Heavy metal ion adsorbent, preparation method and application

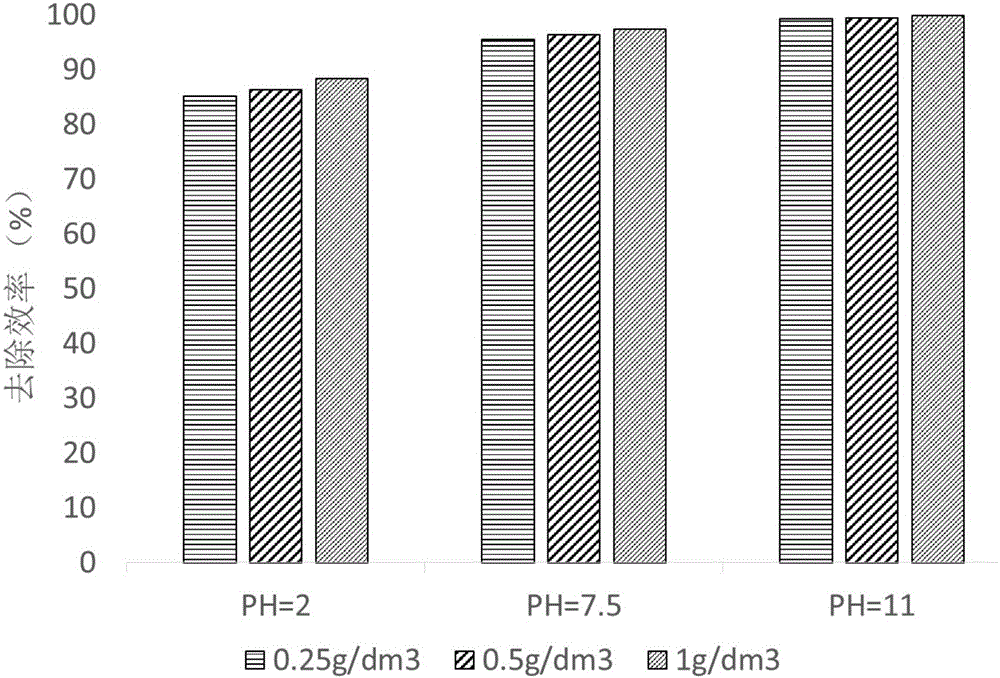

A technology of heavy metal ions and adsorbents, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high cost, large amount of medicine required, and low removal efficiency of heavy metals , to achieve the effect of low cost, good adsorption performance and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

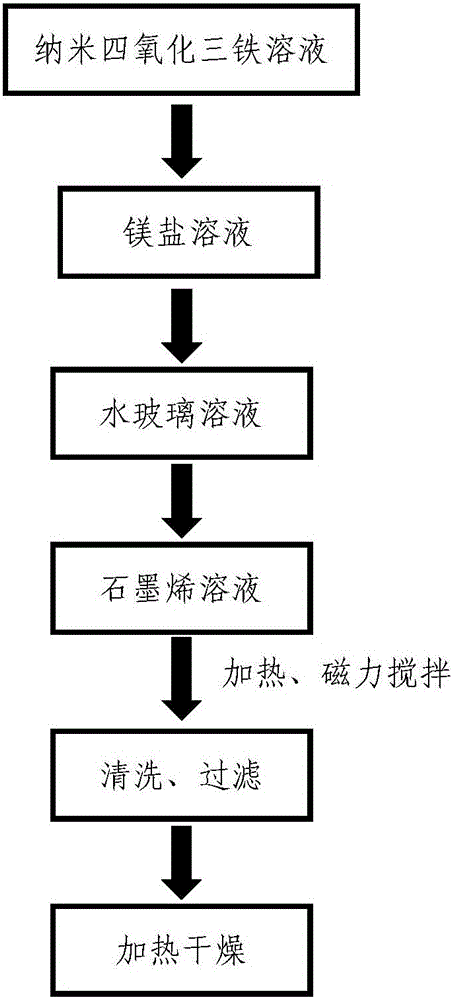

[0045] A Graphene@Fe 3 o 4 @MgO·SiO 2 The preparation method of composite particles is carried out in the following steps:

[0046] (1) Add 200mL mass fraction of 3% nano ferric oxide aqueous solution, 500mL mass fraction of 5% magnesium chloride solution, 500mL mass fraction of 5% water glass in the reactor with heating, stirring and strong ultrasonic device (the proportioning ratio of quartz sand and alkali is 1:1) solution and 100mL mass fraction are 1% graphene solution, in the solution adding process, reaction device keeps strong ultrasonic and rapid stirring, then the solution is heated to 50 ℃, wherein Stirring speed is 1500RMP, ultrasonic frequency is 80MHz; co-precipitation produces graphene@Fe 3 o 4 @MgO·SiO 2 Composite particles;

[0047] (2) Wash the mixture obtained in step (1) by filtration, collect the filter residue, dry the obtained filter residue at 80° C., and then fully grind the obtained filter residue until it is powdery.

Embodiment 2

[0049] A Graphene@Fe 3 o 4 @MgO·SiO 2 The preparation method of composite particles, the preparation method is the same as in Example 1, the difference is only that: the raw material is 200mL mass fraction of 3% nano iron ferric oxide aqueous solution, 500mlL mass fraction is 6% magnesium chloride solution, 500mL mass fraction is 3% water The glass (quartz sand and alkali ratio is 2:1) solution and 100mL graphene solution with a mass fraction of 1%, the co-precipitation temperature is 40°C.

Embodiment 3

[0051] A Graphene@Fe 3 o 4 @MgO·SiO 2 The preparation method of the composite particles, the preparation method is the same as in Example 1, the difference is only that: the raw material is 200mL mass fraction of 4% nano iron ferric oxide aqueous solution, 500mL mass fraction is 7% magnesium chloride solution, 500mL mass fraction is 7% water The glass (quartz sand and alkali ratio is 2:1) solution and 100mL graphene solution with a mass fraction of 1%, the co-precipitation temperature is 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com