Siliceous composite plate, and preparation method and application thereof

A composite plate and silicon technology, which is applied in the field of energy saving and environmental protection, can solve the problems of short service life of thermal insulation materials, etc., and achieve the effects of strong oxidation resistance, increased heat utilization rate, and improved combustion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

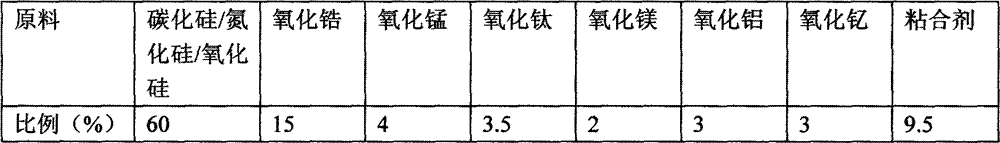

[0028] a) Batching: Put the raw materials into the machine according to the ratio in Table 1 and stir them.

[0029]

[0030] Table 1

[0031] b) Dissolving: Mix the various raw materials described in step a) together, and dissolve the adhesive relatively, and put in an appropriate amount of water.

[0032] c) Co-precipitation: zirconia is precipitated out of the precipitate, causing other soluble raw materials to precipitate together.

[0033] d) Filtration and water washing: filter the precipitated raw materials and purify and wash them with water.

[0034] e) Drying: Dry the siliceous composite material to 1% at a temperature of 80 degrees.

[0035] f) Airflow crushing: This is one-time crushing, using the self-grinding effect of the siliceous composite material, and impacting the material with high-speed airflow or hot steam generated by compressed air, so that the siliceous composite materials have strong collision and friction with each other , in order to achieve ...

Embodiment 2

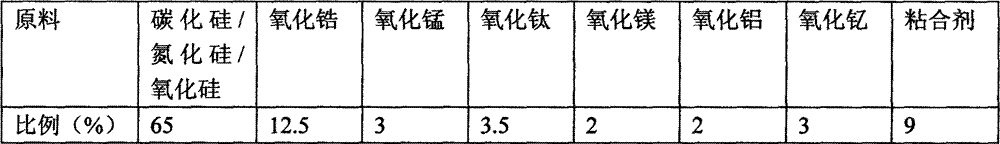

[0039] a) Ingredients: Put the raw materials into the machine according to the ratio shown in Table 2 and stir them, among which 10% zirconia, 3% titanium oxide and 1% yttrium oxide are mixed, and the remaining raw materials are added in the secondary crushing.

[0040]

[0041] Table 2

[0042] b) Dissolving: Mix the various raw materials described in step a) together, and dissolve the adhesive relatively, and put in an appropriate amount of water.

[0043] c) Co-precipitation: zirconia is precipitated out of the precipitate, causing other soluble raw materials to precipitate together.

[0044] d) Filtration and water washing: filter the precipitated raw materials and purify and wash them with water.

[0045] e) Drying: Dry the siliceous composite material to 1% at a temperature of 100 degrees.

[0046] f) Jet milling: There are two times of milling here, and after the first milling, step g) is performed for sintering. After sintering, add the remaining zirconia 2.5%, t...

Embodiment 3

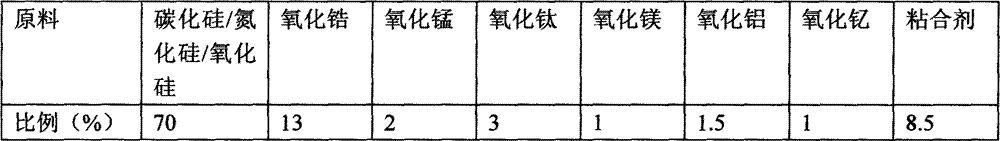

[0050] a) Ingredients: Put the raw materials into the machine according to the ratio shown in Table 3 and stir them. For the first crushing, put 5% of zirconia, 1% of titanium oxide, 0.5% of yttrium oxide, and no magnesia. Put in 4.5% zirconia, 1.5% titanium oxide, 0.5% yttrium oxide, and no magnesia for crushing, and put 3.5% zirconia, 0.5% titanium oxide, and 1% magnesia for the third crushing.

[0051]

[0052] table 3

[0053] b) Dissolution: Mix the various raw materials of the implementation method 3 together, and dissolve the adhesive relatively, and put in an appropriate amount of water.

[0054] c) Co-precipitation: zirconia is precipitated out of the precipitate, causing other soluble raw materials to precipitate together.

[0055]d) Filtration and water washing: filter the precipitated raw materials and purify and wash them with water.

[0056] e) Drying: Dry the siliceous composite material to 1% at a temperature of 120 degrees.

[0057] f) Jet milling: There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com