Patents

Literature

167 results about "Trithiocyanuric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

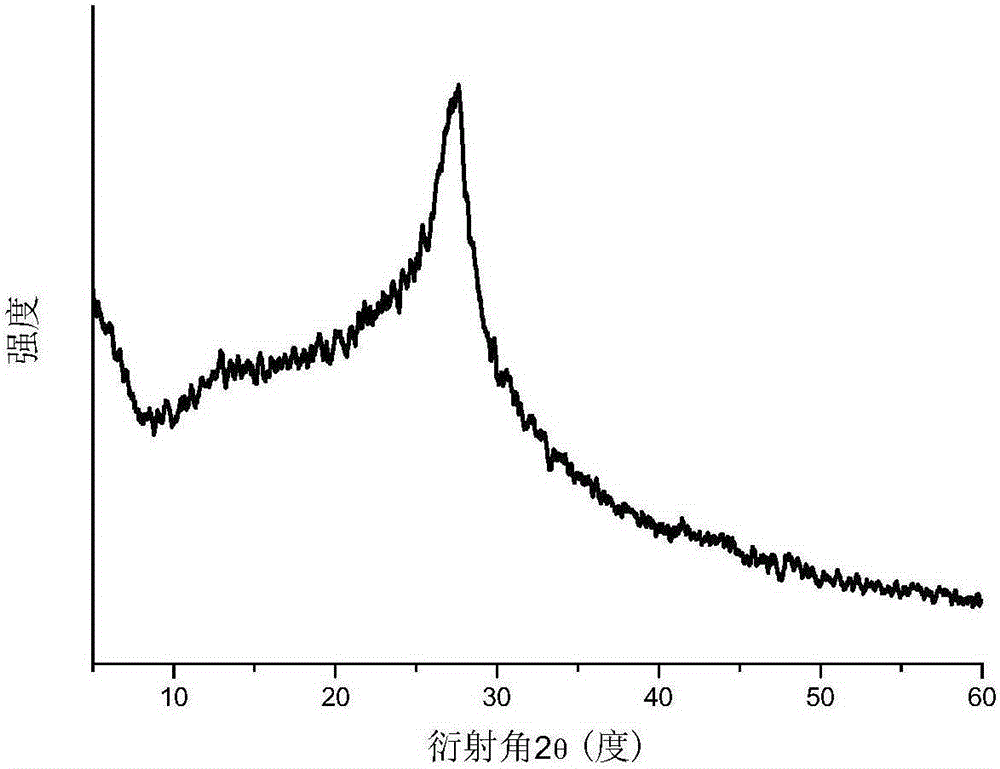

Preparation method for multi-hole carbon nitride photocatalytic material doped with sulphur

InactiveCN103861632AReduce pollutionGood repeatabilityPhysical/chemical process catalystsHydrogen productionSurface-active agentsSolvent

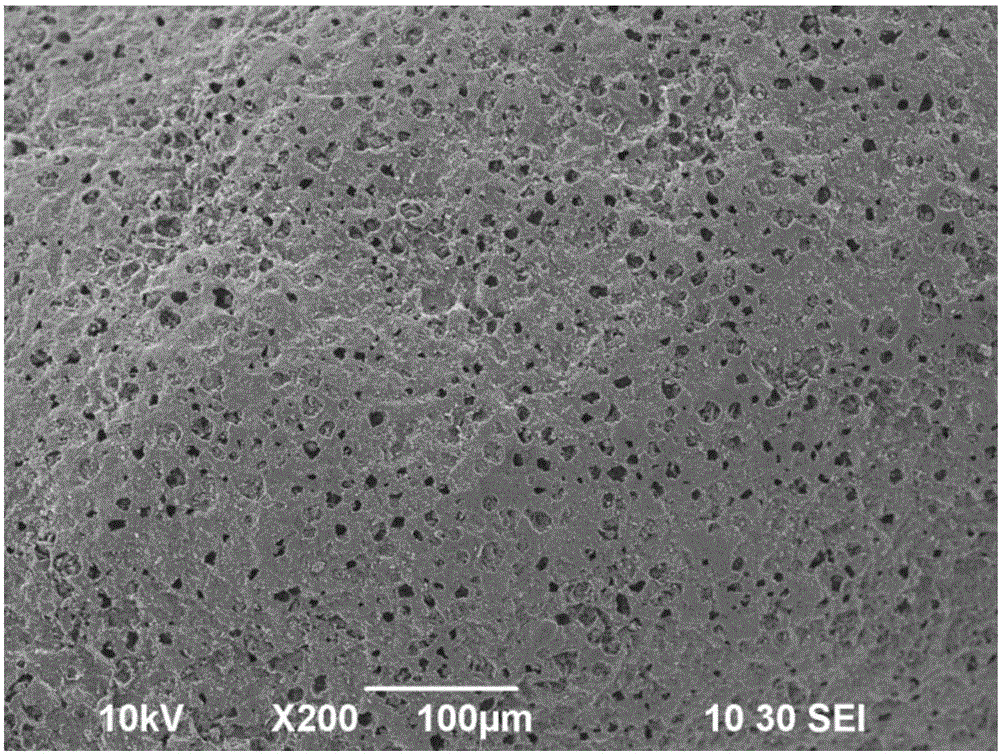

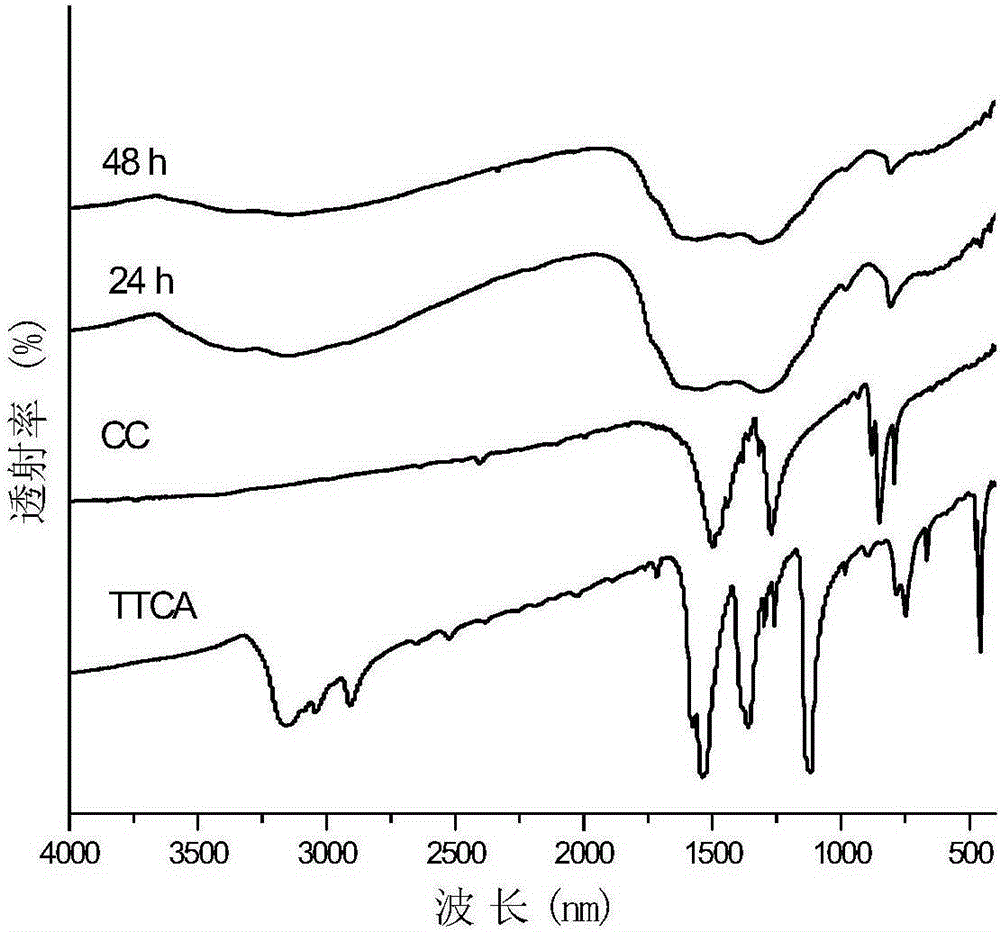

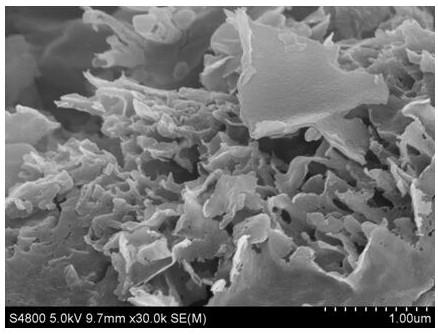

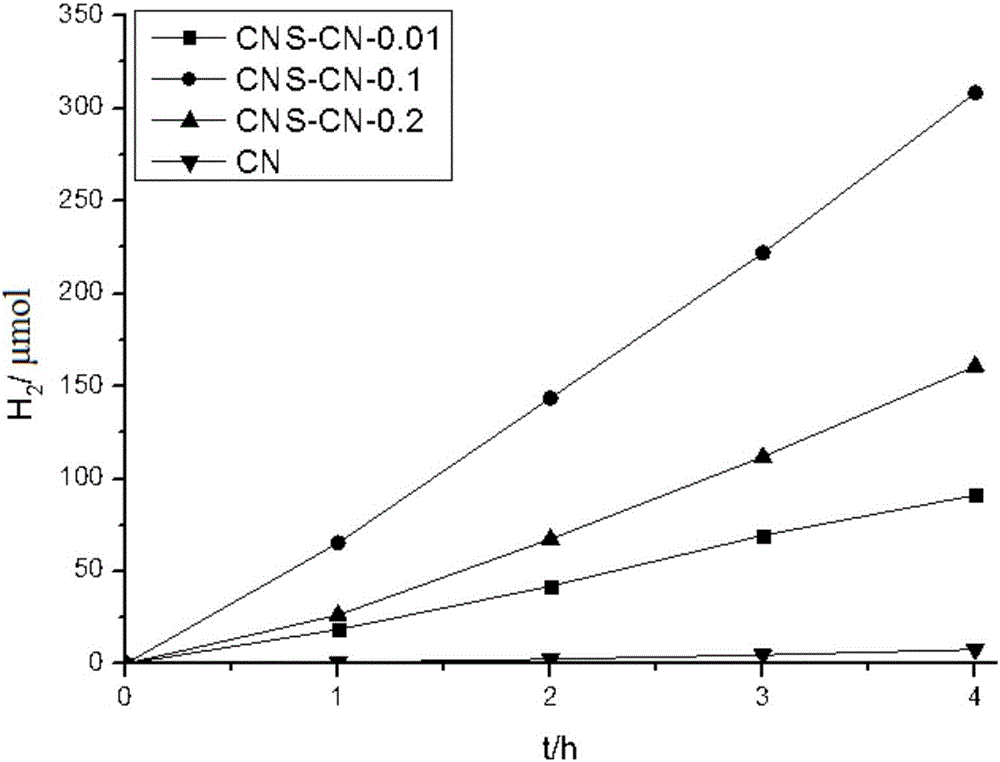

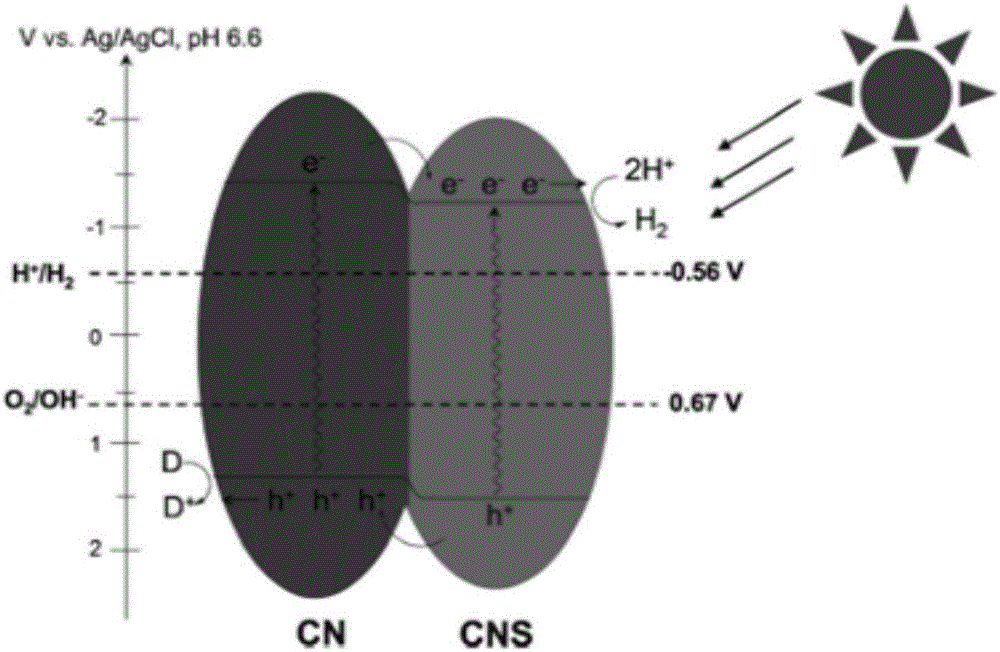

The invention discloses a preparation method for a multi-hole carbon nitride photocatalytic material doped with sulphur, belonging to the technical field of synthesis of photocatalytic materials. The preparation method comprises the following steps of preparing a super-molecule polymer through simple hydro-thermal treatment by taking melamine and trithiocyanuric acid as a raw material and taking water as a solvent, and burning in an inert atmosphere so as to obtain a three-dimensional network sulphur-doped multi-hole carbon nitride photocatalytic material. The preparation method provided by the invention has the advantages that simplicity and easiness in preparation are achieved, a method for burning a super-molecule polymer is adopted, any template agent and a surface active agent do not need to be added, a reaction system is simplified, the cost is low, the pollution of a reagent is slight, the reaction repeatability is good, a preparation condition is mild, the time consumption of a synthetic process is short, and the requirement on equipment is high; the multi-hole carbon nitride photocatalytic material doped with sulphur has excellent catalytic activity in a catalyzing hydrogen production reaction, and the hydrogen production rate of the material is 8.3 times and 5.2times that of a product obtained by burning melamine and trithiocyanuric acid under the same condition.

