Patents

Literature

35results about How to "Overcoming high temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medium-high-temperature through type metal solar collector tube

ActiveCN102207341ASimple manufacturing processImprove toughnessSolar heat devicesSolar thermal energy generationHeat resistanceHigh pressure

The invention discloses a medium-high-temperature through type metal solar collector tube which comprises a metal parent tube, the outer surface of the metal parent tube is covered with an anti-corrosion coating and an absorption coating in sequence from inside to outside, wherein the anti-corrosion coating is a high phosphorous chemical nickel-plated coating, the thickness of the high phosphorous chemical nickel-plated coating is 10 to 20 Mum, and the absorption coating comprises a metal infrared reflecting sub-coating, a metal ceramic medium-high-temperature heat absorbing sub-coating and areflection reducing sub-coating in sequence from inside to outside. The medium-high-temperature through type metal solar collector tube disclosed by the invention solves the problems of corrosion of materials at a medium-high temperature of 200 to 500 DEG C, and heat resistance and oxidation resistance of the heat absorbing coating, realizes corrosion, heat and high pressure resistance, and has low cost, a simple preparation process and high practicality.

Owner:HUANENG POWER INTERNATIONAL +2

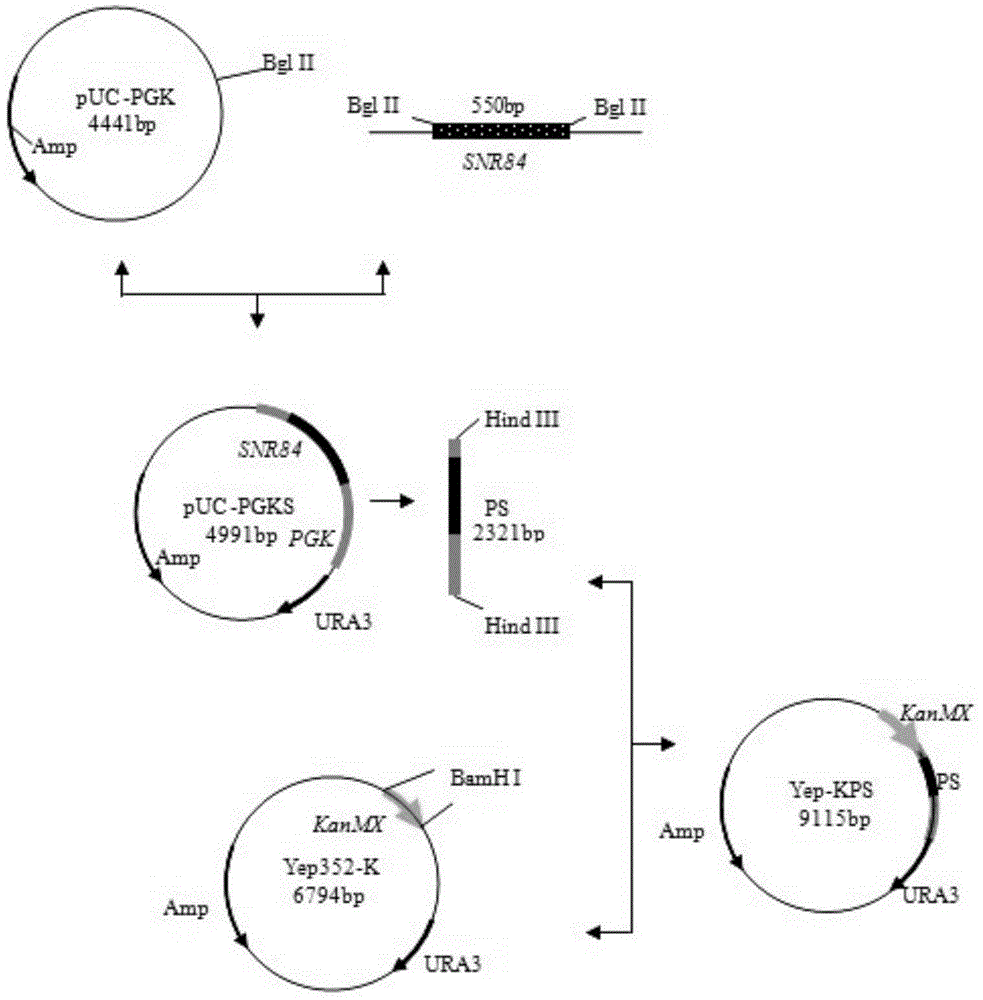

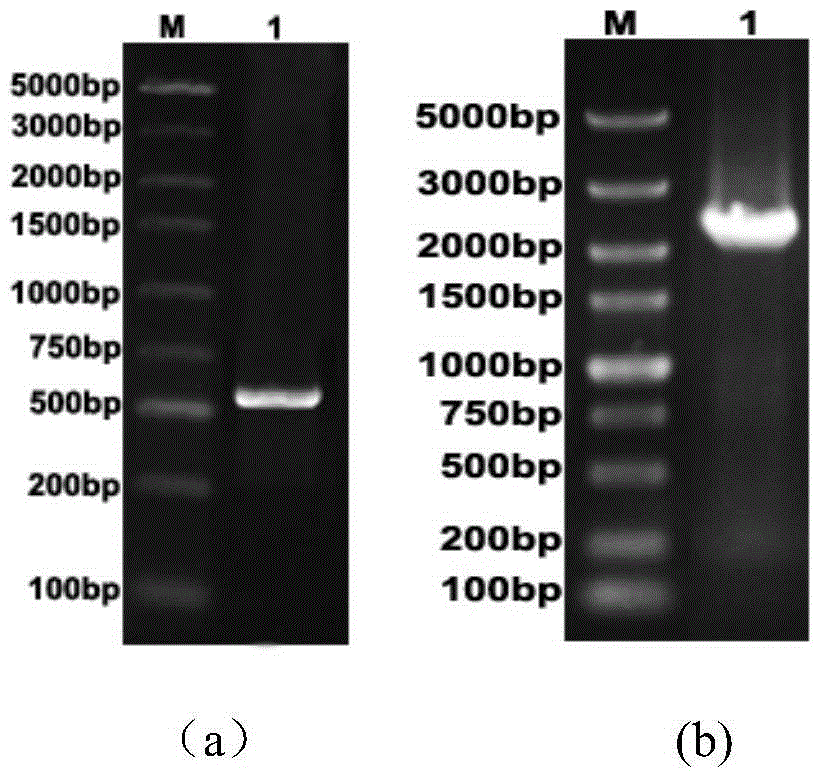

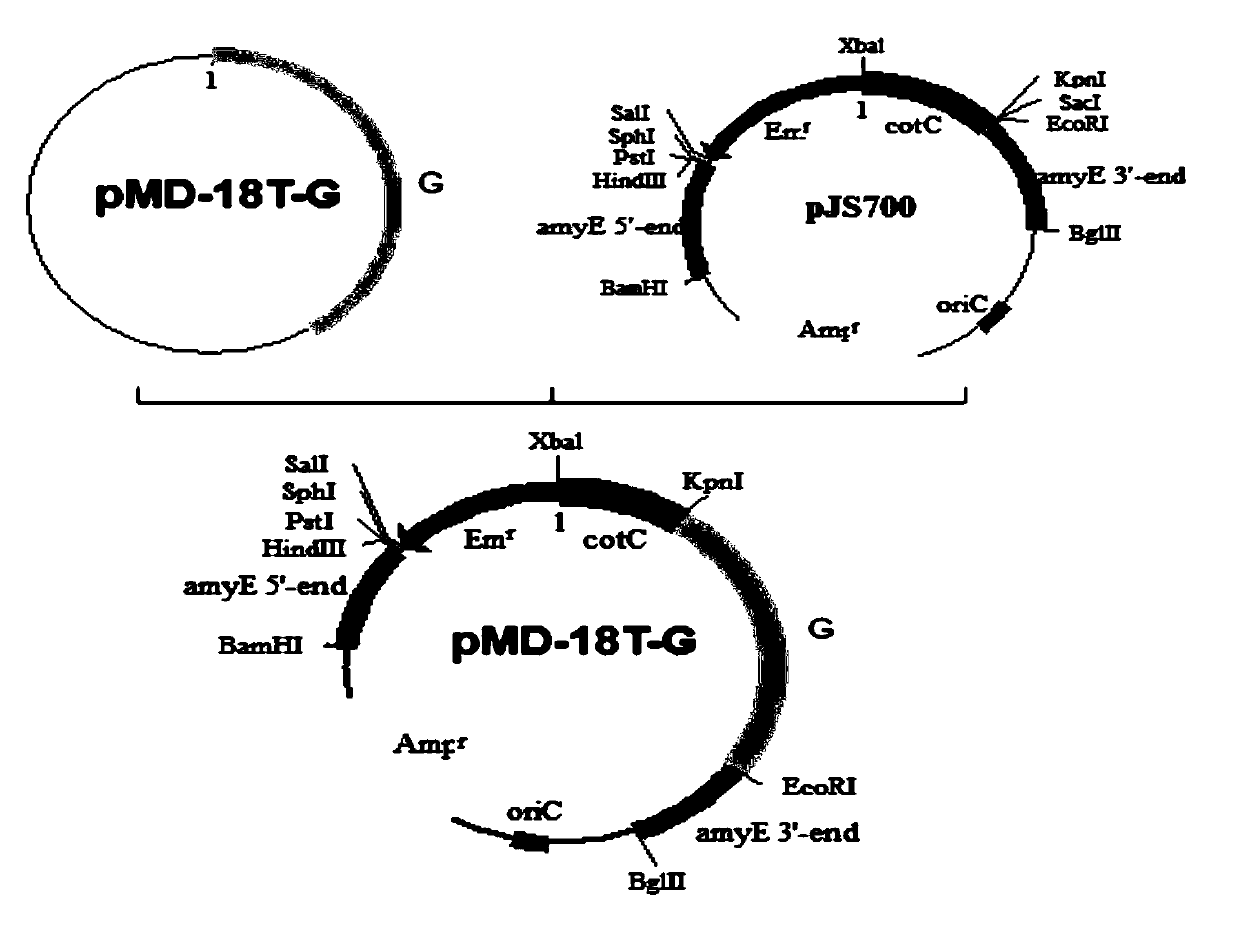

High-resistant yeast strain and preparation method thereof

ActiveCN104017742AOvercoming high temperature resistanceOvercome High Glucose ToleranceFungiPre-baking dough treatmentHeat shockBiotechnology

The invention discloses a high-temperature-resistant, high-sugar-resistant and freezing-resistant high-resistant yeast strain and a preparation method thereof. The preparation method comprises the following steps: over-expressing a complete sequence of H / ACA snoRNA (SNR84) by selecting and using a strong promoter PGK1 in a parent yeast strain to obtain the high-resistant yeast strain. The cell activity of the strain is remarkably improved in high-temperature, high-sugar and freezing environments in comparison with that of the parent strain. Saccharomyces cerevisiae are good in high-temperature resistance in heat shock treatment, high-sugar resistance in high-sugar dough and freezing resistance in frozen dough, the technical obstacle and the quality detect in a bread making process are overcome, and the application prospect is wide.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

