Patents

Literature

34results about How to "Fine grain size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

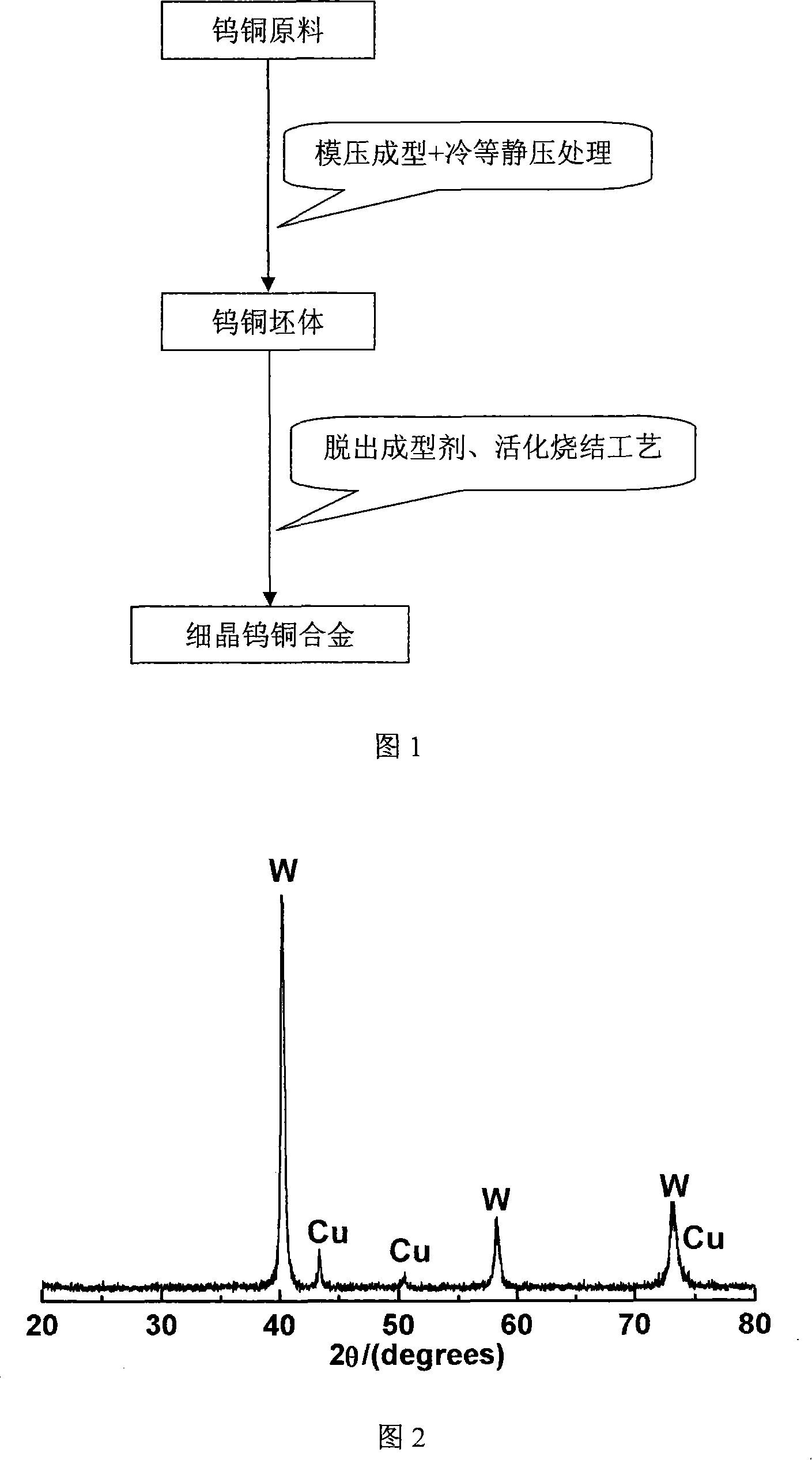

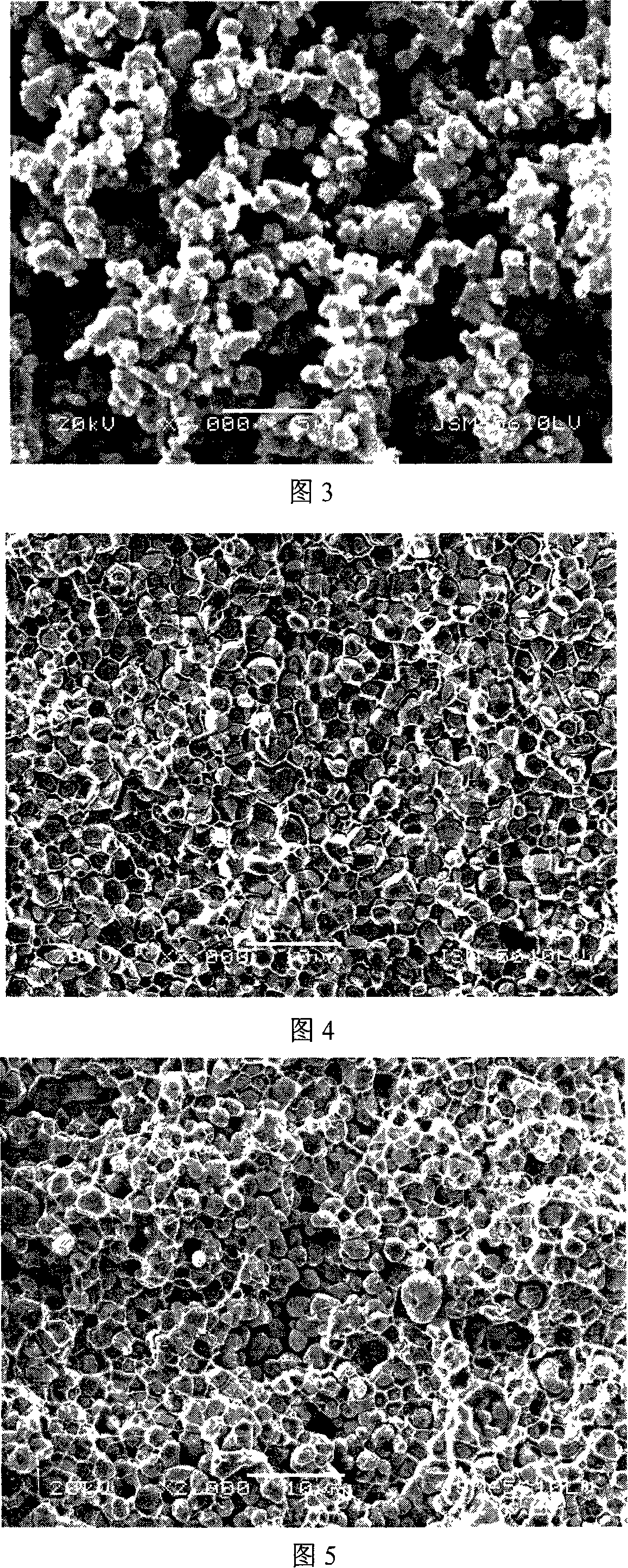

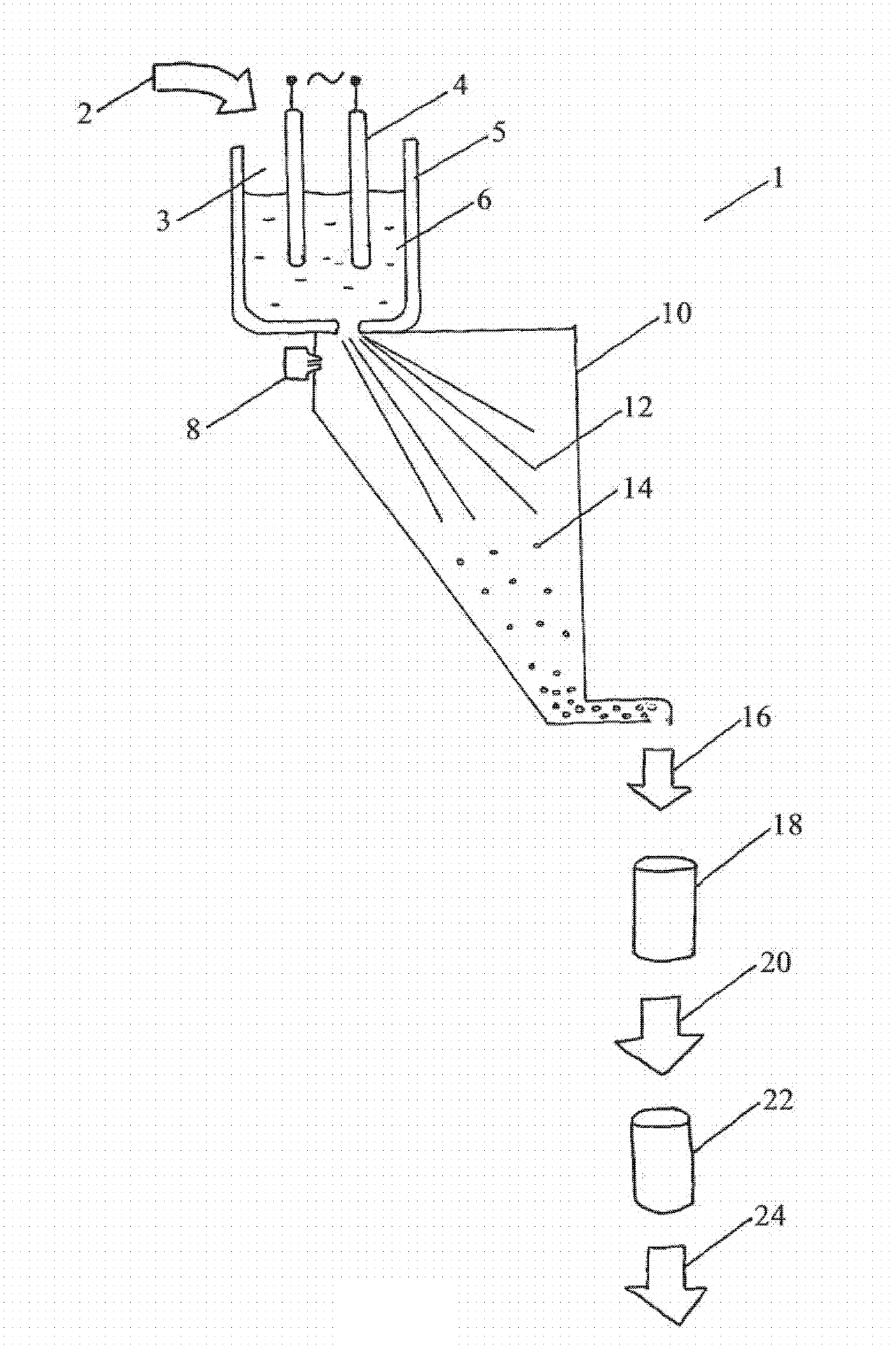

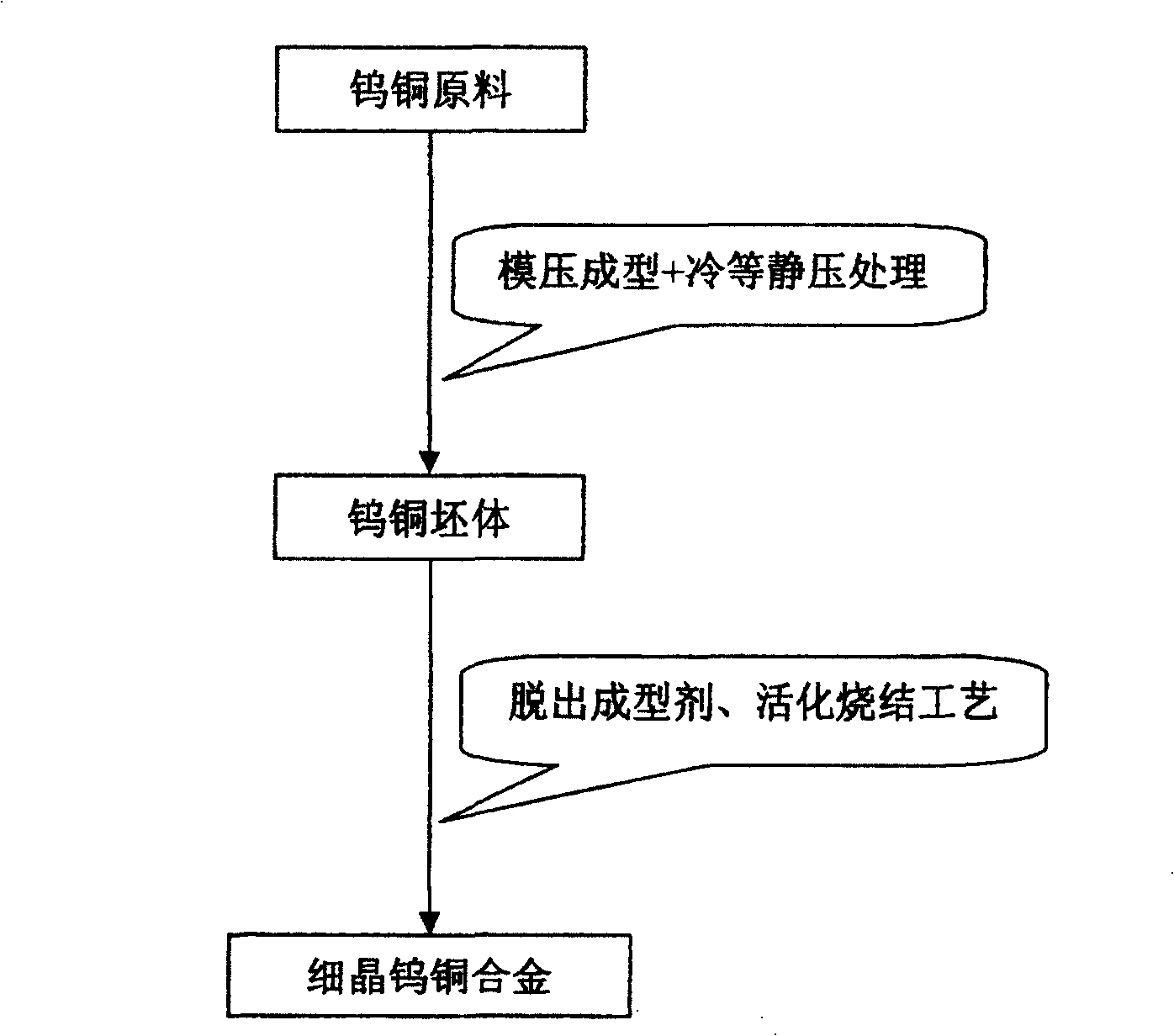

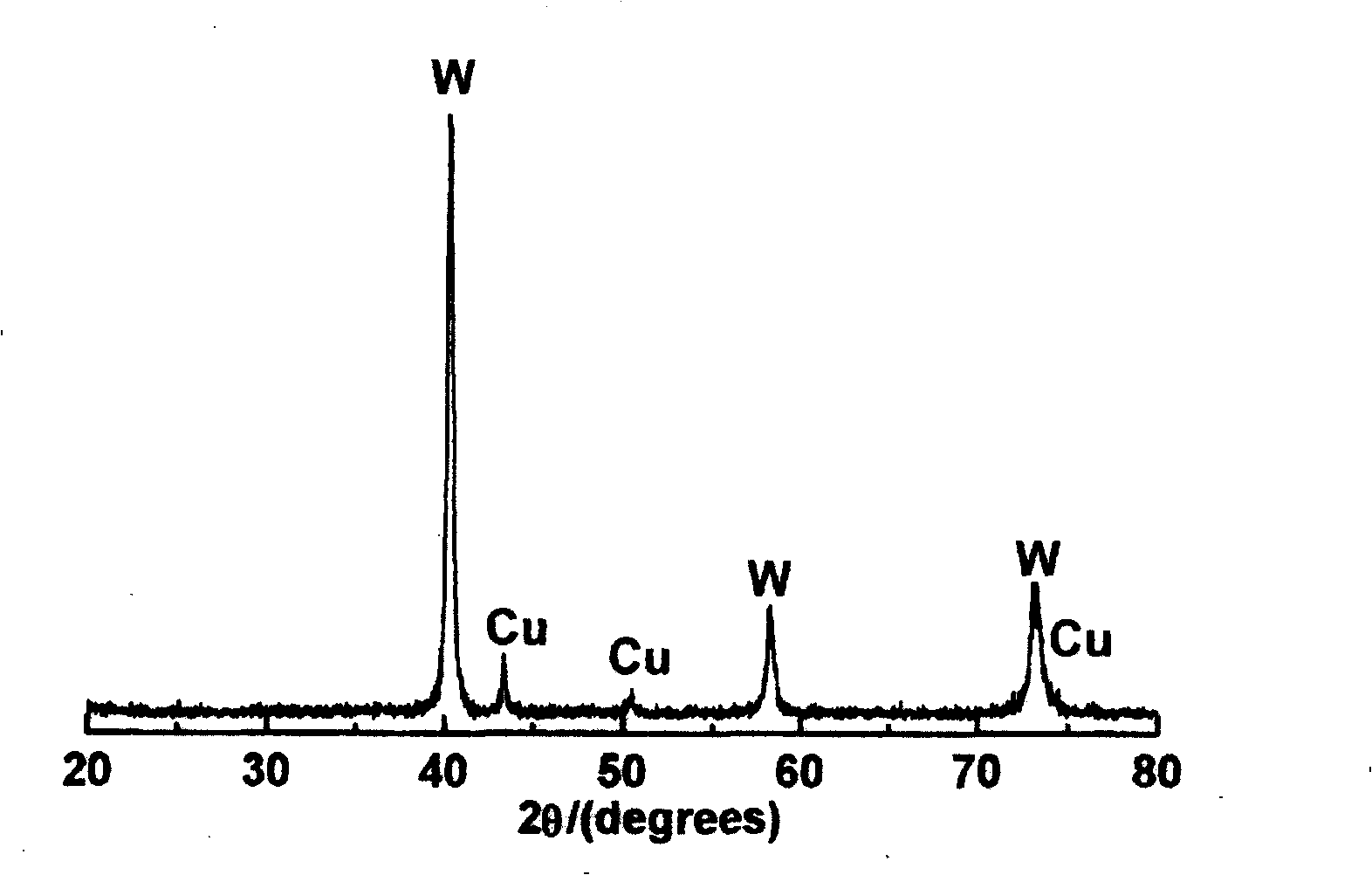

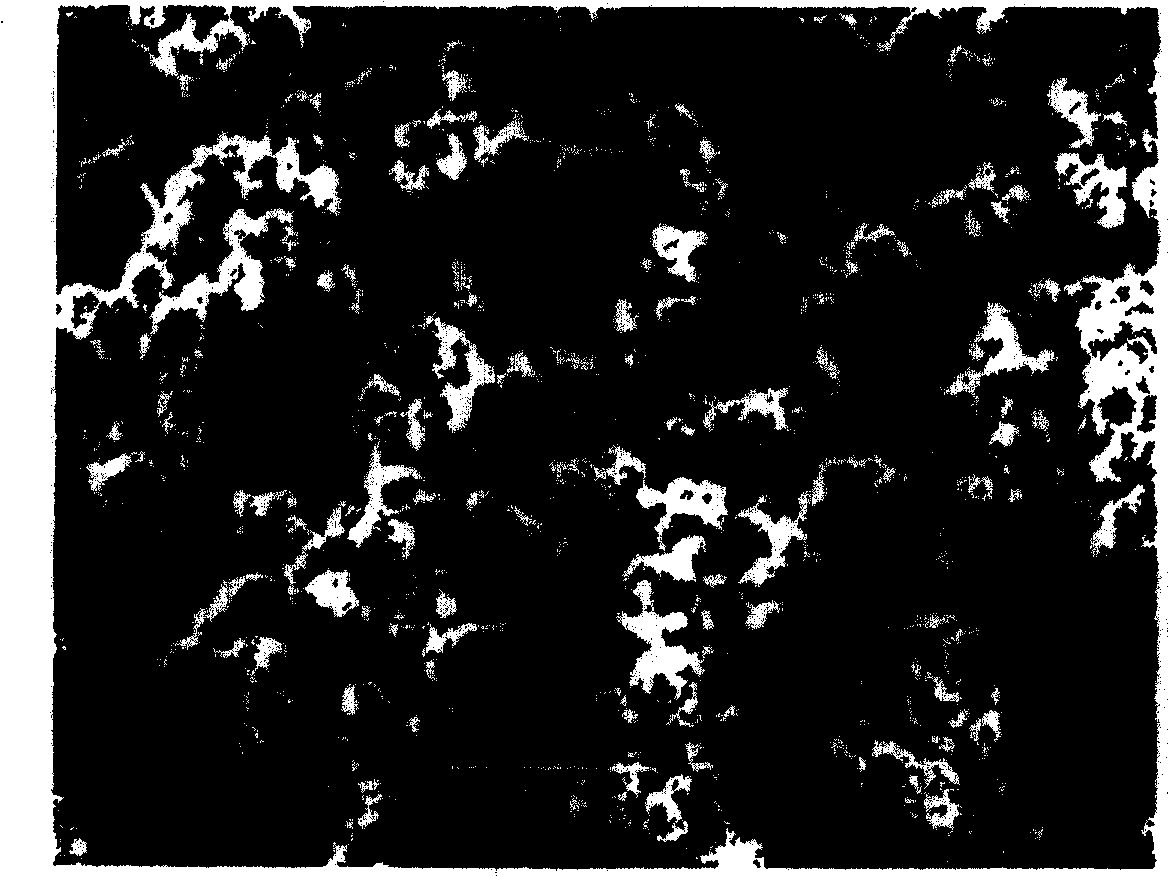

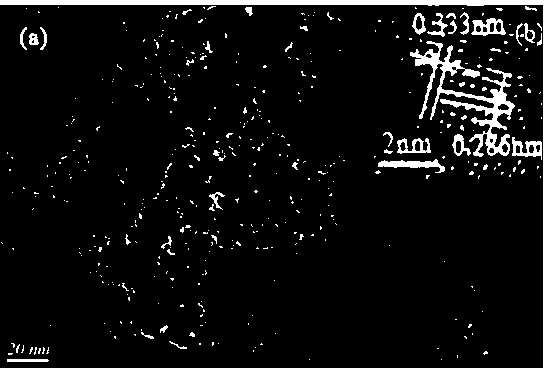

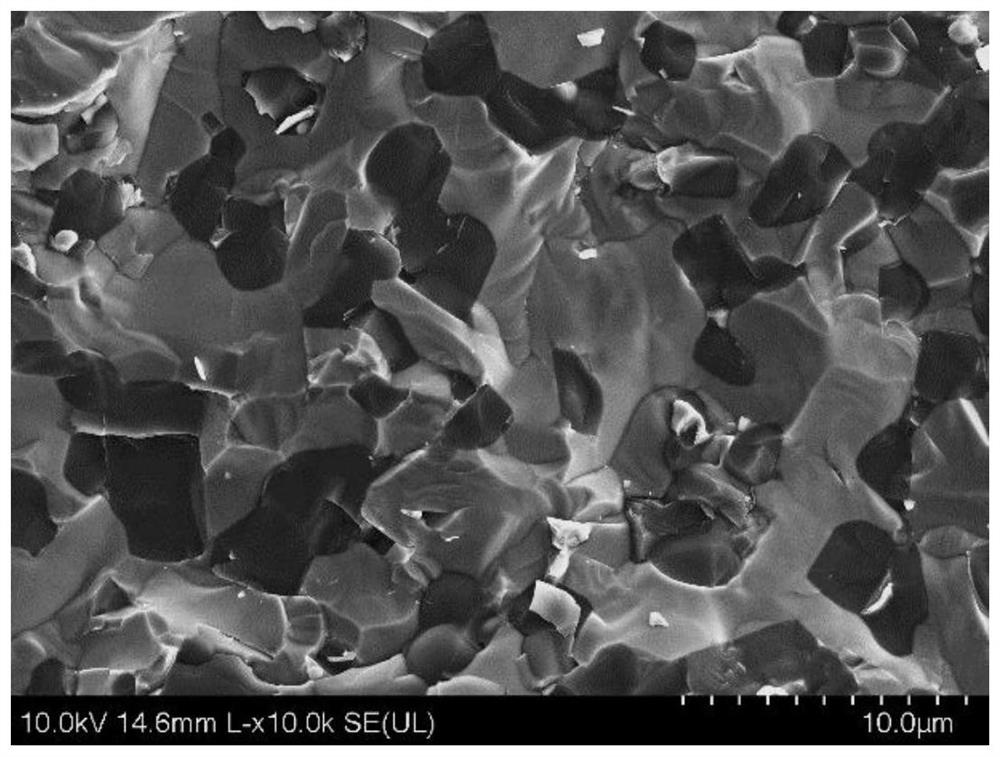

Activated sintering preparation method of fine crystalline non-magnetic wolfram-copper alloy

The present invention belongs to an activated sintering method of a high-density aplitic non-magnetic Tungsten-Cu alloy. Tungsten-Cu composite powders are adopted as raw materials with an average particle size of less than 500nms, and the average size of the tungsten particles is less than 300nms. The base bodies of needed shapes and sizes are prepared adopting conventional moulding method and directly sent into a welding furnace to be sintered in a mixed atmosphere of protection and reducibility or in an atmosphere of reducibility. The sintering temperature is 1100-1340 degrees Celsius system, the heat holding time is 40-60 minutes and the present invention adulterates no activating agents. The prepared aplitic Tungsten-Cu alloy adopting the present invention is characterized in that the grain granularity is fine, the average grain size of tungsten is less than or equal to 800nms, the organizational structure is evenly distributed and the relative density of the alloy is more than 99 percent. The high density Tungsten-Cu alloy prepared using the invention has an excellent mechanical property and thermal conductivity, guards against the aliquation of copper efficiently, and is fine in granularity and high in intensity, plasticity and thermal conductivity. The invention is simple in technics, easy to control, pollution-free, low in investment cost, low in energy consumption and applicable to a mass industrial production.