Owner:JILIN UNIV

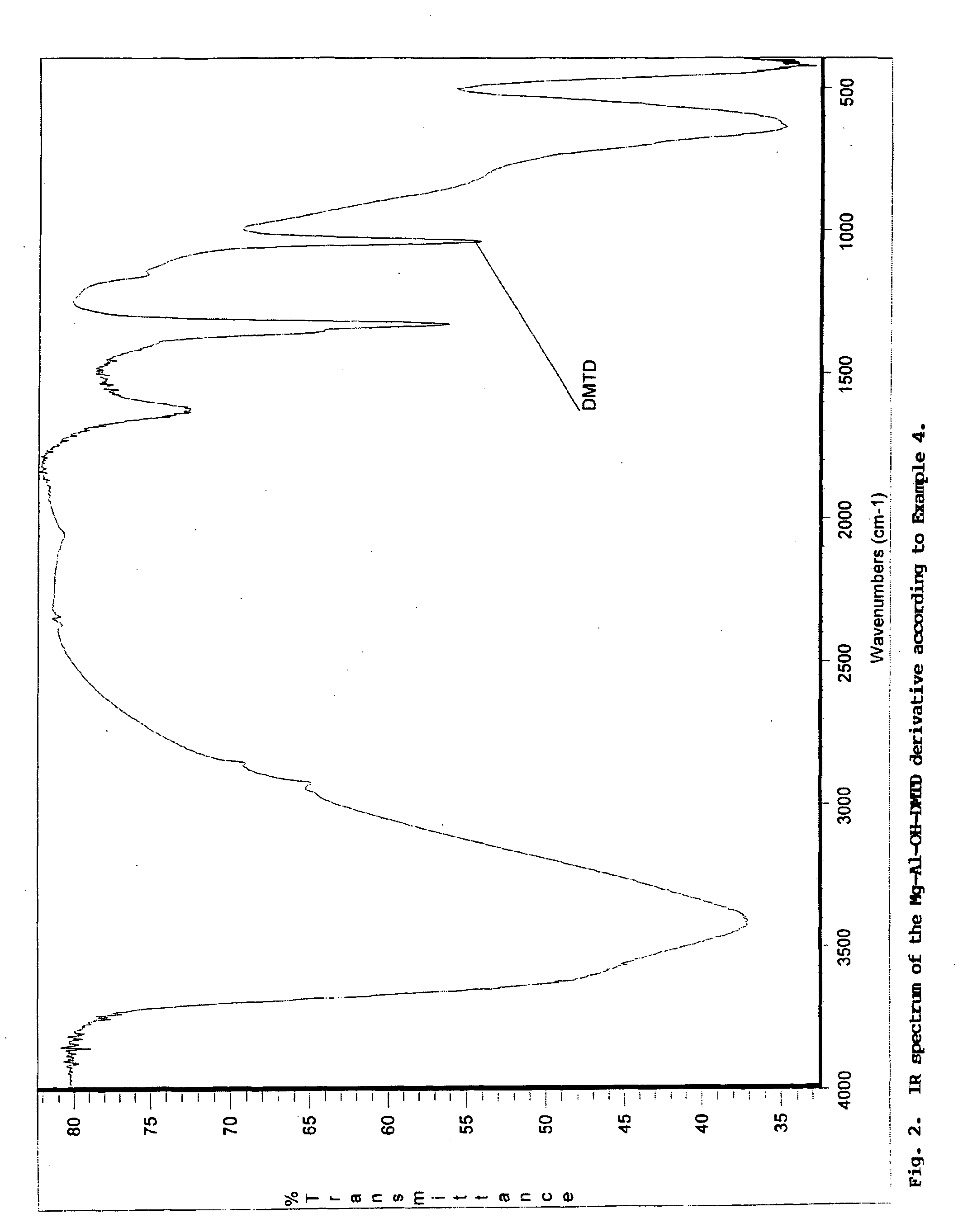

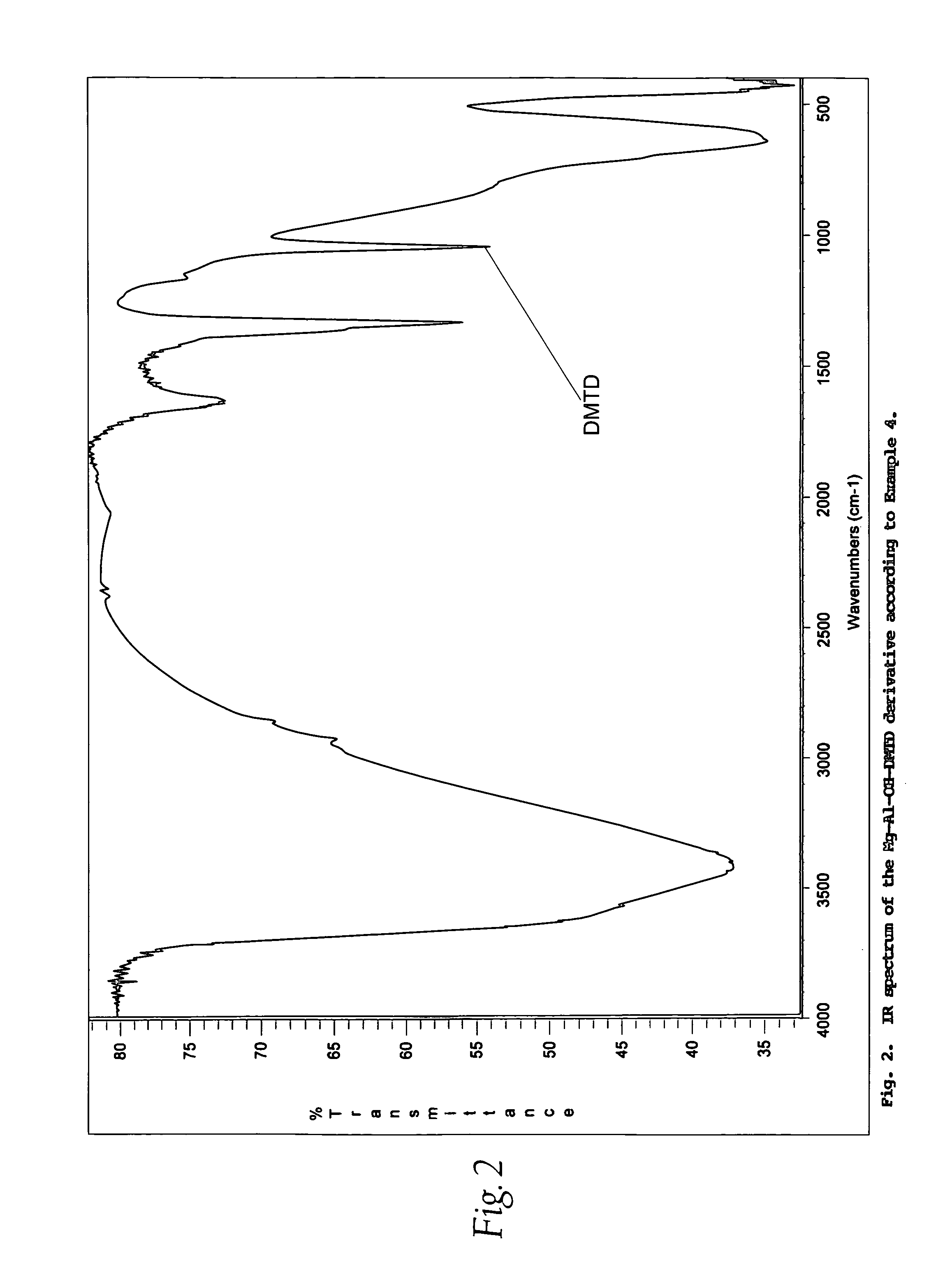

Corrosion inhibitor composition applicable for aluminum and steel protection and procedure

InactiveUS7662241B2High chemistryEffective corrosionOther chemical processesSolid state diffusion coatingMolybdatePhosphate

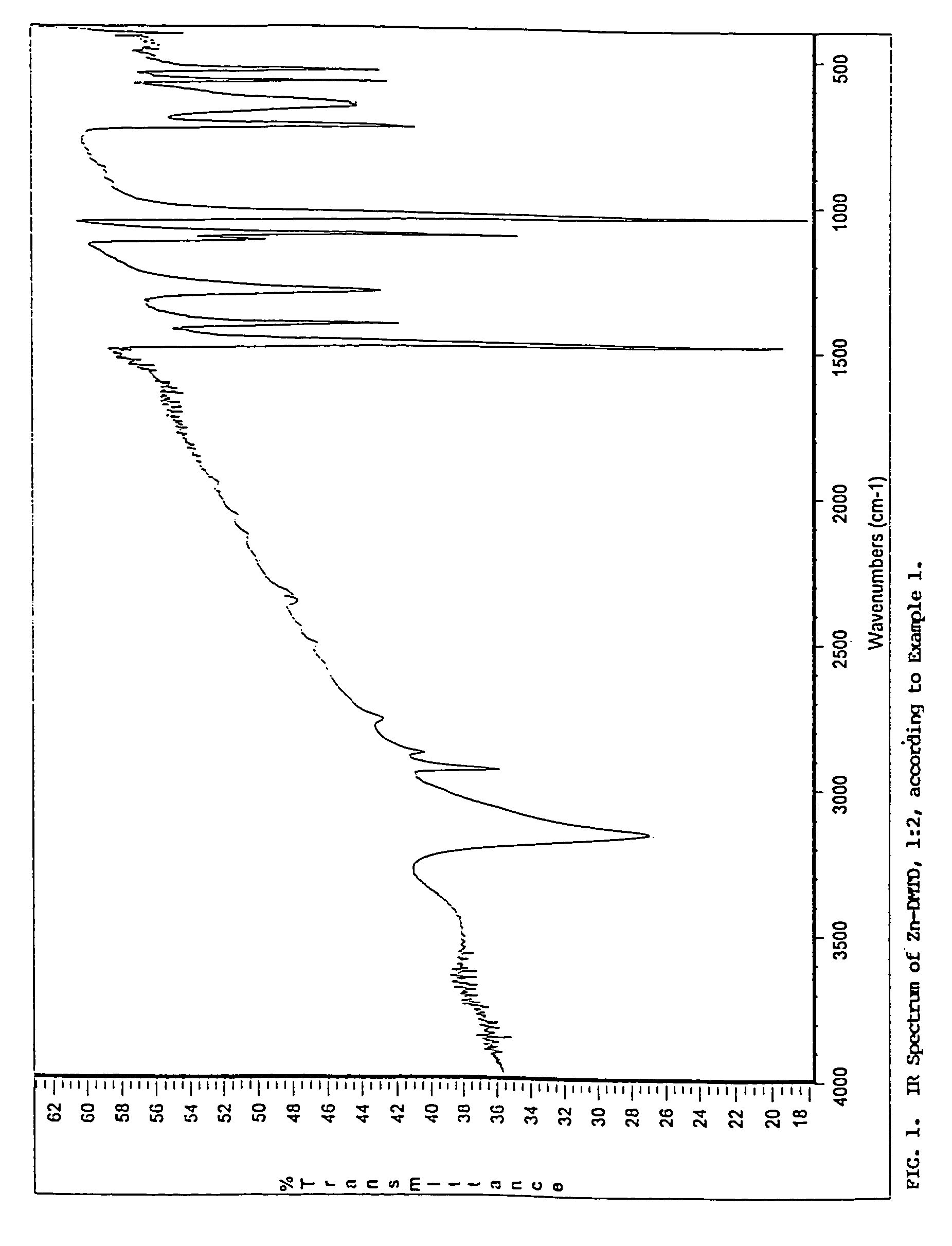

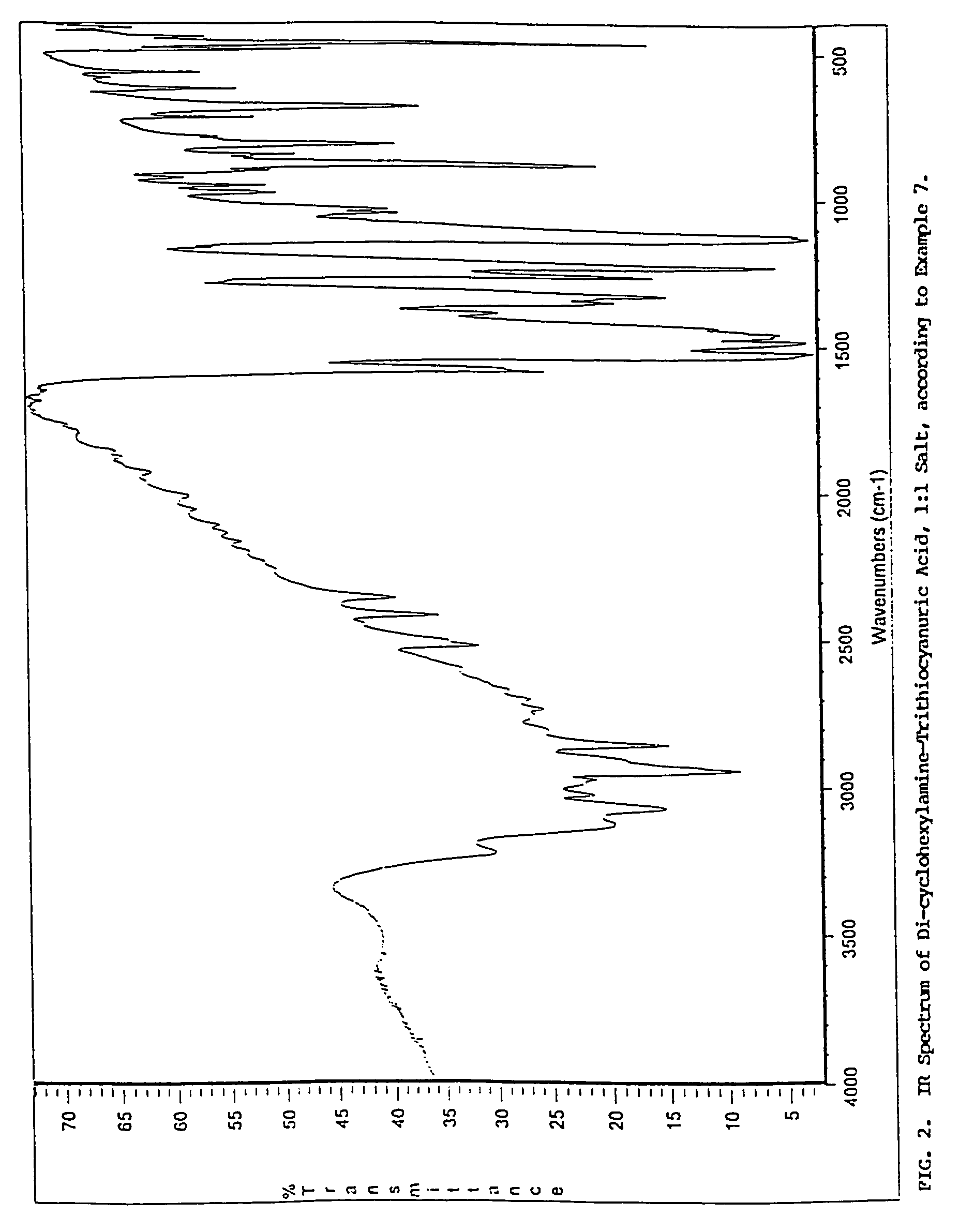

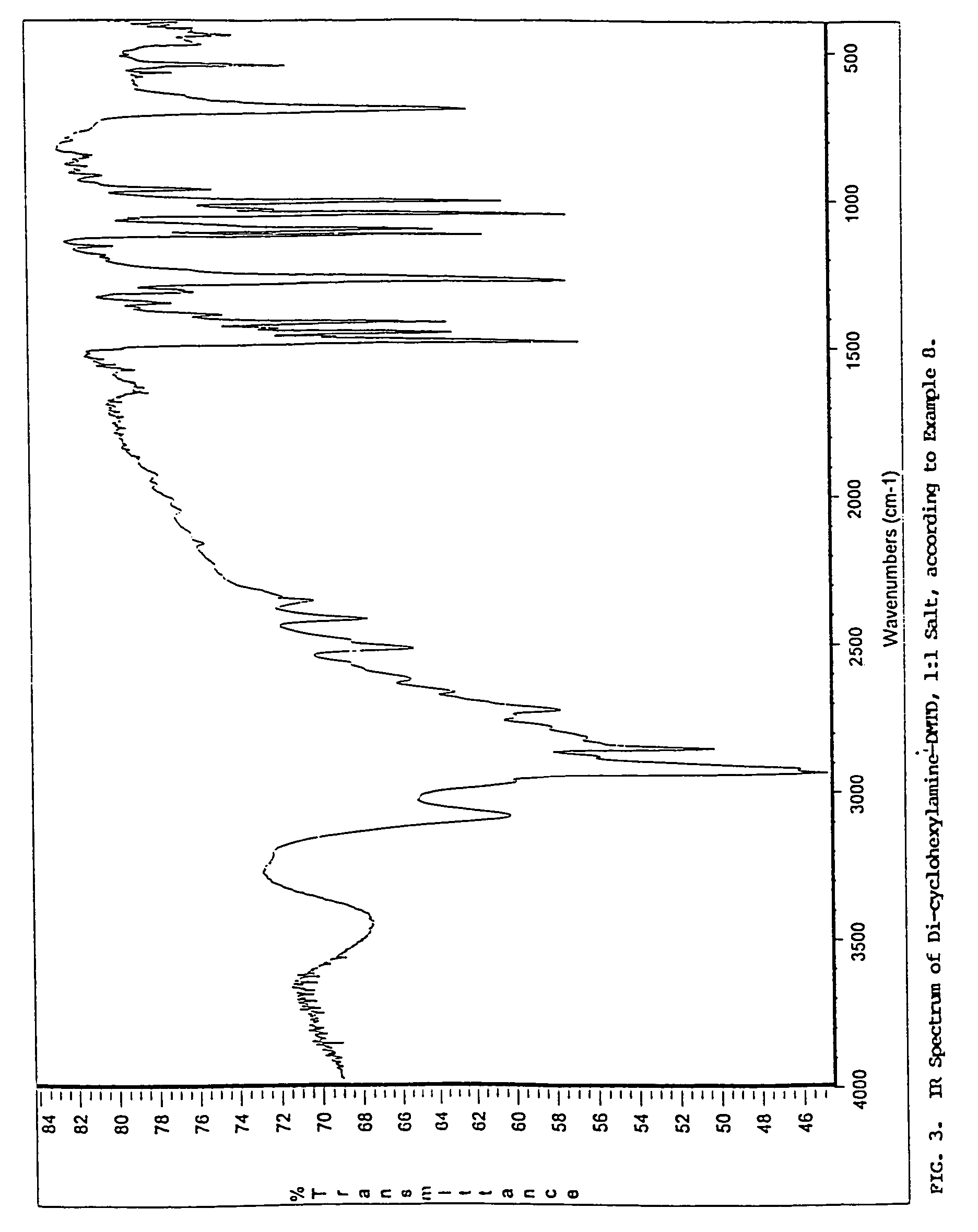

A corrosion-inhibiting composition for application to a metal substrate, such as aluminum or steel, and in connection with a paint, and the synthesis of the composition. The active inhibitor constituent of the composition can be selected from the group consisting of 2,5-dimercapto-1,3,4 thiadiazole (DMTD), 2,4-dimercapto-s-triazolo-[4,3-b]-1,3-4-thiadiazole, trithiocyanuric acid (TMT), and derivatives of DMTD and TMT, including various N— or S— and N, N—, S— and N—,S-substituted derivatives of DMTD, including salts of DMTD of the general formula: M(DMTD)n, where n=1,2 or 3, and M is a metal cation and preferably M=Zn(II), Bi(III), Co(II), Ni(II), Cd(II), Pb(II), Ag(I), Sb(III), Cu(II), Li(I), Ca(II), Sr(II), Mg(II), La(III), Ce(III), Pr(III), Al(III) or Zr(IV). DMTD, TMT, and their derivatives may also be combined with phosphates, molybdates, borates, silicates, tungstates, phosphotungstates, phosphomolybdates, cyanamides, carbonates, SiO2 and mixtures thereof.

