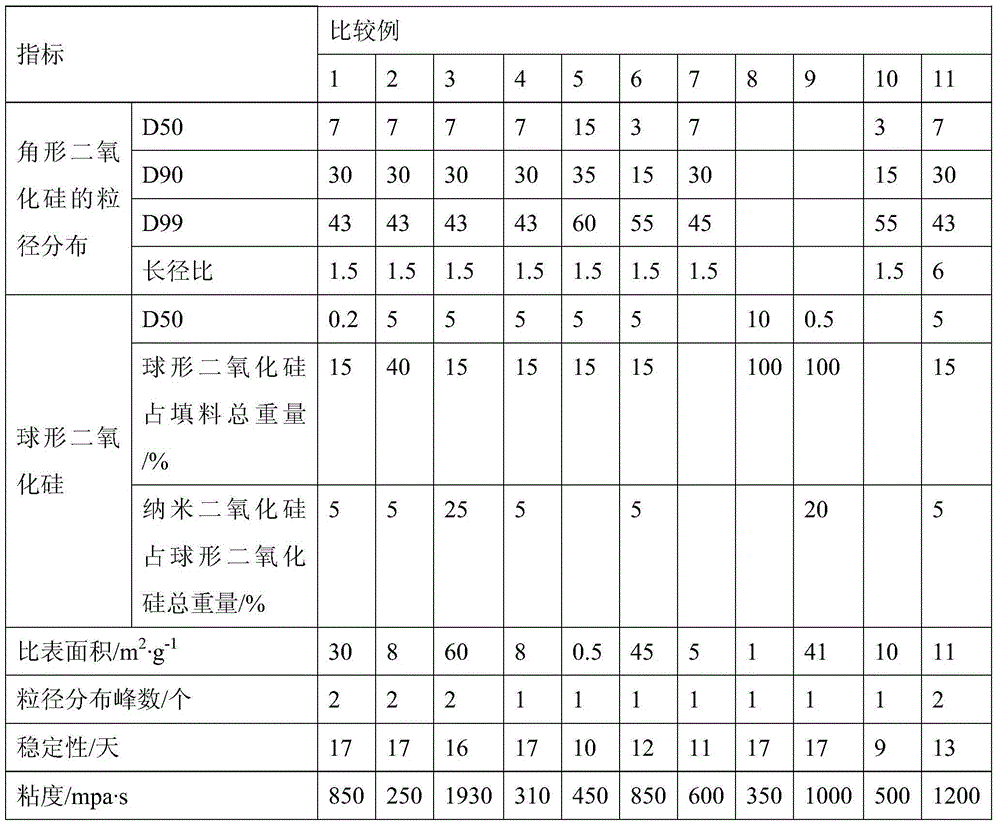

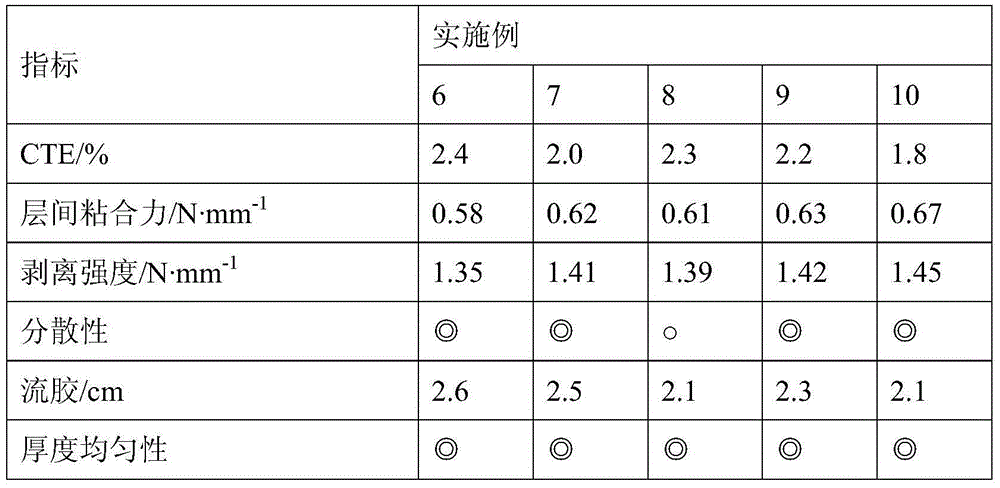

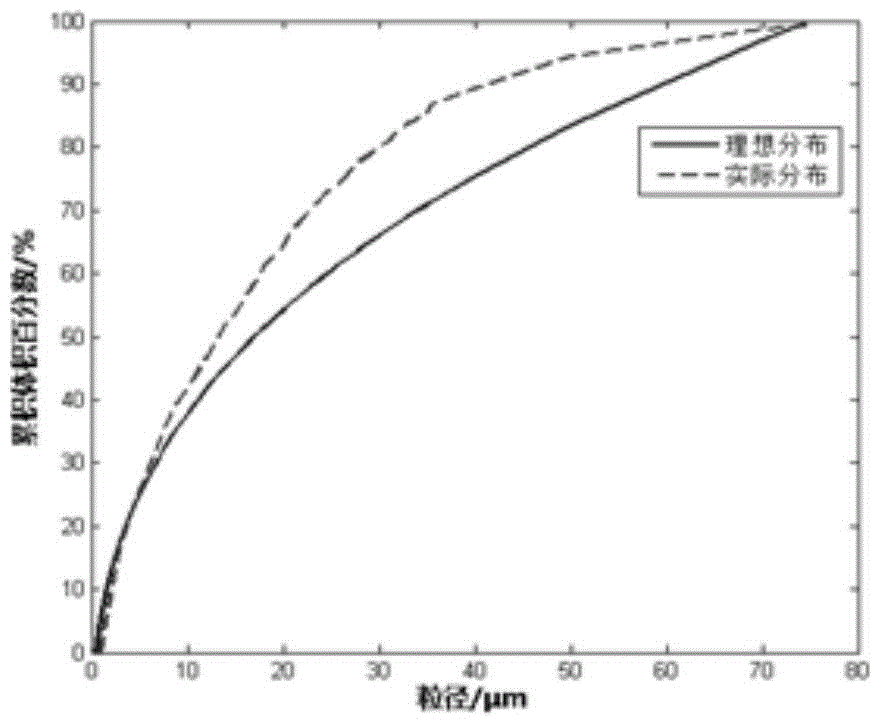

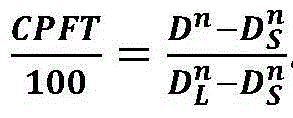

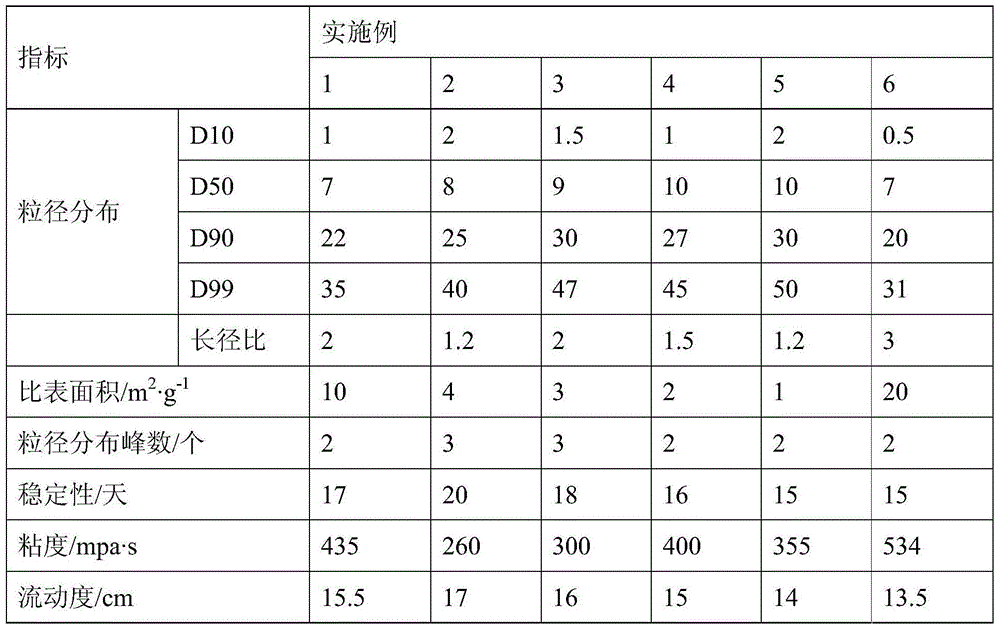

Filler composition and application thereof

ActiveCN104558688AImprove liquidityImprove mobilitySynthetic resin layered productsCircuit susbtrate materialsCopper foilParticle-size distribution

The invention relates to a filler composition and application thereof. The filler composition comprises a spherical siliceous micro powder filler and an angular siliceous micro powder filler, and can be used for preparing a copper clad laminate substrate and bonding sheet resin composition. The filler composition is formed by compounding the angular siliceous micro powder filler and the spherical siliceous micro powder filler, which have specific particle size distribution, the flowability of the composition and the sedimentary stability in a solution or resin system can be improved, the thickness uniformity and the component uniformity of the copper clad laminate substrate are improved, and not only the sagging and gummosis problems are solved, but also the production cost is reduced greatly.