Owner:WUHAN UNIV OF TECH

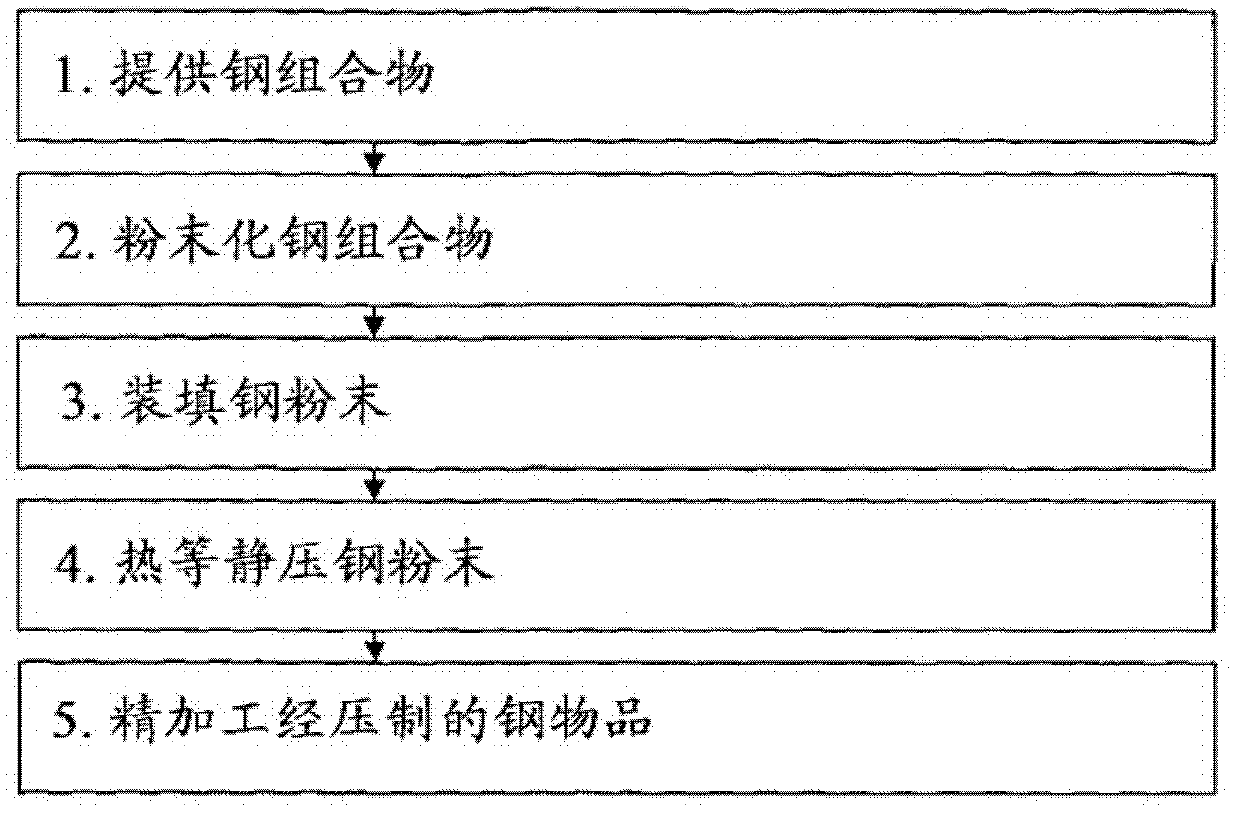

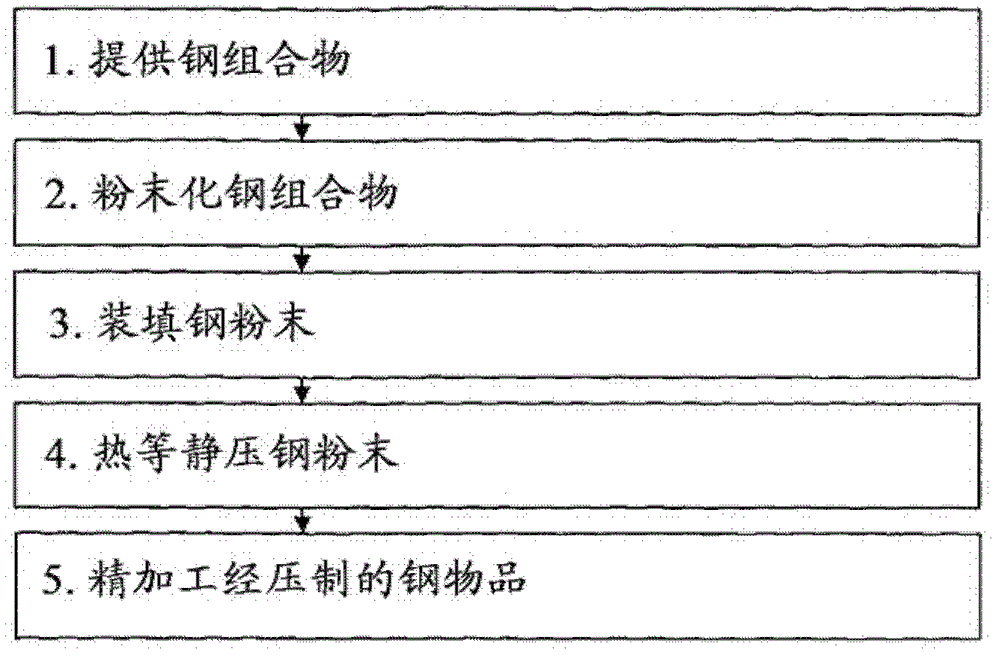

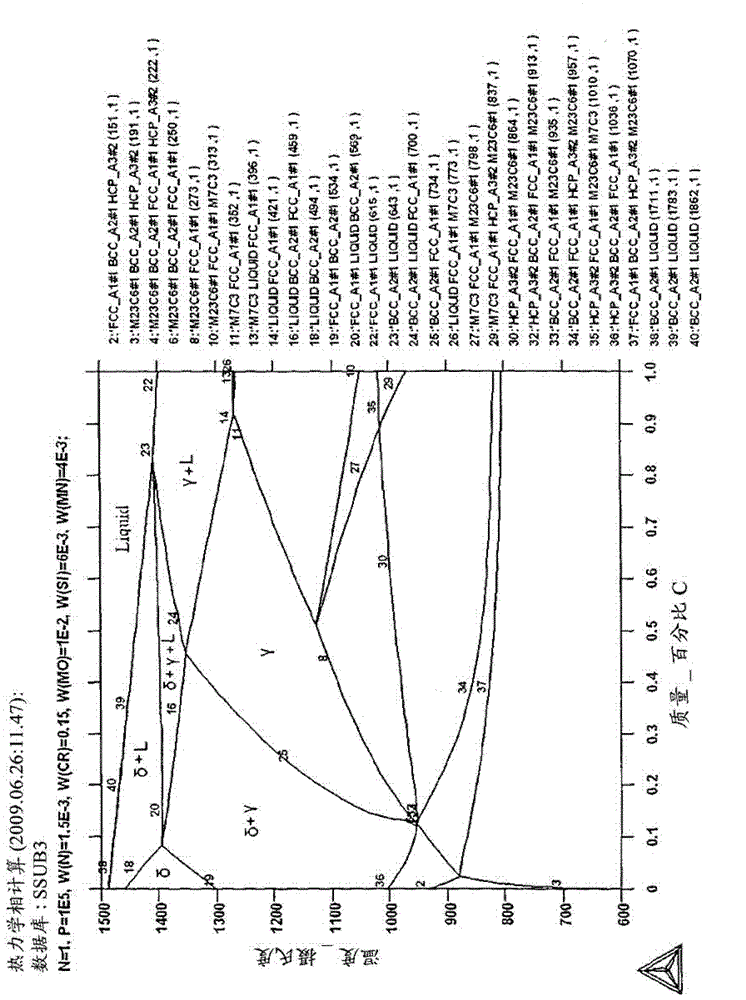

Bearing steels

There is provided a novel bearing steel composition and a method of forming a bearing. The bearing steel composition comprises: Carbon 0.4 to 0.8 wt%; Nitrogen 0.1 to 0.2 wt%; Chromium 12 to 18 wt%; Molybdenum 0.7 to 1.3 wt%; Silicon 0.3 to 1 wt%; Manganese 0.2 to 0.8 wt%; and Iron 78 to 86.3 wt%.

Owner:AB SKF

Rare earth appended surfacing alloy and surfacing technique for preparation of aluminium matrix composite material

InactiveCN101037755ATypical appearanceFine grain sizeMetallic material coating processesWelding/cutting media/materialsRare earthGraphite

The invention discloses a novel build-up welding alloy in order to solve the problem that aluminium composite materials have coarsening structure and is difficult to be controlled by the preparation process. The build-up welding alloy comprises , Ni, C, Co, Nb, Cr, Fe, Ti, Al and W, and mass percents of each component are as follows: rare earths: 6-8%; Ni: 45-48%; C: 0.6%; Co: 6-8%; Nb: 4%; Cr: 4-6%; Fe: 2-3%; Ti: 0.8-1.2%; Al: 4%;the residuel of W; in which, rare earths is yttria(Y2O3) or cesium (Cs), C is added in the form of graphite. The disclosed build-up welding alloy of the invention, as fused coating metal, is build-up welded on the surface of aluminium alloy based body using laser build-up welding arts to produce fine crystal grain surface aluminium alloy composite materials, and the surface of aluminium alloy product is intensified and improved.

Owner:SHANGHAI UNIV OF ENG SCI

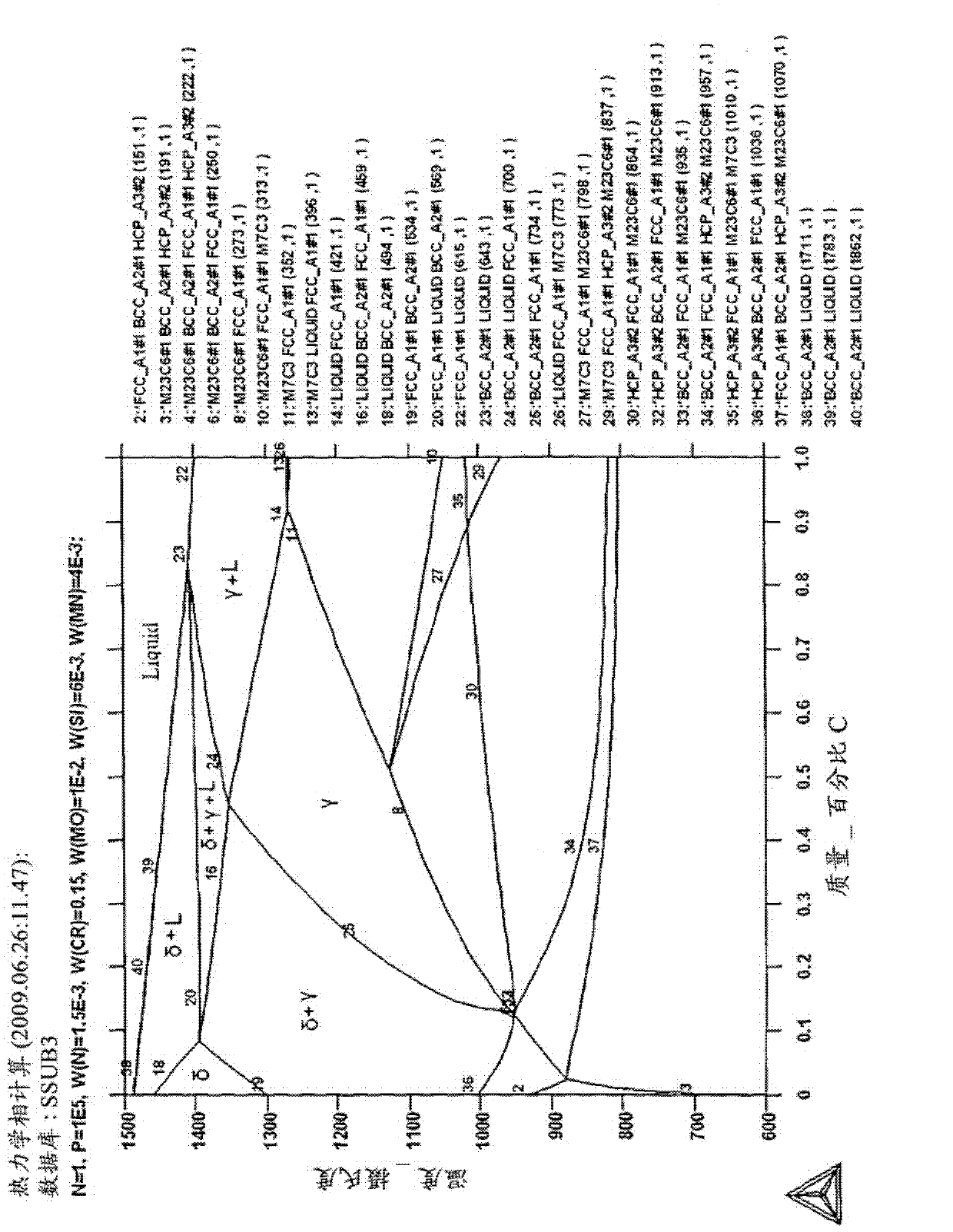

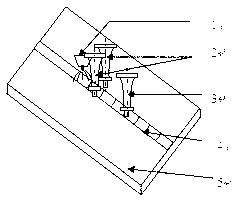

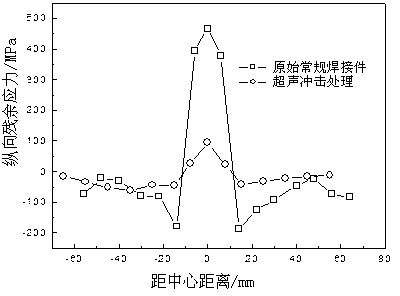

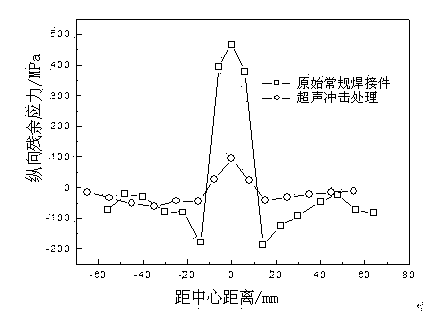

Method for controlling heat crack and residual stress of Fe-based fusion-repair layer via ultrasonic impact

InactiveCN103343205ASmall amount of plastic deformationFine grain sizeProcess efficiency improvementWorking lifeWear resistance

The invention discloses a method for controlling the heat crack and residual stress of a Fe-based fusion-repair layer via an ultrasonic impact, which belongs to the field of process technology. The method comprises the following steps of: step 1, controlling installation for an ultrasonic impact gun for heat crack; step 2, controlling installation for an ultrasonic impact gun for residual stress; and step 3, performing impact treatment on the Fe-based self-fluxing alloy powder fusion-repair layer having a thickness of 0.5-3 mm during a welding process. The method disclosed by the invention has the following advantages that (1) the heat crack tendency of the Fe-based self-fluxing alloy powder fusion-repair layer caused by the difference of material parameters with matrix metal can be suppressed; (2) the surface residual tensile stress of the fusion-repair layer can be reduced, and the working life of a workpiece can be prolonged simultaneously; and (3) the crystalline grain diameter of the fusion-repair layer can be reduced, and the ductility and toughness of the fusion-repair layer can be improved based on improvement for the wear resistance of the fusion-repair layer.

Owner:LIAONING TECHNICAL UNIVERSITY +1

Alloy magnetic material and preparation method thereof

The invention provides an alloy magnetic material and a preparation method thereof, and belongs to the field of metal materials. The alloy magnetic material comprises the following components in percentage by weight: 29 to 33 percent of Nd, 0.9 to 1.3 percent of Cu, 0.9 to 1.3 percent of Al, 0.06 to 0.08 percent of Nb, 0.1 to 0.2 percent of Co, 0.9 to 1.2 percent of Ce, 0.9 to 1.2 percent of B, 2 to 6 percent of Dy and the balance of Fe. The preparation method comprises the following steps of: proportioning the components of the alloy magnetic material, preparing iron alloy powder, preparing composite aluminum-copper alloy powder, mixing the iron alloy powder and the composite aluminum-copper alloy powder, forming by using a highly-oriented magnetic field, performing cold isostatic pressing, performing vacuum high temperature sintering, performing double tempering to obtain the alloy magnetic material. The alloy magnetic material is high in magnetic property and low in material cost; and the preparation method for the alloy magnetic material is simple, low in production cost, safely operated and suitable for industrial production.

Owner:江苏禾一电热材料有限公司

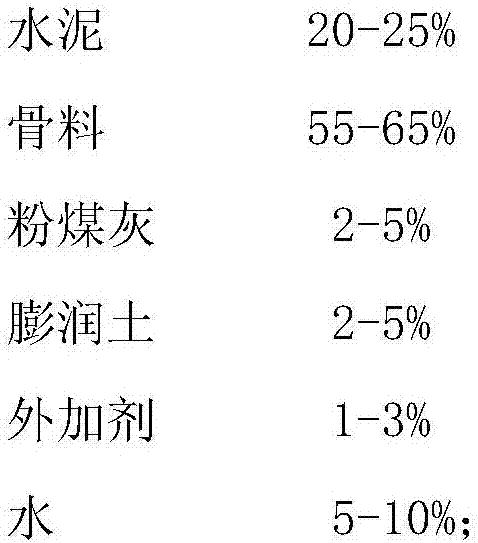

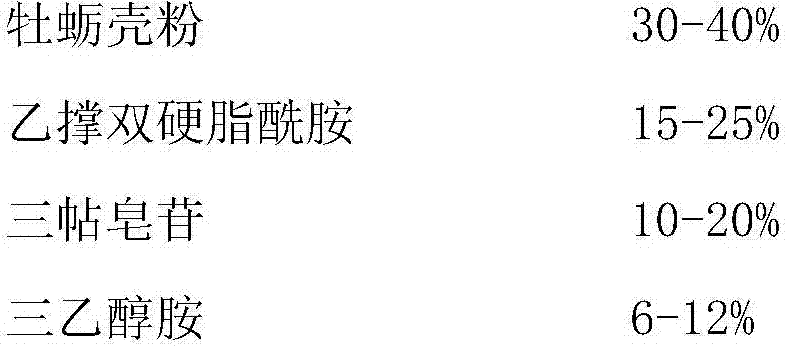

Antifreeze concrete

The invention discloses an antifreeze concrete, and belongs to the technical field of architecture construction. The antifreeze concrete comprises the components of cement, aggregate, fly ash, superfine slag powder, antifreeze water reducing agent and water, wherein the antifreeze water reducing agent is composed of, by weight, 40-50% of microcrystalline muscovite powder, 15-25% of ethylene bi-stearamide, 10-20% of triterpenoid saponins, 5-10% of bentonite, and 5-10% of naphthalene sulfonate. When the antifreeze water reducing agent is added to the concrete, on the one hand the compactness of the concrete can be greatly improved, on the other hand the average air void spacing coefficient and water binder ratio can be significantly reduced, the average air void spacing coefficient can be reduced to 20 micro meters or below, the water binder ratio can be reduced to 0.20 or below, in the meantime the strength of the concrete is also greatly improved, and the strength can reach C90 or above, so that excellent freeze resistance performance can be obtained; the antifreeze concrete is particularly suitable for use in the cold north or underground, and good engineering quality is guaranteed.