Owner:LUMIMOVE

Preparation method of rubber for outer glue layer of power steering tube of automobile

The invention discloses a preparation method of rubber for an outer glue layer of a power steering tube of an automobile and belongs to the technical field of rubber parts for automobiles. The preparation method comprises the following steps: mixing chlorosulfonated polyethylene, fast extruding furnace black, carbon black prepared by a cracking process, magnesium oxide, zinc diethyl dithiocarbamate, dilauryl thiodipropionate, zinc stearate, 2,2'-dithiodibenzo thiazole, trioctyl trimellitate and strong magnesium powder in an external mixer, and after mixing, discharging rubber under a condition that the rubber temperature is 160 DEG C to prepare masterbatch; and putting the prepared masterbatch into the external mixer, adding trithiocyanuric acid and sulfur in the raw materials and mixing; and after mixing, sequentially extruding at a certain temperature interval to prepare the rubber for the outer glue layer of the power steering tube of the automobile. Compared with the rubber for the outer glue layer of the power steering tube of the automobile prepared in the prior art, the rubber prepared by the preparation method has the advantage that the heat resistance of the rubber is effectively improved by mutual synergistic effect among the raw materials and matching corresponding extrusion temperatures.

Owner:南京中配橡塑制品有限公司

Preparation method of nitrogen-sulfur co-doped three-dimensional graphene, prepared product and product application thereof

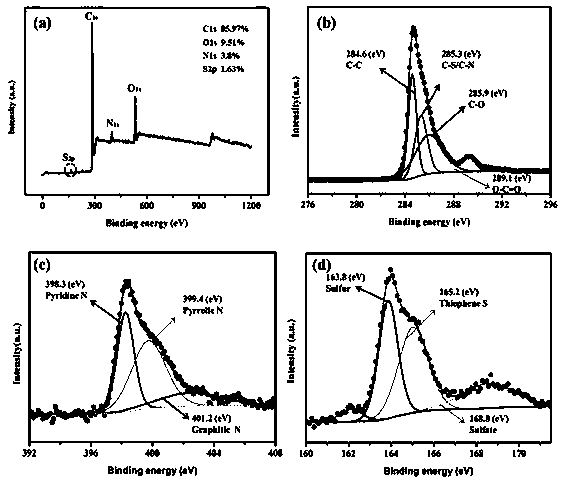

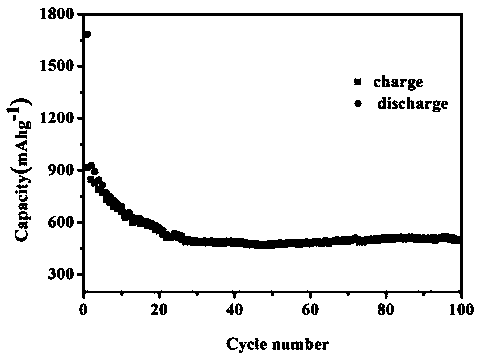

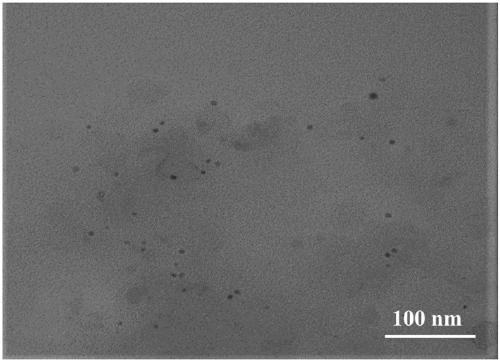

InactiveCN108470890AInhibition of agglomerationDoping amount is controllableMaterial nanotechnologyCell electrodesLithium-ion batteryLithium electrode

The invention provides a preparation method of nitrogen-sulfur co-doped three-dimensional graphene. Graphene oxide is dispersed in deionized water to obtain graphene oxide dispersion liquid, and melamine powder and an ethanol solution of trithiocyanuric acid are added, uniformly dispersed and then placed into a hydrothermal reactor for hydrothermal reaction; hydrothermal products are dried, and finally heat treatment is conducted. The invention further provides the nitrogen-sulfur co-doped three-dimensional graphene and application of the graphene as an electrode material. The prepared producthas nitrogen element content of 3-10% and sulfur element content of 0.5-3%. The preparation method has the advantages that an experimental method is safe, non-toxic, low in cost and simple to operate. A hydrothermal method is adopted to achieve doping, three-dimensional construction and graphene oxide reduction. The prepared three-dimensional graphene has a large specific surface area and can beapplied in the fields of lithium ion batteries, supercapacitors, electrocatalysis and the like.

Owner:SHAANXI UNIV OF SCI & TECH

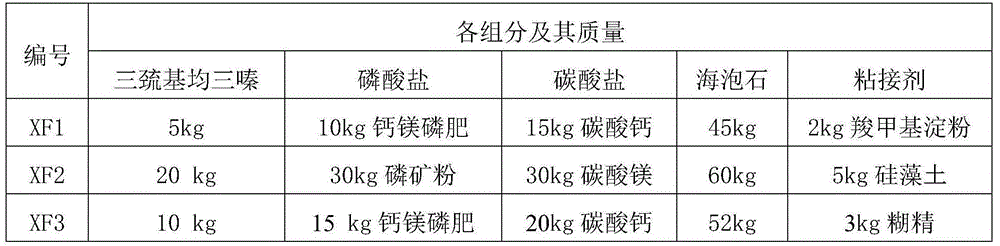

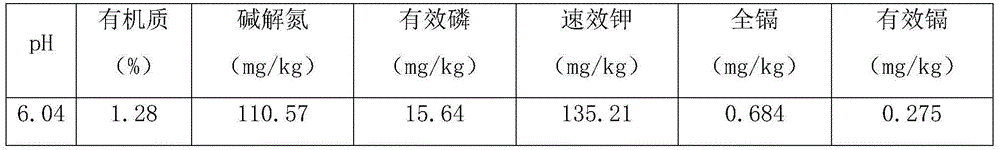

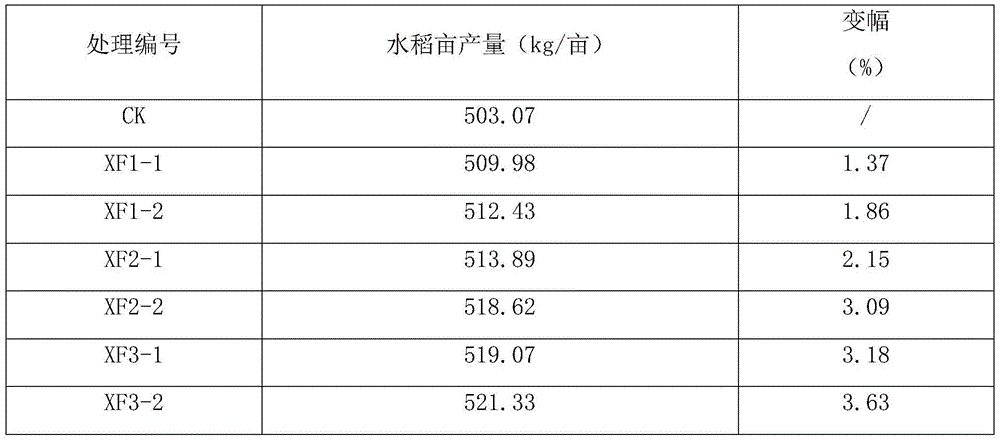

Soil repairing agent and preparation method thereof

ActiveCN104531159AReduce contentReduce absorptionAgriculture tools and machinesContaminated soil reclamationAdhesiveSoil heavy metals

The present invention relates to a soil repairing agent and a preparation method thereof, and belongs to the field of agriculture. The technical problem solved by the present invention is to provide a soil repairing agent and a preparation method thereof. The soil repairing agent of the present invention comprises, by weight, 5-20 parts of trithiocyanuric acid, 10-30 parts of a phosphate, 15-30 parts of a carbonate, 45-60 parts of sepiolite, and 2-5 parts of an adhesive, wherein the phosphate is preferably a calcium-magnesium-phosphorus fertilizer and / or phosphorus ore powder, the carbonate is preferably calcium carbonate and / or magnesium carbonate, and the adhesive is preferably carboxymethyl starch, dextrin or diatomite. Further the invention discloses the preparation method of the repairing agent. According to the present invention, the soil repairing agent provides good repairing effects on the heavy metal cadmium-polluted soil, particularly the contents of heavy metals such as lead, cadmium and the like in the soil can be substantially reduced, various components are harmless to human body and environments, and the soil repairing agent has the characteristic of green environmental protection.

Owner:CHENGDU NEWSUN CROPSCI

High-performance nitrile butadiene rubber cable jacket material and preparation method thereof

InactiveCN105254953AGood mechanical propertiesImprove water resistanceInsulated cablesInsulated conductorsCarbon nanotubeCorrosion

The invention discloses a high-performance nitrile butadiene rubber cable jacket material. The high-performance nitrile butadiene rubber cable jacket material comprises following raw materials: nitrile butadiene rubber, polyvinyl chloride, chlorinated polyethylene, fluororubber, zinc oxide, trithiocyanuric acid, dicumyl peroxide, triallyl isocyanurate, the accelerator TMTD (tetramethylthiuram disulfide), the accelerator CZ, carbon nano tubes, nano silicon nitride, nano boron nitride, nano titanium dioxide, dibutyl phthalate, dioctyl sebacate, trioctyl trimellitate, coumarone resin, stearic acid, zinc stearate, calcium stearate, the anti-aging agent MB, the anti-aging agent RD, lanthanum stearate and a silane coupling agent. The invention further provides a preparation method of the high-performance nitrile butadiene rubber cable jacket material. The method has simple process and mild condition; the obtained jacket material has high strength, good weather resistance, good corrosion resistance and excellent processability, can meet requirements of cables in multiple fields and has long service life.

Owner:ANHUI LAND GRP

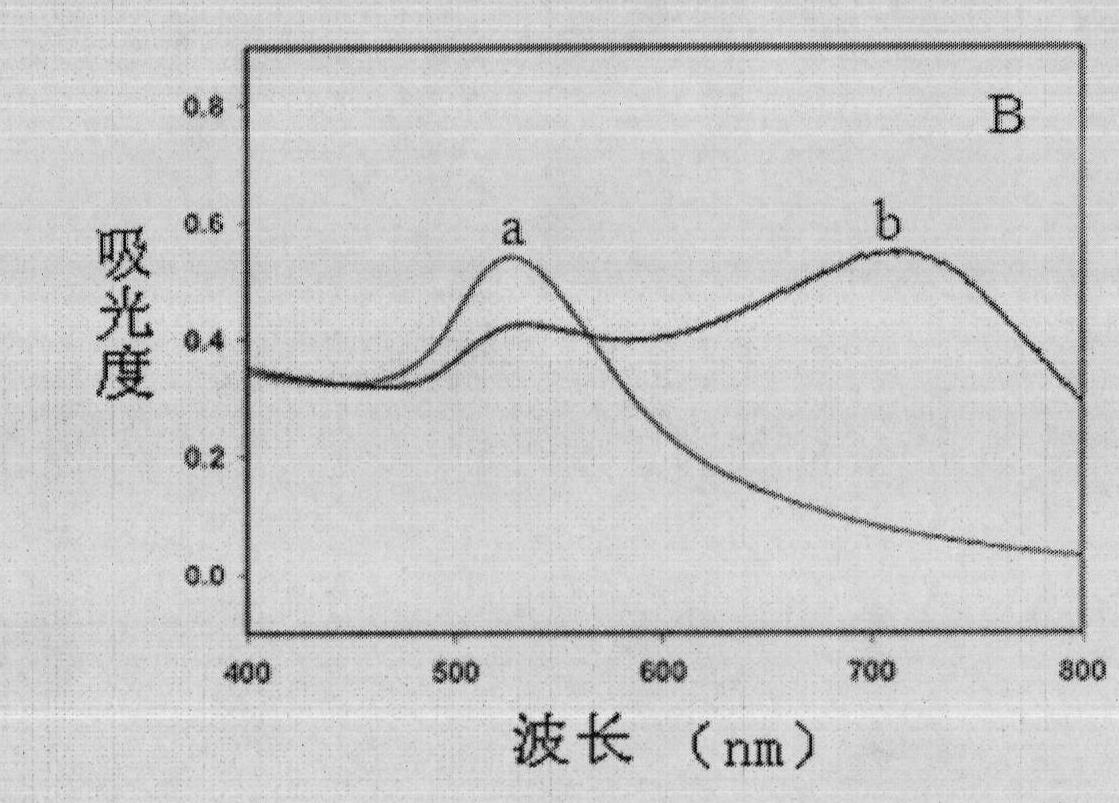

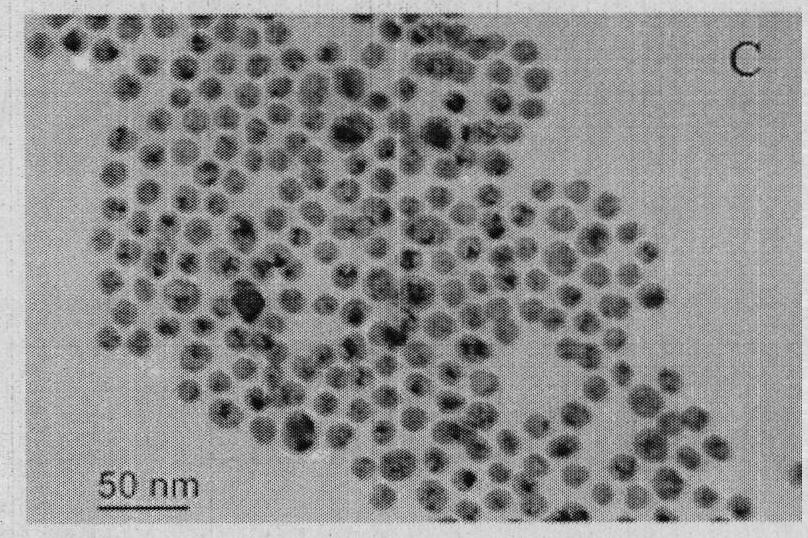

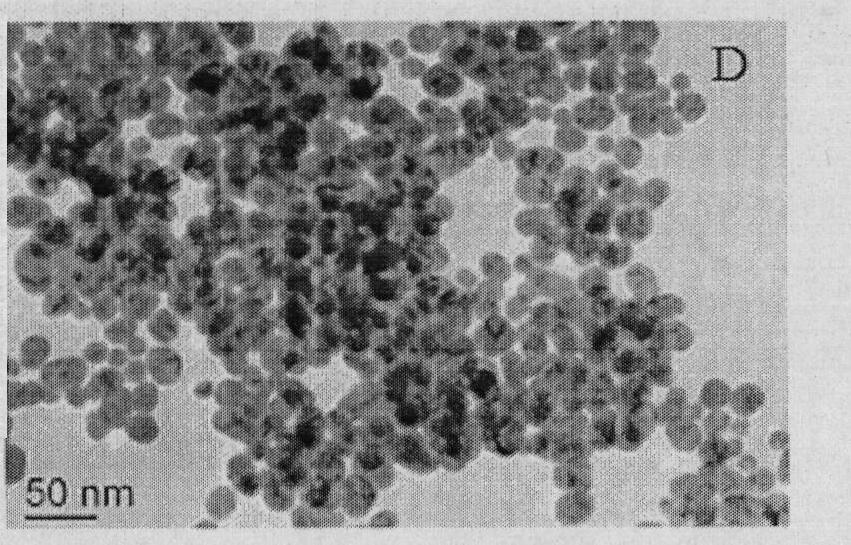

Trithiocyanuric acid dressed gold-size nanoprobe-based colorimetric determination method of mercury ions

InactiveCN102374988AWill not cause secondary pollutionStrong specificityMaterial analysis by observing effect on chemical indicatorNanoparticleAqueous solution

The invention discloses a method for simply and quickly measuring mercury ions based on gold-size nanoprobe which is dressed by trithiocyanuric acid, which is characterized in that: trithiocyanuric acid is adopted as a recognition element of the mercury ions, and gold-size nanoparticles which are dressed by the trithiocyaunuric acid as a probe to realize the colorimetric determination of content of mercury ions in a water solution. By utilizing the method for measuring the mercury ions, no pollution is caused on the environment, selectivity on the mercury ions is good, and the interference of a majority of metal ions can be avoided; and the required instrument is simple, the price is low, and the method is suitable for being used in simple and crude fields such as countryside and the like.

