Patents

Literature

37results about How to "Raw material formula is reasonable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

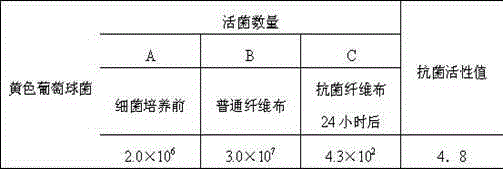

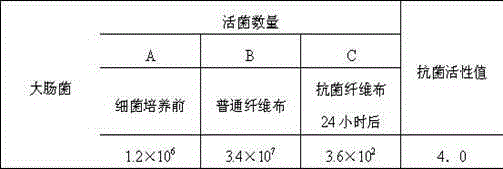

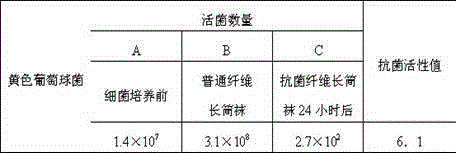

Antibacterial fiber

InactiveCN103334175ARaw material formula is reasonableWon't fall off easilyMonocomponent polyesters artificial filamentArtifical filament manufactureFiberMedical equipment

The invention discloses an antibacterial fiber. The fiber comprises following raw materials, by weight: 1 to 15% of silver oxide powder or silver nitrate powder; and one or more selected from polybutylene terephthalate, polyamide, polypropylene and polyethylene; with the balance being polyethylene glycol terephthalate. The raw materials are mixed uniformly and then the fiber is produced by melting spinning. The formula of the antibacterial fiber is reasonable; antibacterial material is embedded into the matrix material of the fiber, so that the active compounds will not fall off easily; the stability of the fiber is excellent; and the fiber is capable of preventing and killing bacterial in a long term. Antibacterial and mould-proof effects of the fiber are excellent; the fiber is capable of preventing bacterial, and also controlling and preventing fungus (mould) effectively. Blending ratio is low, and the antibacterial performance is excellent; and the fiber is capable of keeping bacterial away; so that the blending ratio is reduced, cost is saved, and antibacterial performance is enhanced. The fiber is safe to use, and can be widely applied in the field of medical equipment, medical clothes, military, household textile product, clothes, and outdoor activities.

Owner:LUMICA SPECIAL FIBER LIANYUNGANG

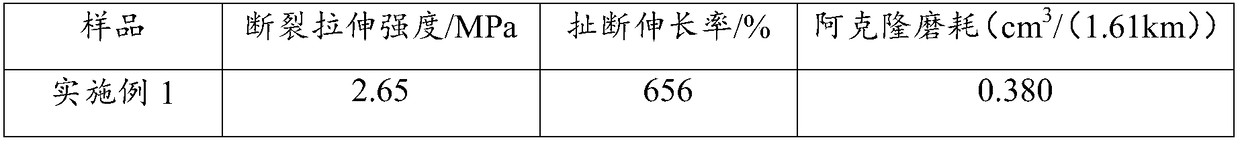

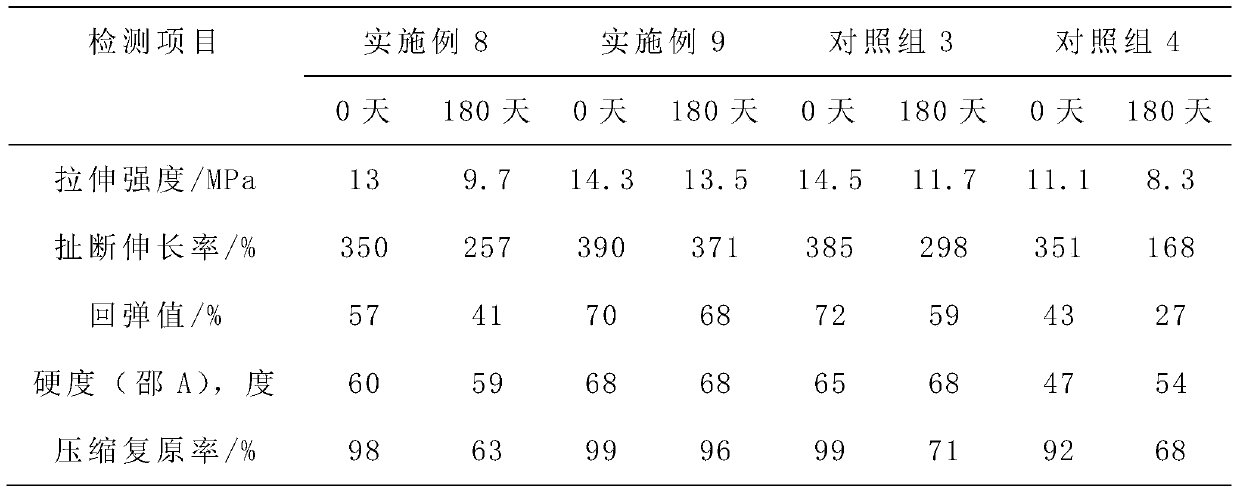

Environment-friendly rubber prefabricated track coiled material and preparation method thereof

The invention discloses an environment-friendly rubber prefabricated track coiled material and a preparation method thereof, and relates to the technical field of track coiled materials. The rubber prefabricated track coiled material is mainly prepared from the following raw materials in parts by weight: 30 to 60 parts of ethylene propylene rubber, 40 to 80 parts of reclaimed rubber, 20 to 50 parts of an LLDPE and HDPE blend, 1 to 30 parts of a nanometer rare earth oxide, 5 to 10 parts of a vulcanizing agent, 6 to 12 parts of paraffin oil, 10 to 15 parts of naphthenic oil, 1 to 5 parts of zincoxide and 50 to 200 parts of a filler, wherein the reclaimed rubber is a mixture of butyronitrile reclaimed rubber and butyl chloride reclaimed rubber, and the mass ratio of the butyronitrile reclaimed rubber to the butyl chloride reclaimed rubber is 2: (0.5 to 1). The environment-friendly rubber prefabricated track coiled material solves the problem that a rubber track coiled material is low inabrasive resistance, tensile strength and elasticity and not environmentally friendly at present, the obtained rubber prefabricated track coiled material is excellent in physical and mechanical performances and has excellent tensile strength and abrasive resistance, the product is free of noxious substance residue, and the recycled reclaimed rubber is cost-saving, safe and environmentally friendly.

Owner:湖南盛亚体育实业有限公司

Free oiling and self-lubricating elevator guideway guide shoes and preparation method thereof

InactiveCN101358013ARaw material formula is reasonableEasy to prepareElevatorsDomestic articlesLubricationHardness

The invention provides a nonoiling self-lubricating elevator guide shoe and a preparation method thereof. The raw material contains polytetrafluoroethylene, carbon fiber and bronze powder. The manufacturing process includes the following steps: (1) the materials are prepared in accordance with the formula; (2) the prepared materials are fed into industrial molds; (3) the materials are treated by die-casting forming; (4) surface hardness and smoothness are detected; (5) the materials are processed by vacuum insulation. The elevator guide shoe of the invention is manufactured adopting polytetrafluoroethylene, bronze powder and carbon fiber according to the proportion, the raw materials formula is reasonable, the preparation method is simple; compared with the prior guide shoes, the elevator guide shoe prepared with the method has the advantages of self lubrication without applying oil, low noise, good wear resistance, low friction coefficient, long service life, high strength and abrasion resistance, and the vibration in the running process of the elevator is reduced, and compared with the prior guide shoe slider, the service life of the product of the invention is prolonged by 6 to 8 times.

Owner:郭自刚

Co-extrusion production method for deeply-embossed composite plastic-wood plate with mixed color

ActiveCN104004369ARaw material formula is reasonableGood product performanceSynthetic resin layered productsWood layered productsMaleic anhydrideVacuum pumping

The invention provides a co-extrusion production method for a deeply-embossed composite plastic-wood plate with a mixed color, and relates to the technical field of plastic-wood material production. The production method mainly comprises a pelleting process, a co-extrusion process and a deep-embossing process. Needed raw materials comprise 40-60% of bamboo / wood powder, 15-30% of PE, 4-10% of talcum powder, 10-15% of toner, 2-5% of a coupling agent and 3-5% of a maleic anhydride grafted mateiral. The extrusion process comprises mixing material particles obtained in the pelleting process with color masterbatch with stirring, then adding into an extruder for extruding to obtain plates, and controlling the pressure in a cylinder of the extruder to be 0.06 MPa by utilizing vacuum-pumping equipment connected with the cylinder. By utilizing the provided co-extrusion production method for the deeply-embossed composite plastic-wood plate with mixed color, the raw-material formula is reasonable, the product performances are good, the plastic-wood plate with mixed color is produced and possesses patterns with different colors, and the variety of products is improved; and after extrusion molding and hot embossing are continuously performed on the composite plastic-wood plate, cooling and once-more heating are not needed, the production process reaches the purpose of saving energy, and the embossing depth reaches 0.4-0.8 mm, so that the lines are not easy to rub down.

Owner:ANHUI SENTAI WPC GRP CO LTD

Production technology for plastic-wood plate with mixed color

ActiveCN104004370ARaw material formula is reasonableGood product performanceMaleic anhydrideFlue gas

The invention provides a production technology for a plastic-wood plate with mixed color, and relates to the technical field of plastic-wood material production. The production technology mainly comprises a pelleting process and an extrusion process. In the pelleting process, needed raw materials comprise 40-60% of bamboo / wood powder, 15-30% of PE, 4-10% of talcum powder, 10-15% of toner, 2-5% of a coupling agent and 3-5% of a maleic anhydride grafted material. The extrusion process comprises: mixing material particles obtained in the pelleting process with color masterbatch with stirring, then adding into an extruder for extruding to obtain plates, and controlling the pressure in a cylinder of the extruder to be 0.06 MPa by utilizing vacuum-pumping equipment connected with the cylinder. By utilizing the production technology for plastic-wood plate with mixed color, the raw-material formula is reasonable, the product performances are good, the plastic-wood plate with mixed color is produced and possesses patterns with different colors, and the variety of products is improved; and the extruder cylinder is connected with the vacuum-pumping equipment in the extrusion process, so that the interior of the cylinder is a low-pressure environment, moisture, flue gas and air in the cylinder are timely exhausted, and thus the product performances are improved.

