Patents

Literature

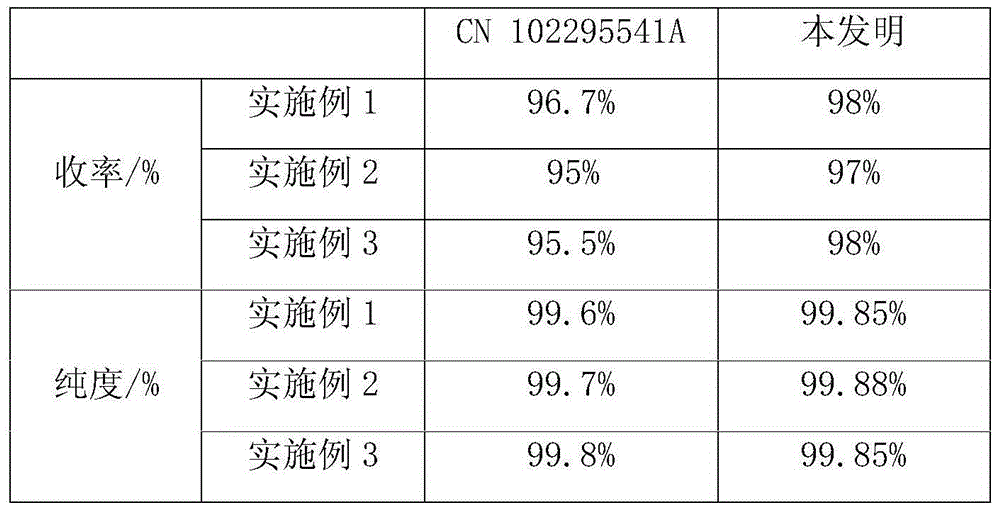

65 results about "Butyl chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Butyl chloride may refer to: n-Butyl chloride tert-Butyl chloride sec-Butyl chloride Isobutyl chloride

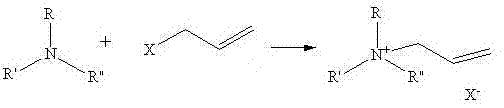

Method for synthesizing quaternary ammonium salt ionic liquid by microwave radiation heating

InactiveCN102344377AGood acid and alkali resistanceReduce volumeOrganic compound preparationAmino compound preparationHalohydrocarbonButyl chloride

The invention provides a method for synthesizing quaternary ammonium salt ionic liquid by microwave radiation heating, which comprises the following steps: mixing tertiary amine compounds (N,N-dimethylethanolamine, trimethylamine or triethanolamine) and halohydrocarbon compounds (allyl chloride, n-butyl chloride, n-butyl bromide, octadecyl chloride) with a molar ratio of 1:1.05-1:2 under a microwave radiation heating condition, putting the mixture into a microwave reactor to perform a microwave reaction with an adjusted microwave power of 100 W-400 W, a heating temperature of 30 DEG C-80 DEG C, and reaction time of 1 min-15 min so as to obtain a crude product, removing residual halohydrocarbon compounds in the crude product to obtain quaternary ammonium salt ionic liquid with halogens as anions; the halohydrocarbon compounds are chlorinated hydrocarbon compounds or brominated hydrocarbon compounds. The preparation method of the invention is simple, does not require the addition of any solvent except reaction raw materials, and can prepare high-purity quaternary ammonium salt ionic liquid simply, efficiently, rapidly, and economically.

Owner:SOUTH CHINA UNIV OF TECH

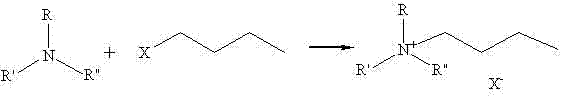

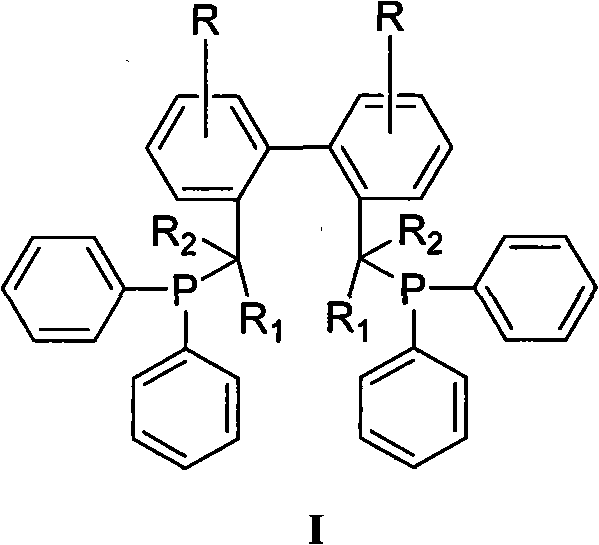

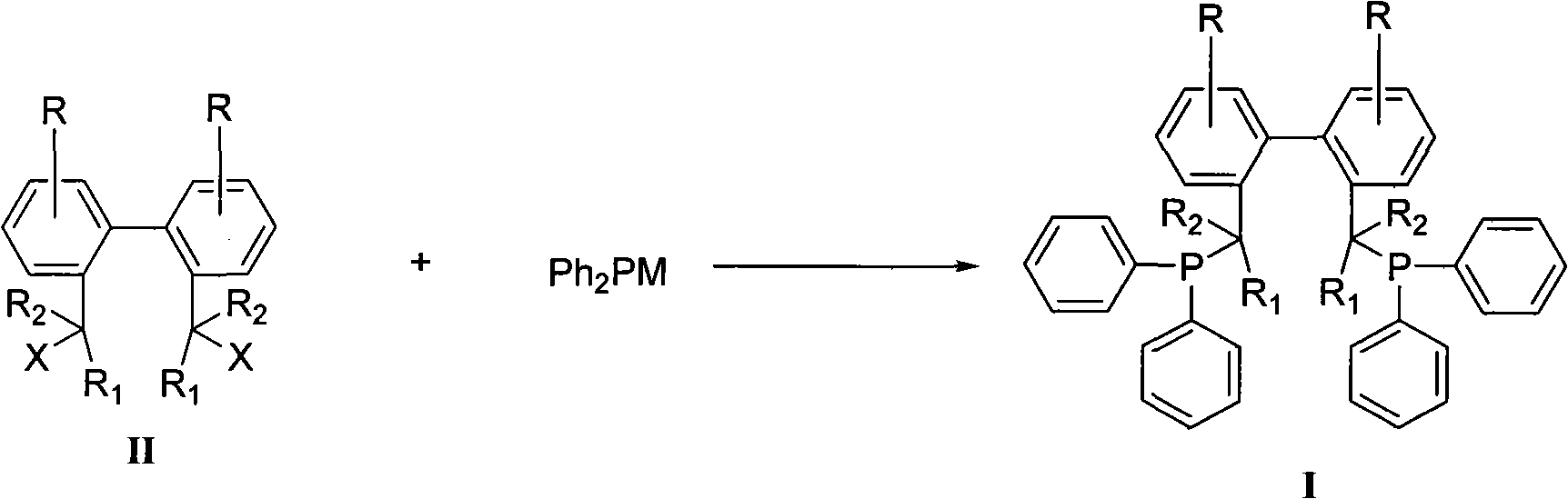

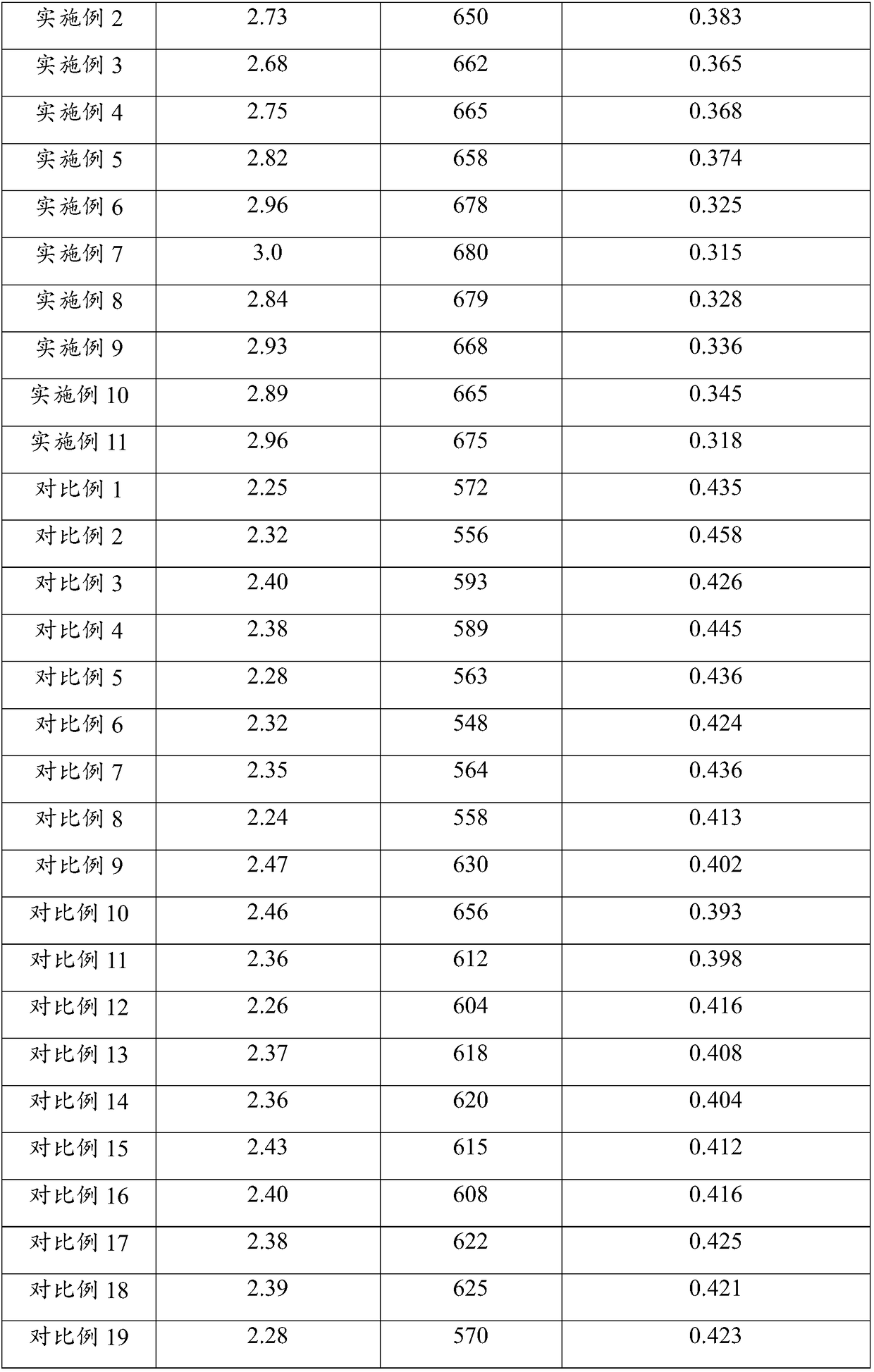

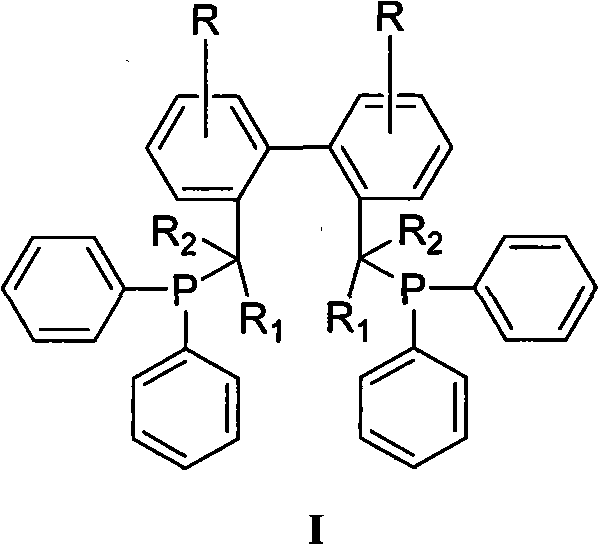

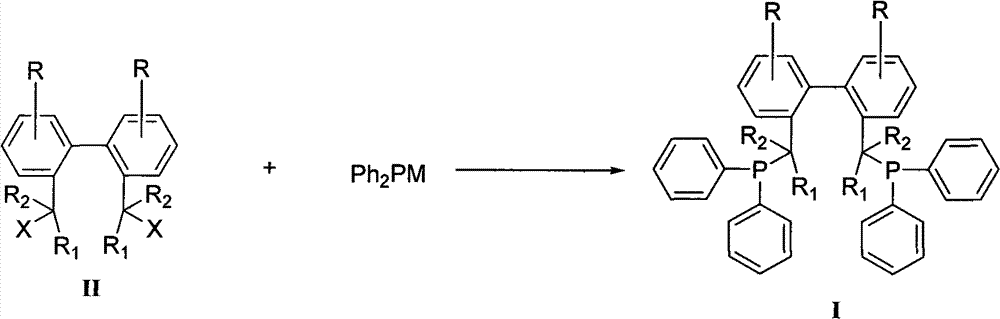

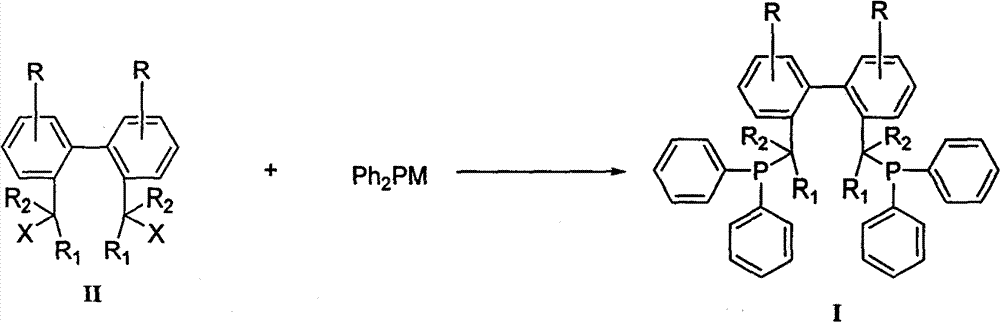

Method for preparing biphenyl diphosphine ligand

ActiveCN102010442ASimple and fast operationSuitable for industrial productionGroup 5/15 element organic compoundsButyl chlorideDiphosphines

The invention discloses a new method for preparing a biphenyl diphosphine ligand 2,2'-diphenylphosphinomethyl-1,1'-biphenyl (BISBI) and derivatives thereof. The method is characterized by comprising the following steps: (1) under the protection of inert gases, adding 40-60 parts of triphenylphosphine and 250-360 parts of ether solvents to a reaction flask, stirring the mixture to dissolve the mixture and adding 3-20 parts of alkali metals and 0-5 parts of electron-rich aromatics to the reaction flask to react for 2-24 hours at 20-120 DEG C to prepare a diphenulphosphine metal compound and a phenyl metal compound; (2) dropwise adding 15-20 parts of tertiary butyl chloride to the reaction solution to remove the generated phenyl metal compound; and (3) dropwise adding the solution formed by 15-40 parts of 2,2'-disubstituted methyl-1,1'-biaryl compound and 20-40 parts of ether solvent to the reaction solution with phenyl metal compound removed to react for 6-24 hours at 0-40 DEG C and carrying out extraction, drying, concentration and recrystallization to obtain the diphosphine ligand 2,2'-diphenylphosphinomethyl-1,1'-biphenyl (BISBI) and the derivatives thereof. The method has the characteristics of cheap and easily obtained raw materials and mild reaction conditions, is simple and convenient for operation, and is easy to realize industrial production.