Owner:GUANGDONG SHENGYI SCI TECH

Filler composition and application thereof

ActiveCN104558689AImprove liquidityImprove stabilitySynthetic resin layered productsMetal layered productsThermal dilatationPolymer science

The invention relates to a filler composition and application thereof. The filler composition comprises an angular siliceous micro powder filler, and can be used for preparing a copper clad laminate substrate and bonding sheet resin composition. The filler composition is formed by an angular silicon dioxide with the specific particle size distribution or the mixture of at least two angular silicon dioxides with different particle sizes and the specific particle size distribution, the flowability of the composition and the sedimentary stability in a solution or resin system can be improved, the coefficient of thermal expansion is reduced remarkably, the bonding interface between resin and an inorganic filler, the interlayer adhesiveness between laminates and the adhesive force between a resin layer and a copper foil are improved, and the production cost is reduced greatly.

Owner:GUANGDONG SHENGYI SCI TECH

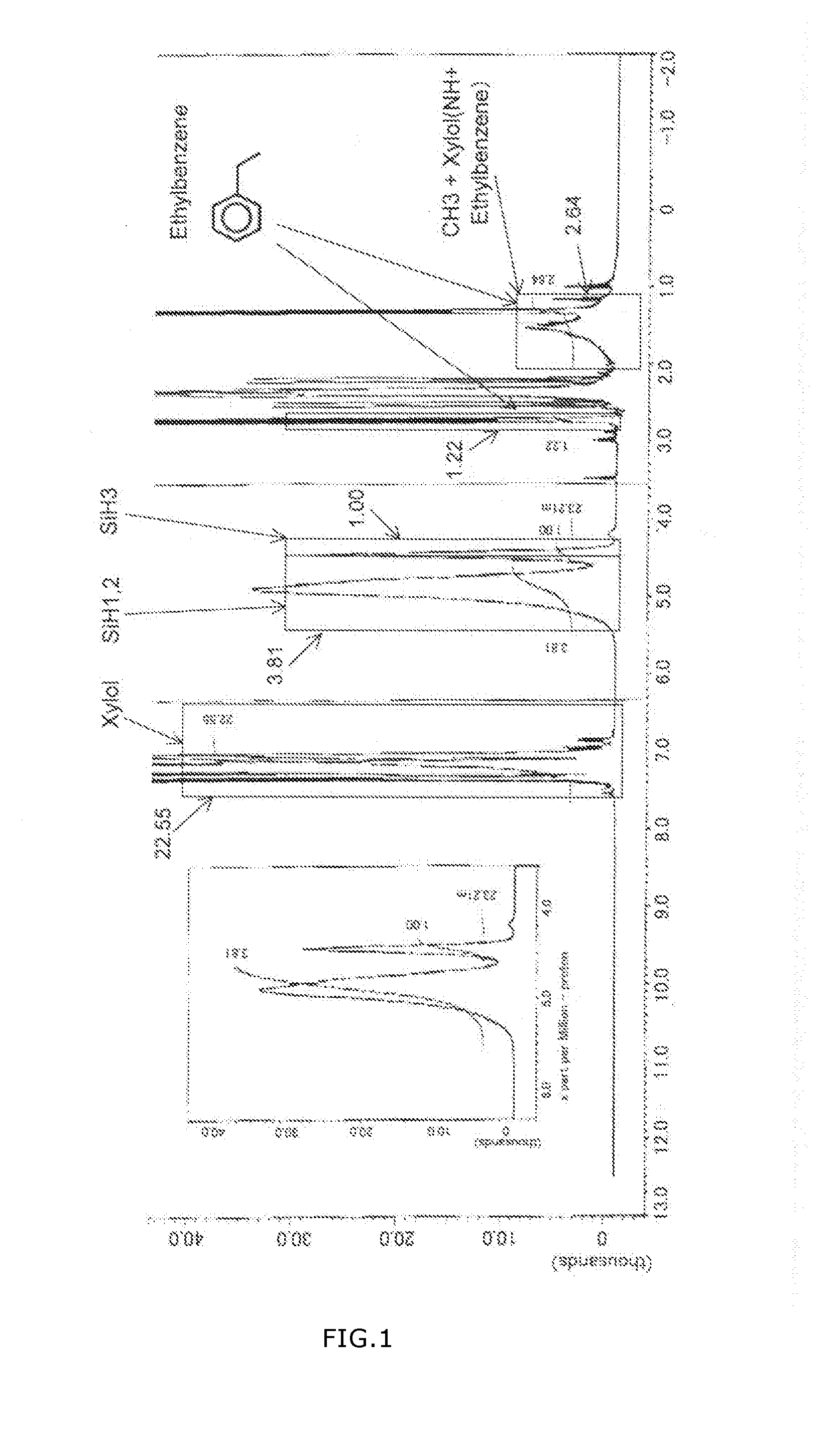

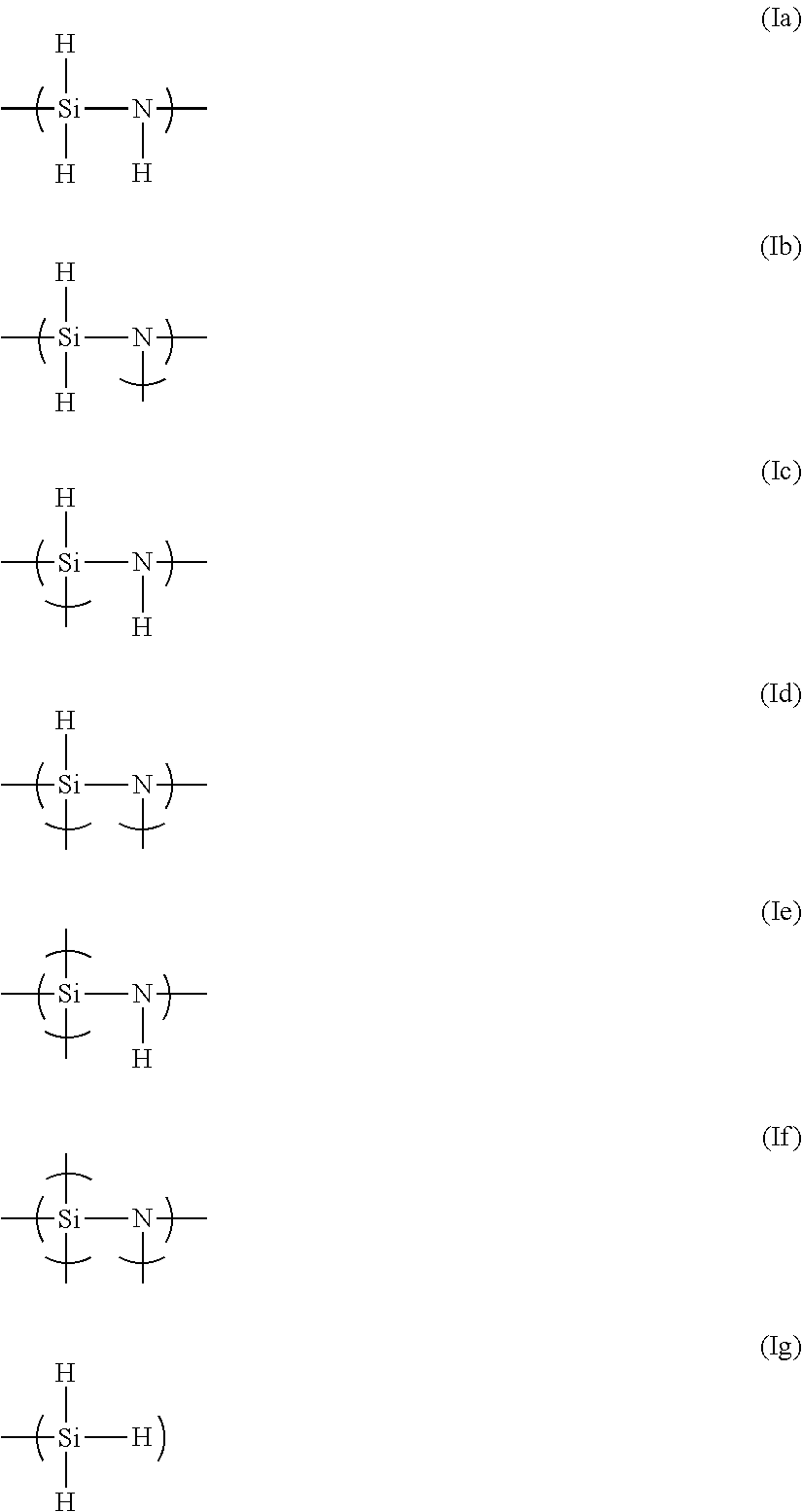

Perhydropolysilazane, composition containing same, and method for forming silica film using same

