Patents

Literature

183 results about "Amorphous boron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods to improve in-film particle performance of amorphous boron-carbon hardmask process in pecvd system

ActiveUS20170062218A1Reduce particle pollutionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingBoron containingDelayed time

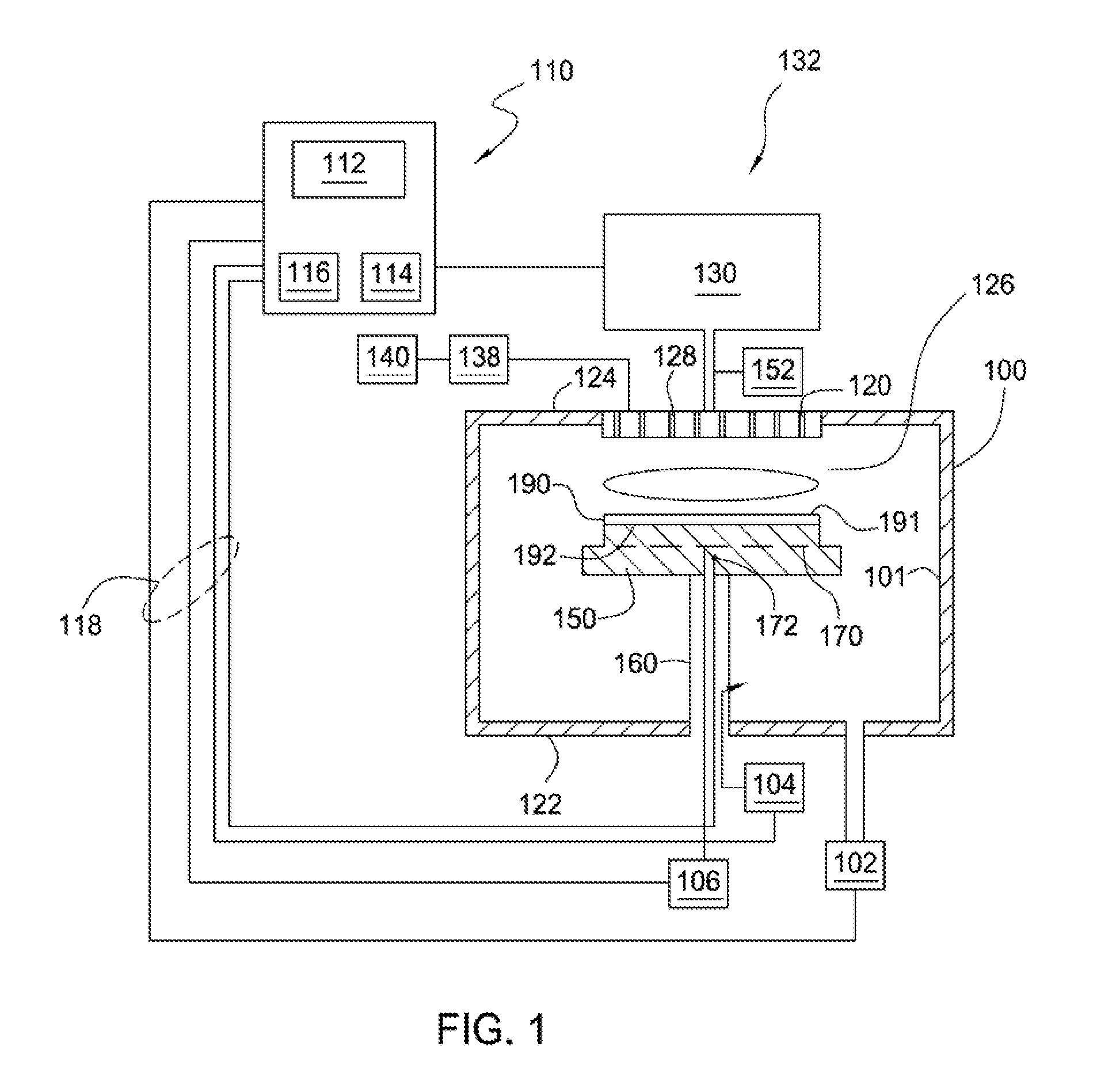

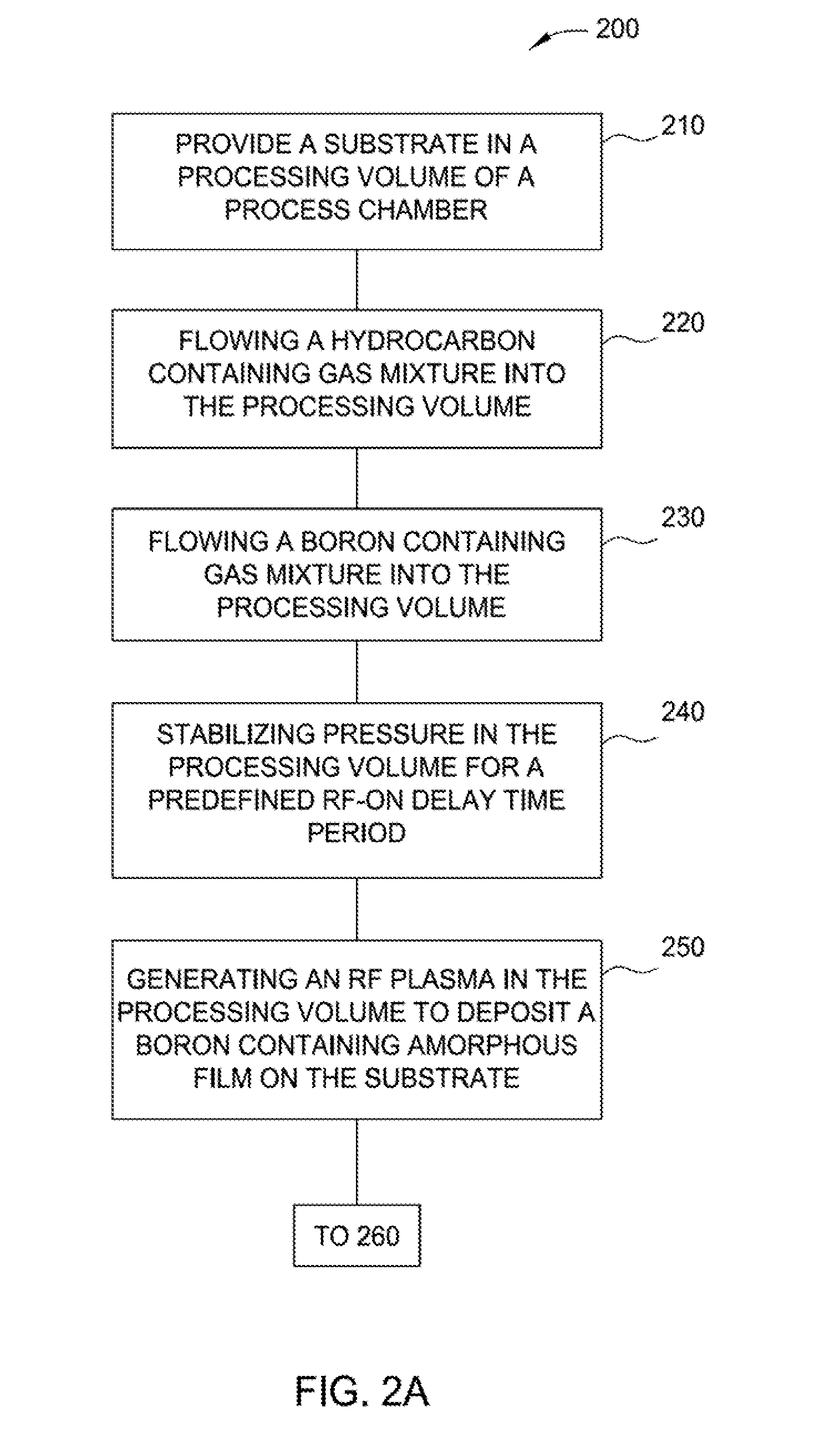

Implementations of the present disclosure generally relate to the fabrication of integrated circuits. More particularly, the implementations described herein provide techniques for deposition of boron-containing amorphous carbon films on a substrate with reduced particle contamination. In one implementation, the method comprises flowing a hydrocarbon-containing gas mixture into a processing volume having a substrate positioned therein, flowing a boron-containing gas mixture into the processing volume, stabilizing the pressure in the processing volume for a predefined RF-on delay time period, generating an RF plasma in the processing volume after the predefined RF-on delay time period expires to deposit a boron-containing amorphous film on the substrate, exposing the processing volume of the process chamber to a dry cleaning process and depositing an amorphous boron season layer over at least one surface in the processing volume of the process chamber.

Owner:APPLIED MATERIALS INC

Method for surface boriding of hard alloy

The invention discloses a new method for surface boriding of hard alloy, which sequentially comprises the following steps of: removing an oxidation layer on the surface of the hard alloy; embedding the hard alloy into a solid boriding agent, putting the mixture into a nearly-closed boriding container, and putting the container into an induction heating furnace; vacuumizing the furnace, stopping vacuumizing until the vacuity is over 100 Pa, and filling inert gas or hydrogen; after the gas in the furnace reach the pressure, starting to perform induction heating to reach the boriding temperature of between 800 and 1,300 DEG C, and performing heat preservation for 0.5 to 8 hours to realize gas-solid phase boriding. The solid boriding agent comprises the following components in percentage by weight: 5 to 50 percent of boron supply agent, 2 to 40 percent of activating agent and the balance of fillers, wherein the boron supply agent is one or more of powdered B4C, BN and amorphous boron; the activating agent is two or more of powdered KBF4, NaBF4, NH4BF4, (NH4)2CO3, rare earth oxide and Mg powder, and one of the mixture is an activating agent containing a B element; and the filler consists of graphite powder granules and SiC powder or Al2O3 powder. Through the method, the boriding thickness of sintered hard alloy blank is more than 0.1 millimeter and is close to 1 millimeter, so the surface abrasion resistance of the hard alloy is improved greatly.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

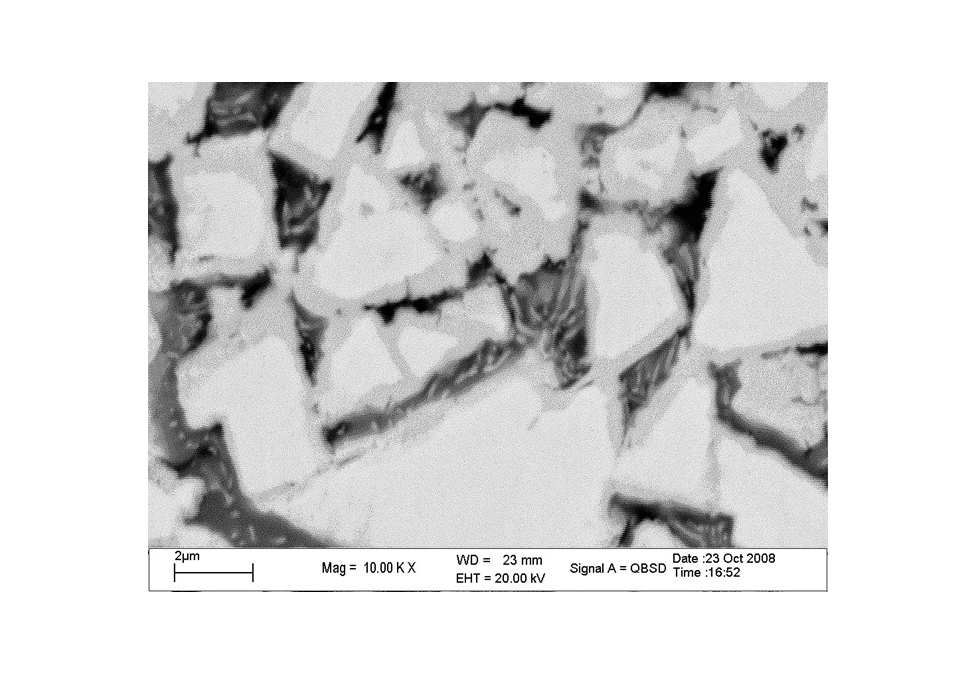

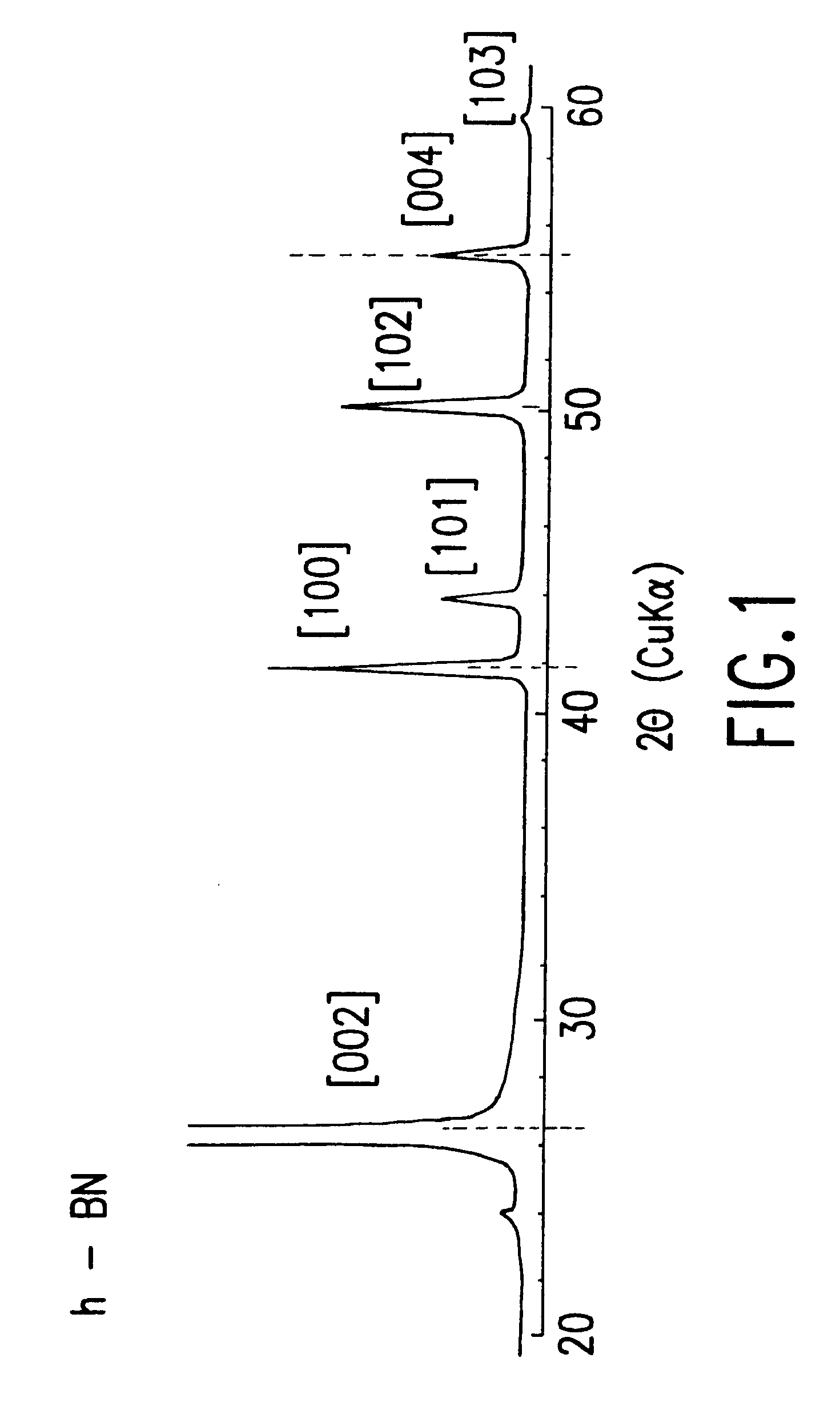

Crystalline turbostratic boron nitride powder and method for producing same

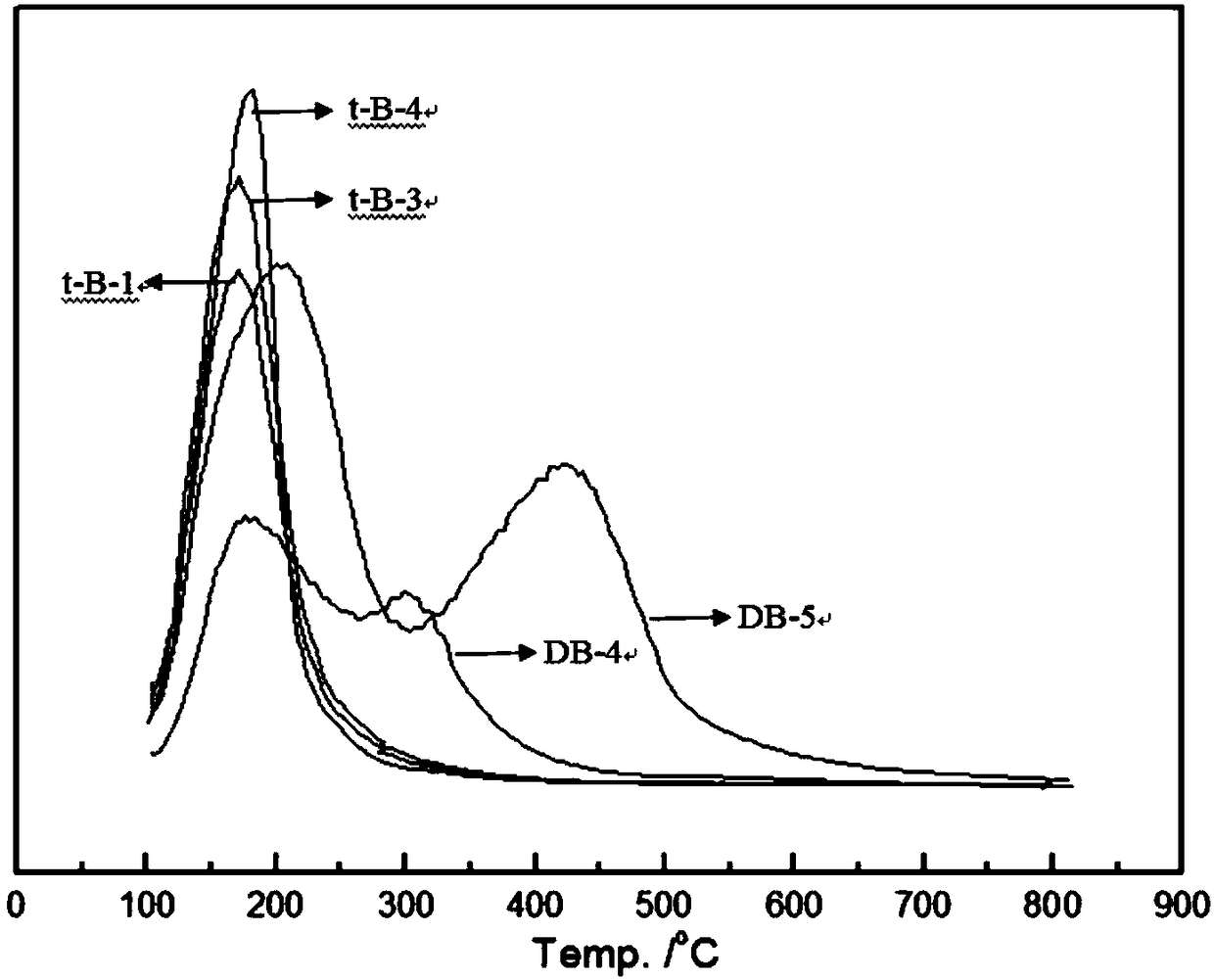

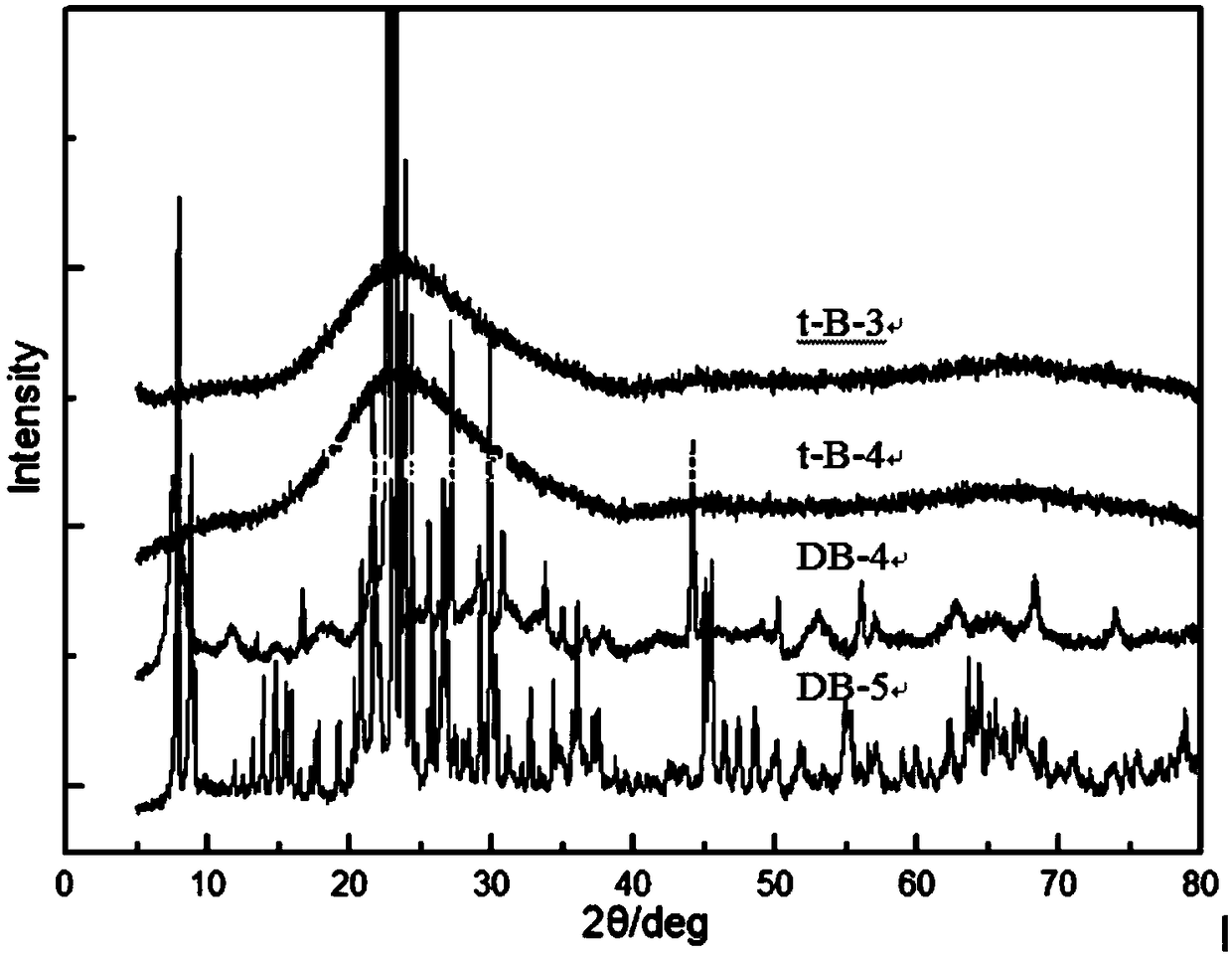

InactiveUS6306358B1Nitrogen compoundsSynthetic resin layered productsBoron nitrideAtmospheric pressure

Turbostratic boron nitride (t-BN) powder having excellent sinterability. A mixture of boric acid anhydride and urea is charged in a reaction vessel together with alkali-borate, heated step by step in the vessel in an nonoxidizing gas atmosphere of one atmospheric pressure or above, and kept at a temperature from 850° C. to 950° C. to yield an intermediate product formal substantially of an amorphous boron nitride powder (first reaction step). Then the intermediate product is heated and kept at a temperature from 1200° C. to 1400° C. to crystallize crystalline t-BN, and the product is purified by washing with water and aqueous solution to obtain pure crystalline t-BN powder.