Owner:成都欣华源科技有限责任公司

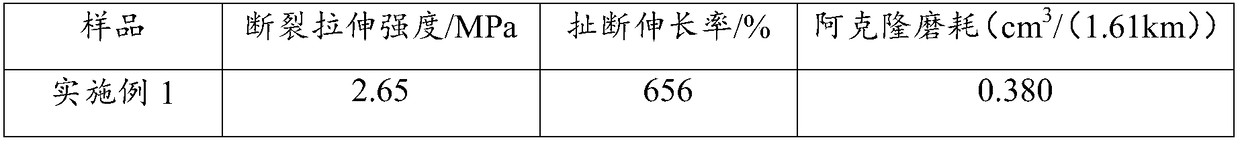

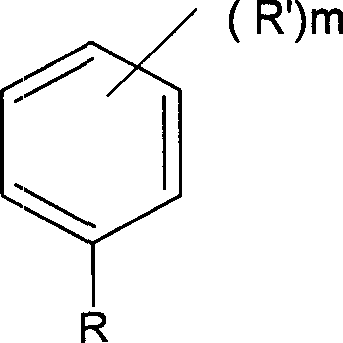

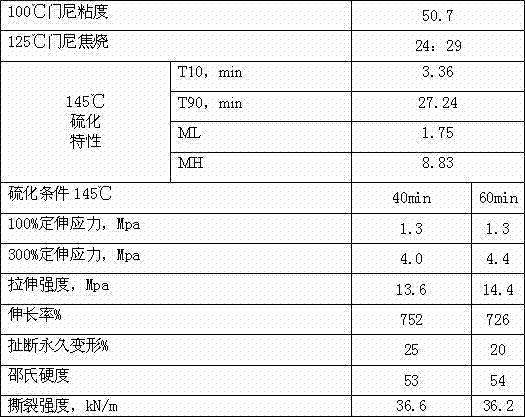

Environment-friendly rubber prefabricated track coiled material and preparation method thereof

The invention discloses an environment-friendly rubber prefabricated track coiled material and a preparation method thereof, and relates to the technical field of track coiled materials. The rubber prefabricated track coiled material is mainly prepared from the following raw materials in parts by weight: 30 to 60 parts of ethylene propylene rubber, 40 to 80 parts of reclaimed rubber, 20 to 50 parts of an LLDPE and HDPE blend, 1 to 30 parts of a nanometer rare earth oxide, 5 to 10 parts of a vulcanizing agent, 6 to 12 parts of paraffin oil, 10 to 15 parts of naphthenic oil, 1 to 5 parts of zincoxide and 50 to 200 parts of a filler, wherein the reclaimed rubber is a mixture of butyronitrile reclaimed rubber and butyl chloride reclaimed rubber, and the mass ratio of the butyronitrile reclaimed rubber to the butyl chloride reclaimed rubber is 2: (0.5 to 1). The environment-friendly rubber prefabricated track coiled material solves the problem that a rubber track coiled material is low inabrasive resistance, tensile strength and elasticity and not environmentally friendly at present, the obtained rubber prefabricated track coiled material is excellent in physical and mechanical performances and has excellent tensile strength and abrasive resistance, the product is free of noxious substance residue, and the recycled reclaimed rubber is cost-saving, safe and environmentally friendly.

Owner:湖南盛亚体育实业有限公司

Method for preparing polyalphaolefin from 1-octene

Disclosed is a method for preparing a high-viscosity polyalphaolefin, chiefly useful as an industrial oil, with high yield under conditions of the room temperature and atmospheric pressure, the method including: prepolymerizing 1-decene or 1-dodecene using a catalyst composed of ethyl aluminum dichloride (EADC) and t-butyl chloride (TBC) to obtain a prepolymer, and bringing 1-octene into contact with the prepolymer used as a catalyst under conditions of the room temperature and atmospheric pressure. Using the method makes it possible to prepare a high-viscosity polyalphaolefin from 1-octene less expensive than 1-decene or 1-dodecene, the polyalphaolefin having a kinetic viscosity of at least 90 cSt at 40 DEG C and a viscosity index of at least 135 to overcome the problem with a low-viscosity polyalphaolefin from 1-decene or 1-dodecene.

Owner:HONAM PETROCHEM

Manufacturing method of alkyl benzene solvent and its application

InactiveCN1824632AHigh selectivityHigh reaction yieldCopper organic compoundsHydrocarbonsReaction temperatureButyl chloride

The present invention relates to a preparation method of alkyl benzene solvent. It is made up by adopting tert-butyl chloride or tert.-butyl alcohol and dimethylbenzene or ethylbenzene through a certain reaction process. Its reaction temperature is 0-50 deg.C, reaction pressure is normal pressure, the mole ratio of tert.-butyl chloride or tert.-butyl alcohol and dimethylbenzene or ethylbenzene is 1.5-1-1:1.5, the catalyst dose is 0.5-20% of solvent weight. The catalyst is an ion liquid catalyst or one of anhydrous aluminium trichloride, anhydrous iron trichloride, sulfuric acid and hydrofluoric acid. The invented alkyl benzene solvent purity is 98%-100%, boiling range is 200-215 deg.C and relative density is 0.86-0.88. It can be used for synthesis of phthalocyanine copper.

Owner:彭光辉

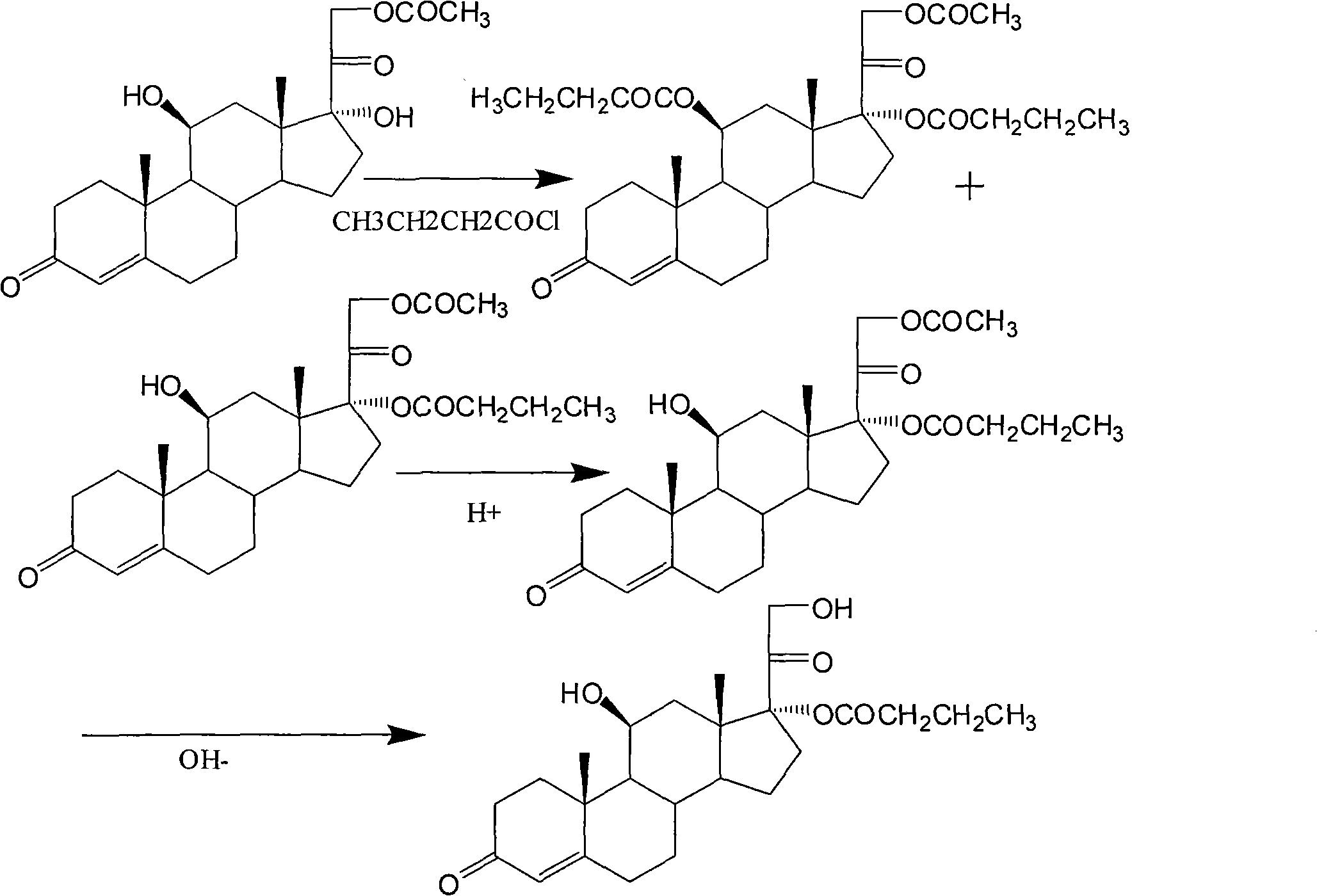

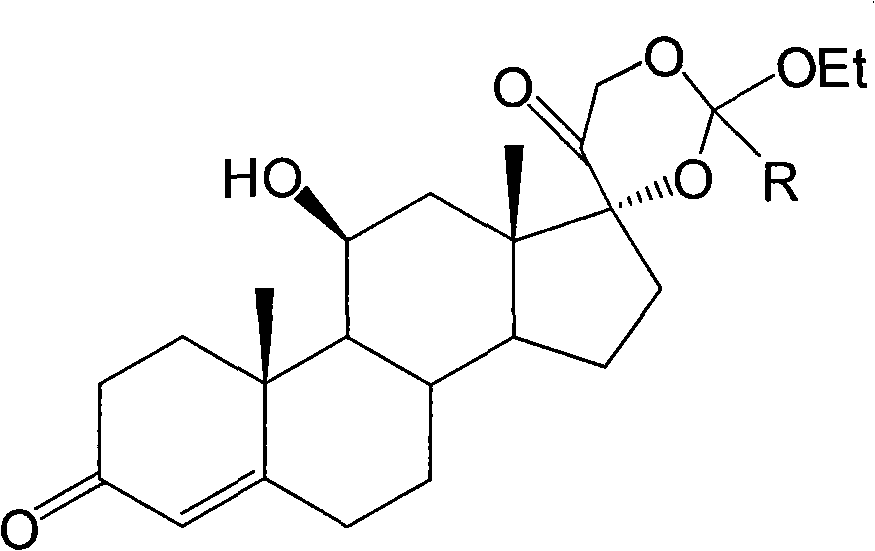

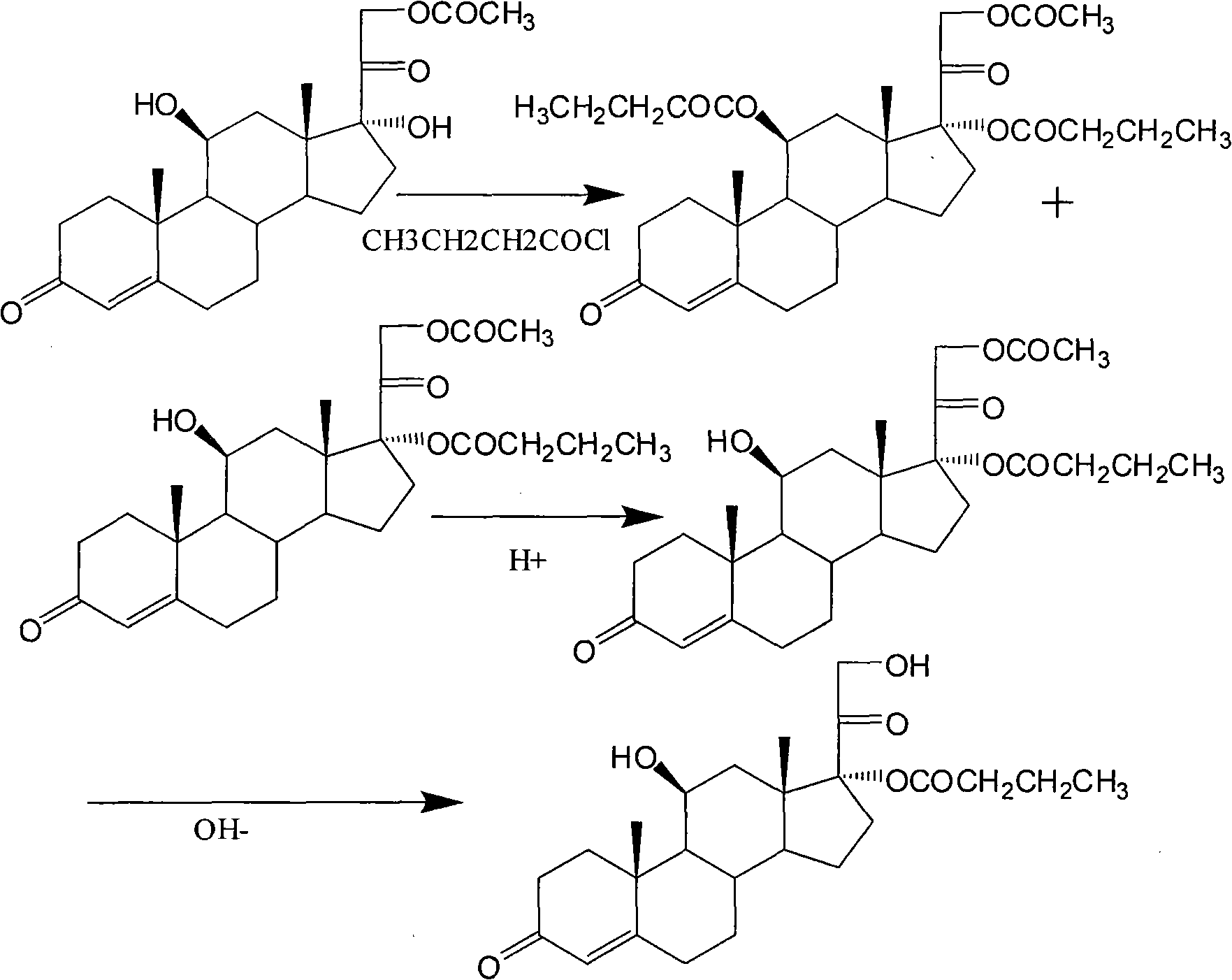

Synthesis of hydrocortisone butyrate

The invention relates to synthesis of hydrocortisone butyrate, which comprises the following steps of: A. carrying out acylation reaction on hydrocortisone acetate adopted as a raw material and butyl chloride in an organic solvent I under the condition of existence of a catalyst; after the reaction is finished, adding acid to adjust a pH value being smaller than 5; diluting or recrystallizing to obtain hydrocortisone 17alpha-butyrate-21-acetate; and B. adopting the hydrocortisone 17alpha-butyrate-21-acetate as a raw material, adding inorganic alkali in an organic solvent II and carrying out selective hydrolysis reaction to obtain hydrocortisone 17alpha-butyrate.