Owner:杨小英

Preparation method of hierarchical porous alumina foam ceramic comparable to aerogel

The invention develops a preparation method of a hierarchical porous alumina foam ceramic comparable to aerogel. The method includes the steps of: 1) preparing nano aluminum sol particles; 2) adding asurfactant into a suspensoid of the aluminum sol particles prepared in step 1) to obtain a sol suspensoid; 3) adjusting the pH of the sol suspensoid obtained in step 2) to 4-10; 4) foaming the product obtained in step 3) by mechanical agitation to obtain an ultra-stable aluminum sol foam slurry; and 5) drying the slurry obtained in step 4) to obtain the alumina porous ceramic. The foam structurehas uniform and complete air holes, and adopts tens of microns of closed pores based first-level pores as the main body, and the pore wall has a mesoporous second-level pore structure. Compared with the existing foam ceramics, the new material has higher specific surface area and air hole rate, and is comparable to aerogel as a light heat insulation material.

Owner:TSINGHUA UNIV +1

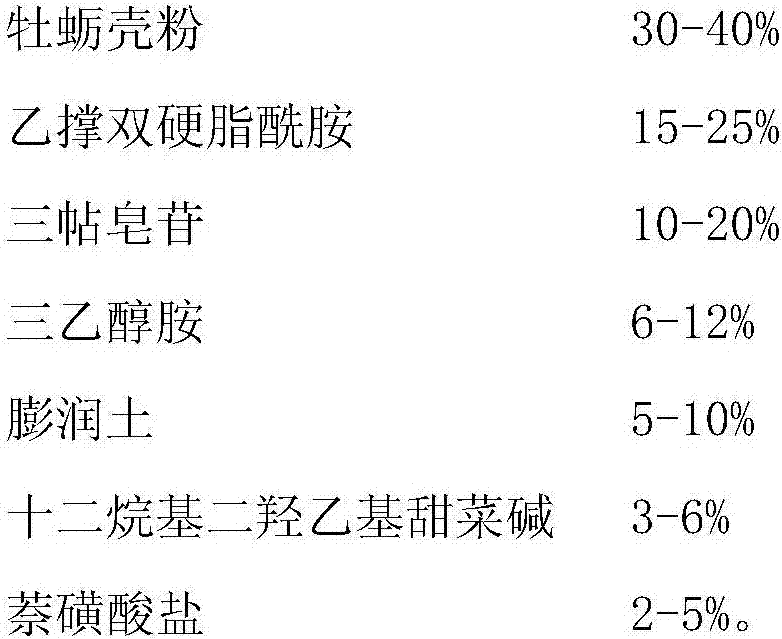

Impermeable concrete

The invention discloses an impermeable concrete, and belongs to the technical field of building civil engineering. The impermeable concrete is composed of cement, aggregate, fly ash, bentonite, admixtures and water, wherein the admixtures are prepared from, by mass, 30%-40% oyster shell powder, 15%-25% ethylene bis stearamide, 10%-20% triterpenoid saponin, 6%-12% triethanolamine, 5%-10% bentonite,3%-6% dodecyl dihydroxyethyl betaine and 2%-5% naphthalene sulfonate. According to the impermeable concrete, the admixtures are added, the freeze prevention and freeze resistance performance are guaranteed, at the same time, the anti-permeability performance is greatly improved, the anti-permeability grade of the impermeable concrete reaches above P12, and the impermeable concrete is especially suitable for the case of concrete impermeability requirements such as buildings in the cold north.

Owner:杨小英

Technology for manufacturing low-temperature mold pressing tee through X80 steel plate

ActiveCN109465610AAvoid dimples or wrinklesReduce lossesFurnace typesHeat treatment furnacesHeating timeSheet steel

The invention discloses a technology for manufacturing a low-temperature mold pressing tee through an X80 steel plate. According to the technology, a tee pipe fitting is prepared through the X80 steelplate by combining a welding technology with a pressing forming technology, the grain size and strength loss allowances caused by multiple times of heating and long heating time in the machining process are increased, and the tee pipe fitting can be normally used for a long time in the -45 DEG C extremely cold weather. The tee pipe fitting prepared through the technology has the small grain size,high strength and low welding crack sensitivity coefficient, the homogeneity degree of all parts of the product is greatly improved, and the tee pipe fitting can be suitable for the -45 DEG C operating environment.

Owner:河北恒通管件集团有限公司

Preparation method for high performance as cast condition neodymium iron boron magnet

ActiveCN102623166BFine grain sizeFine grainPermanent magnetsInductances/transformers/magnets manufactureMaterials preparationMagnetic energy

The invention relates to the technical field of permanent magnetic material preparation and in particular to a preparation method for a high performance as cast condition neodymium iron boron magnet. By means of the composite process combining technology of casting and large strain plastic deformation and the technology of double orientation, grain size is effectively refined, and grain boundary and grain orientation are controlled, so that the high performance neodymium iron boron magnet which is fine in grains, even in grain boundary phase distribution and complete in grain orientation is prepared, and good matching of high coercivity and high magnetic energy product is obtained.

Owner:临沂银凤新材料技术服务有限公司

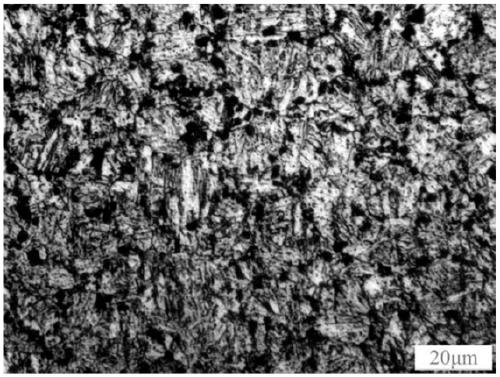

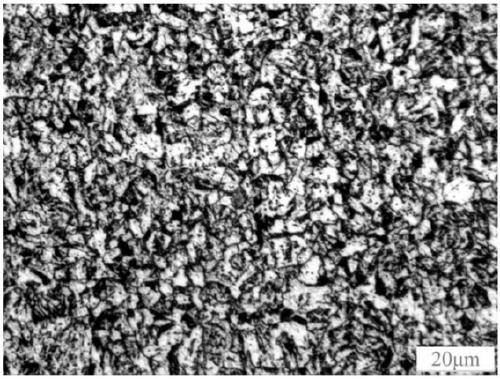

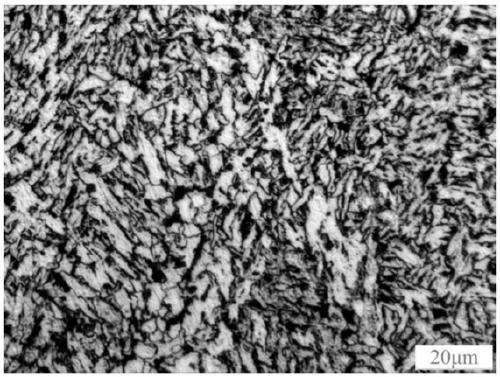

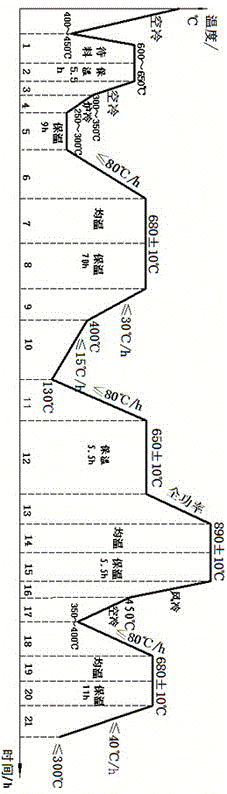

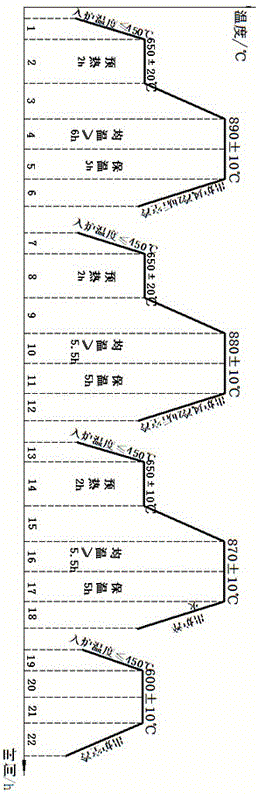

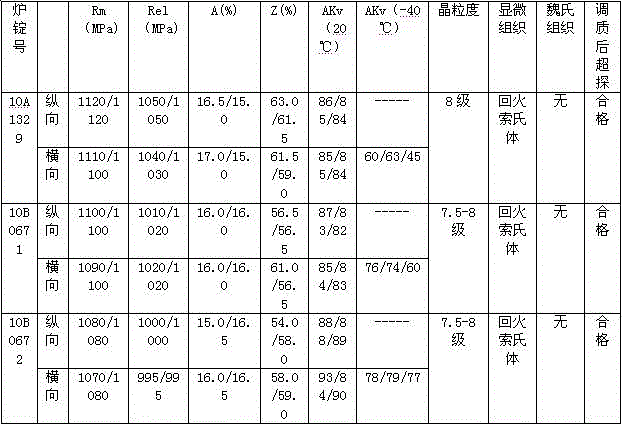

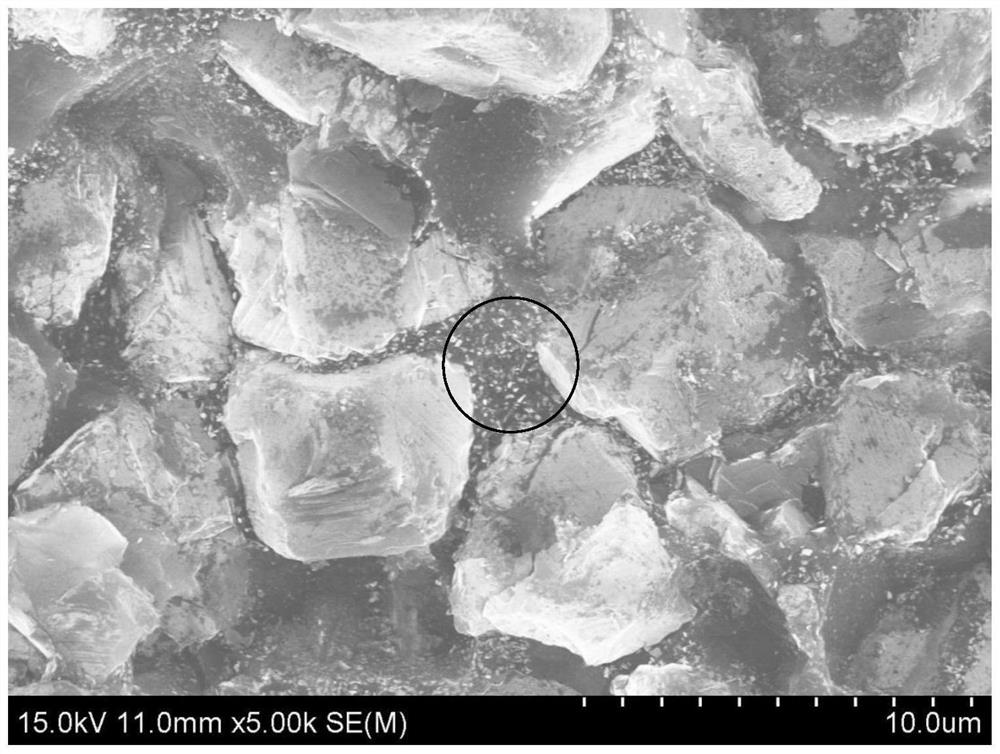

A processing method for grain refinement of crnimov high pressure steel forgings

ActiveCN103981347BHigh low temperature impact toughnessFine grain sizeProcess efficiency improvementTemperature controlChemical composition

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

High-performance trapezoidal aluminum alloy material and production method thereof

ActiveCN111455230AImprove mechanical propertiesHigh strengthCasting cleaning apparatusFerrosiliconHydrogen content

The invention discloses a high-performance trapezoidal aluminum alloy material, which comprises the following components in percentage by weight: 7.4% to 7.5% of Si, not more than 0.12% of F3, 0.42% to 0.46% of Cu, 0.4% to 0.45% of Mg, 0.1% to 0.15% of Ti, less than 0.02% of total content of impurities and the balance of aluminum. The production method comprises the following steps of adding a cold material with the same component and a proportion of 15% to 20% of the capacity of a smelting furnace, adding electrolytic aluminum liquid materials, realizing component uniformity of aluminum liquid through electromagnetic stirring treatment, adding the alloy materials in sequence, obtaining a pure aluminum solution through refining, degasification box and filter box steps, achieving horizontalcasting through balance regulation, enabling the regulating amount of the aluminum liquid to be matched with the rotating speed of a casting machine, reasonably distributing a cooling mode, cooling water flow and pressure, forming an optimal state from liquid to crystallization in a cooling area of a crystallizer, and ensuring the grain size of the trapezoidal aluminum alloy. The high-performancetrapezoidal aluminum alloy material has the advantages of uniform product component, high strength, fine grain size, level 1 pinhole degree, low hydrogen content and few impurities, and the mechanical properties of an alloy product are comprehensively improved.