ActiveUS20160379817A1Improve stabilityFew defectSemiconductor/solid-state device manufacturingCoatingsHydrogen contentSilica membrane

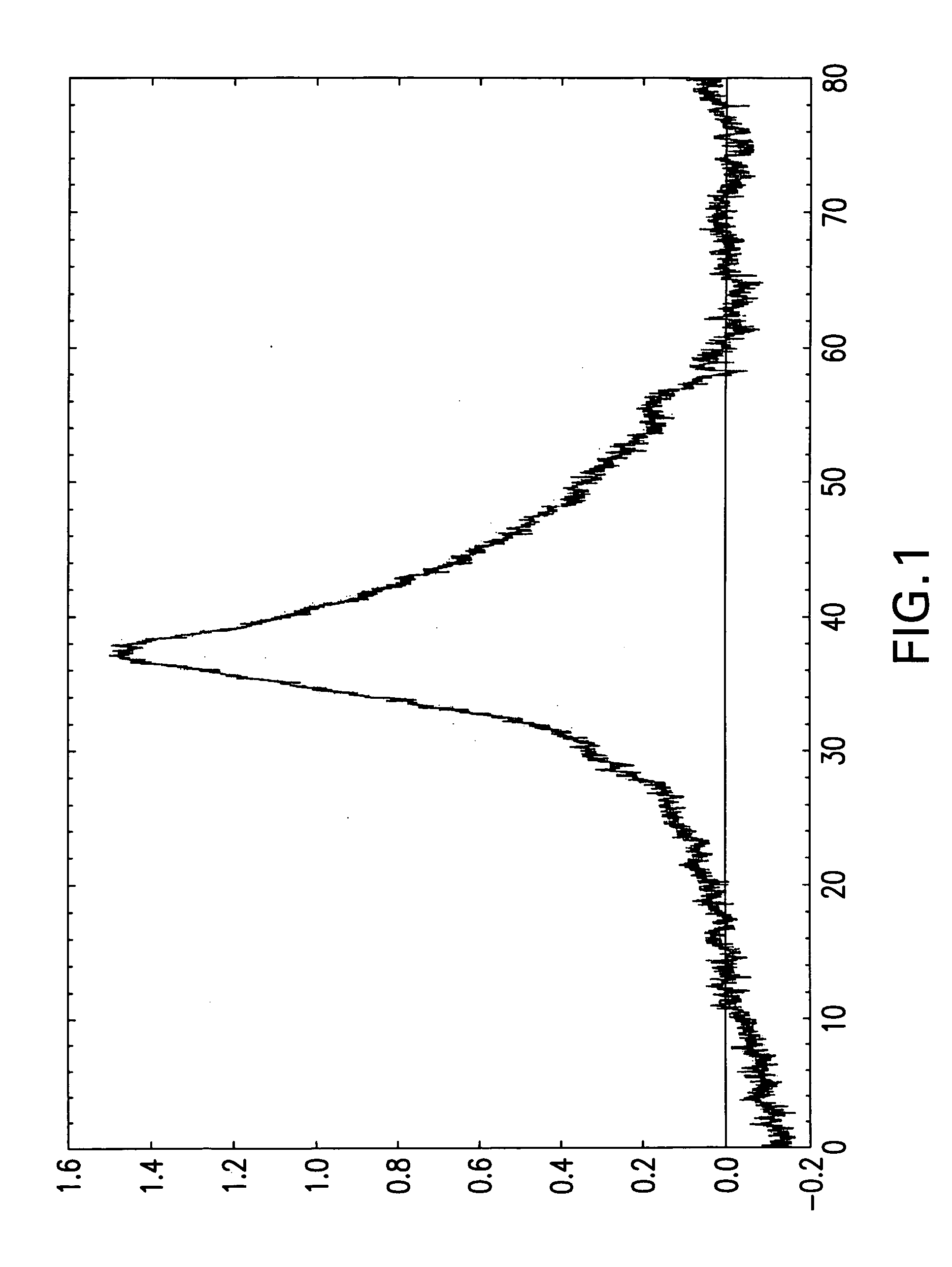

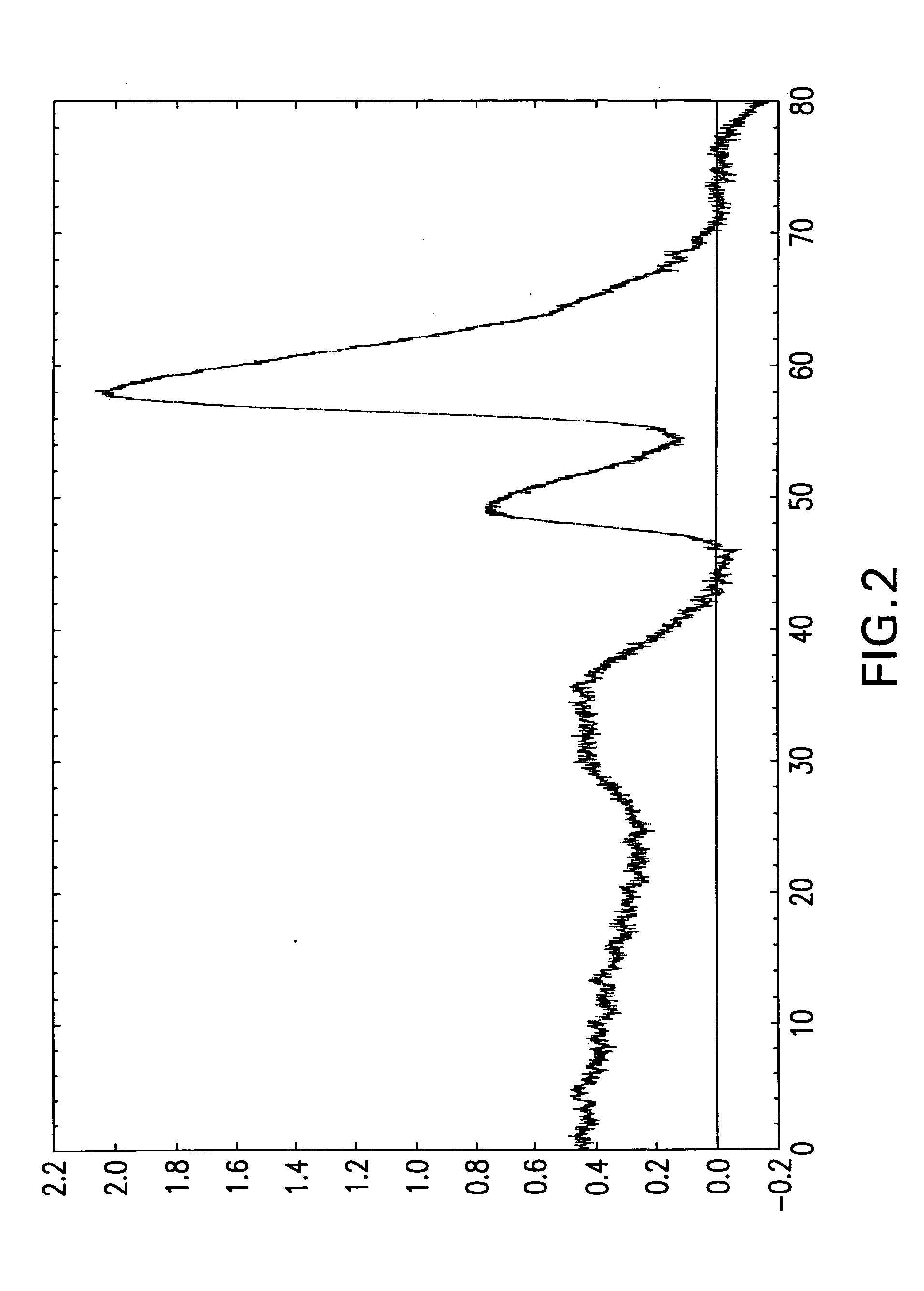

[Problem] To provide a perhydropolysilazane making it possible to form a siliceous film with minimal defects, and a curing composition comprising the perhydropolysilazane.[Means for Solution] The present invention provides a perhydropolysilazane having a weight-average molecular weight of 5,000 to 17,000, characterized in that when 1H-NMR of a 17% by weight solution of said perhydropolysilazane dissolved in xylol is measured, the ratio of the amount of SiH1,2 based on the aromatic ring hydrogen content of the xylol is 0.235 or less and the ratio of the amount of NH based on the aromatic ring hydrogen content of the xylol is 0.055 or less, and a curing composition comprising the perhydropolysilazane. The present invention also provides a method for forming a siliceous film, comprising coating the curing composition on a substrate and heating.

