Colloidal bismuth pectin tablets and preparation method thereof

A technology of colloidal bismuth pectin and bismuth pectin tablets, which is applied in the fields of pill delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problem of poor swelling and dispersion effects of drugs, large particle size of drug particles, Poor fluidity and other problems, to achieve comprehensive and targeted protection, small particle size, excellent flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

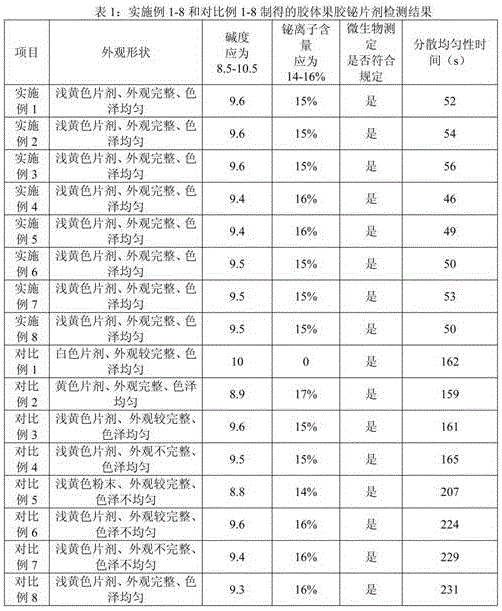

Examples

Embodiment 1

[0025] A colloidal bismuth pectin tablet, comprising the following raw materials in parts by weight: 20 parts of colloidal bismuth pectin as bismuth, 8 parts of sucralfate as aluminum, 60 parts of white dextrin, 11 parts of polyvinylpyridinone, low Substitute 2 parts of hydroxypropyl cellulose, 5 parts of pharmaceutical silicon dioxide and 0.2 parts of magnesium stearate.

[0026] Its preparation method comprises the following steps:

[0027] (1) Add colloidal bismuth pectin and bismuth pectin to distilled water at a temperature of 60°C, stir, and perform homogenization treatment in a high-pressure homogenizer at 40Mpa to obtain glue;

[0028] (2) Add sucralfate, white dextrin, 75% polyvinylpyridone, low-substituted hydroxypropyl cellulose, drug With silicon dioxide and 70% magnesium stearate by magnesium stearate gross weight portion, stir, carry out homogeneous treatment in high-pressure homogenizer under 40Mpa, obtain mixed mortar;

[0029] (3) Spray the mixed mortar obta...

Embodiment 2

[0032] A colloidal bismuth pectin tablet, comprising the following raw materials in parts by weight: 30 parts of colloidal bismuth pectin as bismuth, 2 parts of sucralfate as aluminum, 120 parts of β-cyclodextrin, and 7 parts of sodium carboxymethyl starch , 6 parts of polyethylene glycol, 1 part of medical silicon dioxide and 2.8 parts of palmitic alcohol.

[0033] Its preparation method comprises the following steps:

[0034] (1) Add colloidal bismuth pectin and bismuth pectin to distilled water at a temperature of 80°C, stir, and perform homogenization treatment in a high-pressure homogenizer at 60Mpa to obtain glue;

[0035] (2) Add sucralfate, β-cyclodextrin, 85% carboxymethyl starch sodium, polyethylene glycol, medicinal Silica and the palmitic alcohol of 62% by palmitic alcohol gross weight portion, stir, carry out homogeneous treatment in high-pressure homogenizer under 60Mpa, obtain mixed mucilage;

[0036] (3) Spray the mixed mortar obtained in step (2), granulate,...

Embodiment 3

[0039] A colloidal bismuth pectin tablet, comprising the following raw materials in parts by weight: 22 parts of colloidal bismuth pectin as bismuth, 7 parts of sucralfate as aluminum, 100 parts of lactose, 8 parts of polyvinylpyridone, polyethylene glycol 3 parts of alcohol, 5 parts of medical silicon dioxide and 0.8 part of magnesium stearate.

[0040] Its preparation method comprises the following steps:

[0041] (1) Add colloidal bismuth pectin and bismuth pectin to distilled water at a temperature of 65°C, stir, and perform homogenization treatment in a high-pressure homogenizer at 55Mpa to obtain glue;

[0042] (2) Add sucralfate, lactose, 78% polyvinylpyridone, polyethylene glycol, medicinal silicon dioxide and The magnesium stearate of 68% by magnesium stearate gross weight part, stirs, carries out homogeneous treatment in high-pressure homogenizer under 55Mpa, obtains mixed mortar;

[0043] (3) Spray the mixed mortar obtained in step (2), granulate, and dry to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com