Owner:河南中孚技术中心有限公司

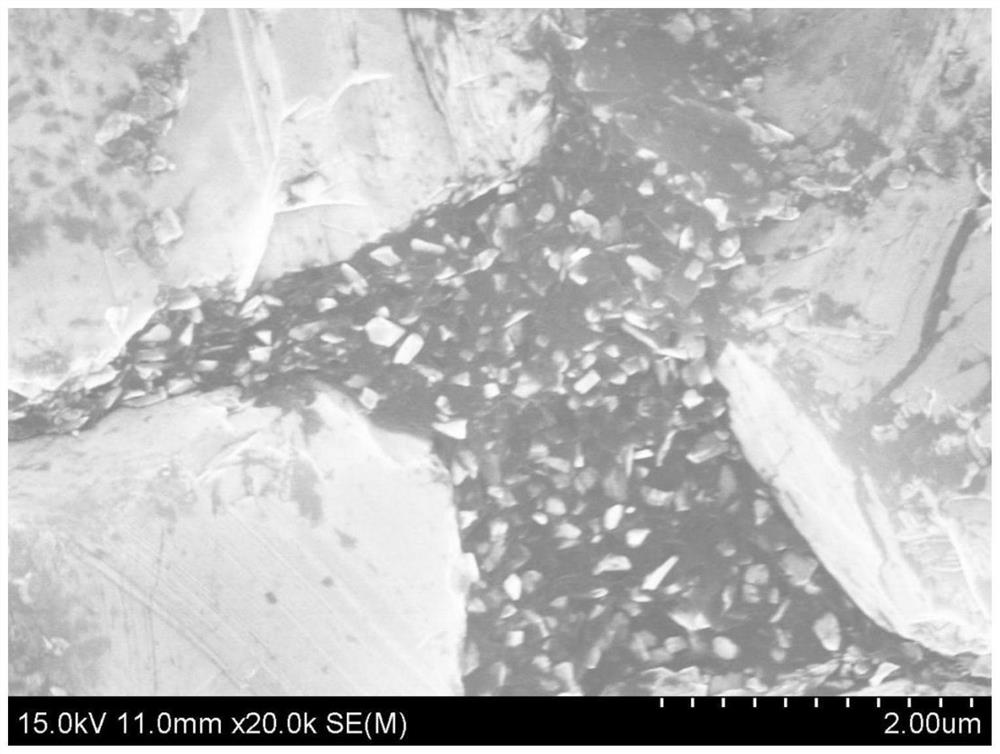

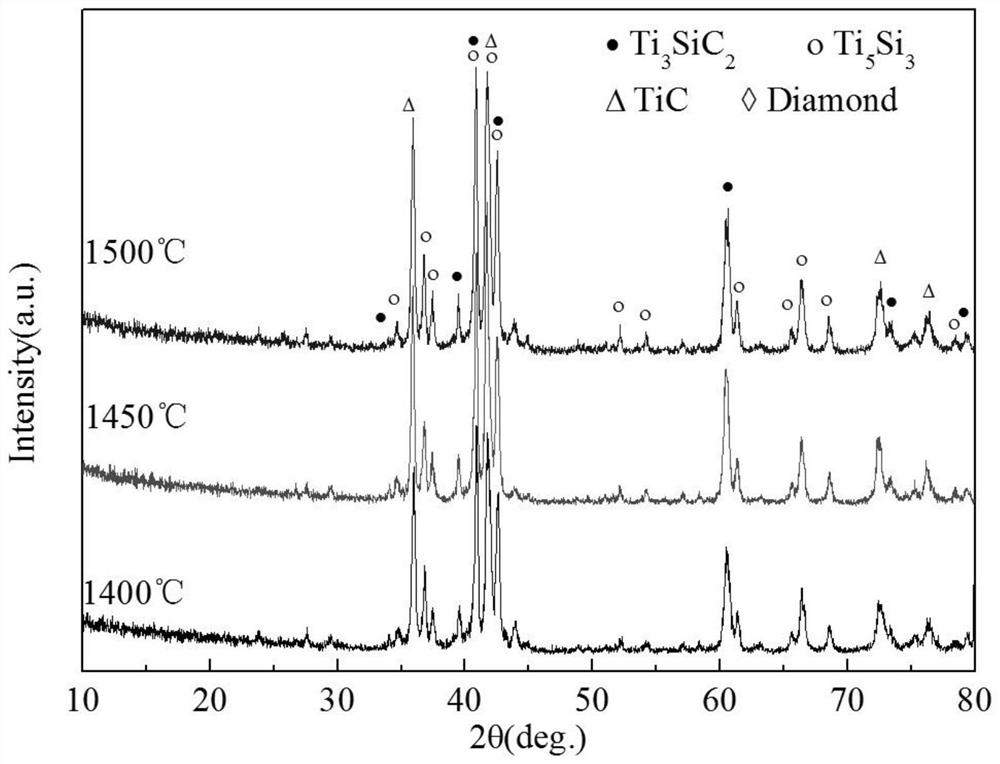

Polycrystalline diamond combined with compound generated through in-situ reaction and preparation method of polycrystalline diamond

The invention provides a polycrystalline diamond combined with a compound generated through in-situ reaction and a preparation method of the polycrystalline diamond and belongs to the technical field of superhard composite materials. The preparation method comprises the following steps: carrying out ball milling on Ti powder, Si powder and nano-diamond, and carrying out mechanical alloying to obtain a binding agent material, wherein the molar ratio of the Ti powder to the Si powder is equal to 3, and the molar ratio of the nano-diamond to the Si powder is greater than 2 and is less than or equal to 5; and mixing the binding agent material with micron diamond, pre-pressing the obtained mixture, and carrying out high-temperature and high-pressure sintering on the obtained pre-pressed blank to obtain the polycrystalline diamond combined with the compound generated through in-situ reaction. Due to excessive addition of the nano-diamond and high-pressure environment, the nano-diamond is left after reacting with Ti and Si and can be reserved; and the problem that Ti, Si and compounds thereof which are not completely reacted are easily left in a shed frame area away from the diamond when Si, Ti, B, Ni are added in a traditional PCD preparation method and soft spots are left is solved.

Owner:YANSHAN UNIV

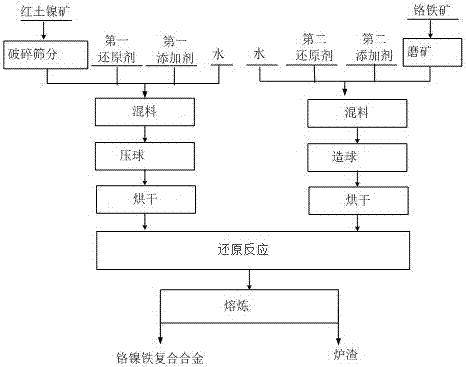

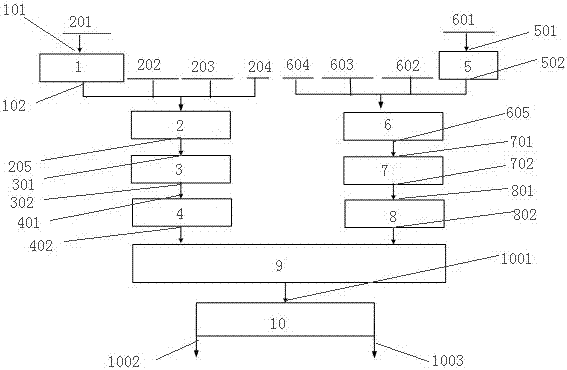

System and method for producing Cr-Ni-Fe composite alloy in double-process pelleting mode

PendingCN107142352AImprove heat utilizationIncrease production capacityHearth type furnacesGranularityDistribution system

The invention relates to a system and method for producing Inconel composite alloys by double-process ball making, wherein the system includes: a crushing and screening device, a first mixing device, a ball pressing device and a first drying device connected in sequence; The ore grinding device, the second mixing device, the pelletizing device and the second drying device; the rotary hearth furnace with a double-layer material distribution system connected to the first drying device and the second drying device respectively; A smelting device connected to a rotary hearth furnace. The present invention uses the mixed pellets of chromite and lateritic nickel ore as raw material, and adopts double-layer material distribution system and double-process ball making method according to the unique characteristics of raw materials, strictly controls the particle size and diameter of the two raw material pellets, and improves the speed of rotation. Heat utilization and production capacity of the hearth furnace.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Sol-gel preparation method of aluminum hydroxide

InactiveCN104512919ASynthesis temperature is lowSimple chemical reactionAluminium hydroxide preparationWater bathsAluminium chloride

The invention discloses a sol-gel preparation method of aluminum hydroxide. The preparation method comprises the following steps: step one, preparing an aluminum chloride solution from aluminum chloride and deionized water, and then dropwise adding hydrochloric acid into the solution to adjust the pH value; step two, adding the prepared solution into a reaction flask provided with a reflux apparatus, a magnet stirrer, and a temperature meter, carrying out reactions in a water bath at a constant temperature, then heating under stirring, and refluxing; step three, after the reactions, cooling to the room temperature, filtering, washing the reaction product by acetone, and then drying the reaction product in a baking oven so as to obtain the aluminum hydroxide powder. In the provided preparation method, the raw materials are dispersed into a solvent to prepare a solution with low viscosity in advance, thus the uniformity in the molecular level can be achieved in a very short time, compared to the reactions performed in a solid, and the chemical reactions can be carried out more easily in a solution, so the synthesis temperature is lower, moreover, the obtained product is finer, and the flame retardant effect is better.

Owner:QINGDAO SHOUSHENG IND

Activated sintering preparation method of fine crystalline non-magnetic wolfram-copper alloy

The present invention belongs to an activated sintering method of a high-density aplitic non-magnetic Tungsten-Cu alloy. Tungsten-Cu composite powders are adopted as raw materials with an average particle size of less than 500nms, and the average size of the tungsten particles is less than 300nms. The base bodies of needed shapes and sizes are prepared adopting conventional moulding method and directly sent into a welding furnace to be sintered in a mixed atmosphere of protection and reducibility or in an atmosphere of reducibility. The sintering temperature is 1100-1340 degrees Celsius system, the heat holding time is 40-60 minutes and the present invention adulterates no activating agents. The prepared aplitic Tungsten-Cu alloy adopting the present invention is characterized in that the grain granularity is fine, the average grain size of tungsten is less than or equal to 800nms, the organizational structure is evenly distributed and the relative density of the alloy is more than 99 percent. The high density Tungsten-Cu alloy prepared using the invention has an excellent mechanical property and thermal conductivity, guards against the aliquation of copper efficiently, and is fine in granularity and high in intensity, plasticity and thermal conductivity. The invention is simple in technics, easy to control, pollution-free, low in investment cost, low in energy consumption and applicable to a mass industrial production.

Owner:WUHAN UNIV OF TECH

Bearing steels

ActiveCN102498227BFine grain sizeImprove corrosion resistanceShaftsBearing componentsManganeseMaterials science

There is provided a novel bearing steel composition and a method of forming a bearing. The bearing steel composition comprises: Carbon 0.4 to 0.8 wt %; Nitrogen 0.1 to 0.2 wt %; Chromium 12 to 18 wt %; Molybdenum 0.7 to 1.3 wt %; Silicon 0.3 to 1 wt %; Manganese 0.2 to 0.8 wt %; and Iron 78 to 86.3 wt %.

Owner:AB SKF

Nano zirconium dioxide with high specific surface area and synthesis method thereof

InactiveCN103274465BGood dispersionHigh crystallinityMaterial nanotechnologyZirconium oxidesSynthesis methodsReaction temperature

The invention discloses a nano zirconium dioxide with high specific surface area and a synthesis method thereof and belongs to the field of synthesis of nano materials and catalysts. The method is characterized in that an organic solvent serves as an auxiliary agent, and the nano zirconium dioxide with high specific surface area is synthesized by the combination of vapor phase hydrolysis and a hydrothermal method, wherein the obtained sample is high in crystallinity, has the particle size of 2.0-4.3nm, and the specific surface area of 448m<2>.g<-1>. The synthesis method comprises the following steps: mixing a zirconium source (Zr(OC4H9)4) and an organic solvent according to a certain rate, stirring for a certain time, isolating the mixture from distilled water, filling in a high-pressure reaction kettle for reacting in an air-tight mode, and synthesizing the nano zirconium dioxide. Because the vapor phase hydrolysis can be combined with the hydrothermal method, the reaction temperature, reaction time and organic solvent are regulated so as to control the hydrolysis and crystallization speed of the zirconium source in a synergetic mode; and therefore, the nano zirconium dioxide has the characteristic of small and adjustable grain size, particularly has high specific surface area and has more advantages when applied to catalysts and catalyst carriers.

Owner:TAIYUAN UNIV OF TECH

Magnesium aluminate spinel crucible for high-temperature alloy and preparation method thereof

InactiveCN111393169AImprove thermal shock resistanceImprove corrosion resistanceCrucible furnacesCeramicwareCrucibleRefractory

The invention relates to the technical field of refractory materials. The magnesium aluminate spinel crucible for the high-temperature alloy comprises the following raw materials: magnesium aluminatespinel, SiC, graphite, an antioxidant and a binding agent, the magnesium aluminate spinel comprises magnesium aluminate spinel particles and magnesium aluminate spinel powder, and the SiC comprises SiC particles and SiC powder; the method comprises the following steps: putting the raw materials into a stirrer according to a weight ratio, and stirring to obtain pug; putting the stirred pug into a sealed container for ageing; putting the aged pug into a rubber mold, putting the rubber mold into an isostatic pressing machine, and carrying out pressure molding to obtain a semi-finished product; putting the formed semi-finished product into a drying kiln to be dried; and putting the dried semi-finished product into a firing kiln, and firing to obtain the finished crucible. The crucible disclosed by the invention has high thermal shock resistance and high erosion resistance, and the service life of the crucible at the use temperature of not higher than 1300 DEG C can reach 100 heat times orabove.

Owner:山东铭特陶瓷材料有限公司

Method for controlling heat crack and residual stress of Fe-based fusion-repair layer via ultrasonic impact

InactiveCN103343205BSmall amount of plastic deformationFine grain sizeProcess efficiency improvementWorking lifeAlloy

The invention discloses a method for controlling the heat crack and residual stress of a Fe-based fusion-repair layer via an ultrasonic impact, which belongs to the field of process technology. The method comprises the following steps of: step 1, controlling installation for an ultrasonic impact gun for heat crack; step 2, controlling installation for an ultrasonic impact gun for residual stress; and step 3, performing impact treatment on the Fe-based self-fluxing alloy powder fusion-repair layer having a thickness of 0.5-3 mm during a welding process. The method disclosed by the invention has the following advantages that (1) the heat crack tendency of the Fe-based self-fluxing alloy powder fusion-repair layer caused by the difference of material parameters with matrix metal can be suppressed; (2) the surface residual tensile stress of the fusion-repair layer can be reduced, and the working life of a workpiece can be prolonged simultaneously; and (3) the crystalline grain diameter of the fusion-repair layer can be reduced, and the ductility and toughness of the fusion-repair layer can be improved based on improvement for the wear resistance of the fusion-repair layer.

Owner:LIAONING TECHNICAL UNIVERSITY +1

A process for manufacturing low-temperature molded tee by using x80 steel plate

ActiveCN109465610BRefined grain sizeHigh strengthFurnace typesHeat treatment furnacesHeating timePipe fitting

The invention discloses a technology for manufacturing a low-temperature mold pressing tee through an X80 steel plate. According to the technology, a tee pipe fitting is prepared through the X80 steelplate by combining a welding technology with a pressing forming technology, the grain size and strength loss allowances caused by multiple times of heating and long heating time in the machining process are increased, and the tee pipe fitting can be normally used for a long time in the -45 DEG C extremely cold weather. The tee pipe fitting prepared through the technology has the small grain size,high strength and low welding crack sensitivity coefficient, the homogeneity degree of all parts of the product is greatly improved, and the tee pipe fitting can be suitable for the -45 DEG C operating environment.