Owner:MERCK PATENT GMBH

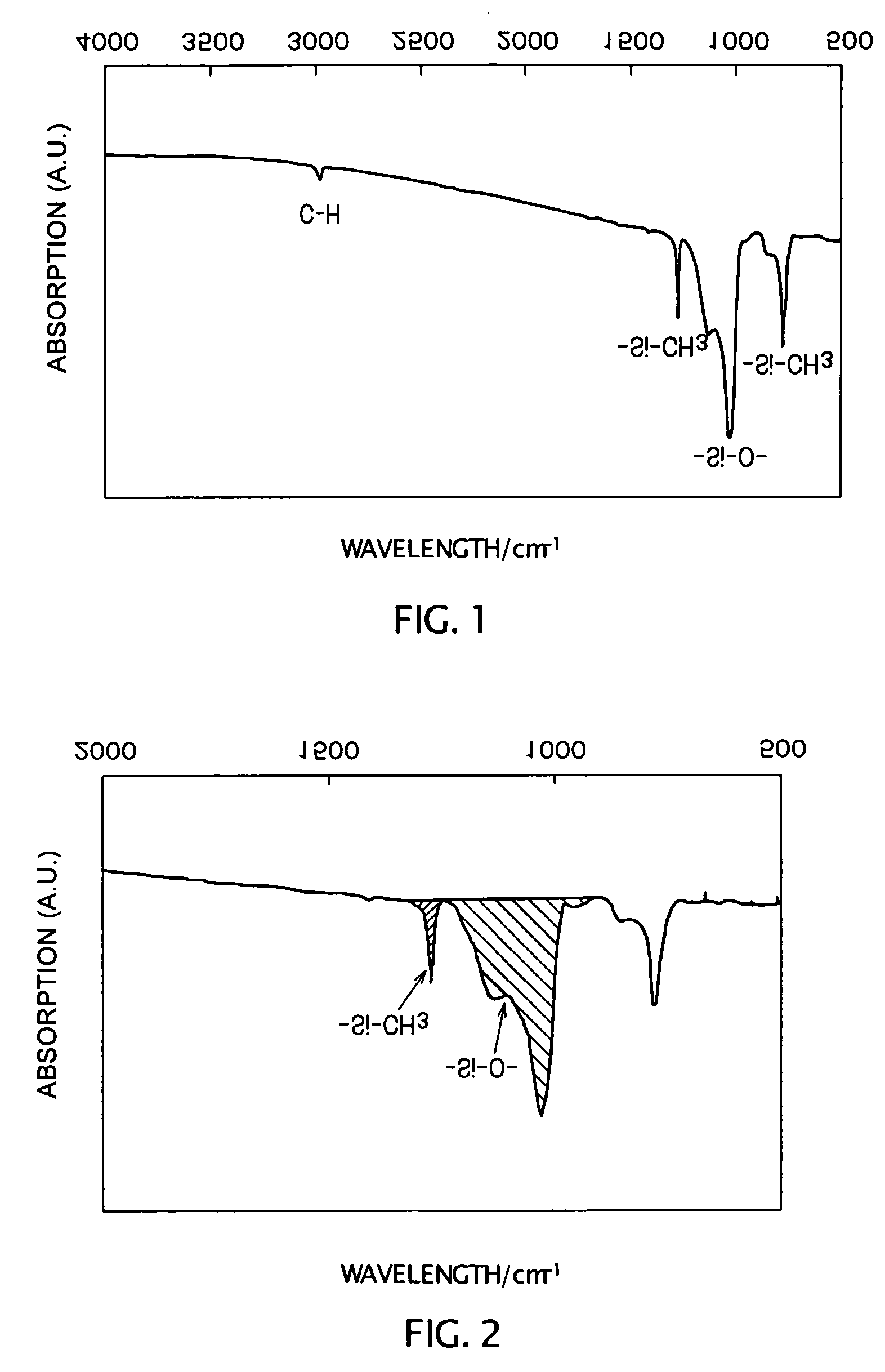

Coating composition and low dielectric siliceous material produced by using same

InactiveUS7754003B2Lower levelHigh mechanical strengthFibre treatmentPretreated surfacesOrganic solventChemical resistance

Owner:MERCK PATENT GMBH

Anti-senstivity, anti-caries, anti-staining, anti-plaque, ultra-mild oral hygiene agent

ActiveUS20090169493A1Avoid painReduce tooth sensitivityCosmetic preparationsToilet preparationsStainingPhosphate

This invention relates to a composition useful as a dentifrice comprising a surfactant agent consisting essentially of monoalkyl and dialkyl phosphate esters, wherein the ratio of monoesters to diesters is greater than 1, and optionally an abrasive agent consisting essentially of siliceous materials.

Owner:RHODIA OPERATIONS SAS

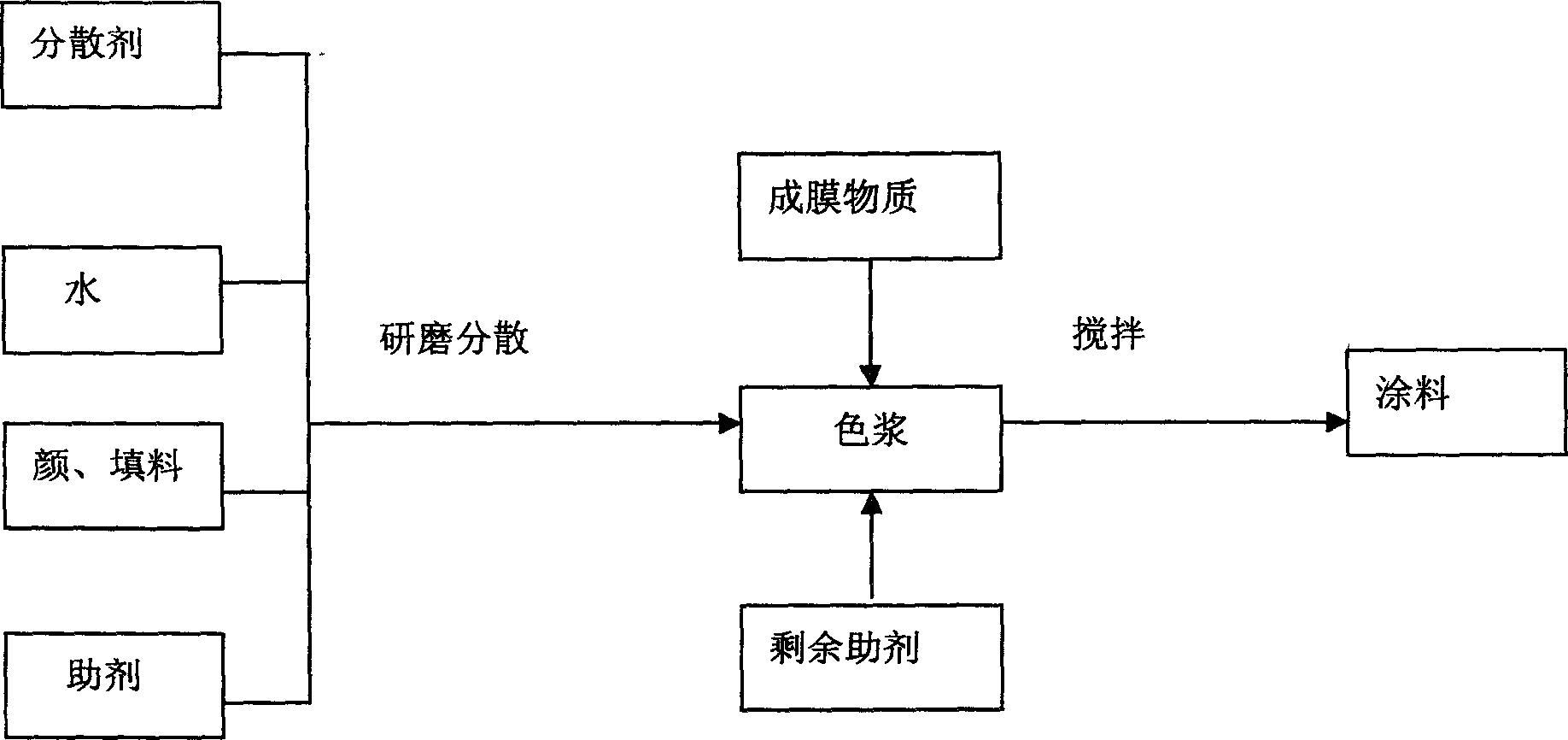

Calcium silicate hydrate nano coating and its production method

The nanometer hydrated calcium silicate paint consists of filming emulsion 37.0-39.0 wt%, pigment 5.07-6.20 wt%, talcum powder 6.50-7.50 wt%, hydrated calcium silicate powder 10.15-11.0 wt%, filming assistant 0.38-0.88 wt%, defoaming agent 0.4-0.9 wt% and water 34.52-40.50 wt%. The hydrated calcium silicate powder is prepared with cheap diatomite as siliceous material and lime as calcium material, and through dynamic hydrothermal process, and has low crystallization degree and very great specific surface area. Using the nanometer hydrated calcium silicate as stuffing for building paint can raise the adhesion force, water resistance, alkali resistance, water resistance, ageing resistance and antifouling performance of paint greatly and is favorable environment protection.