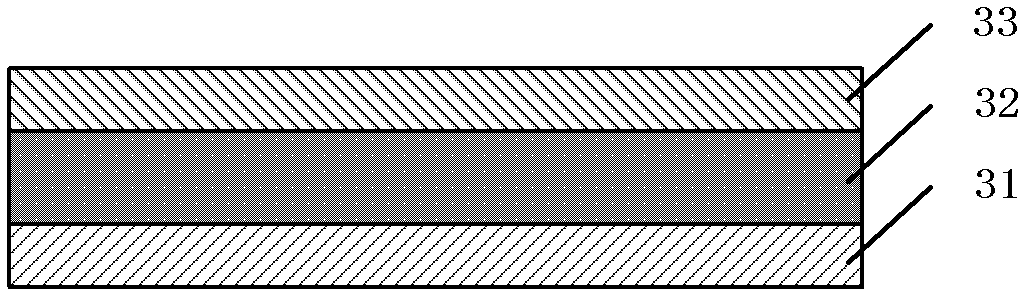

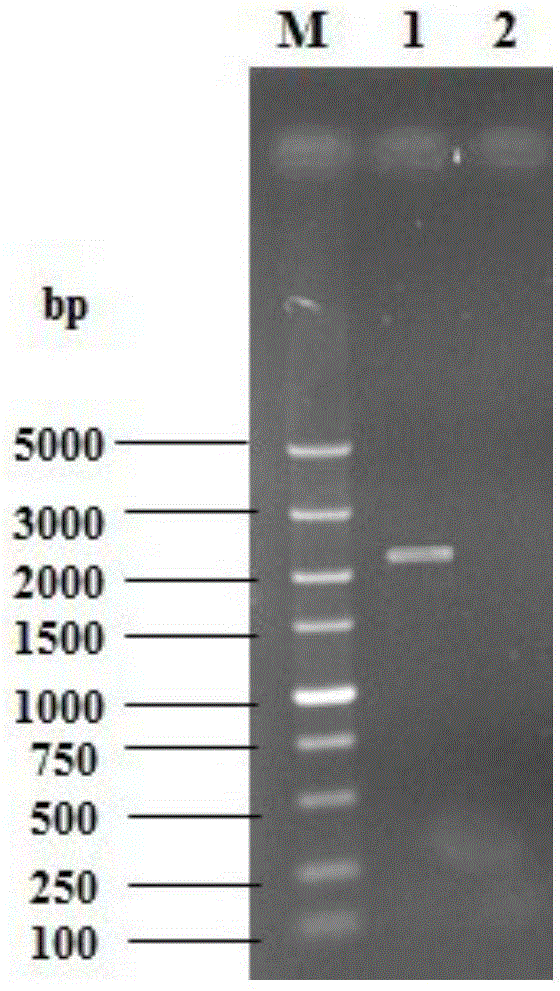

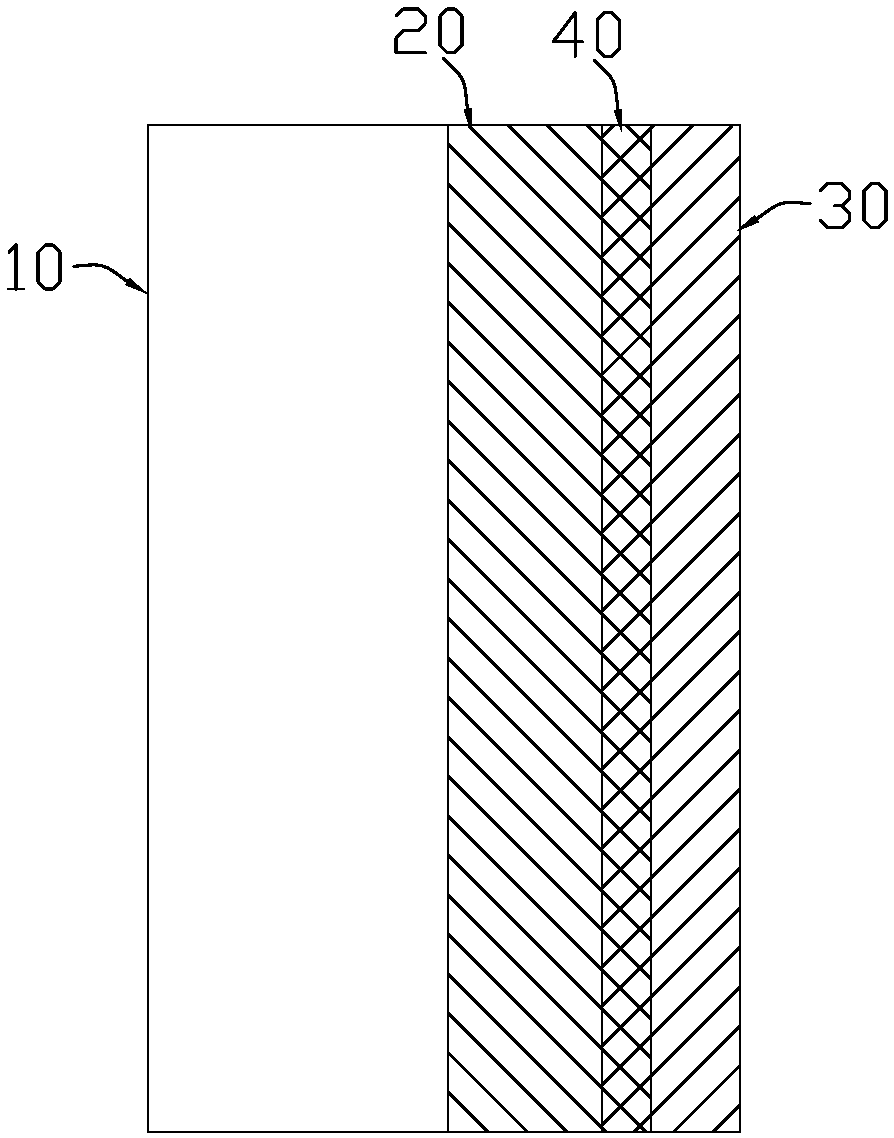

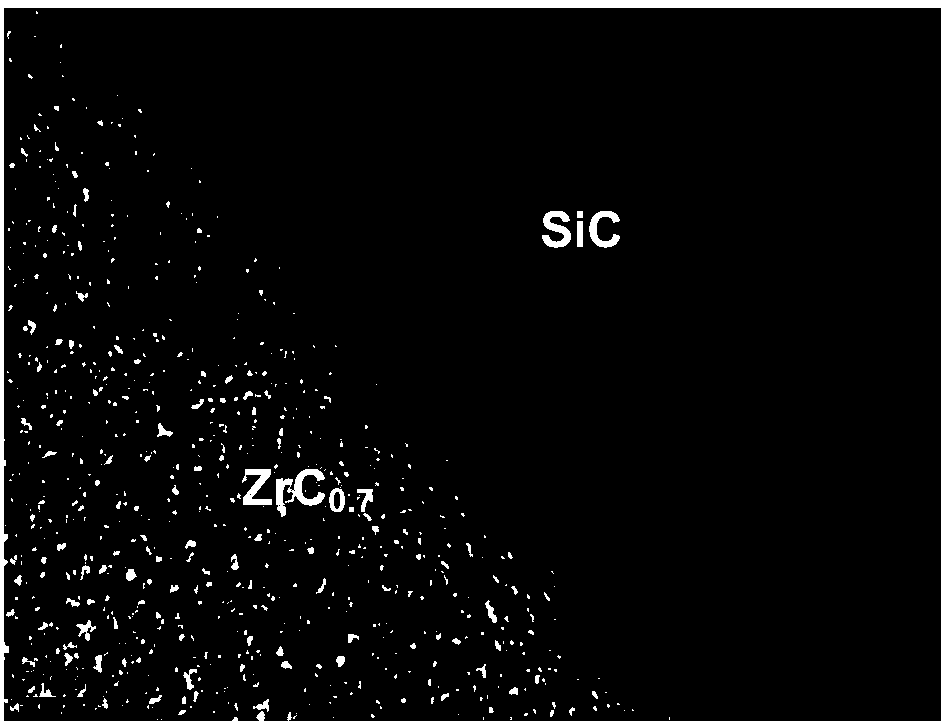

Fuel cladding and fuel component

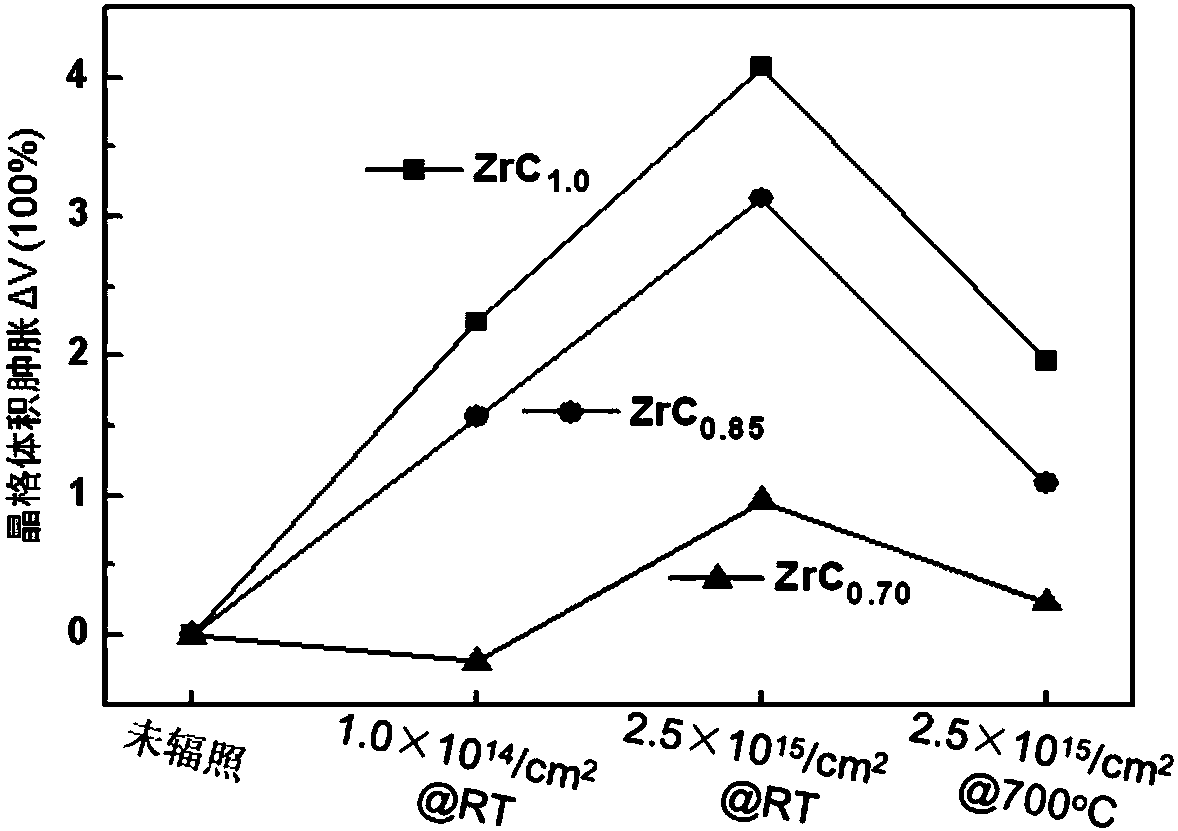

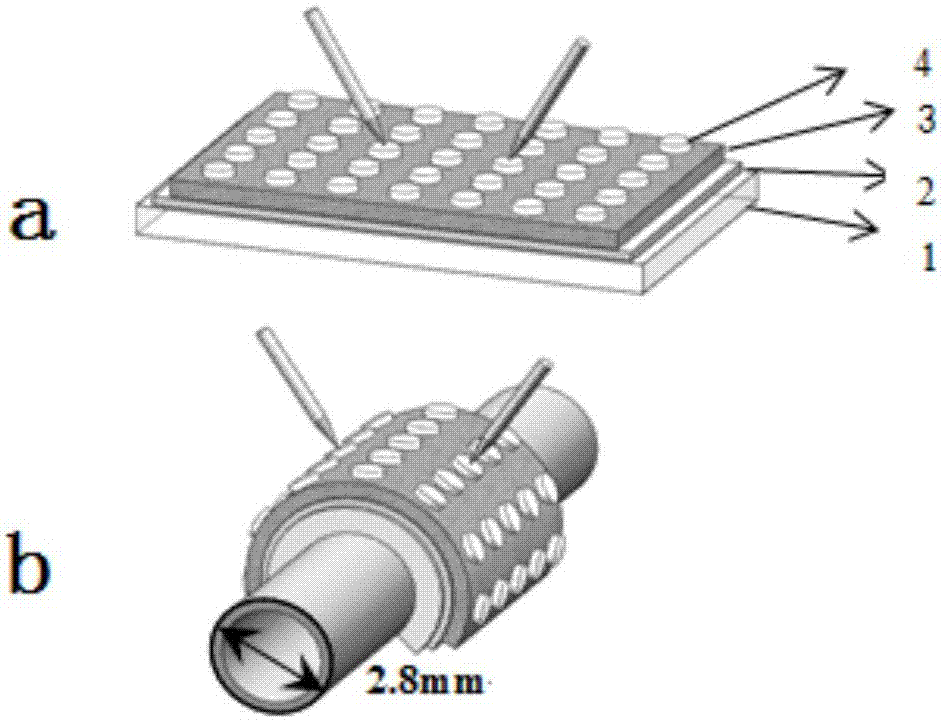

ActiveCN107799185AOvercome stressOvercoming interfacial diffusionOptical rangefindersFuel elementsInter layerNuclear reactor

The invention discloses a fuel cladding and a fuel component; the fuel cladding includes a zirconium alloy base, an intermediate layer arranged on the zirconium alloy base and having nonstoichiometryand gradient characteristics, and an ambient shielding layer arranged on the intermediate layer; the intermediate layer and the ambient shielding layer form a gradient composite coating of nonstoichiometry on the zirconium alloy base. The fuel cladding and the fuel component have the advantages that the problem that a traditional zirconium alloy cladding with single coating experiences interfacialstress and interfacial diffusion and zero tolerance to high temperature vapor oxidation is solved; through synergic design and the gradient composite coating of nonstoichiometry in the fuel cladding,the fuel cladding is applicable to accident fault-tolerant nuclear fuel claddings, and anti-accident ability of a nuclear reactor to maintain nuclear fuel component structure and functional integrality under severe conditions and its safety threshold are greatly increased.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

Acrylic ester pressure sensitive adhesive, pressure sensitive adhesive tape and preparation method of acrylic ester pressure sensitive adhesive

ActiveCN107868639AResistant to electrolyteHigh temperature resistancePressure sensitive film/foil adhesivesGraft polymer adhesivesElastomerPolymer science

The invention relates to the technical field of a pressure sensitive adhesive, in particular to an acrylic ester pressure sensitive adhesive, a pressure sensitive adhesive tape and a preparation method of the acrylic ester pressure sensitive adhesive. The acrylic ester pressure sensitive adhesive provided by the invention is prepared from the following raw materials in parts by weight: 8 to 12 parts of 2-ethylhexyl acrylate, 7 to 10 parts of butyl acrylate, 3 to 4 parts of acrylic acid, 4 to 6 parts of vinyl acetate, 3 to 4.5 parts of methyl methacrylate, 3 to 4 parts of hydroxyethyl methylacrylate, 2 to 3 parts of trimethylolpropane triacrylate, 4 to 6 parts of isoprene rubber with double bonds, 4 to 6 parts of SBS elastomers with double bonds, 45 to 60 parts of solvents and 0.3 to 0.6 part of initiating agents. The acrylic ester pressure sensitive adhesive provided by the invention uses the isoprene rubber and the SBS elastomers for modifying the acrylic ester pressure sensitive adhesive, so that the acrylic ester pressure sensitive adhesive has the advantages of acrylic ester, and also has the electrolyte-resistant and high-temperature-resistant performance of rubber; the defectof poor electrolyte-resistant and high-temperature-resistant performance of the existing acrylic ester pressure sensitive adhesive can be effectively overcome.

Owner:东莞市骏青电子科技有限公司

Green printing and dyeing aid and preparation method thereof

ActiveCN108396574ASimple processRaw materials are easy to getDyeing processGlycoside formationFatty alcohol

The invention discloses a green printing and dyeing aid which is prepared from the following components in parts by weight: 15-25 parts of alkyl glycoside modified amino silicon oil, 5-10 parts of silicyl benzsulfamide-acrylic copolymer, and 5-10 parts of fatty alcohol polyoxyethylene ether sodium sulfate. A preparation method for the green printing and dyeing aid comprises the following steps: uniformly mixing alkyl glycoside modified amino silicon oil, silicyl benzsulfamide-acrylic copolymer, and fatty alcohol polyoxyethylene ether sodium sulfate, and stirring for 3-4 hours at a temperaturebeing 50-60 DEG C, thereby obtaining a green printing and dyeing aid finished product. The green printing and dyeing aid has the characteristics of being remarkable in uniform dyeing effect, high in color firmness, good in acid and alkaline resistance, good in hand feeling, not liable to fade, and free of stimulus on skin of a human body, has self-degrading ability, is safe, green and environmentally friendly in use.

Owner:江门市新会区德盈化工有限公司

High-comprehensive property environment-friendly type modified aqueous polyurethane preparation method

The invention provides a high-comprehensive property environment-friendly type modified aqueous polyurethane preparation method. The method comprises the following steps: 1) respectively preparing a polyester performed polymer and a polyalcohol performed polymer; 2) blending the materials to obtain a composite polyurethane performed polymer; 3) using a polysiloxane oligomer to modify the compositepolyurethane performed polymer to obtain organosilicon-modified polyurethane; 4) using a neutralizer for neutralizing the organosilicon-modified polyurethane; 5) dispersing an emulsion with deionizedwater to obtain the high-comprehensive property environment-friendly type modified aqueous polyurethane; and 6) performing vacuum-pumping to remove a solvent to obtain the product, wherein the operation is easy and large-scale production is easy. The method employs different performed polymers, the polyurethane performed polymer is modified through physical blending, the performed polymer and polysiloxane are subjected to addition polymerization and chain extension to prepare the organosilicon-modified polyurethane copolymer, the technical problem of poor compatibility of organosiloxane and polyurethane is overcome, and the comprehensive properties of the product are high.

Owner:四川方壹特建筑工程有限公司

Transparent flexible oxide ferroelectric memory

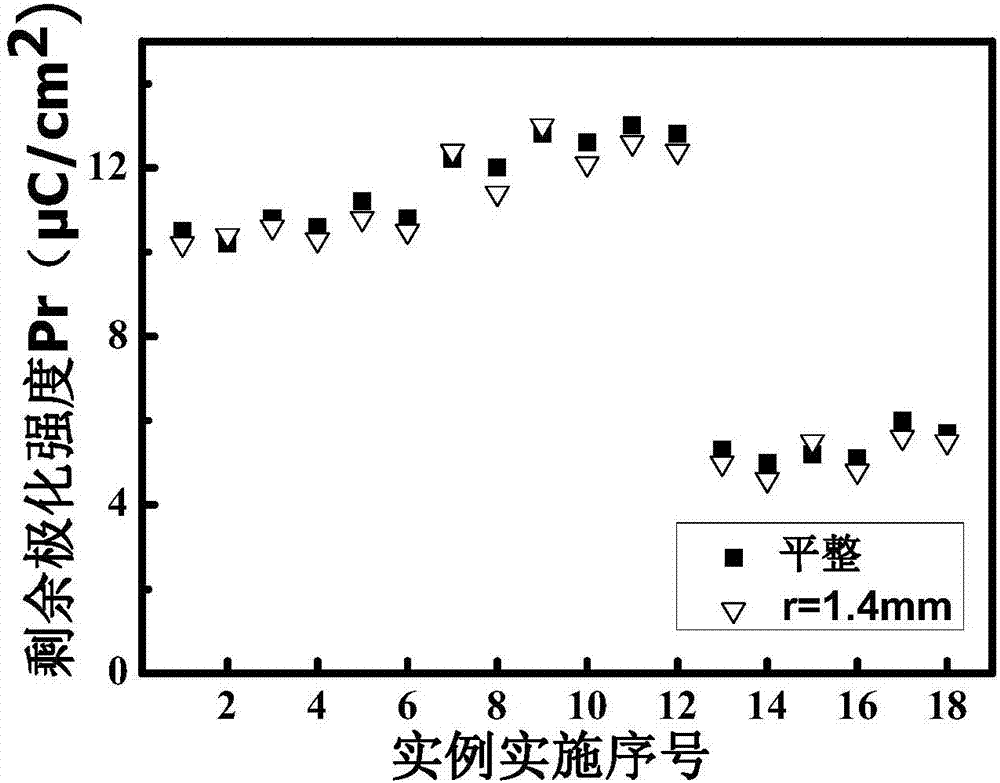

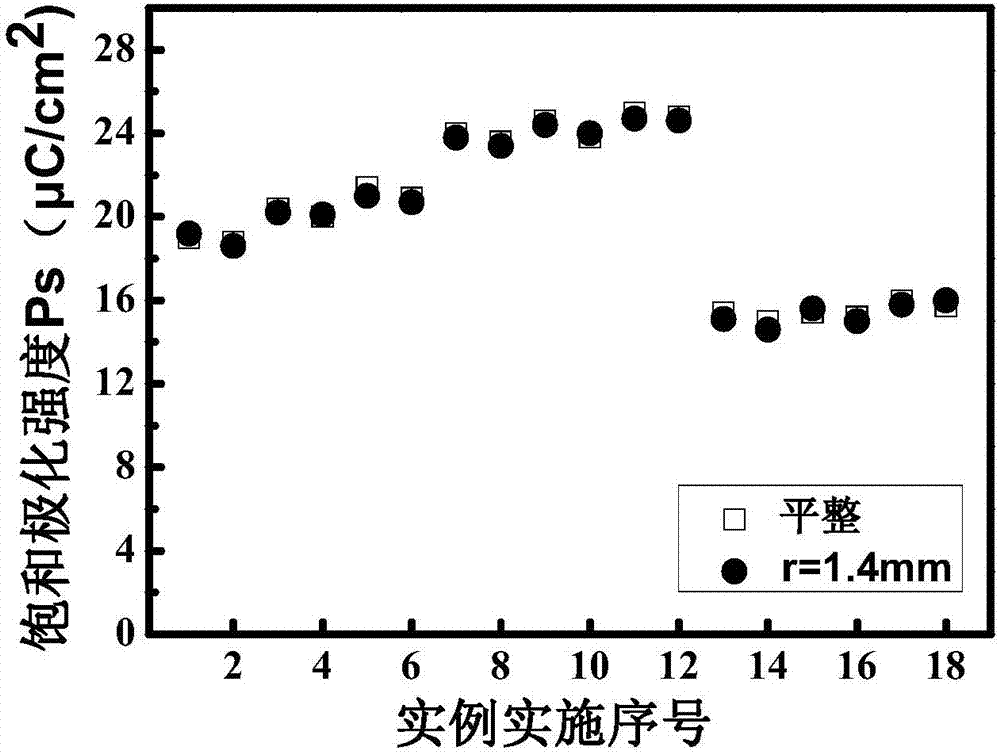

ActiveCN107221532AHigh light transmittanceImprove high temperature resistanceSolid-state devicesSemiconductor devicesTransmittanceTemperature resistance

The invention discloses a transparent flexible oxide ferroelectric memory. The transparent flexible oxide ferroelectric memory consists of a mica substrate, a ZnO-doped transparent electrode, an oxide ferroelectric film and an ITO transparent electrode which are connected in sequence. According to the ferroelectric memory disclosed by the invention, the stratified perovskite oxide ferroelectric film serves as a ferroelectric functional layer; the light-admitting quality of the ferroelectric memory is high, and the light transmittance of visual light with the wavelength of over 400 nm is more than 80%; the ferroelectric memory is flexible and resistant to bending, and when the bending radius is 1.4 mm, the saturated polarization intensity and remaining polarization intensity approach to numeral values in a smooth state; the high temperature resistance is high, and after 450-degree annealing, the saturated polarization intensity and remaining polarization intensity are free of obvious change; and the transparent flexible oxide ferroelectric memory has wide application prospects.