Owner:YAMAMOTO OSAMU

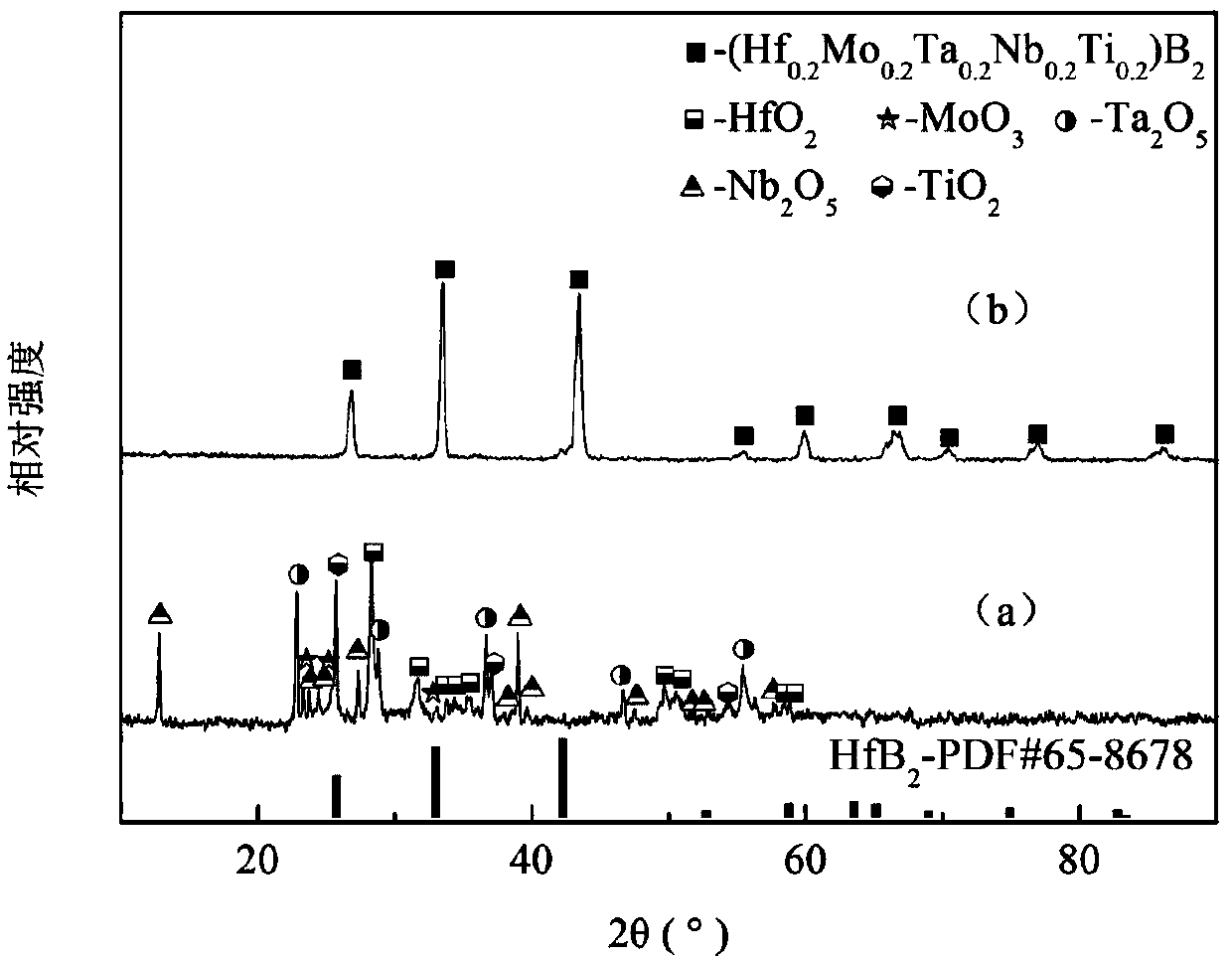

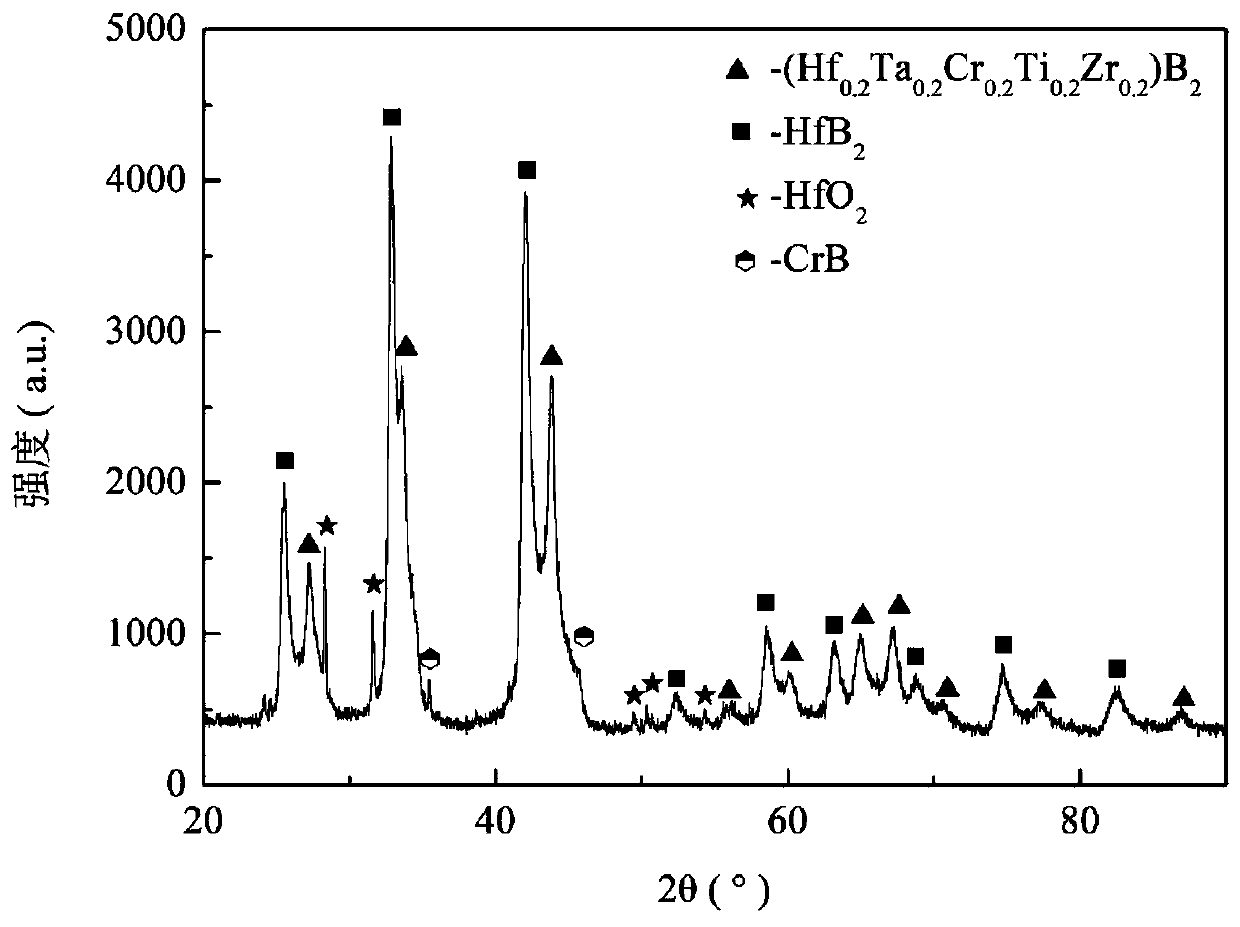

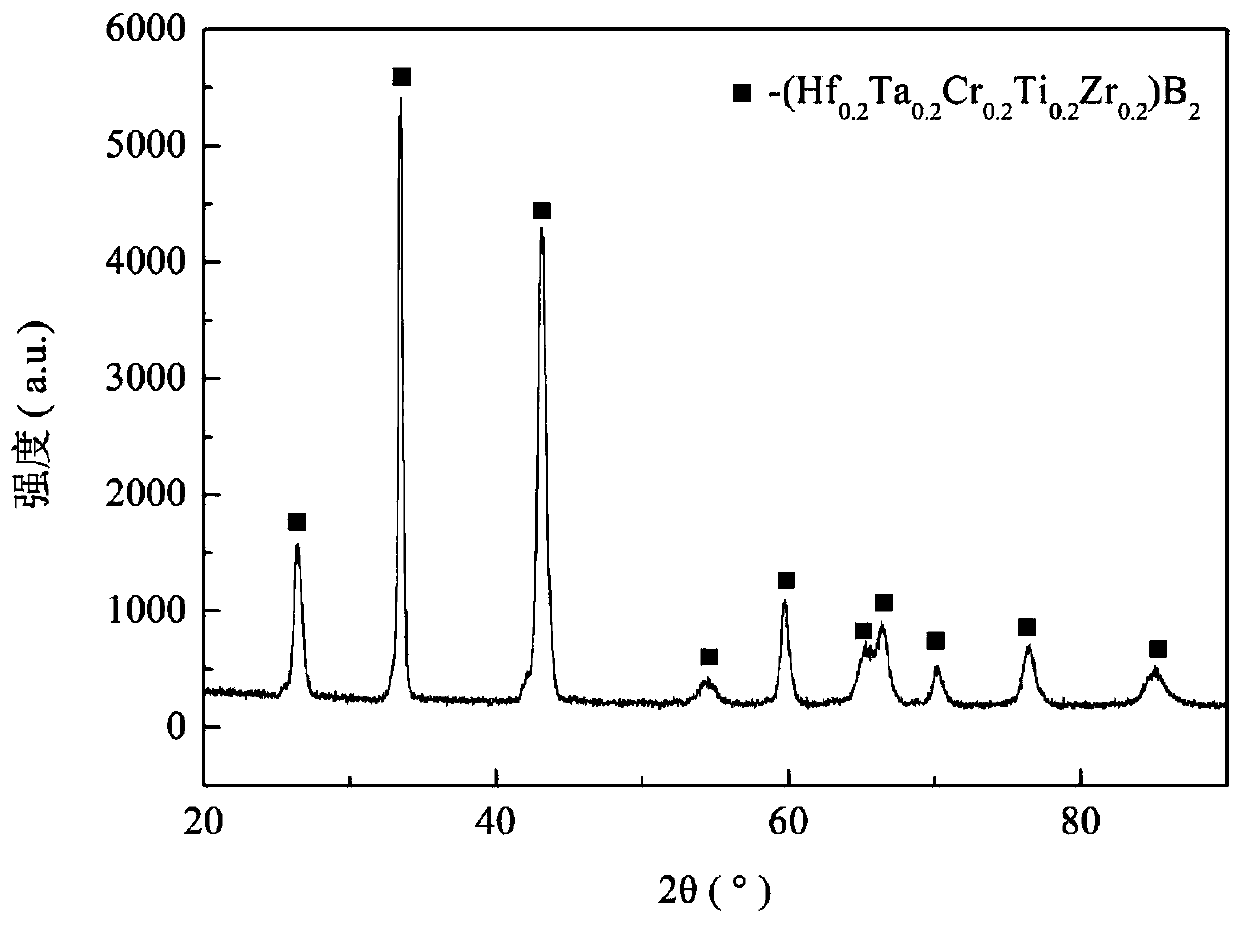

Ceramic with multi-element high entropy as well as preparation method and application of ceramic

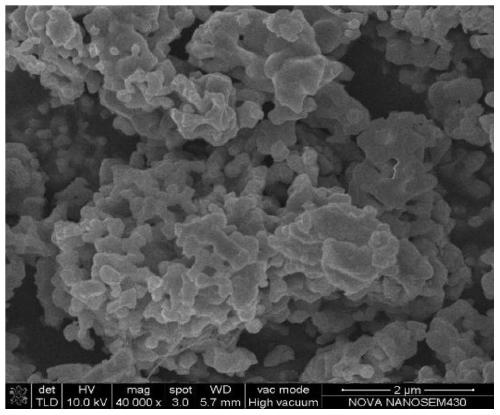

The invention belongs to the technical field of ceramic materials and discloses a ceramic with multi-element high entropy as well as a preparation method and application of the ceramic. The ceramic isprepared by the following steps: taking an oxide of Me1, an oxide of Me2, an oxide of Me3, an oxide of Me4, an oxide of Me5 and amorphous boron powder as raw materials, performing ball milling, mixing and pressing into a green body; adding the green body into a graphite crucible, and performing vacuum heat treatment to obtain (Me1xMe2yMe3zMe4nMe5m)B2 solid solution powder; raising the temperatureof the solid solution powder to 1000-1400 DEG C by adopting spark plasma sintering, filling a protective atmosphere, and raising to a temperature of 1800-2200 DEG C for calcining, thereby obtaining the product. The prepared multi-element high-entropy ceramic has the relative density of more than 95%, the hardness of 25-35GPa, the breaking tenacity of 2-8MPa*m1 / 2 and the grain size of 0.1-1.1 microns, and after the heat treatment of 1000-1500 DEG C, the weight change rate is 0.3-1%.

Owner:GUANGDONG UNIV OF TECH

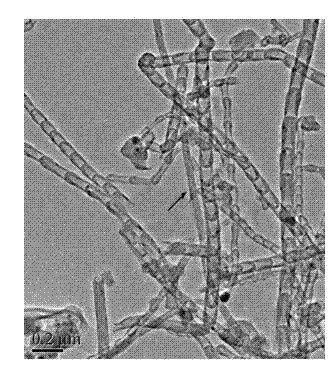

Method for preparing hexagonal boron nitride nano composite structure

InactiveCN103043633AIncrease the degree of mixingIncrease productionMaterial nanotechnologyNitrogen compoundsChemical industryMicro nano

As an important III-V main group compound, hexagonal boron nitride (h-BN) has multiple excellent physical and chemical properties, such as high-temperature resistance, oxidation resistance, corrosion resistance, self-lubrication and high thermal conductivity, and can be widely used in the fields of chemical industry, machinery, electronics, aerospaces, and the like. In recent years, a research on BN is relatively focused on BN nanotubes; by contrast, the research on BN nanowires is little, and a report on relevant BN micro-nano composite structures is rarer. The novel BN micro-nano composite structure is synthesized by taking amorphous boron powder, ferric chloride hexahydrate, absolute ethyl alcohol, high-purity nitrogen and liquid ammonia as raw materials. The synthetic method is simple in technology; the raw materials are nontoxic, environment-friendly and low in cost; the product purity is high; the yield is high; no purification is required; and scale production is facilitated. In addition, the novel BN micro-nano composite structure has a very high specific surface area, and has very wide development and application prospects in the fields of catalyst carrier materials, novel energy storage materials, ceramic compound materials and polymer composites.