Owner:河北恒通管件集团有限公司

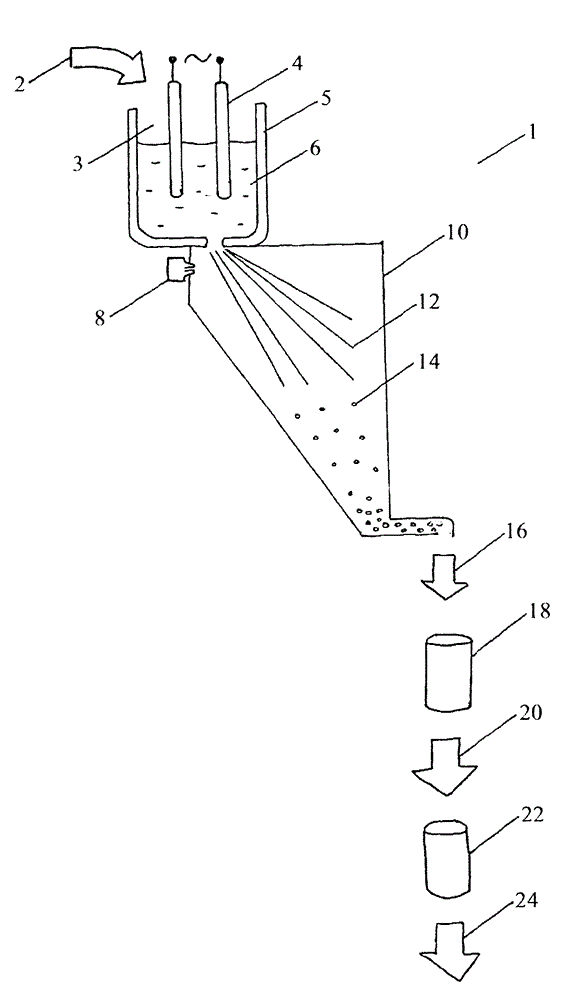

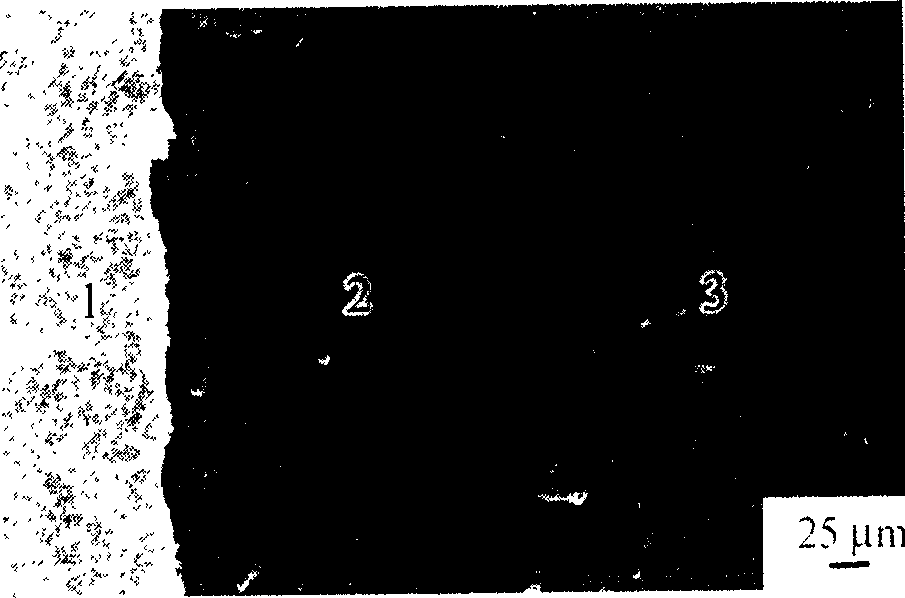

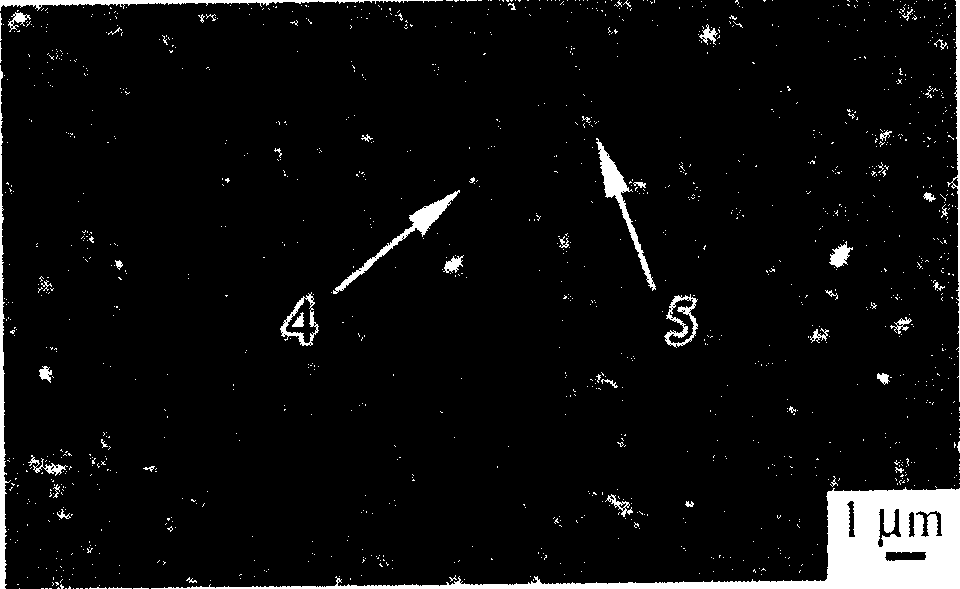

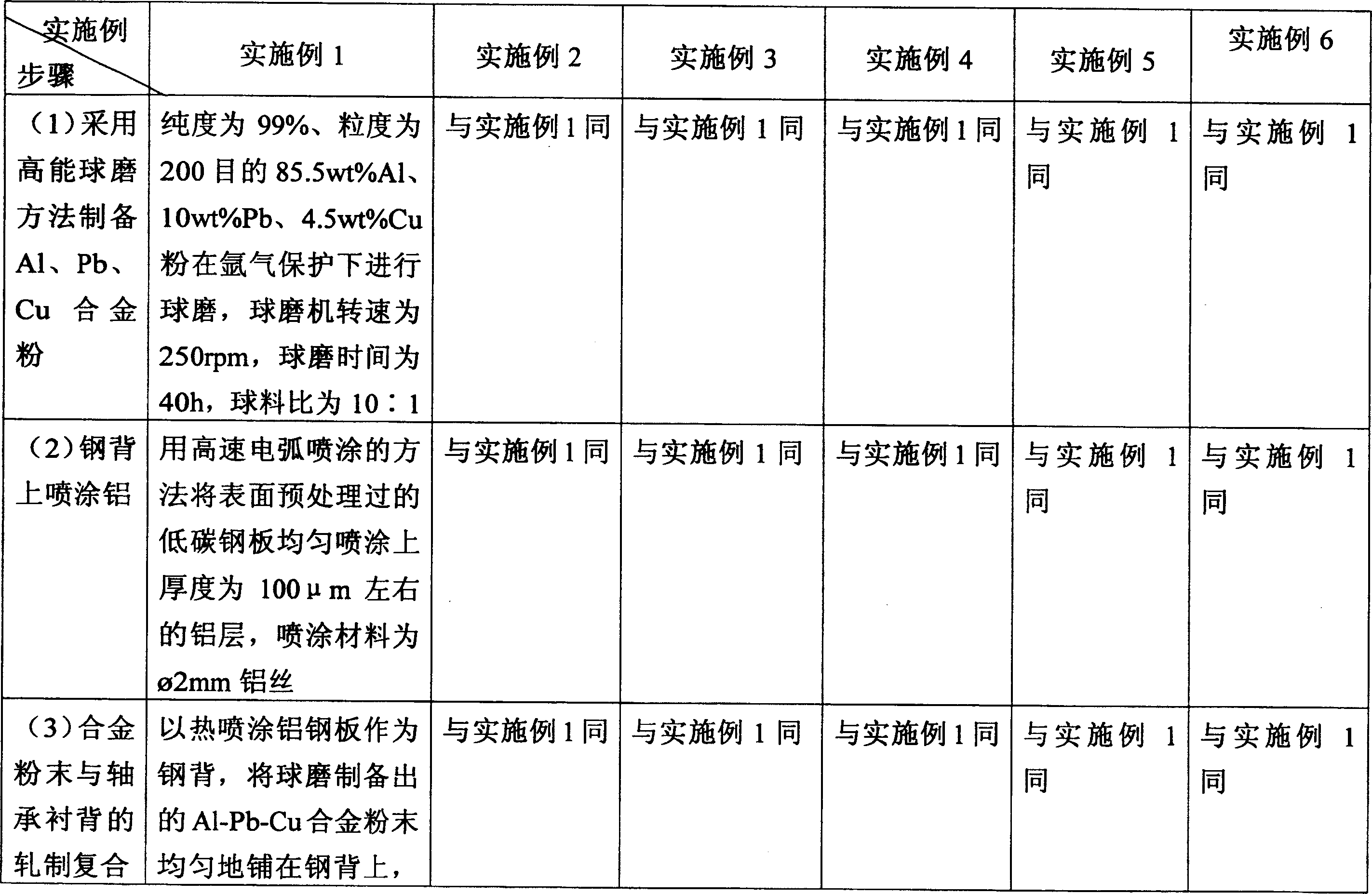

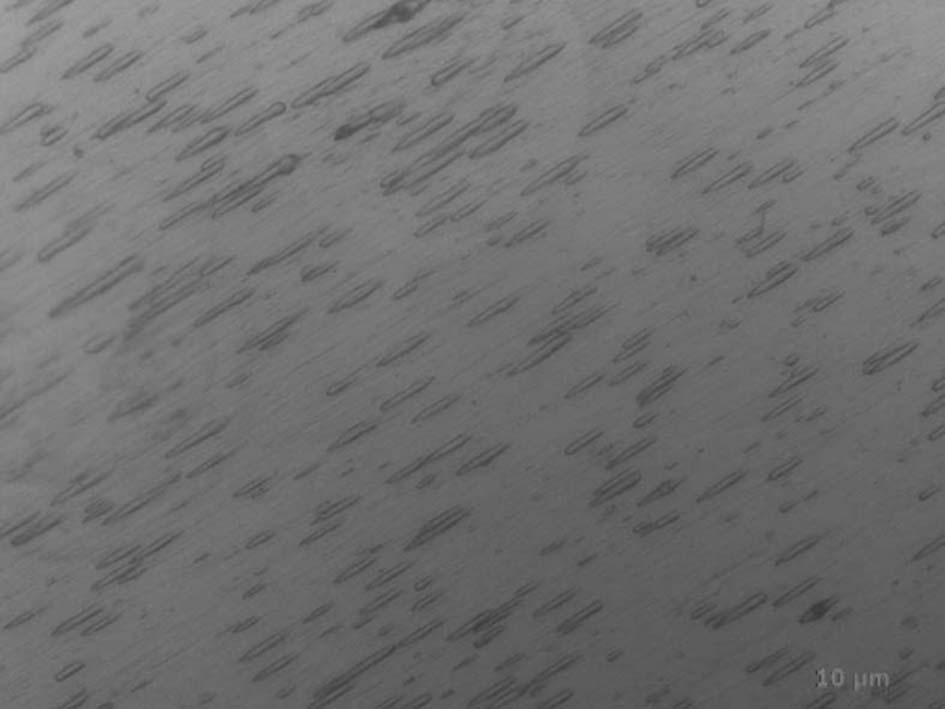

Method for producing bearing shell material of nano composite aluminium base

InactiveCN1231319CAvoid specific gravity segregationImprove wear resistanceThermal sprayingHigh energy

The invention relates to a manufacturing method of a nanocomposite aluminum-based bearing material, which uses high-purity, particle-sized Al, Pb, and Cu powders according to a certain weight percentage of Al+Pb+Cu under argon protection, and uses a ball mill to perform high-energy ball milling. , After ball milling in a ball mill at a certain speed for a certain period of time, the powder prepared by ball milling is rolled and compounded on a thermal sprayed aluminum steel back by continuous powder pressing, and then sintered at different temperatures under the protection of argon, and then cooled. The invention has the advantages of simple process, low manufacturing cost, and easy realization of large-scale industrial production. The invention can obtain a nanocrystalline Al-based solid solution as a matrix on which Pb and Cu are evenly distributed. 9 al 4 、CuAl 2 The nano-phase composite structure of the second phase, the wear resistance of the manufactured Al-Pb-Cu bearing material has been greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

High-strength stainless steel wire for interventional medical treatment and preparation method thereof

The invention provides a high-strength stainless steel wire for interventional medical treatment. The high-strength stainless steel wire comprises the following chemical components in percentage by mass: 0.01%-0.09% of C, 0.01%-1.00% of Si, 0.01%-2.00% of Mn, 0.005%-0.05% of P, 0.01%-0.30% of S, 7%-15% of Ni, 14%-20% of Cr, 0.01%-0.08% of N, 0.01%-0.5% of La+Ce, 0.01%-1% of Y and the balance of Fe, wherein the equivalent weight of Ni is less than or equal to 35, and the equivalent weight of Ni is equal to Ni+0.65Cr+0.98Mo+1.05Mn+0.35Si+12.6 C. A preparation method of the stainless steel wire comprises the steps of vacuum melting, blank forging, wire rough blank drawing and wire drawing. Stainless steel is based on the chemical components, and a certain Ni equivalent is guaranteed. A certain martensite volume fraction is obtained by designing the pass compression amount, the drawing speed and the drawing temperature, so that the strength is regulated and controlled. A martensite structure with a certain crystal face orientation is obtained by combining a drawing die and the pass sectional area compression amount. In addition, through the grain refining effect of rare earth elements and the precipitation strengthening effect of in-situ authigenic rare earth nitride, the high-strength steel wire is finally obtained.

Owner:南通普创医疗科技有限公司

A high-performance trapezoidal aluminum alloy material and its production method

ActiveCN111455230BImprove mechanical propertiesHigh strengthCasting cleaning apparatusFerrosiliconHydrogen content

The invention discloses a high-performance trapezoidal aluminum alloy material, the composition of which is: silicon Si 7.4-7.5%, iron Fe≤0.12%, copper Cu0.42-0.46, magnesium Mg0.4-0.45%, titanium Ti0. 1-0.15%, the total impurity content is <0.02%, and the balance is aluminum. The production method is as follows: add cold material with the same composition, the ratio is 15-20% of the capacity of the melting furnace, then add the electrolytic aluminum liquid ingredients, through electromagnetic stirring treatment to achieve uniform composition of the aluminum liquid, add alloy materials in turn, through refining, degassing box, The pure aluminum solution is obtained from the filter box, and the horizontal casting is achieved through the balance adjustment. The adjustment amount of the aluminum liquid matches the speed of the casting machine, and the cooling method, cooling water flow and pressure are reasonably distributed, forming a process from liquid to crystallization in the cooling area of the crystallizer. The best condition, to ensure the grain size of the trapezoidal aluminum alloy. The product of the invention has uniform composition, high strength, fine grain size, first-class pinhole degree, low hydrogen content and few impurities, and comprehensively improves the mechanical properties of the alloy product.