Owner:CHONGQING UNIV

Composition for treating substrate and process of treatment

Owner:ICT COATINGS

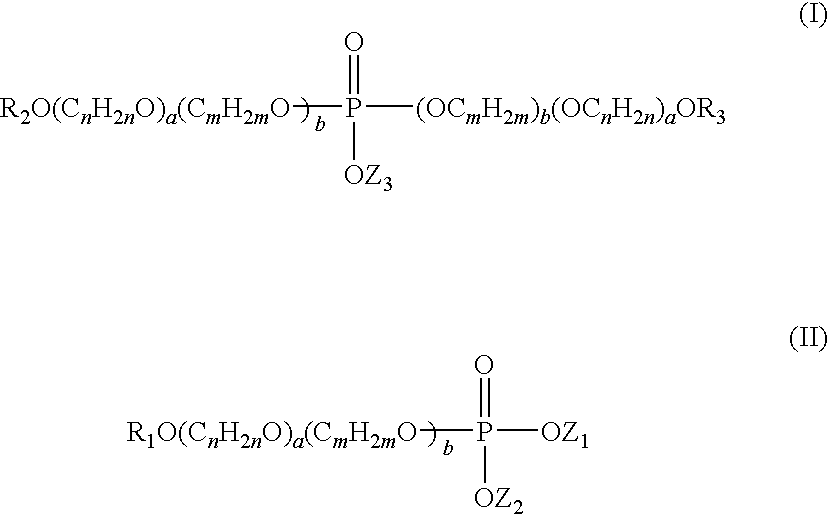

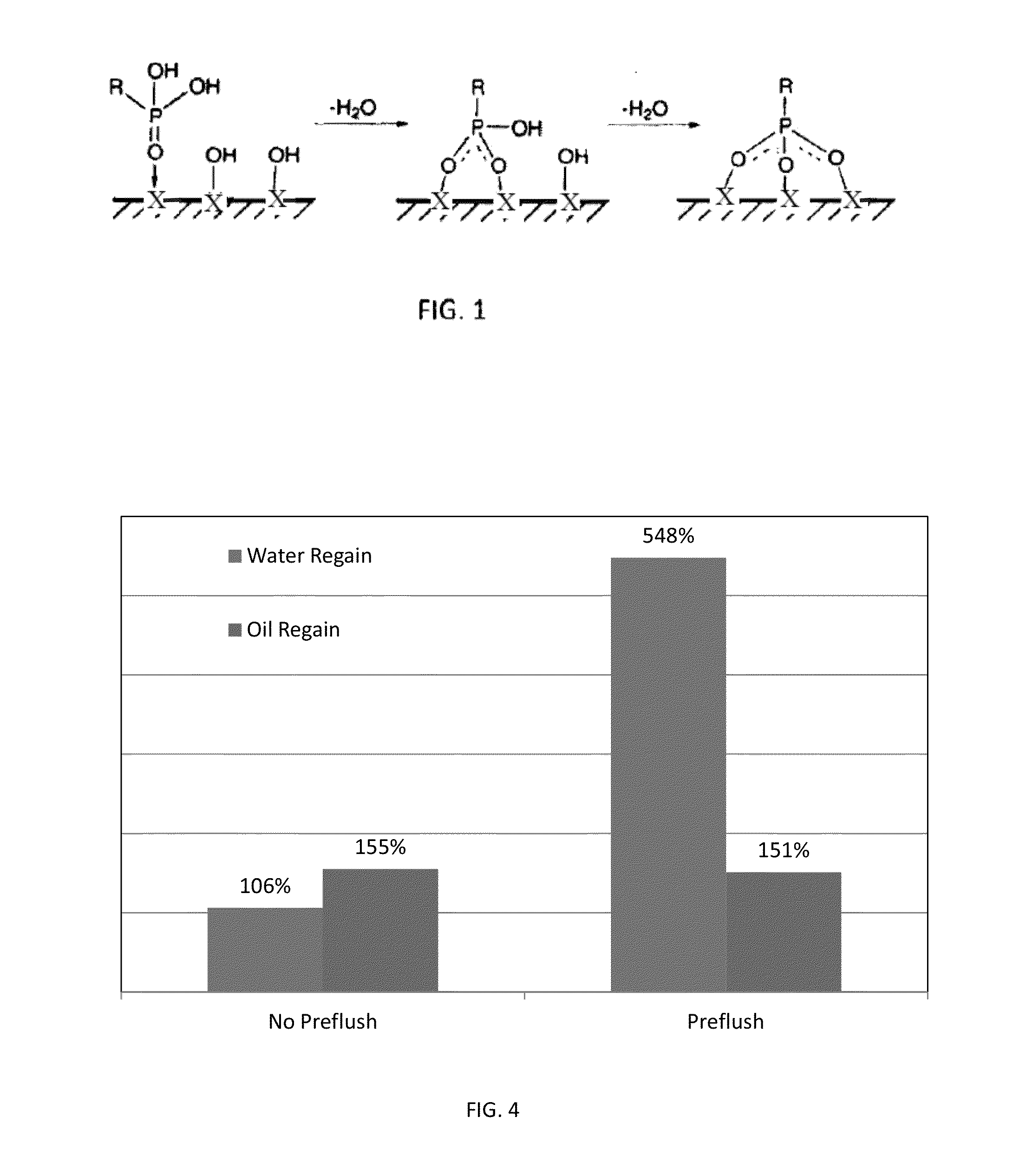

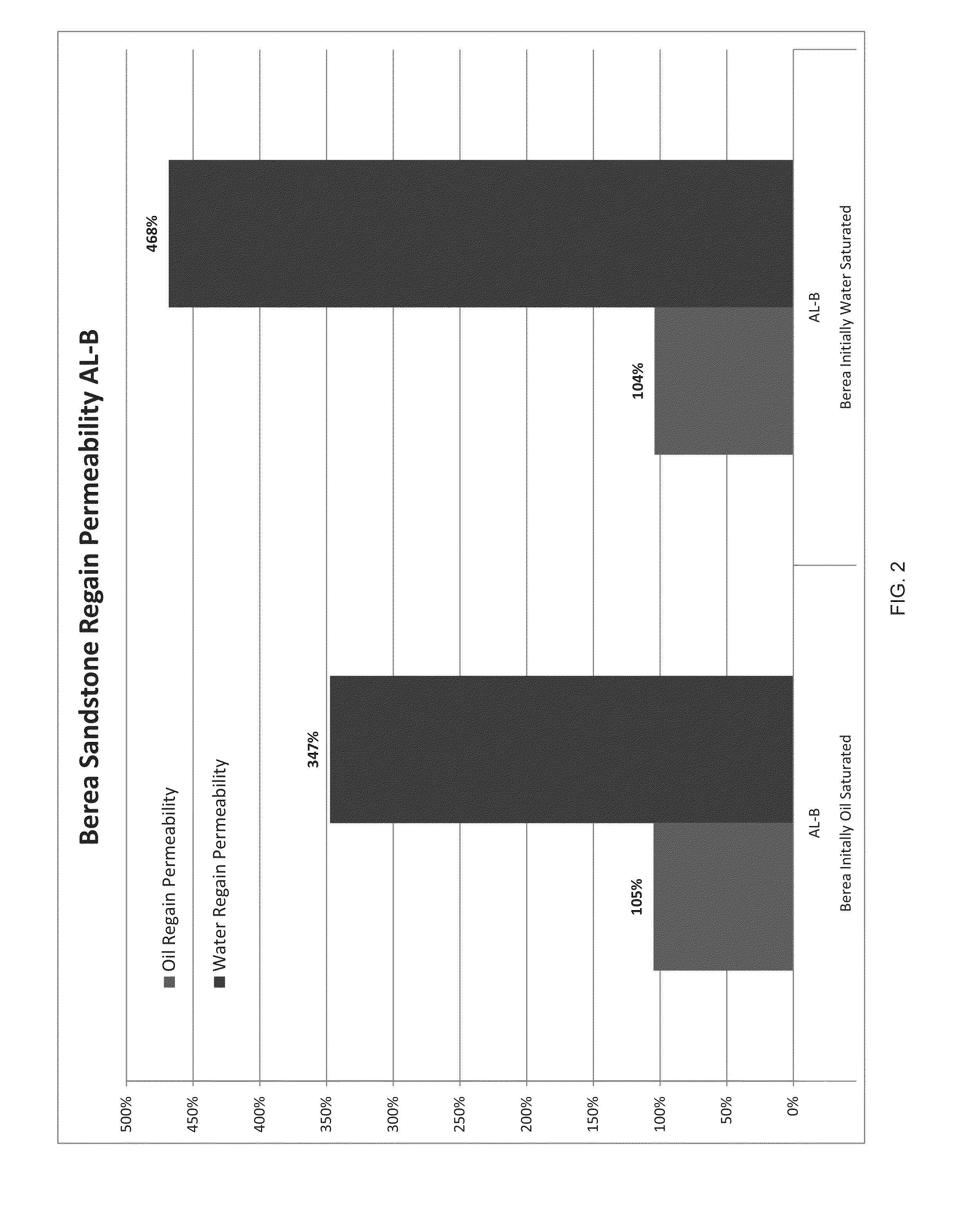