Owner:TIANJIN JINYAO GRP

Preparation method of industrial musk tonalide

InactiveCN102050715AExtended reaction timeHigh selectivityCarbonyl compound preparation by condensationP-isopropyltolueneDistillation

The invention relates to a preparation method of industrial musk tonalide, which comprises the following steps: carrying out Friedel-Crafts alkylation by using p-isopropyl toluene and 2,3-dimethyl-1-butene as raw materials and using tertiary butyl chloride as a hydrogen absorption agent to synthesize an intermediate 1,1,3,4,4,6-hexamethyl tetrahydronaphthalene; and in a dichloromethane solvent, carrying out Friedel-Crafts alkylation on the intermediate used as the raw material and acetyl chloride, thereby obtaining the product musk tonalide (7-acetyl-1,1,3,4,4,6-hexamethyl tetrahydronaphthalene, AHMT). Compared with the existing method and technology, the method provided by the invention is simple to operate, has the characteristics of high reaction speed, high yield and the like, and realizes industrial production; and the product can be simply purified by thermally dissolving out pigments by using anhydrous alcohol without distillation or rectification.

Owner:HENAN UNIV OF SCI & TECH

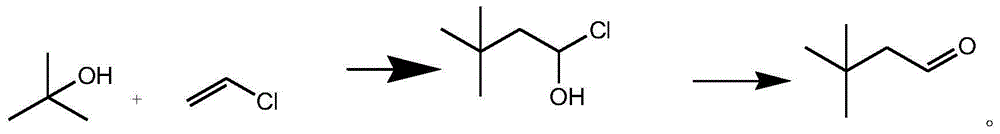

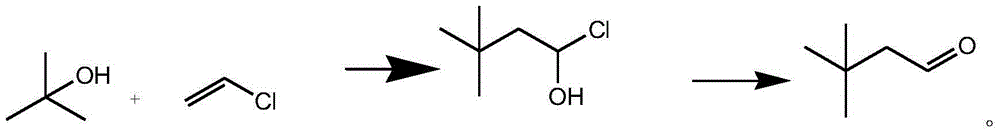

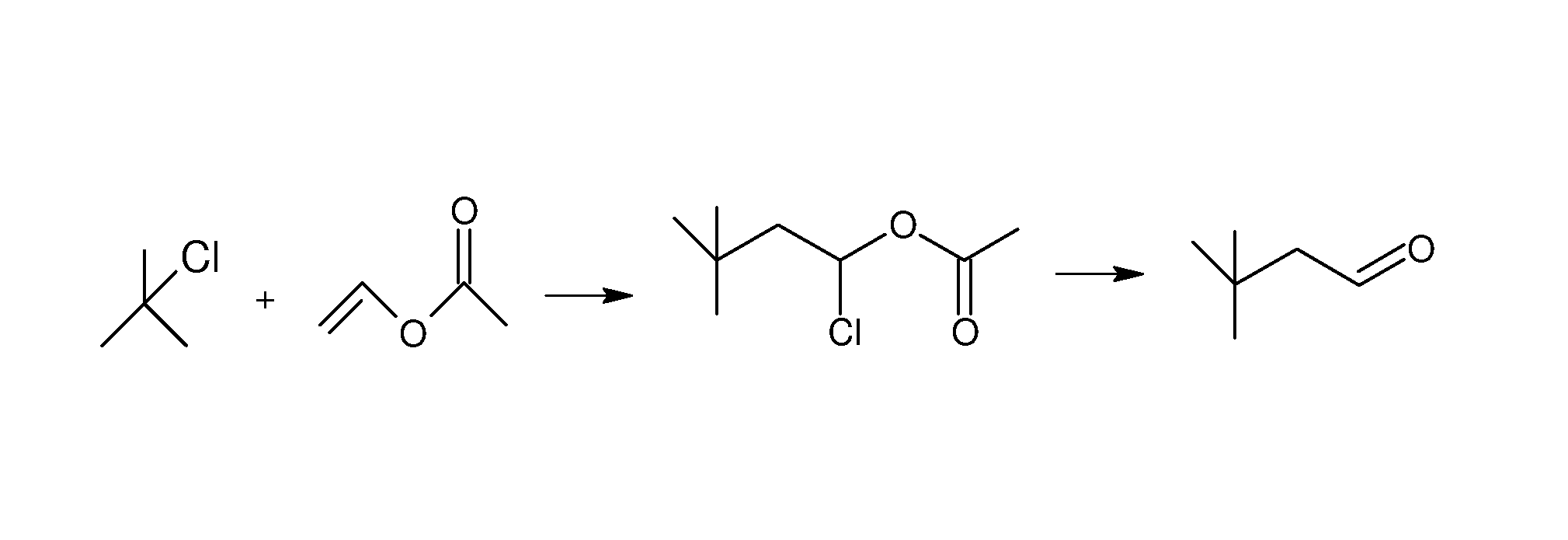

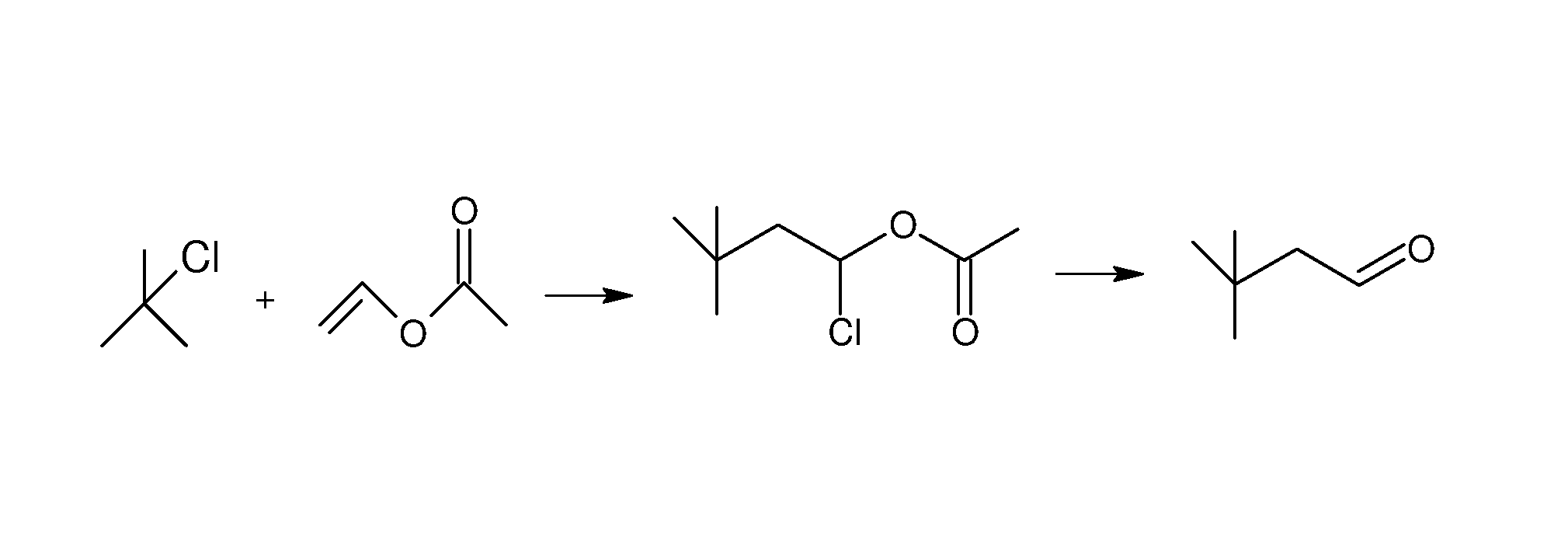

Preparation method for 3, 3-dimethylbutyraldehyde

InactiveCN104817442AIncrease costNo side effectsOrganic compound preparationHydroxy compound preparationButyl chlorideHydrolysis

The invention discloses a preparation method for 3, 3-dimethylbutyraldehyde. The method includes: taking tert-butyl alcohol and vinyl chloride as raw materials and dichloromethane as the reaction solvent to conduct catalytic synthesis of 1-hydroxy-3, 3-dimethyl butyl chloride, then under the action of a catalyst, controlling the temperature at 40DEG C-60DEG C, conducting hydrolysis disproportionation on 1-hydroxy-3, 3-dimethyl butyl chloride to prepare a hydrolysis disproportionation reaction mixture containing 3, 3-dimethylbutyraldehyde; and finally subjecting the hydrolysis disproportionation reaction mixture containing 3, 3-dimethylbutyraldehyde to rectification purification, thus obtaining 3, 3-dimethylbutyraldehyde. Compared with the prior art, the raw materials used by the method are low in price, the production cost can be reduced, the temperature needed by the reaction process is low, wherein the disproportionation temperature is 40DEG C-60DEG C, and compared with the 100DEG C-110DEG C disproportionation temperature in the prior art, the preparation method provided by the invention has the characteristics of milder reaction conditions, no need for high temperature, no special requirement for production equipment, high production safety, higher product purity, and yield up to over 97%.

Owner:QINGDAO CHENGHUI SHUANGDA BIOLOGICAL TECH CO LTD

Method for the synthesis of low cost initiators for telechelic polyisobutylenes

ActiveUS20140235905A1Low costHighly desirableOrganic compound preparationCatalystsPtru catalystIsopropyl