Owner:EAST CHINA NORMAL UNIV

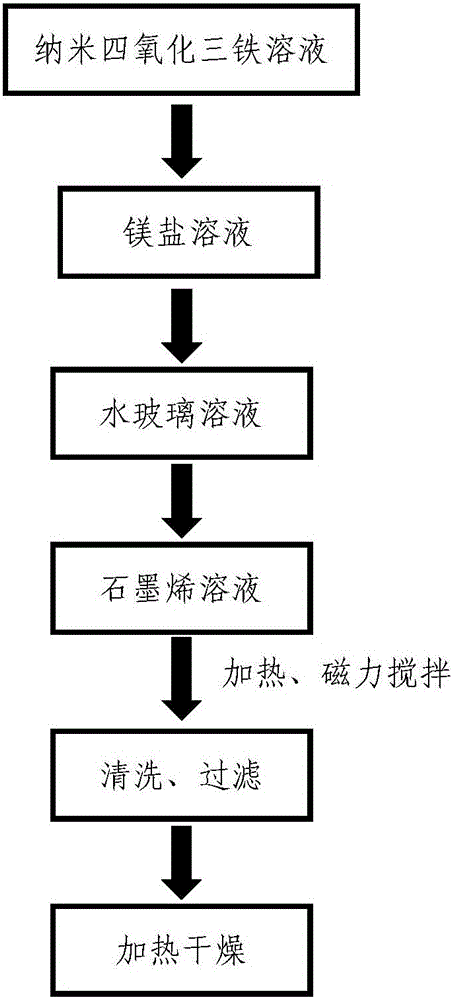

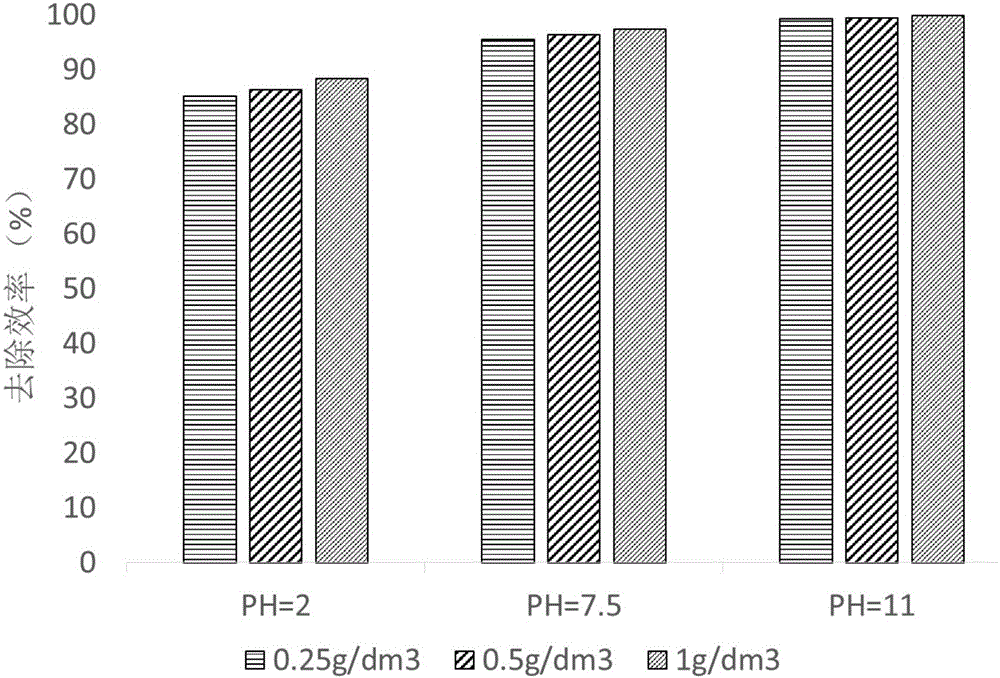

Heavy metal ion adsorbent, preparation method and application

ActiveCN106076261AHelps to completely removeRapid precipitationOther chemical processesWater contaminantsMagnesium saltSorbent

The invention provides a heavy metal ion adsorbent, a preparation method and application. The heavy metal ion adsorbent is prepared by mixing, by weight, 5-10 parts of graphene@Fe3O4@MgO.SiO2 composite particles, 10-25 parts of trithiocyanuric acid trisodium salt, 5-15 parts of hydroxide and 50-80 parts of deionized water. The composite particles are prepared from nano-iron oxide, graphene, magnesium salt and sodium silicate through a coprecipitation method. According to the adsorbent, heavy metal ions can be captured in a chemical chelation mode and then enriched in a physical absorption mode, a relatively stable structure can be rapidly formed, and the metal ions can be immobilized and prevented from being released to the environment; besides, the adsorbent can be treated in a burying mode, and secondary pollution to the environment can be avoided.

Owner:郑州普利飞尔环保科技有限公司

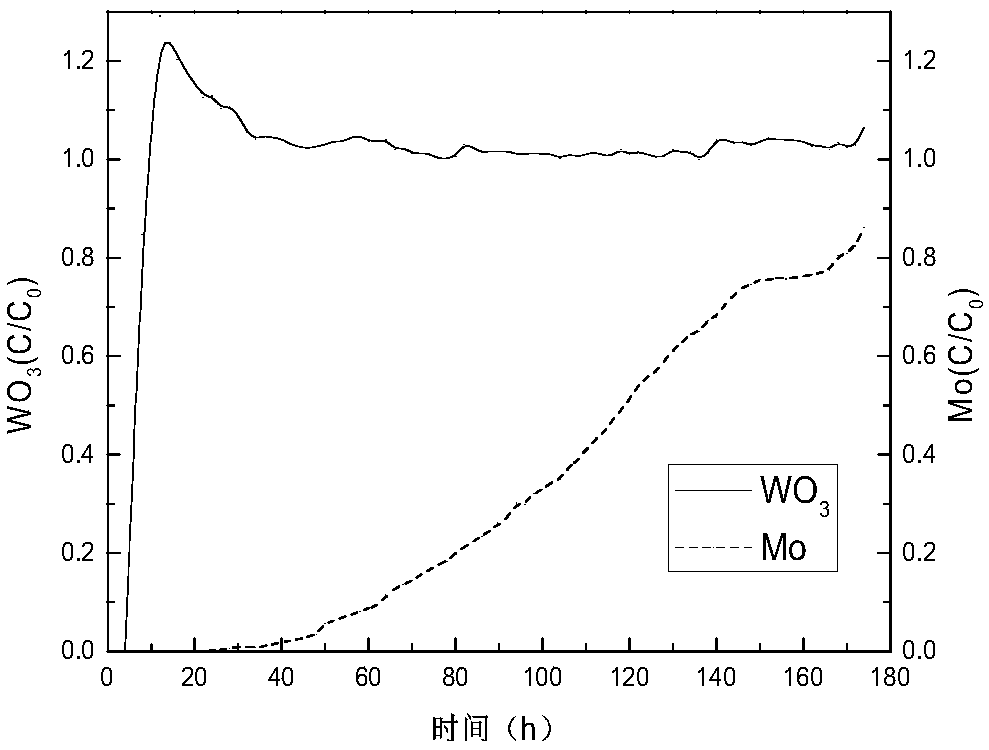

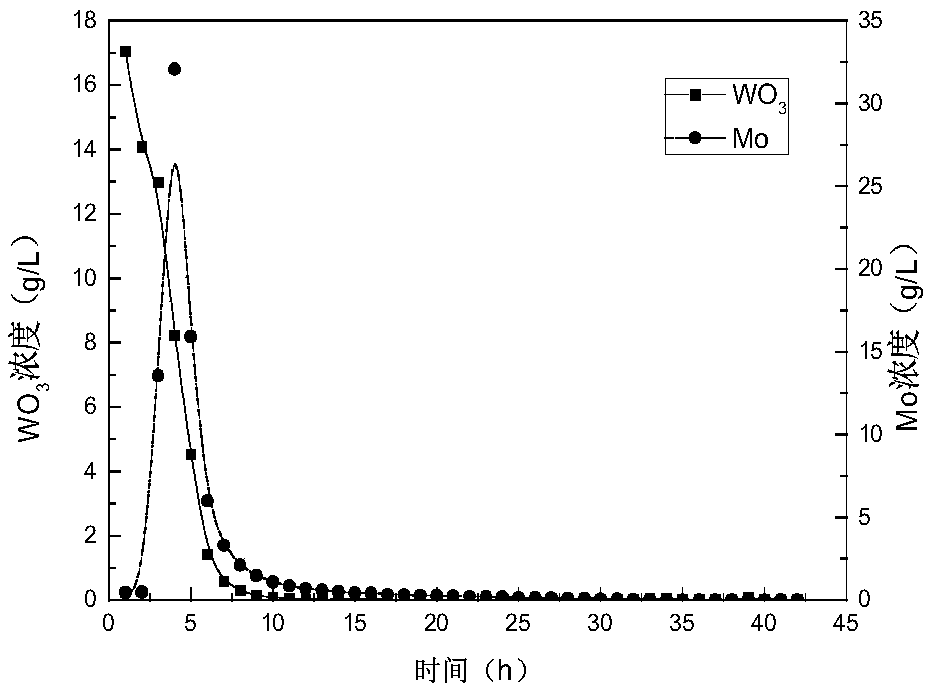

Method for separating molybdenum from tungstate solution through ion exchange

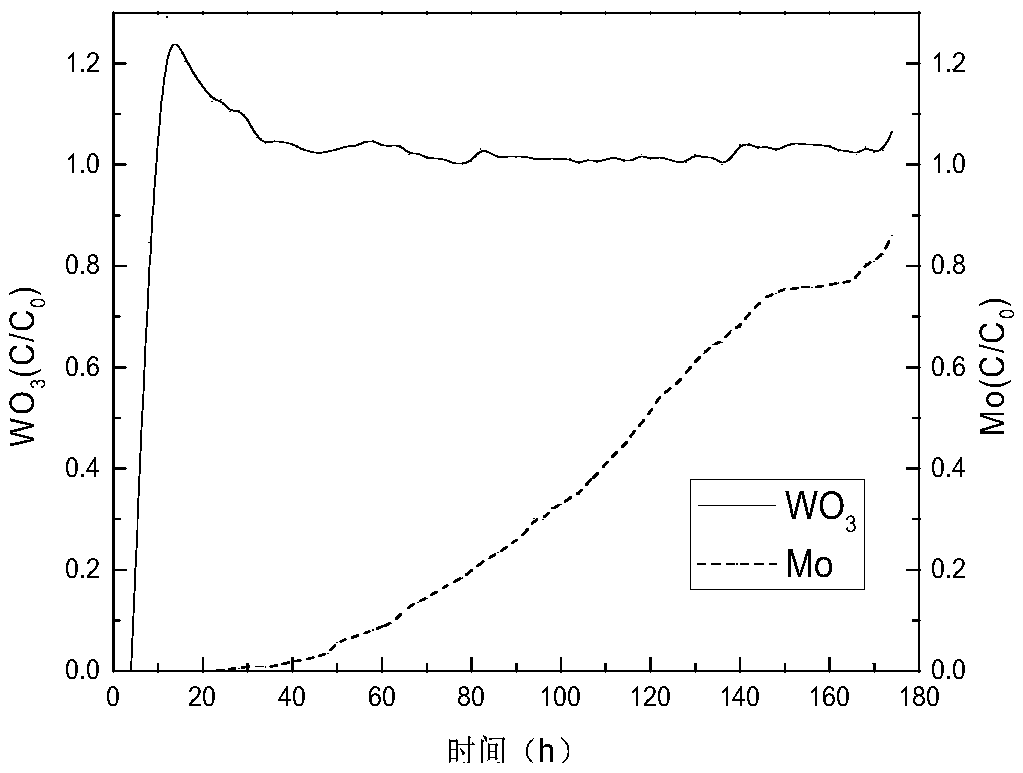

ActiveCN109534403ATransportation safetySafe storageTungsten compounds preparationMolybdateVulcanization

The invention discloses a method for separating molybdenum from a tungstate solution through ion exchange. The method includes the steps that trithiocyanuric acid is added into the molybdenum-containing tungstate solution to carry out vulcanization reaction, so that a tungstate solution containing thiomolybdate is obtained; the tungstate solution containing the thiomolybdate is subjected to ion exchange by adopting weak-base anion-exchange resin so as to adsorb the thiomolybdate, and a tungstate solution is obtained; and the weak-base anion-exchange resin loaded with the thiomolybdate is desorbed by an alkaline desorption solution, so that a molybdate solution is obtained. According to the method, the separating effect of molybdenum in the high-tungsten low-molybdenum solution is good, tungsten loss is little, operation is simple, no hydrogen sulfide is released in the vulcanization process, a hydrogen sulfide recovery facility is not needed, no oxidant is used in the desorption process, molybdenum is easy to recover, the service life of the resin is prolonged, and industrial application is facilitated.

Owner:CENT SOUTH UNIV

Preparation method for rubber for inner rubber layer of car power steering hose

The invention discloses a preparation method for rubber for the inner rubber layer of a car power steering hose, and belongs to the technical field of car rubber pieces. The preparation method comprises the following steps: adding chlorosulfonated polyethylene, fast extruding furnace black, cracking carbon black, magnesium oxide, zinc diethyl dithiocarbamate, dilauryl thiodipropionate, zinc stearate, 2,2'-dithio-dibenzo thiazole, trioctyl trimellitate and magnesium strong powder into an internal mixer for banburying; after banburying, discharging rubber at the rubber temperature of 160 DGE C to obtain a master batch; adding the prepared master batch into the internal mixer, and adding in trithiocyanuric acid and sulphur for mixing; after mixing, sequentially squeezing out within a certain temperature range to obtain rubber for the inner rubber layer of the car power steering hose. Compared with that manufactured rubber for an inner rubber layer of a car power steering hose in the prior art, the rubber adopts the synergistic effects of the raw materials and the corresponding squeezing temperatures to effectively improve the heat resistance property of the rubber.

Owner:南京中配橡塑制品有限公司

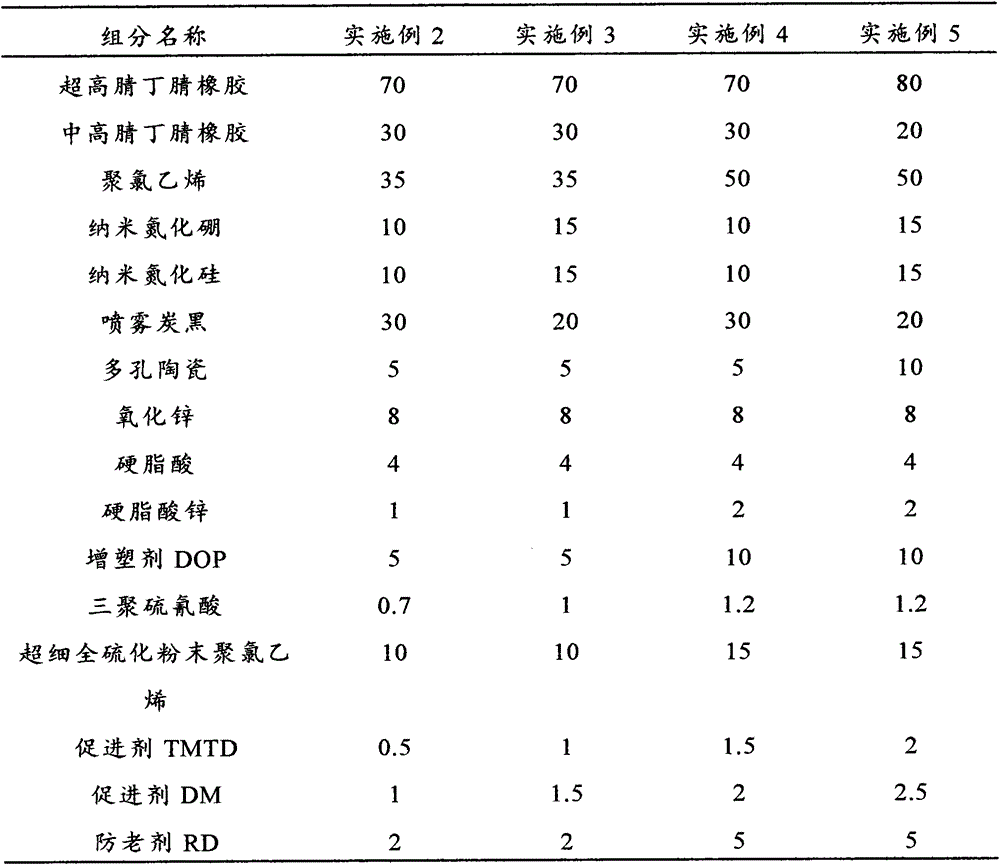

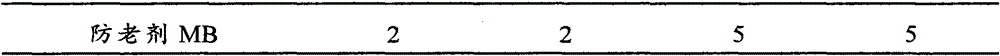

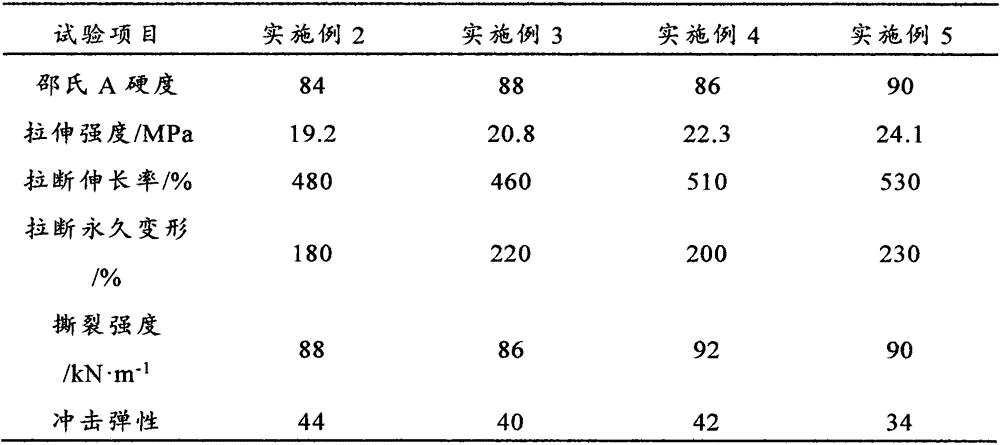

Nitrile rubber/polyvinyl chloride composite material and preparation method thereof