Owner:NANJING UNIV OF SCI & TECH

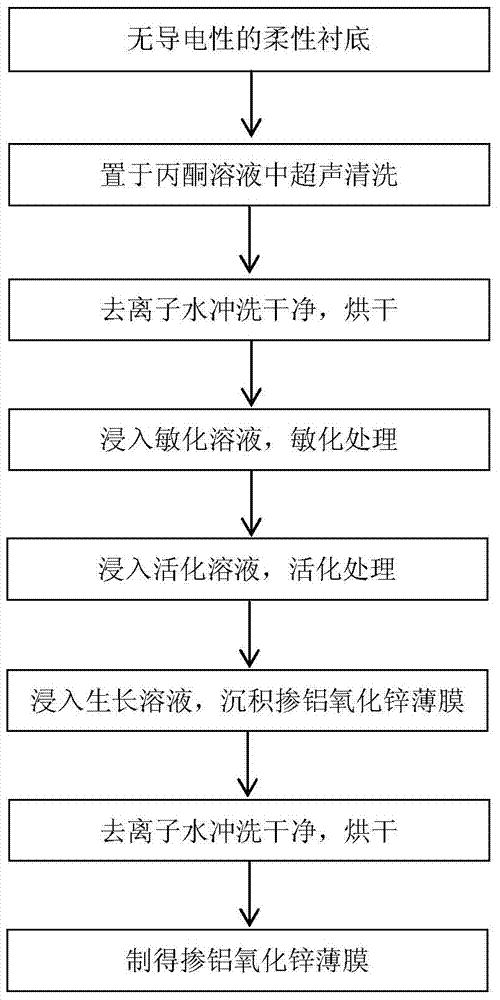

Method used for preparing aluminium-doped zinc oxide thin film via electroless deposition

ActiveCN104498916AOvercoming high temperature resistanceOvercome conductivityLiquid/solution decomposition chemical coatingElectroless depositionHigh pressure

The invention discloses a method used for preparing aluminium-doped zinc oxide thin film via electroless deposition. According to the method, a non-conducting flexible substrate is immersed into a sensitizing solution and an active solution respectively so as to realize surface activation of the non-conducting flexible substrate; the activated non-conducting flexible substrate is immersed into a growth solution containing Zn(NO3)2, Al(NO3)3, and dimethylamine-borane so as to realize deposition of the aluminium-doped zinc oxide thin film on the flexible substrate. The method is simple; equipment is simple; high temperature or high pressure environment is not needed; and the method is suitable for large scale industrial production, and can be widely used for photoelectric field.

Owner:GUANGXI UNIV

Preparation method for environment-friendly modified waterborne polyurethane

The invention provides a preparation method for environment-friendly modified waterborne polyurethane. The preparation method comprises the following steps: (1) separately preparing a polyester prepolymer and a polyalcohol prepolymer; (2) carrying out blending so as to obtain a composite polyurethane prepolymer; (3) modifying the composite polyurethane prepolymer with a polysiloxane oligomer so asto obtain organosilicon-modified polyurethane; (4) neutralizing the organosilicon-modified polyurethane with a neutralizer; (5) dispersing an emulsion with deionized water so as to obtain environment-friendly modified waterborne polyurethane with high comprehensive properties; and (6) removing solvents through vacuum-pumping so as to the product modified waterborne polyurethane. The preparation method is easy to operate and can easily realize large-scale production. According to the invention, different prepolymers are employed, and the polyurethane prepolymer is modified via physical blending and then subjected to addition polymerization and chain extension reaction with polysiloxane, so the technical problem of poor compatibility between organosiloxane and polyurethane is overcome, andthe product has high comprehensive properties.

Owner:何俊

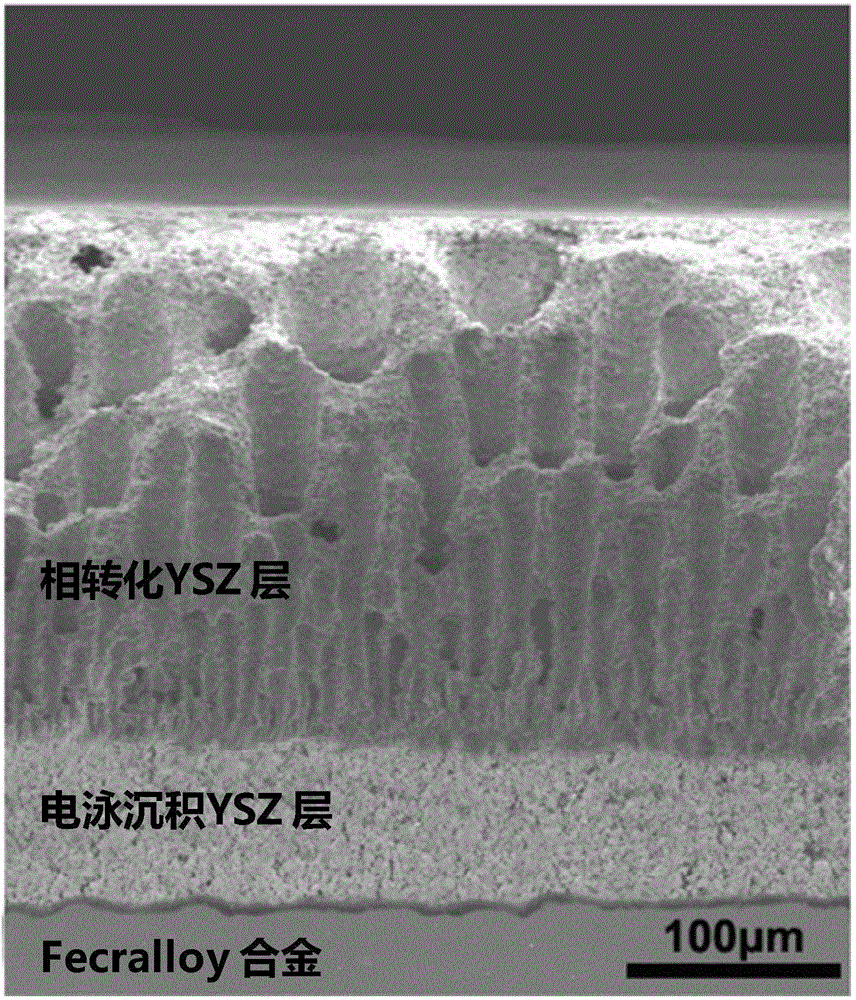

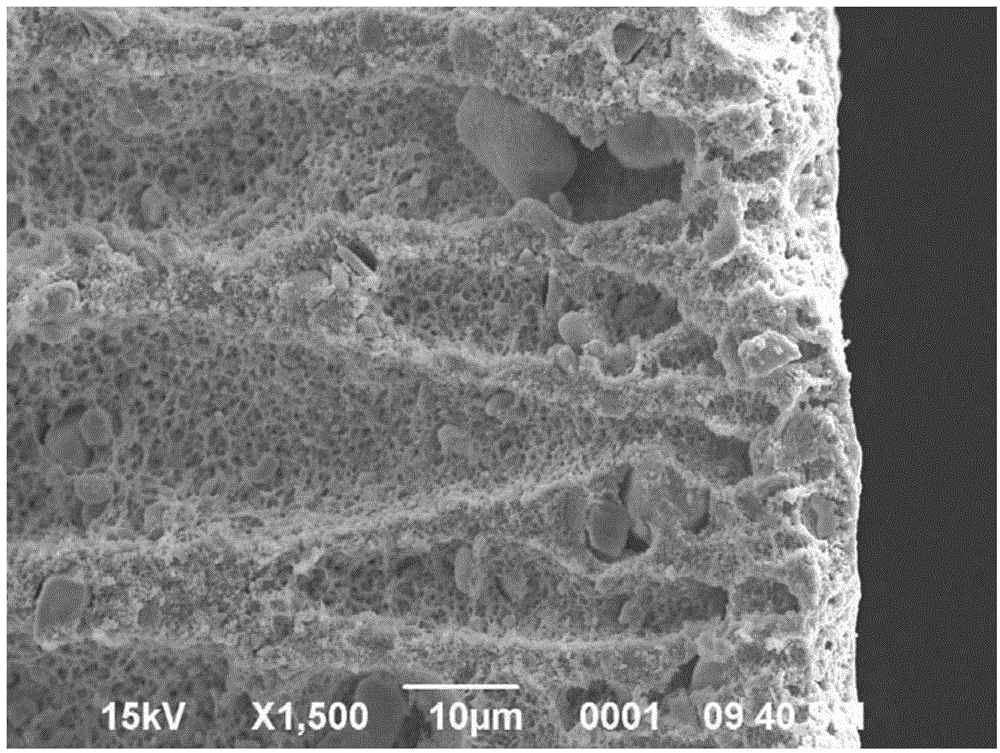

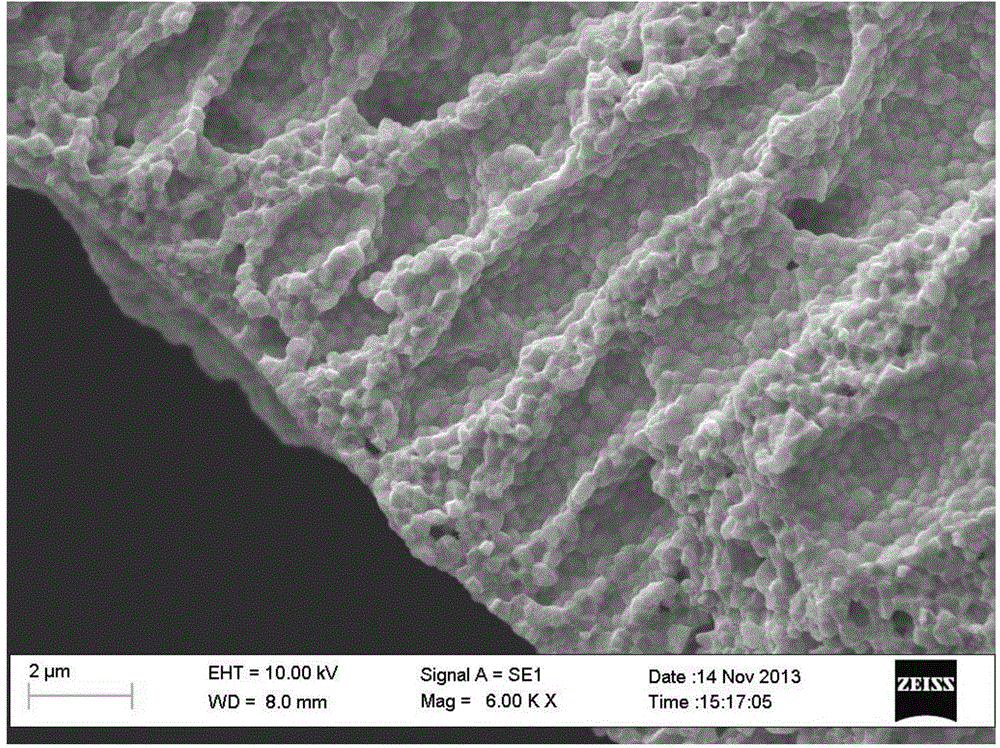

Preparation method for sintering resistant thermal barrier ceramic coating structure

InactiveCN104790013ABroad pore size distributionHigh temperature sintering abilityElectrophoretic coatingsArgon atmosphereCeramic coating

The invention relates to a preparation method for a sintering resistant thermal barrier ceramic coating structure. The method includes: preparation of electrophoretic deposition turbid liquid, preparation of an electrophoretic coating, preparation of a phase inversion coating slurry, preparation of a phase inversion coating, sintering and other steps. According to the nonsolvent-induced phase separation principle and impregnation method, a porous ceramic coating with an asymmetric structure is prepared on the surface of high temperature alloy, the coating is sintered under air and argon atmosphere in two steps in the coating sintering, and a thermal barrier coating with an asymmetric structure is obtained. Compared with the prior art, the thermal barrier coating prepared by the method provided by the invention has the characteristics of simple process, stable microstructure, good sintering resistance and good thermal shock resistance, the method can prepare coatings on complex shape and asymmetric geometric surfaces, and is easy for mass industrial production. Compared with the prior art, the invention has a lot of advantages.

Owner:SHANGHAI JIAO TONG UNIV +1

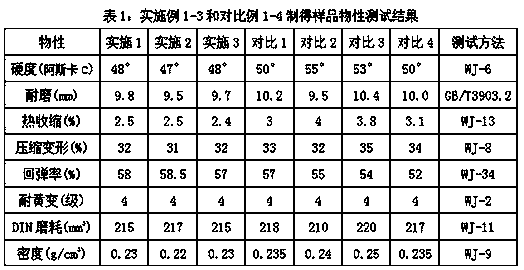

Anti-shrinkage modified EVA foam shoe material and preparation method thereof

InactiveCN109021375AGuaranteed stabilityReduce the value of the residual stressFootwearCross-linkFoaming agent

The invention relates to an anti-shrinkage modified EVA foam shoe material. The material comprises 40-43 parts of Formosa Plastics 7470, 5-6 parts of Formosa Plastics 7350, 6-8 pieces of Taiju 3312, 7-8 parts of Dow 3745, 10-12 an anti-shrinkage agent 203#, 1-1.5 parts of zinc oxide, 6-8 parts of an anti-wear agent, 2-3 parts of a filler, 0.3-0.5 part of an activator, 0.6-0.7 part of a cross-linking agent, 2-2.5 parts of a foaming agent and 3-4 parts of titanium dioxide. High-melting point and low-melt strength components are selected, so the product maintains molecular stability during use, the strain force required by the shrinkage deformation of the product is improved, the material has a low melt strength when the melting point of the material is reached in the production process of the product, the resistance to volume expansion is reduced, and the residual stress of the product after molding is reduced, thereby the shrinkage tendency is reduced, and the problem of heat shrinkagedeformation of the finished product is solved while ensuring "light, flexible, soft and elastic" basic characteristics.