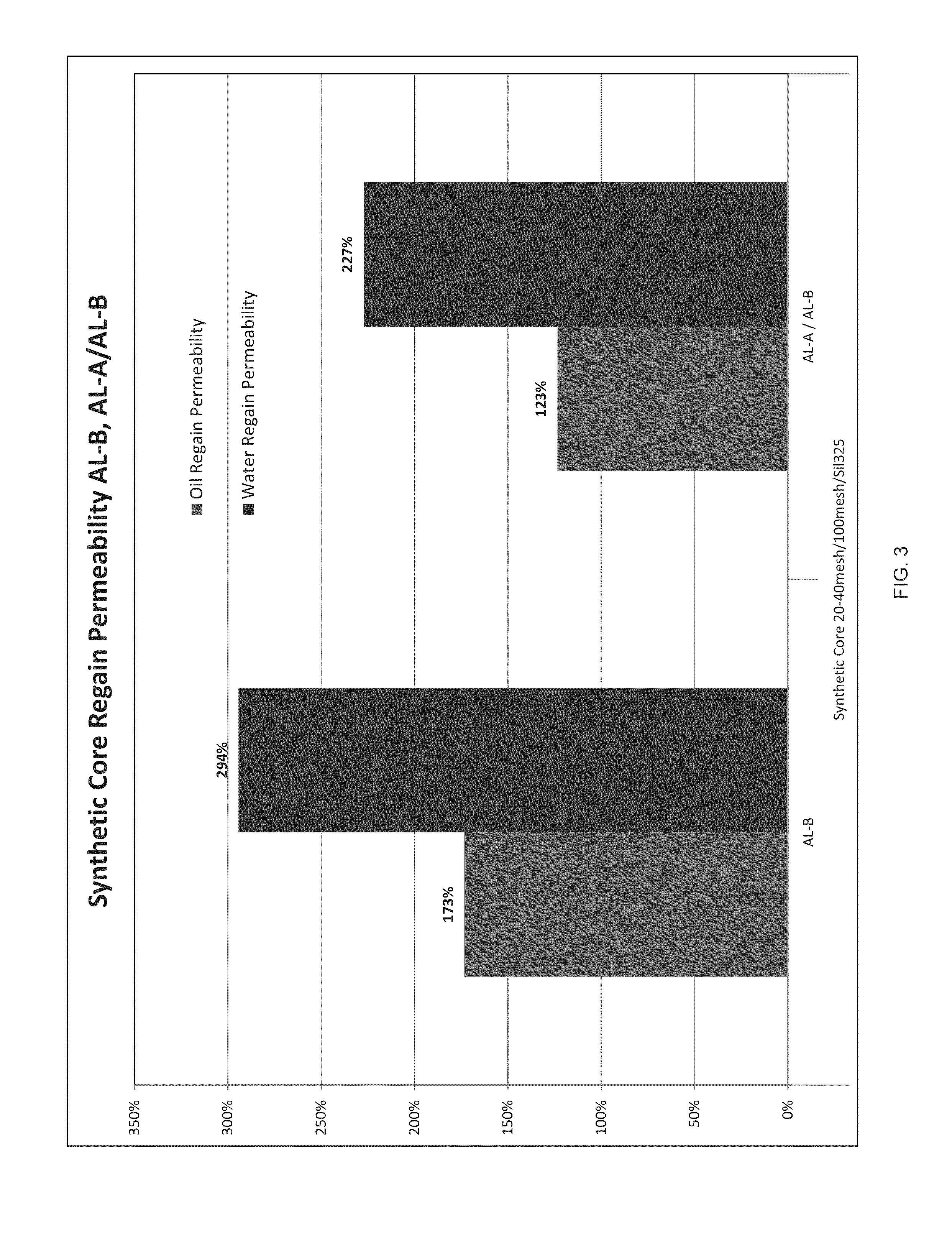

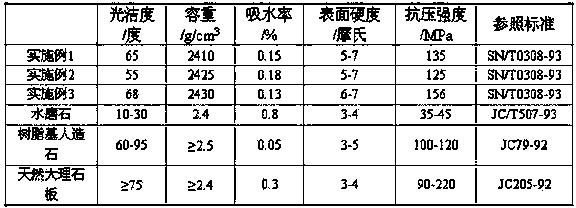

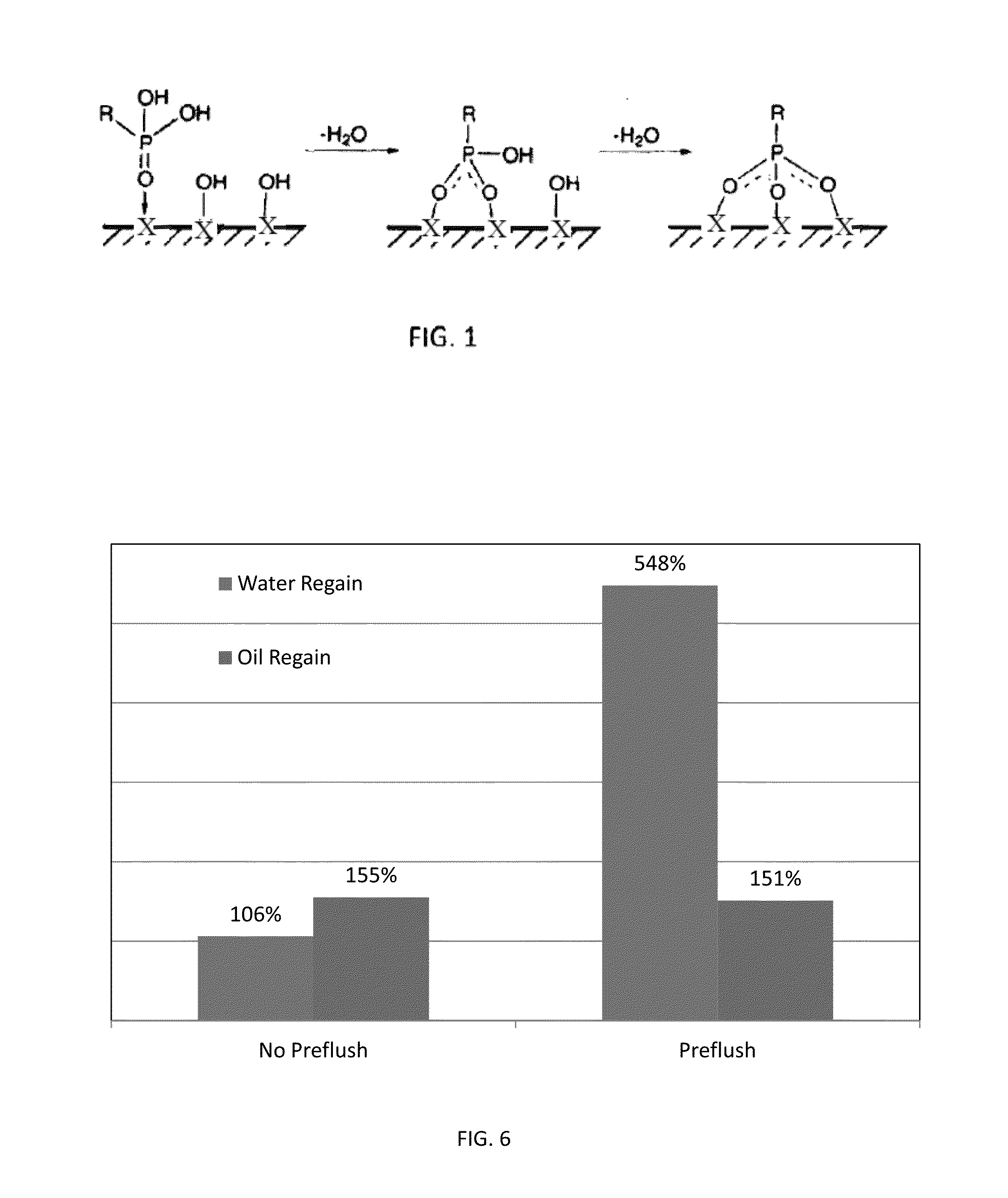

Method of using surface modifying treatment agents to treat subterranean formations