The invention provides a nitrile rubber / polyvinyl chloride composite material and a preparation method thereof. The nitrile rubber / polyvinyl chloride composite material is prepared from the following raw materials: ultra-high-nitrile nitrile rubber, medium-high-nitrile nitrile rubber, polyvinyl chloride, porous ceramics, nano boron nitride, nano-silicon nitride, spray furnace black, zinc oxide, stearic acid, zinc stearate, a plasticizer DOP, trithiocyanuric acid, ultra-fine fully vulcanized powder polyvinyl chloride, an accelerant TMTD, an accelerant DM, an anti-aging agent RD and an anti-aging agent MB. According to the composite material, part of carbon black is replaced by the porous ceramics as a reinforcing agent, and meanwhile nano-silicon nitride and nano boron nitride are used and then sulfurized after being mixed, so that a lubricating film is formed on the surface of a rubber product so as to generate a self-lubricating effect, and therefore, the wear resistance of the material is improved; the ultra-fine fully vulcanized powder polyvinyl chloride is used as a vulcanizing agent, the stability, the heat resistance and the hardness of the material are improved. Therefore, the prepared nitrile rubber / polyvinyl chloride composite material has good hardness, elasticity, heat resistance and wear resistance.

Owner:东莞市鸿韬高分子科技有限公司

Pre-dispersed master batch particle for rubber vulcanization cross-linking and preparation method of pre-dispersed master batch particle

ActiveCN104844856AImprove vulcanization efficiencyIncrease the degree of cross-linkingRubber materialDispersity

The invention discloses a pre-dispersed master batch particle for rubber vulcanization cross-linking and a preparation method of the pre-dispersed master batch particle. The pre-dispersed master batch particle comprises, by weight, 30-50 parts of trithiocyanuric acid, 20-40 parts of 1, 1'-dithiobiscaprolactam, 3-10 parts of coupling agents, 3-10 parts of inorganic fillers, 5-10 parts of softening oil, 2-5 parts of processing agents and 5-40 parts of rubber carriers. By the preparation method of the pre-dispersed master batch particle, dispersity of active components is improved, the master batch particle is uniformly discharged, the surface of the particle is smooth, the master batch particle has fine processing performance and is used for preparing rubber materials, vulcanization time is shortened, and the mechanical property of vulcanized rubber is effectively improved.

Owner:NINGBO ACTMIX POLYMER

Preparation method of 3D (three-dimensional) porous nitrogen-sulfur doped anode carbon material based on short rod construction

InactiveCN108821258AEasy to operateLow costCell electrodesCarbon preparation/purificationHierarchical porousMaterials science

The invention discloses a 3D (three-dimensional) porous nitrogen-sulfur doped anode carbon material based on short rod construction. The material is prepared with a method comprising steps as follows:a uniform solution containing trithiocyanuric acid is slowly added to an aqueous graphene oxide solution containing dissolved melamine, and a mixed solution is sufficiently stirred at 50-120 DEG C; aproduct is calcined in inert atmosphere at 550-1150 DEG C, and the 3D porous nitrogen-sulfur doped anode carbon material based on the short rod construction is obtained. The 3D porous nitrogen-sulfurdoped anode carbon material based on the short rod construction has a short rod-like porous shell structure and comprises a framework formed by polymerization of melamine and trithiocyanuric acid supermolecules, a 3D structure formed by the framework and graphene and a doping structure of nitrogen-sulfur atoms in graphene. The carbon material as an anode of a lithium battery and a sodium batteryhas good rate capability, and by means of the larger specific surface area and hierarchical porous structure, sulfur loading is easy to realize. The preparation method is simple to operate and low incost, and large-scale preparation can be realized.