Owner:林伟坤

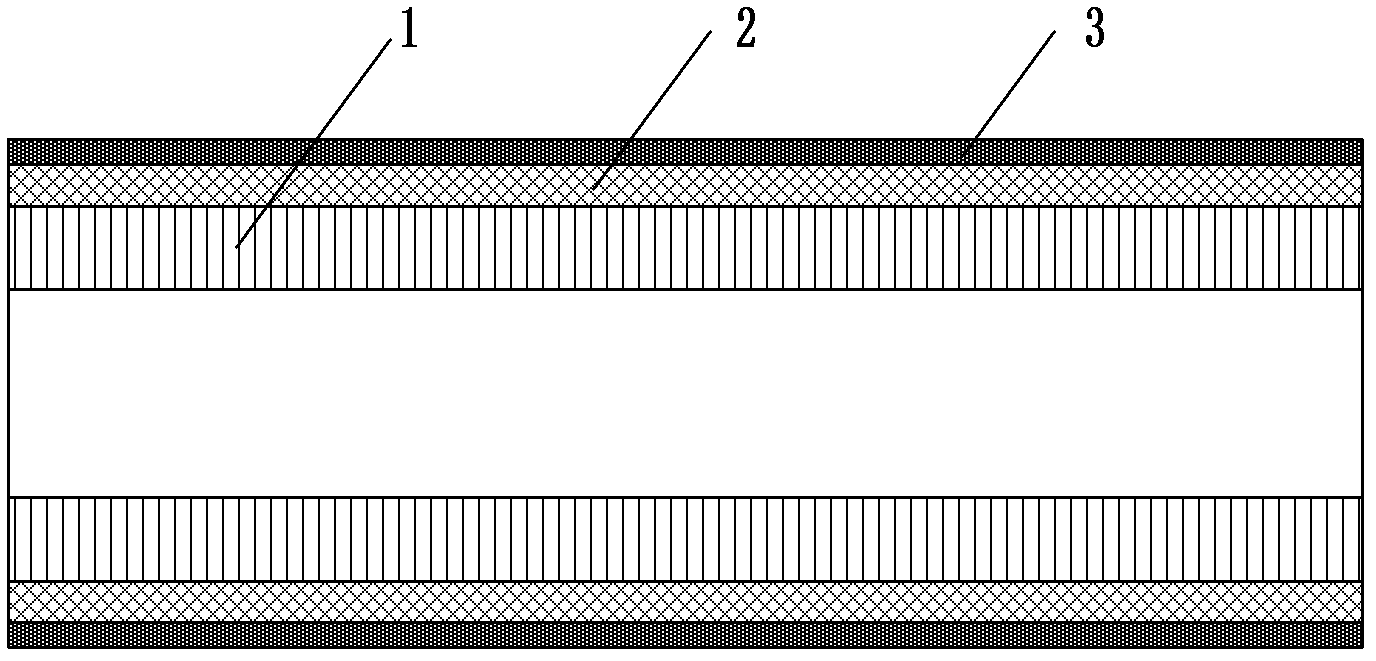

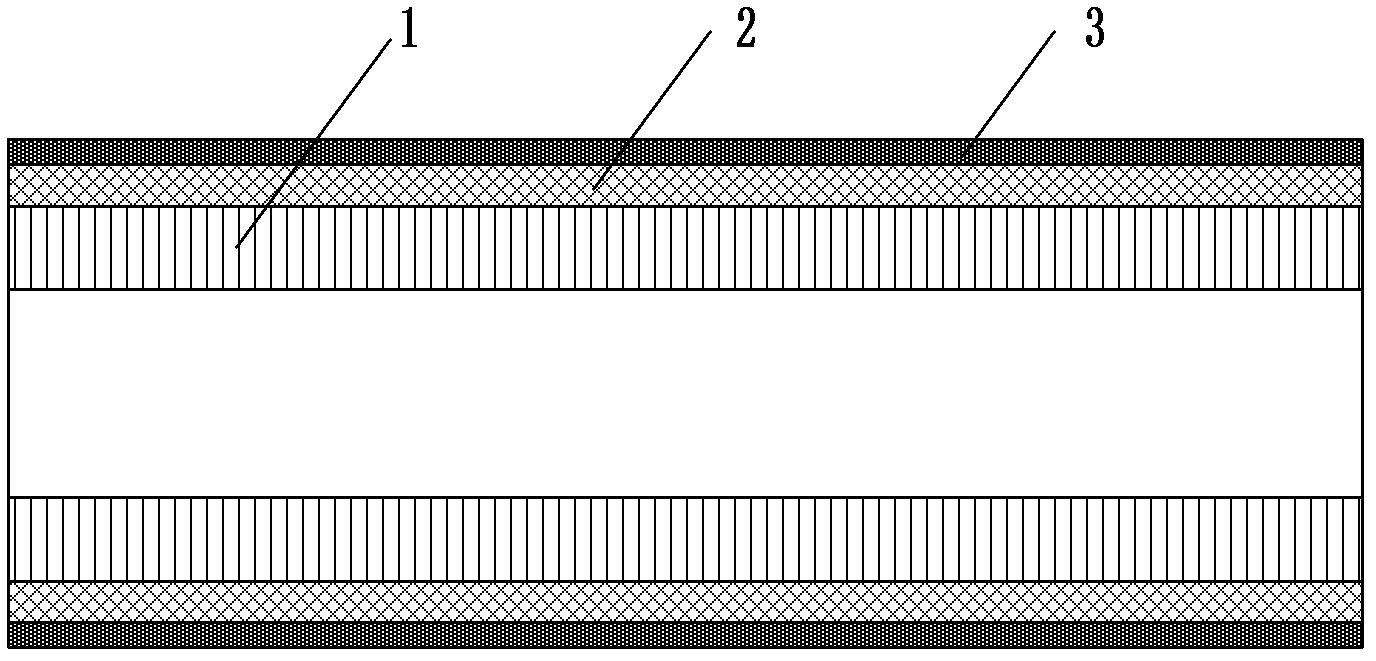

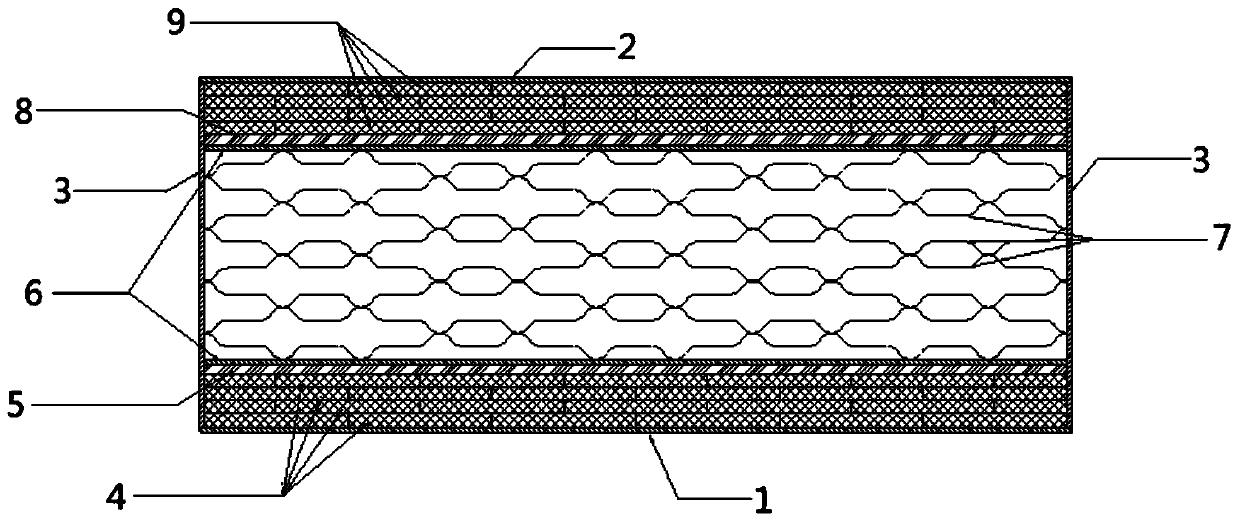

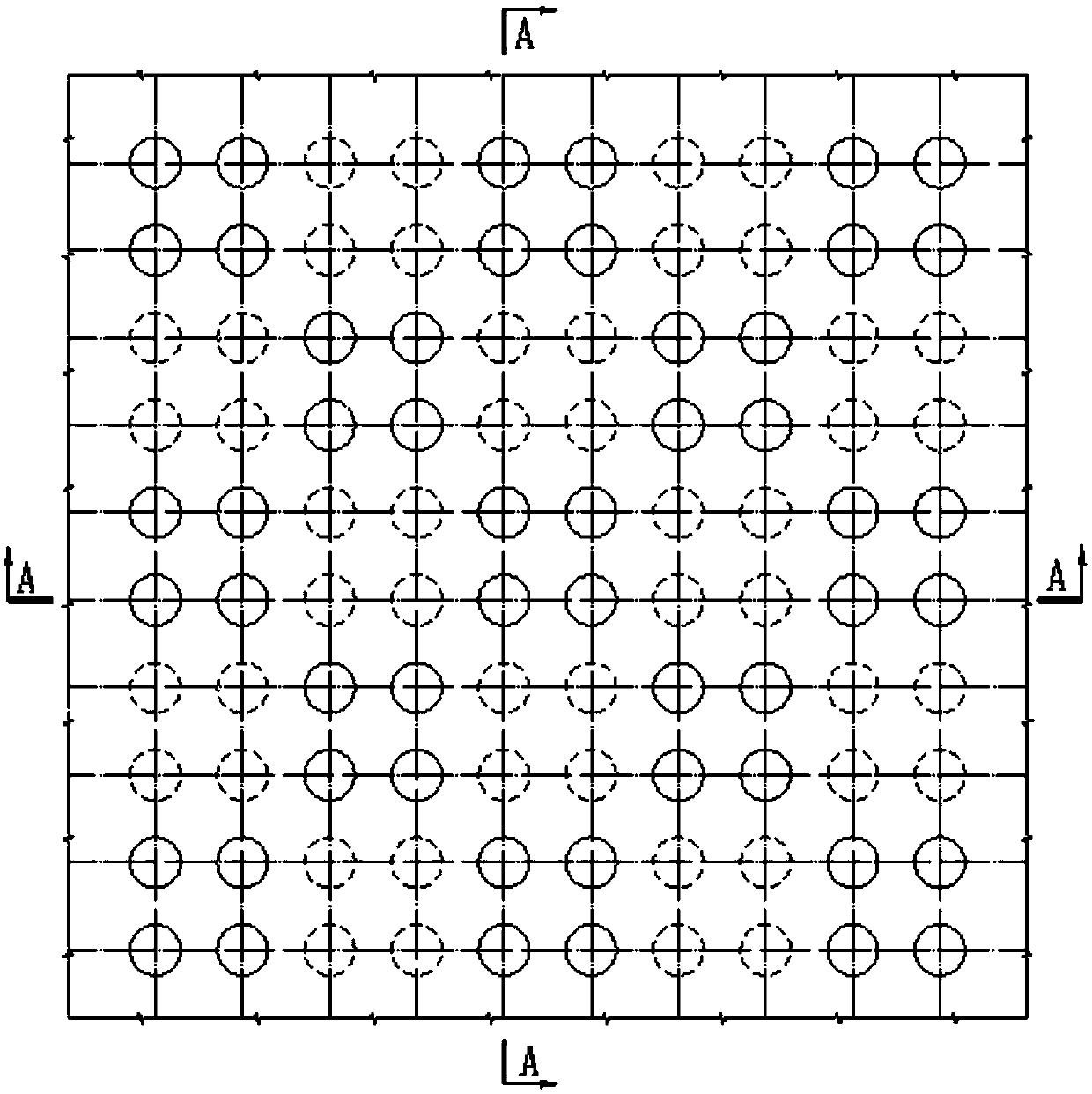

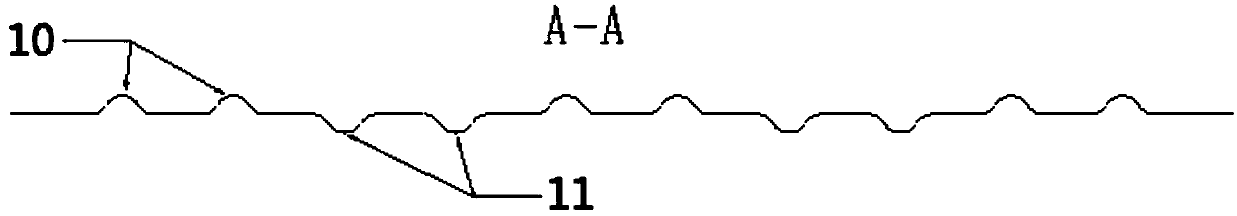

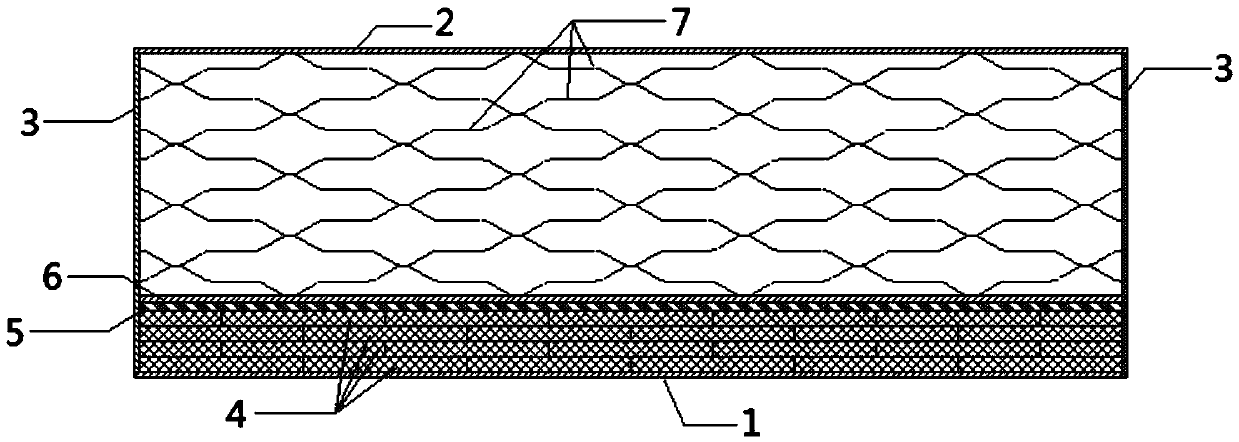

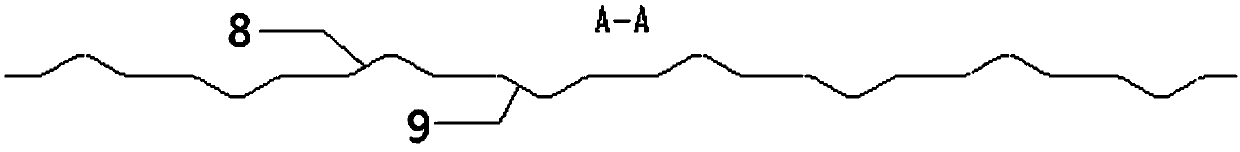

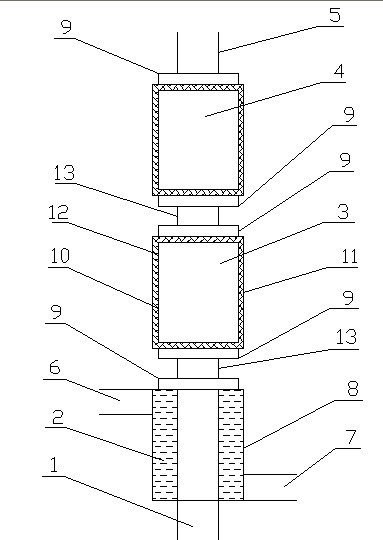

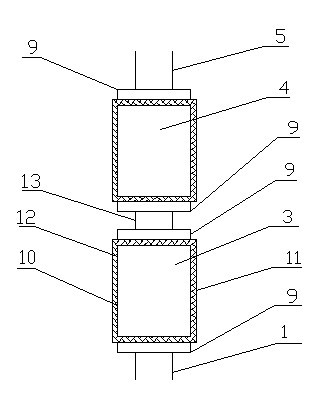

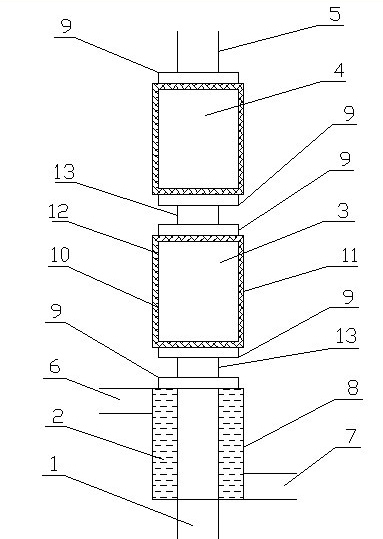

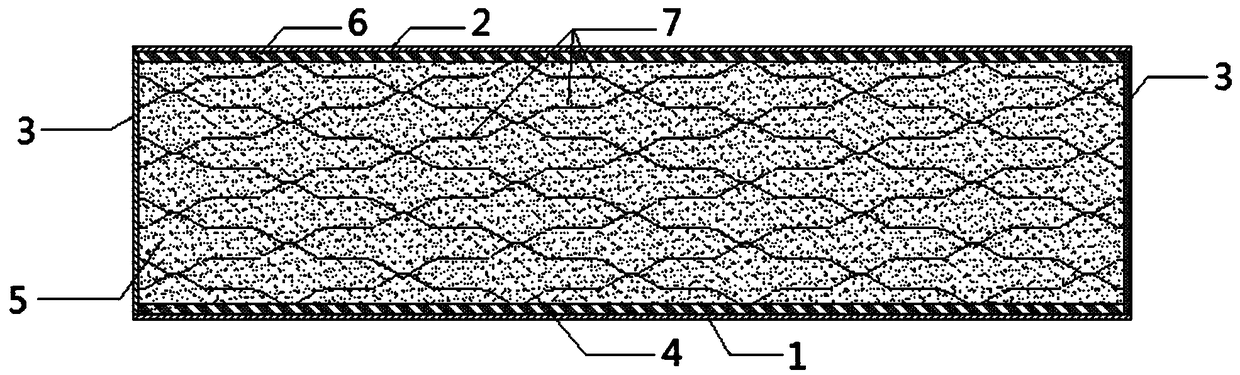

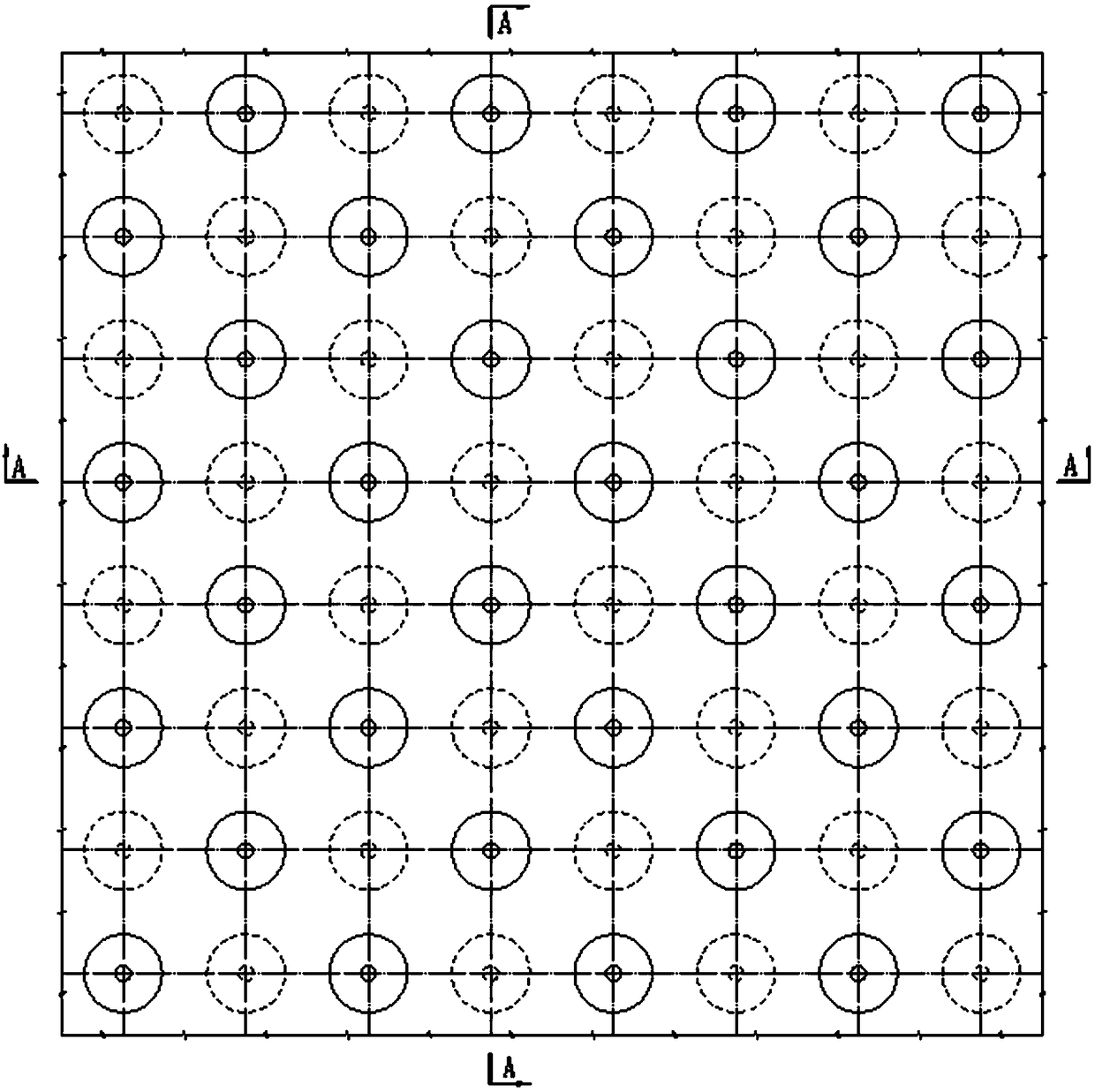

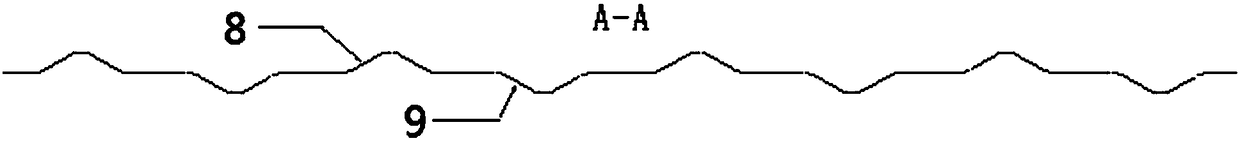

Composite metal heat-preservation layer filled with shielding materials at two sides

ActiveCN109616226AGood thermal insulation functionAdded radiation shielding functionThermal insulationNuclear energy generationMetal foilRadiation shield

The invention discloses a composite metal heat-preservation layer filled with shielding materials at two sides. The composite metal heat-preservation layer comprises a heat preservation outer box, andinner-side neutron shielding layers, outer-side neutron shielding layers, reflecting metal foil sheets, an inner-side gamma shielding layer and an outer-side gamma shielding layer which fill the heatpreservation outer box, wherein the neutron shielding layers and the gamma shielding layers are inorganic shielding materials with metal characteristics; the filling sequence on the thickness sectionof the heat preservation layer is as the follows in sequence: an inner shell plate of the heat preservation outer box, the inner-side neutron shielding layer, the inner-side gamma shielding layer, the metal reflection foil sheets, the outer-side gamma shielding layer, the outer-side neutron shielding layer and an outer shell plate of the heat preservation outer box; and the metal reflection foilsheets are in a corrugated shape of forward-reverse double ball sockets which are vertically and horizontally arranged at regular intervals, or a regularly changed forward-reverse triangular corrugated shape or a chocolate corrugated shape, wherein two adjacent layers of the metal reflection foil sheets are stacked in a back-to-back staggered mode that the top point of one forward ball socket faces the top point of one corresponding reverse ball socket. The invention provides the composite metal heat-preservation layer with a heat-preservation and heat-insulation function and a radiation shielding function, and the composite metal heat-preservation layer can be used in a high-temperature radiation environment for a long time without needing of replacement.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

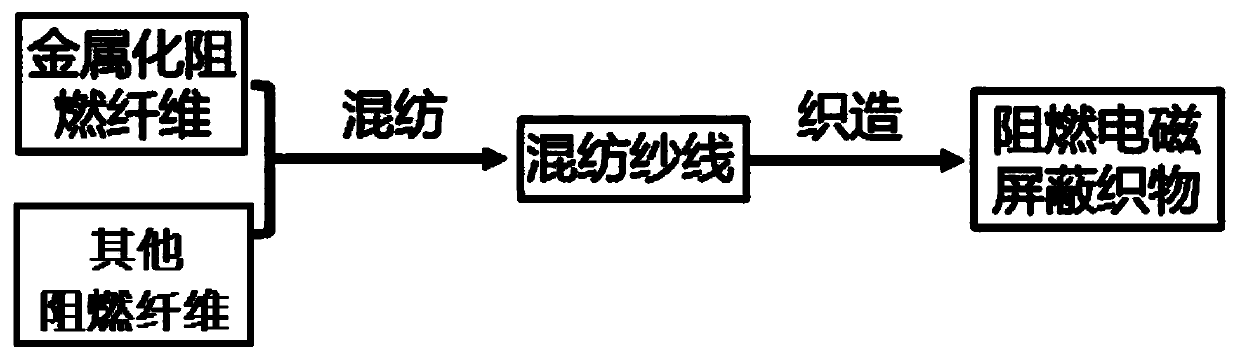

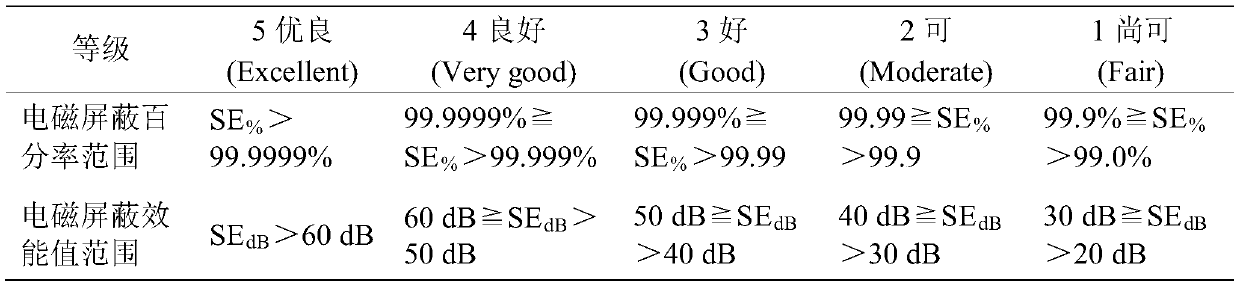

Flame-retardant electromagnetic shielding fabric and preparation method thereof