ActiveUS20150083416A1Minimize and prevent retention of waterAvoid depositionFluid removalDrilling compositionProduction rateAcid derivative

A well treatment fluid contains a surface modifying treatment agent having an anchor and a hydrophobic tail. The surface modifying treatment agent is an organophosphorus acid derivative. After the well treatment fluid is pumped into a well penetrating the subterranean formation, the anchor binds to the surface of the formation. The subterranean formation is a siliceous formation or a metal oxide-containing subterranean formation. The anchor bonds to a Si atom when the formation is a siliceous formation and to the metal of the metal oxide when the formation is a metal oxide-containing formation. After being bound to the surface of the formation, frictional drag within the well is reduced. This allows for faster recovery of formation fluids. The bonding of the surface modifying treatment agent onto the formation may further be enhanced by first pre-treating the formation with a non-aqueous fluid. By increasing the number of sites for the surface modifying treatment agent to bind onto the surface of the subterranean formation, productivity is improved.

Owner:BAKER HUGHES INC

High-performance forsterite refractory raw material and preparation method thereof

The invention relates to a high-performance forsterite refractory raw material and a preparation method thereof. The method comprises the following steps: mixing 65-85 weight percent of fine magnesite powder with 15-35 weight percent of siliceous raw material fine powder, adding 1-10 weight percent of binding agent, and ball-milling for 1-3 hours to obtain a ball-milling material; then adding water being 3-10 weight percent of the ball-milling material into the ball-milling material, stirring, pressing to form a blank body, drying, and calcining at 1200-1400 DEG C to obtain a calcining material; grinding the calcining material to the particle size smaller than 0.045mm, and adding an additive being 0.2-2 weight percent of the calcining material and the binding agent being 1-10 weight percent of the calcining material, and ball-milling to obtain a secondary ball-milling material; and adding 3-10 weight percent of water into the secondary ball-milling material, stirring, pressing to form a blank body, drying, and secondary calcining at 1450-1650 DEG C to obtain the high-performance forsterite refractory raw material. The raw material has the advantages of wide sources, low production cost and easiness in sintering, and the prepared high-performance forsterite refractory raw material has large volume density, low porosity and stable high temperature properties.

Owner:WUHAN UNIV OF SCI & TECH

Selectivated metallosilicate catalyst composite for alkylaromatic conversion, process for the preparation thereof, and use thereof in hydrocarbon conversion

InactiveUS6864200B2Speed up the processMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystSilenes

A repeated “soak and dry” selectivation process for preparing a modified metallosilicate catalyst composite is disclosed comprising of a mixture of amorphous silica, alumina and a pore size controlled metallosilicate useful for alkylaromatic conversion. The process comprises (a) contacting an intermediate pore metallosilicate with an organosilicon compound in a solvent for a specific duration and then recovering the solvent, (b) combining the organosilicon compound treated metallosilicate with water and then drying the catalyst, (c), repeating the steps a) and b) above and (d) calcining the catalyst in an oxygen containing atmosphere sufficient to remove the organic material and deposit siliceous matter on the metallosilicate. In a another embodiment, when the organosilicon compound is water soluble, step (b) may be avoided.

Owner:INDIAN PETROCHEMICALS CORPORATION LIMITED

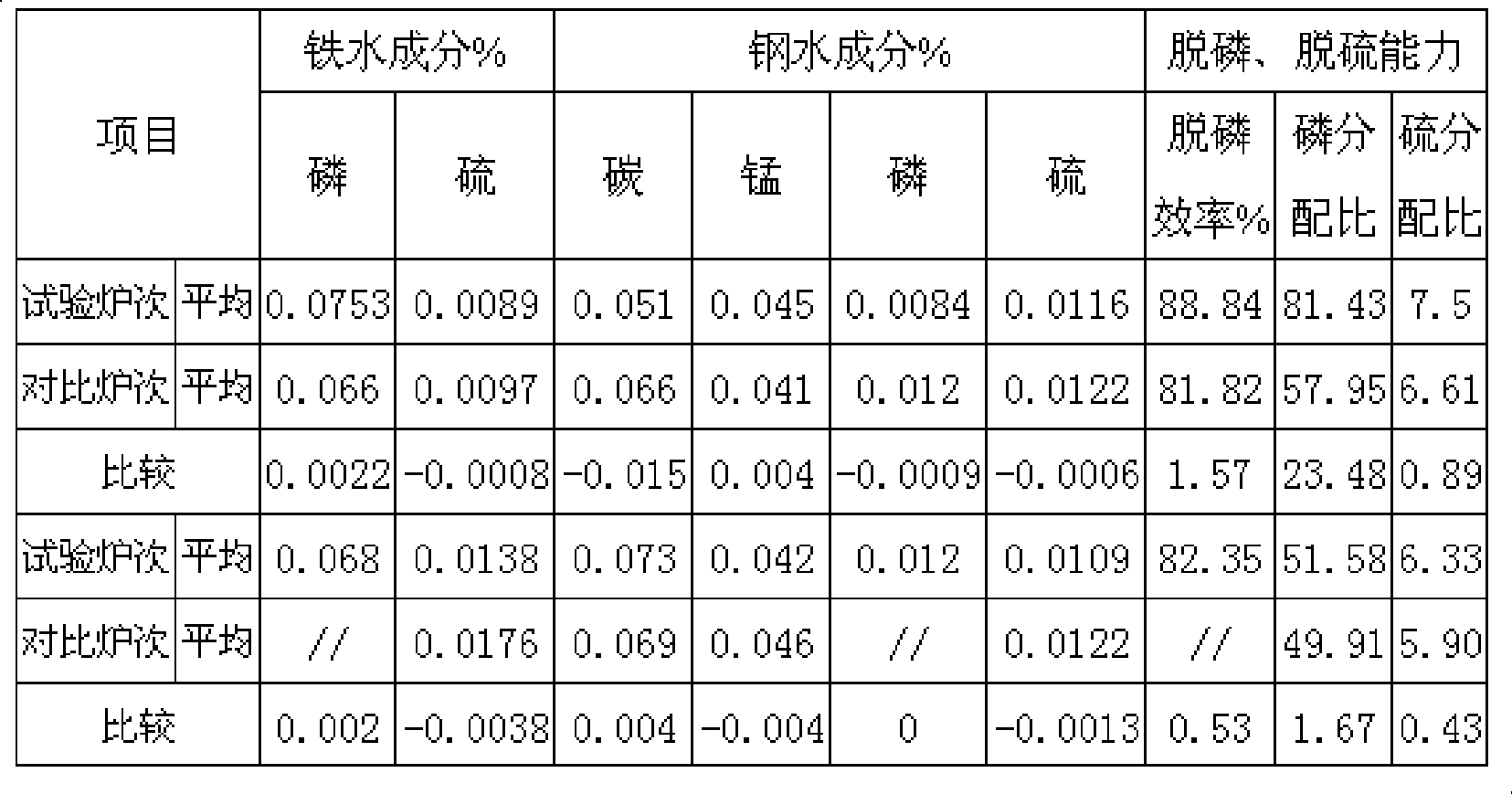

Slag-forming constituent and preparation thereof

ActiveCN101413042AFast slag formationReduce consumptionManufacturing convertersProcess efficiency improvementSteelmakingSludge

The invention belongs to the metallurgical field, and particularly relates to a slag former and a method for preparing the same. The technical problem solved by the invention is to provide a slag former with quick slagging by utilizing steelmaking sludge as a main material. The slag former consists of the following materials in weight percentage: 25 to 35 percent of steelmaking sludge, 25 percent of manganese ore with high silica, 34 to 45 percent of quartz sand and 5 percent of magnesium chloride. The average slag forming time of the slag former is 4.4 minutes, which is 1.5 minutes shorter than the prior slaggng method, and the average dephosphorizing efficiency is improved by 6.75 percent. Therefore the slag former maximally recovers iron in the sludge and lowers iron and steel consumption.