Owner:SHAANXI UNIV OF SCI & TECH

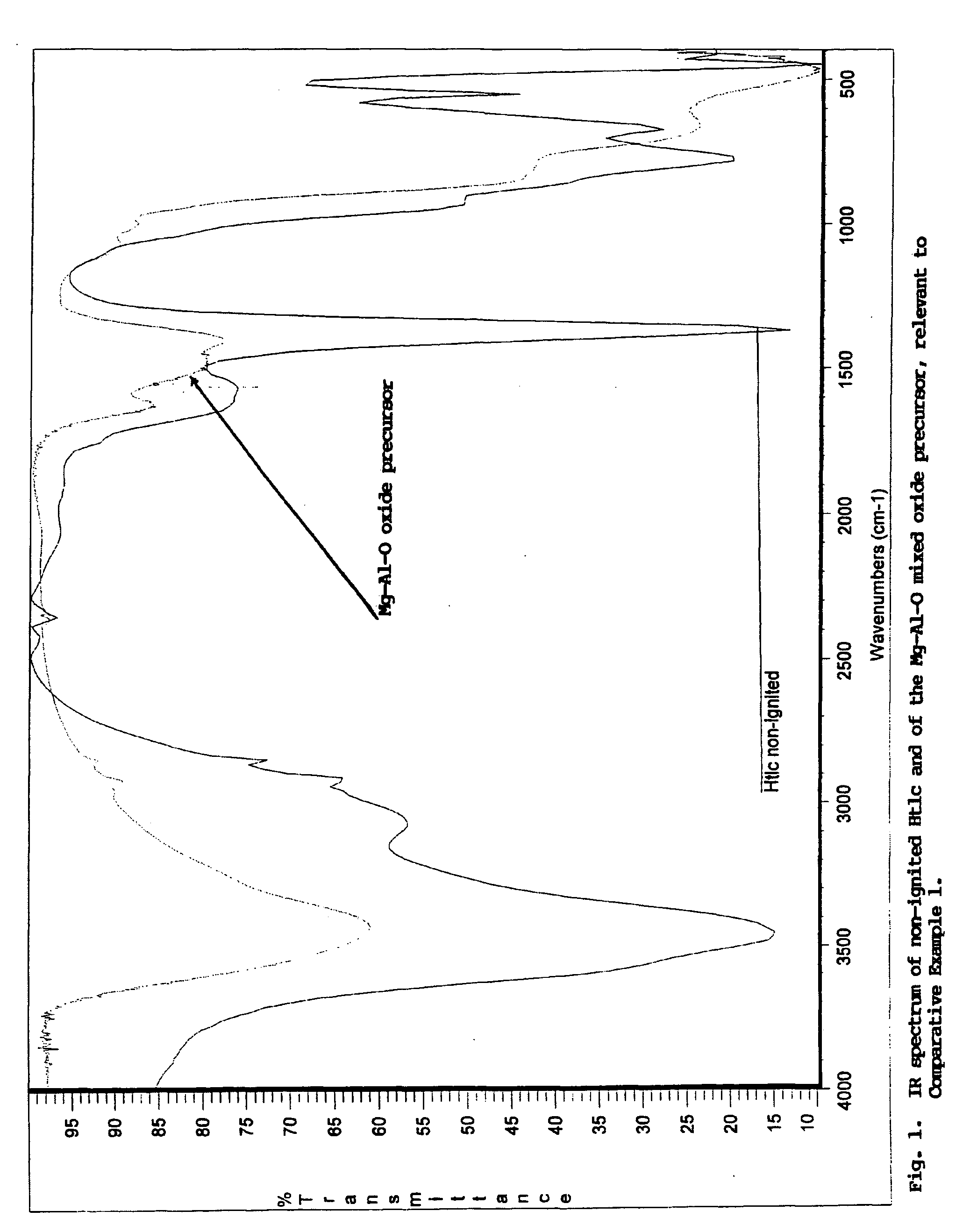

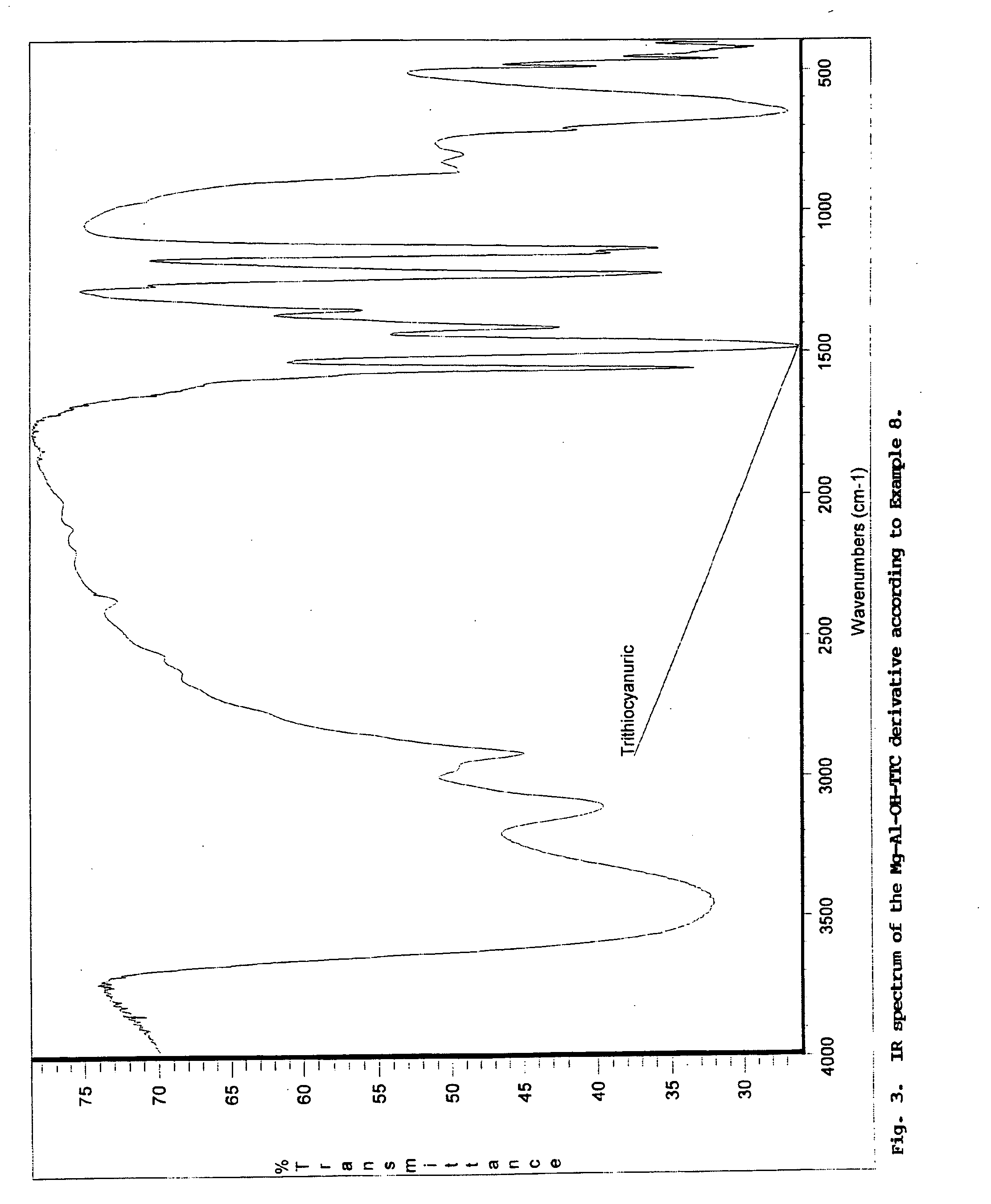

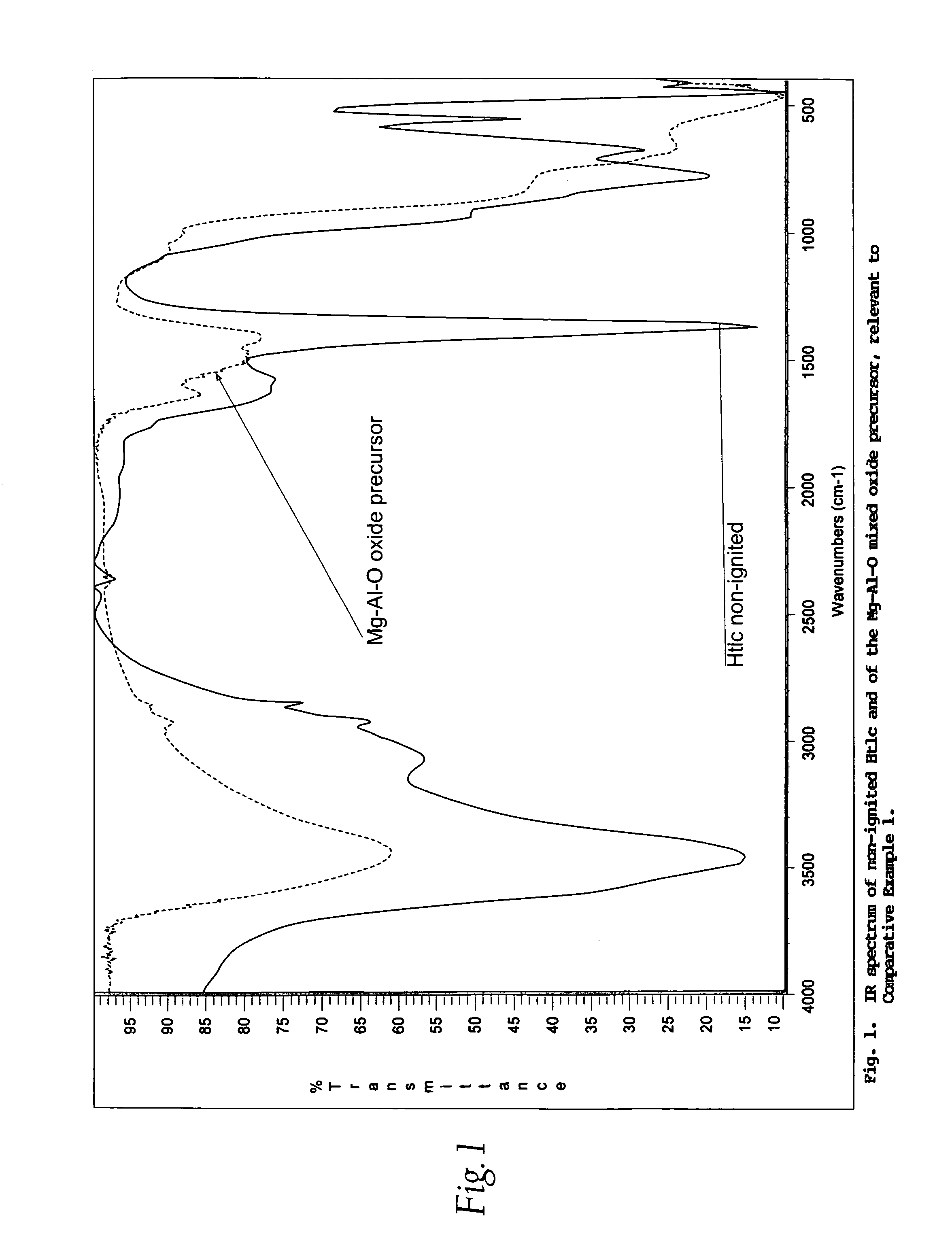

Pigment grade corrosion inhibitor host-guest compositions and procedure

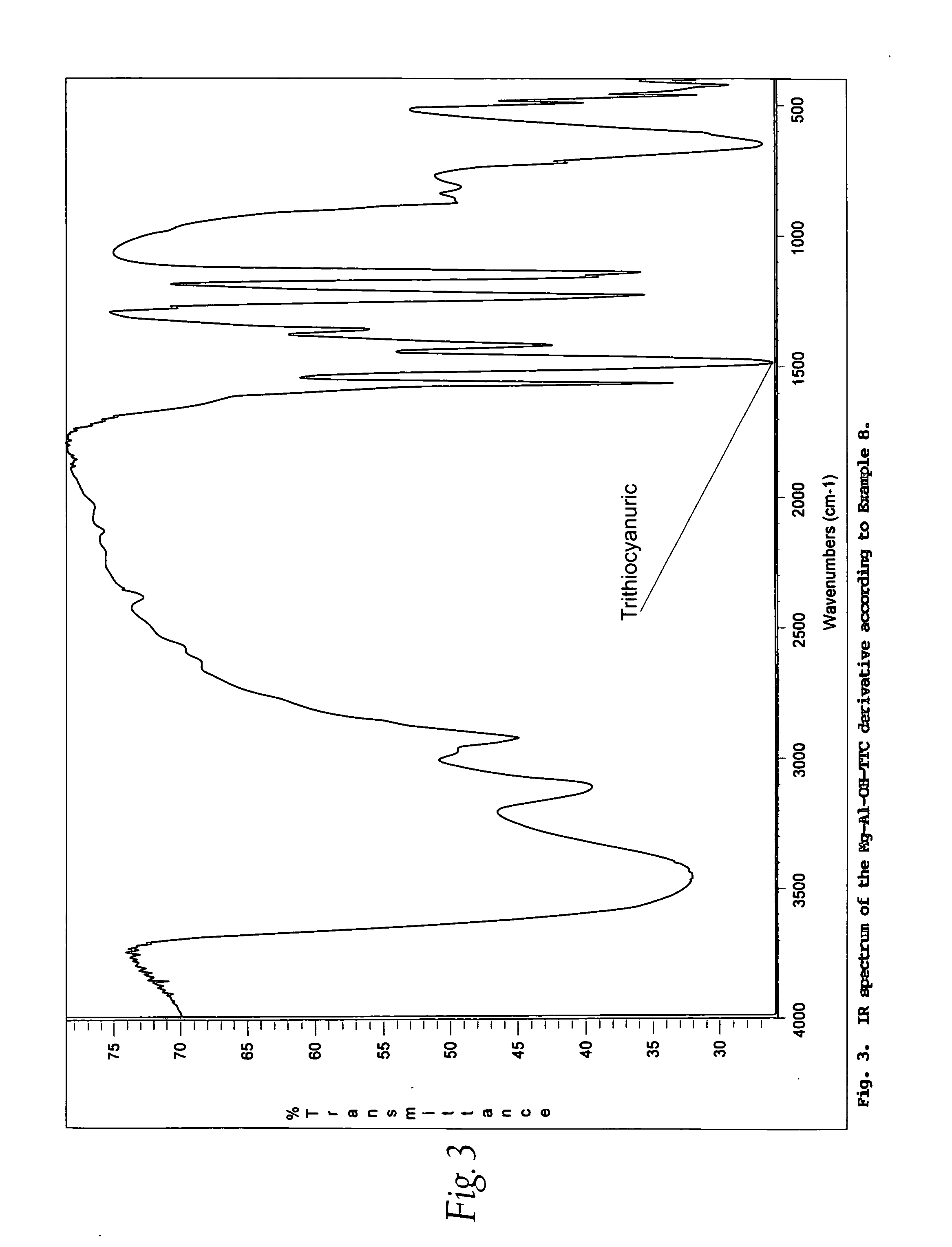

InactiveUS20050022693A1High chemistryEffective corrosionPigmenting treatmentOther chemical processesO-Phosphoric AcidPyrrole

A pigment grade corrosion inhibitor and a method of forming the inhibitor is disclosed. The inhibitor is comprised of a host species comprised of an inorganic compound having a layered structure and a guest species comprised an anionic species of a weak acid. The host species is preferably a double hydroxide having a structure of: [M(II)1-xM(III)x(OH−)2] [An−x / n.y H2O], where M(II) is a divalent metal cationic species, M(III) is a trivalent metal cationic species, and An− is an anionic species, preferably with the species present in a range of: 0.2≦M(III) / (M(II)+M(III))≦0.4. The guest species include: ortho-phosphoric, pyrophosphoric, tripoly-phosphoric, polyphosphoric acid; mono- and di-alkyl or aryl-esters of ortho-phosphoric and pyrophosphoric acid; metaphosphoric, trimeta-phosphoric, poly-metaphosphoric acid; phosphorous (phosphonic) acid; derivatives of phosphonic acid; alkyl and aryl esters of thio-phosphoric and dithio-phosphoric acid; molybdic, phospho-molybdic, silico-molybdic acid; boric acid; cyanamidic acid; nitrous acid; derivatives of thio- and dithiocarbonic acid, including o-alkyl esters; derivatives of dithiocarbamic acid, including N-alkyl dithiocarbamates; pyrrolidinecarbodithioic acid; thio-organic compounds functionalized with at least one —SH group of acidic character, including: 2,5-dimercapto-1,3,4-thiadiazole (DMTD), 2,4-dimercapto-s-triazolo-[4,3-b]-1,3-4 thiadiazole, trithiocyanuric acid (TMT), and dithiocyanuric acid, various N—,S— and N,N—, S,S— and N,S-substituted derivatives of the above DMTD and TMT compounds; various S-substituted derivatives of trithiocyanuric acid; dimer and polymer derivatives of the above DMTD and TMT compounds, including 5,5′ dithio-bis (1,3,4 thiadiazole-2(3H)-thione or (DMTD)2, and (DMTD)n, polymers of DMTD and (TMT)2, dimers and polymers of TMT; various combinations of all the above; soluble salts of DMTD and TMT; poly-ammonium salt of DMTD or (DMTD)n and TMT formed with polyamines; mercapto-benzothiazole, mercapto-benzoxazole, mercapto-benzimidazole, and combinations, thereof; di- and poly-mercapto compounds, including: di-mercapto derivatives of thiophene, pyrrole, furane, diazoles, and thiadiazoles; di- and tri-mercapto derivatives of pyridine, diazines, triazines, benzimidazole, and benzothiazole, including dimercaptopyridine, 2, 4-dithiohydantoine, and 2,4,-dimercapto-6-amino-5-triazine; and carboxylic and di-carboxylic acids, including ascorbic, salicylic acid, phthalic acid, nitro-phthalic acid, succinic acid, and derivatives of succinic acid, including 1-(benzothiazol-2-ylthio)succinic acid.

Owner:LUMIMOVE

Low-temperature-resistant flame-retardant cable for ship

InactiveCN105153601AImprove mechanical propertiesExcellent resistance to heat and oxygenRubber insulatorsInsulated cablesPolymer scienceAcrylic rubber

The invention discloses a low-temperature-resistant flame-retardant cable for a ship. The cable comprises a cable core and a sheath. The sheath is prepared from a modified fluororubber material. The modified fluororubber material comprises the following raw materials: fluororubber 2601, fluororubber 2605, fluorine-containing acrylic rubber, maleic anhydride grafted ethylene propylene diene monomer rubber, cis-1,4-polyisoprene rubber, polycaprolactone, carbon black, light calcium carbonate, modified diatomite, zinc borate, magnesium hydroxide, boron carbide, stearic acid, zinc oxide, trithiocyanuric acid, bisphenol AF, divinyl benzene, an accelerant, an antiaging agent, a plasticizer and a coupler. The low-temperature-resistant flame-retardant cable for the ship disclosed by the invention is high in strength, good in low-temperature resistance, excellent in flame-retardant resistance and long in service life.

Owner:ANHUI HUAYU CABLE GRP

Large-area perovskite solar cell composite photoelectric conversion layer and preparation method therefor

InactiveCN106784323AWide absorption wavelength rangeWell formedSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellCyanuric acid

The invention relates to a perovskite solar cell composite photoelectric conversion layer and a preparation method therefor. The perovskite solar cell composite photoelectric conversion layer comprises a three-dimensional perovskite type photoelectric conversion material thin film and a polymerizable two-dimensional layered perovskite type photoelectric conversion material thin film; the composition of the polymerizable two-dimensional layered perovskite type photoelectric conversion material thin film is NMX<4>, wherein N is cyanuric acid, melamine, trithiocyanuric acid, ammonium triphosphate, amino cyclotriphosphazene or a mixture thereof; M is Pb<2+>, Sn<2+>, Ge<2+>, Cu<2+>, Ni<2+>, Mn<2+>, Zn<2+>, Fe<2+> or a mixture thereof; and X is Cl<->, Br<->, I<-> or a mixture thereof. The polymerizable two-dimensional layered perovskite type photoelectric conversion material is used as the material of a perovskite solar cell composite photoelectric conversion layer and a hole transport layer at the same time, so that the large-area perovskite solar cell preparation process is simplified, and the photoelectric conversion efficiency can be stabilized and improved.

Owner:TIANJIN VOCATIONAL INST

Narrow band-gap carbon nitride visible light photocatalyst and preparation method thereof

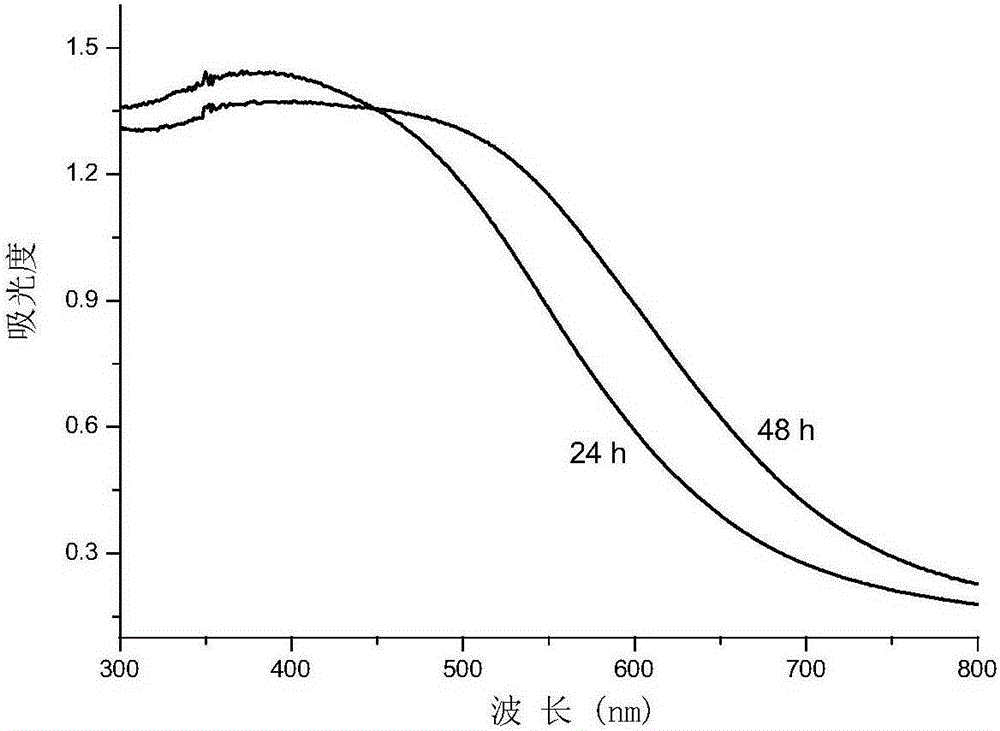

ActiveCN105195202AEffective Photocatalytic DegradationReduced bandgap widthPhysical/chemical process catalystsNitrogen and non-metal compoundsSolar photocatalysisPhoton

The invention discloses a preparation method of a narrow band-gap carbon nitride visible light photocatalyst, and belongs to the technical fields of material preparation and solar photocatalysis. The preparation method comprises the following steps: 1) dispersing cyanuric chloride and trithiocyanuric acid into an organic solvent according to the molar ratio of 1: (0.2-5), and stirring at the room temperature to obtain a reaction mixture; 2) transferring the reaction mixture into a tetrafluoroethylene-lined hydrothermal reaction still, and carrying out heat treatment to obtain the narrow band-gap graphite phase carbon nitride visible light photocatalyst. The invention also discloses the catalyst prepared through the preparation method. According to the preparation method, the band gap width of carbon nitride is decreased, the visual light absorption range is enlarged, and the photon-generated carrier separation and migration efficiency is improved; the catalyst prepared through the method is stable in property, nontoxic, and easy to recycle, can be circularly used, conforms to the requirement of practical production, and facilitates large-scale popularization.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

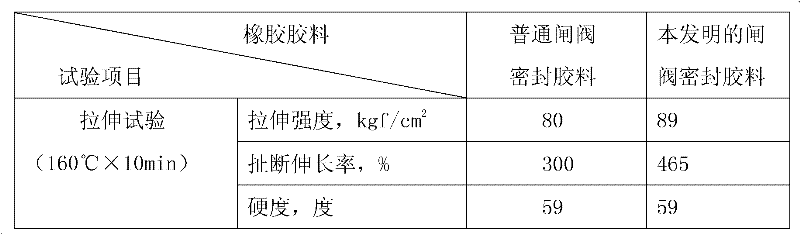

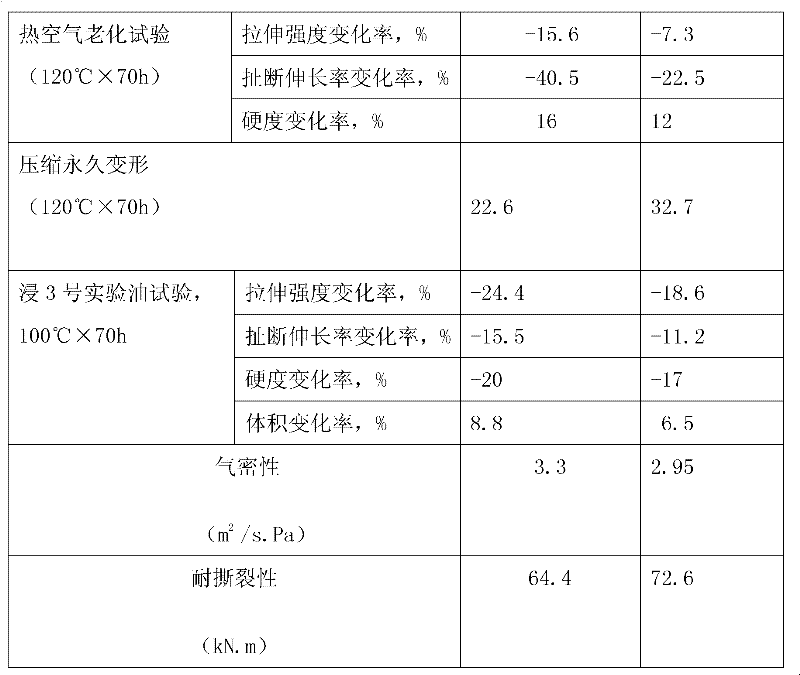

O-shaped seal ring rubber sizing material of parallel gate valve end surfaces and preparation method thereof

The invention discloses an O-shaped seal ring rubber sizing material of parallel gate valve end surfaces, which is formed by mixing a rubber sizing material A and a rubber sizing material B, wherein the rubber sizing material A comprises the following raw materials in part by weight: 85-95 parts of nitrile rubber 3304, 0.3-0.5 parts of sulphur, 4-6 parts of zinc oxide, 1-1.5 parts of stearic acid, 1-2 parts of 2,6-Di-tert-butyl-p-methyl phenol (BHT), 1-2 parts of anti-aging agent RD, 1-2 parts of anti-aging agent 4010Na, 3-4 parts of microcrystalline wax, 22-25 parts of fast extruding carbon black N660, 62-65 parts of high wear-resistant carbon block N330, 18-22 parts of dioctyl phthalate, 10-15 parts of magnesium carbonate, 3-4 parts of accelerator M, 1-2 parts of 2,2'-dibenzothiazoledisulfde (DM) and 1-2 parts of accelerator PZ; and the rubber sizing material B comprises the following raw materials in part by weight: 82-87 parts of polyacrylate rubber, 13-18 parts of silicon rubber, 1-2 parts of zinc stearate, 1-3 parts of anti-aging agent RD, 0.4-0.6 parts of gum easyT-78, 1-2 parts of Rhine wax, 45-55 parts of fast extruding carbon black, 10-14 parts of quartz powder, 5-8 parts of hydroxy silicone oil, 4-6 parts of Pb2O4, 0.7-0.9 parts of Trithiocyanuric acid (TCY) and 1-2 parts of accelerator Na-2. The seal ring rubber lining sizing material disclosed by the invention has good comprehensive performance. The produced O-shaped seal ring of the parallel gate valve end surfaces has the characteristics of good gas tightness, weather resistance, low temperature resistance, oil resistance and the like, and also has low material cost.