InactiveCN111364148AImprove spinnabilityGood flexibilityWeft knittingFibre typesEngineeringMetal fibers

The invention discloses a flame-retardant electromagnetic shielding fabric and a preparation method thereof, and belongs to the technical field of textile materials for electromagnetic protection andpreparation methods thereof. The metalized flame-retardant fiber with good spinnability and flexibility and other flame-retardant fibers are blended and woven to obtain an electromagnetic shielding fabric which is based on the full-flame-retardant fiber and has good high-temperature flame-retardant performance, excellent electromagnetic shielding effect and good wearing comfort at the same time. The fabric and the preparation method overcome the inherent defects that a metal fiber blended fabric is limited in shielding effectiveness and poor in comfort, and a common metallized organic fiber blended fabric is not resistant to high temperature and poor in flame retardance; and the prepared flame-retardant electromagnetic shielding fabric can be used for meeting the electromagnetic protectionrequirements of occasions with higher requirements on electromagnetic shielding, high-temperature flame retardance and wearing comfort, such as radar workstations, naval vessels, airplane cockpits, medical treatment, electric power, mines, petrochemical engineering and the like.

Owner:苏州耐科泰斯纺织新材料有限公司

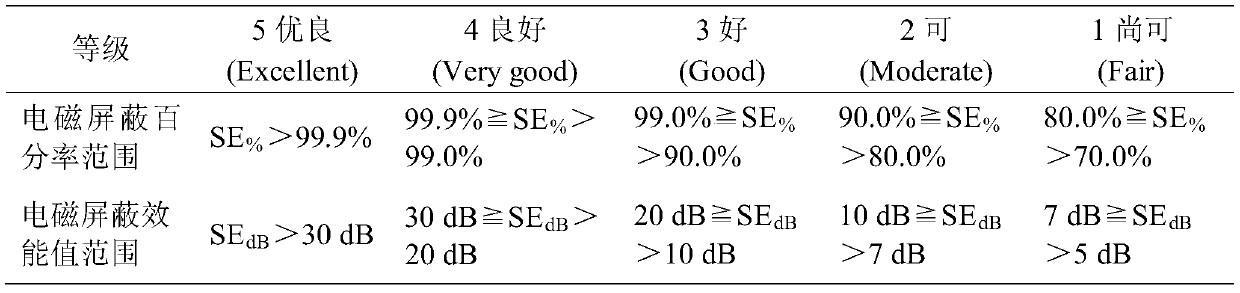

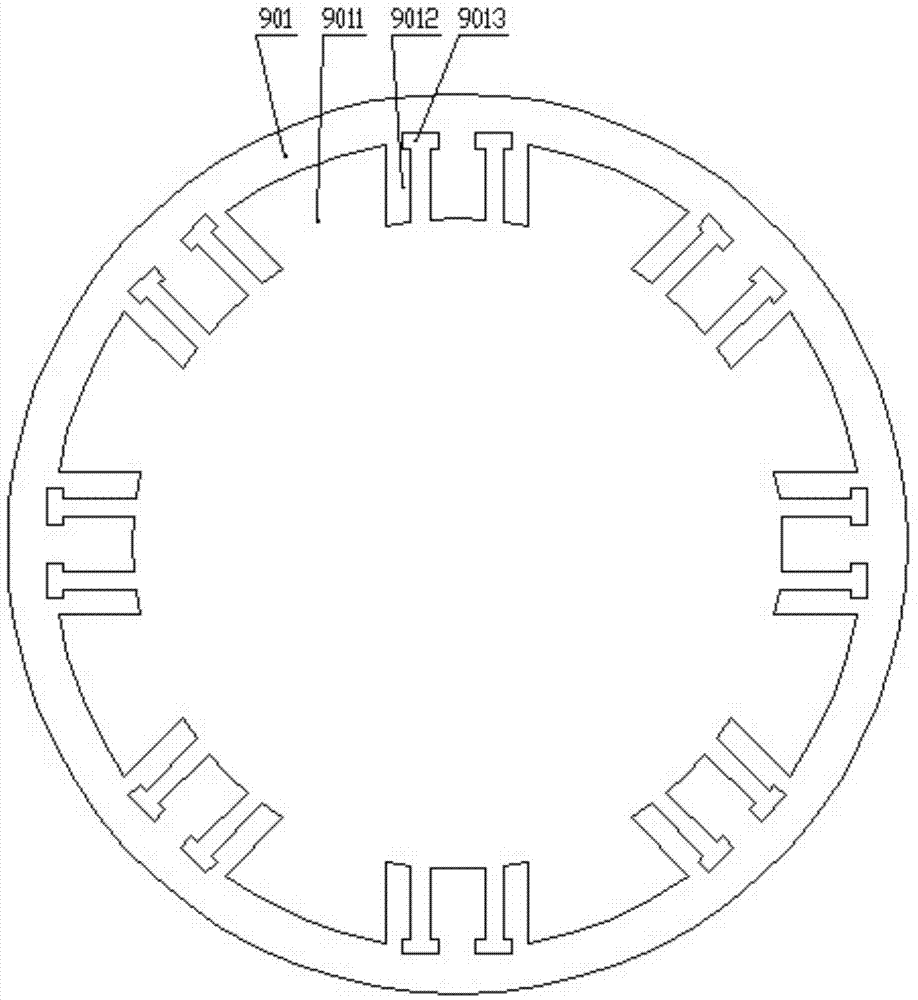

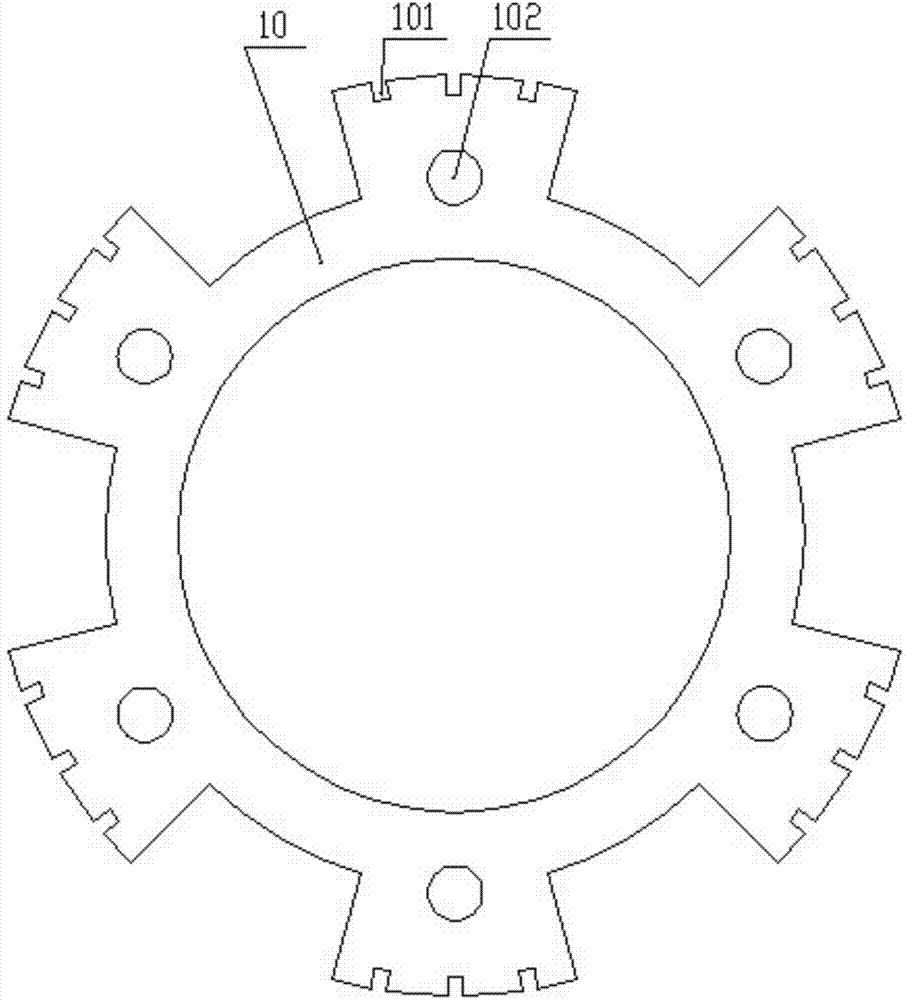

Hybrid excitation switched reluctance motor and stator structure thereof

InactiveCN104753280AImprove reliabilityLow reliabilitySynchronous motorsMagnetic circuit stationary partsLow noiseElectric machine

The invention discloses a stator structure of a hybrid excitation switched reluctance motor. The stator structure comprises a salient stator core provided with stator slots and stator teeth and a plurality of armature windings. Each stator tooth is provided with a permanent magnet slot in which a permanent magnet is fixed. One electrical excitation winding is disposed between every two adjacent stator teeth; each electrical excitation winding crosses in electrical excitation winding slots of every two adjacent stator teeth. The invention further discloses the hybrid excitation switched reluctance motor comprising the stator structure and a salient rotor core. The outer periphery of each rotor tooth of the salient rotor core is provided with a small slot. The stator structure allows the hybrid excitation switched reluctance motor to features high power density, high operating efficiency, high reliability, operational stability, low noise and wide range of operating speed, is especially suitable for the field of wind power and allows the development of the motor techniques in the field of wind power to be greatly promoted.