Owner:GUANGXI UNIV

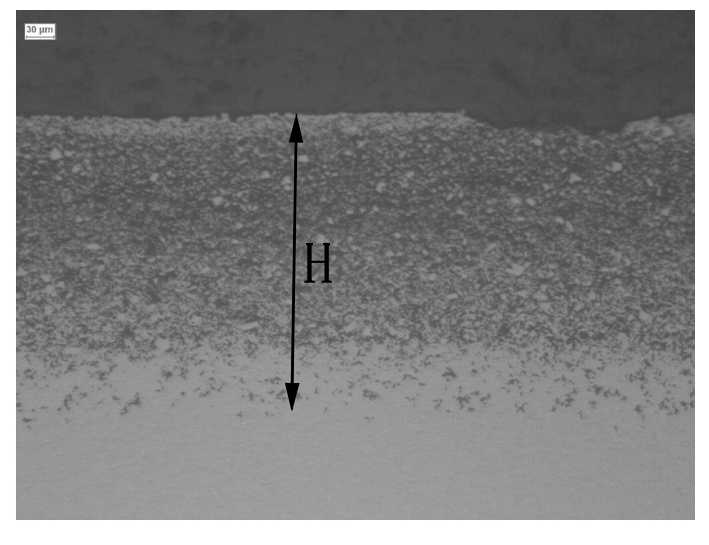

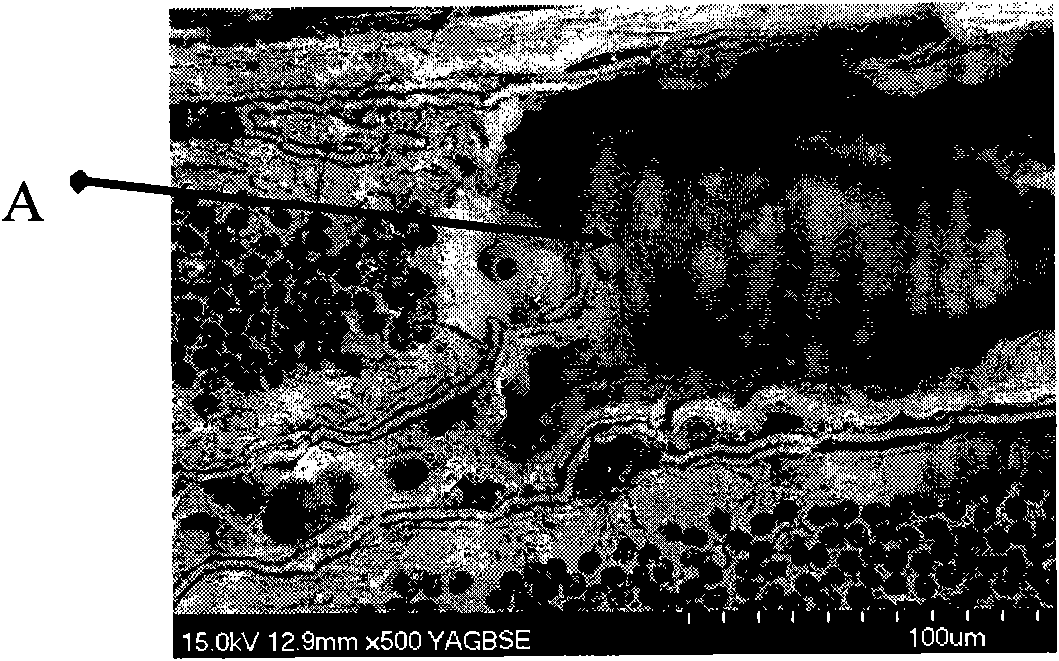

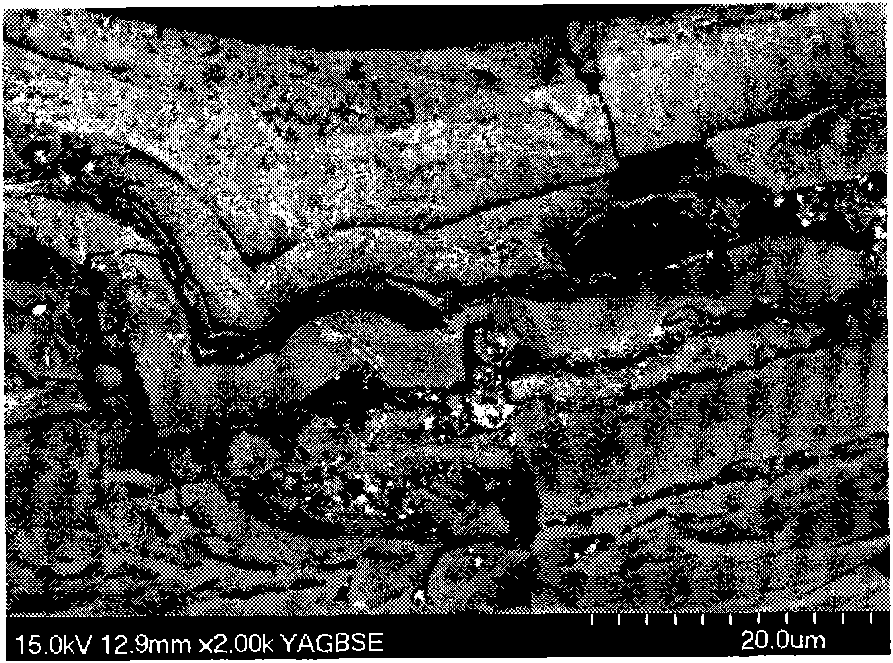

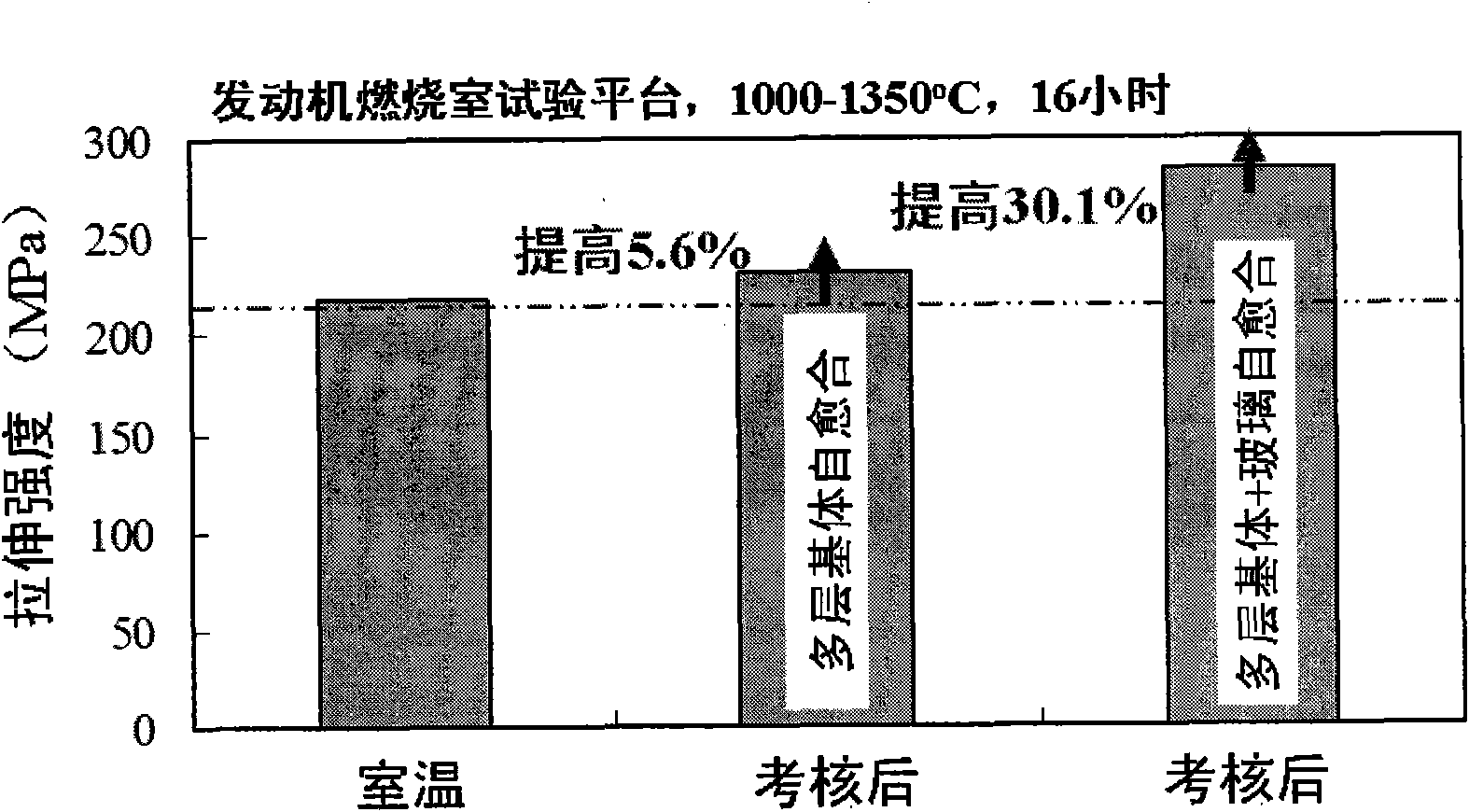

Dual self-healing modification method for silicon carbide ceramic matrix composite material

The invention relates to a dual self-healing modification method for a silicon carbide ceramic matrix composite material, which is technologically characterized in that a fiber preform is used as a reinforcement, a pyrolytic carbon interface is prepared by chemical vapor infiltration, a silicon carbide matrix is prepared by the chemical vapor infiltration, and silicon carbide matrixes and amorphous boron carbide matrixes (alpha-B4C) are alternately prepared by the chemical vapor infiltration until the density of the composite material is greater than 2.0 g.cm<-3>; two silicon carbide coatings are formed by chemical vapor deposition, and borosilicate glass is used for sealing and filling by a method of brushing costing and sintering. The method has strong designability, simple process and good repeatability, can obviously improve the oxidation resistance of CMC-SiC and can meet the application requirement of sealing sheets / adjustment sheets, inner cones, floating wall tiles, flame tubes and other members of an aircraft engine with high thrust-weight ratio for long-life CMC-SiC.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

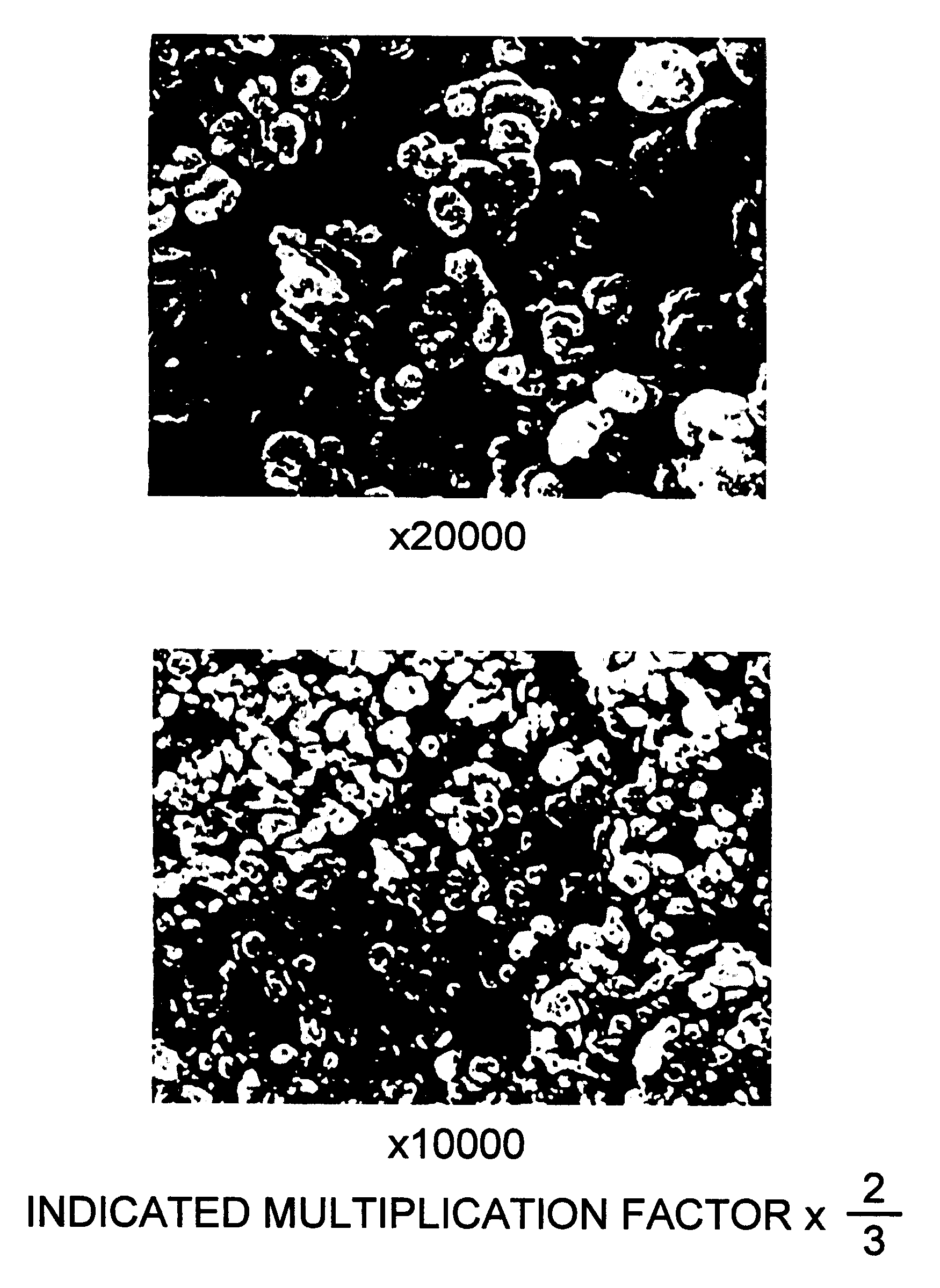

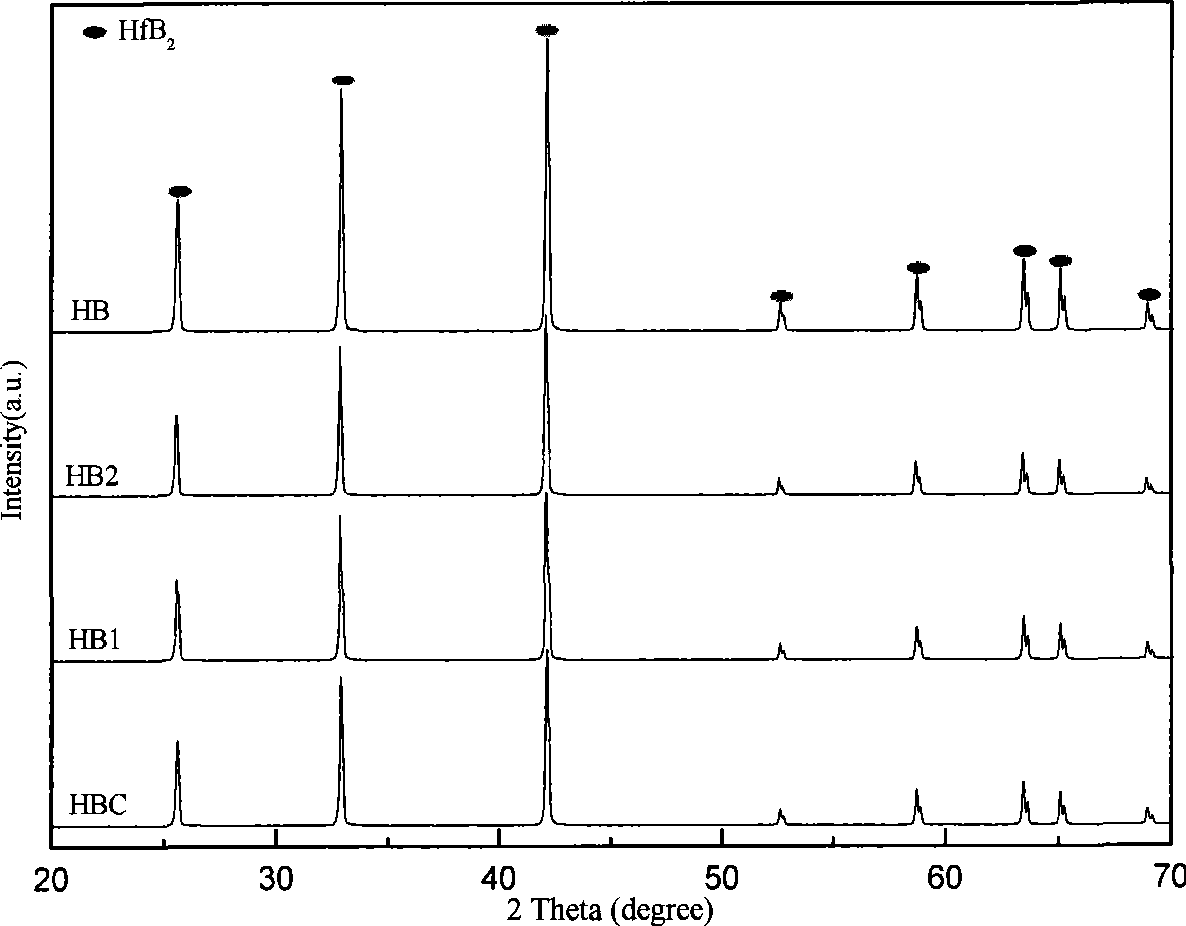

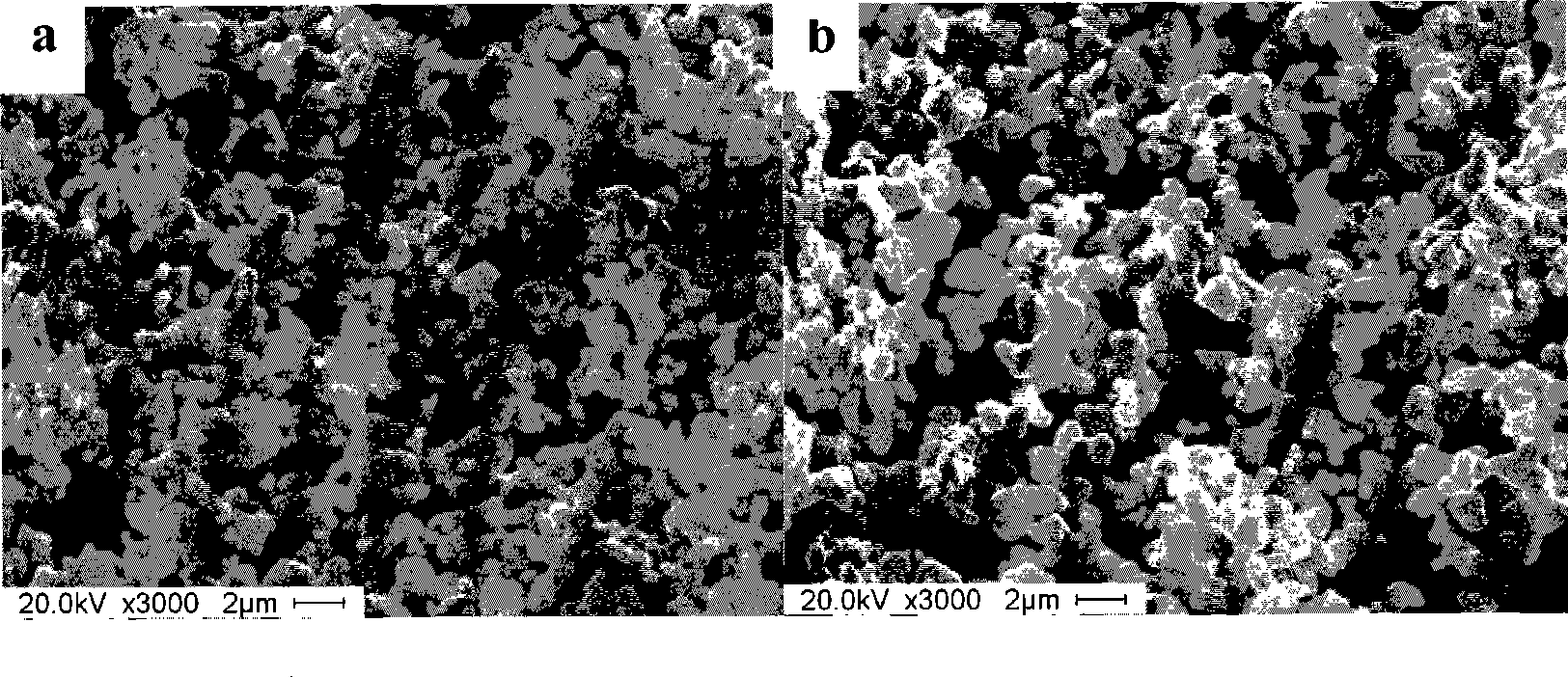

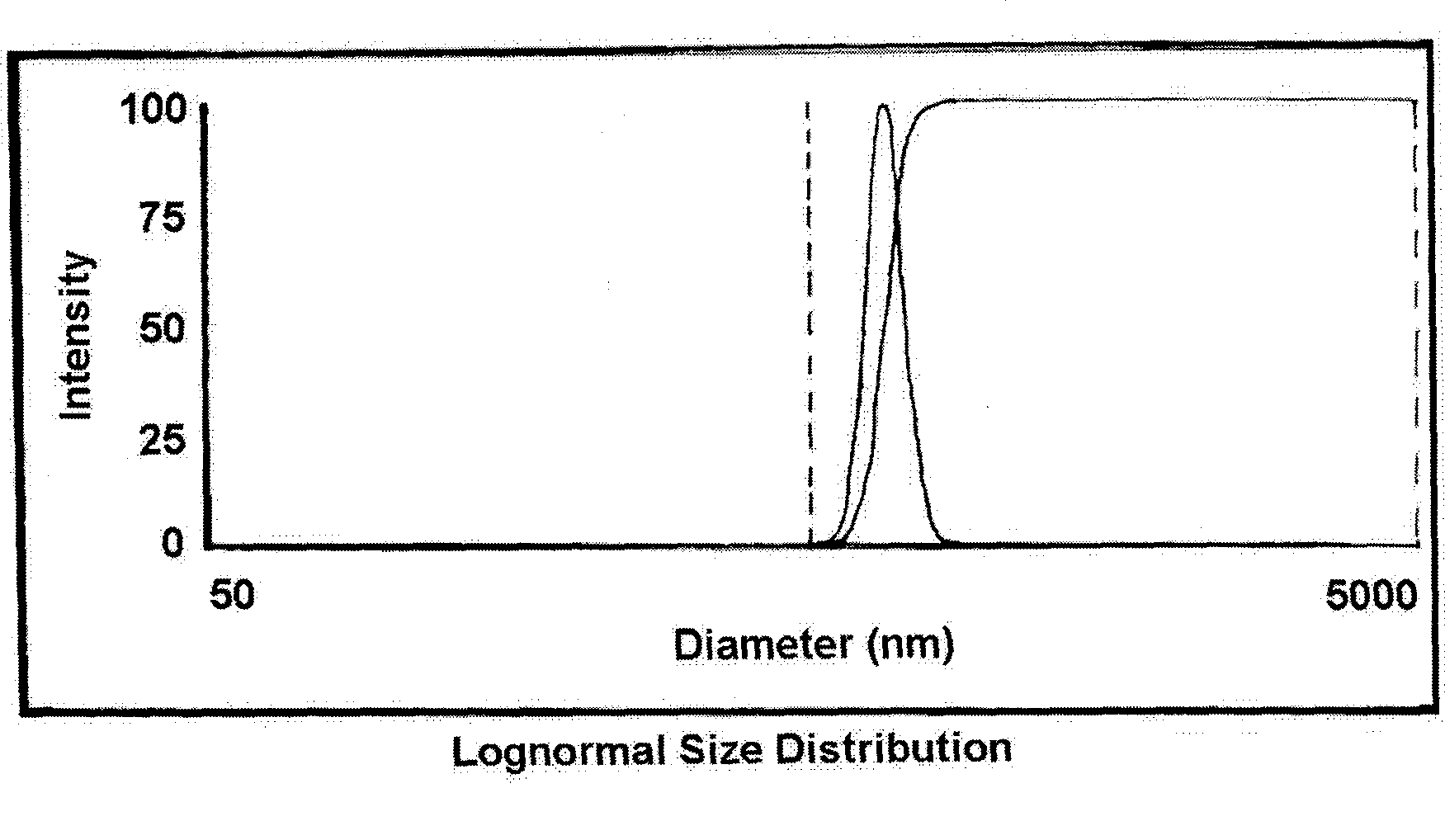

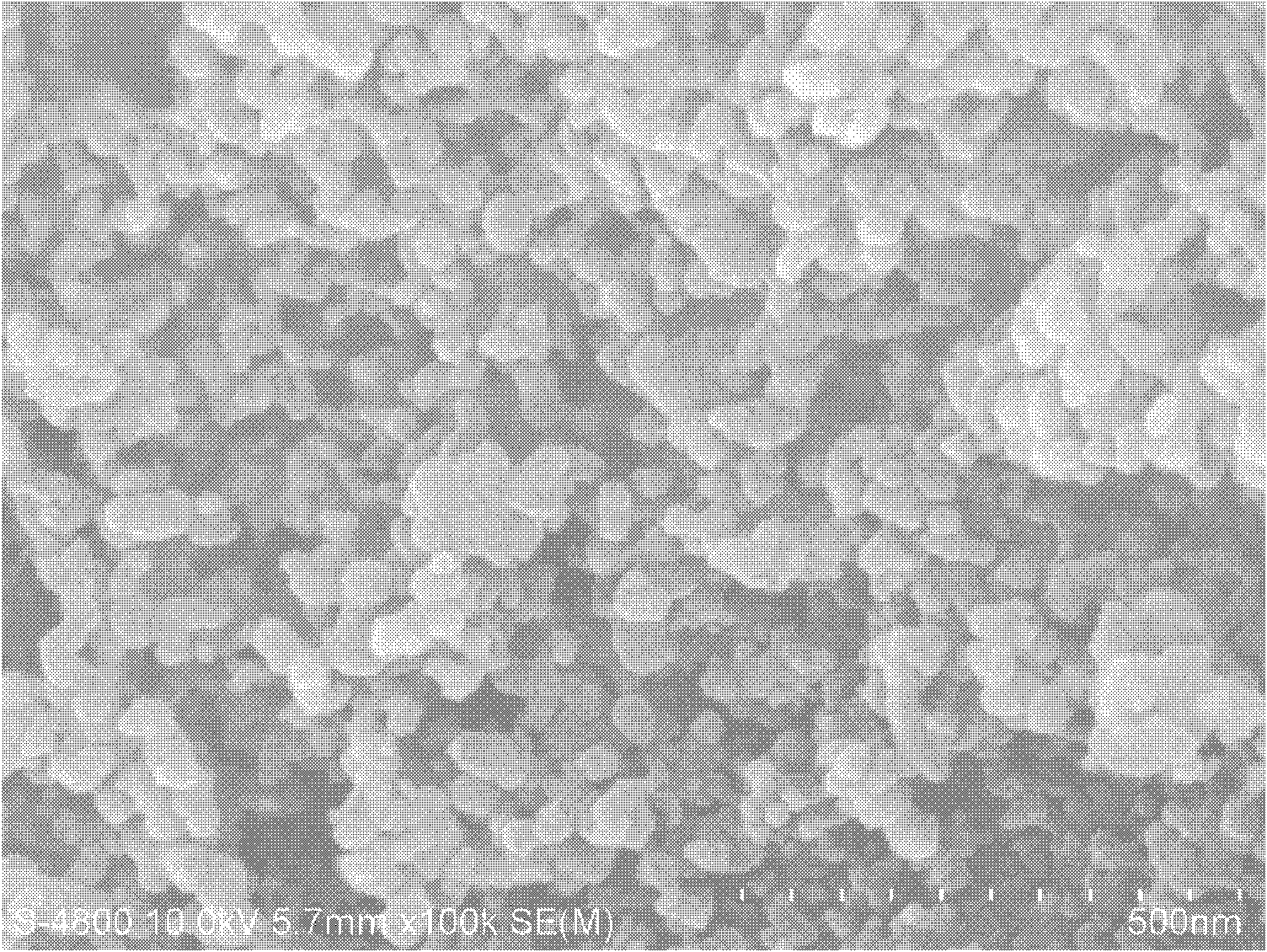

Synthesis of high-purity hafnium boride powder

The invention relates to hafnium boride powder with advantages of high purity, good dispersibility, small grain size and narrow distribution range, and a process for synthesizing the powder. The invention is characterized in that the process adopts hafnium oxide, boron carbide, graphite and amorphous boron as raw materials and is based on carbothermic / borothermic reduction reaction, wherein, in the carbothermic reduction, the mass ratio of HfO 2, B4C and C ranges from (1-5 / 4):(5 / 7-6 / 7):(0-3 / 2); and in the borothermic reduction, the mass ratio of HfO2 and B is 1:(10 / 3-4). Through adjusting the proportion of the raw materials, controlling the synthesizing process, adopting relatively cheap HfO2 raw material, the invention can synthesize the HfB2 powder with oxygen content less than 0.2wt% under the conditions that the temperature is 1500-1600 DEG C, an Ar atmosphere is adopted, or the vacuum degree is smaller than 1 Pa. SEM and laser grading analysis show that the distribution range of powder grain diameter is narrow (the polydispersity coefficient is 0.005), and the average grain diameter is around 1Mum. All of the parameters are superior to the ordinary commercial HfB2 powder, the preparation process and the required equipment are simple, the cost is low and the yield is high.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