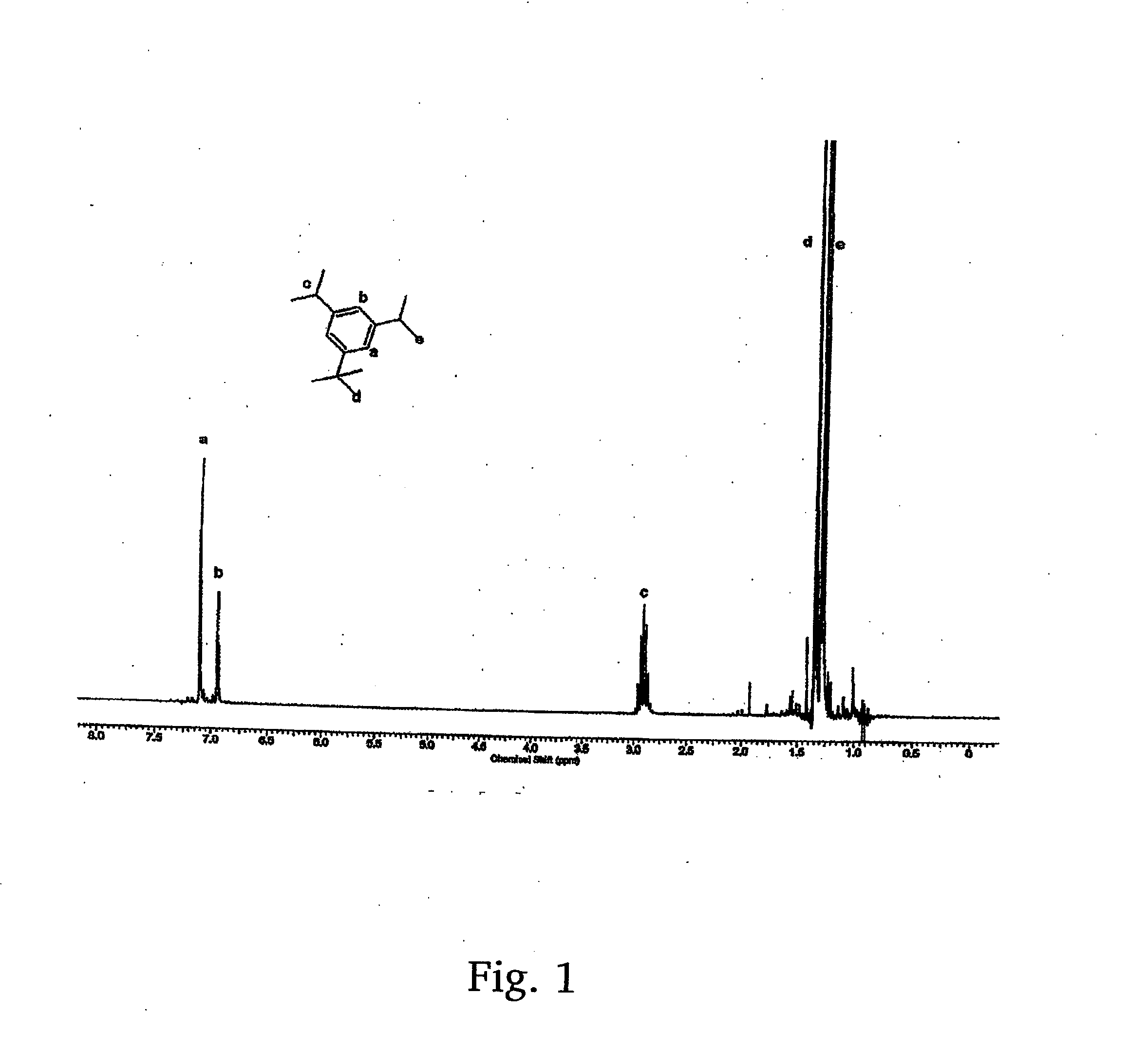

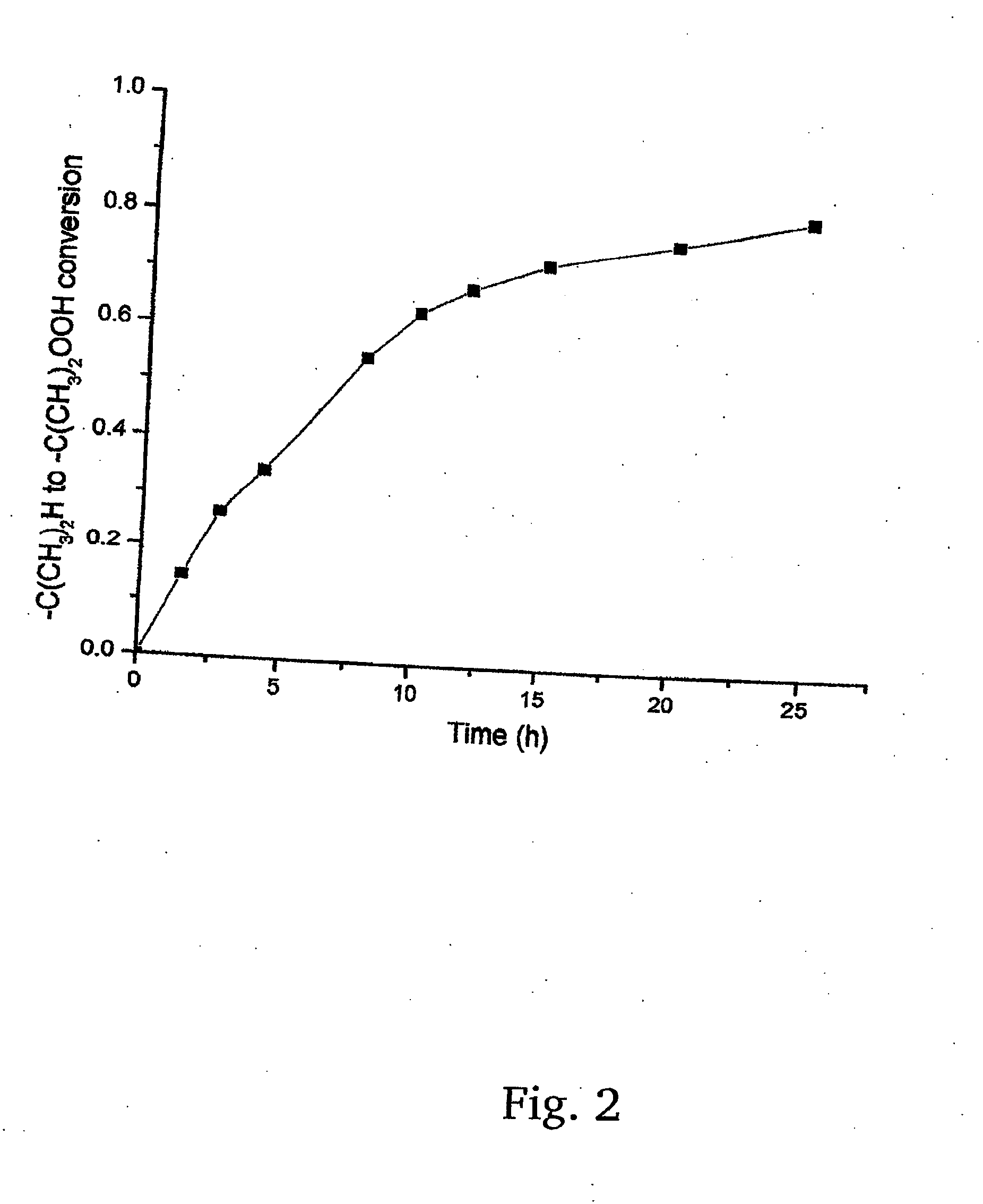

A method for the synthesis of 1,3-di(chloropropyl)-5-tert-butyl benzene includes the steps of conducting Friedl-Crafts alkylation of 1,3-diisopropyl benzene by tert-butyl chloride in the presence of an alkylation catalyst to obtain 1-tert-butyl-3,5-diisopropylbenzene; peroxidizing the 1-tert-butyl-3,5-diisopropyl benzene by gaseous oxygen in the presence of a peroxidation catalyst in a basic solution to obtain 1,3-di(peroxypropyl)-5-tert-butylbenzene; reducing the 1,3-di(peroxypropyl)-5-tert-butylbenzene with a reducing agent to 1,3-di(hydroxyl propyl)-5-tert-butylbenzene; and chlorinating the 1,3-di(hydroxypropyl)-5-tert-butylbenzene to obtain 1,3-di(chloropropyl)-5-tert-butyl benzene.

Owner:THE UNIVERSITY OF AKRON

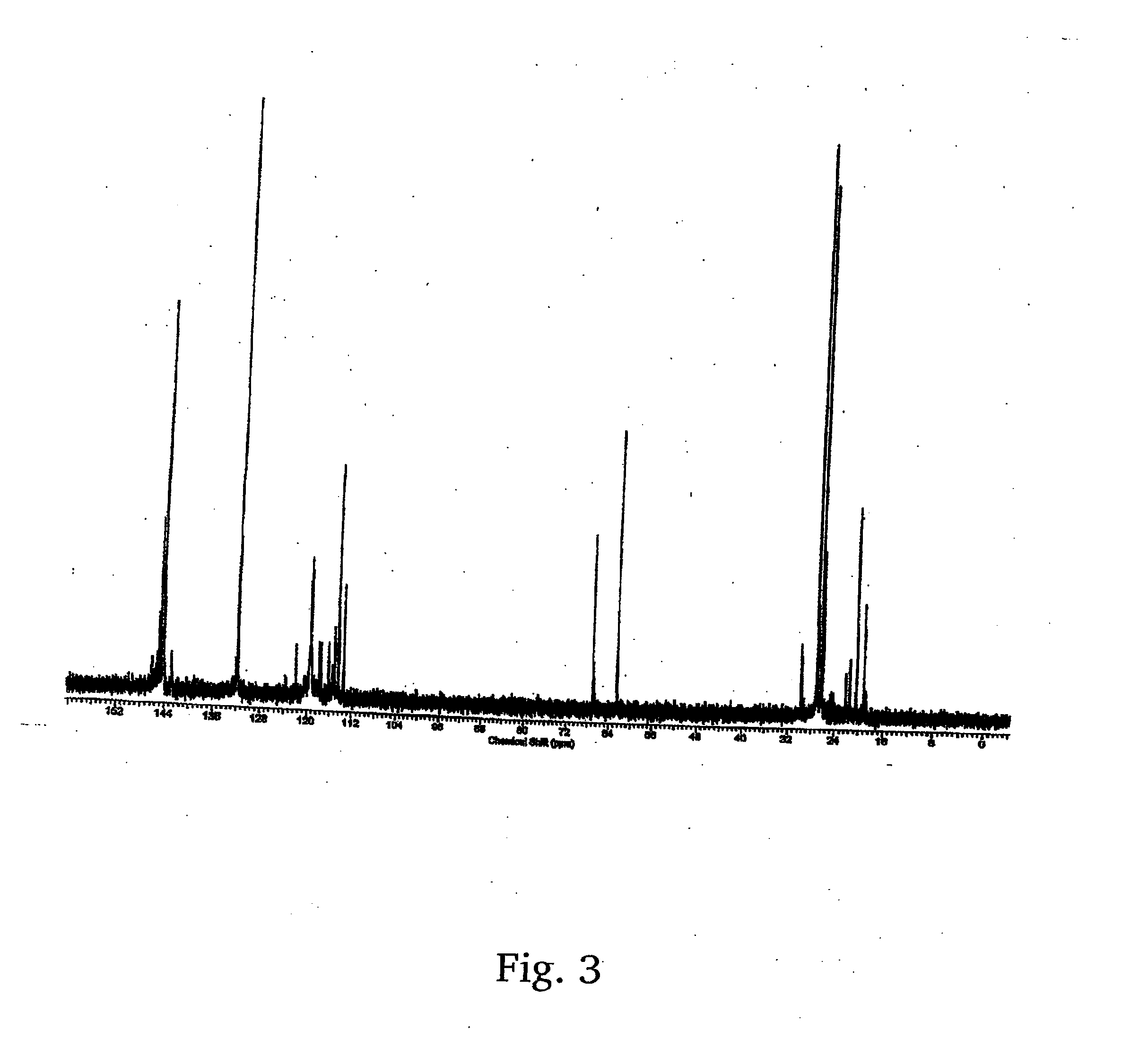

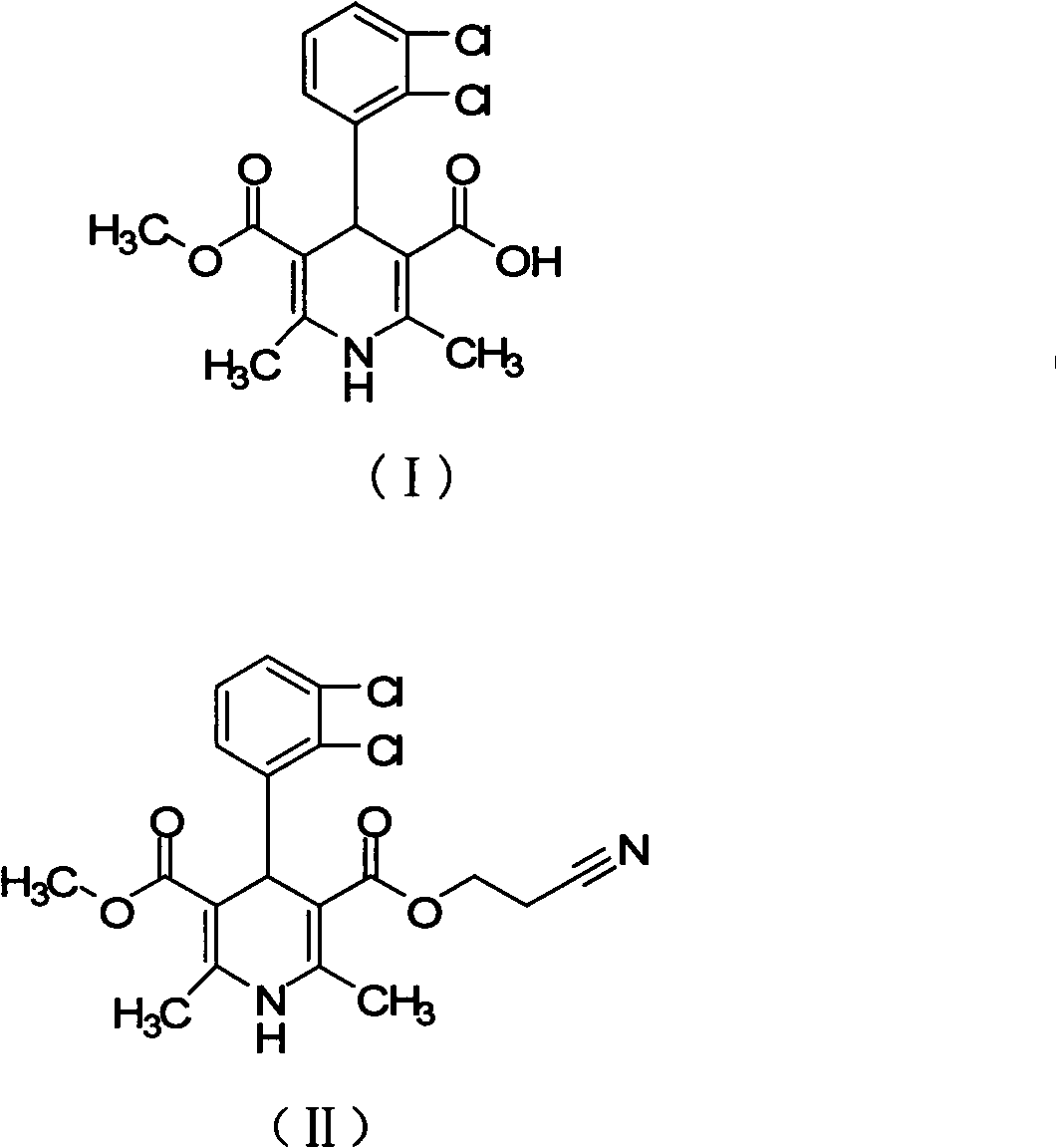

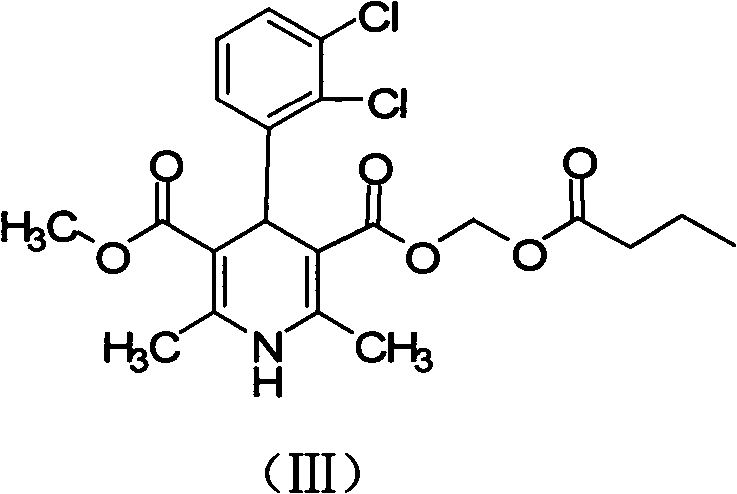

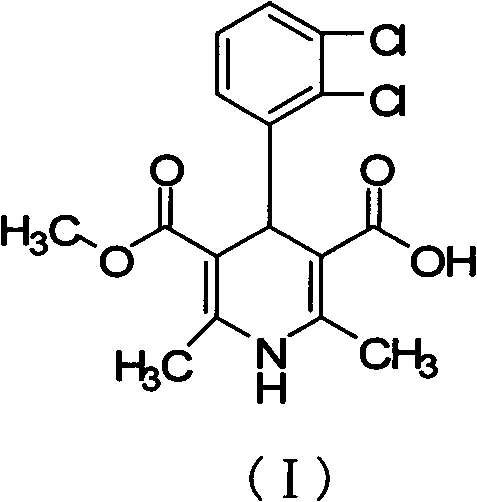

Preparation method of clevidipine butyrate intermediate

InactiveCN102391174AMild reaction conditionsPost-processing is simpleOrganic chemistryEthyl esterBenzene

The invention relates to a preparation method of a clevidipine butyrate intermediate, namely 4-(2,3-dichlorophenyl)-1,4-dihydro-2,6-dimethyl-3 ,5- dipicolinic acid monomethyl ester (I). The preparation method is characterized by taking 3-(2,3-dichlorophenyl)-2-acetyl benzene gadoleic acid methyl ester and 3-amino-2-butenoic acid (2-cyano) ethyl ester as materials, cyclizing the materials to obtain 4-(2,3-dichlorophenyl)-1,4-dihydro-2,6-dimethyl-3,5-pyridinedicarboxylic acid methyl (2-cyano) ethyl ester (II), and hydrolyzing the II under alkaline conndition, thus obtaining the product 4-(2,3-dichlorophenyl)-1,4-dihydro-2,6-dimethyl-3 ,5- dipicolinic acid monomethyl ester (I). The preparation method has the advantages as follows: the starting material is cheap and easy to obtain, the production cost is reduced, the reaction operation is simple, industrialization is easy, the purity of the obtained material is high and byproducts are few; the byproducts in the preparation method are fewer than that in the preparation of the clevidipine butyrate by butyl chloride methyl ester; the purity is high and the crude product can achieve 99.5%; and medicinal standard requirements can be met.

Owner:SHANDONG INST OF PHARMA IND

Method for preparing gamma-tertiary butyl-chlorobenzene butanone

InactiveCN101700996AEasy to absorb moistureReaction is easy to controlOrganic compound preparationCarbonyl compound preparationChlorobenzeneButyl chloride

The invention relates to a method for preparing gamma-tertiary butyl-chlorobenzene butanone. The method is characterized by comprising the following steps of: (1) acylation reaction: sucking butyrolactone into a clean and dry reaction kettle and strring, and then adding zinc chloride into the reaction kettle for reaction to generate semi-finished butyl chloride; (b) hydrolysis reaction: adding dichloroethane and aluminium choride into a clean and dry reaction kettle, dropwise adding the butyl chloride into the reaction kettle while stirring; then continuing to dropwise adding tedin benzene , and steaming off dichloroethane to generate the gamma-tertiary butyl-chlorobenzene butanone. 3gamma-tertiary butyl-chlorobenzene butanone products prepared by the method are pale yellow granules, wherein the content of the 3gamma-tertiary butyl-chlorobenzene butanone is more than or equal to 90 percent, and the pH value is larger than or equal to 3.85. The reaction process of the method is easy to control, the utilization rate of raw materials and the yield of the products are improved, and the method conforms to the requirements on environmental protection and cleaner production and improves the economic benefits of enterprises.

