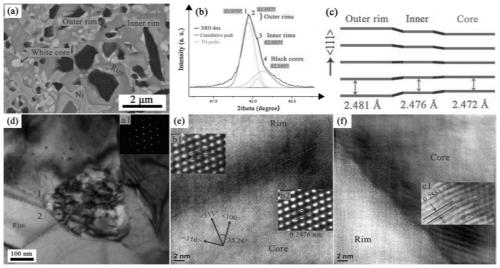

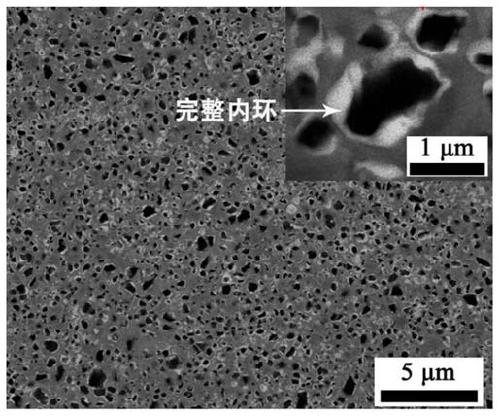

Ti (C, N) base metal ceramic with homogeneous ring core structure and preparation method thereof

A homogeneous ring and base metal technology, applied in the field of cermets, can solve problems such as inhomogeneous ring core interface structure, incomplete inner ring phase, reduction, etc., to achieve the promotion of diffusion reaction speed, fine grain size, and grain size uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 43Ti(C,N)-4TiC-15WC-9Mo 2 C-5TaC-24.5Ni-0.5C cermet

[0044] In the present embodiment 1, the mass parts of cermet component raw materials are as follows: 43 parts of Ti (C, N) powder, 4 parts of TiC powder, 15 parts of WC powder, 9 parts of Mo 2 C powder, 5 parts of TaC powder, 24.5 parts of Ni powder and 0.5 part of carbon powder, the total amount is 100 parts.

[0045] The preparation steps of the cermet are: the weighed TiC / WC / Mo 2 Put the C / TaC powder in the ball milling tank, add absolute ethanol until the surface of the ball and the powder is covered; carry out roller milling on the ball milling tank, the ball to material ratio is 10:1, the speed is 100r / min, the ball milling time is 20h, after drying Afterwards, vacuum storage; followed by secondary ball milling, with a ball-to-material ratio of 8:1, a rotational speed of 100r / min, and a ball milling time of 60h; after ball milling, 3% molten paraffin was added to the mixture and vacuum stirred for 2h; the pow...

Embodiment 2

[0049] 50Ti(C,N)-2TiC-15WC-9Mo 2 C-5TaC-18.8Ni-0.2C cermet

[0050] In the present embodiment 2, the mass parts of cermet component raw materials are as follows: 50 parts of Ti (C, N) powder, 2 parts of TiC powder, 15 parts of WC powder, 9 parts of Mo 2 C powder, 5 parts of TaC powder, 18.8 parts of Ni powder and 0.2 part of carbon powder, the total amount is 100 parts.

[0051] The preparation steps of the cermet are: the weighed TiC / WC / Mo 2 Put the C / TaC powder in the ball mill tank, add absolute ethanol until the surface of the ball and the powder is covered; carry out roller milling on the ball mill barrel, the ball-to-material ratio is 12:1, the speed is 120r / min, the ball milling time is 30h, and dried Afterwards, it was stored in vacuum; followed by secondary ball milling, the ball-to-material ratio was 12:1, the rotational speed was 100r / min, and the ball milling time was 60h; after ball milling, 2% molten paraffin was added to the mixture, and vacuum stirring was ca...

Embodiment 3

[0054] 55Ti(C,N)-5TiC-24WC-6TaC-5Ni-4.2Co-0.8C cermet

[0055] The mass parts of cermet component raw materials in the present embodiment 3 are as follows: 65 parts of Ti (C, N) powder, 5 parts of TiC powder, 18 parts of WC powder, 2 parts of TaC powder, 5 parts of Ni powder and 4.2 parts Part of cobalt, 0.8 part of carbon powder, the total amount is 100 parts.

[0056] The preparation steps of the cermet are as follows: put the weighed TiC / WC / TaC powder in a ball milling tank, add absolute ethanol until the surface of the ball and the powder is submerged; perform roller milling on the ball milling tank, the ball-to-material ratio is 15: 1. The rotation speed is 140r / min, the ball milling time is 20h, and it is dried and stored in vacuum; after that, the second ball milling is carried out, the ball-to-material ratio is 10:1, the speed is 100r / min, and the ball milling time is 50h; after ball milling, in the mixture Add 2% molten paraffin to the mixture, and carry out vacuum s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com