Owner:ANHUI SENTAI WPC GRP CO LTD

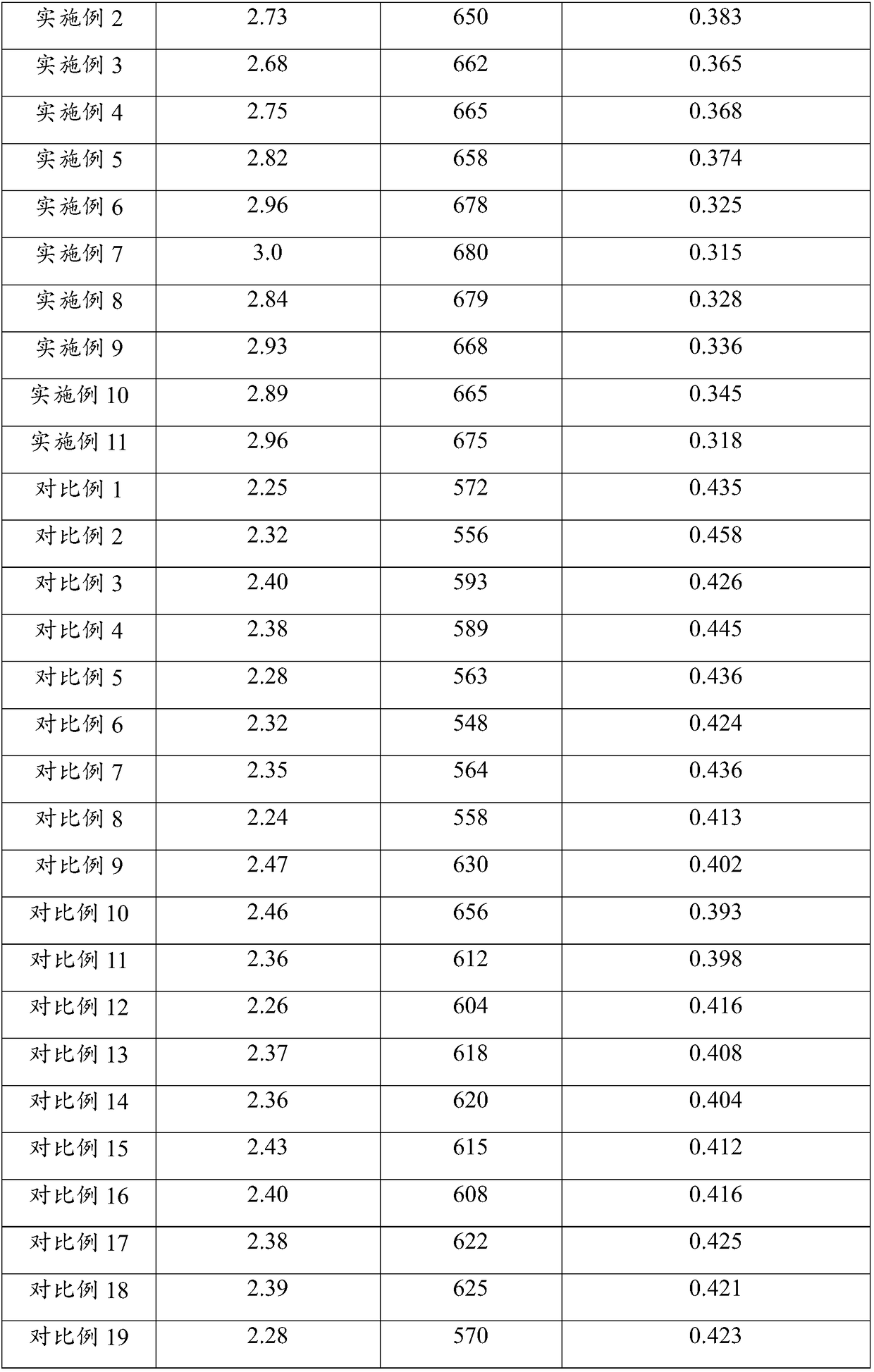

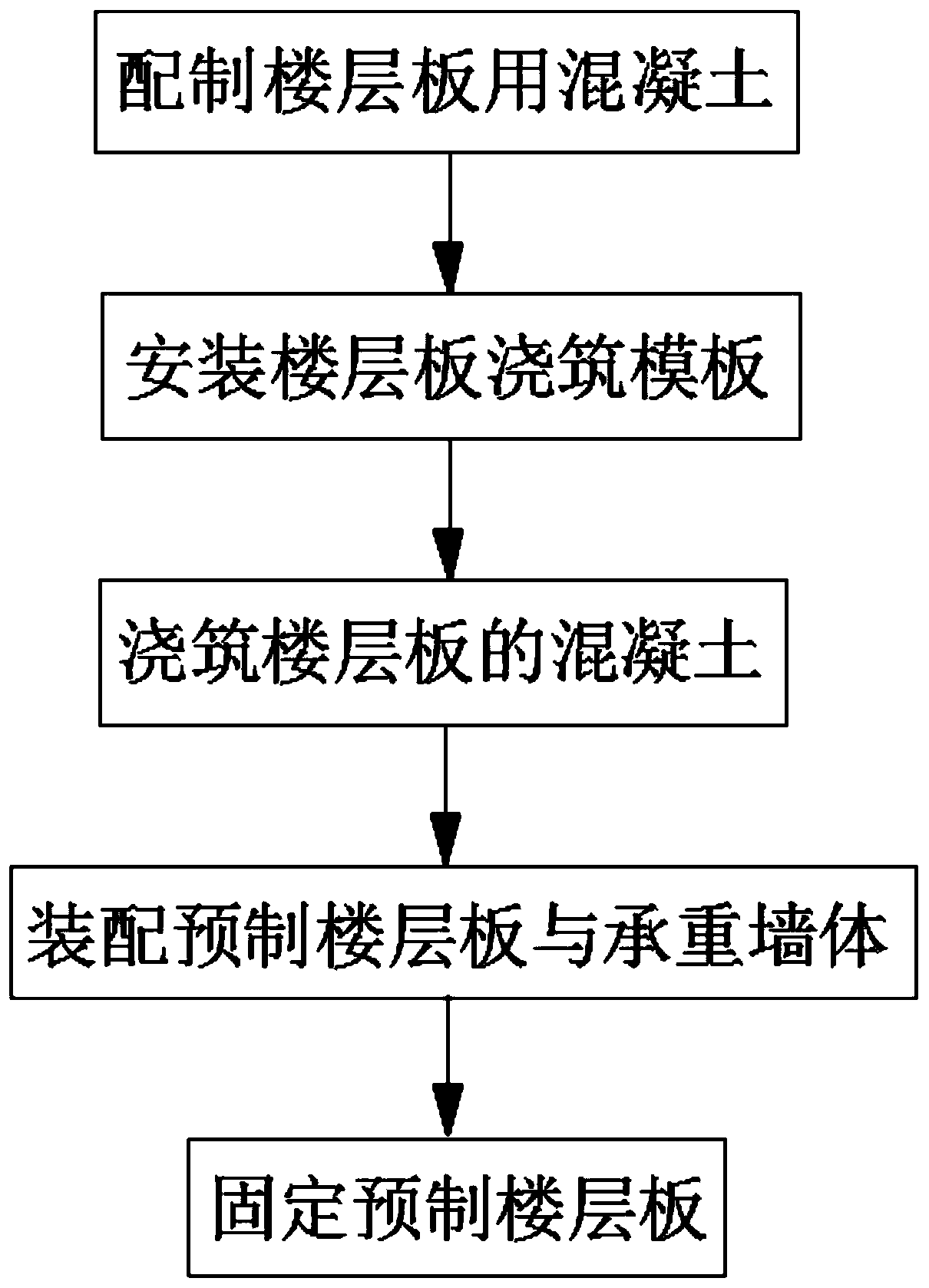

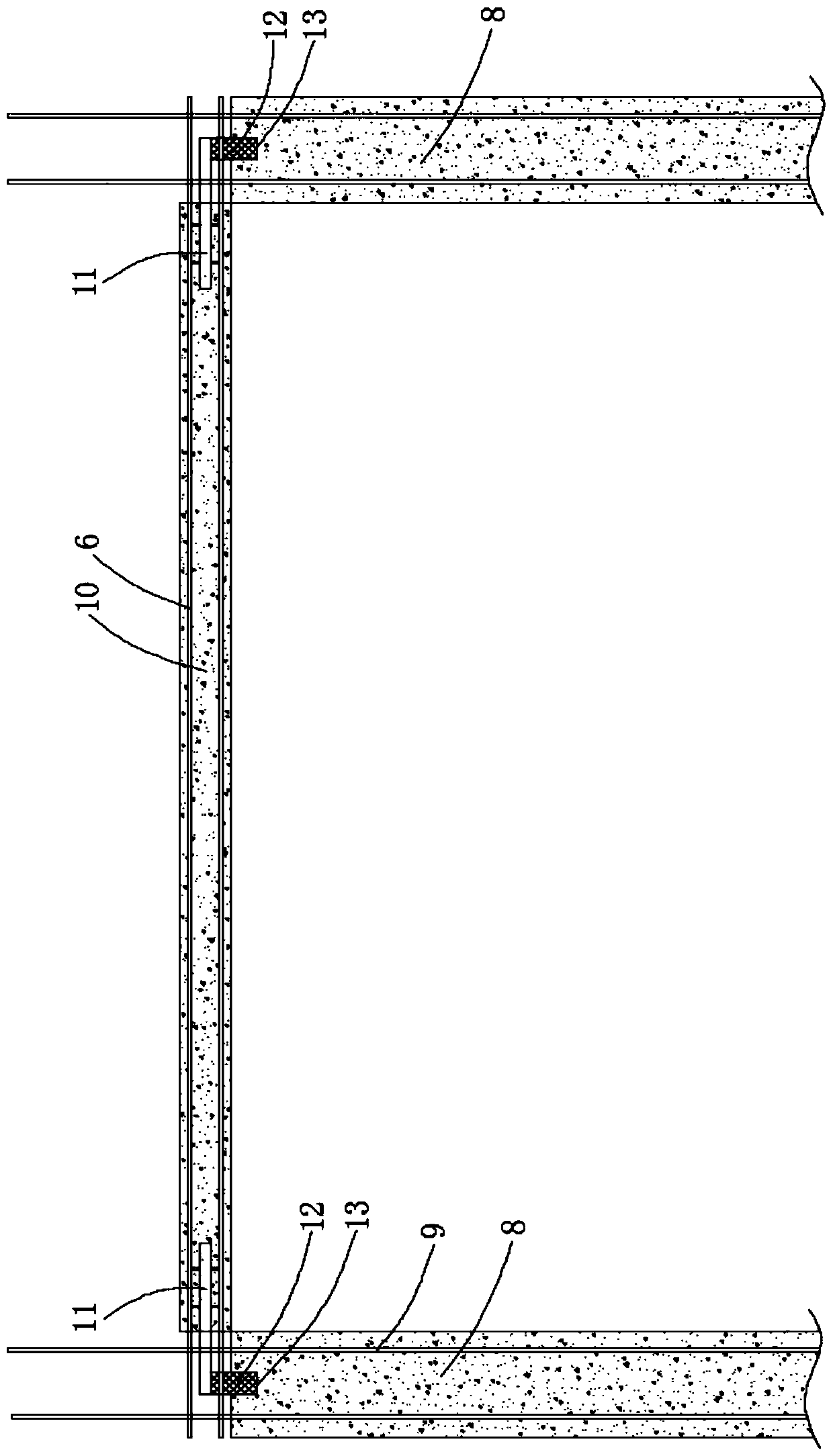

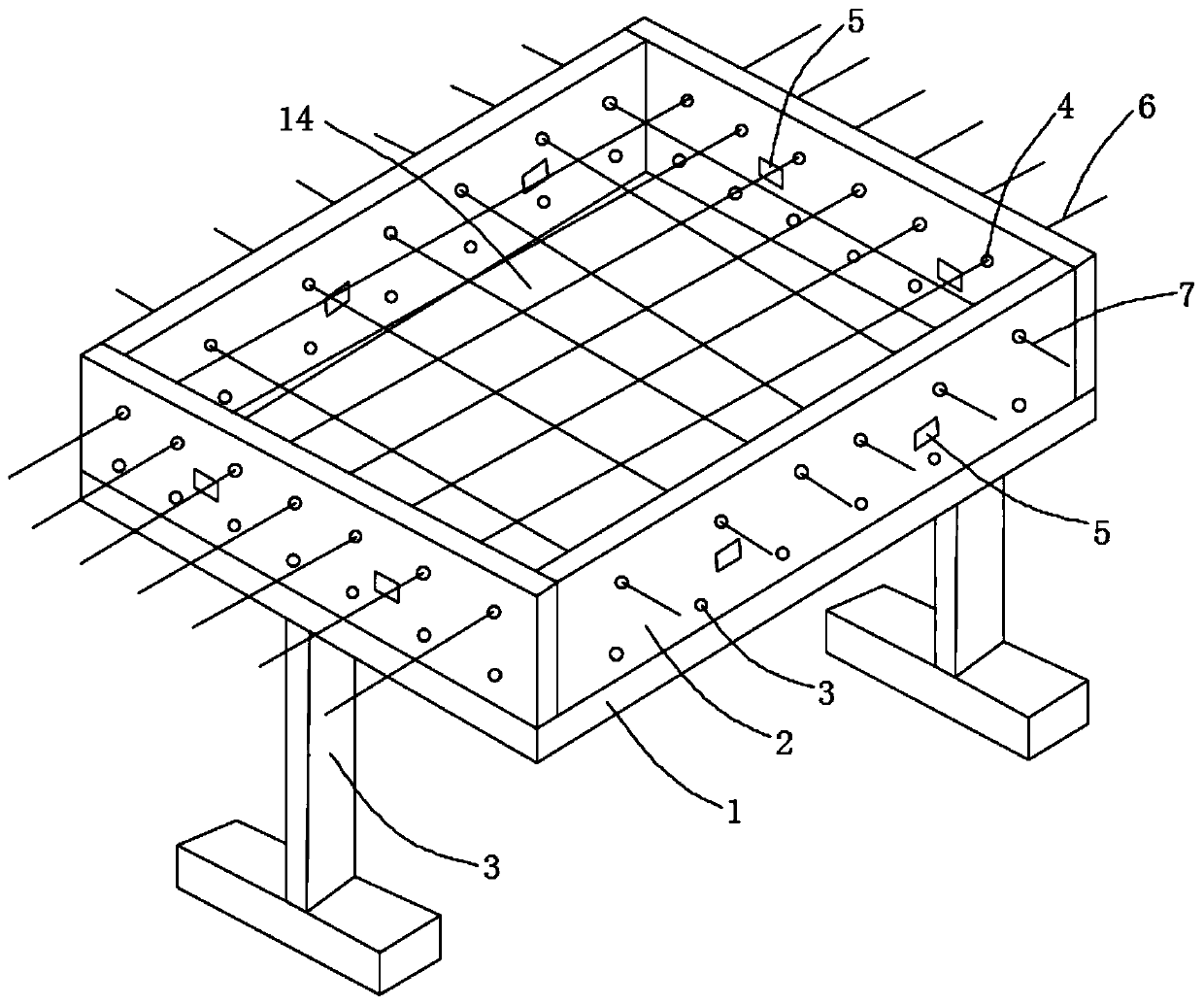

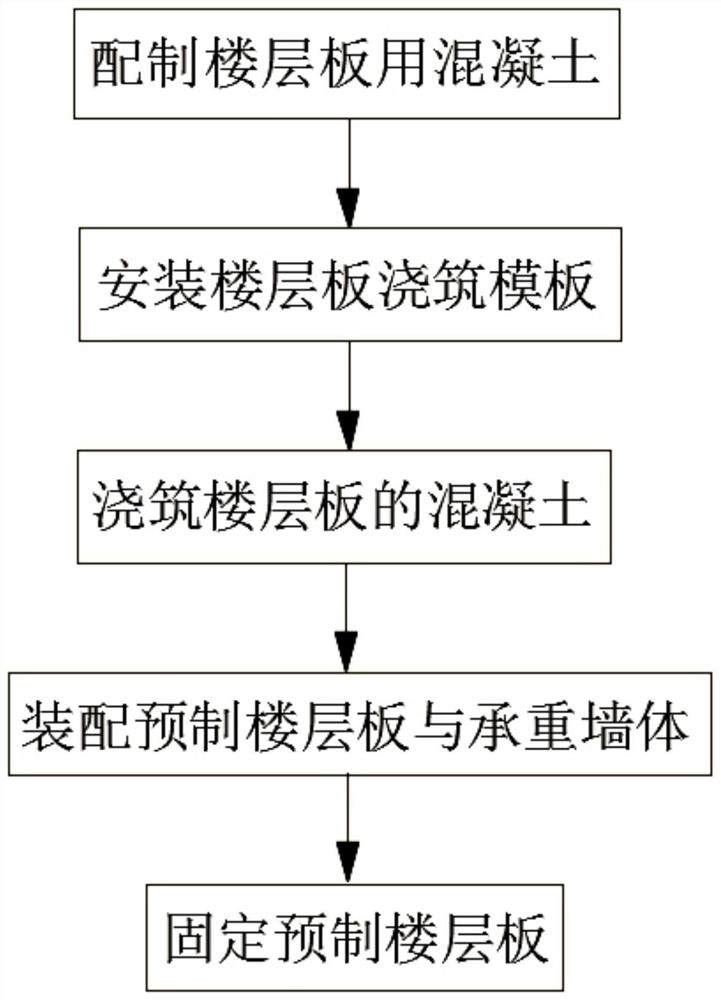

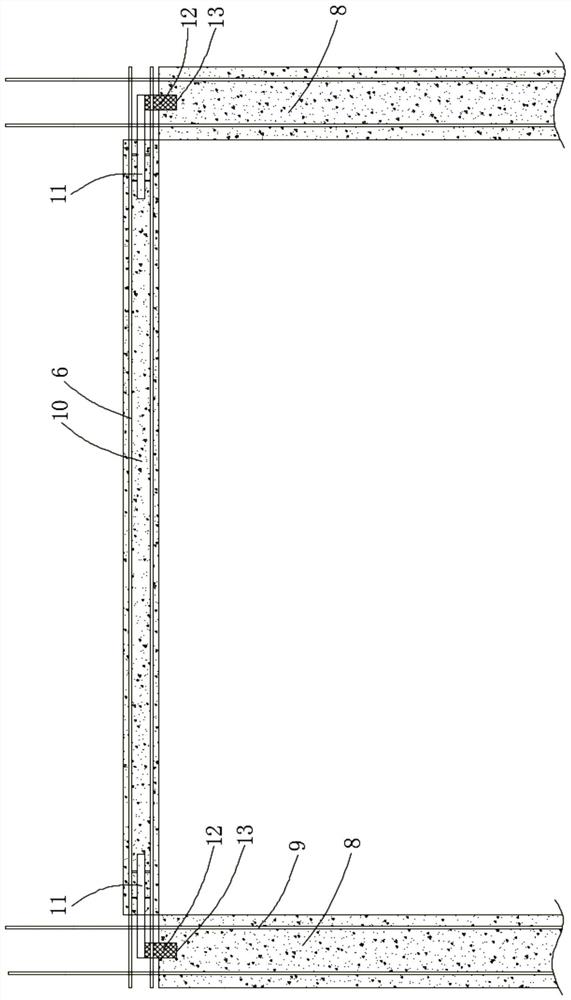

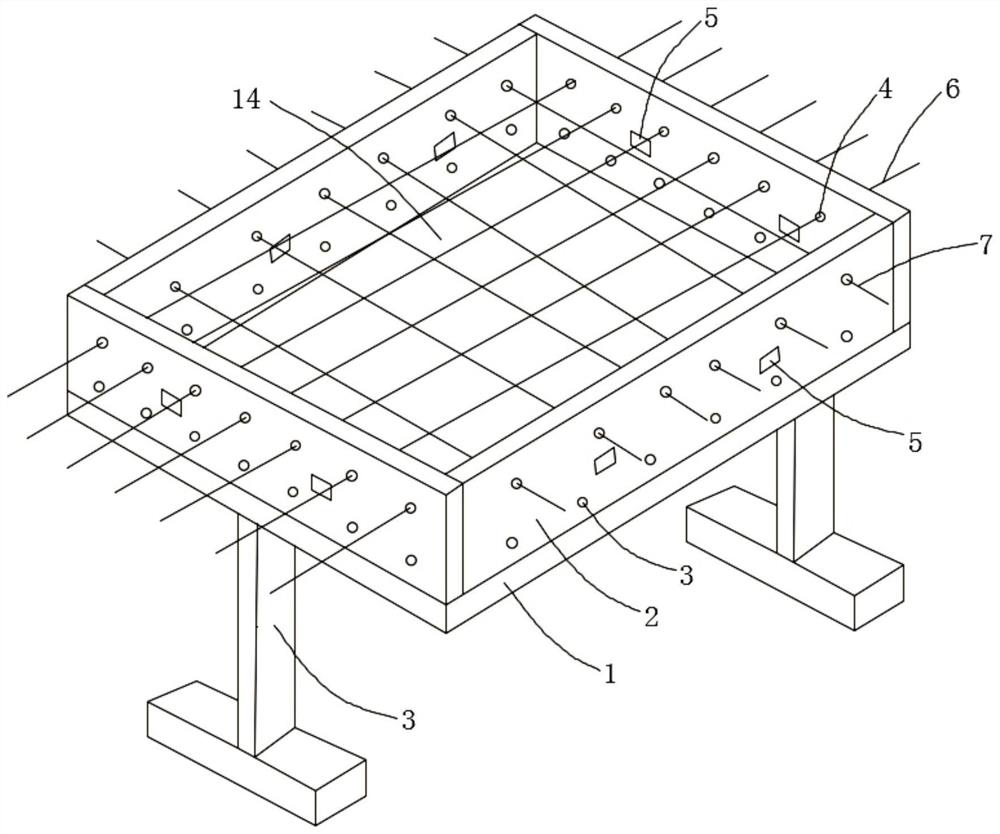

Prefabricated type concrete floor plate environmental protection construction method

ActiveCN111364658ARaw material formula is reasonableFast constructionFloorsCeramic shaping apparatusArchitectural engineeringLoad-bearing wall

The invention relates to a prefabricated type concrete floor plate environmental protection construction method. The prefabricated type concrete floor plate environmental protection construction method comprises the following construction steps that S1, concrete for floor plates is prepared, specifically, cement, water, fine grain gangue, blast furnace water granulated slag micro powder, a cementaccelerator, a defoamer and a water reducer are together put into a concrete stirrer, and the concrete for the floor plates is obtained for standby application; S2, a floor plate pouring formwork is mounted; S3, the concrete of the floor plates is poured; S4, prefabricated floor plates and a bearing wall are fabricated; and S5, the prefabricated floor plates are fixed. According to the prefabricated type concrete floor plate environmental protection construction method, a bottom surface formwork and the pouring formwork can be circularly applied to pouring the concrete floor plates, the floorplates are matched and assembled with the bearing wall more reasonably, and the construction technology of the whole floor plates is environment-friendly and energy-saving.