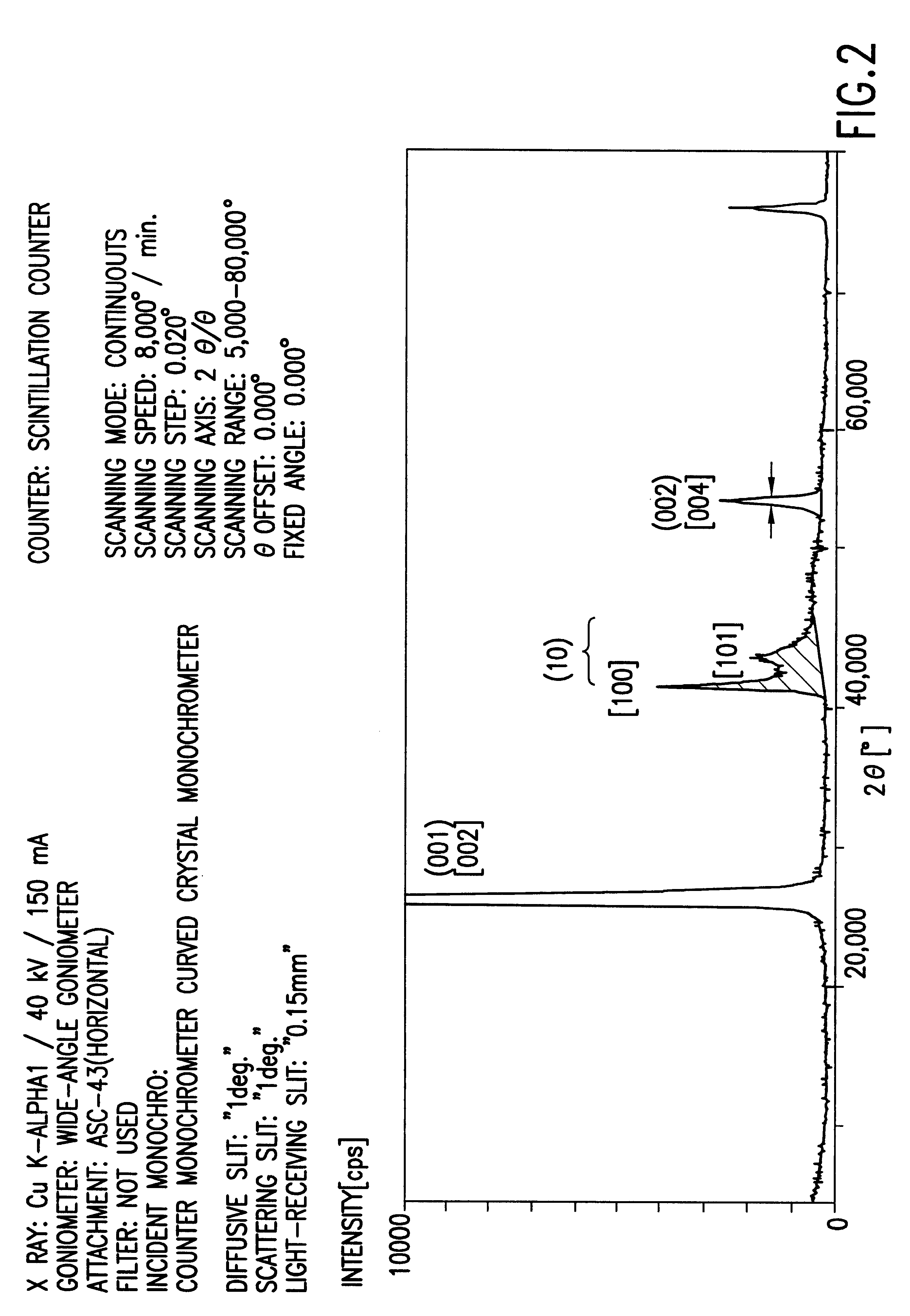

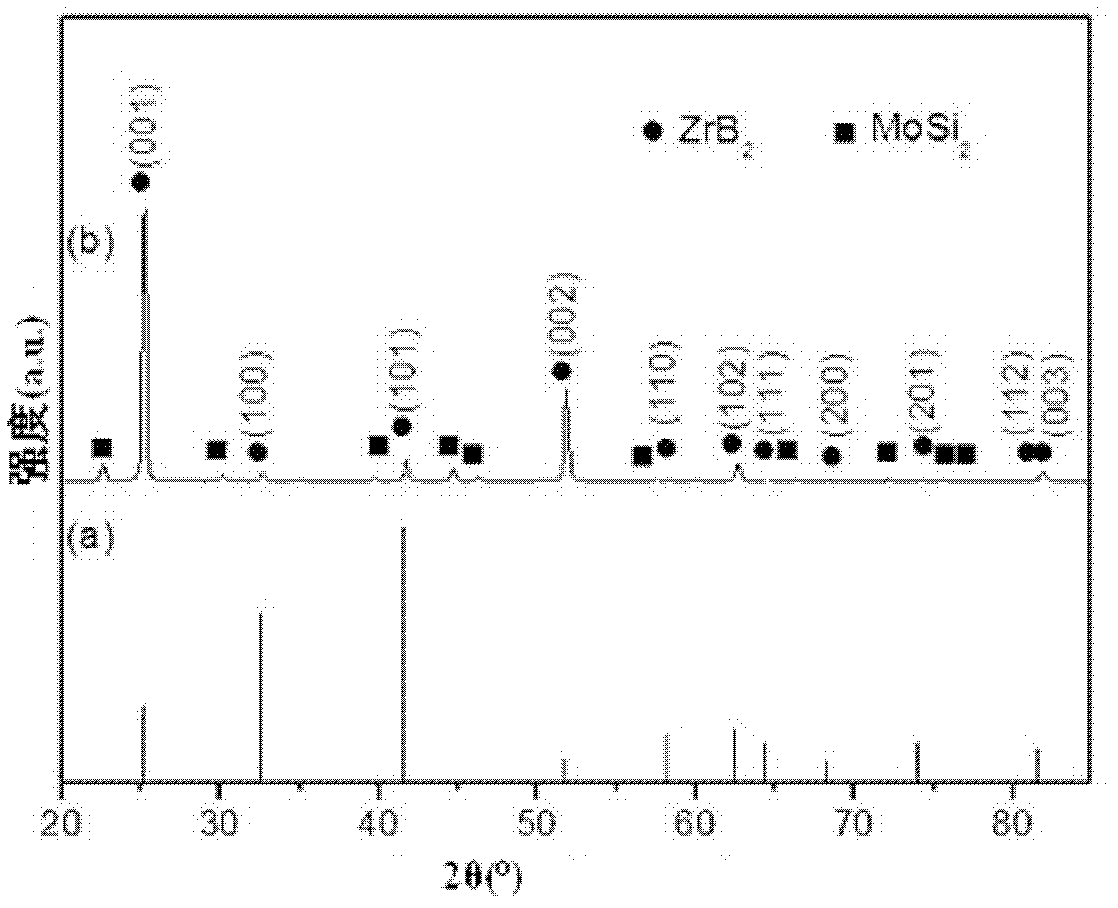

Method for preparing texturing boride super-high-temperature ceramic

The invention discloses a method for preparing texturing boride super-high-temperature ceramic. The method for preparing the texturing boride super-high-temperature ceramic comprises the steps that IVB group metal simple substance, amorphous boron powder, silica powder, and transition metal are adopted as raw materials, and complex-phase powder containing boride seed crystal and silicide particles is prepared; and slurry is prepared by mixing the complex-phase powder and boride ceramic powder, a ceramic body is prepared by means of the casting process technology or high-intensity magnetic field orientation process technology, and then hot pressed sintering is carried out on the ceramic body. According to the method for preparing the texturing boride super-high-temperature ceramic, the boride seed crystal is enabled to grow in the ceramic body in a orientation-arrangement mode due to the preparation of boride seed crystal with anisotropic microstructure and the adoption of the casting process technology or high-intensity magnetic field orientation process technology for preparation of the ceramic body, and then the texturing boride super-high-temperature ceramic with anisotropic crystal particle morphology is prepared. According to the ceramic prepared with the method, relative density is more than 98%, material Lotgering orientation factor f (001) can reach to 0.95, and obvious anisotropism can be represented by each performance.

Owner:江苏先进无机材料研究院

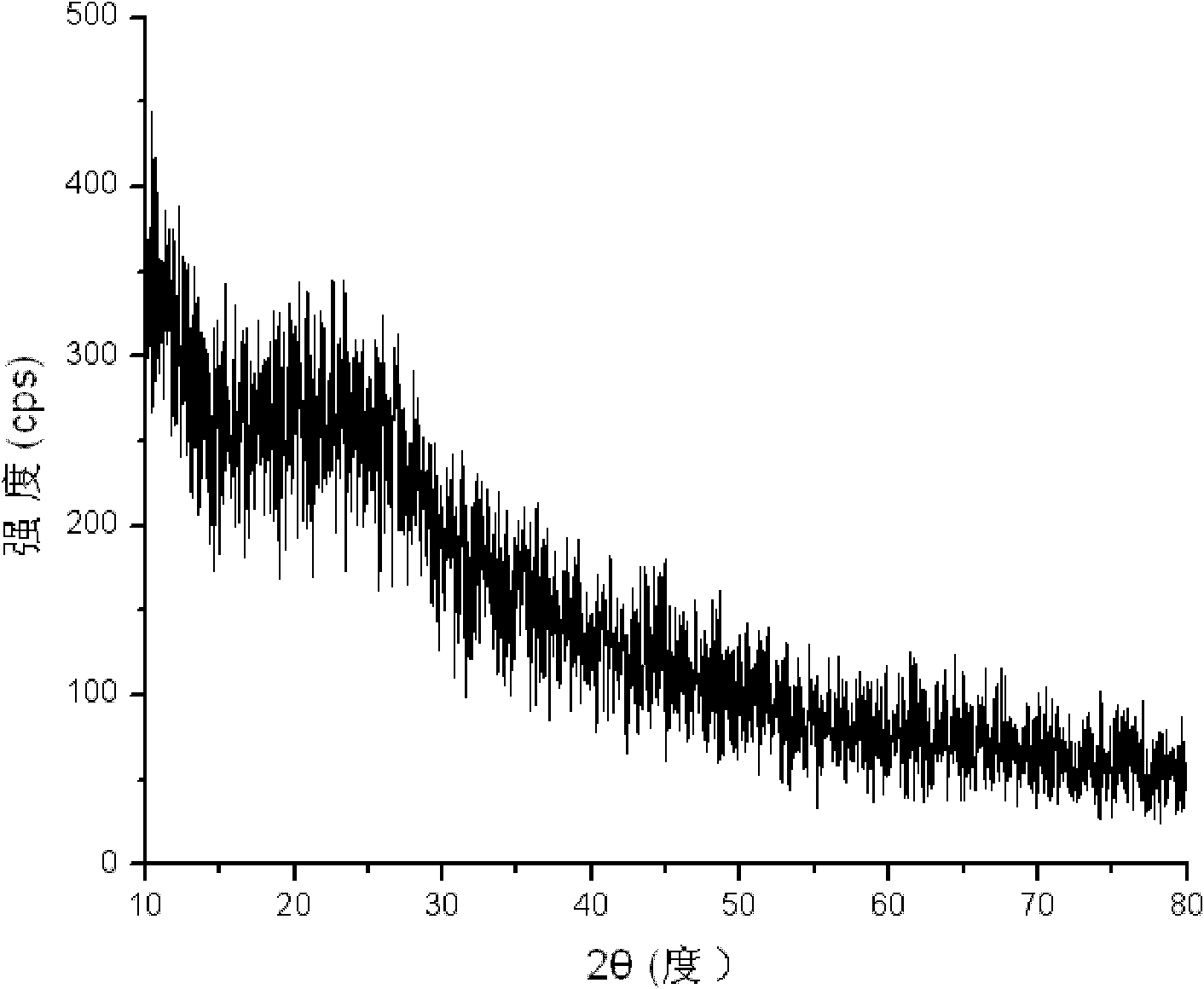

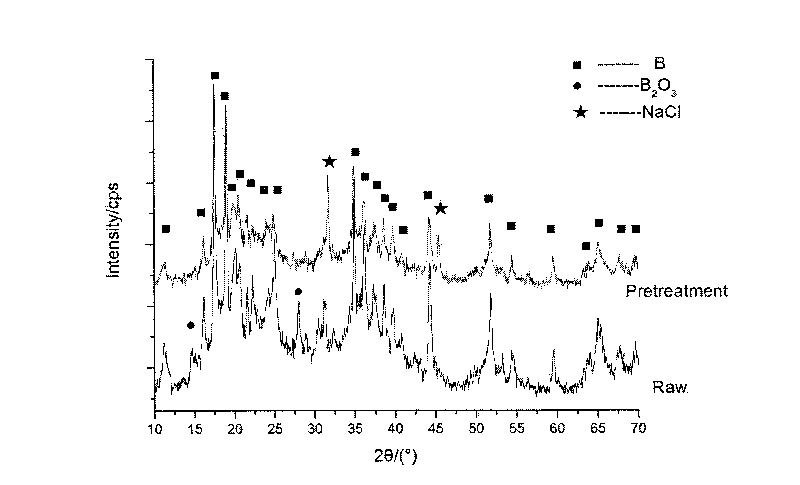

Method for preparing nano boron powder

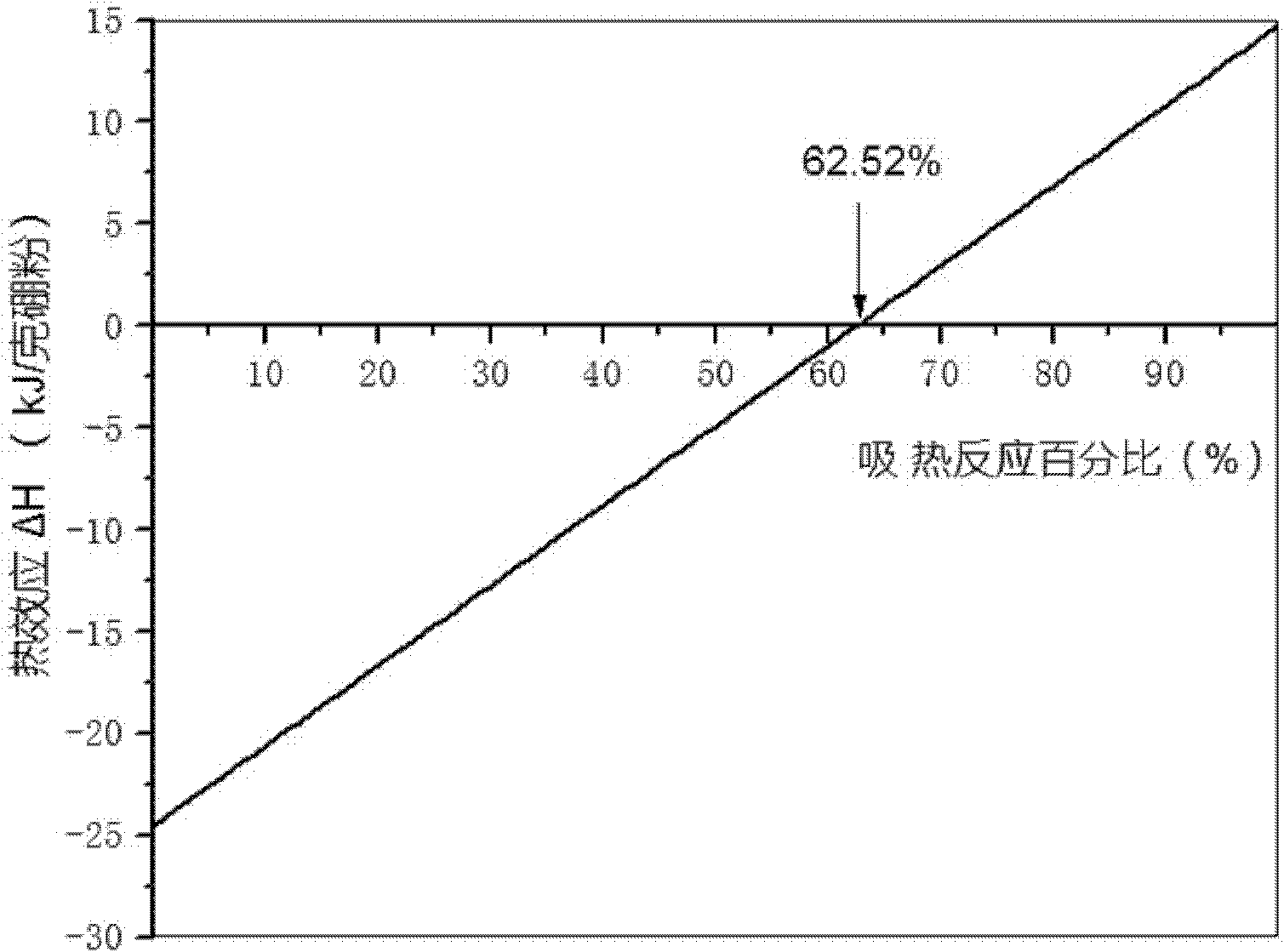

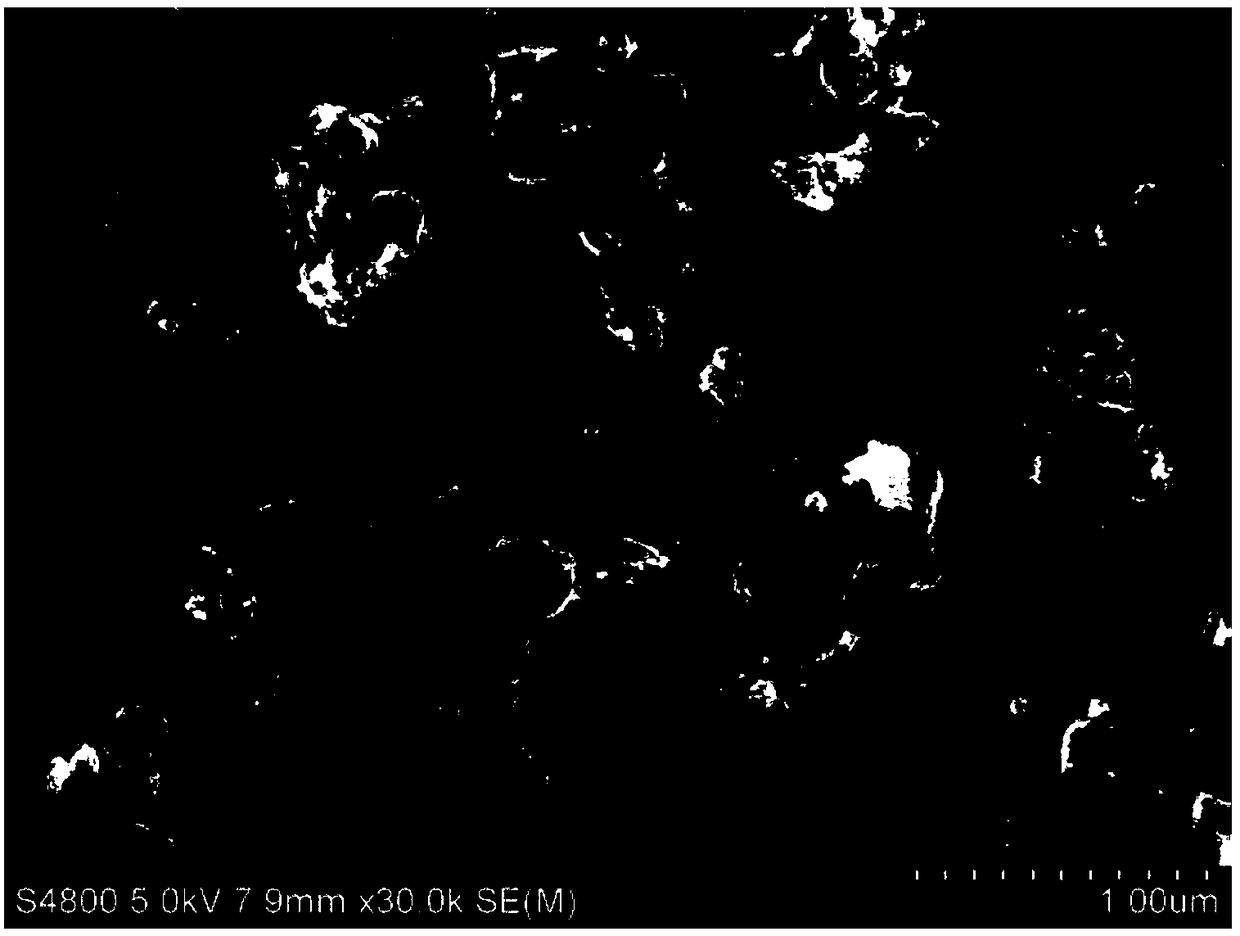

The invention relates to a method for preparing nano boron powder. B203, Mg and KBH4 are taken as reaction materials, and mixed at the protection of argon at the temperature of 700-850 DEG C to trigger the self-propagating reaction; and the obtained reaction rough product is separated and purified to obtain the nano boron powder. The method of the invention has the following beneficial effects: (1) reactivity diluent KBH4 is added in a B203 / Mg system on the basis of synthesizing boron powder by traditional magnesiothermic reduction and by virtue of endothermic reaction, so as to control heat effect of the reaction system, realize energy conserving effect and control self-propagating reaction temperature, thus restraining side reaction and by-product impurities, effectively improving the purity of the product and acquiring amorphous boron powder with higher purity; (2) reaction product particles are avoided from sintering and agglomerating due to the generation of H2O and H2; realizing to refine and control boron powder granularity to prepare the nano boron powder; and (3) the method of the invention has moderate and controllable reaction conditions, simple process and reduced energy consumption, and is suitable for industrial production.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