Owner:BEIJING GENERATOR MECHANICAL & ELECTRICAL TECH

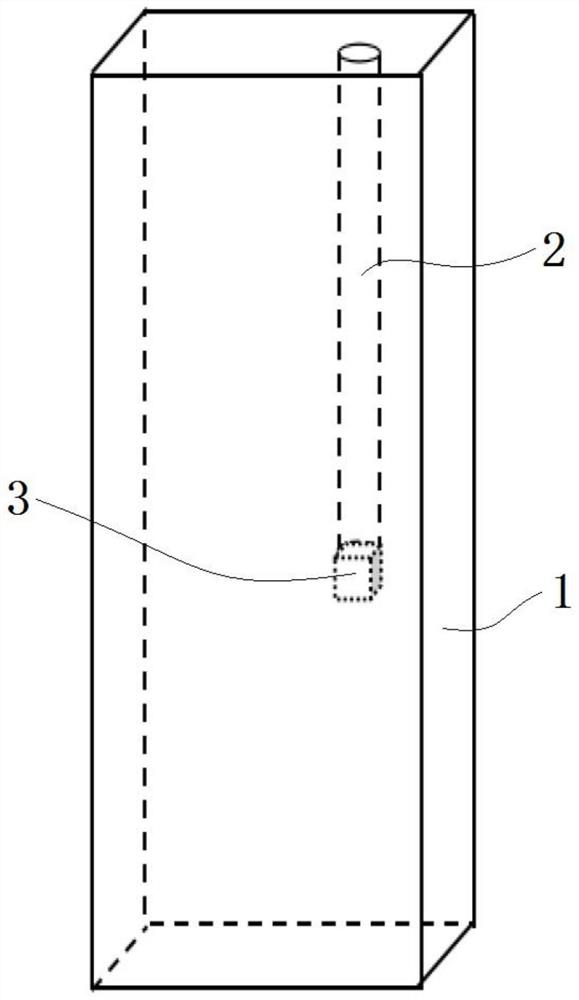

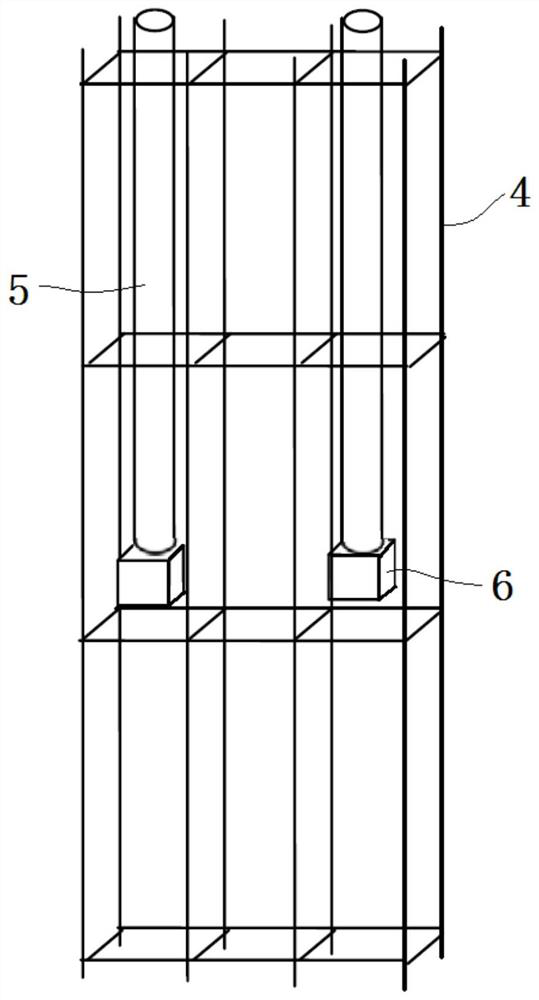

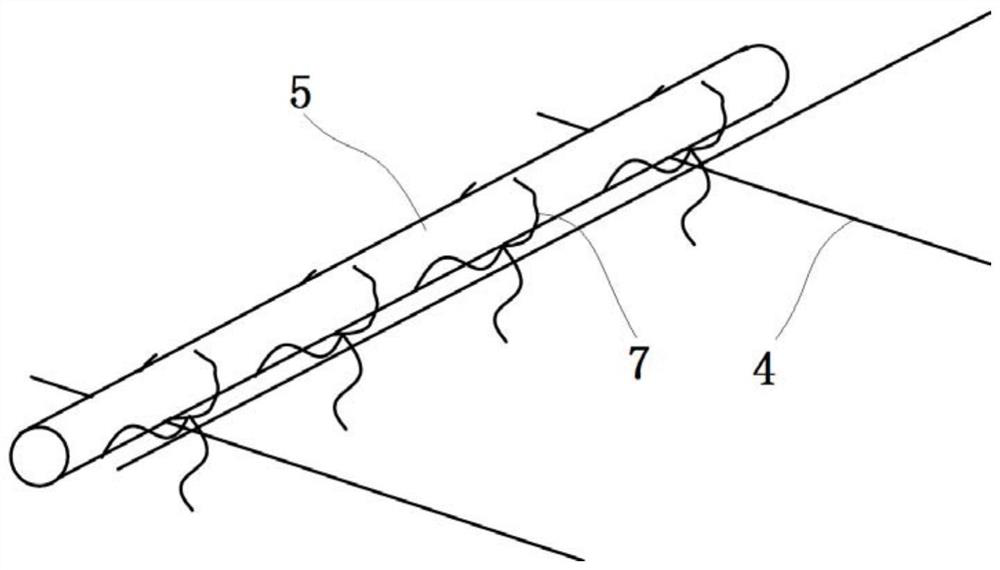

Absorption type ALC (Autoclaved Lightweight Concrete) wallboard pipeline integrated production method

The invention discloses an absorption type ALC (Autoclaved Lightweight Concrete) wallboard pipeline integrated production method. According to the absorption type ALC wallboard pipeline integrated production method, a rod-shaped loose body and a block-shaped loose body are fixed to a reinforcement cage to form an embedded line pipe structure, and the rod-shaped loose body and the block-shaped loose body are connected together; and the rod-shaped loose body and the block-shaped loose body are prepared by foaming a material with the melting point of 60 DEG C to 200 DEG C. The manufacturing costis low, and the performance of the ALC wallboard is not affected.

Owner:范潇淏

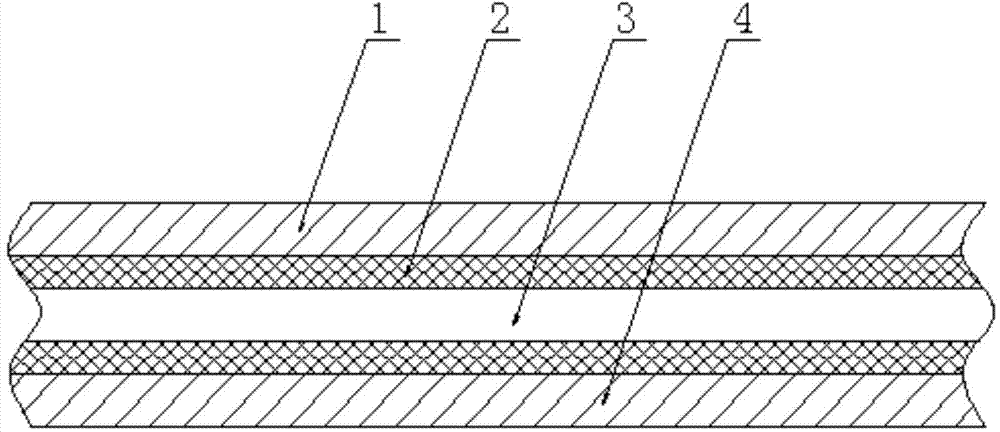

Novel conveying belt

InactiveCN104118155AOvercoming high temperature resistanceOvercome longevityConveyorsLayered productsEngineeringTemperature resistance

The invention discloses a novel conveying belt. The novel conveying belt consists of an upper-cover rubber layer, a lower-cover rubber layer, fabric layers and middle rubber layers, wherein multiple fabric layers and middle rubber layers are alternatively composited between the upper-cover rubber layer and the lower-cover rubber layer. The novel conveying belt disclosed by the invention has the advantages that the technical difficulties of poor high-temperature resistance, short service life and large self weight of the traditional conveying belt are overcome; due to adoption of the upper-cover rubber layer and the lower-cover rubber layer compounded and formed by multiple high-temperature-resistant materials, and under the normal-use condition of the conveying belt below 180 DEG C, the elongation deformation is small, and the abrasion resistance is excellent. The middle rubber layers play a role in improving the bonding strength of the fabric layers with the upper-cover rubber layer and the lower-cover rubber layer and isolating from the heat, and can resist high temperature of 500 DEG C in short time.

Owner:天津市渤海胶带有限公司

Nuclear-grade equipment and single-side shielding material filling insulation layer for pipelines

ActiveCN109595428AGood thermal insulation functionAdded radiation shielding functionThermal insulationNuclear energy generationNuclear gradeInsulation layer

The invention discloses nuclear-grade equipment and a single-side shielding material filling insulation layer for pipelines. A insulation outer box, a neutron shielding layer, a gamma shielding layerand metal reflective foils are included, the neutron shielding layer, the gamma shielding layer and the metal reflective foils are contained inside the insulation outer box, and the neutron shieldinglayer and the gamma shielding layer are both made of an inorganic shielding material with metallic properties; the sequence of filling in the thickness section of the insulation layer is an inner shell plate of the insulation outer box, the neutron shielding layer, the gamma shielding layer, the metal reflective foils and an outer shell plate of the insulation outer box; and the metal reflective foils are in shapes of waves of positive and negative circular cone bosses regularly arranged vertically and horizontally at intervals, and every two adjacent layers of the metal reflective foils are stacked in a back staggered manner with the peak of one positive and negative circular cone boss abutting against the peak of the other positive and negative circular cone boss. The composite metal insulation layer with the insulation and heat isolation functions and the screen radiation shielding function is provided, the insulation layer can be used in a high temperature radiation environment fora long time without replacement, and the requirements of nuclear grade equipment and the insulation layer for the pipelines are met

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Tail gas dust collector for basalt fibers

InactiveCN102626578AHigh temperature resistantAnti-acid and anti-alkaliCombination devicesEngineeringWater jacket

The invention discloses a tail gas dust collector for basalt fibers, which comprises an admission pipe, a cooling device, a first dust collection module, a second dust collection module, an escape pipe, a water jacket, a water inlet pipe and a water outlet pipe, wherein the water jacket is arranged in the cooling device, and the water inlet pipe and the water outlet pipe are connected with the cooling device. The tail gas dust collector for the basalt fibers also comprises connecting pipes and a flange, wherein the connecting pipes are respectively connected between the cooling device and the first dust collection module and between the first dust collection module and the second dust collection module. According to the tail gas dust collector for the basalt fibers, by adopting the high temperature-resistant basalt fibers and a grade dust collection mode, fine particles in tail gas can be effectively removed, and thereby, the effect of purifying the tail gas and improving the air quality is achieved.

Owner:苏州企航新能源有限公司

Lithium ion battery and anode piece

InactiveCN102610821AHigh resistivityIncrease Positive PolarizationSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrical batteryLithium-ion battery

The invention belongs to the technical field of lithium ion batteries and particularly relates to an anode piece of a lithium ion battery. The anode piece comprises an anode current collector and an anode diaphragm coated on the anode current collector; the anode diaphragm comprises an anode active substance, a bonding agent and a conductive additive; the anode diaphragm further comprises a positive temperature coefficient material which is (VmR1-m)2)3, wherein R is at least one of Cr, Ba, Al, In, Ga, Sr and Pb, and m is not smaller than 0.5 and not more than 1; and the positive temperature coefficient material accounts for 4.5-30% relative to the total weight of the anode diaphragm. According to the invention, because the anode piece comprises the positive temperature coefficient material, the impedance of the anode diaphragm increases at high temperature to result in the increase of anode polarization, in a charging process, anode potential decreases, corresponding anode oxidation capacity decreases therewith, and thus, the high-temperature cycle performance of the lithium ion battery is increased. In addition, the invention further discloses a lithium ion battery comprising the anode piece.

Owner:NINGDE AMPEREX TECH +1

Rubber for truck bumper

InactiveCN104672645AOvercoming high temperature resistanceOvercome agingBumpersButyl chlorideTemperature resistance

The invention discloses rubber for a truck bumper. The rubber comprises the following components in parts by weight: 80 parts of chlorosulfonated polyethylene, 52 parts of acrylonitrile-butadiene rubber, 8-19 parts of fast extruding carbon black, 10-15 parts of pyrolysis carbon black, 2-4 parts of indirect zinc oxide, 1-8 parts of magnesium oxide, 0.2-1 part of diethyl aminodithioformic acid, 0.4-1.5 part of thiodipropionic acid biglycerol trilaurate, 0.5-1 part of zinc stearate, 2-4 parts of 2,2'-dithiobisbenzothiazole, 0.3-0.5 part of trithiocyanuric acid, 5-8 parts of trioctyl trimellitate, 1-5 parts of magnetism strong powder, 2-3 parts of sulphur and 1-3 parts of butyl chloride. According to the rubber for the trunk bumper, the defects of poor high-temperature resistance performance, easy aging, short service life and the like in the prior art can be overcome, and the advantages of high high-temperature performance, difficulty in aging and long service life are realized.