Owner:PANZHIHUA GANGCHENG GROUP

Polymers and their use in asphalt compositions and asphalt concretes

A modified asphalt composition comprising a naphthenic asphalt, and a high-vinyl block copolymer is presented. The modified asphalt composition is prepared by combining a naphthenic asphalt and a high-vinyl block copolymer. Further an asphalt concrete is presented, such concrete comprises an asphalt, a functionalized block copolymer, and a siliceous aggregate. A diblock copolymer is presented, such copolymer comprises a vinyl block comprising conjugated vinyl aromatic units, a diene block comprising conjugated diene units and substantially devoid of a tapered block section between the vinyl block and the diene block wherein the diblock copolymer comprises a vinyl content of at least about 20%, and a molecular weight of at least about 50,000.

Owner:FIRESTONE POLYMERS LLC

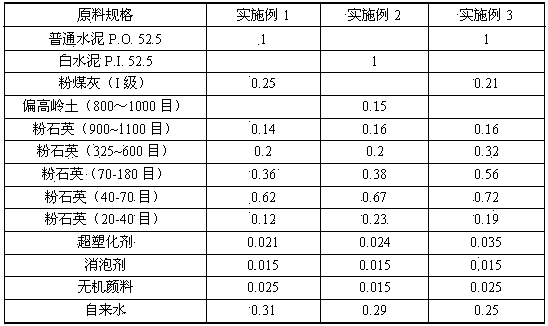

Remote procedure call (RPC) design-based inorganic synthetic quartz plate and preparation technology thereof

The invention discloses a remote procedure call (RPC) design-based inorganic synthetic quartz plate and a preparation technology thereof. The RPC design-based inorganic synthetic quartz plate is characterized in that a quartz powder decorating plate is prepared from a binding material, an inorganic aggregate, inorganic powder, an admixture and water according to a certain ratio, and the product can be prepared according to a certain technological process. By adopting the RPC design-based inorganic synthetic quartz plate, an implementation scheme of an inorganic artificial stone of taking common concrete as a basic theory, and then carrying out fussy and complicated surface treatment process is abandoned; the inorganic artificial stone is designed and manufactured by an RPC preparation theory as a core concept; the natural quartz powder is adopted as an active silicon material, so as to reduce the material cost. By implementation of the method, not only is a new direction of recycled efficient utilization of the quartz powder exploited, but also a new design concept is initiated for preparation of the synthetic inorganic plate; meanwhile, a new application way is also initiated for practice and application of the RPC theory.

Owner:GUIZHOU LIANHE NEW BUILDING MATERIAL

Selectivated metallosilicate catalyst composite for alkylaromatic conversion, process for the preparation thereof, and use thereof in hydrocarbon conversion

InactiveUS20020151758A1Speed up the processMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystSilenes

A repeated "soak and dry" selectivation process for preparing a modified metallosilicate catalyst composite is disclosed comprising of a mixture of amorphous silica, alumina and a pore size controlled metallosilicate useful for alkylaromatic conversion. The process comprises (a) contacting an intermediate pore metallosilicate with an organosilicon compound in a solvent for a specific duration and then recovering the solvent, (b) combining the organosilicon compound treated metallosilicate with water and then drying the catalyst, (c), repeating the steps a) and b) above and (d) calcining the catalyst in an oxygen containing atmosphere sufficient to remove the organic material and deposit siliceous matter on the metallosilicate. In a another embodiment, when the organosilicon compound is water soluble, step (b) may be avoided.

Owner:INDIAN PETROCHEMICALS CORPORATION LIMITED

Heavy goods vehicle tire comprising a tread based on a modified polyisoprene, process for preparing same

ActiveUS20150322183A1Improve propertiesReduce rolling resistanceTyresSpecial tyresRolling resistanceSilenes

A heavy-duty vehicle tire comprising a tread consisting of a crosslinked rubber composition comprising a reinforcing filler of siliceous type and a synthetic polyisoprene modified by grafting with a compound comprising at least one group Q, and at least one group A, which are joined to one another by at least one and preferably one “spacer” group Sp, in which:Q comprises a dipole containing at least one and preferably one nitrogen atom,A comprises an associative group comprising at least one nitrogen atom,Sp is an atom or group of atoms forming a bond between Q and A.The heavy-duty vehicle tire according to the invention has a satisfactorily improved rolling resistance / wear resistance compromise.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

Method of pumping aqueous fluid containing surface modifying treatment agent into a well

A well treatment fluid contains a surface modifying treatment agent having an anchor and a hydrophobic tail. The surface modifying treatment agent is an organophosphorus acid derivative. After the well treatment fluid is pumped into a well penetrating the subterranean formation, the anchor binds to the surface of the formation. The subterranean formation is a siliceous formation or a metal oxide-containing subterranean formation. The anchor bonds to a Si atom when the formation is a siliceous formation and to the metal of the metal oxide when the formation is a metal oxide-containing formation. After being bound to the surface of the formation, frictional drag within the well is reduced. This allows for faster recovery of formation fluids. The bonding of the surface modifying treatment agent onto the formation may further be enhanced by first pre-treating the formation with an aqueous fluid. By increasing the number of sites for the surface modifying treatment agent to bind onto the surface of the subterranean formation, productivity is improved.

Owner:BAKER HUGHES INC

Siliceous composite plate, and preparation method and application thereof

ActiveCN102924066ARaw material formula is reasonableThe preparation method is reasonableFurnace componentsCasings/liningsAdhesiveThermal insulation

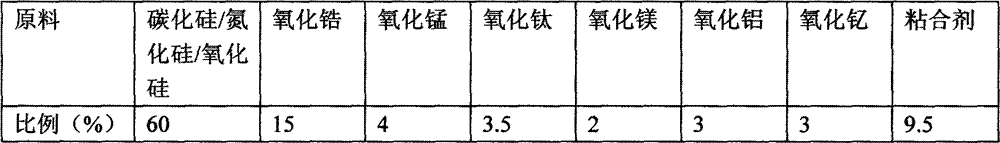

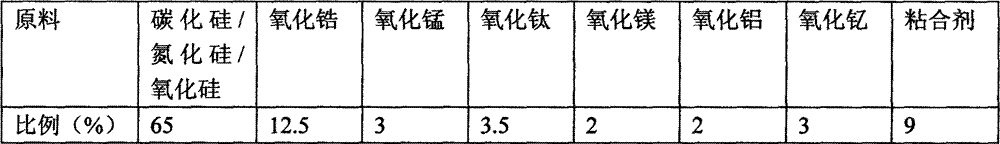

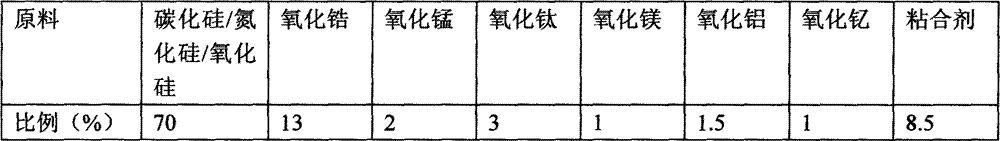

The invention discloses a siliceous composite plate, and a preparation method and application thereof. The siliceous composite plate comprises, by weight, 60%-70% of silicon carbide / silicon nitride / silicon oxide, 10%-15% of zirconium oxide, 2%-4% of manganese oxide, 3%-3.5% of titanium oxide, 1%-2% of magnesium oxide, 1.5%-3% of alumina, 1%-3% of yttrium oxide and 2%-10% of adhesive. The siliceous composite plate has the advantages of being resistant to high temperature, small in deformation, high in strength and oxidation-resistant capability and regular in appearance and remarkably prolonging service life, and solves the problems that in the prior art, a fire-resistant thermal insulation material is poor in oxidation resistance, cracks easily, and is poor in thermal insulation performance and high-temperature bending strength and the like. The siliceous composite plate can be applied to waste incineration furnaces, industrial kilns, boilers, smelting furnaces, engines and power station combustion furnaces and has the capability of being resistant to any thermal shock.

Owner:珠海圣世科技有限公司

Nano silicon thermal insulation material and preparation method thereof

ActiveCN104476857AImprove thermal conductivityLow thermal conductivityCeramic layered productsFiberExtinction

The invention provides a nano silicon thermal insulation material. The nano silicon thermal insulation material comprises a high temperature layer and a low temperature layer which is composited onto the high temperature layer; the low temperature layer consists of 60 to 80 parts by weight of nano silicon dioxide, 5 to 15 parts by weight of inorganic fibers and 15 to 35 parts of carbon black; the high temperature layer consists of 60 to 80 parts by weight of nano silicon dioxide, 5 to 15 parts by weight of inorganic fibers and 15 to 35 parts of an infrared shading agent; the infrared shading agent is one or more of titanium dioxide, zirconia, silicon carbide and potassium hexatitanate whisker. According to the nano silicon thermal insulation material, the effective extinction coefficient and the temperature resistance of different infrared shading agents of different types are adequately utilized, and the nano silicon thermal insulation material with ultralow heat conduction coefficient which can be used in a high temperature area can be prepared by utilizing different infrared shading agents of different types in a gradient manner.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com