Owner:西安市初元建设工程有限公司

Heatproof and anticorrosive coating for power distribution cabinet shell, preparation method thereof, and power distribution cabinet shell

InactiveCN108395823ARaw material formula is reasonableImprove high temperature resistanceFireproof paintsAnti-corrosive paintsSolventPerlite

The invention discloses a heatproof and anticorrosive coating for a power distribution cabinet shell, a preparation method thereof, and the power distribution cabinet shell. The coating comprises organosilicon epoxy resin polymer, polyurethane resin, novolac epoxy resin, nanometer cerium oxide, graphene, calcined kaolin, modified zeolite powder, rutile titanium dioxide, expanded perlite, an ethylene-tetrafluoroethylene copolymer, nanometer titanium dioxide, mica powder, glass beads, ammonium triphosphate, a leveling agent and a solvent. The coating has an extremely high thermal stability, extremely high corrosion resistance and strong surface adhesion, and is applied to the surface of the power distribution cabinet shell in order to greatly improve the heat and corrosion resistance of thepower distribution cabinet shell and improve the use safety of a power distribution cabinet.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

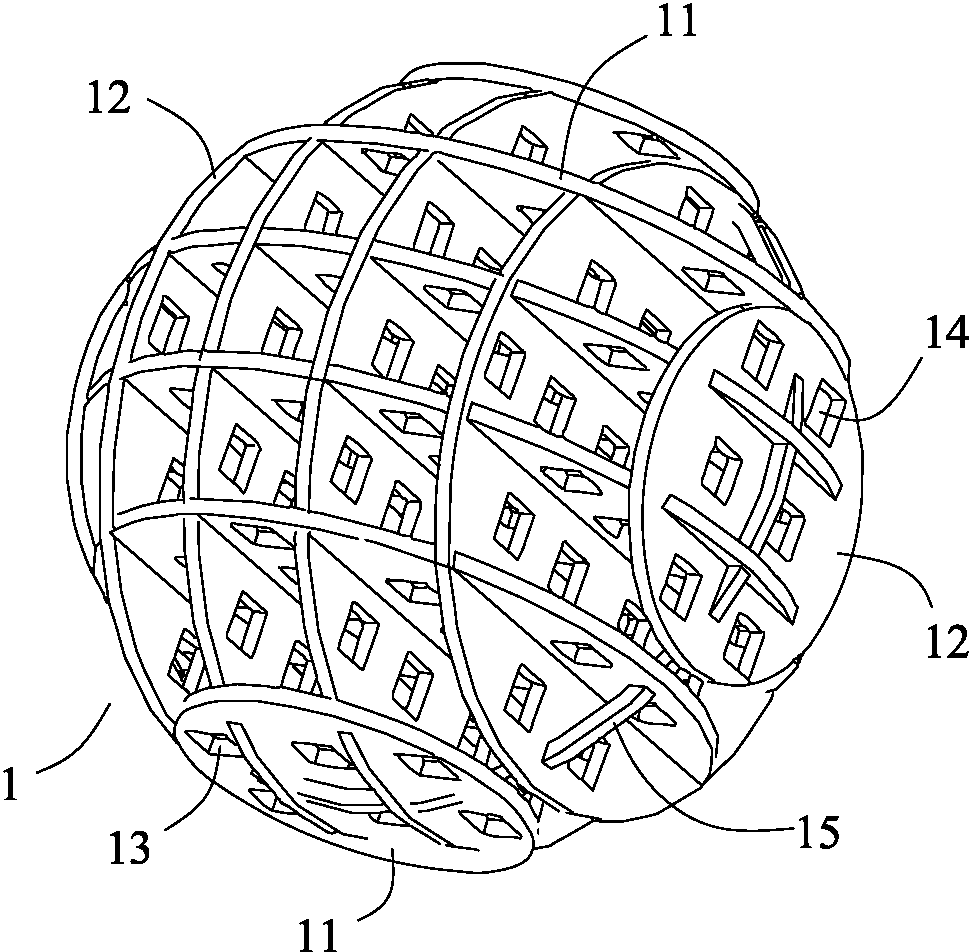

Nonmetal barrier explosion-proof material

InactiveCN103274139AIngenious structural designSimple structureContainer filling methodsBottlesFlame propagationEngineering

The invention discloses a nonmetal barrier explosion-proof material. The nonmetal barrier explosion-proof material comprises a sphere which is integrally formed by means of injection molding, the sphere comprises a ring, a plurality of transverse round plates and a plurality of longitudinal round plates, each transverse round plate is provided with a plurality of longitudinal through holes, and each longitudinal round plate is provided with a plurality of transverse through holes. The nonmetal barrier explosion-proof material is skillful in structural design, reasonable in raw material formula, simple and compact in integral structure, high in strength, less prone to deformation, easy to process and manufacture and low in cost, has good explosion-proof effect and is capable of enabling a plurality of small compartments with a certain barrier effect to be formed in a container so that flame propagation can be suppressed effectively. Meanwhile, the nonmetal barrier explosion-proof material has good heat conductivity so that most heat released by combustion can be absorbed rapidly, and good explosion suppression performance is achieved. Additionally, by reasonably optimizing flaky raw materials and the proportion, the nonmetal barrier explosion-proof material is good in corrosion resistance and explosion-proof performance and high in safety performance, and pollution to oils or blockage of oil delivery pipelines is avoided effectively.