Owner:扬州市天平化工厂有限公司

Repairing rubber cement for tire curing capsule and preparation method thereof

ActiveCN102634300AWon't fall offReduce use costNon-macromolecular adhesive additivesPolymer scienceButyl chloride

The invention discloses a repairing rubber cement for a tire curing capsule and a preparation method of the repairing rubber cement. The repairing rubber cement comprises the following components in parts by weight: 100 parts of butyl chloride cement, 30-50 parts of carbon black and the other assistant agent. According to the invention, the butyl chloride cement is taken as a main raw material, the butyl chloride cement is used for binding the repairing cement and the curing capsule when the curing capsule is repaired, so that the repairing rubber cement is good in binding performance, the curing cement can not fall off during repairing in a curing way, the capsule is well crosslinked with the repairing glue after being cured, the tire curing capsule scrapped by soft hole and mechanical damage can be reused, and the use cost of the curing capsule can be reduced, so that the production cost of the tire can be reduced.

Owner:GUIZHOU TIRE

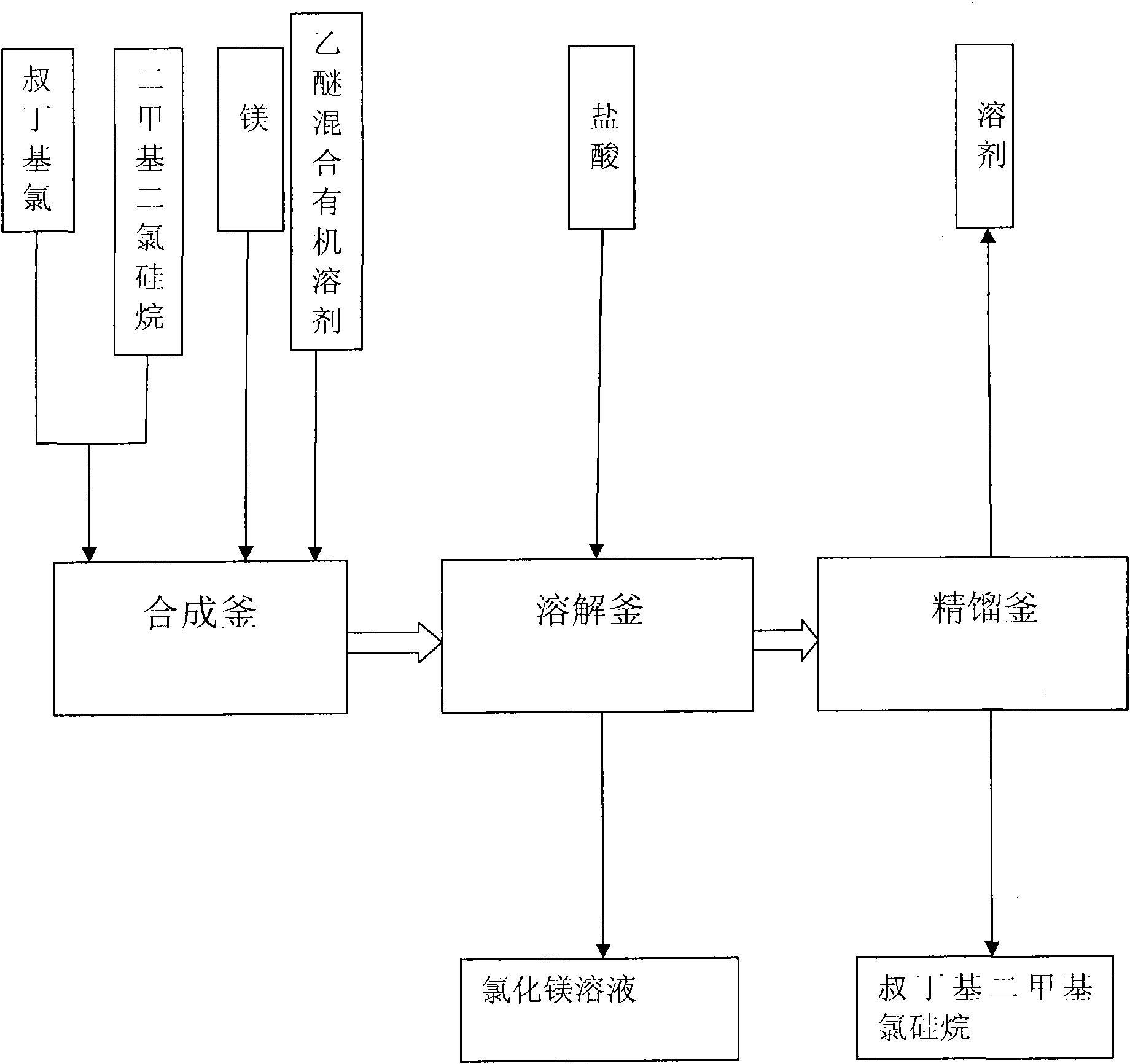

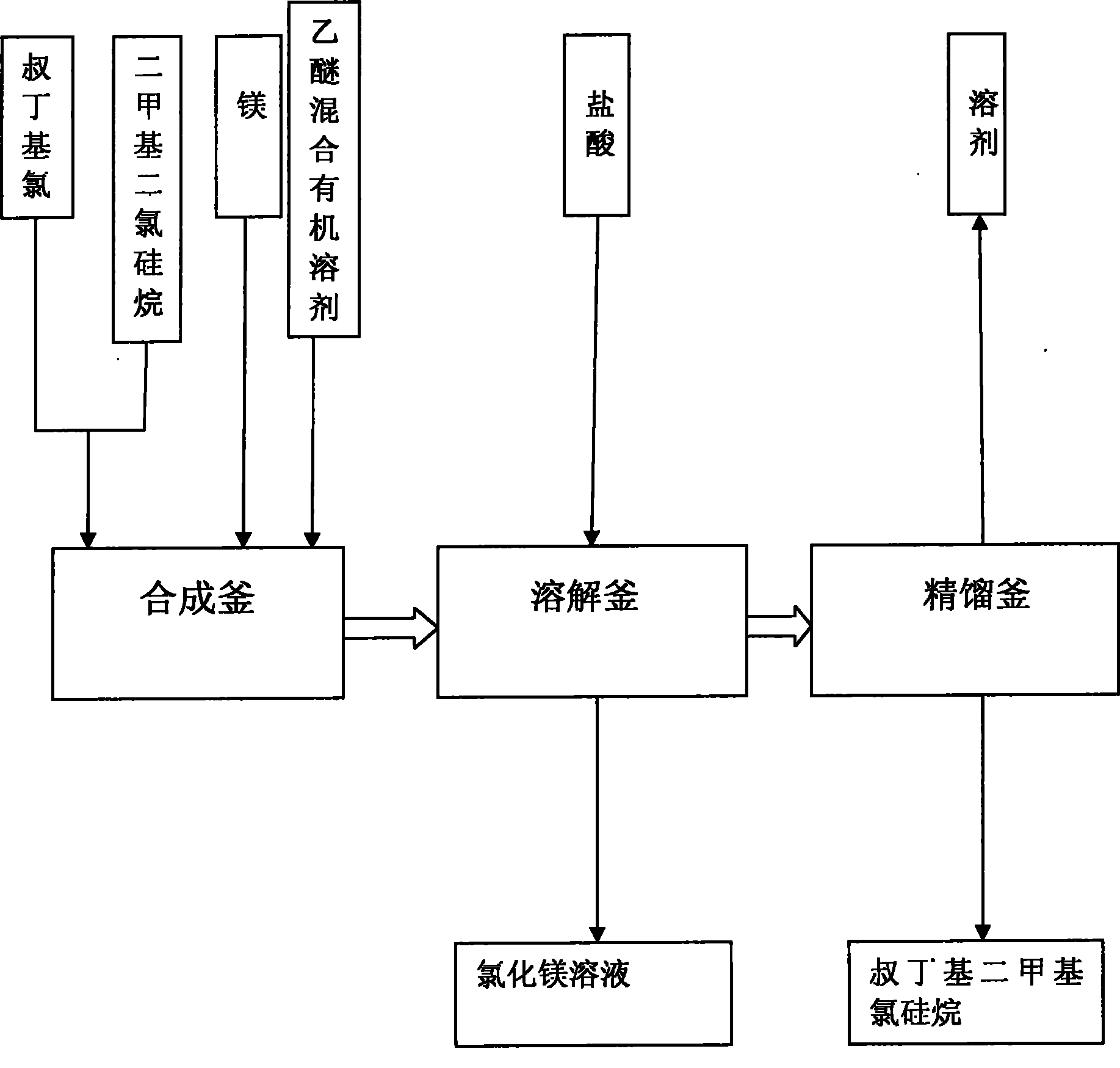

Method for preparing tert-butyldimethyl chlorosilane

InactiveCN101817842AEasy to operateEasy to controlGroup 4/14 element organic compoundsButyl chlorideDissolution

The invention relates to a method for preparing tert-butyldimethyl chlorosilane, which is characterized by comprising the following steps of: a, in a synthesis kettle, putting 10 to 15 weight parts of magnesium into 160 to 240 volume parts of mixed solvent consisting of ether and cyclohexane, dripping mixed solution consisting of 35 to 55 weight parts of tertiary butyl chloride and 50 to 78 weight parts of dimethyl dichlorosilane into the mixed solvent at the temperature of between 40 and 55 DEG C, a preserving heat for 2.5 to 3.5 hours after the dripping is finished to obtain a synthesized material; b, transferring the synthesized material to a dissolution kettle, cooling the synthesized material to between 10 and 15 DEG C, then dripping 400 to 600 volume parts of 25 to 30 percent hydrochloric acid into the dissolution kettle, standing and demixing the solution, and removing wastewater at the bottom to obtain upper liquor; and c, transferring the upper liquor in the dissolution kettle to a rectification kettle to perform purification, and removing the solvent to obtain a tert-butyldimethyl chlorosilane product. The method has the advantages of simple synthesis process, high safety and stable product yield.

Owner:HAIMEN BEST FINE CHEM

Process for producing wear-resistant highly-elastic butyl chloride regenerated rubber

InactiveCN105037791AIncrease elasticityImprove wear resistancePlastic recyclingWear resistantButyl chloride

The invention provides a process for producing wear-resistant highly-elastic butyl chloride regenerated rubber. The process comprises the following steps: a, conducting testing, cleaning and impurity removing on a waste butyl chloride rubber raw material; b, feeding the raw material into a pulverizer to be pulverized and granulated to form colloidal particles; c, feeding the colloidal particles, an antioxygen and a plasticizing agent into a desulfurizing device for desulfurization; d, adding a toughening agent, an accelerating agent, a lubricating agent and a fire retarding agent for processing; e, cooling, detecting and packaging a processed product. The process has the benefits that a series of additives of the toughening agent, the accelerating agent, the lubricating agent and the like is added for processing, the elasticity and the abrasion resistance of the product is effectively improved, moreover, heat energy needed in the production process is converted from solar energy, and energy conservation and environmental protection are achieved.

Owner:NANTONG DEAN CHEM

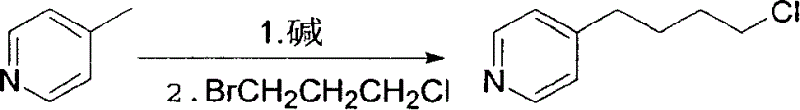

Synthesis process of Tilofiban hydrochloride intermediate

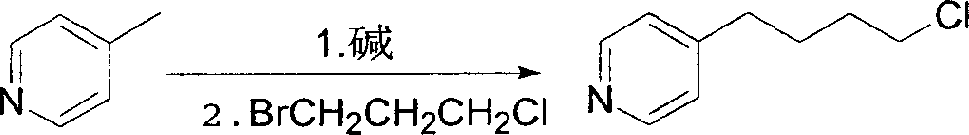

The present invention discloses the synthesis process of 4-(4-pyrindyl) butyl chloride as the intermediate of angina pectoris treating medicine Tilofiban hydrochloride.

Owner:LUNAN PHARMA GROUP CORPORATION

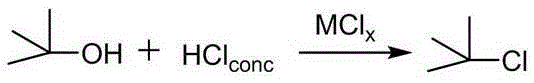

Preparation method of tert-butyl chloride

InactiveCN105399595AIncreased concentration of chloride ionsSolve the use problemHalogenated hydrocarbon preparationMetal chloridePtru catalyst

The invention discloses a preparation method of tert-butyl chloride. The tert-butyl chloride is synthesized through a chlorination reaction of tert-butyl alcohol under the catalysis of a metal chloride. The metal chloride is added as a catalyst in the preparation method, so the method has the advantages of simple production process, less device investment, realization of the reaction rate reaching 95% or above, and realization of the purity of a gas phase reaching 99.5% or above.