Owner:河南中孚技术中心有限公司

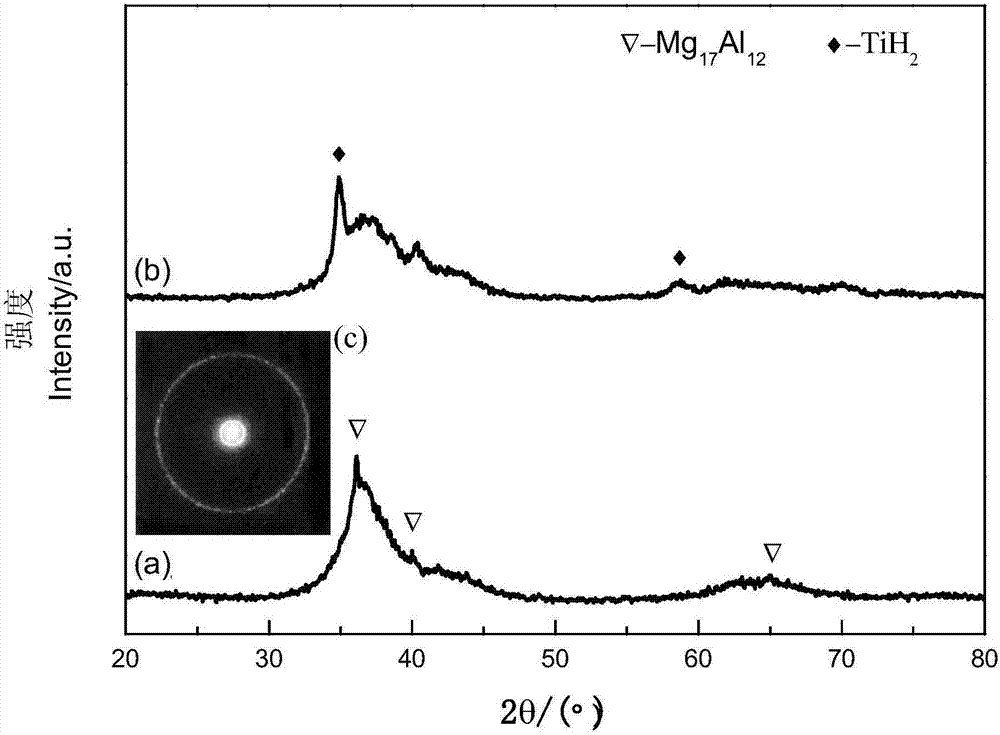

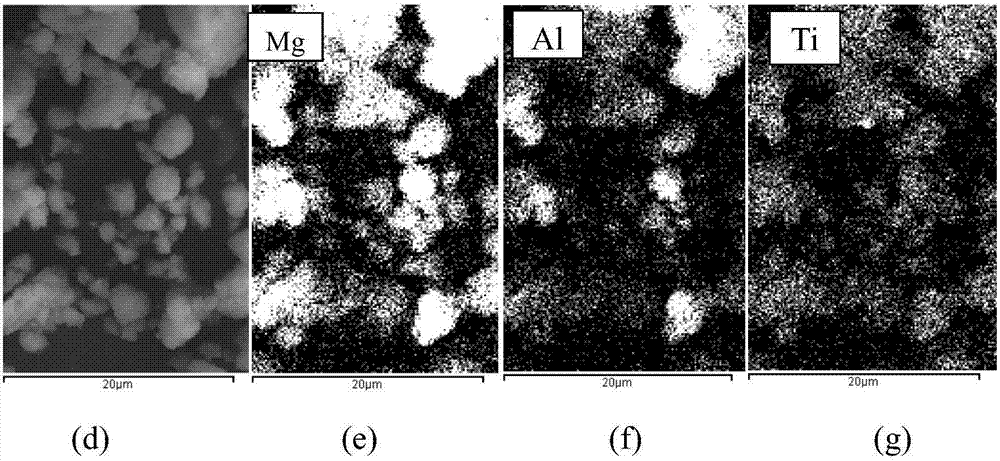

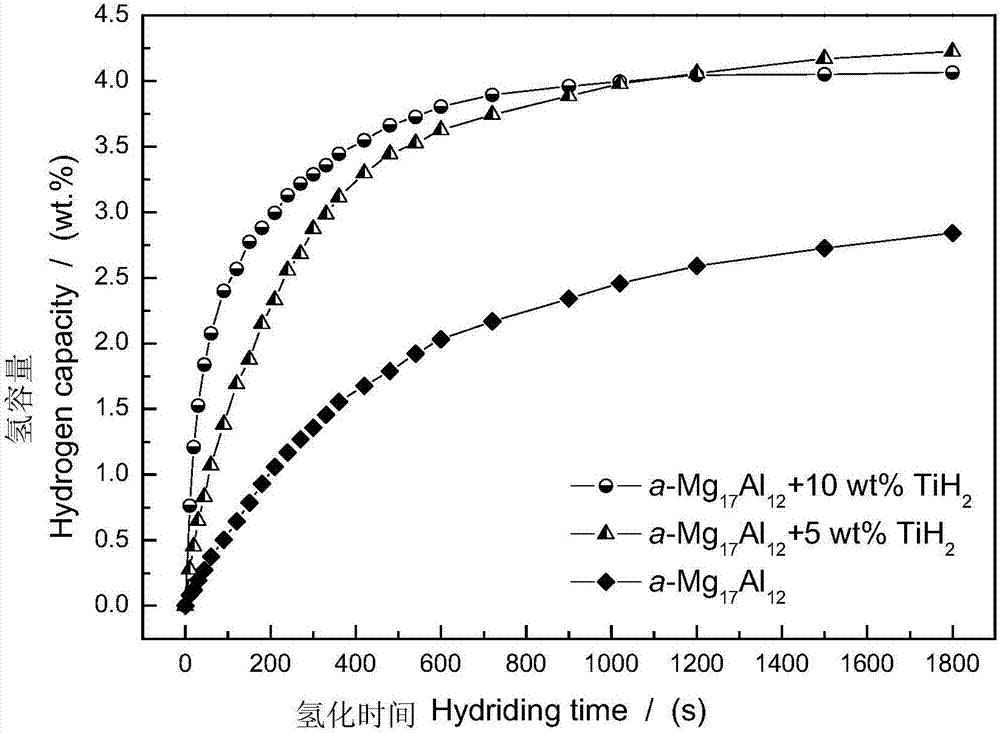

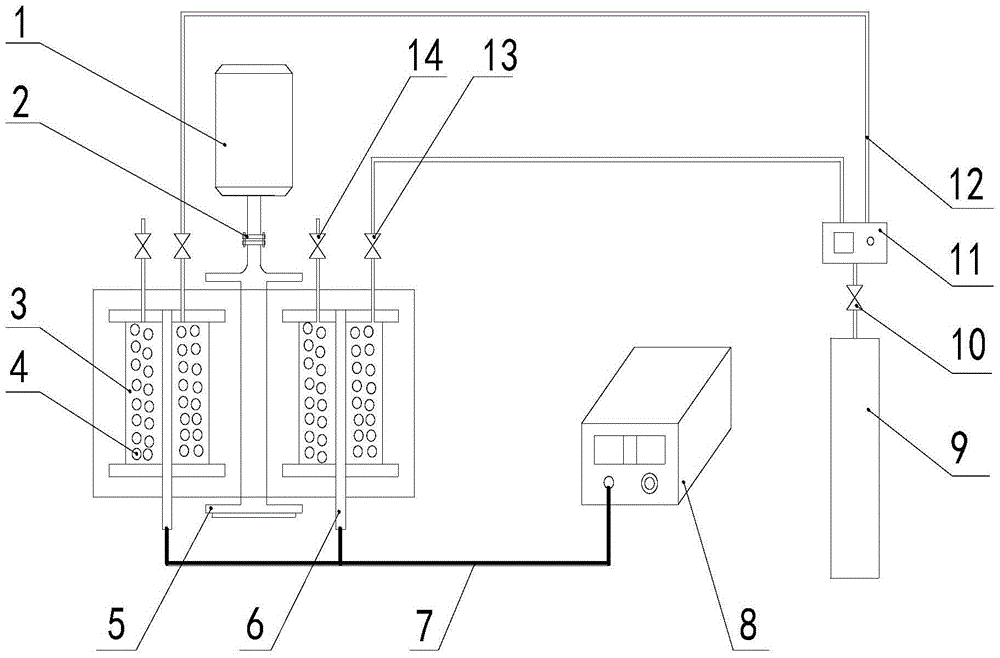

A kind of amorphous magnesium aluminum matrix composite hydrogen storage material and preparation method thereof

InactiveCN105584989BSimple processReduce manufacturing costHydrogen productionHydrogen absorptionAtmosphere

The invention discloses an amorphous magnesium-aluminum-base composite hydrogen storage material and a preparation method thereof. The amorphous magnesium-aluminum-base composite hydrogen storage material is prepared from an amorphous Mg17Al12 matrix and a transition metal hydride in a mass ratio of 100:(0.5-10), wherein the transition metal hydride is one or more of TiH2, ZrH2 and ScH2. The preparation method comprises the following steps: a) in an inert atmosphere, uniformly mixing raw materials Mg powder and Al powder according to the proportioning of the Mg17Al12, and preparing amorphous Mg17Al12 matrix powder by low-temperature ball milling; and b) carrying out mechanical ball milling on the prepared amorphous Mg17Al12 matrix powder and transition metal hydride powder under the protection of the inert gas to obtain the amorphous magnesium-aluminum-base composite hydrogen storage material. The composite hydrogen storage material has excellent medium / low-temperature hydrogen absorption / desorption properties.

Owner:ZHEJIANG UNIV

A method for preparing Aln nano-powder by plasma-assisted high-energy ball milling

InactiveCN103990534BMany crystal defectsFine grain sizeMaterial nanotechnologyNitrogen compoundsHigh energyEngineering

Owner:DALIAN UNIV OF TECH

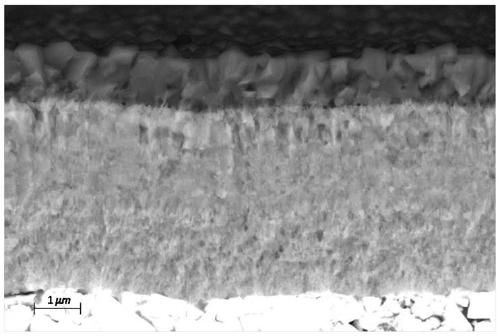

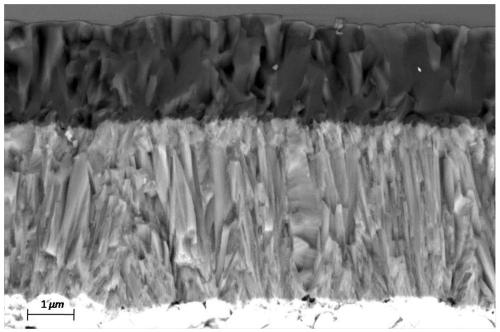

Coating coating on blade substrate and preparation method thereof

ActiveCN110331380BFine grain sizeHigh blade toughnessChemical vapor deposition coatingCemented carbideKnife blades

The invention provides an overlay coating on a blade substrate and a preparation method thereof. The overlay coating comprises at least four alternately deposited TiN layers and TiCN layers, at leastfive alternately deposited TiCNO layer and TiN layers, an AlTiCNO layer, an aluminum oxide nucleating layer and an aluminum oxide coating, wherein the thickness of each of the TiN layers and TiCN layers is 0.5-1.0 [mu]m, the thickness of each of the TiCNO layer and TiN layers is 0.5-1.0 [mu]m, the thickness of the AlTiCNO layer is 0.1-1.5 [mu]m, the thickness of the aluminum oxide nucleating layeris 0.1-0.8 [mu]m, and the thickness of the aluminum oxide coating is 3-10 [mu]m. The preparation method comprises the step of depositing the coatings successively on a hard alloy blade at corresponding temperatures, atmospheres and air pressures by means of a chemical vapor deposition method. The blade coated by the coating is higher in hardness and wear resistance, higher in wear-resistant degree and longer in service life.

Owner:ZHUZHOU HUARUI PRECISION CUTTINGS TOOLS CO LTD

NbCr2 bonded WCrRuTaV hard alloy and preparation method thereof

The invention discloses a WCrRuTaV refractory high-entropy hard alloy with NbCr2 as a binder and a preparation method of the WCrRuTaV refractory high-entropy hard alloy, and belongs to the technical field of hard alloy materials. Refractory metal elements W, Cr, Ru, Ta and V are adopted as raw materials, and high-entropy hard alloy powder is prepared through mechanical alloying; and the high-entropy hard alloy powder and the NbCr2 powder are evenly mixed and then subjected to spark plasma sintering, and the block hard alloy material is obtained. The NbCr2-bonded WCrRuTaV refractory high-entropy hard alloy obtained through the method has the superfine grain size and the high density, meanwhile, the hard alloy is uniform in component distribution and excellent in performance, and therefore the NbCr2-bonded WCrRuTaV refractory high-entropy hard alloy has the good application prospect.