Owner:TONGLING XINTE VALVE

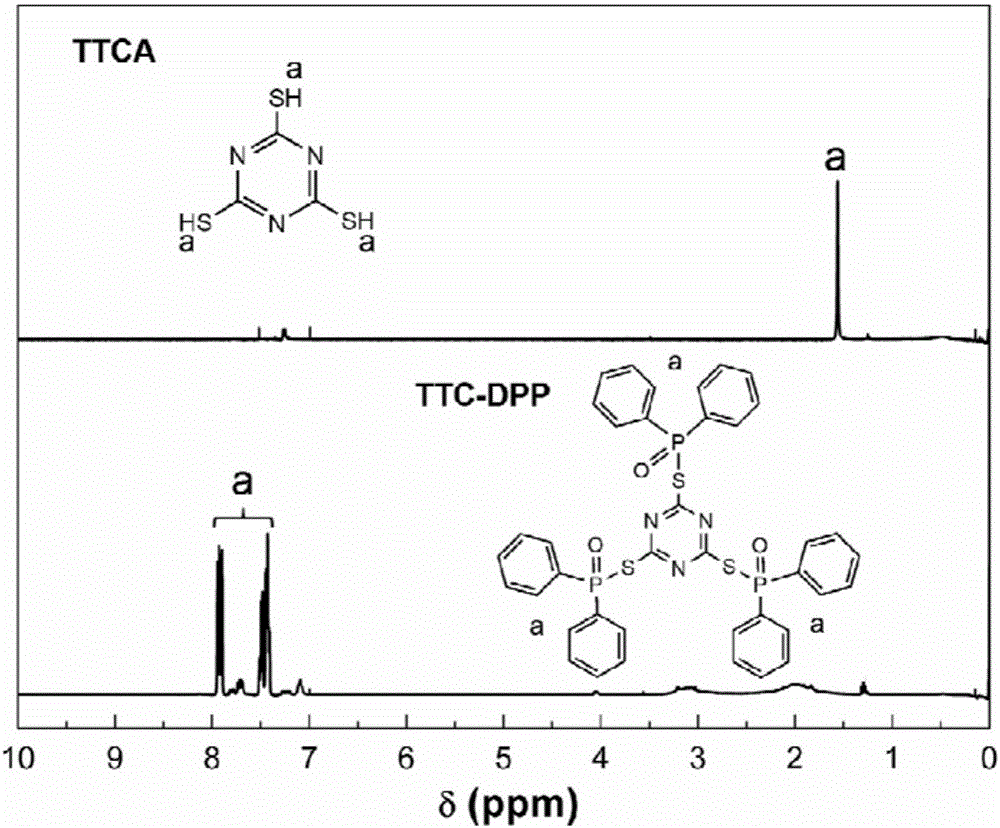

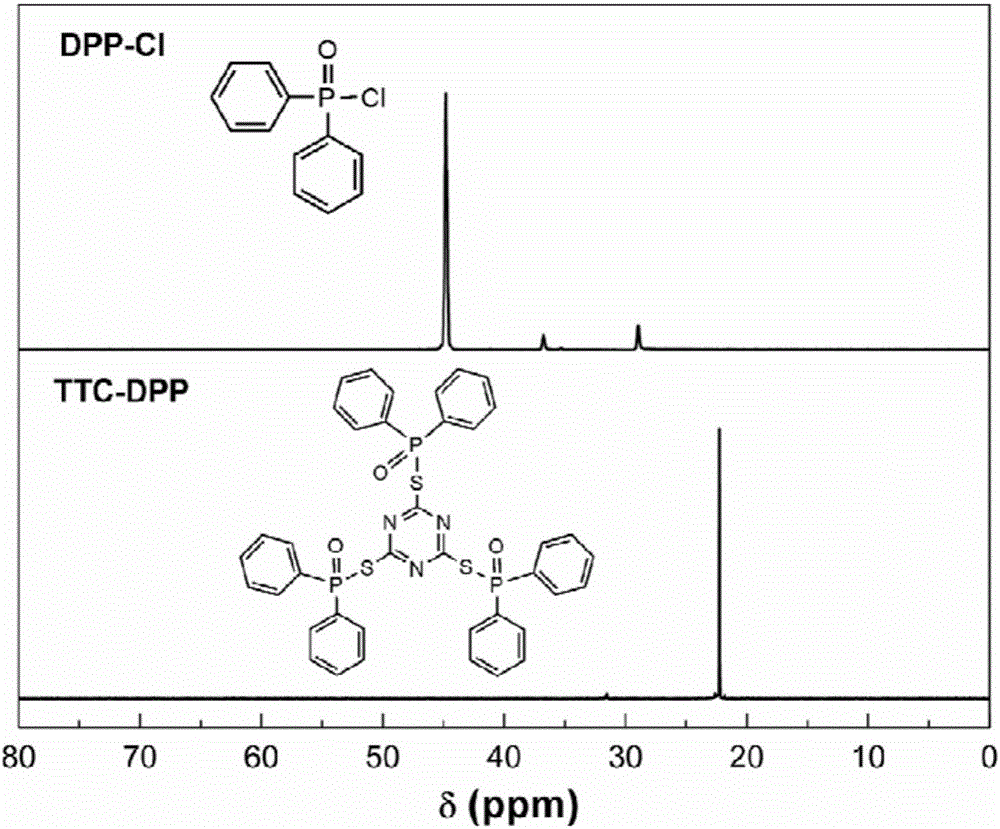

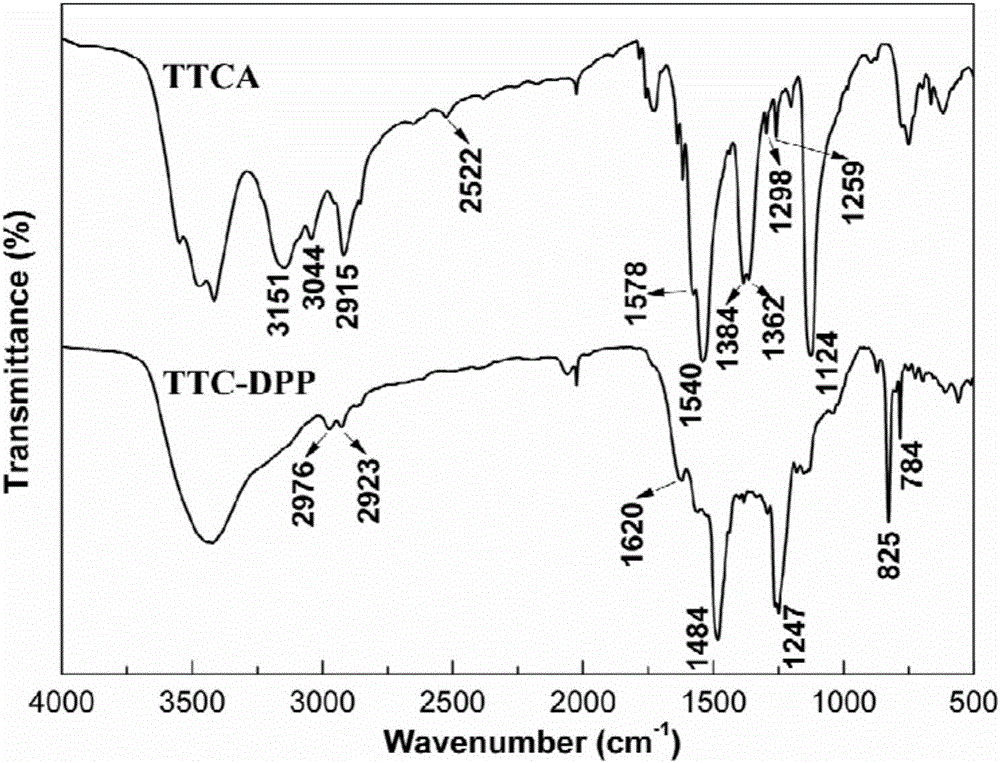

Intumescent flame retardant containing phosphorus, nitrogen and sulfur and preparation method of intumescent flame retardant

InactiveCN105801624AImprove interface compatibilityImprove water resistanceGroup 5/15 element organic compoundsEthyl groupCarbonization

The invention belongs to the technical field of halogen-free flame retarding, and particularly relates to an intumescent flame retardant containing phosphorus, nitrogen and sulfur and a preparation method of the intumescent flame retardant.The molecular structural formula of the flame retardant is as follows (please see the formula in the description), wherein R represents an ethyl group or phenyl group.The preparation method comprises the steps that trithiocyanuric acid is dissolved in organic solvent, an acid binding agent is added, phosphinic chloride is added under the ice bath and nitrogen protecting conditions, reacting continues under the ice bath condition, then reacting under heating is performed under the nitrogen condition, and filtering is performed to remove precipitates and then remove the solvent, wherein the molar ratio of the acid binding agent to phosphinic chloride is (1.0-1.5):1, and the molar ratio of phosphinic chloride to trithiocyanuric acid is 3:1.According to the intumescent flame retardant containing phosphorus, nitrogen and sulfur, the contents of phosphorus, nitrogen and sulfur are all high, phosphorus, nitrogen and sulfur have the synergistic flame retarding effect, therefore, the composite material can quickly promote carbonization of a polymer in the heated or combustion process, oxygen and heat insulation is achieved, and releasing of combustible gas and toxic flue gas is reduced; meanwhile, the flame retardance of the composite material can be further improved by cooperating with a small quantity of a flame retardant synergist.

Owner:HEFEI UNIV

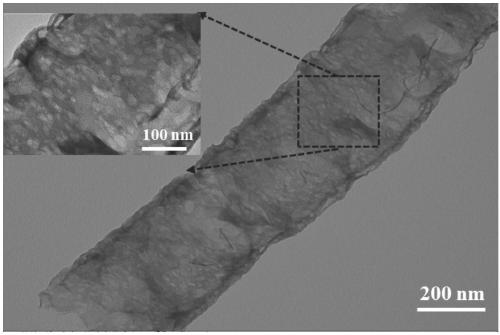

Sulfur-doped g-C3N4/C-dot porous composite photocatalyst and preparing method and application thereof

ActiveCN109395763AChange shapeImprove visible light absorptionPhysical/chemical process catalystsWater/sewage treatment by irradiationChemical compositionSulfur

The invention relates to a sulfur-doped g-C3N4 / C-dot porous composite photocatalyst and a preparing method and application thereof. A chemical composition of the photocatalyst comprises sulfur-doped C3N4 and C-dot nano-particles, and a microstructure of the catalyst comprises rod-shaped and porous structures. An S-C3N4 precursor prepared by mixing tripolycyanamide and trithiocyanuric acid and a C-dot prepared with the alkali-assisted ultrasound method are compositely calcined, and the S-C3N4 / C-dot nanometer composite photocatalyst is prepared. By means of the sulfur-doped g-C3N4 / C-dot photocatalyst prepared with the method, absorption of a visible light area can be enhanced, and transferring of photo-induced charges can be promoted; meanwhile, as the basal morphology is adjusted and controlled by the C-dot, the porous structure is remarkably formed, the specific area is increased, the preparing method is low in cost, simple in technology and environmentally friendly, and a prepared photocatalysis composite material has good application prospects when being used for treating wastewater.

Owner:SHANDONG UNIV

High-pressure rubber hose

InactiveCN104676149AOvercoming structural complexityOvercome CorrosivityFlexible pipesPolythiocyanogenCorrosion resistant

The invention discloses a high-pressure rubber hose. The high-pressure rubber hose comprises an inner rubber layer, a frame layer and an outer rubber layer, which are tightly stacked together from inside to outside. When the inner rubber layer is prepared, various components are matched according to corresponding weight parts and then smelted in a smelting machine, after smelting, rubber is discharged under the condition of 220 degrees Centigrade, then 1.5 parts of trithiocyanuric acid and 2 parts of sulfur are added for mixing. After mixing, the rubber is extruded at the temperature of 300 degrees Centigrade to obtain the inner rubber layer; when the outer rubber layer is prepared, various components are matched according to corresponding weight parts and smelted in the smelting machine and then added with 1.8 parts of sulfur for mixing and are extruded after mixing to obtain the outer rubber layer. The high-pressure rubber hose can overcome defects of complicated structure, poor corrosion resistance, short service life and the like in the prior art and has the advantages of simple structure, high corrosion resistance and long service life.

Owner:LIUZHOU CITY TONGJIN AUTOMOBILE PARTS MFG CO LTD

Pigment grade corrosion inhibitor host-guest compositions and procedure

InactiveUS20080258114A1Maximize loadingEffective corrosionPigmenting treatmentOther chemical processesO-Phosphoric AcidThio-

A pigment grade corrosion inhibitor and a method of applying the inhibitor is disclosed. The inhibitor is comprised of a host species comprised of an inorganic compound having a layered structure and a guest species comprised an anionic species of a weak acid. The host species is preferably a double hydroxide having a structure of: [M(II)1-x M(III)x (OH−)2] [An−x / n·y H2O], where M(II) is a divalent metal cationic species, M(III) is a trivalent metal cationic species, and An− is an anionic species, preferably with the species present in a range of: 0.2≦M(III) / (M(II)+M(III))≦0.4. The guest species include: various phosphoric acids and derivatives thereof; boric acid; cyanamidic acid; nitrous acid; derivatives of thio- and dithiocarbonic acid; thio-organic compounds functionalized with at least one —SH group of acidic character, including: 2,5-dimercapto-1,3,4-thiadiazole (DMTD), 2,4-dimercapto-s-triazolo-[4,3-b]-1,3-4 thiadiazole, trithiocyanuric acid (TMT), and dithiocyanuric acid.

Owner:LUMIMOVE

Preparation and application of zinc hydroxystannate-palygorskite-trithiocyanuric acid compound smoke-suppressed fire retardant

ActiveCN104119614AImprove flame retardant performanceGood smoke suppressionPalygorskiteHydroxy group

The invention provides a zinc hydroxystannate-palygorskite-trithiocyanuric acid compound smoke-suppressed fire retardant having good smoke-suppressed fire-retardant performance. The zinc hydroxystannate-palygorskite-trithiocyanuric acid compound smoke-suppressed fire retardant is prepared by compounding a zinc hydroxystannate-palygorskite clay composite (the structure and the performance refer to CN102515185A) with trithiocyanuric acid according to the mass ratio of 20:1 to 1:1. Experiments show that the compound of trithiocyanuric acid and the zinc hydroxystannate-palygorskite clay composite has a good synergetic effect; the fire retardant prepared by taking the compound as the additive has a good carbon forming effect, and therefore, the zinc hydroxystannate-palygorskite-trithiocyanuric acid compound smoke-suppressed fire retardant provided by the invention can be widely used for modifying plastics and various kinds of rubbers.

Owner:NORTHWEST NORMAL UNIVERSITY

Preparation of organic sulfur heavy metal capturing agent and recycling and treating method of filtrate thereof

InactiveCN105036281ASimple production processShort cycleOrganic chemistryWater/sewage treatmentSodium hydrosulfidePrecipitation

The invention discloses preparation of an organic sulfur heavy metal capturing agent and a recycling and treating method of filtrate thereof. The effective component of the organic sulfur heavy metal capturing agent is 2,4,6-trithiocyanuric acid trisodium salt. A production method for the organic sulfur heavy metal capturing agent comprises the following steps: adding cyanuric chloride into an aqueous solution of sodium hydrosulfide and / or sodium sulfide for reaction, adding a sodium hydroxide solution to adjust the pH to 12 or above, and reacting for 2 hours to obtain an aqueous solution of 2,4,6-trithiocyanuric acid trisodium salt; cooling the reaction liquid, crystallizing, and carrying out centrifugal separation to obtain a 2,4,6-trithiocyanuric acid trisodium salt product; adding hydrochloric acid into the filtrate generated from centrifugal separation, carrying out precipitation and centrifugal filtration, adding the sodium hydroxide solution to adjust the pH to 12 or above to obtain the aqueous solution of 2,4,6-trithiocyanuric acid trisodium salt; repeating the steps; the filtrate generated from centrifugal filtration is subjected to a multi-effect salt steaming system. The preparation has the advantages of being simple in production process, short in production cycle, high in yield and few in by-products.

Owner:SHANXI CHEM RES INST

Method for preparing three-dimensional porous nitrogen-sulfur doped carbon nanosheet

InactiveCN109019565AEasy to operateLow costMaterial nanotechnologyCell electrodesGraphite oxidePolymerization

The invention relates to a three-dimensional porous nitrogen-sulfur doped carbon nanosheet. A method for preparing the three-dimensional porous nitrogen-sulfur doped carbon nanosheet comprises the following steps: an uniform solution containing thiocyanuric acid is slowly added to an aqueous solution of graphene oxide in which melamine is dissolved, and the materials are fully stirred at 50 to 120DEG C; a product is subjected to two-stage heat treatment at 300-500 DEG C and 700-900 DEG C under vacuum environment, inert atmosphere is introduced until the temperature is lowered, and the three-dimensional porous nitrogen-sulfur doped carbon nanosheet is obtained. The method adopts melamine and trithiocyanuric acid to form a carbon skeleton by molecular polymerization, and a three-dimensionalcarbon material is constructed into with the participation of graphene; at the same time, melamine and trithiocyanuric acid are used as nitrogen and sulfur-doped nitrogen sources and sulfur sources,and the graphene carbon material is subjected to nitrogen and sulfur doping. The carbon material has good rate performance as a lithium and sodium battery anode, and a large specific surface area anda multi-stage pore structure are easy to realize sulfur loading. The preparation method has the advantages of simple operation and low cost, and can realize large scale preparation.