Owner:胡元军

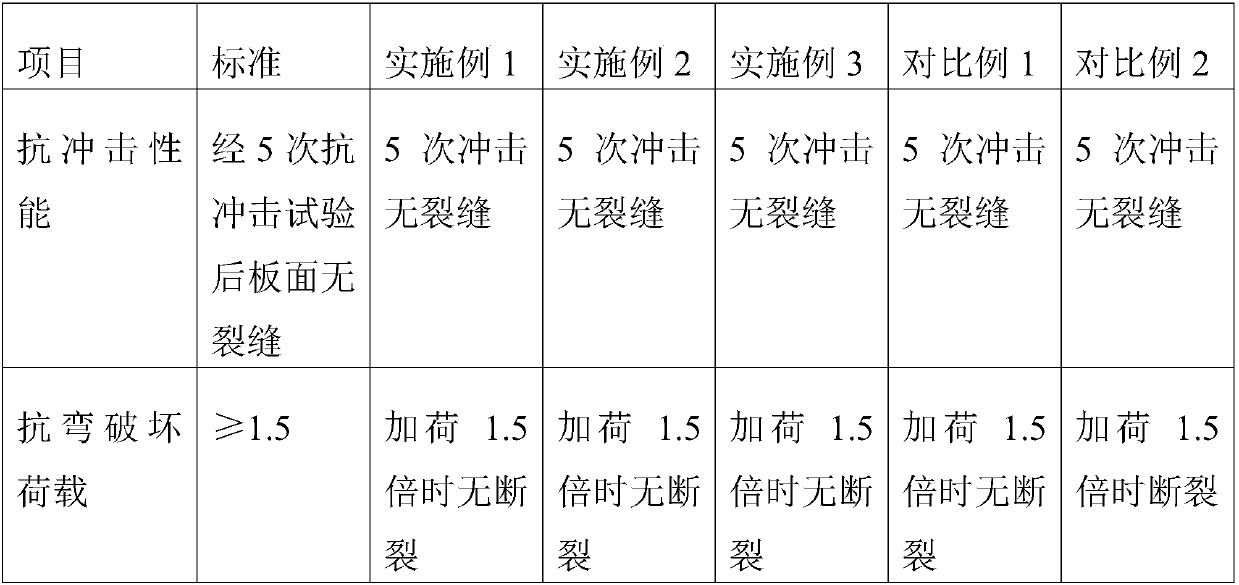

Light composite thermal insulation wallboard and preparation method thereof

The invention discloses a light composite thermal insulation wallboard. The light composite thermal insulation wallboard comprises an upper panel layer and a lower panel layer, wherein a filling layeris arranged between the upper panel layer and the lower panel layer; the filling layer is mainly prepared from the following raw materials: cement, polystyrene granules, hydroquinone, maleic anhydride, zeolite powder, ethylene phosphate and redispersion latex. The light composite thermal insulation wallboard disclosed by the invention is reasonable in formula of the raw materials, and polyphenylgranule mortar is taken as a core material, and calcium silicate is taken as panel layer materials, and an appropriate amount of admixtures are added to prepare the light composite thermal insulationwallboard. The wallboard has excellent performances of being solid, light, thin in body, high in strength, impact-resistant, strong in hanging force, heat-insulating, sound-insulating, fireproof, waterproof, easy in cutting and slotting and the like. A preparation method is simple, easy to implement, low in equipment requirements and reduced in production cost.

Owner:GUANGXI HONGFA HEAVY IND MACHINE

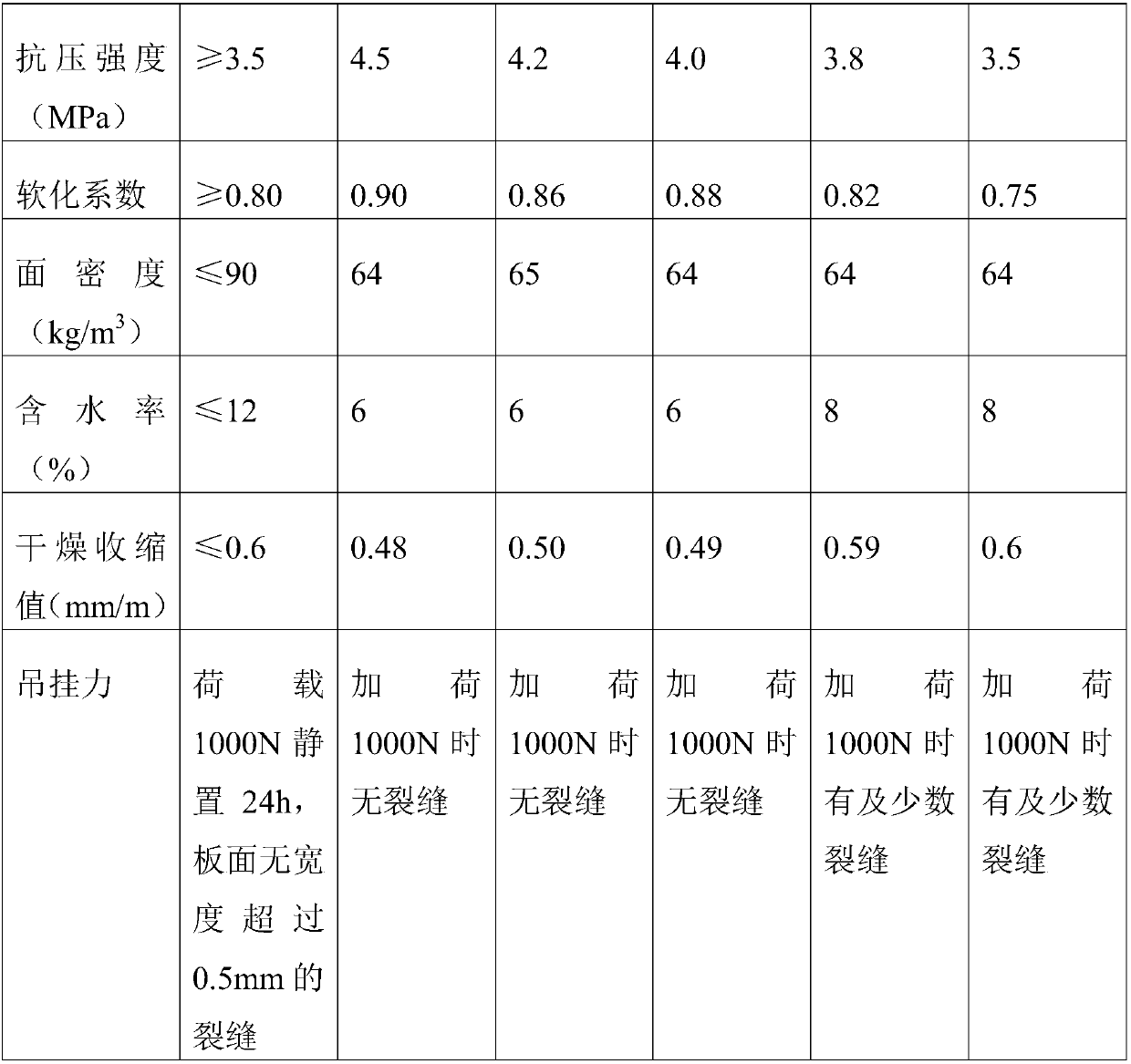

Pet food cat food containing enzymolysis quail meat and preparation method of pet food cat food

InactiveCN111955618AImprove palatabilityIncrease feed intakeAnimal feeding stuffAccessory food factorsBiotechnologyAnimal science