Owner:NANCHANG INST OF SCI & TECH

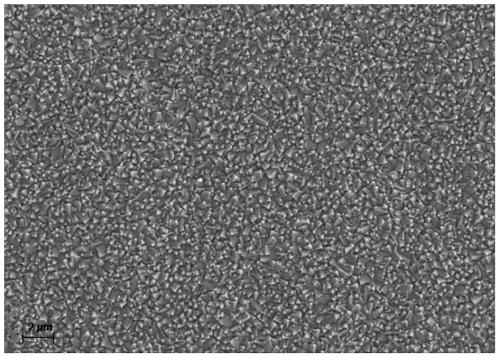

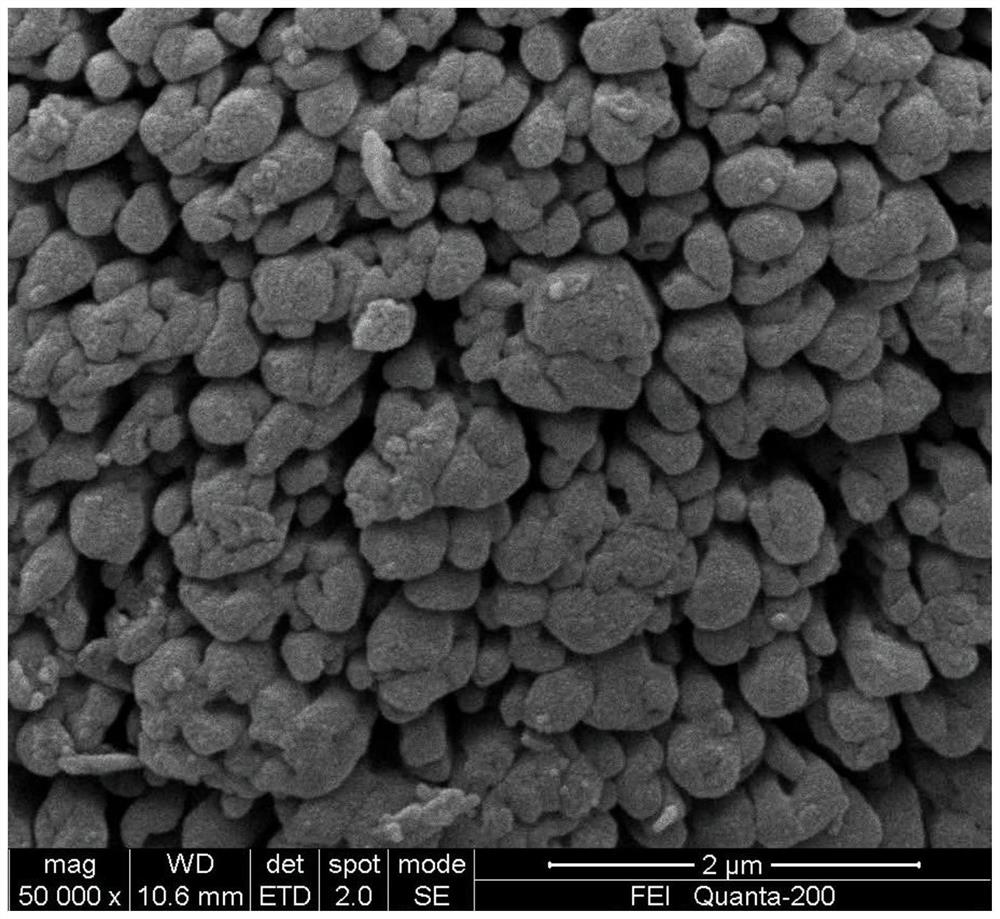

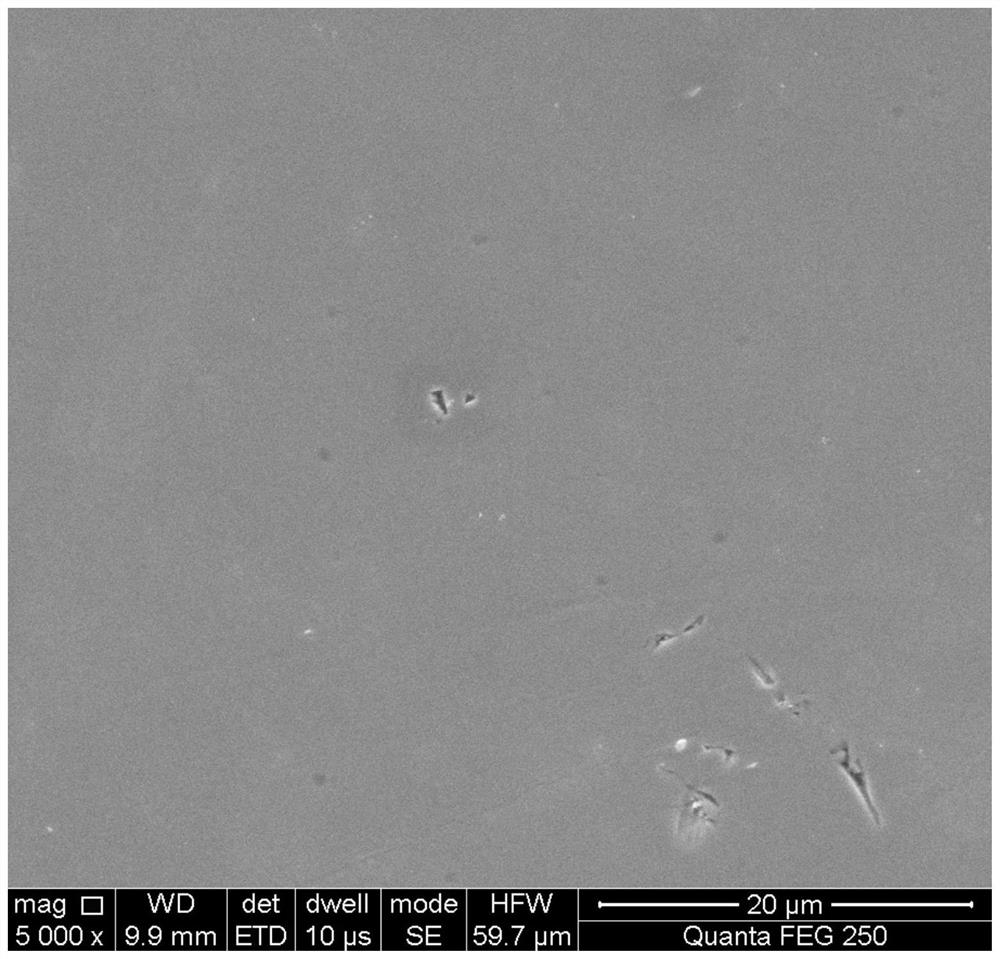

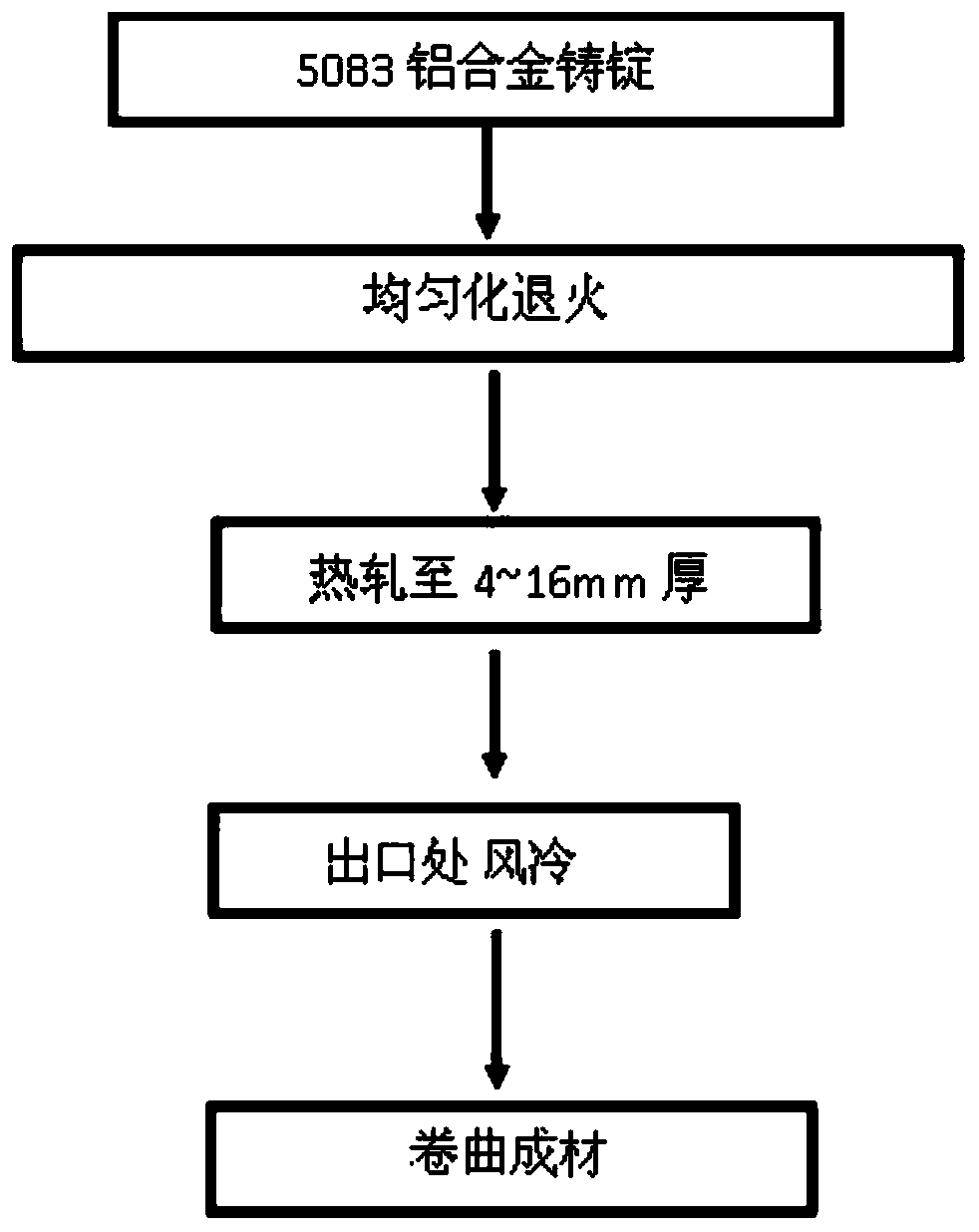

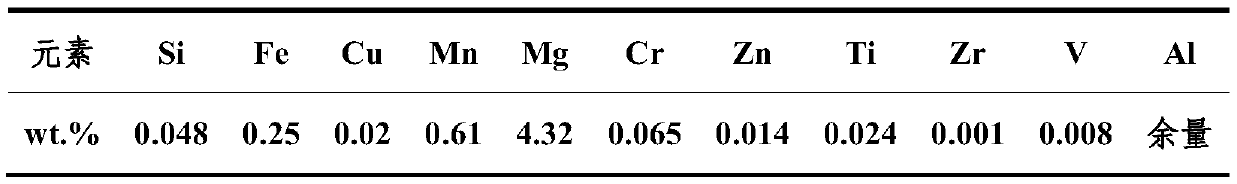

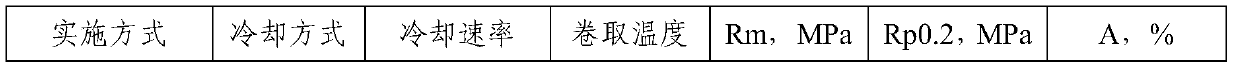

A kind of 5 series aluminum alloy plate and its preparation method and application

ActiveCN108531791BHigh strengthHigh elongationWork cooling devicesMetal rolling arrangementsUltimate tensile strengthAluminium alloy

The invention relates to a 5-series aluminum alloy panel, as well as a preparation method and application thereof. The preparation method of the 5-series aluminum alloy panel is characterized by forced cooling a hot-rolled aluminum alloy panel to be below 200 DEG C at the cooling speed being 15 to 25 DEG C / s. By adopting the cooling method provided by the invention, a fine-grain panel with the grain size being smaller than 30mum can be prepared, so that the strength and the extensibility of the 5XXX-series, particularly 5083 aluminum alloy panel material are improved.

Owner:CRRC QINGDAO SIFANG CO LTD

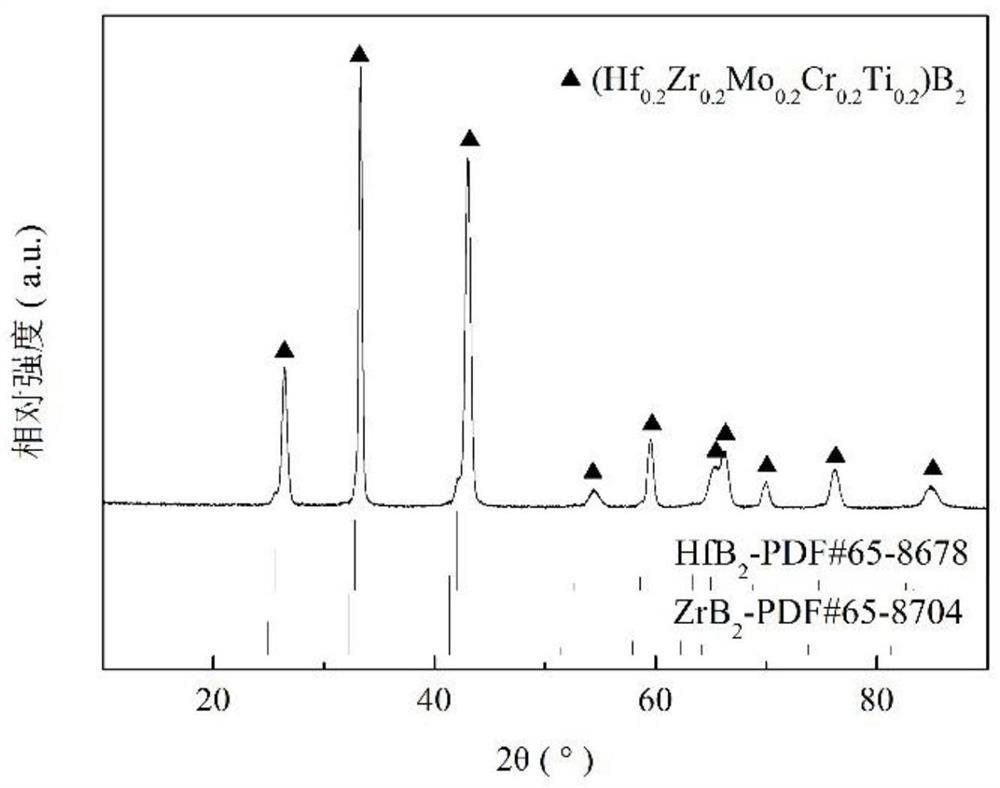

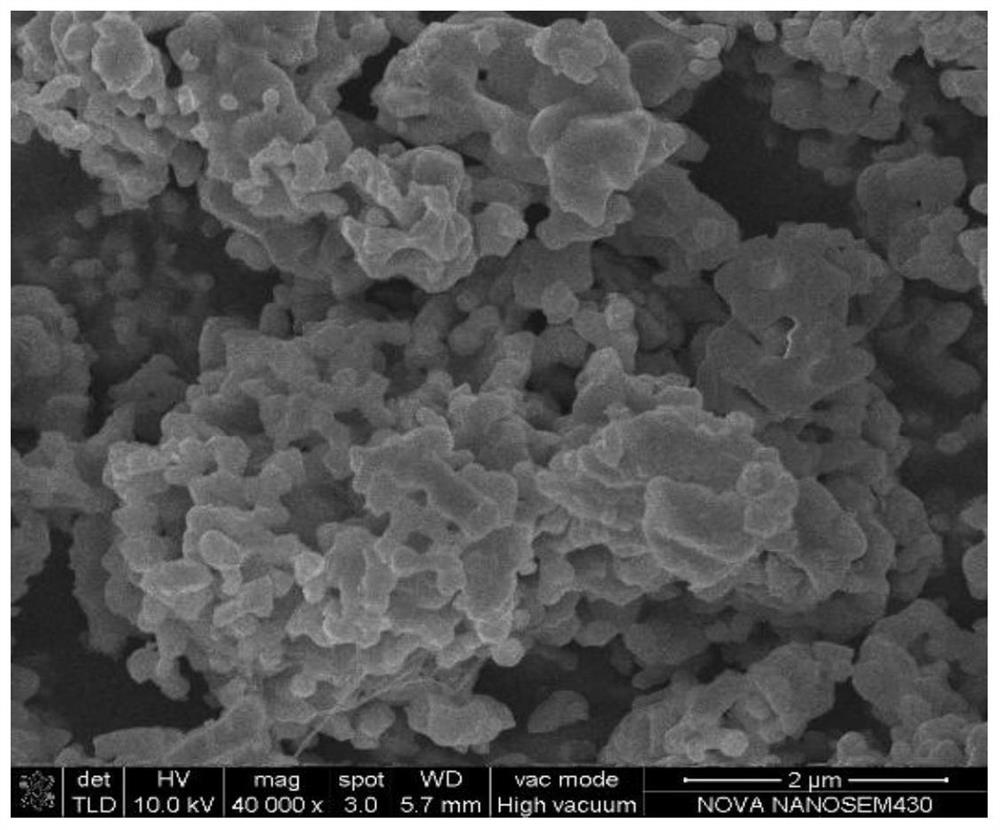

A high-entropy ceramic composite material with oxidation resistance and its preparation method and application

The invention belongs to the technical field of ceramic materials, and discloses a high-entropy ceramic composite material with oxidation resistance and its preparation method and application. The ceramic composite material (Hf 0.2 Zr 0.2 Mo 0.2 Cr 0.2 Ti 0.2 )B 2 ‑xvol% SiC is in HfO 2 , ZrO 2 、MoO 3 、Cr 2 o 3 、TiO 2 Adding solvent and ball milling medium to the amorphous boron powder is mixed, and the mixed powder is pressed into a green body, and heat treatment is carried out under vacuum conditions, and the vacuum heat treatment is carried out to obtain (Hf 0.2 Zr 0.2 Mo 0.2 Cr 0.2 Ti 0.2 )B 2 High-entropy solid solution powder obtained after mixing SiC (Hf 0.2 Zr 0.2 Mo 0.2 Cr 0.2 Ti 0.2 )B 2 ‑xvol% SiC high-entropy composite material powder is obtained by filling the high-entropy composite material powder with a protective atmosphere when the temperature is raised to 1000-1400°C by spark plasma sintering, and then calcined at 1800-2200°C, where 0≤x≤30. The relative density of the obtained high-entropy ceramic composite material is 95%-99.9%, the grain size of the high-entropy ceramic composite material is 1-3 μm, and the fracture toughness is 4-12 MPa·m 1 / 2 , after heat treatment at 1600°C-2000°C, the weight change rate is 0.3-2wt%.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com