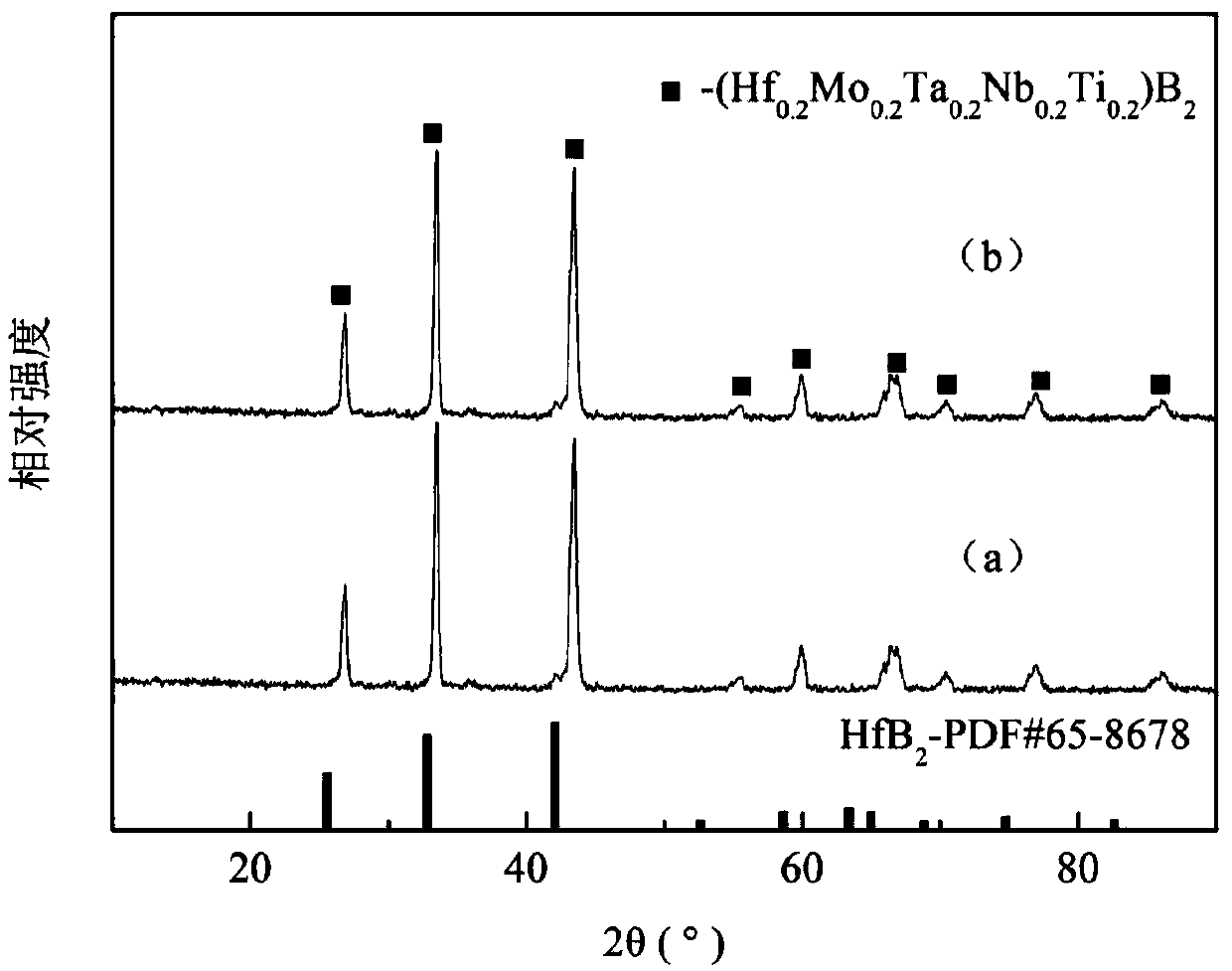

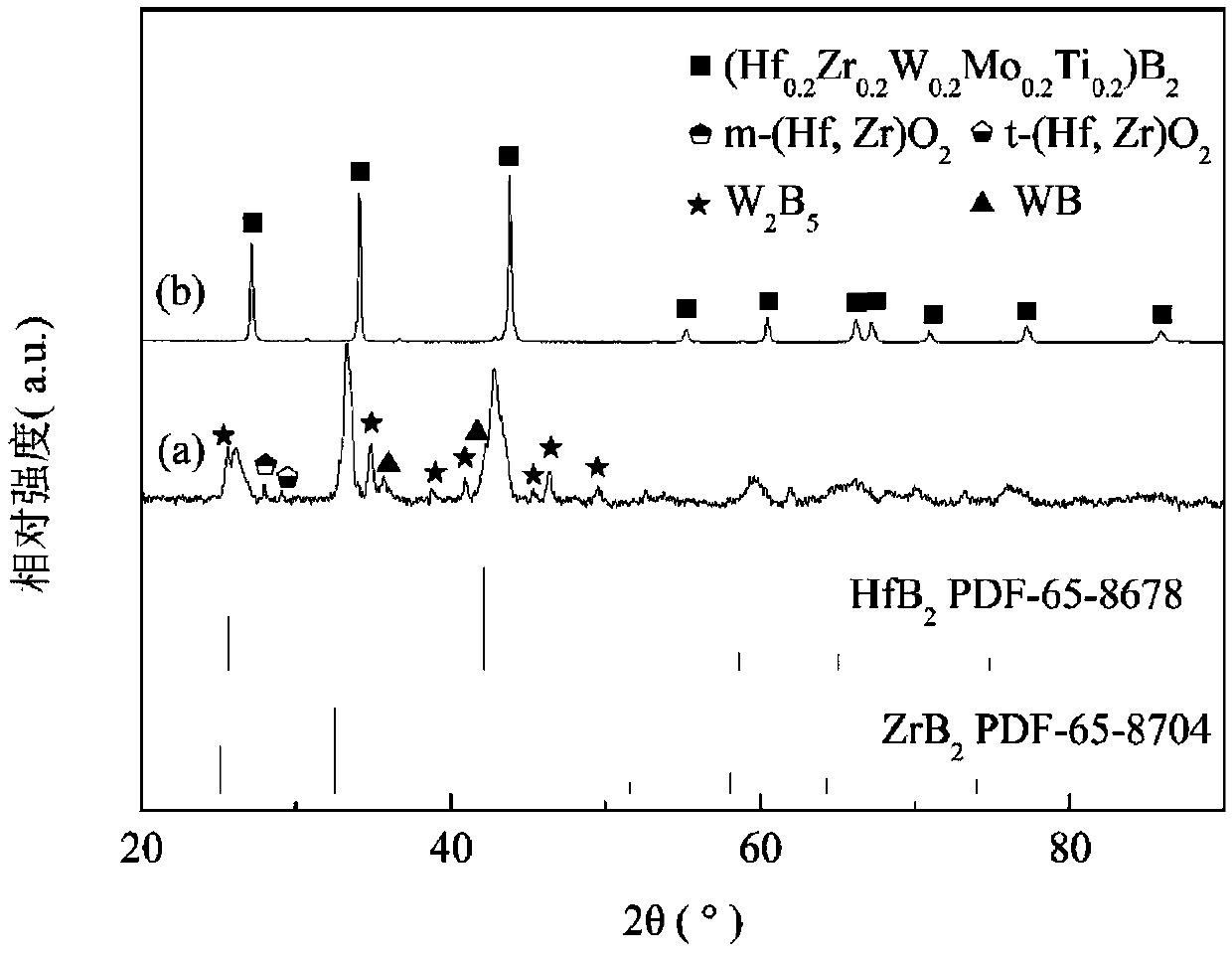

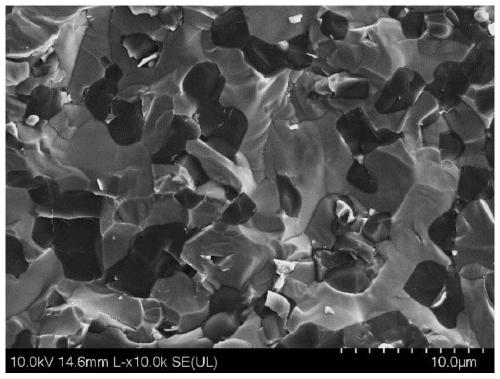

High-entropy ceramic with high-temperature strength and hardness as well as preparation method and application thereof

The invention belongs to the technical field of ceramic materials, and discloses a high-entropy ceramic with high-temperature strength and hardness as well as a preparation method and application thereof. The ceramic is characterized in that HfO2, ZrO2, WO3, MoO3, TiO2 and amorphous boron powder are treated as raw materials; the raw materials are subjected to ball milling and mixing and then are pressed into a blank; the blank is subjected to vacuum heat treatment in a graphite crucible to obtain (HfxZryWzMonTim)B2 solid melt powder; the solid melt powder is subjected to spark plasma sintering, and protecting atmosphere is charged while the temperature of the solid melt powder is increased to 1000-1400 DEG C, and then the temperature is increased to 1800-2200 DEG C for roasting the solid melt powder to obtain the product. The molecular formula of the ceramic is (HfxZryWzMonTim)B2, wherein x is greater than or equal to 0 and less than or equal to 1; y is greater than or equal to 0 and less than or equal to 1; z is greater than or equal to 0 and less than or equal to 1; n is greater than or equal to 0 and less than or equal to 1; m is greater than or equal to 0 and less than or equalto 1; and the sum of x, y, z, n and m is equal to 1; the hardness of the ceramic is 28-42GPa; the breaking tenacity is 5-10MPa.m<1 / 2>; the flexure strength and the high temperature strength are 800-1500MPa; and the weight rate after heat treatment is 0.3-0.5%.

Owner:GUANGDONG UNIV OF TECH

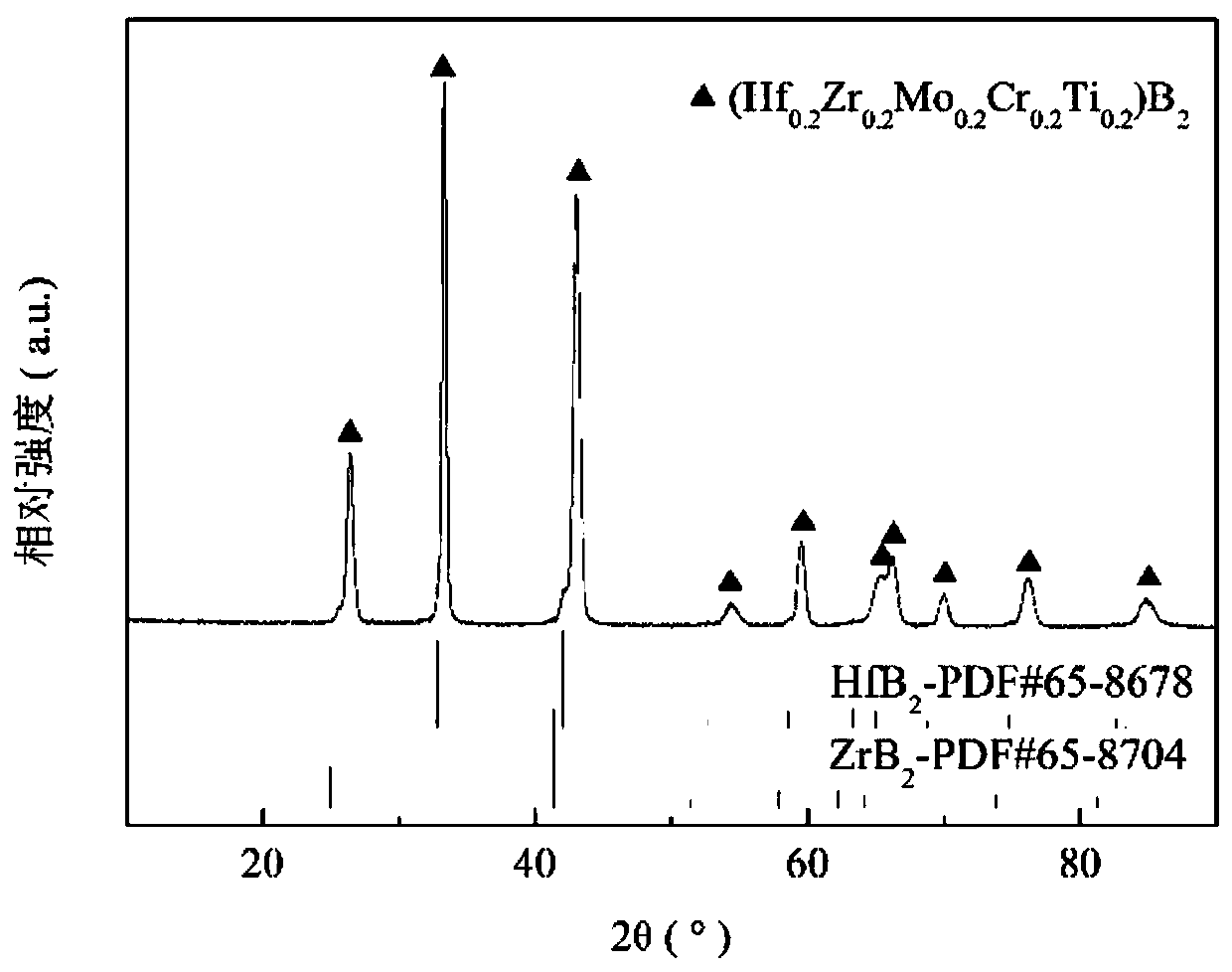

High-entropy ceramic composite material with oxidation resistance as well as preparation method and application of high-entropy ceramic composite material

The invention belongs to the technical field of ceramic materials, and discloses a high-entropy ceramic composite material with oxidation resistance and a preparation method and application of the high-entropy ceramic composite material with oxidation resistance. The ceramic composite material (Hf0.2Zr0.2Mo0.2Cr0.2Ti0.2)B2-xvol%SiC is prepared by the following steps: adding a solvent and a ball milling medium into HfO2, ZrO2, MoO3, Cr2O3, TiO2 and amorphous boron powder, and conducting mixing; pressing the mixed powder into a green body; conducting heat treatment under the vacuum condition soas to (Hf0.2Zr0.2Mo0.2Cr0.2Ti0.2)B2 high-entropy solid solution powder; and mixing the obtained high-entropy solid solution powder with SiC to a (Hf0.2Zr0.2Mo0.2Cr0.2Ti0.2)B2-xvol%SiC high-entropy composite material powder, heating the high-entropy composite material powder to 1000-1400 DEG C by adopting spark plasma sintering, introducing a protective atmosphere, conducting heating to 1800-2200 DEG C, and conducting calcining to obtain the high-entropy composite material powder, wherein x is greater than or equal to 0 and less than or equal to 30. The relative density of the obtained high-entropy ceramic composite material is 95%-99.9%, the grain size of the high-entropy ceramic composite material is 1-3 [mu]m, the fracture toughness is 4-12 MPa * m<1 / 2>, and the weight change rate is 0.3-2 wt% after heat treatment at the temperature of 1600-2000 DEG C.