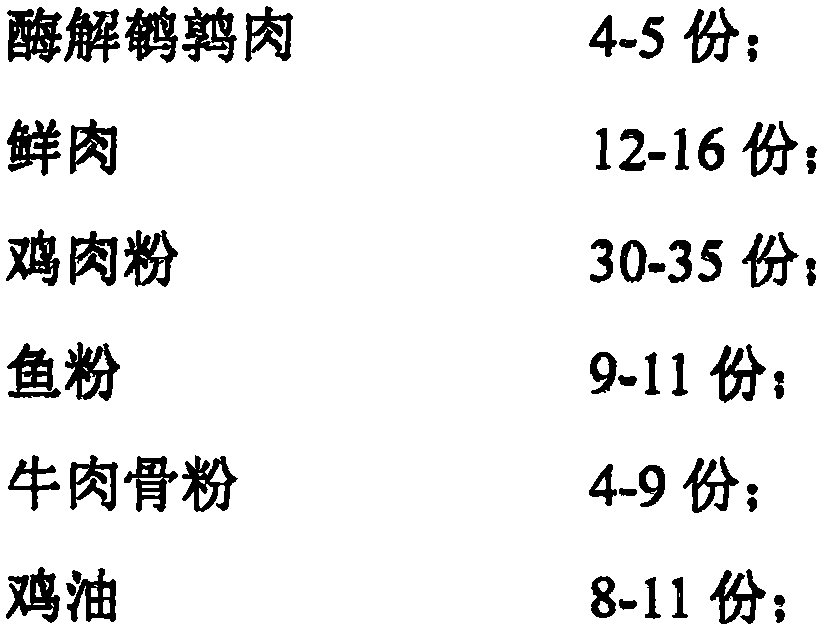

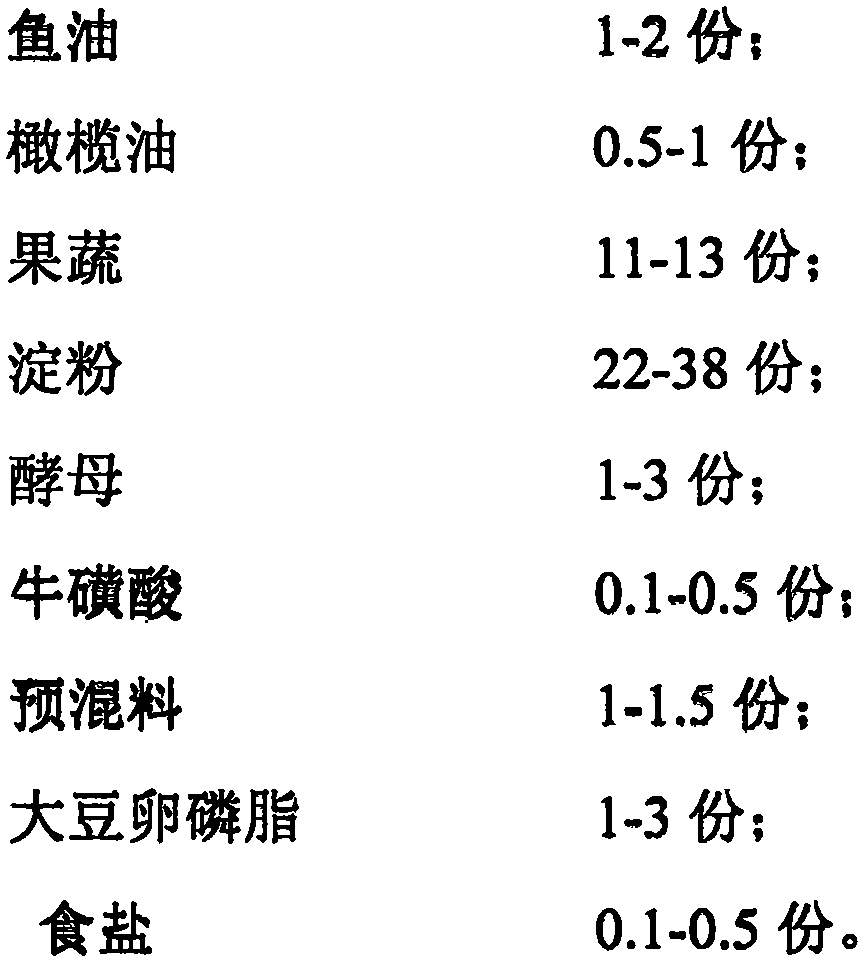

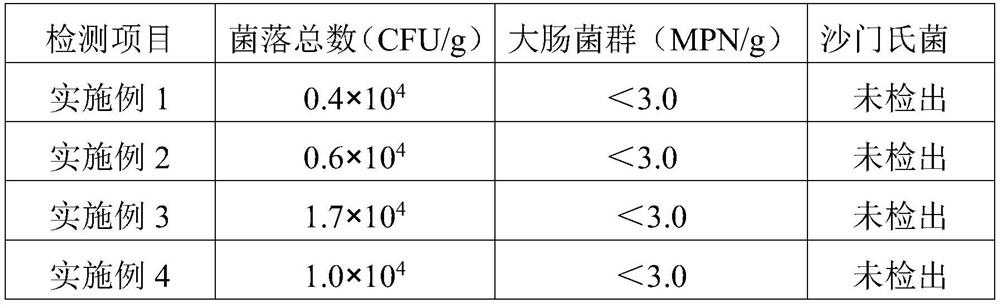

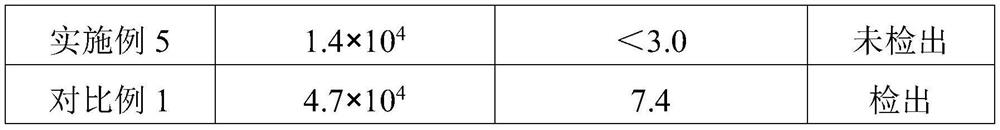

The invention belongs to the field of pet food, and discloses pet food cat food containing enzymolysis quail meat and a preparation method of the pet food cat food. The pet food cat food is prepared from the following raw materials in parts by weight: 3-5 parts of enzymolysis quail meat; 10 to 18 parts of fresh meat; 25 to 40 parts of chicken meal; 8-12 parts of fish meal; 3-10 parts of beef bonemeal; 8 to 11 parts of chicken oil; 1-2 parts of fish oil; 0.5 to 1 part of olive oil; 8-13 parts of fruits and vegetables; 20 to 40 parts of starch; 1-3 parts of yeast; 0.1 to 0.5 part of taurine; 1to 1.5 parts of premix; 1-3 parts of soybean lecithin; 0.1 to 0.5 part of table salt. The pet cat food not only can improve the palatability of the cat food so as to increase the feed intake of cats,but also can improve the hair state of the cats, is balanced in nutrition, and effectively promotes the healthy growth of the cats.

Owner:麦仕宠物食品(上海)有限公司

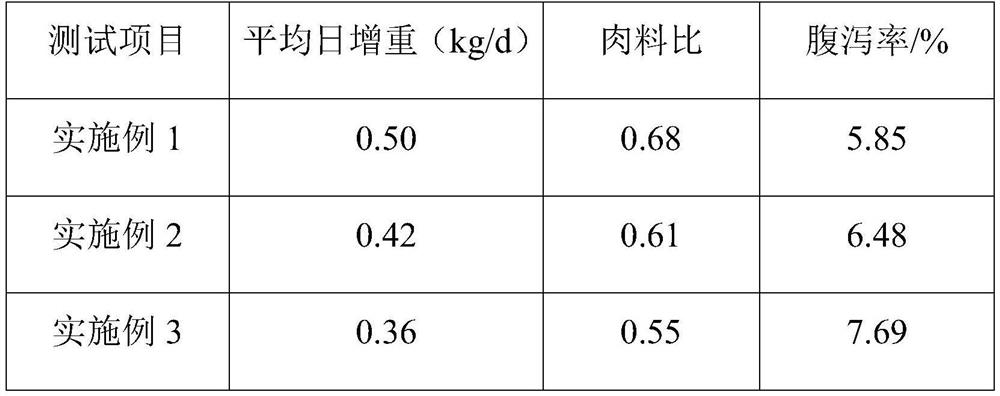

Piglet feed capable of promoting growth and preparation method thereof

PendingCN113812538AImprove feeding effectRaw material formula is reasonableFood processingAnimal feeding stuffBiotechnologyAnimal science

The invention discloses a piglet feed capable of promoting growth and a preparation method thereof. The piglet feed capable of promoting growth is reasonable in raw material formula, rich in nutrition, free of harmful substance residues, free of drug resistance and simple in preparation method. A tea polyphenol / ulva lactuca extract is added to the piglet feed capable of promoting growth, so that the intestinal function of piglets is remarkably improved, the immunity is enhanced, the feeding increasing effect of the piglets is further improved, and the piglet feed has remarkable economic benefits and social benefits and is wide in market prospect.

Owner:合肥嘉博生物科技有限公司

Tea wine

InactiveCN107446766AProtect NutrientsFull of nutritionOrganic active ingredientsDigestive systemAloe tomentosaSugar

The invention discloses tea wine. The tea wine is prepared from the following raw materials in parts by weight: 9 to 21 parts of green tea, 25 to 55 parts of Baijiu, 14 to 21 parts of white granulated sugar, 3 to 5 parts of cortex cinnamoni, 2 to 8 parts of honey, 1 to 3 parts of yeasts, 1 to 5 parts of aloes, 5 to 10 parts of tea polyphenols, 4 to 10 parts of folium artemisiae argyi, and 80 to 100 parts of purified water. The tea wine disclosed by the invention has a reasonable raw material formula, grains used as raw materials are not needed, nutrient components of the green tea can be protected to the maximum limit, and a plurality of nutrient components such as the tea polyphenols, amino acids and vitamins cannot be destroyed. The pure taste of the tea wine is ensured, and the nutrition is rich.

Owner:柳州市茶霖酒业科技有限责任公司

Method for molding automobile transmission gearbox gear stand through powder metallurgy

InactiveCN109722600ARaw material formula is reasonableSimple processFurnace typesHeat treatment furnacesPowder metallurgyHardness

The invention discloses a method for molding an automobile transmission gearbox gear stand through powder metallurgy. The method comprises the steps of raw material mixing, pressing, drying, sintering, quenching, tempering, finishing, rust prevention and the like. Raw materials comprise, by weight part, 100-120 parts of iron powder, 1.0-2.0 parts of graphene, 1.0-2.0 parts of nickel powder, 1.0-2.0 parts of manganese powder, 0.5-0.6 part of a lubricating agent, 0.1-0.2 part of a silane coupling agent, 3-4 parts of copper powder, 0.5-1.0 part of chromium powder, 1.0-1.5 parts of zinc powder, 0.1-0.15 part of silicon dioxide, 1-2 parts of tungsten carbide and 0.5-1.0 part of titanium powder. According to the method, the raw material formula is reasonable, the process is simple, and the production efficiency is high. The automobile transmission gearbox gear stand prepared through the method has the beneficial effects of uniform in overall density, good in strength and hardness, good in rust prevention performance and the like.

Owner:益阳市再超粉末冶金有限公司

Chinese medicinal composition for treatment of cardiovascular diseases, preparation method and application thereof

InactiveCN108721494AWith sedationHypnoticAnthropod material medical ingredientsInanimate material medical ingredientsAdemetionineFructus psoraleae

The invention discloses a Chinese medicinal composition for treatment of cardiovascular diseases. The Chinese medicinal composition is composed of the following components by weight: 1-2 parts of Codonopsis pilosula, 1-2 parts of lumbricus, 1-2 parts of ophiopogon japonicas, 1-2 parts of Schisandra chinensis, 1-2 parts of stir-fried spina date seed, 1-2 parts of fructus psoraleae, 1-3 parts of peach kernel, 1-3 parts of safflower, 1-3 parts of Ligusticum wallichii, 1-3 parts of ground beetle, 1-3 parts of cassia twig, 1-4 parts of raw oyster, 1-3 parts of raw dragon bone, 1-3 parts of astragalus, and 1 part of licorice. In addition, the invention also provides a preparation method and application of the Chinese medicinal composition for treatment of cardiovascular diseases. The Chinese medicinal composition for treatment of cardiovascular diseases provided by the invention can treat qi deficiency and blood stasis type cardiovascular and cerebrovascular diseases, has the characteristicsof simple preparation and significant curative effect, thus having broad application prospects and market value.

Owner:INNER MONGOLIA MEDICAL UNIV

Composite decoration paper preparation method

InactiveCN110670405ARaw material formula is reasonableGood wear resistanceWater-repelling agents additionNon-macromolecular organic additionThermal insulationBall mill

The invention discloses a composite decoration paper preparation method, which comprises: preparing a modified impregnation liquid: weighting 20-30 parts by mass of formaldehyde, 18-25 parts by mass of melamine, 3-5 parts by mass of diethylene glycol, 1-2 parts by mass of sodium hydroxide and 4-7 parts by mass of water, adding into a reaction kettle, continuous stirring, slowly heating to 60-80 DEG C, stopping the heating, carrying out thermal insulation for 30 min, adding 20-40 parts of soybean glue, cooling to 40-45 DEG C, adding 2-5 parts of an aldehyde removing agent into the reaction kettle, and cooling to a room temperature so as to spare; completely and uniformly mixing 5-8 parts by mass of ultrafine Al2O3 powder, 1-3 parts by mass of ultrafine quartzite powder and 0.1-0.3 part by mass of pigment powder in a ball mill to obtain composite reinforced powder; dipping; carrying out spray coating; and drying. According to the preparation method of the invention, the raw material formula is reasonable, the prepared decoration paper is good in wear resistance, the service life of the decoration paper is prolonged, the formaldehyde emission is reduced, and the method is simple in process and reduces the production cost.

Owner:江苏星光新材料科技有限公司

Raw material formula of hawthorn sparkling wine

InactiveCN104745428ARaw material formula is reasonableHigh in nutrientsAlcoholic beverage preparationSodium bicarbonateAlcohol

The invention discloses a raw material formula of hawthorn sparkling wine. The formula comprises 15 parts to 20 parts of sweetening alcohol, 25 parts to 30 parts of haw slices, 5 parts to 6 parts of sodium bicarbonate, 40 parts to 50 parts of lemon juice, 1.1 parts to 1.2 parts of hawthorn essence, 15 parts to 20 parts of granulated sugar, 0.2 part to 0.3 part of sodium benzoate, 30 parts to 35 parts of glucose, 0.4 part to 0.5 part of saccharin, 1000 parts to 1100 parts of cooled boiled water and 4 parts to 5 parts of citric acid. The raw material formula is reasonable and the product is tasty.