Owner:JINAN CHENGHUI SHUANGDA CHEM

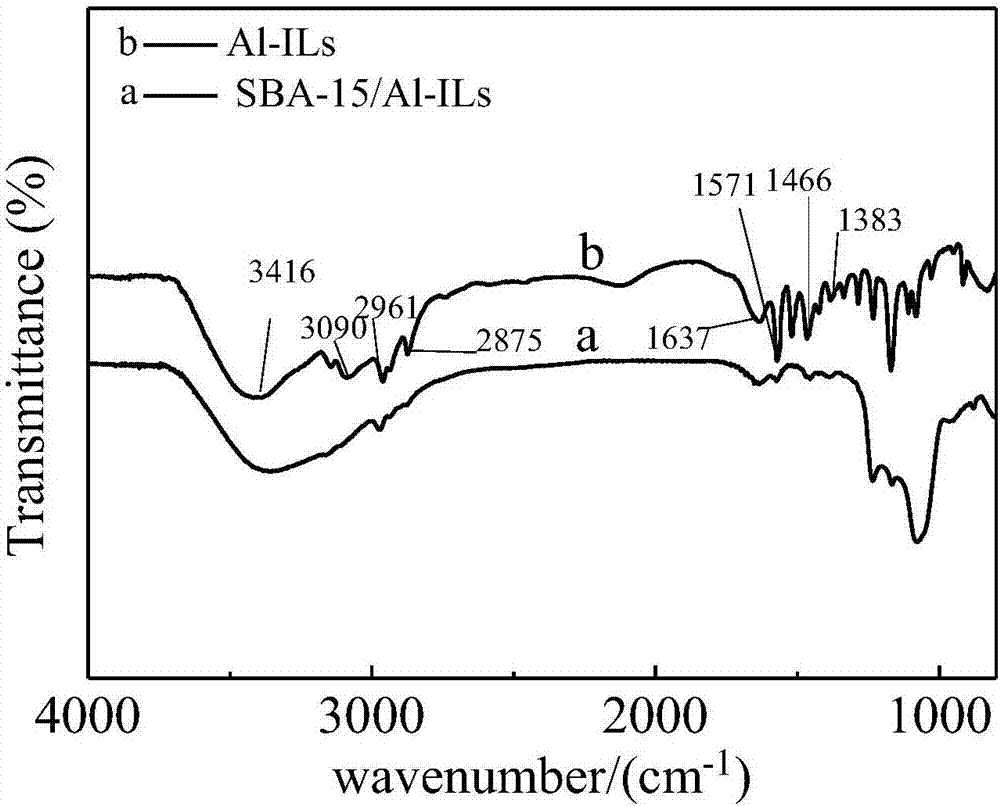

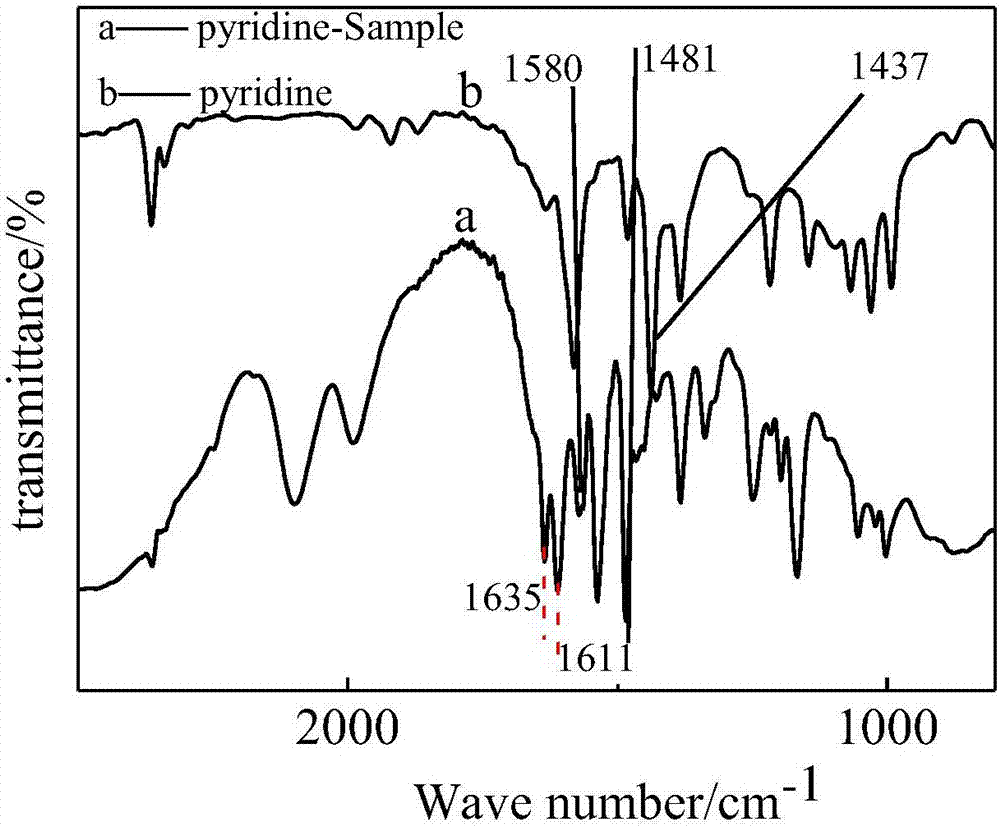

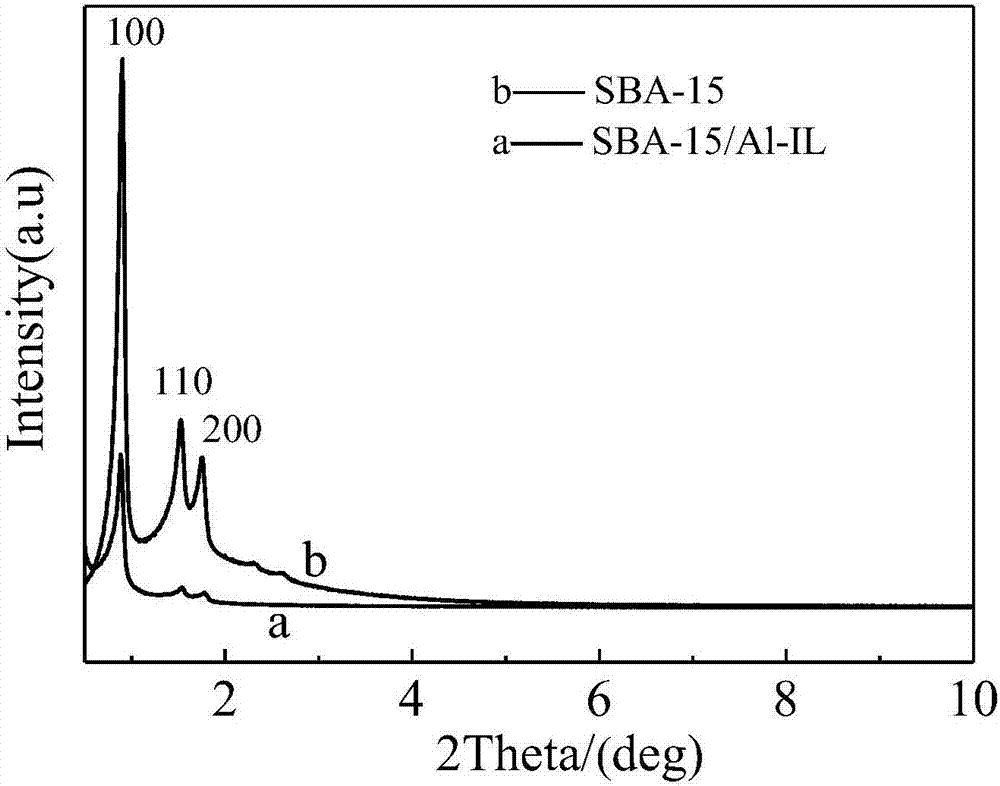

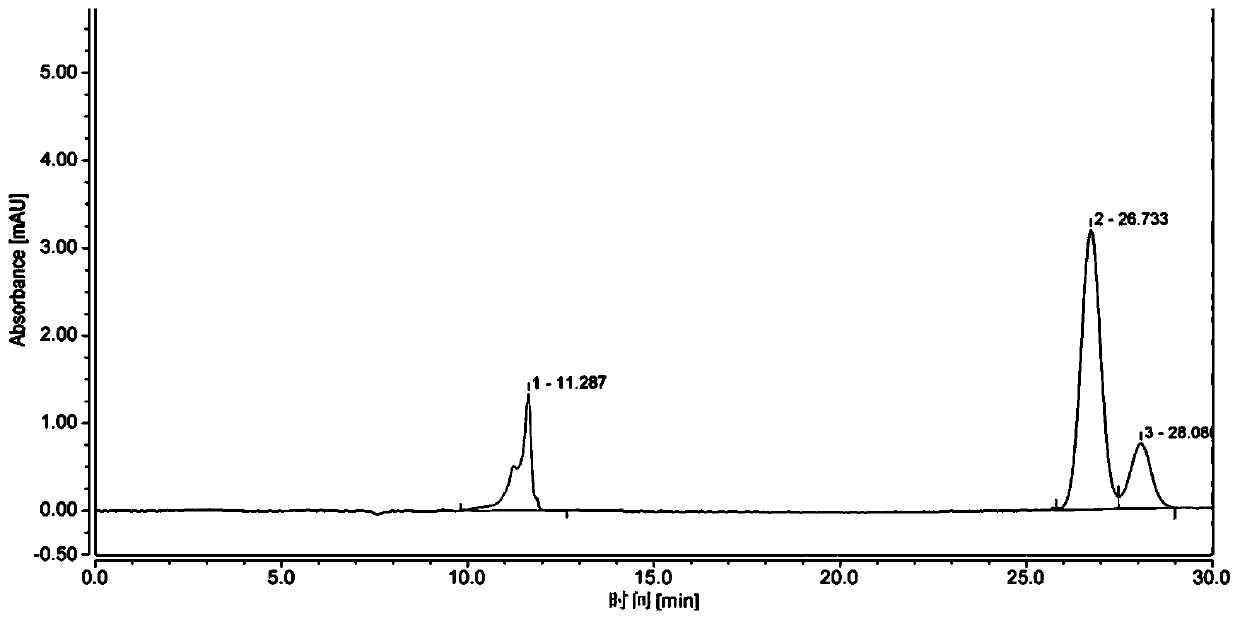

In-situ preparation method for acidic aluminum chlorate ionic liquid loaded SBA-15 catalyst and application

InactiveCN106955743AReduce dosageEasy to separateOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAluminium chloridePtru catalyst

The invention provides an in-situ preparation method for an acidic aluminum chlorate ionic liquid loaded SBA-15 catalyst and an application. The preparation method comprises the following steps: 1) preparing SBA-15; and 2) preparing an acidic aluminum chlorate ionic liquid loaded SBA-15 catalyst: adding SBA-15 into ethyl acetate, uniformly stirring, adding methylimidazole, heating to 80-85 DEG C and stirring; slowly adding n-butyl chloride and reacting under an inert gas condition; after the ending of reaction, evaporating the excessive ethyl acetate and washing with diethyl ether, thereby acquiring an intermediate product; adding aluminum chloride into the intermediate product, thereby acquiring the acidic aluminum chlorate ionic liquid loaded SBA-15 catalyst. According to the invention, the immobilization for the ionic liquid is performed in the manner of in-situ compounding and the purifying process of the ionic liquid is changed, so that the problems of operation difficulty, complex post-processing process and serious loss caused by excessive ionic liquid viscosity in the purifying process can be reduced.

Owner:JIANGSU UNIV

Process for producing 1,2,3,4-tetrachlorohexafluorobutane

ActiveUS20090216054A1Accelerated corrosionLow costHalogenated hydrocarbon separation/purificationPreparation by halogen additionButadiene DioxideButyl chloride

Disclosed is a process for producing 1,2,3,4-tetrachlorohexafluorobutane safely in a high yield in the industrial viewpoint and at low cost in the economical viewpoint. Specifically disclosed is a process for producing 1,2,3,4-tetrachlorohexafluorobutane which process comprises: (1) a step of chlorinating 1,3-butadiene, thereby preparing a mixture containing 1,2,3,4-tetrachlorobutane, and (2) a step of allowing the 1,2,3,4-tetrachlorobutane prepared in the step (1) to react with a fluorine gas in the presence of a diluting gas in a gas phase, thereby preparing a mixture containing 1,2,3,4-tetrachlorohexafluorobutane.

Owner:RESONAC CORP

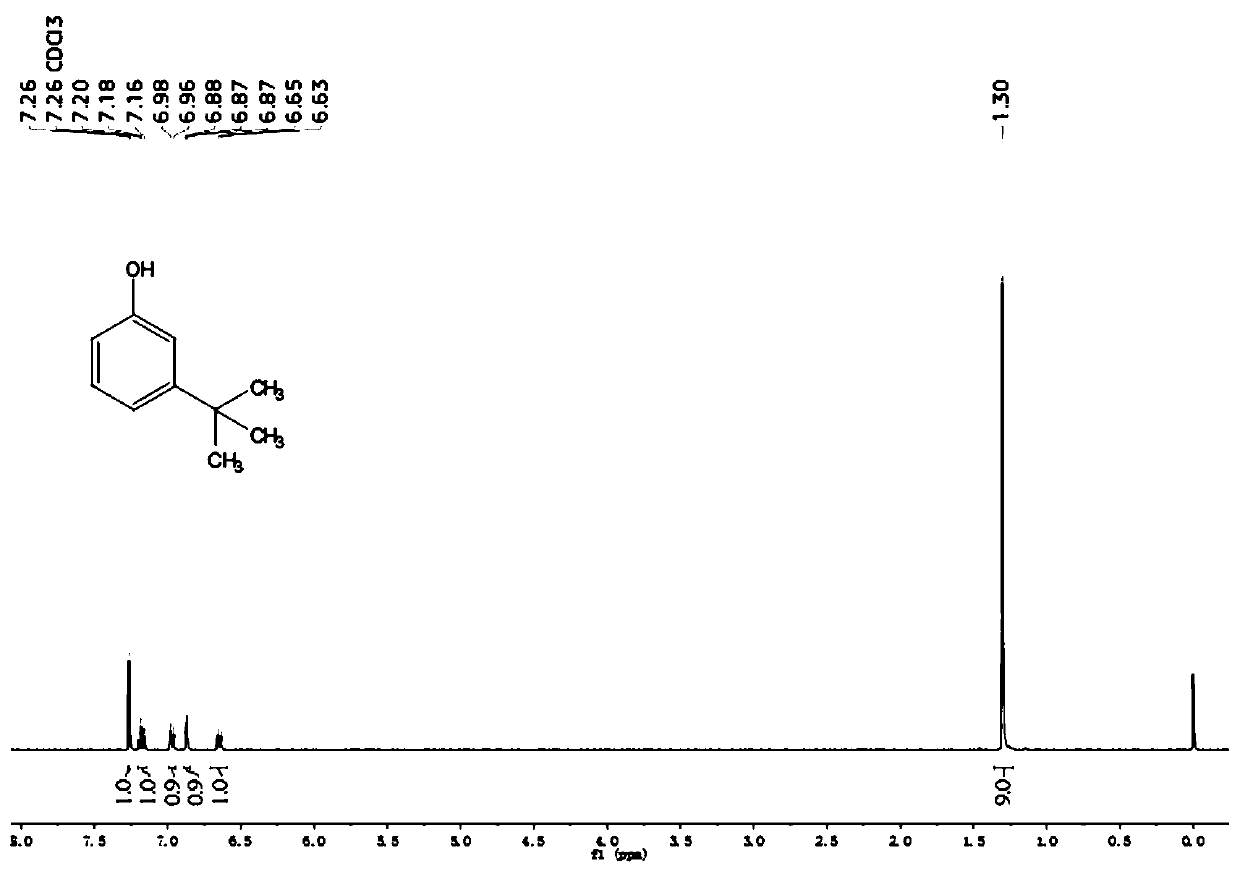

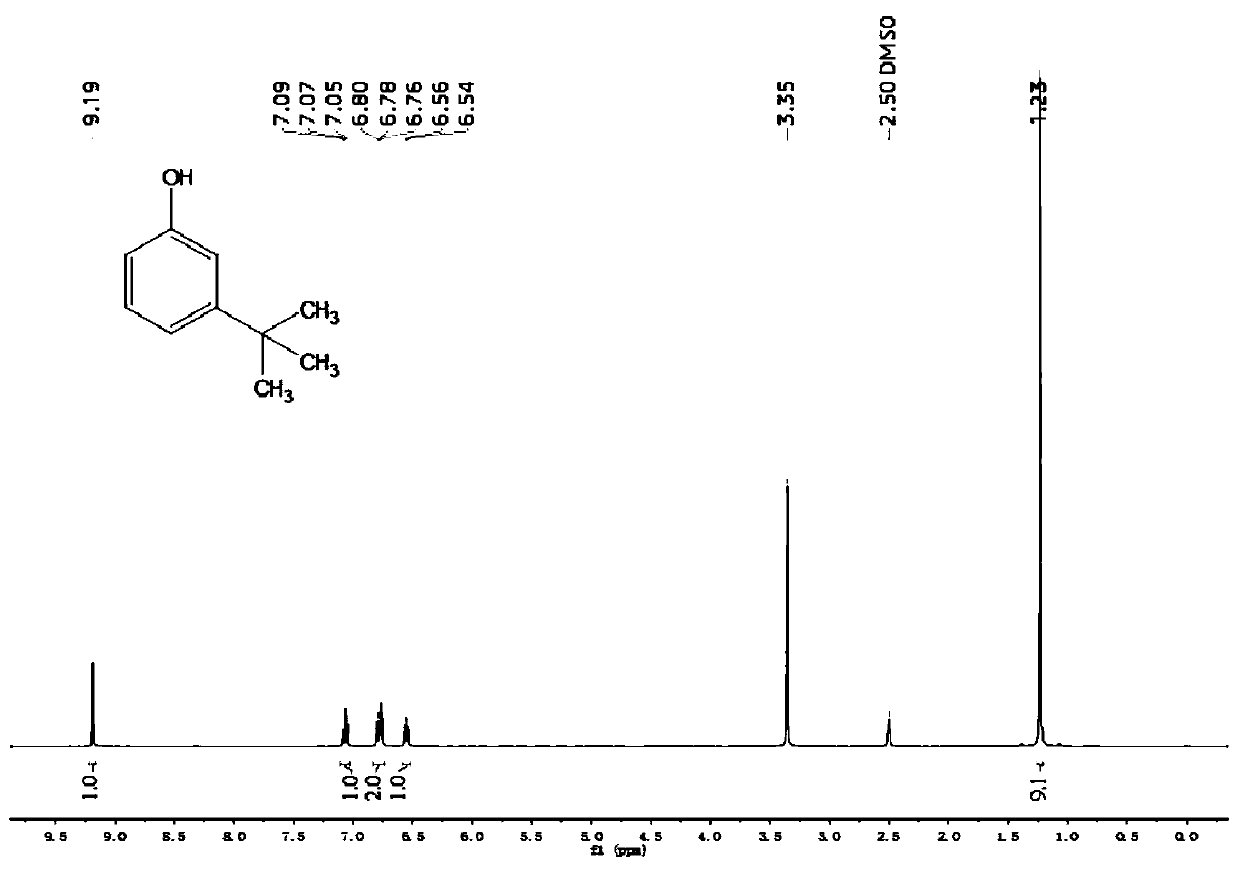

Green preparation process of m-tert-butylphenol

PendingCN110903171AProcess raw materials are cheap and easy to getSimple processOrganic chemistryOrganic compound preparationTert butyl phenolPtru catalyst