Owner:GUANGDONG UNIV OF TECH

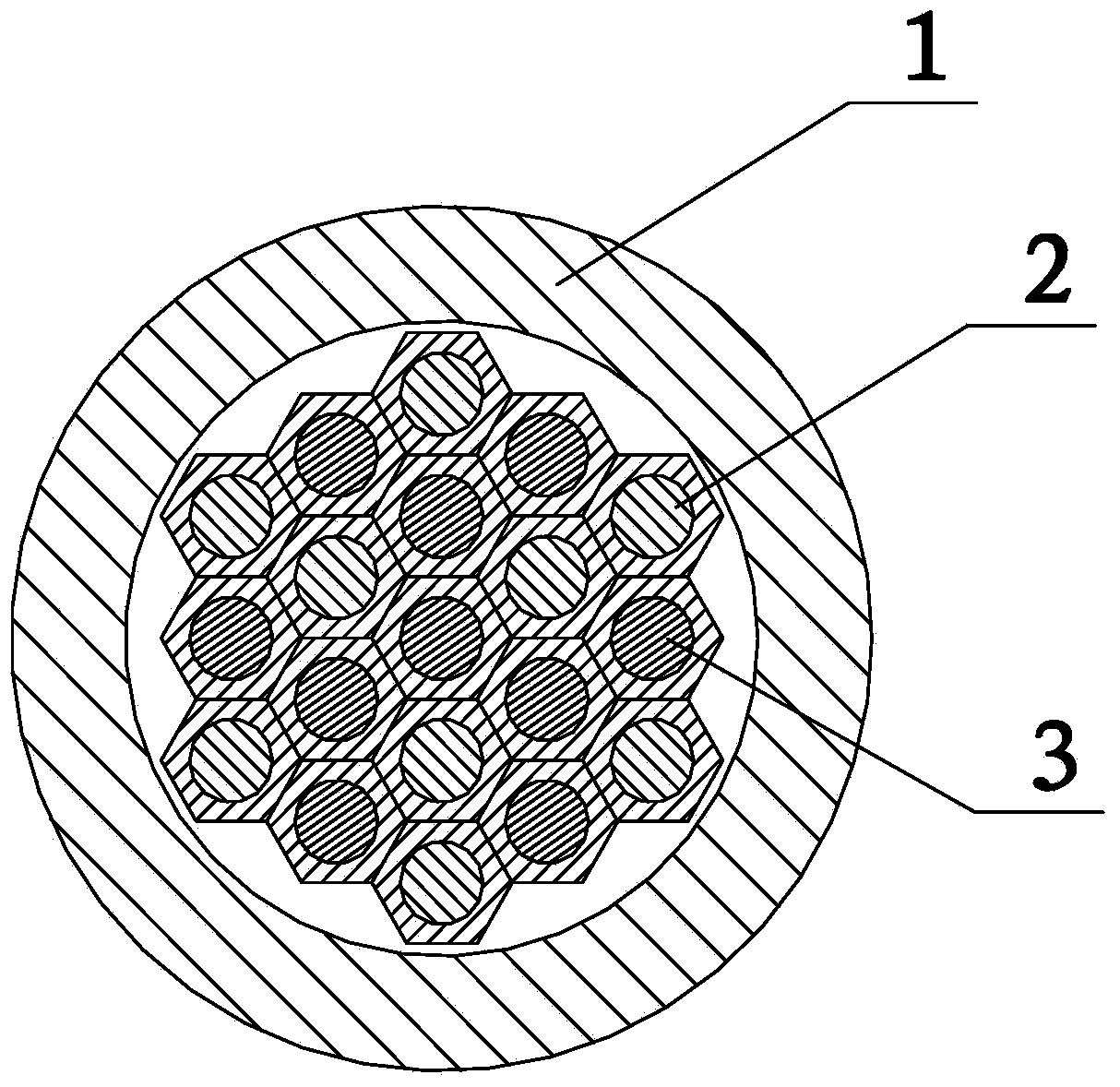

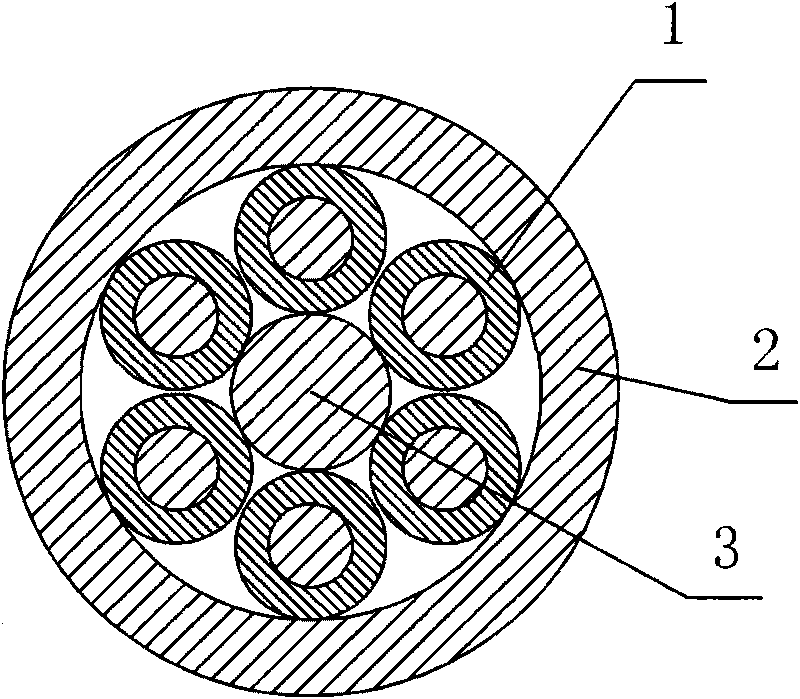

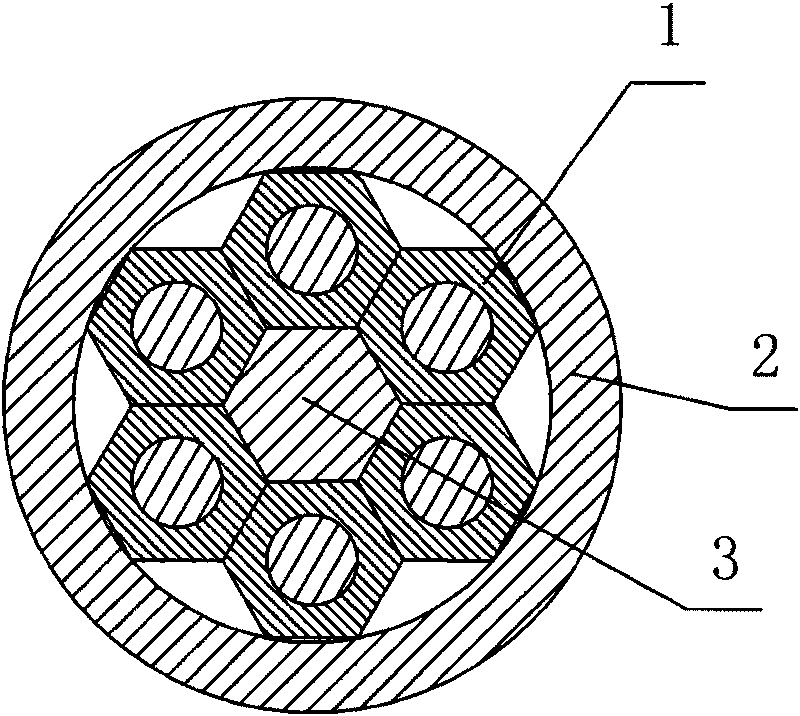

Preparation method of rectangular multicore composite superconductive strip

ActiveCN103440931AEvenly distributedNo reunionSuperconductors/hyperconductorsSuperconductor devicesAlloySlurry

The invention discloses a preparation method of a rectangular multicore composite superconductive strip. The preparation method comprises the following steps of step one. preparing mixed slurry by using amorphous boron powder, magnesium powder and a malic acid ethanol solution; step two. preparing tubing precursor powder; step three. tubing, carrying out rotary swaging, and drawing, thus obtaining a Cu-Nb-MgB2 single-core rod; step four. placing the Cu-Nb-MgB2 single-core rod and a Cu-NbTi single-core rod in a Cu-Ni alloy tube for secondary packaging, thus obtaining a secondary complex; five. processing the secondary complex into a wire rod, then carrying out rotary swaging and drawing so as to obtain a rectangular multicore composite strip; step six. winding a high-silica glass fiber to form a disk, and clamping the two ends of the disk to be flat; and step seven. carrying out thermal treatment so as to obtain the rectangular multicore composite superconductive strip. Compared with a single MgB2 and NbTi superconducting material, the composite superconductive strip prepared by the method is relatively wide in temperature using range and has relatively high using magnetic field.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH +1

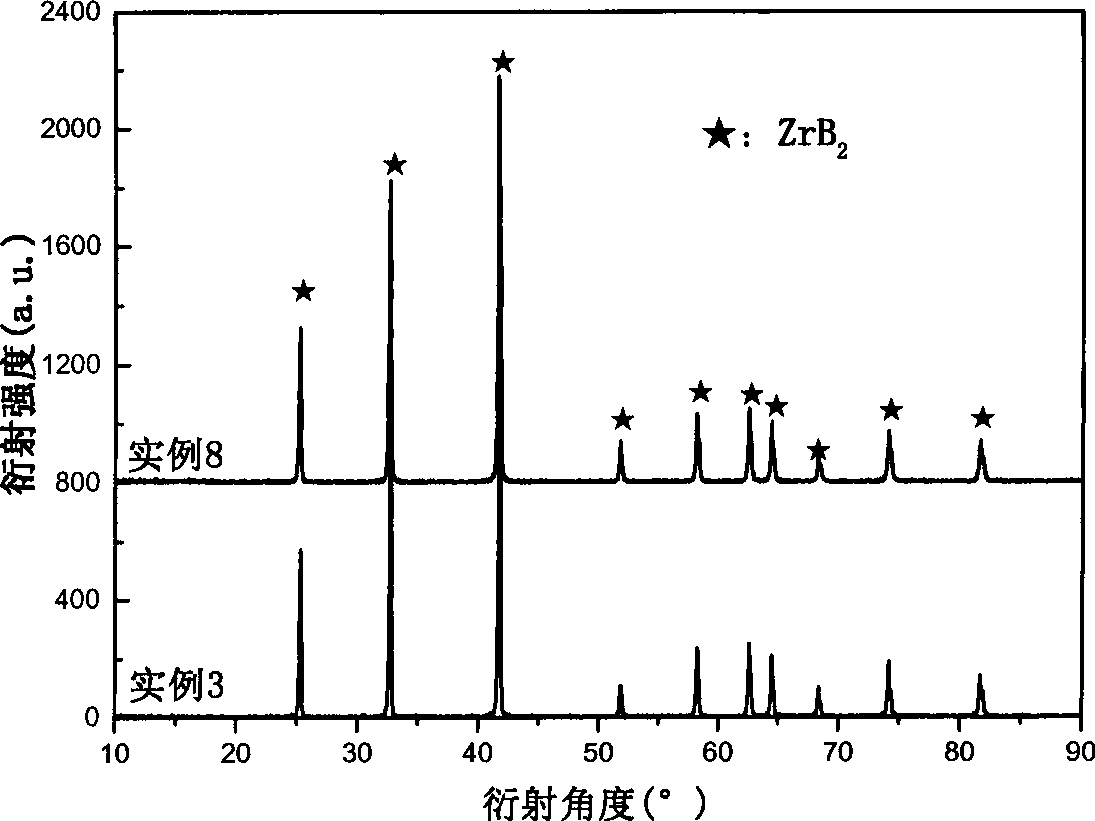

Preparation of nano zirconium diboride ceramic powder

InactiveCN101486577ASynthesis temperature is lowGuaranteed normal productionMetal boridesChemical treatmentCoprecipitation

The invention relates to a preparation method for nano zirconium diboride ceramic powder, which is characterized by comprising the following steps: 1) selecting materials: selecting according to a mol ratio of 1 : 3 to 1 : 5 between Zr and amorphous boron powder in soluble zirconium salt; 2) selecting one of the two methods as follows: a) using a coprecipitation method for gel forming to obtain xerogel; b) using a sol-gel method for gel forming to form the xerogel; 3) preparing precursor powder; 4) synthesizing quickly: arranging the materials into a large current reaction synthesizer; the inside of a black lead reactor is protected by vacuum or insert gases; applying a large current directly on the black lead reactor, quickly heating to 800 and 1500 DEG C at the temperature rising speed of 50 to 500 DEG C / min, preserving the temperature for 0 to 60 minutes to obtain a powder sample; and 5) chemical processing for obtaining the nano zirconium diboride ceramic powder. The method has the characteristics of quick synthesizing speed and high efficiency; the purity of the obtained nano zirconium diboride ceramic powder is high (equal to or more than 95 percent); and the grain diameters of the obtained nano zirconium diboride ceramic powder are uniform and thin(the average grain diameter is equal to or less than 300nm).

Owner:WUHAN UNIV OF TECH

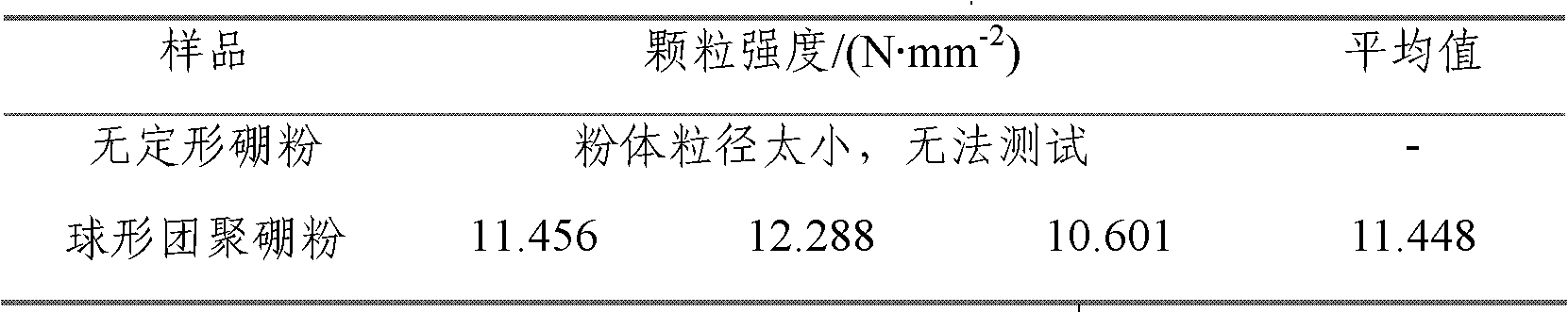

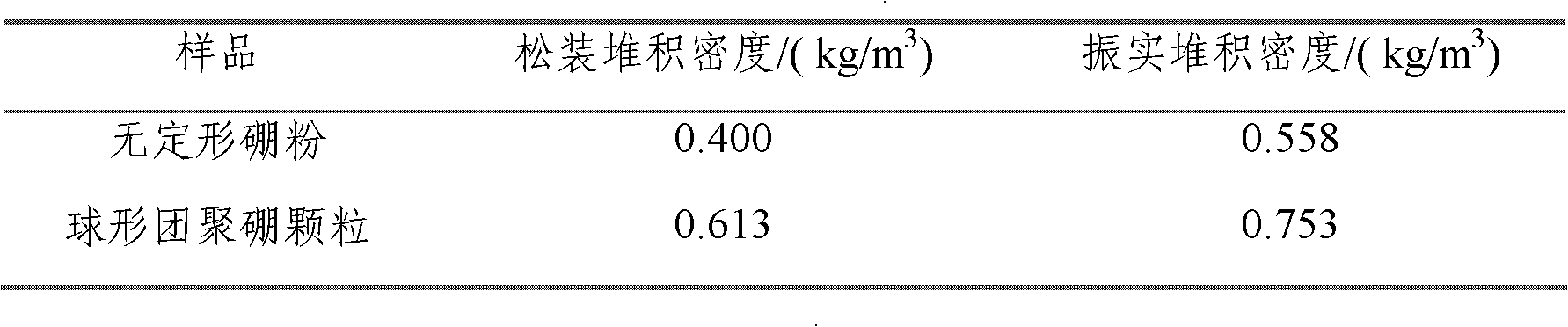

Preparation method of high-strength spherical agglomerated boron particles

The invention discloses a preparation method of high-strength spherical agglomerated boron particles, which comprises the following steps: (1) dissolving 8-9 weight parts of polyurethane prepolymer adhesive into 15-25 times of ethyl acetate or ethanol to be uniformly mixed with 0.5-1.2 weight parts of isocyanate curing agents to obtain premix; (2) adding 80-95 weight parts of amorphous boron powder into the premix to be mixed; (3) adding 0.02-0.05 weight part of curing catalyst; and (4) screening the obtained particle materials with a standard screen of 60-140 meshes, and carrying out vacuum drying. The boron particles prepared by the method of the invention have higher strength and can not be broken easily when being added into propellants, and the obtained agglomerated boron particles have controllable particle size and higher granulating rate.

Owner:XIAN MODERN CHEM RES INST

High-entropy ceramic with high toughness and high wear resistance and preparation method and application thereof

The invention belongs to the technical field of ceramic processing, and discloses high-entropy ceramic with high toughness and high wear resistance and a preparation method and application thereof. The molecular formula of the high-entropy ceramic is (Me1aMe2bMe3cMe4dMe5e)B2, and a, b, c, d and e are greater than or equal to 0.1 and less than or equal to 0.9; Me1 and Me5 are Hf, Zr or Ti; Me2 is Nb or Ta; Me3 is Cr, and Me4 is Mo; the high-entropy ceramic is prepared by the following steps: ball-milling and mixing Me1 oxide, Me2 oxide, Me3 oxide, Me4 oxide, Me5 oxide and amorphous boron powder; pressing into a green body, heating to 800-1200DEG C, calcining, carrying out washing, suction filtration and drying, heating obtained high-entropy boride powder to 1600-1700DEG C by spark plasma sintering, pressurizing by use of a protective atmosphere, heating to 1700-1900DEG C, and sintering to obtain the high-entropy ceramic. The relative density of the high-entropy ceramic is 95-100%, the fracture toughness of the high-entropy ceramic is 8-20 MPa.m < 1 / 2 >, and the grain size of the high-entropy ceramic is 1-3 microns.

Owner:GUANGDONG UNIV OF TECH

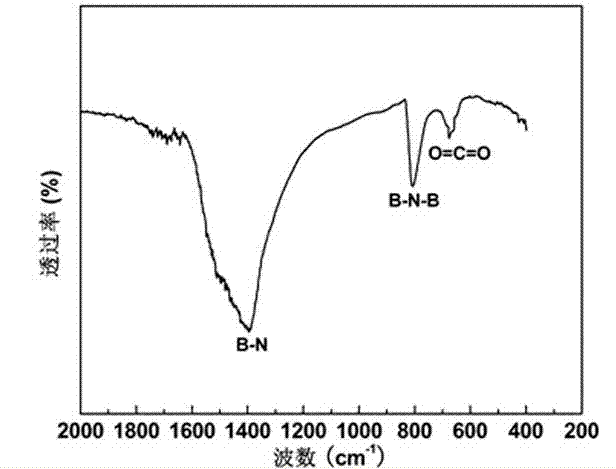

Amorphous boron nitride adsorbent and preparation method and application thereof

InactiveCN106824043AMany active sitesImprove adsorption capacityNitrogen compoundsOther chemical processesOrganic sulfide compoundHigh energy

The invention relates to an amorphous boron nitride adsorbent and a preparation method and an application thereof. The preparation method comprises the steps of dissolving boric acid and urea into a mixed solution of water and methyl alcohol, carrying out recrystallization and carrying out high-temperature and rapid burning on the recrystallized solid in a nitrogen atmosphere. The preparation method is simple; and the obtained amorphous boron nitride has multiple active sites, can be used for adsorption desulfurization of fuel oil, and is capable of adsorbing organic sulfide in the fuel oil at high energy efficiency and high selectivity.

Owner:JIANGSU UNIV

Solid acid catalyst and preparation method and applications thereof

ActiveCN108654594AReduce manufacturing costLow costMetal/metal-oxides/metal-hydroxide catalystsAmino compound preparation by condensation/addition reactionsLanthanideSolid acid

The invention relates to a solid acid catalyst and a preparation method and applications thereof. The catalyst includes lanthanide rare earth metal ions, halogen and a carrier. The carrier includes aboron-silicon composite oxide and silicon oxide; and the boron-silicon composite oxide is an amorphous compound, and can be obtained by mixing boron source and silicon source compounds, adjusting pH to form gel, adding a surfactant as a pore forming agent during a gel synthesizing process, and performing hydrothermal reaction, hole expansion with ammonia, drying and roasting, etc. According to thecatalyst, the amorphous boron-silicon composite having a high specific surface area and specific pore size distribution is molded to form the carrier and a lanthanide rare earth metal oxide which canform a specific acid site and the halogen are added for modification. The catalyst can be used for direct amination of isobutene to prepare tert-butylamine; and high isobutene one-way conversion rateand tert-butylamine selectivity can be achieved, and the catalyst has good stability.

Owner:WANHUA CHEM GRP CO LTD

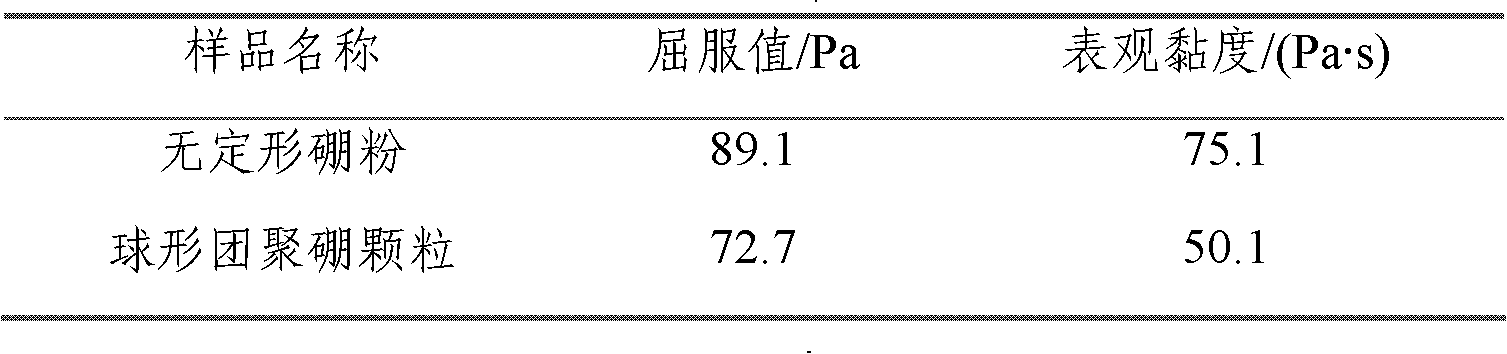

Method for granulating amorphous boron powder

InactiveCN101531556AHarm reductionReduce pollution emissionsMaterial granulationExplosivesPolyurethane adhesiveMass ratio

The invention discloses a method for granulating amorphous boron powder, and in particular relates to a method for kneading and granulating amorphous boron powder for fuel-rich propellant. The method for granulating amorphous boron powder comprises the following steps: (1) premixing ethyl acetate, liquid polyurethane adhesive prepolymer, isocyanate curing agents and curing catalyst well according to a mass ratio which is 40-50:8-9:1-2:0.1-0.05 and controlling material temperature to between 35 and 40 DEG C; (2) mixing the amorphous boron powder with the premixed material; and (3) passing the obtained granular material through a 30-mesh standard sieve and drying the obtained granular material. In the process of granulating the amorphous boron powder, the method adopts the ethyl acetate which has little harm to environment and low dosage as a solvent for dispersing adhesive, and adopts a star-type stirring paddle to ensure that agglomerate mixtures can be denser under the cutting and extruding action of the stirring paddle. Granules obtained by the method are high in strength, are not easy to break when the granules are applied in formulations of fuel-rich propellant, and enable medicine pulp to be low in yield value and apparent viscosity.