Owner:QINGDAO XIUXIAN FOODS

Method for preparing low-sugar low-calorie table sugar applicable to coffee

InactiveCN103039782AHighlight substantive featuresSignificant progressFood preparationBiotechnologyIcing sugar

The invention relates to a method for preparing low-sugar low-calorie table sugar applicable to coffee. The low-sugar low-calorie table sugar comprises the following components by weight: 1.33 to 6.67 percent of stevioside RA97, 35 to 45 percent of erythritol, 10 to 15 percent of isomaltooligosacharide, 35 to 45 percent of isomaltitol, 0.1 to 0.3 percent of citric acid, 0.05 to 0.15 percent of sodium citrate, 0.2 to 0.3 percent of lactic acid and 0.4 to 0.6 percent of calcium metasilicate. The process comprises the following steps: throwing the erythritol and 50 to 70 percent of the isomaltitol into a multidimensional mixing machine and mixing; dissolving the isomaltooligosacharide, the citric acid, the sodium citrate, the lactic acid and the residual isomaltitol into water to obtain mixed aqueous solution; throwing the mixed materials into a fluidized bed from the lower part of the fluidized bed to form fine powder; continuously atomizing and dispersing the mixed aqueous solution on the power in the fluidized bed and drying to obtain table sugar powder; and mixing the table sugar powder and the calcium metasilicate uniformly to obtain the finished product.

Owner:苏州工业园区尚融科技有限公司

Structural column mold shell and preparation method thereof

InactiveCN109797965AEasy to prepareEasy to implementCeramic shaping apparatusForms/shuttering/falseworksRebarUltimate tensile strength

The invention discloses a structural column mold shell which is formed and enclosed by a plurality of concrete slabs and forms a cavity. The plurality of concrete slabs are arranged on the same horizontal surface and are formed integrally. One side of the mold shell is provided with an opening, the concrete slab is made of layers of steel bars and concrete, and the layers of the steel bars are horizontally distributed from top to bottom inside the slab. The raw material formula of the concrete of the structural column mold shell is reasonable, and layers of steel bars are placed in the mold shell to improve the mechanical properties of the mold shell as a whole. The mold shell is simply installed on the structural column during the construction, then pouring is carried out, and no demolition is needed in later stage, thereby avoiding the safety hazard caused by the removal of the formwork and reducing the workload of the workers. The mold shell is light and thin, the thickness of the mold shell is 15-20 mm, the mold shell and the structural column can be better combined into one whole after the construction, and the work intensity of the constructors can be reduced. The preparationmethod of the structural column mold shell is simple, and is easy to implement and master.

Owner:GUANGXI HONGFA HEAVY IND MACHINE

Novel traditional Chinese medicine for treating cervical and lumbar degenerative disease and preparation technology thereof

InactiveCN105343771AEasy to prepareQuick resultsAnthropod material medical ingredientsSkeletal disorderCentipedeMyrrh

The invention discloses a novel traditional Chinese medicine for treating cervical and lumbar degenerative disease and a preparation technology thereof. The invention is characterized in that the novel traditional Chinese medicine is mainly composed of the following raw materials: long-noded pit viper, agkistrodon, zaocys dhumnade, centipede, scorpion, ground beeltle, cudweed herb, rhizoma drynariae, achyranthcs bidentata blume, green tangerine peel, spina gleditsiae, buck grass, leech, myrrh, Chinese angelica, notopterygium root, bark of ash and ground beetle. Authentic traditional Chinese medicinal materials are selected. The novel traditional Chinese medicine of the invention has reasonable formula and rigorous composition, has efficacy of expelling evil-wind and removing dampness, relieving swelling and pain, detoxifying and engendering flesh, promoting thrombolysis and promoting reunion of fractured tendons and bones, and has advantages of significant effect, short treatment course, high cure rate and no side-effect. In addition, the novel traditional Chinese medicine is simple and convenient to make and has a wide application prospect.

Owner:杨丛刚

Instant artificial rice and processing method thereof

InactiveCN107048342AImprove eating effectIncrease the degree of staple foodFood scienceLevel ivBanana powder

The invention discloses a method for processing instant artificial rice. The method comprises the following steps of: step 1, obtaining raw materials, wherein a first group of raw materials comprises 30-60 parts of potato whole powder, a second group of raw materials comprises 3-6 parts of rice flour, 10-20 parts of corn flour and 15-25 parts of soybean flour, a third group of raw materials comprises 5-10 parts of chestnut powder, 15-20 parts of Chinese yam flour and 20-30 parts of banana powder, and a fourth group of raw materials comprises 3-5 parts of edible oil, 5-10 parts of potato starch and 80-100 parts of water; step 2, blending the fourth group of raw materials evenly, adding the mixture into the third group of raw materials, and blending the mixture evenly; step 3, blending the first group of raw materials and the second group of raw materials evenly, mixing the mixture evenly with material obtained in step 2, extruding the mixture to obtain primary product of rice-like artificial rice, wherein a single screw extruder is adopted for performing extrusion forming, a first-stage barrel temperature of the single screw is 50-70 DEG C, a second-stage barrel temperature is 60-80 DEG C, a third-stage barrel temperature is 70-100 DEG C, a fourth-stage barrel temperature is 90-120 DEG C, and a fifth-stage barrel temperature is 80-95 DEG C; and step 4, performing puffing-drying to obtain the instant artificial rice.

Owner:钟静涛

Fruity tea wine

InactiveCN107446767AProtect NutrientsFull of nutritionOrganic active ingredientsDigestive systemYeastAloe arborescens

The invention discloses a fruity tea wine. The fruity tea wine is prepared from the following raw materials in parts by weight: 9 to 21 parts of green tea, 25 to 55 parts of baijiu, 14 to 21 parts of white granulated sugar, 3 to 5 parts of apple pulp, 2 to 8 parts of fructose, 1 to 3 parts of yeast, 1 to 5 parts of aloe, 5 to 10 parts of tea polyphenols, 4 to 10 parts of orange pulp and 80 to 100 parts of pure water. The tea wine disclosed by the invention has reasonable formula and do not need food as raw materials, and can maximally protect nutritional components of the green tea without damaging various nutrients such as tea polyphenols, amino acids and vitamins to ensure pure taste and rich nutrients of the tea wine.

Owner:柳州市茶霖酒业科技有限责任公司

Tea wine, and preparation method thereof

InactiveCN107475029ARaw material formula is reasonableProtect NutrientsOrganic active ingredientsDigestive systemChemistryAmino acid

The invention discloses tea wine. The tea wine is composed of, by weight, 10 to 20 parts of tea, 30 to 50 parts of baijiu, 15 to 20 parts of white granulated sugar, 3 to 5 parts of Chinese yam, 2 to 8 parts of fructose, 1 to 3 parts of yeast, 1 to 5 parts of folium artemisiae argyi, 5 to 10 parts of tea polyphenols, 4 to 10 parts of red ginseng, and 80 to 100 parts of purified water. The invention also discloses a preparation method of the tea wine. The tea wine is reasonable in formula; grain is not taken as raw materials; the nutrients of tea are protected as far as possible; nutrients such as tea polyphenols, amino acids, and vitamins are not destroyed; the pure mouthfeel of tea wine is ensured; and the tea wine is abundant in nutrients.

Owner:柳州市茶霖酒业科技有限责任公司

Preparation method of hydrogel medicine for treating chronic rhinitis

InactiveCN108904773ASolve the difficult problemThe way of medicine is flexibleAerosol deliveryOintment deliveryDiseaseSide effect

The invention belongs to the field of medicine preparation technologies and relates to a preparation method of a hydrogel medicine for treating chronic rhinitis. Natural plant ingredients are used asmain raw materials and the ingredients permeate in hydrogel to form the medicine for preventing and treating nasal diseases. The raw materials comprise cornus canadensis, catnip, radix scrophulariae,charred schizonepeta spike, Chinese yam, fistular onion bulb, ginger slice, distilled water, starch, sodium chloride, coptis, licorice, balloonflower root, xanthium, Centipeda minima, flos magnoliae liliflorae, senecio, old luffa stem, ethanol and hydrogel. The preparation method comprises the following steps: preparation of a first concentrate of the natural plants, preparation of a second concentrate of the natural plants, preparation of luffa stem powder and preparation of the product. As the medicine is in the form of hydrogel, it can be ensured that the medicine can fully reach the nasalcavity, and the uncomfortable symptom caused by a spray which enters the throat also can be overcome. The hydrogel medicine has good efficacy. In addition, the prepration process is simple, the raw material formula is reasonable, the hydrogel medicine has no toxic or side effect, and the application environment is good.

Owner:山东景仲生物科技有限公司

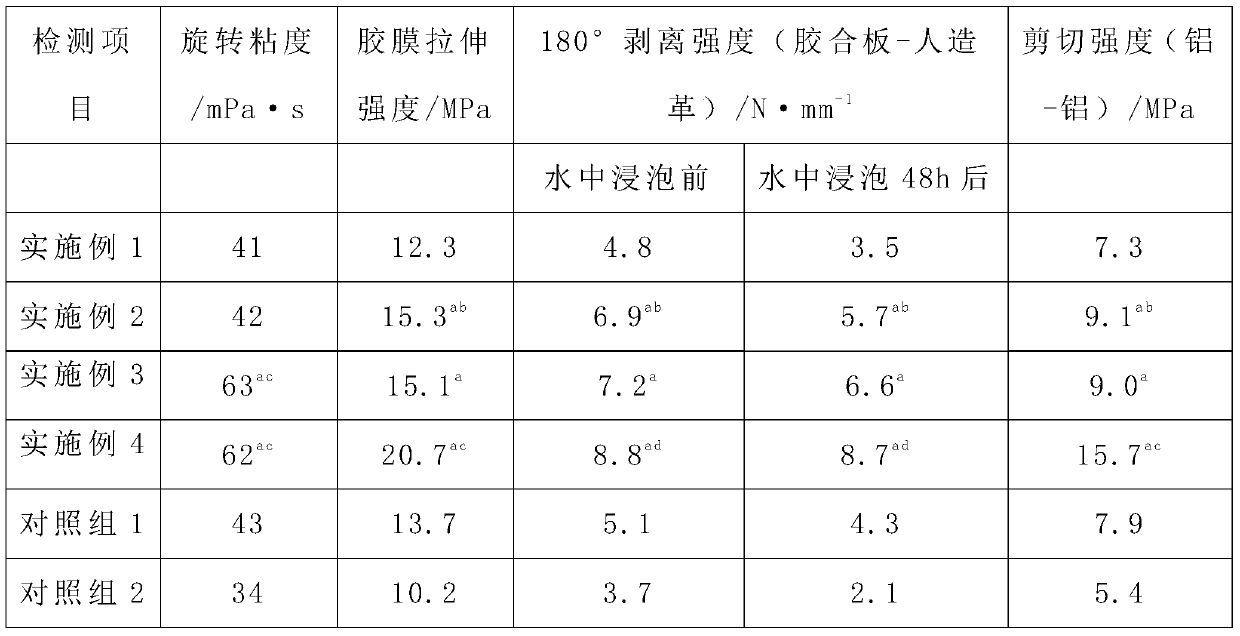

A kind of two-component waterborne polyurethane adhesive and the construction method of paving stadium