The invention discloses a preparation process of m-tert-butylphenol. The method includes the steps of: (1) adopting phenol and tert-butyl chloride as the raw materials, taking acidic clay and concentrated sulfuric acid as the catalyst, carrying out alkylation reaction to obtain the main product m-tert-butylphenol and the byproduct p-tert-butylphenol by one step, and performing separation; and (2)taking unreacted phenol and the p-tert-butylphenol by-product obtained in the step (1) as the raw materials, and taking acidic clay and aluminum trichloride as the catalyst, and carrying out rearrangement reaction to obtain m-tert-butylphenol in one step. Compared with the prior art, the preparation process of m-tert-butylphenol provided by the invention has the advantages of cheap and easily available raw materials, simple technology, good atom economy, greenness and environmental protection, is suitability for industrial production, and has important practical significance for improvement ofthe economic and social benefits of the tert-butylphenolation industry.

Owner:广州市金柏利发展有限公司

Rubber for truck bumper

InactiveCN104672645AOvercoming high temperature resistanceOvercome agingBumpersButyl chlorideTemperature resistance

The invention discloses rubber for a truck bumper. The rubber comprises the following components in parts by weight: 80 parts of chlorosulfonated polyethylene, 52 parts of acrylonitrile-butadiene rubber, 8-19 parts of fast extruding carbon black, 10-15 parts of pyrolysis carbon black, 2-4 parts of indirect zinc oxide, 1-8 parts of magnesium oxide, 0.2-1 part of diethyl aminodithioformic acid, 0.4-1.5 part of thiodipropionic acid biglycerol trilaurate, 0.5-1 part of zinc stearate, 2-4 parts of 2,2'-dithiobisbenzothiazole, 0.3-0.5 part of trithiocyanuric acid, 5-8 parts of trioctyl trimellitate, 1-5 parts of magnetism strong powder, 2-3 parts of sulphur and 1-3 parts of butyl chloride. According to the rubber for the trunk bumper, the defects of poor high-temperature resistance performance, easy aging, short service life and the like in the prior art can be overcome, and the advantages of high high-temperature performance, difficulty in aging and long service life are realized.

Owner:南京中配橡塑制品有限公司

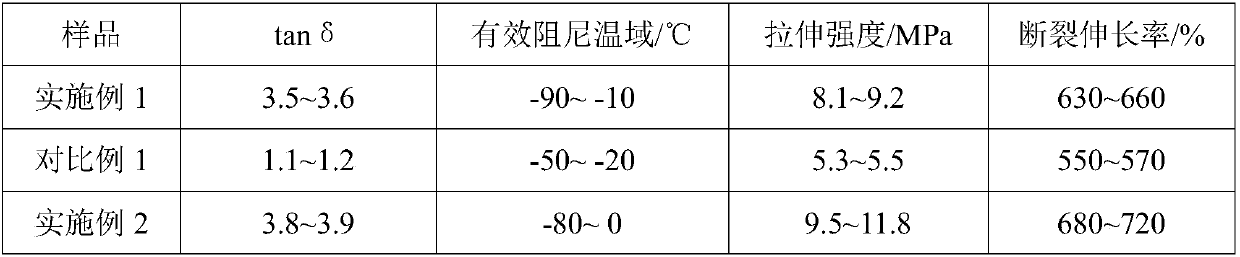

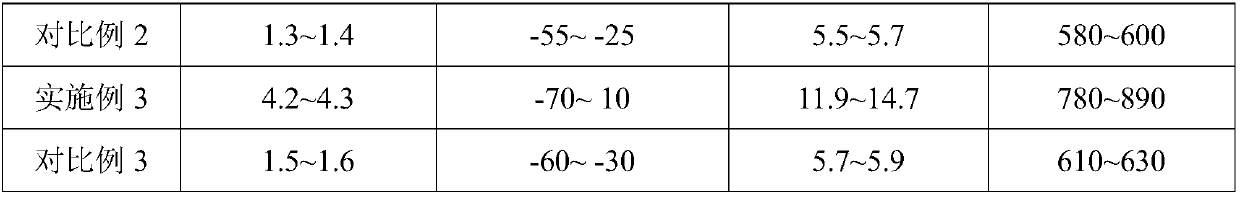

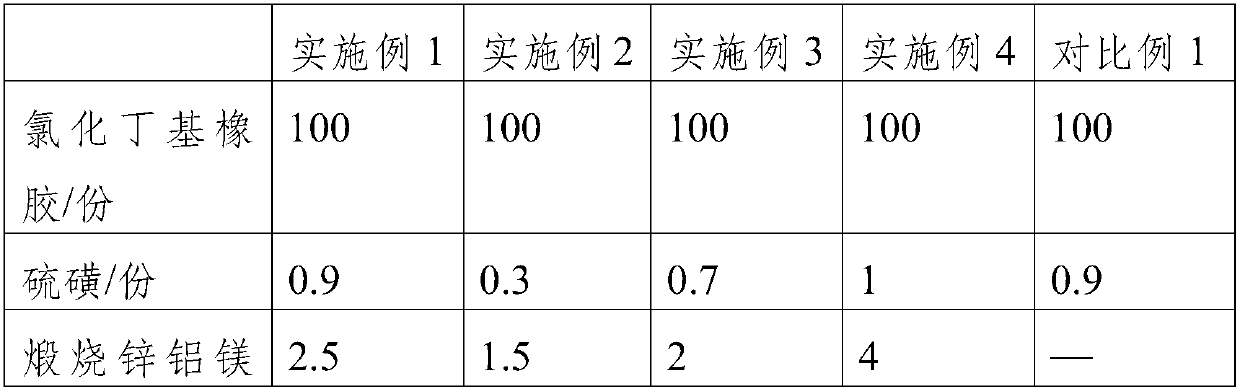

Silicone rubber/hindered phenol composite modified butyl chloride damping rubber and preparation method thereof

ActiveCN107629340AExpand the scope ofImprove damping performanceHeat-exchange elementsPolymer scienceButyl chloride

Owner:SHANGHAI UNIV OF ENG SCI

Medicinal butyl chloride rubber plug and production technology thereof

ActiveCN109679240AReduce defective rateImprove the problem of bubbling bubblesCross-linkVulcanization

The invention discloses a medicinal butyl chloride rubber plug. The medicinal butyl chloride rubber plug comprises the following raw material compositions: chlorinated butyl rubber, a vulcanizing agent, stearic acid, a reinforcing agent and an accelerant, wherein the vulcanizing agent and / or the reinforcing agent comprise / comprises calcined hydrotalcite containing zinc and magnesium, and the calcined hydrotalcite containing zinc and magnesium is prepared by carrying out calcinations at the temperature of 250 to 490 DEG C on hydrotalcite containing zinc and magnesium. The calcined hydrotalcitecontaining zinc and magnesium is added into the medicinal butyl chloride rubber plug, the calcined hydrotalcite containing zinc and magnesium is of memory effect and high adsorption performance, the bubble problem on the surface of the rubber plug can be improved, and the defective rate of the rubber plug in vulcanization slice discharge process is reduced; the active centers on the surface of thecalcined hydrotalcite containing zinc and magnesium are distributed uniformly, uniform dispersion of the hydrotalcite inside rubber is beneficial for improving the cross-linking strength of rubber, and the cleanliness and tear resistance of the rubber plug are promoted.

Owner:江阴市海华橡塑有限公司

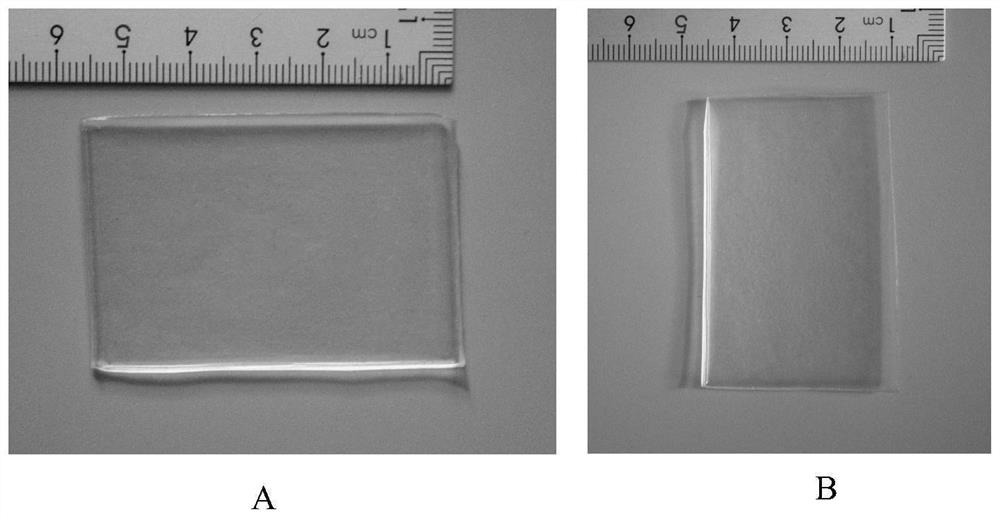

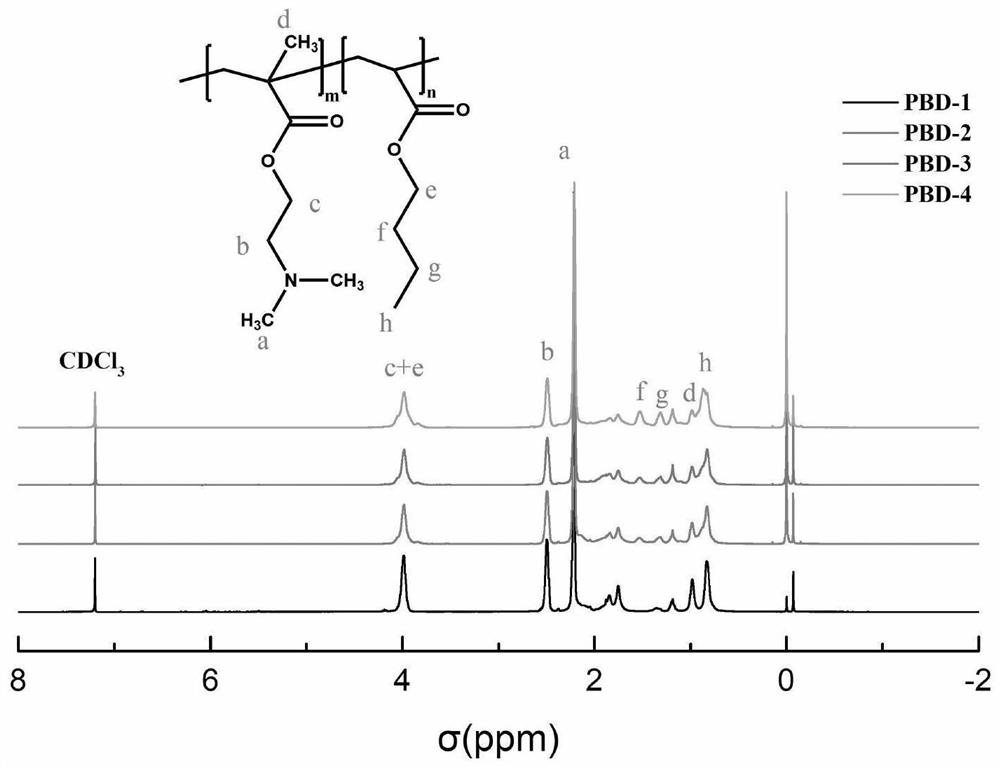

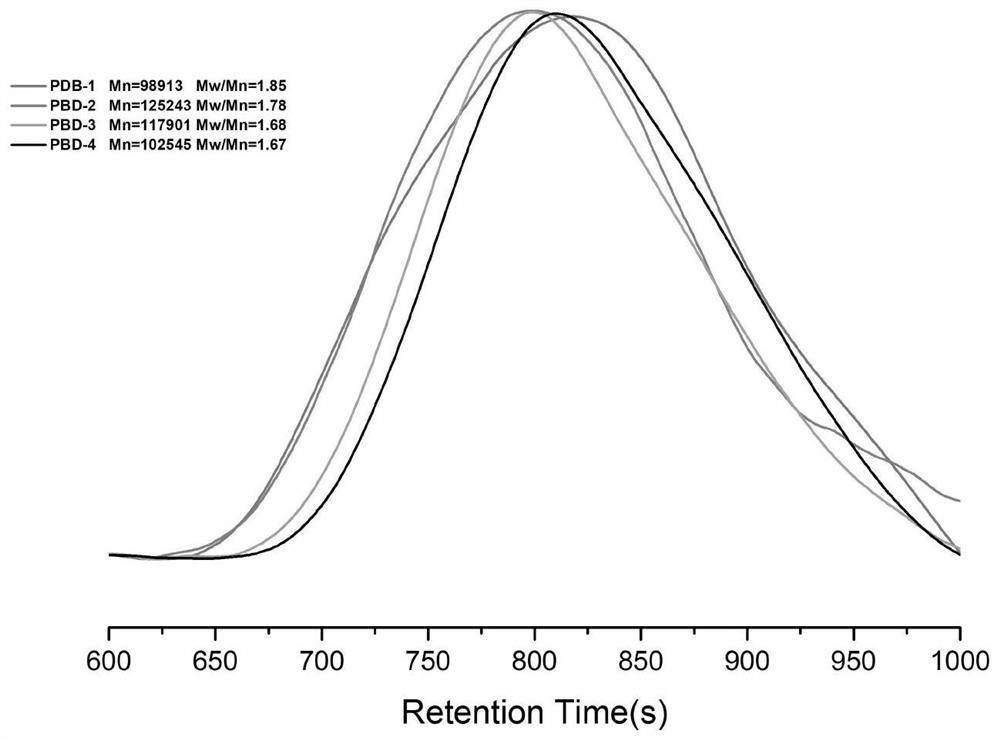

Preparation method of acrylic quaternary ammonium salt film with contact antibiosis and antifogging functions