Owner:南京中配橡塑制品有限公司

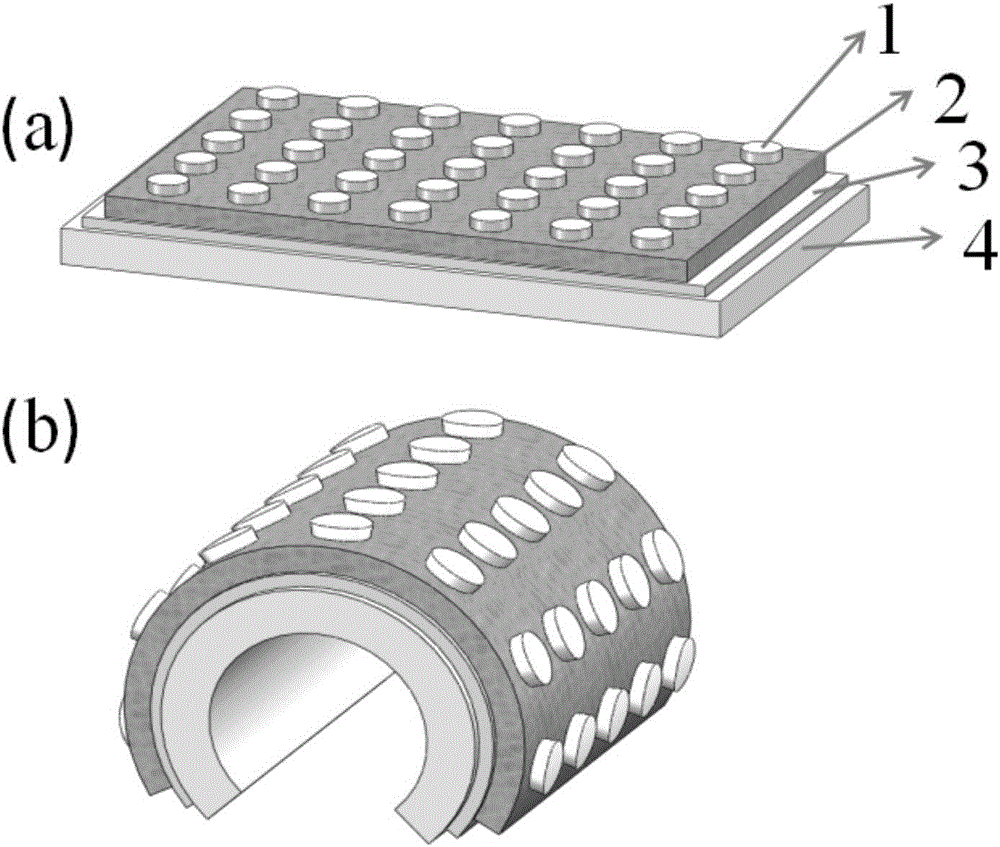

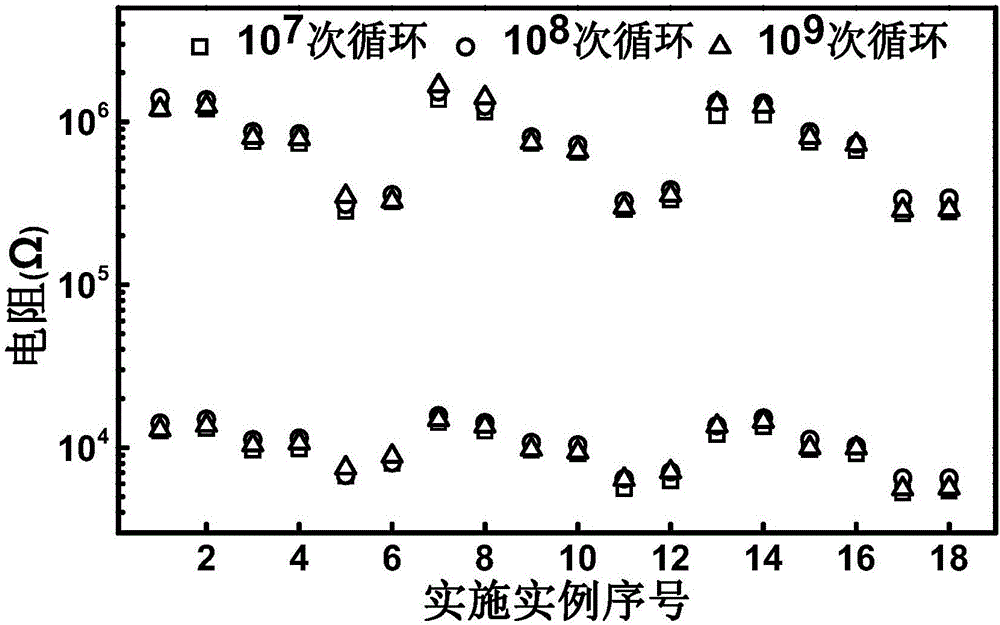

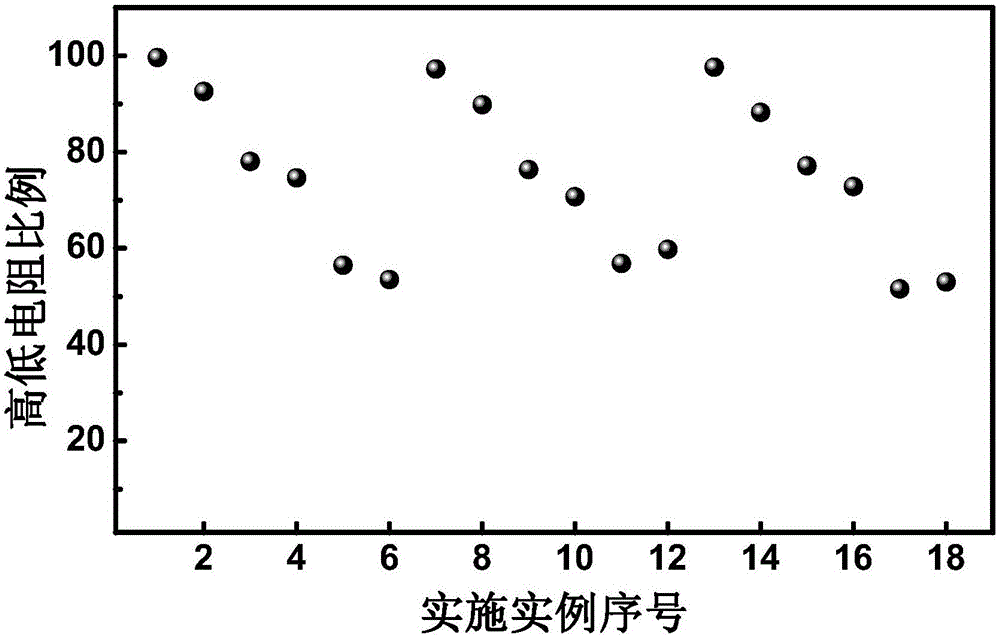

Flexible high-temperature resistant BaTi<1-x>Co<x>O3 resistive random access memory

ActiveCN106654008AOvercoming high temperature resistanceOvercoming poor resistive performanceElectrical apparatusFlexible electronicsTemperature resistance

The invention discloses a flexible high-temperature resistant BaTi<1-x>Co<x>O3 resistive random access memory. The structure of the flexible high-temperature resistant BaTi<1-x>Co<x>O3 resistive random access memory is as follows: a bottom electrode is arranged on a substrate; a BaTi<1-x>Co<x>O3 resistance-change functional layer is arranged on the bottom electrode, wherein x is 0.05-0.3; a top electrode is arranged on the functional layer; and the substrate is flexible mica. The flexible high-temperature resistant resistive random access memory has excellent resistance-change property and good flexible bending property, and can resist bending for 106 times when the bending radius is 1mm; the resistance-change property does not obviously change; the heat temperature resistance is excellent; good resistance-change property can be kept after annealing at 500 DEG C; and the flexible high-temperature resistant BaTi<1-x>Co<x>O3 resistive random access memory has a good application prospect in the field of a flexible memory and a flexible electronic device.

Owner:NANJING UNIV OF SCI & TECH

Rubber for electric automobile

The invention discloses a rubber for an electric automobile. The rubber for the electric automobile is composed of the components in parts by weight as follows: 67 parts of chlorosulfonated polyethylene, 36 parts of nitrile rubber, 1 part of fast extruding furnace black, 23 parts of thermal carbon black, 2-4 parts of indirect zinc oxide, 3-5 parts of magnesium oxide, 0.2-1 part of zinc diethyl dithiocarbamaate, 0.4-1.5 parts of glucosinolates two double laurel propionate, 0.5-1 part of zinc stearate, 2-4 parts of 2,2'-disulfbenzothiazole, 0.3-0.5 part of trithiocyanuric acid, 5-8 parts of trioctyl trimellitate, 1-5 parts of heat stabisizer, 2-3 parts of sulphur and 1-3 parts of butyl IIR. By adopt the rubber for the electric automobile, the defects in the prior art that the resistance to high temperature is poor, the rubber is easy to age and the service life is short can be overcome, so that the advantages that the resistance to high temperature is good, the rubber is not easily aged and the service life is long can be achieved.

Owner:南京中配橡塑制品有限公司

Waste-ceramic-based electric power insulator sintered brick and production technique thereof

The invention discloses a waste-ceramic-based electric power insulator sintered brick which is prepared from the following raw materials in percentage by mass: 5-10% of cement, 10-20% of iron ore tailing slag, 10-60% of ceramic electric power insulator particle, 5-10% of ceramic electric power insulator powder, 1-3% of curing agent and the balance of water. The production technique comprises the following steps: material selection and proportioning, casting, vibrational compaction, sintering for dehydration, and cooling. The production technique can effectively classify and recover various waste ceramic insulators, and converts the waste ceramic insulators into main raw materials of building bricks, thereby greatly enhancing the recovery rate and recovery value of the waste ceramic insulators, effectively avoiding waste of resources, lowering the operating cost for electric power line construction, and overcoming the defects of low load-bearing capacity, loose structure, high tendency to damage, poor high-temperature resistance, poor heat-insulating property and poor electric insulation property in the traditional slag brick.

Owner:STATE GRID CORP OF CHINA +1

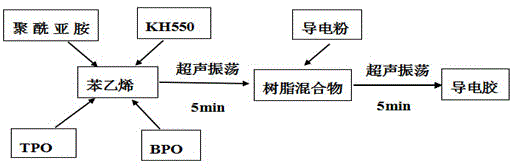

Conductive ceramic powder-based polyimide conductive rubber and preparation method thereof

InactiveCN104371587AStable mechanical propertiesImprove electrical performanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEpoxyBenzoyl peroxide

The invention discloses conductive ceramic powder-based polyimide conductive rubber and a preparation method thereof. The conductive rubber comprises the following components in parts by weight: 100 parts of polyimide as resin matrix, 40-50 parts of conductive ceramic powder as conductive packing, 30-40 parts of styrene as a diluent, 2-5 parts of a silane coupling agent KH550 as a coupling agent, 8-10 parts of triethanolamine as a heat curing agent, 2-4 parts of TPO (theroplastic polyolefin) as a photoinitiator, 2-4 parts of BPO (benzoyl peroxide) as a thermal initiator, 2-4 parts of 2-ethyl-4-methylimidazole as a curing accelerator, and 1-2 parts of polyethylene glycol 400 as a conductive promoter; and the solidifying mode is heat solidification at a medium temperature. The polyimide conductive rubber obtained by the method is excellent in stability and heat resistance; and the defects that epoxy resin conductive rubber is poor in stability and high-temperature resistance can be overcome.

Owner:HARBIN INST OF TECH

Synthetic rubber for high-speed tire

InactiveCN104672646AOvercoming high temperature resistanceOvercome agingSpecial tyresPolymer scienceAcrylonitrile

The invention discloses synthetic rubber for a high-speed tire. The synthetic rubber comprises the following components in parts by weight: 67 parts of chlorosulfonated polyethylene, 39 parts of butadiene-acrylonitrile rubber, 13 parts of fast extruding furnace black, 20 parts of heat-cracking soot, 2-4 parts of indirect-process zinc oxide, 3-5 parts of magnesium oxide, 0.2-1 part of zinc diethyl dithiocarbamate, 0.4-1.5 parts of dilauryl thiodipropionate, 0.5-1 part of zinc stearate, 2-4 parts of 2,2'-dithiobenzothiazole, 0.3-0.5 part of trimerization thiocyanic acid, 5-8 parts of trioctyl trimellate, 1-5 parts of strong magnesium powder, 2-3 parts of sulfur and 2-3 parts of isoamyl IR. According to the synthetic rubber for high-speed tire disclosed by the invention, the defects such as low high-temperature resistance, aging simplicity and short service life in the prior art can be overcome, so that the advantages of high high-temperature resistance, aging difficulty and long service life are realized.

Owner:南京中配橡塑制品有限公司

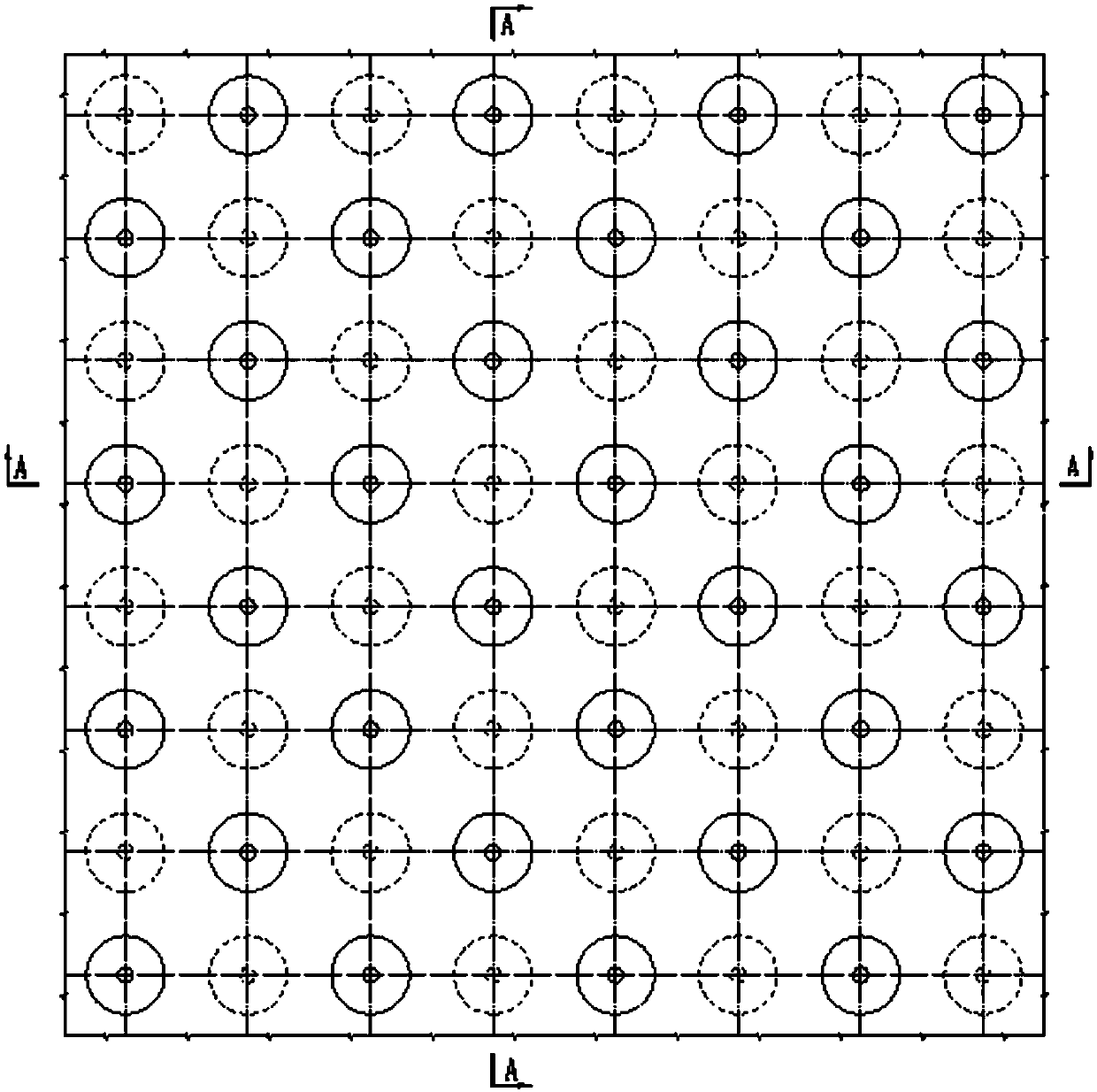

Diffusively filled composite insulating layer for nuclear class equipment and pipelines

ActiveCN109296869AGood thermal insulation functionAdded radiation shielding functionThermal insulationShieldingWave shapeBoron carbide

The invention discloses a diffusively filled composite insulating layer for nuclear class equipment and pipelines. The diffusively filled composite insulating layer for nuclear class equipment and pipelines comprises an insulating outer box, inside and outside gamma shielding layers filling the insulating outer box, boron carbide powder and metal reflective foils. The inside and outside gamma shielding layers are made from an inorganic shielding material with metal characteristics; the filling sequence on the thickness section of the insulting layer is as follows: an inner shell plate of the insulating outer box, the inside gamma shielding layer, the metal reflective foils, the outer gamma shielding layer and an outer shell plate of the insulating outer box, and the boron carbide powder isuniformly diffused in a cavity between two adjacent metal reflective foils; the metal reflective foils are of forward and backward cone bump wave shapes which are regularly arranged in a spaced manner vertically and transversely, and the two adjacent metal reflective foils are stacked in a backward staggered manner as the vertexes of the forward and backward cone bumps are opposite. The inventionprovides the compound metal insulating layer which not only has an insulating and heat-isolating function, but also has a radiation shielding function, and the compound metal insulating layer can serve in a high-temperature radiation environment for a long time without being replaced.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Carp spring viraemia oral vaccine capable of being added into feed

InactiveCN110747219AOvercoming high temperature resistanceOvercome the disadvantages that cannot be added to the feedSsRNA viruses negative-senseViral antigen ingredientsDiseaseSpore

The invention discloses a carp spring viraemia oral vaccine capable of being added into feed. G protein of a carp spring viraemia virus is displayed on the spore surface by a spore surface display technology, spores of recombinant bacteria are obtained by enrichment culture and spore induction, and a solid recombinant vaccine is prepared by freeze drying. The vaccine disclosed by the invention canbe directly fed by being added into feed to avoid or reduce the outbreak of the spring viraemia disease of carps, and has a relatively good immunoprophylaxis effect on the spring viraemia of the carps.