ActiveCN106479422BRaw material formula is reasonableImprove performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention relates to double-component waterborne polyurethane adhesive and a construction method for paving a stadium. The double-component waterborne polyurethane adhesive comprises, by weight, a component A, a component B and 70-140 parts of deionized water, wherein the component A comprises, by weight, 6-20 parts of water-dispersible isocyanate; the component B comprises, by weight, 40-60 parts of waterborne hydroxyl acrylic acid dispersion, 5-8 parts of flexible plasticizing auxiliaries, 0.2-0.5 part of nonionic surfactant, 0.02-0.06 part of defoaming agent, 1-3 parts of pigment and 1-2 parts of antioxidant. The double-component waterborne polyurethane adhesive used for paving the stadium has the advantages that the adhesive is reasonable in raw material formula, excellent in performance and environmentally friendly; the adhesive is good in initial adhesiveness, high in toughness, good in resilience and excellent in physical performance by adding the flexible plasticizing auxiliaries.

Owner:北京纽科尔斯科技有限公司

Faint scent type tea wine and preparation method thereof

InactiveCN107418843ARaw material formula is reasonableProtect NutrientsAlcoholic beverage preparationChemistryAmino acid

The invention discloses faint scent type tea wine. The faint scent type tea wine comprises the following raw materials in parts by weight: 10 to 20 parts of tea, 30 to 50 parts of Baijiu, 15 to 20 parts of white granulated sugar, 3 to 5 parts of lotus leaves, 2 to 8 parts of aloe, 1 to 3 parts of yeast, 1 to 5 parts of green plum, 5 to 10 parts of tea polyphenol, 4 to 10 parts of the root of kudzu vine and 80 to 100 parts of pure water. The invention also discloses a preparation method of the tea wine. The tea wine is reasonable in raw material formula, does not need to take grains as raw materials, can protect the nutritional ingredients of the tea maximally and does not break various nutritional ingredients such as the tea polyphenol, amino acid and vitamin. Pure taste of the tea wine is guaranteed and the nutrition is rich.

Owner:柳州市茶霖酒业科技有限责任公司

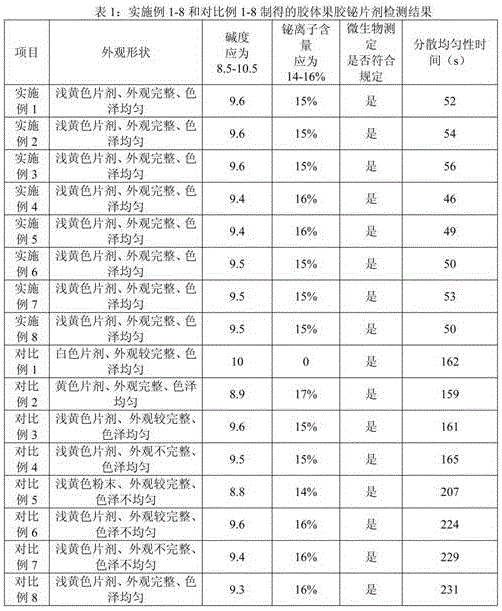

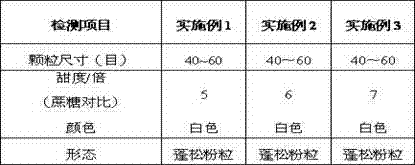

Colloidal bismuth pectin tablets and preparation method thereof

InactiveCN106038585AUniform appearanceComplete appearanceOrganic active ingredientsInorganic active ingredientsSucrose sulfateBismuth / pectin

The invention discloses colloidal bismuth pectin tablets and a preparation method thereof. The colloidal bismuth pectin tablets consist of the following raw materials in parts by weight: 20-30 parts of colloidal bismuth pectin in terms of the content of bismuth, 2-8 parts of sucralfate in terms of the content of aluminum, 60-120 parts of a filling agent, 7-11 parts of a disintegrating agent, 2-6 parts of a binding agent, 1-5 parts of medicinal silicon dioxide and 0.2-2.8 parts of a lubricating agent. The colloidal bismuth pectin tablets disclosed by the invention are reasonable in the prescription of raw materials; the prepared colloidal bismuth pectin tablets are uniform and complete in appearance, small in particle size of particles therein and good in expansion effect in a stomach, and in addition, the colloidal bismuth pectin tablets are excellent in flowing property and good in distribution performance; and a formed gel can cover all ulcer surfaces of a patient and can take an excellent effect on treating superficial gastritis and gastric ulcer.

Owner:ZHENGZHOU SIBIAN TECH CO LTD

Preparation method of low-sugar low-calorie table sugar

InactiveCN103039787ARaw material formula is reasonableGood instant solubilityFood preparationMaltitolMaltose

The invention relates to a preparation method of low-sugar low-calorie table sugar. The ingredients include 0.83-1.17% of sucralose, 82.1-91% of glucose, 7-17% of maltitol and 0.4-0.6% of calcium silicate. The method comprises the following steps: feeding maltitol and glucose accounting for 50-70% of the total amount into a multi-vitamin mixing machine, and mixing to obtain a mixed material; dissolving sucralose and the remaining glucose in deionized water to obtain a mixed solution; allowing the mixed material to enter a spray fluidized bed from the bottom of the fluidized bed under a positive pressure and accelerating the upward flow, applying a negative pressure to the upper part of the spray fluidized bed, vibrating from up down to move the mixed material up and down inside the fluidized bed, to form small sugar particles; continuously spraying and dispersing the mixed solution onto the small sugar particles in the fluidized bed by use of multi-point spray guns which are arranged at the side part of the fluidized bed, drying with hot air to obtain powdery table sugar; and thoroughly mixing the powdery table sugar with calcium silicate to obtain the final product of low-sugar low-calorie table sugar.

Owner:苏州工业园区尚融科技有限公司

Formula and processing technology of purple grape fruit and vegetable juice

InactiveCN113180163AFormulation ScienceReasonable formulaFood ingredient functionsBiotechnologyFruit juice

The invention relates to the technical field of fruit juice processing, and concretely relates to a formula and a processing technology of purple grape fruit and vegetable juice. The formula comprises fruit juice, vegetable juice and additives, and the fruit juice comprises raw materials of purple grape juice, aloe juice, guava juice, papaya juice and hawthorn juice; the vegetable juice comprises, by weight, tomato juice, cabbage juice and broccoli juice; and the additives comprises, by weight, oat, honey, xylitol and a compound stabilizer. The raw material formula is scientific and reasonable in formula, unique in flavor and exquisite in preparation, has high economic benefits, social benefits and popularization value; the raw materials are blended according to a reasonable proportion to make effective components of different raw materials fully fused and complemented, so the formula has better blood sugar reducing effect than a single raw material, has prevention and health-care effects, is rich in nutrition, and can be widely accepted by consumers due to price; and due to the homology of medicine and food of the raw materials, the purple grape fruit and vegetable juice is developed as a health-care fruit and vegetable juice beverage, the health-care effect of the health-care fruit and vegetable juice beverage is exerted, and the health-care fruit and vegetable juice beverage has profound significance.

Owner:普洱景谷多上果汁饮品有限公司

Environmental protection construction method of prefabricated concrete floor slab

ActiveCN111364658BRaw material formula is reasonableFast constructionFloorsCeramic shaping apparatusArchitectural engineeringLoad-bearing wall

The invention relates to an environmentally friendly construction method for prefabricated concrete floor slabs, which includes the following construction steps: S1, preparing concrete for floor slabs: mixing cement, water, fine-grained coal gangue, blast furnace slag powder, cement accelerator, disinfectant Foaming agent and water reducing agent are put into the concrete mixer together to get concrete for floor slab for use; S2, install floor slab pouring formwork; S3, pour concrete for floor slab; S4, assemble prefabricated floor slab and load-bearing wall; S5, fixed prefabricated floor slabs. The bottom formwork and pouring formwork of the present invention can be recycled and applied to pouring prefabricated concrete floor slabs, the floor slab and the load-bearing wall are matched and assembled more reasonably, and the construction process of the entire floor slab is environmentally friendly and energy-saving.

Owner:西安市初元建设工程有限公司

Instant sea-tangle leisure food and method of processing the same

InactiveCN101278746BReasonable collocationGood for healthFood preparationAdditive ingredientSnack food

The present invention provides an instant kelp snack food and a processing method thereof. The instant kelp snack food takes fresh tender kelps as the main raw material. The fresh tender kelps are put into a sealed vessel; white granulated sugar, salt, various kinds of flavorings with different tastes, protein and water resolvent and sorbierite are added in, water is added to submerge the kelps, the kelps is cured for more than 12 hours, and the instant kelp snack food can be obtained. The prescription of the snack food of the invention uses the kelps mainly and mixes with other accessory materials, which not only matches nutrition reasonably to bring various kinds of beneficial components function of the kelp, which is convenient for eating, has multiple kinds of tastes, ensures that the surface of a product is not viscous and has good flavor, but the fresh and tender kelps are also boiled, cured and dried, which is better for human body to absorb, and the manufacturing process is easy, which is good for mass production.

Owner:于伟卫

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com