Owner:XIAN MODERN CHEM RES INST

Methods of forming a boron nitride, a method of conditioning a ballistic weapon, and a metal article coated with a monomeric boron-nitrogen compound

A method of forming a boron nitride. The method comprises contacting a metal article with a monomeric boron-nitrogen compound and converting the monomeric boron-nitrogen compound to a boron nitride. The boron nitride is formed on the same or a different metal article. The monomeric boron-nitrogen compound is borazine, cycloborazane, trimethylcycloborazane, polyborazylene, B-vinylborazine, poly(B-vinylborazine), or combinations thereof. The monomeric boron-nitrogen compound is polymerized to form the boron nitride by exposure to a temperature greater than approximately 100° C. The boron nitride is amorphous boron nitride, hexagonal boron nitride, rhombohedral boron nitride, turbostratic boron nitride, wurzite boron nitride, combinations thereof, or boron nitride and carbon. A method of conditioning a ballistic weapon and a metal article coated with the monomeric boron-nitrogen compound are also disclosed.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

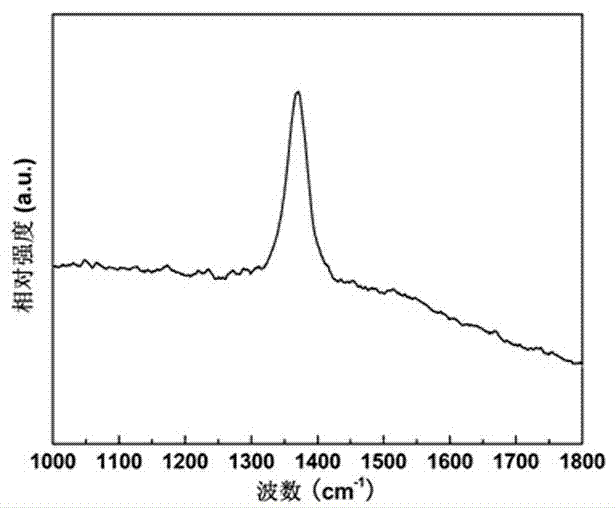

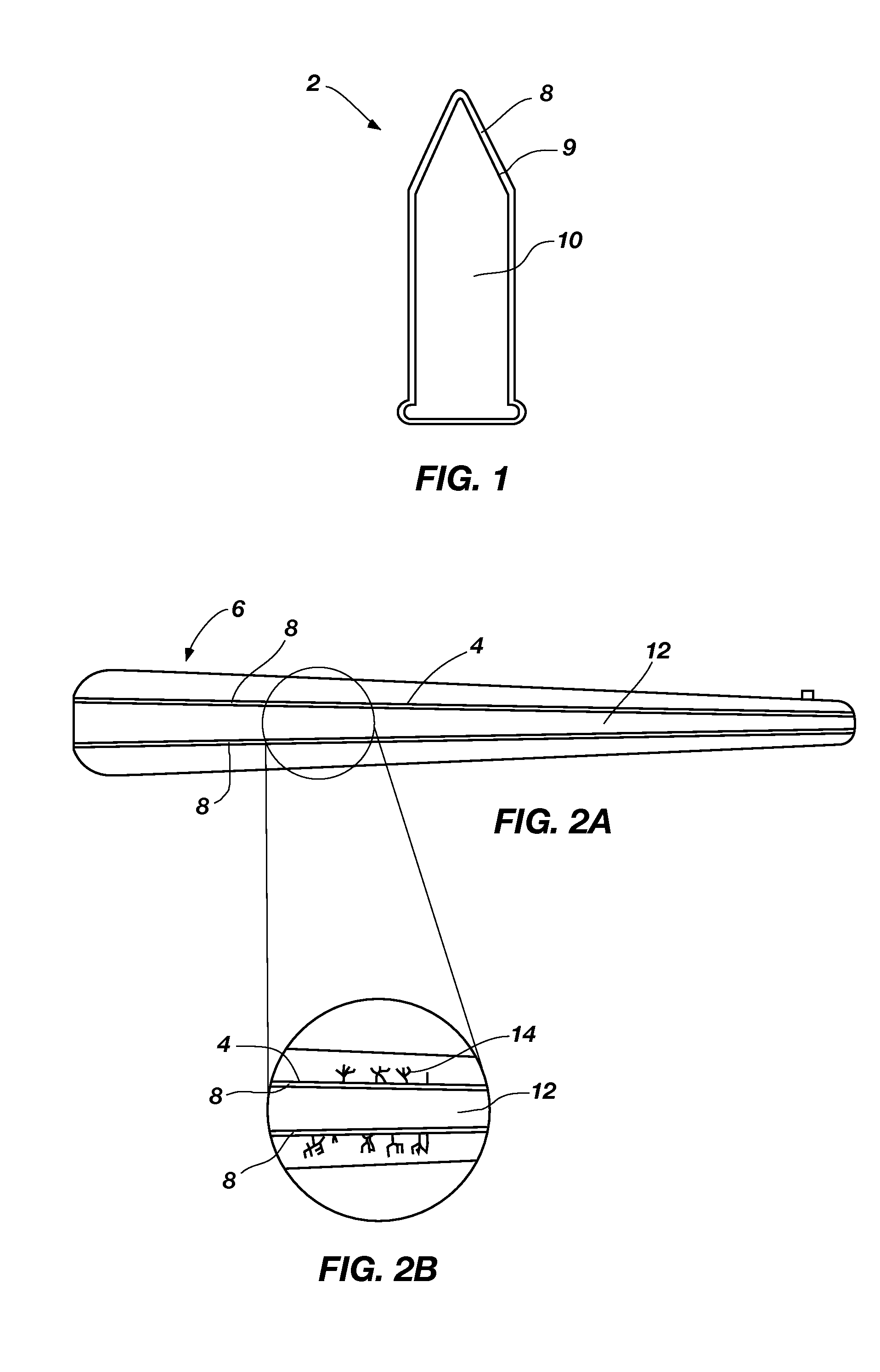

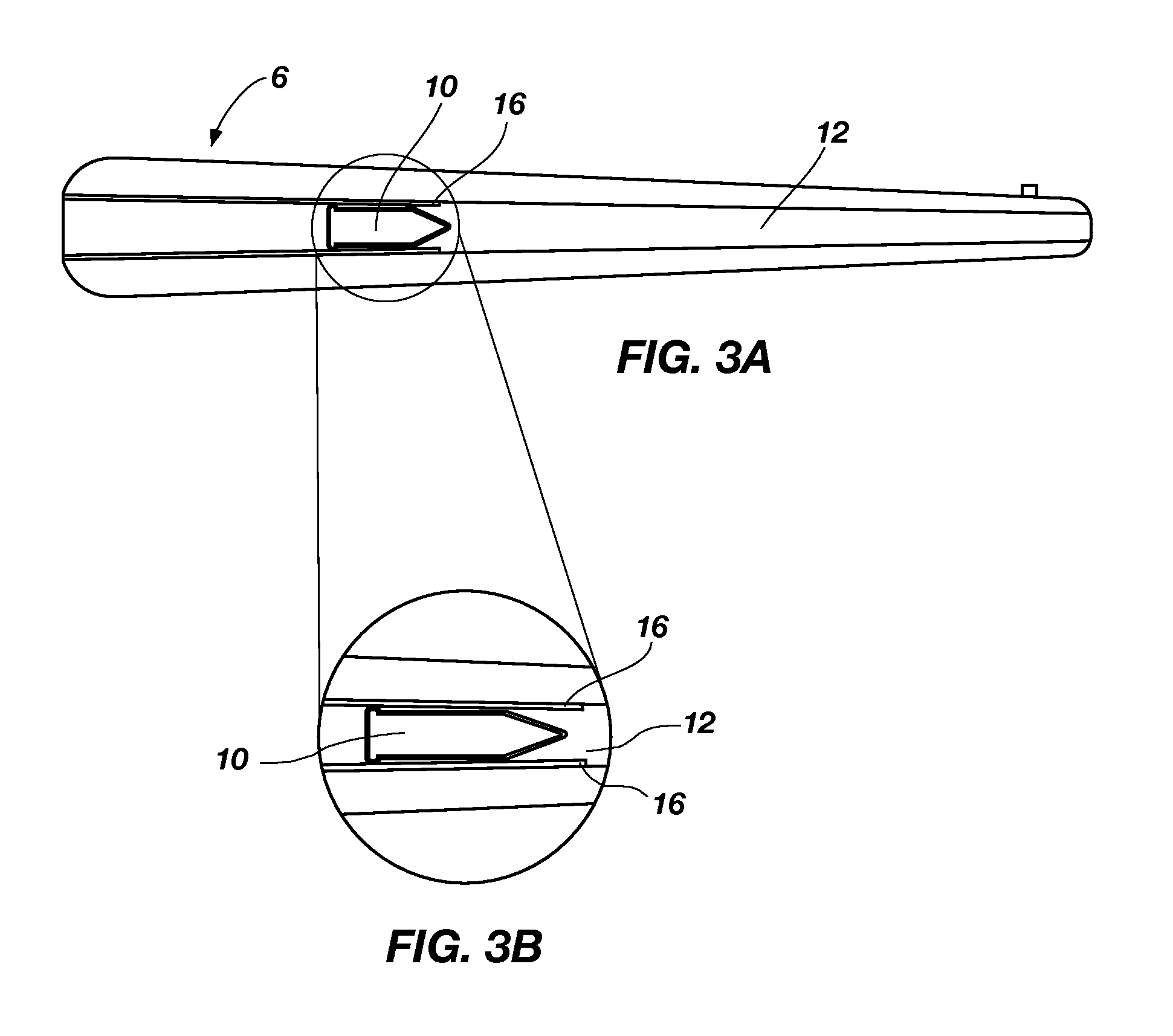

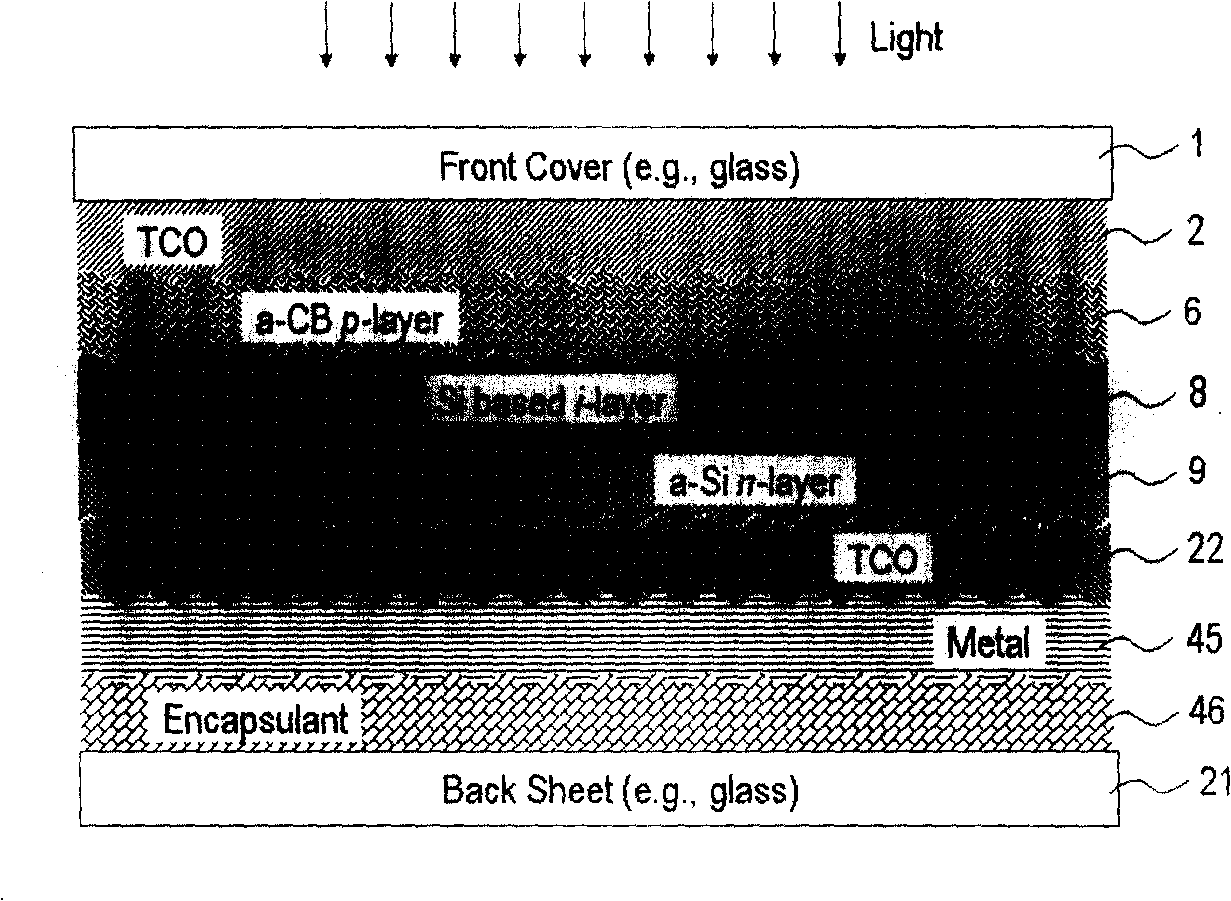

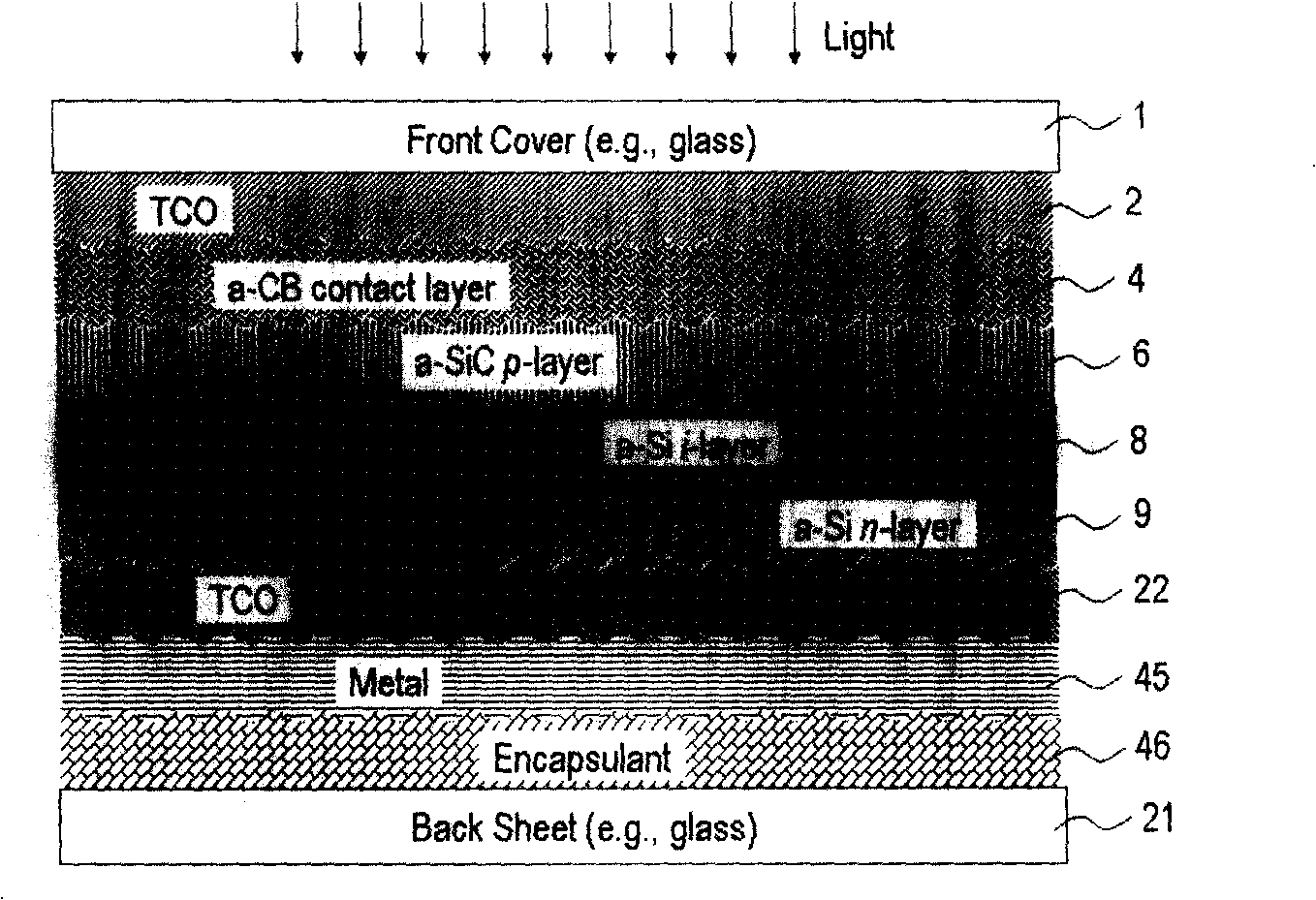

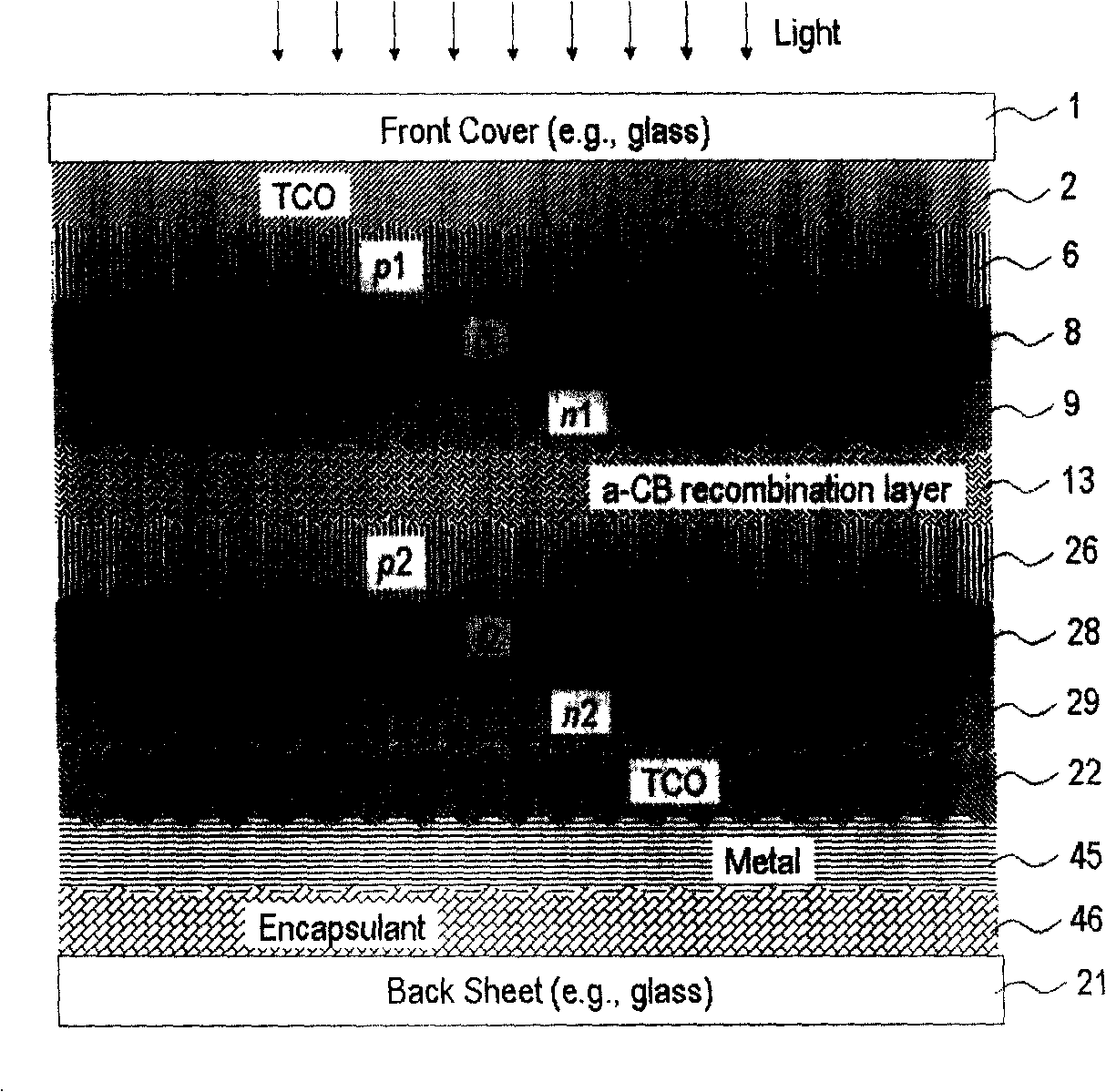

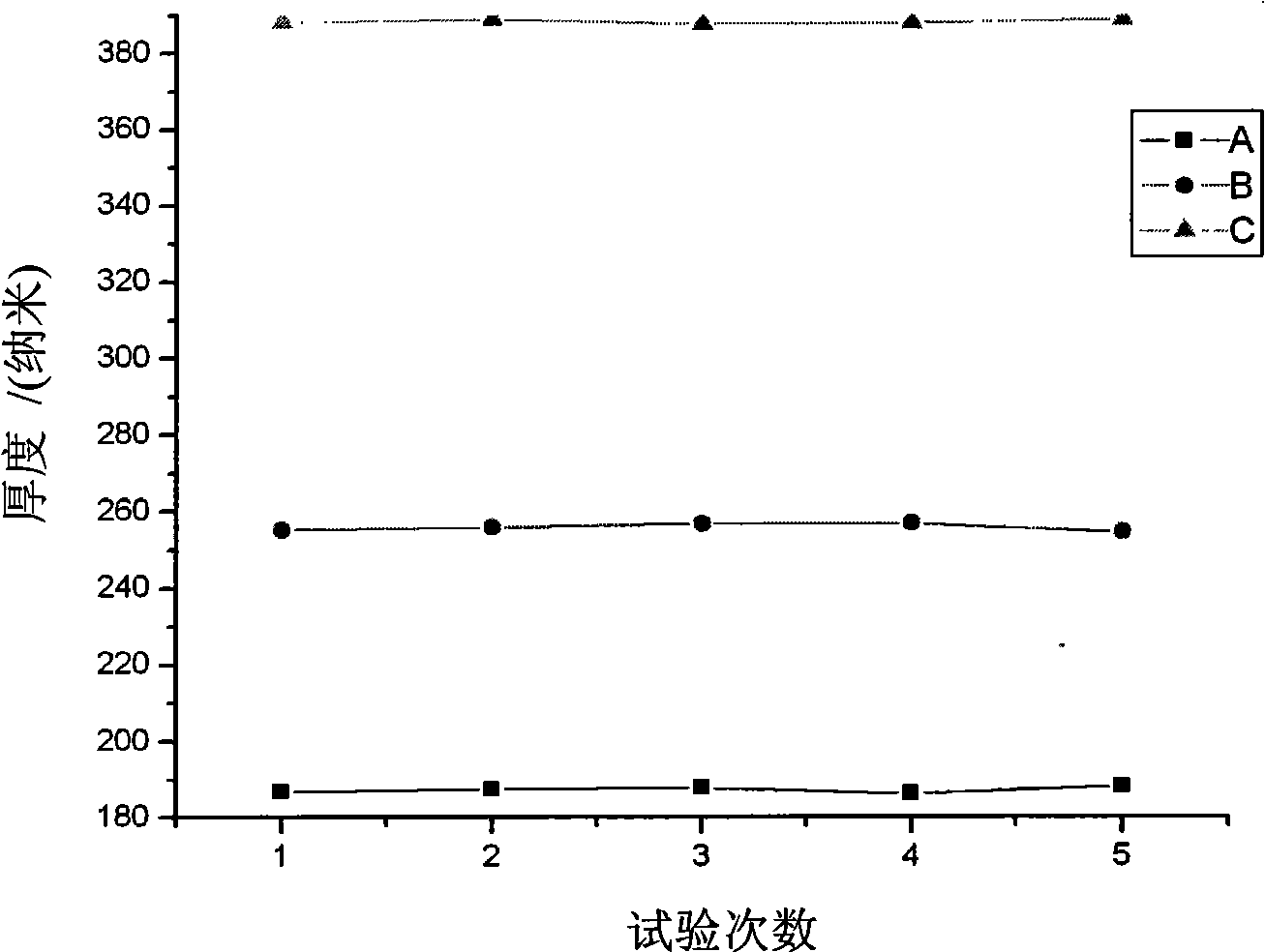

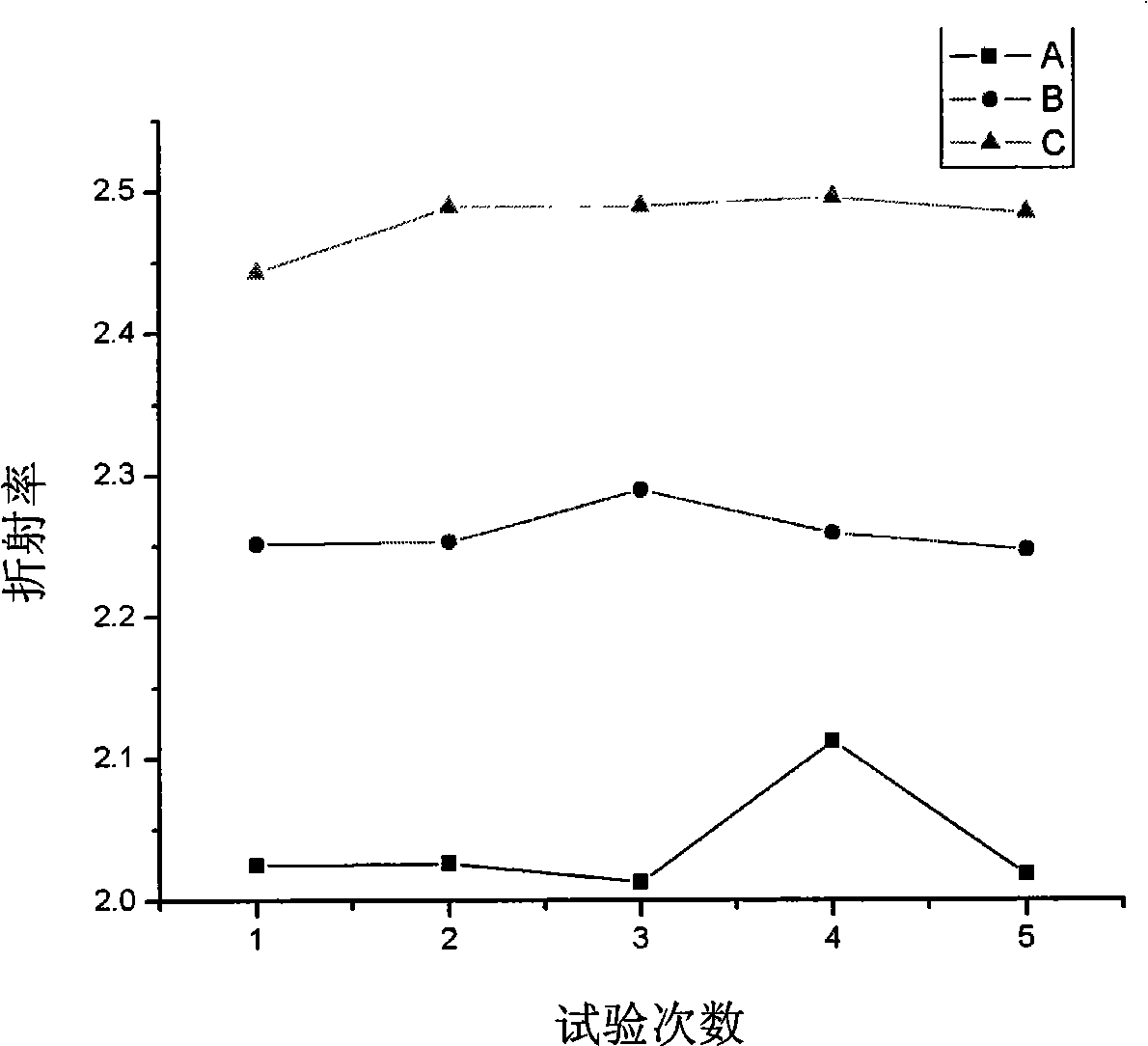

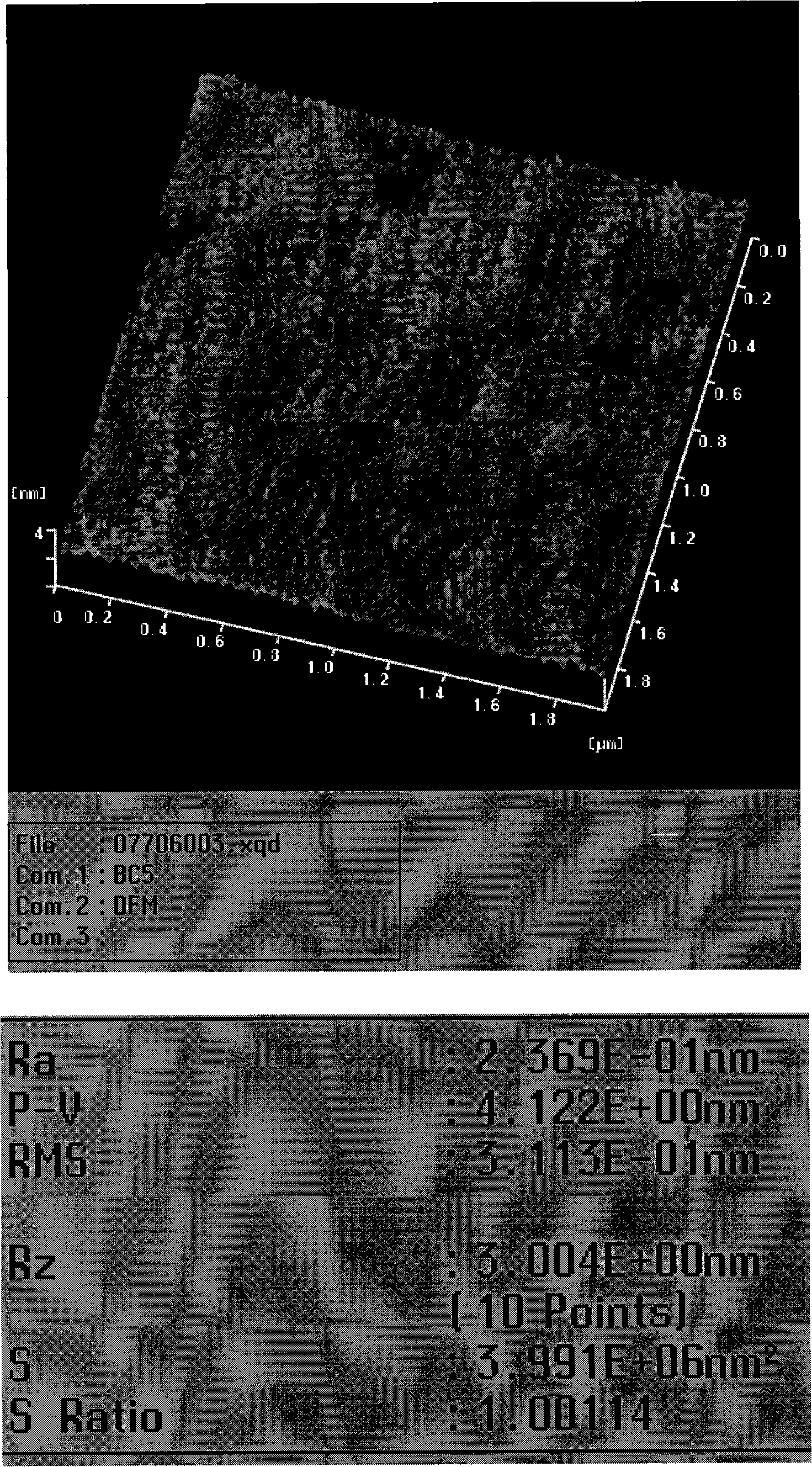

Amorphous boron carbon alloy and photovoltaic application thereof

InactiveCN101246926AImprove compatibilityImprove photoelectric conversion performanceFinal product manufacturePhotovoltaic energy generationSemiconductorSemiconductor thin films

The present invention discloses produce and application of hydrogenation amorphous boron carbon (a-CB) film. Amorphous boron carbon alloy can be formed at low temperature by plasma enhanced chemical vapor deposition method. The p type semiconductor film can be used to single junction and multi-junction photovoltaic devices and improves the capability of single junction and multi-junction photovoltaic devices.

Owner:BEIJING XINGZHE MULTIMEDIA TECH

Method for producing boron carbide film with electron beam evaporation technique

InactiveCN101314842AEasy to controlEasy to operateVacuum evaporation coatingSputtering coatingCrucibleRoom temperature