Owner:ZHEJIANG INST OF FRESH WATER FISHERIES

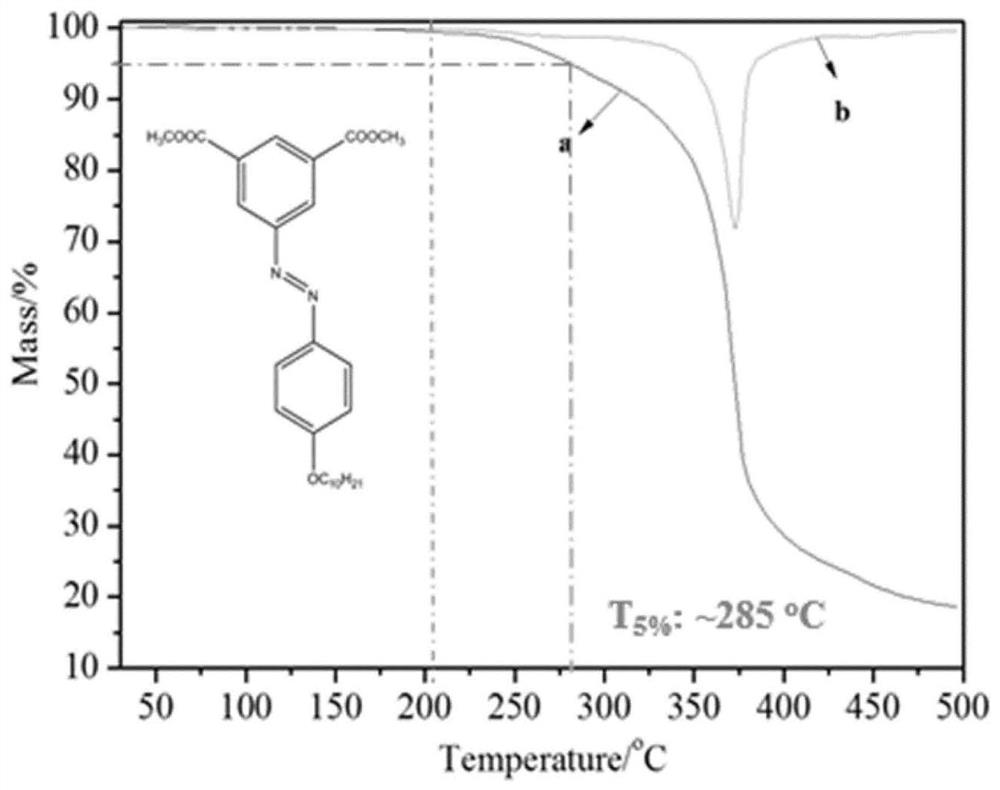

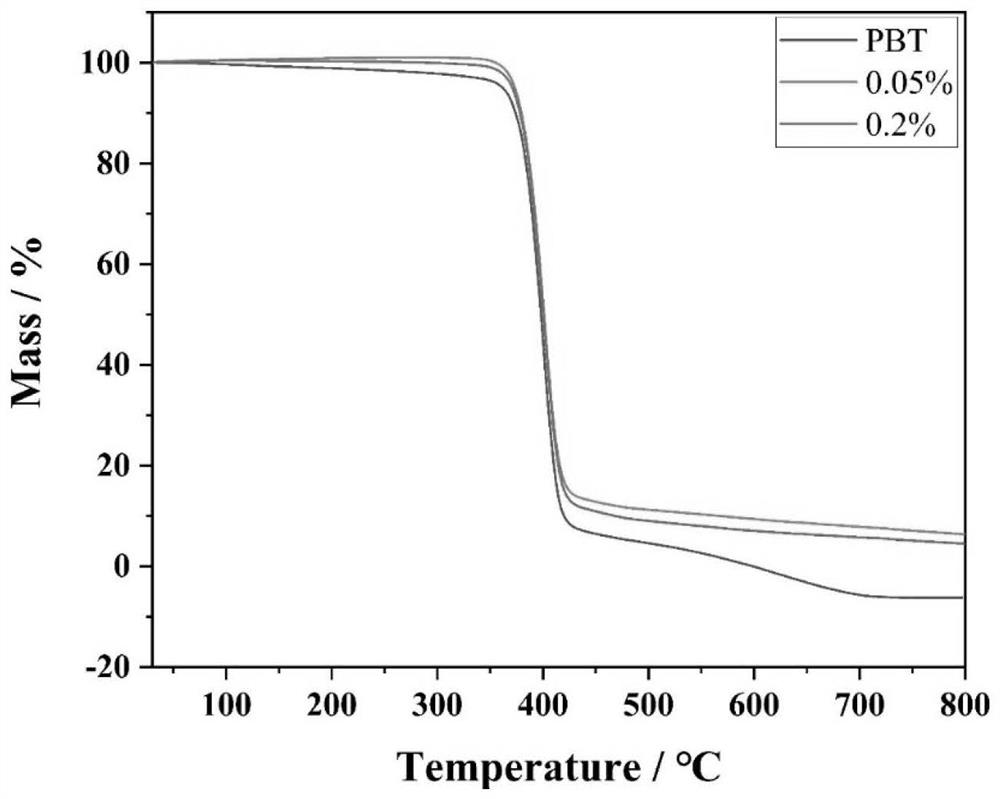

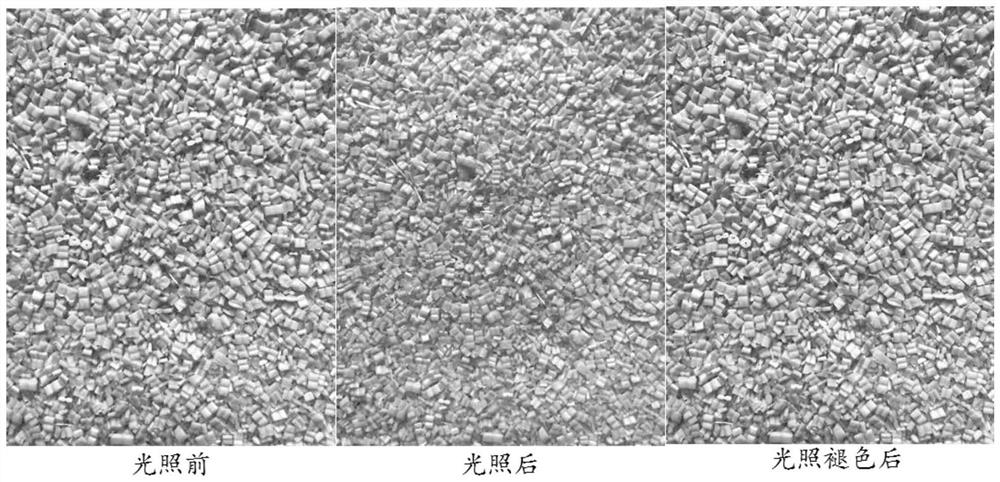

Photochromic azobenzene polyester, preparation method thereof and photochromic polyester fibers

ActiveCN112480381AImprove high temperature resistanceOvercoming high temperature resistanceMonocomponent copolyesters artificial filamentPolyesterDimethyl terephthalate

The invention aims to provide photochromic azobenzene polyester, a preparation method thereof and photochromic polyester fibers. The photochromic azobenzene polyester comprises one or more of a polyester chain segment and an azobenzene chain segment or an azobenzene derivative chain segment, one benzene ring structure in the azobenzene chain segment or the azobenzene derivative chain segment is ona main chain of the photochromic azobenzene polyester, and the other benzene ring structure or the benzene ring derivative structure is on a side chain. Ester exchange is carried out on azobenzene orderivatives thereof, dimethyl terephthalate and dihydric alcohol to obtain the photochromic azobenzene polyester. The azobenzene structure is embedded into a polyester molecular chain, so that the polyester has a photochromic function and also has good melt spinning performance, the polyester fiber obtained by melt spinning the azobenzene structure has good mechanical properties and the photochromic function, and the photosensitive durability is remarkably improved.

Owner:WUHAN TEXTILE UNIV

Automotive lightweight rubber-plastic material

InactiveCN104610599AOvercoming high temperature resistanceOvercome agingPlastic materialsMaterials science

The invention discloses an automotive lightweight rubber-plastic material. The automotive lightweight rubber-plastic material comprises the following components in parts by weight: 32 parts of chlorosulfonated polyethylene, 50 parts of nitrile rubber, 1-8 parts of fast extruding furnace black, 6-13 parts of thermal carbon black, 2-4 parts of indirect zinc oxide, 3-5 parts of magnesium oxide, 0.2-1 part of zinc diethyl dithiocarbamaate, 0.4-1.5 parts of dilauryl thiodipropionate, 0.5-1 part of zinc stearate, 2-4 parts of 2,2'-disulfbenzothiazole, 0.3-0.5 part of trithiocyanuric acid, 5-8 parts of trioctyl trimellitate, 1-5 parts of reinforcement magnesium powder, 2-3 parts of sulphur and 2-4 parts of butyronitrile NBR. The automotive lightweight rubber-plastic material can be used for overcoming the defects of low high-temperature resistance, large possibility of ageing and short service life in the prior art, thereby exerting the advantages of high high-temperature resistance, small possibility of ageing and long service life.

Owner:南京中配橡塑制品有限公司

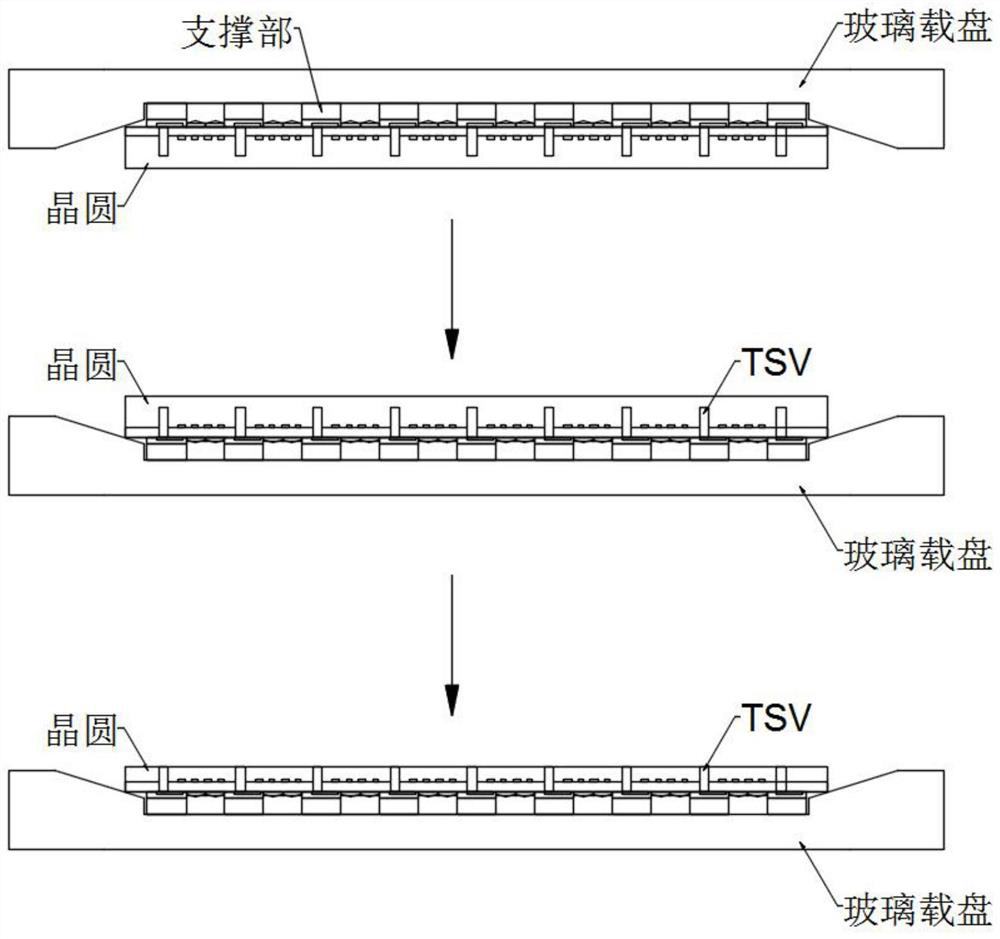

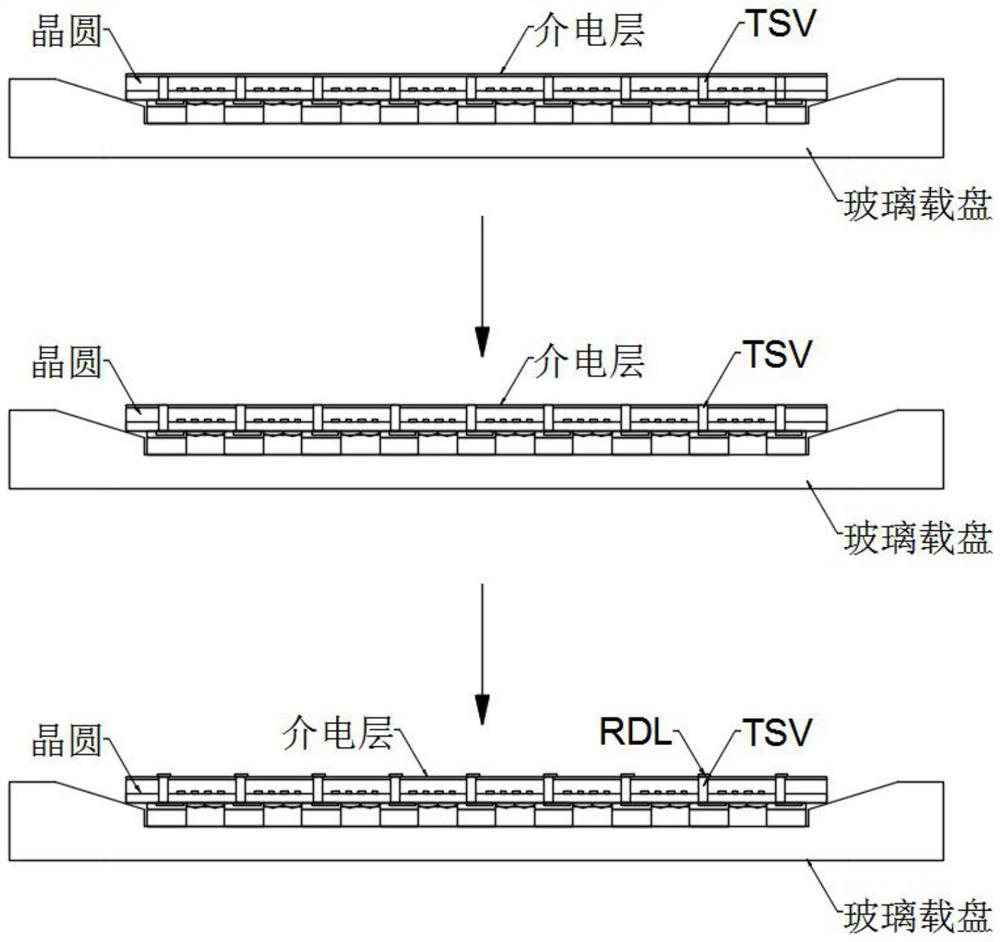

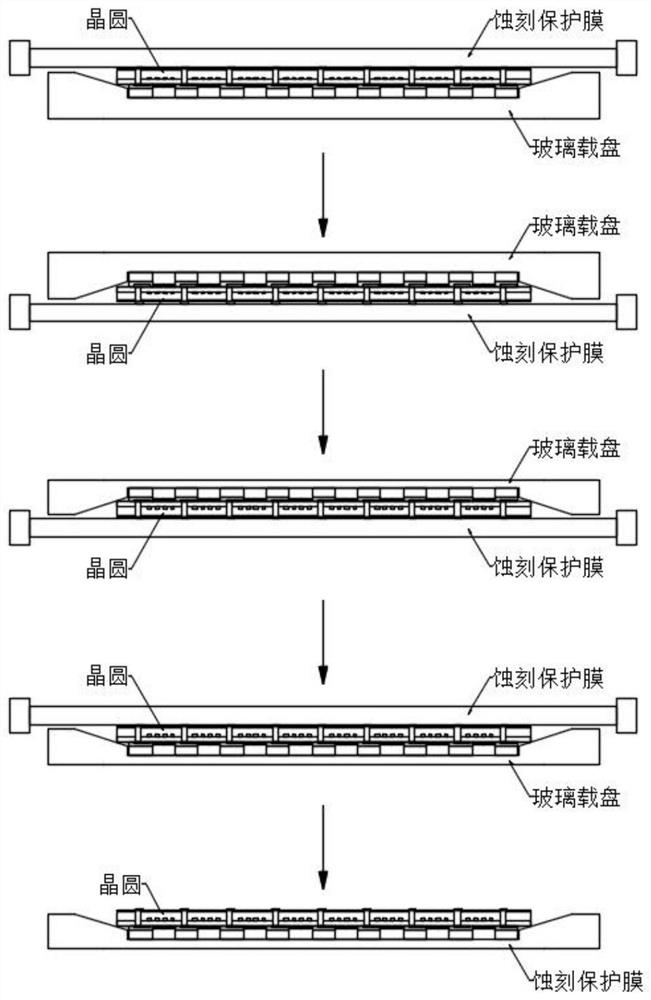

Method for processing CIS (Contact Image Sensor) wafer by utilizing grid type glass carrier plate

PendingCN114361193AOvercoming high temperature resistanceOvercoming craftRadiation controlled devicesContact image sensorChemical plating

The invention discloses a method for processing a CIS wafer by using a grid-type glass carrier plate, and the method comprises the following steps: S1, bonding the front surface of the wafer with the grid-type glass carrier plate, and carrying out the thinning of the back surface of the wafer until a TSV is exposed; s2, depositing a dielectric layer on the back surface of the wafer, and then forming a redistribution line (RDL) and a welding spot through chemical plating; s3, attaching an etching protection film to the back surface of the wafer, thinning the whole glass carrying disc, and then tearing and lifting the etching protection film; s4, performing chemical plating on the surface of the RDL to form a pre-welding layer, and then welding a metal column; and S5, cutting to remove the edges of the wafer and the glass carrier plate to obtain the processed CIS wafer. According to the invention, a polymer bonding block between a glass cover and a wafer in the traditional CIS process is replaced by the grid-type glass carrier plate supporting part, so that the process limitation that the glass carrier plate is not resistant to high temperature and cannot be soaked in acid for a long time is overcome, and meanwhile, after the glass carrier plate is thinned, the edge of the carrier plate and the supporting part still have certain thickness; therefore, stress support during thinning of the back of the wafer is met.

Owner:绍兴同芯成集成电路有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com