Owner:SHAANXI UNIV OF SCI & TECH

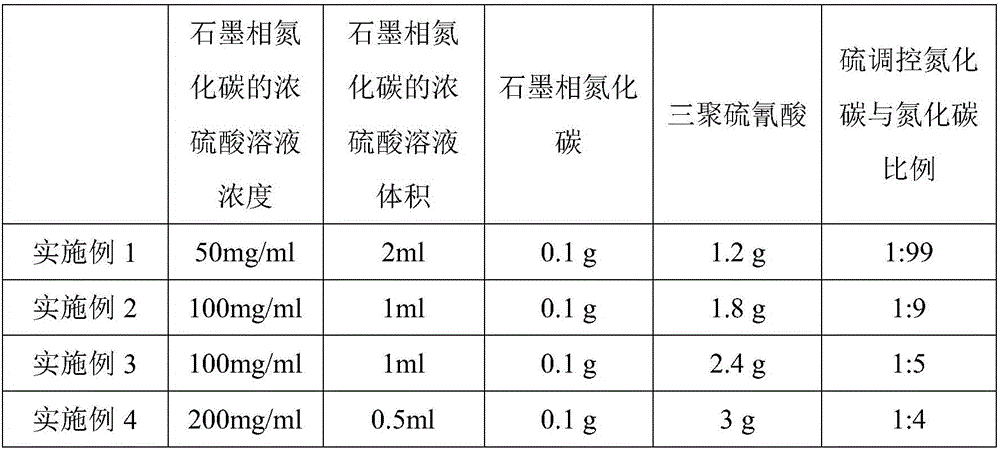

Graphite-phase carbon nitride composite photocatalyst and preparation method thereof

ActiveCN106732720AImprove separation efficiencyImprove mixing uniformityPhysical/chemical process catalystsHydrogen productionSulfurCarbon nitride

The invention discloses a preparation method of a graphite-phase carbon nitride composite. The preparation method comprises the following steps: mixing graphite-phase carbon nitride with concentrated sulfuric acid, heating and stirring the obtained mixture to completely dissolve the graphite-phase carbon nitride in the concentrated sulfuric acid, adding trithiocyanuric acid into the obtained concentrated sulfuric acid solution of the graphite-phase carbon nitride, sufficiently mixing the substances, adding a poor solvent, separating a settled precipitate, drying the precipitate to obtain a sample, and calcining the dried sample in an inert atmosphere, thereby obtaining the composite comprising the graphite-phase carbon nitride and sulfur conditioned graphite-phase carbon nitride; the composite can be used as a photocatalyst. By adopting the preparation method, the mixing uniformity degree of the graphite-phase carbon nitride composite can be effectively increased, furthermore, the separation efficiency of a photon-generated carrier can be furthermore improved, and thus application of the graphite-phase carbon nitride to photocatalysis is widened.

Owner:SOUTHEAST UNIV

Method for treating waste water containing complex copper

InactiveCN103482786ANothing producedLow costMultistage water/sewage treatmentAluminium chlorideSodium salt

The invention relates to a method for treating waste water containing complex copper. The method comprises the following steps: adding hydrochloric acid to adjust the pH value of the waste water to 3.0-4.0; adding 20-200 ppm of sodium hypochlorite and stirring for 2-5 minutes; then, adding sodium hydroxide to adjust the pH value of the waste water to 10.5-11.5; further, adding 50-500 ppm of PAC (Poly Aluminum Chloride) and stirring for 2-5 minutes; then, adding 10-100 ppm of trithiocyanuric acid trisodium salt and stirring for 2-5 minutes; finally, adding 0.5-5 ppm of negative ions, stirring for 10-20 minutes, precipitating for 10-20 minutes, filtering, and measuring the copper content of the filtered water. The invention has the benefits that the method is low in cost and small in consumption, can be used for treating copper of different forms and copper in the complex state in water, is simple to operate, has no secondary pollution, and generates no poisonous gas; the copper removal rate reaches 99.4%.

Owner:SHANGHAI FENGXIN ENVIRONMENTAL PROTECTION TECH

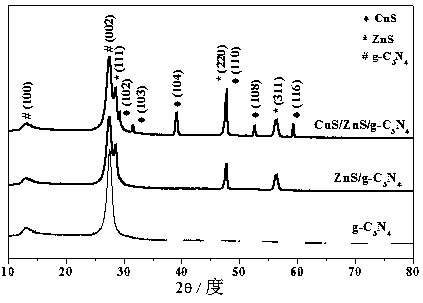

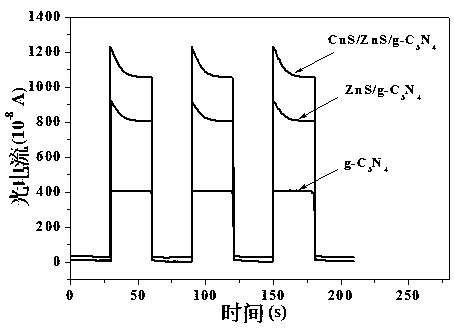

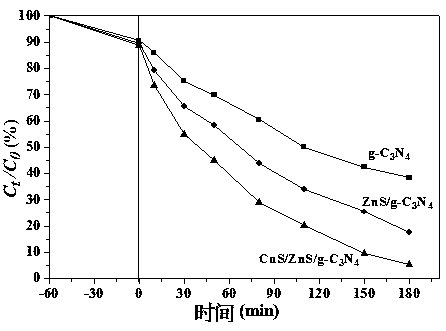

Preparation method of CuS/ZnS/g-C3N4 ternary composite photocatalyst

InactiveCN108786882ARaw materials are easy to getLow costWater/sewage treatment by irradiationWater treatment compoundsPhotocatalytic reactionCopper chloride

The invention relates to the technical field of photocatalysts, in particular to a preparation method of a CuS / ZnS / g-C3N4 ternary composite photocatalyst. A CuS / ZnS / g-C3N4 ternary heterostructure is directly obtained by the preparation method of the CuS / ZnS / g-C3N4 ternary composite photocatalyst through a one-step calcination method. The preparation method comprises the following specific steps: first step: mixing a certain amount of copper chloride dehydrate, zinc chloride and trithiocyanuric acid to form a precursor mixture; and second step: uniformly grinding the mixture, putting the mixture into a tubular furnace for calcination, washing the obtained product with distilled water and anhydrous ethanol, and drying the product, thus obtaining the CuS / ZnS / g-C3N4 ternary composite photocatalyst. The steps are simple; in the photocatalytic reaction, the preparation method is relatively high in photo-induced electron and hole separation efficiency; the raw materials of the ternary composite photocatalyst are easy to obtain and low in cost; the reaction conditions are mild and cause no pollution to the environment; and the preparation method is favorable for industrial production.

Owner:常州科力尔环保科技有限公司

Silicone rubber for sealing two ends of heater

InactiveCN104371331AImprove water resistanceWater resistance, good sealing effectPolymer scienceDiboride

The invention discloses silicone rubber for sealing two ends of a heater. The silicone rubber comprises the following raw materials in parts by weight: 1-2 parts of 1,4-cyclohexanedimethanol, 0.4-1 parts of vanadium diboride, 3-4 parts of polypropylene powder, 1-2 parts of accelerant TT, 0.4-1 part of trithiocyanuric acid, 0.7-1 part of 2-mercaptobenzimidazole, 1-2 parts of 1-hydroxycyclohexyl phenyl ketone, 10-17 parts of superfine barium sulfate, 10-13 parts of bis(2-ethylhexyl)sebacate, 2-3 parts of calcium fluoride, 0.5-1 part of butyltin mercaptide, 3-4 parts of rare earth auxiliaries, 100-110 parts of methyl vinyl phenyl siloxane rubber, 1-2 parts of sulfur, and 0.2-0.5 part of tetrahydrofuran, wherein the rare earth auxiliaries are prepared by the following steps: fully melting magnesium-aluminum silicate and colloid formed by polyvinyl acetal under the condition of taking deionized water as a solvent, so as to form stable and high-viscosity colloidal state, adding the treated acidified rare earth into the high-viscosity colloidal state system to form stable rare earth colloidal liquid, and then mixing and modifying with the esterified zeolite. By adopting the rare earth auxiliaries, not only can the mechanical performance and surface resistance of the finished products be effectively improved, but also the compatibility of materials can be enhanced, the stability of the finished products can be improved, the volume wear can be reduced by rare earth, and the wear resistance of the rubber can be improved.

Owner:滁州君越高分子新材料有限公司

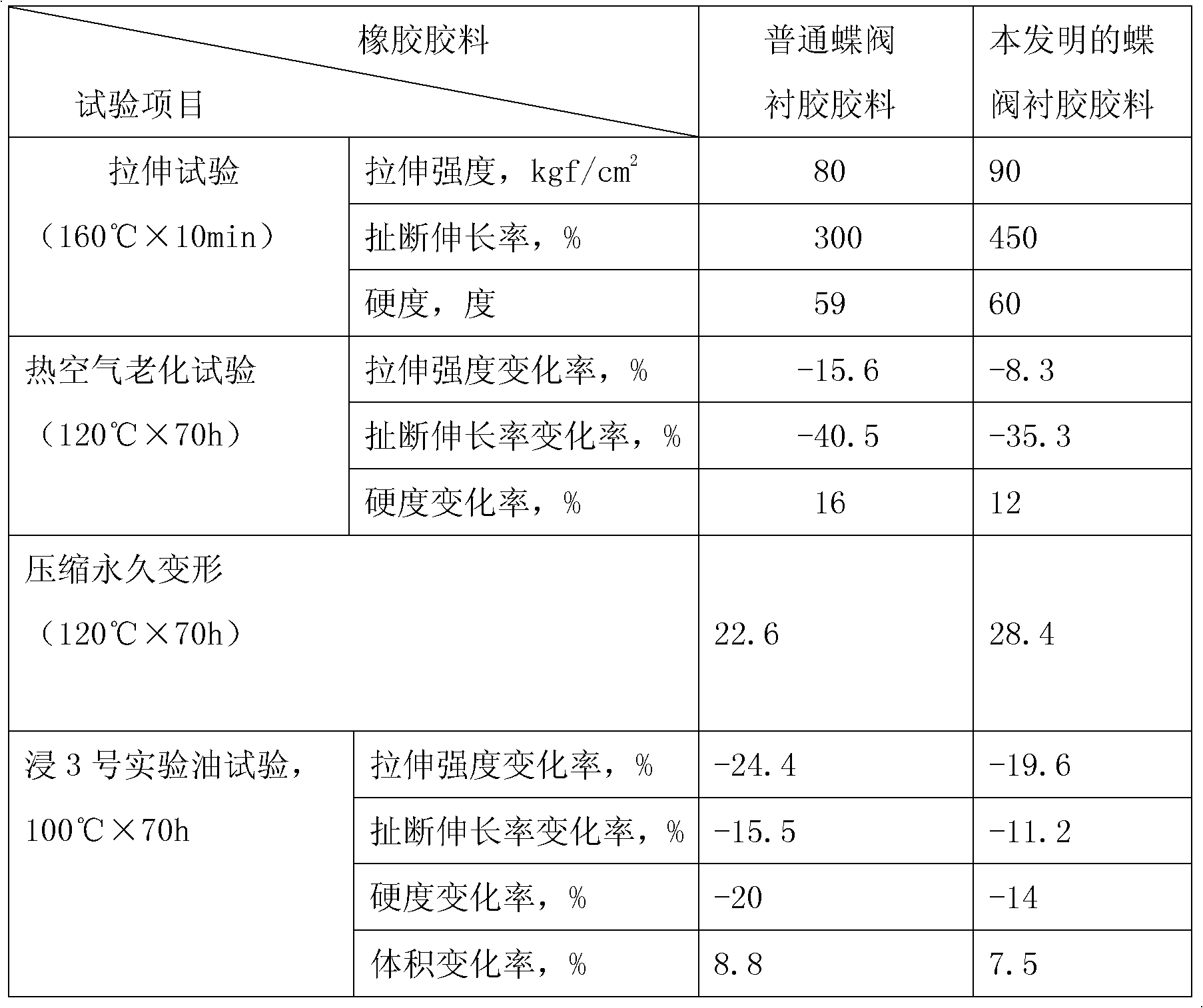

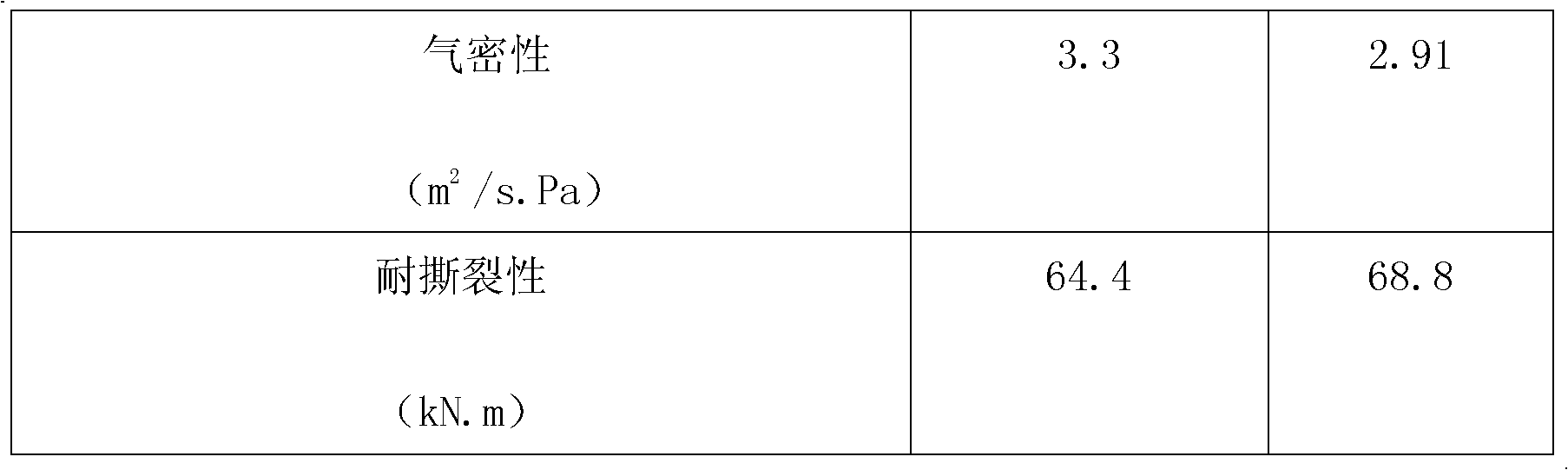

Rubber lining rubber material for corrosion resisting butterfly valve lined with rubber, and preparation method for rubber lining rubber material

The invention discloses a rubber lining rubber material for a corrosion resisting butterfly valve lined with rubber. The rubber lining rubber material is formed by mixing a rubber material A and a rubber material B, wherein the rubber material A comprises the following raw materials in part by weight: 85 to 95 parts of nitrile rubber 3305, 0.3 to 0.5 part of sulphur, 4 to 6 parts of magnesium oxide, 3 to 4 parts of stearic acid, 1 to 2 parts of antioxygen 2,5-di-tert-butylhydroquinone (DTBHQ), 1 to 2 parts of antiager RD, 1 to 2 parts of antiager 4010NA, 3 to 4 parts of paraffin, 22 to 25 parts of fast extrusion carbon black, 62 to 65 parts of high wear resistant carbon black 330, 18 to 22 parts of dioctyl ester, 25 to 35 parts of calcium carbonate, 3 to 4 parts of accelerator, 1 to 2 parts of accelerator tetramethylthiuram disulphide (TMTD), and 1 to 2 parts of accelerator tetraethyl-thinram disulfide (TETD); and the rubber material B comprises the following raw materials in part by weight: 82 to 87 parts of homopolymerization epichloro-hydrin rubber, 12 to 18 parts of copolymerization epichloro-hydrin rubber, 1 to 2 parts of zinc stearate, 1 to 3 parts of antiager RD, 0.4 to 0.6part of rubber change element, 1 to 2 parts of rhine wax, 45 to 55 parts of fast extrusion carbon black, 10 to 14 parts of kieselguhr, 5 to 8 parts of dioctyl ester,4 to 6 parts of lead dioxide, 0.8 part of vulcanizer trithiocyanuric acid (TCY), and 1 to 2 parts of accelerator Na-22. The rubber lining rubber material has good comprehensive performance, and the butterfly valve which is obtained through vulcanization has the characteristics of high air tightness, weather fastness, chilling resistance, and oil resistance and the like; meanwhile, the material cost is low.

Owner:安徽金源流体控制技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com