InactiveCN112592419AGood mechanical propertiesExcellent contact sterilization performanceAntifouling/underwater paintsPaints with biocidesPolymer scienceOrganosolv

The invention discloses a preparation method of an acrylic quaternary ammonium salt film with contact antibiosis and antifogging functions. The preparation method comprises the following steps: respectively adding dimethylaminoethyl methacrylate (DMAEMA) and butyl acrylate (BA) into an ethanol solvent, and initiating free radical polymerization through AIBN to obtain a binary copolymer precursor PBD; dissolving the precursor copolymer in an organic solvent ethanol, adding bromofortune (OB) for ionization to prepare a quaternary ammonium salt polymer PBD-OB, weighing a certain mass of the PBD-OB polymer, dissolving the PBD-OB polymer in an ethanol solution again, adding 1-bromo-4-chlorobutane (BrC4H8Cl) for a cross-linking reaction, pouring into a mold, and naturally volatilizing the solvent at room temperature, and obtaining the acrylic quaternary ammonium salt film with antibacterial and antifogging properties. According to the acrylic quaternary ammonium salt film prepared by the method, the preparation process is simple, controllable and magnifiable, and the film has the characteristics of excellent mechanical property, high light transmittance, excellent antibacterial property,excellent antifogging property and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

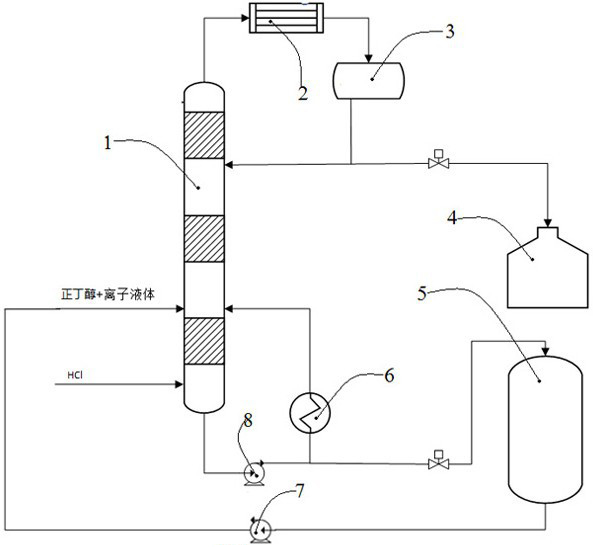

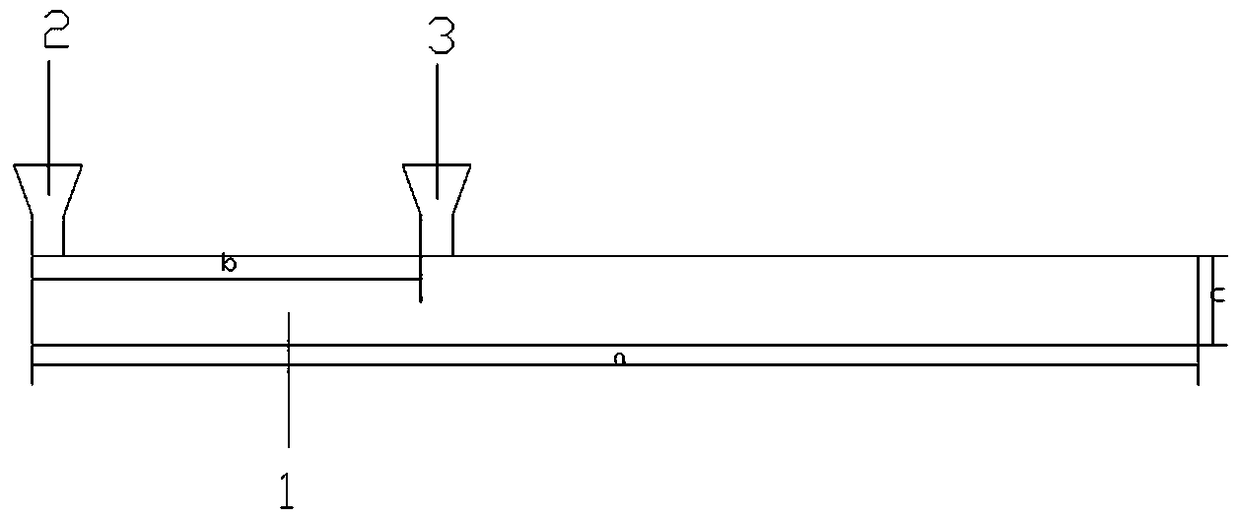

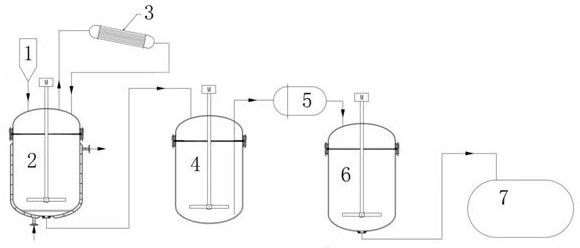

Method for continuously synthesizing chlorobutane in non-aqueous system

PendingCN113896614AShort reaction timeCatalytic performance recoveryHalogenated hydrocarbon preparationBulk chemical productionPtru catalystButyl chloride

The invention relates to a method for continuously synthesizing chlorobutane in a non-aqueous system. The method is characterized in that a non-aqueous system is composed of an ionic liquid 1-butyl-3-methylimidazolium chloride or 1-butylpyridine hydrochloride, n-butyl alcohol and hydrogen chloride, and the ionic liquid is both a solvent and a catalyst for a chlorination reaction; a chemical reaction for continuously synthesizing chlorobutane, n-butanol and hydrogen chloride and rectification of the reaction product 1-chlorobutane are synchronously and continuously carried out in a reaction rectification tower; and hydrogen chloride gas is introduced from the bottom of the reaction rectification tower, n-butanol and the ionic liquid are introduced from the middle of the reaction rectification tower, 1-chlorobutane is extracted from the top of the tower, and part of ionic liquid extracted from the bottom of the tower is subjected to moisture evaporating in a falling-film evaporator, and then returns to the system. According to the method, reaction and rectification are carried out at the same time, operation is simple, the reaction rate is high, almost instantaneous reaction occurs to generate 1-chlorobutane after gas-liquid two-phase contact, the ionic liquid can be regenerated after being simply dehydrated; the purity of 1-chlorobutane is greater than or equal to 99.5%, and the product yield is 90.3-98.2% in terms of n-butanol.

Owner:山东绿色海洋化工研究院有限公司 +1

Method for preparing biphenyl diphosphine ligand

ActiveCN102010442BSimple and fast operationSuitable for industrial productionGroup 5/15 element organic compoundsButyl chlorideDiphosphines

The invention discloses a new method for preparing a biphenyl diphosphine ligand 2,2'-diphenylphosphinomethyl-1,1'-biphenyl (BISBI) and derivatives thereof. The method is characterized by comprising the following steps: (1) under the protection of inert gases, adding 40-60 parts of triphenylphosphine and 250-360 parts of ether solvents to a reaction flask, stirring the mixture to dissolve the mixture and adding 3-20 parts of alkali metals and 0-5 parts of electron-rich aromatics to the reaction flask to react for 2-24 hours at 20-120 DEG C to prepare a diphenulphosphine metal compound and a phenyl metal compound; (2) dropwise adding 15-20 parts of tertiary butyl chloride to the reaction solution to remove the generated phenyl metal compound; and (3) dropwise adding the solution formed by 15-40 parts of 2,2'-disubstituted methyl-1,1'-biaryl compound and 20-40 parts of ether solvent to the reaction solution with phenyl metal compound removed to react for 6-24 hours at 0-40 DEG C and carrying out extraction, drying, concentration and recrystallization to obtain the diphosphine ligand 2,2'-diphenylphosphinomethyl-1,1'-biphenyl (BISBI) and the derivatives thereof. The method has the characteristics of cheap and easily obtained raw materials and mild reaction conditions, is simple and convenient for operation, and is easy to realize industrial production.

Owner:成都欣华源科技有限责任公司

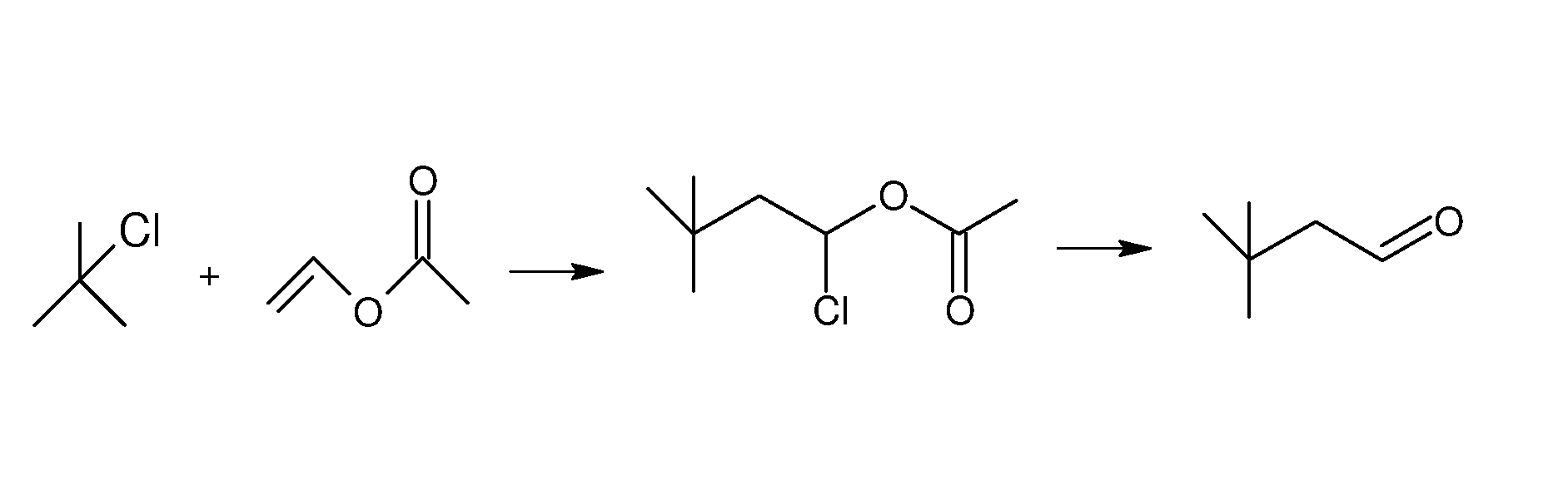

Method for preparing 3,3-dimethylbutyraldehyde

ActiveUS20140114091A1High safety in transportationHigh in storageOrganic compound preparationCarboxylic acid esters preparationAcetic acidButyl acetate

A method for preparing 3,3-dimethylbutyraldehyde. The method includes: providing t-butyl chloride and vinyl acetate as raw materials, conducting a catalytic reaction between the t-butyl chloride and vinyl acetate to yield 1-chloro-3,3-dimethyl butyl acetate in the presence of a catalyst, the weight ratio of t-butyl chloride to vinyl acetate being 1: 0.84-0.93; and controlling a temperature at between 100 and 110° C. for conducting hydrolytic disproportionation of 1-chloro-3,3-dimethyl butyl acetate in the presence of the catalyst to yield a mixture comprising 3,3-dimethylbutyraldehyde; and purifying the mixture by distillation to yield 3,3-dimethylbutyraldehyde, in which, the catalyst is aluminum trichloride, p-toluene sulphonic acid, or iron trichloride.

Owner:JINAN CHENGHUI SHUANGDA CHEM

EPDM/PE (Ethylene-Propylene-Diene Monomer/Polyethylene) mixture with high gel content as well as preparation method and preparation device thereof

InactiveCN109369854AFormulation Component ScienceReasonable designGlycidyl methacrylateEthylene-propylene-diene-monomer

Owner:JIANGSU HENGFENG CABLE

Preparation method of industrial musk tonalide

InactiveCN102050715BExtended reaction timeHigh selectivityCarbonyl compound preparation by condensationP-isopropyltolueneDistillation

The invention relates to a preparation method of industrial musk tonalide, which comprises the following steps: carrying out Friedel-Crafts alkylation by using p-isopropyl toluene and 2,3-dimethyl-1-butene as raw materials and using tertiary butyl chloride as a hydrogen absorption agent to synthesize an intermediate 1,1,3,4,4,6-hexamethyl tetrahydronaphthalene; and in a dichloromethane solvent, carrying out Friedel-Crafts alkylation on the intermediate used as the raw material and acetyl chloride, thereby obtaining the product musk tonalide (7-acetyl-1,1,3,4,4,6-hexamethyl tetrahydronaphthalene, AHMT). Compared with the existing method and technology, the method provided by the invention is simple to operate, has the characteristics of high reaction speed, high yield and the like, and realizes industrial production; and the product can be simply purified by thermally dissolving out pigments by using anhydrous alcohol without distillation or rectification.

Owner:HENAN UNIV OF SCI & TECH

Method for industrially producing sec-butyl lithium

PendingCN113735670AImprove qualityFulfil requirementsHydrocarbon from halogen organic compoundsMetallic lithiumLithium chloride

The invention provides a method for industrially producing sec-butyl lithium. The method for industrially producing sec-butyllithium comprises the following steps: (1) replacing air in a reaction kettle with argon, and adding a solvent; (2) putting lithium particles into a feeder, replacing air with argon, and putting all the lithium particles into the reaction kettle; (3) starting stirring, dropwise adding 2-chlorobutane through a metering pump to react with the metal lithium, and controlling the reaction temperature through the reaction kettle jacket and the feeding speed of the 2-chlorobutane; (4) keeping the temperature for 2-4 hours, pressing the reaction liquid into an intermediate tank by using argon, and leaving excessive metal lithium in the reaction kettle; and (5) pressing the material liquid in the intermediate tank into a filter by using argon to remove the lithium chloride solid, thereby obtaining colorless to faint yellow transparent clear liquid, namely the sec-butyllithium solution. According to the method, excessive metal lithium particles and 2-chlorobutane react in a solvent at a certain temperature to produce sec-butyllithium, so that side reaction is effectively avoided, and the yield is increased.

Owner:GANFENG LITHIUM CO LTD

Method for preparing 3,3-dimethylbutyraldehyde

ActiveUS8841490B2Low costHigh safety in transportation and storageOrganic compound preparationCarboxylic acid esters preparationAcetic acidButyl acetate

A method for preparing 3,3-dimethylbutyraldehyde. The method includes: providing t-butyl chloride and vinyl acetate as raw materials, conducting a catalytic reaction between the t-butyl chloride and vinyl acetate to yield 1-chloro-3,3-dimethyl butyl acetate in the presence of a catalyst, the weight ratio of t-butyl chloride to vinyl acetate being 1:0.84-0.93; and controlling a temperature at between 100 and 110° C. for conducting hydrolytic disproportionation of 1-chloro-3,3-dimethyl butyl acetate in the presence of the catalyst to yield a mixture comprising 3,3-dimethylbutyraldehyde; and purifying the mixture by distillation to yield 3,3-dimethylbutyraldehyde, in which, the catalyst is aluminum trichloride, p-toluene sulphonic acid, or iron trichloride.

Owner:JINAN CHENGHUI SHUANGDA CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com