The invention relates to a method for preparing a boron carbide film by using the electron beam evaporation technology. Boron carbide film material is put in a copple of an electron beam evaporation device, and a substrate which is washed and dried is put on a heating electric furnace of the electron beam evaporation device to lead the substrate to be over the copple, the distance of which is 20 to 30cm from the copple; the filming is executed under the vacuum condition, the filming vacuum degree is more than or equal to 6.0*10<minus 3>Pa, and the temperature of the substrate is controlled between room temperature and 450 DEG C; an electron beam is adjusted to lead the focusing spot on the film material to be smallest; the flux distribution is controlled between 100 to 180mA, and the deposition time is 5 to 120 minutes. The method not only can prepare an amorphous boron carbide film, but also can prepare the boron carbide film with a polycrystalline structure, and also can prepare various boron carbide films with different proportions of B and C components, the surfaces of the prepared boron carbide films are smooth, the films are compact, and the uniformity is good.

Owner:SICHUAN UNIV

Preparation method of boron nitride nanotube hydrophobic membrane

InactiveCN102899659AHigh purityHigh densityMaterial nanotechnologyNitrogen compoundsSteel ballNitrogen gas

The invention relates to a preparation method of a boron nitride nanotube hydrophobic membrane, belonging to the technical field of waterproof nano materials. The preparation method provided by the invention comprises the following steps of: 1) sealing raw materials amorphous boron powder and a plurality of stainless steel balls in a stainless steel ball grinding tank, and placing the stainless steel ball grinding tank in a ball mill for ball milling; 2) after ball milling, placing the sealed stainless steel ball grinding tank in a glove box filled with nitrogen to take out boron powder, dissolving the boron powder and catalyst in organic solvent in the atmosphere of nitrogen after ball milling, and conducting ultrasonic oscillation to prepare boron coating; 3) evenly coating the prepared boron coating on a low-carbon stainless steel substrate and placing the substrate in a sintering furnace for sintering; and 4) after the sintering is completed, continuously feeding N2 / H2 gas into the sintering furnace, keeping gas flow unchanged, and naturally decreasing temperature to room temperature to obtain the boron nitride nanotube hydrophobic membrane based on stainless steel. The nano membrane prepared by adopting the preparation method provided by the invention has the characteristics of high purity and high density, the measured contact angle is 158.1 plus or minus 3.6 degrees and the super-hydrophobic standard is satisfied.

Owner:HARBIN INST OF TECH

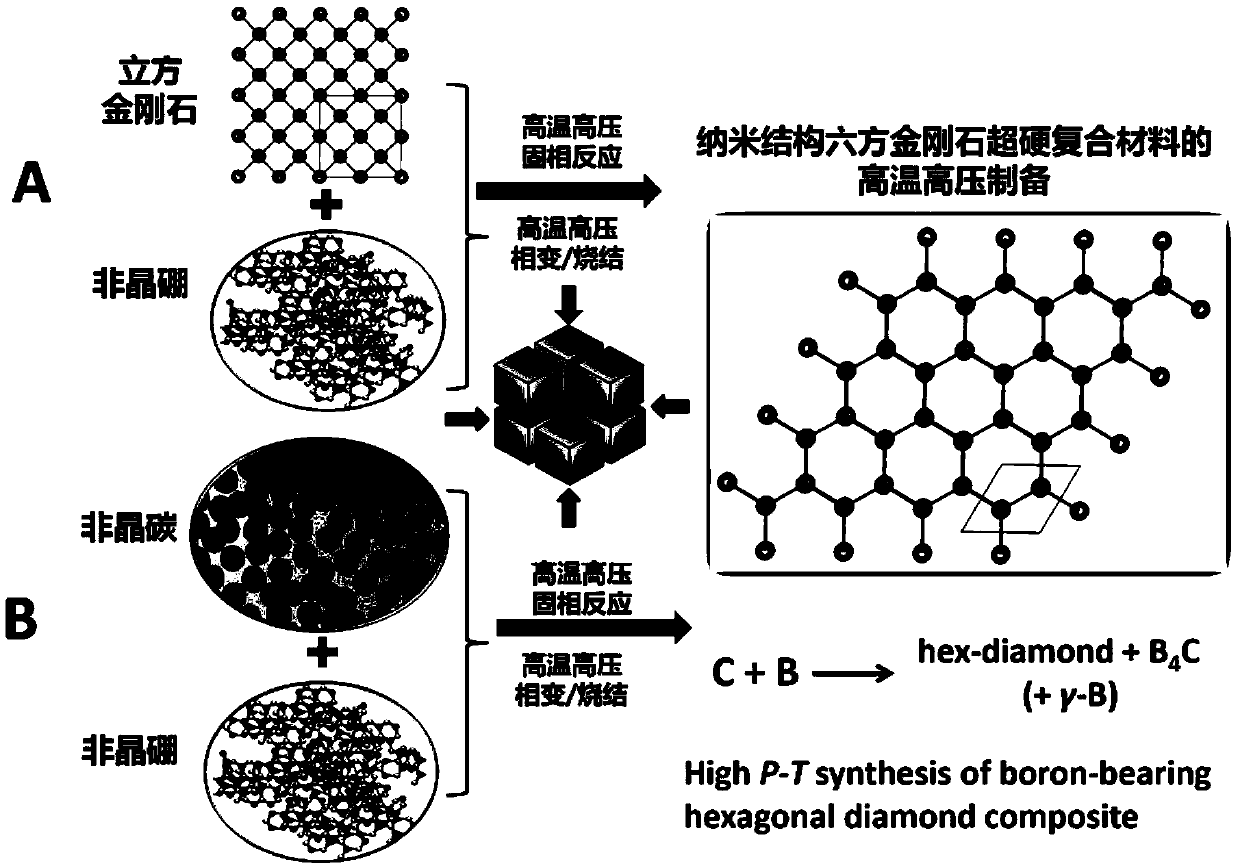

Nano-structured boron-bearing hexagonal diamond polycrystalline superhard composite and preparation method and application thereof

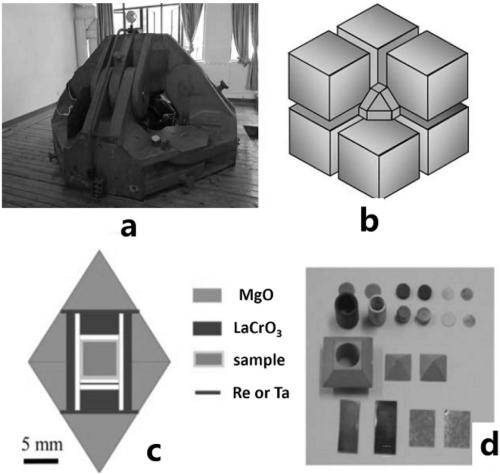

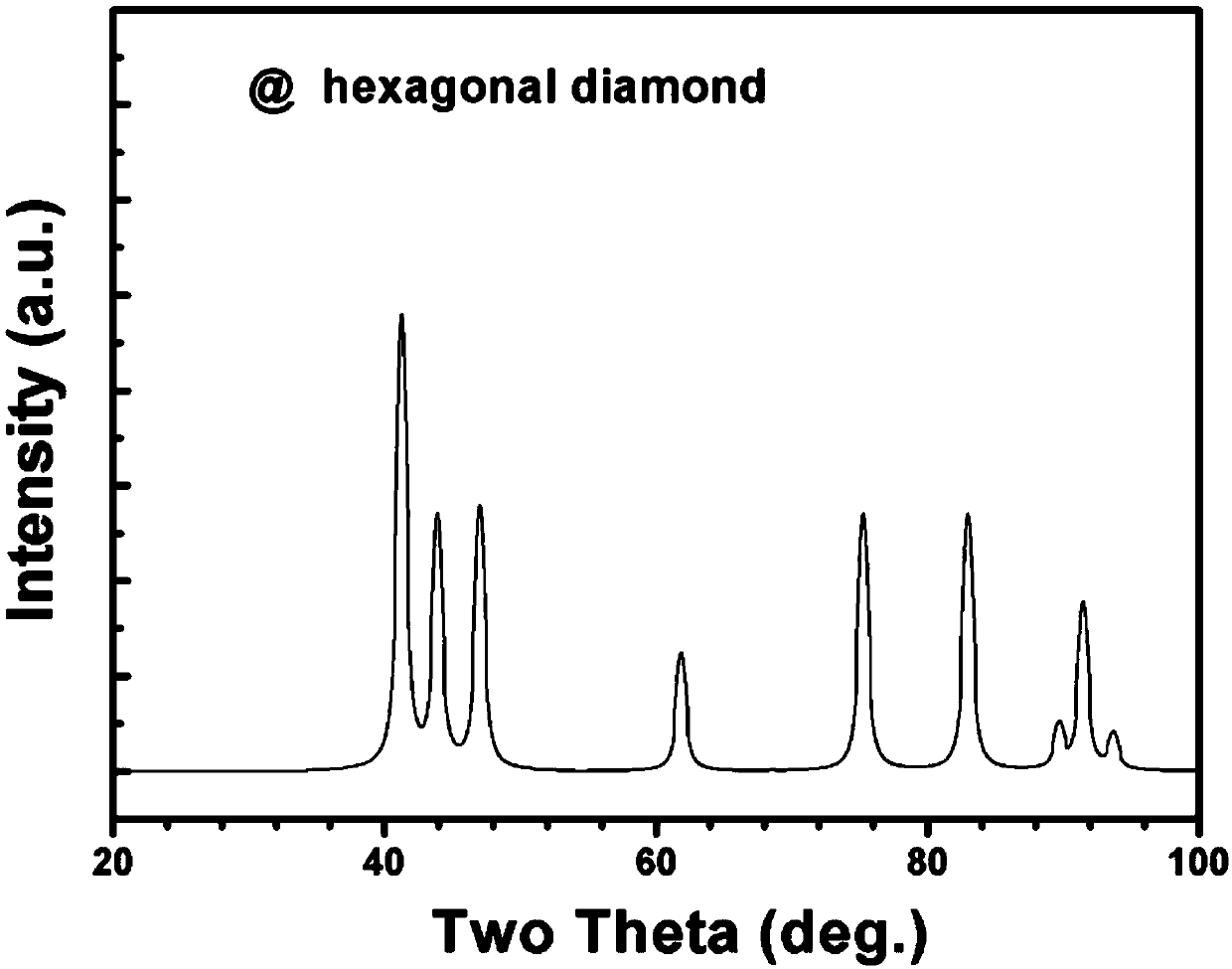

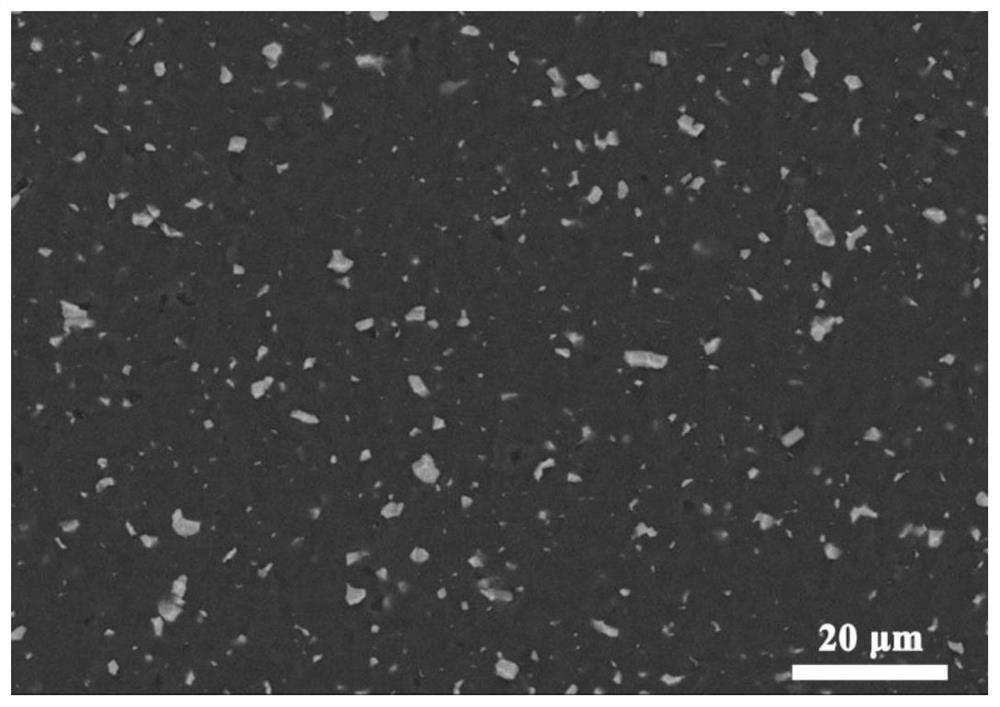

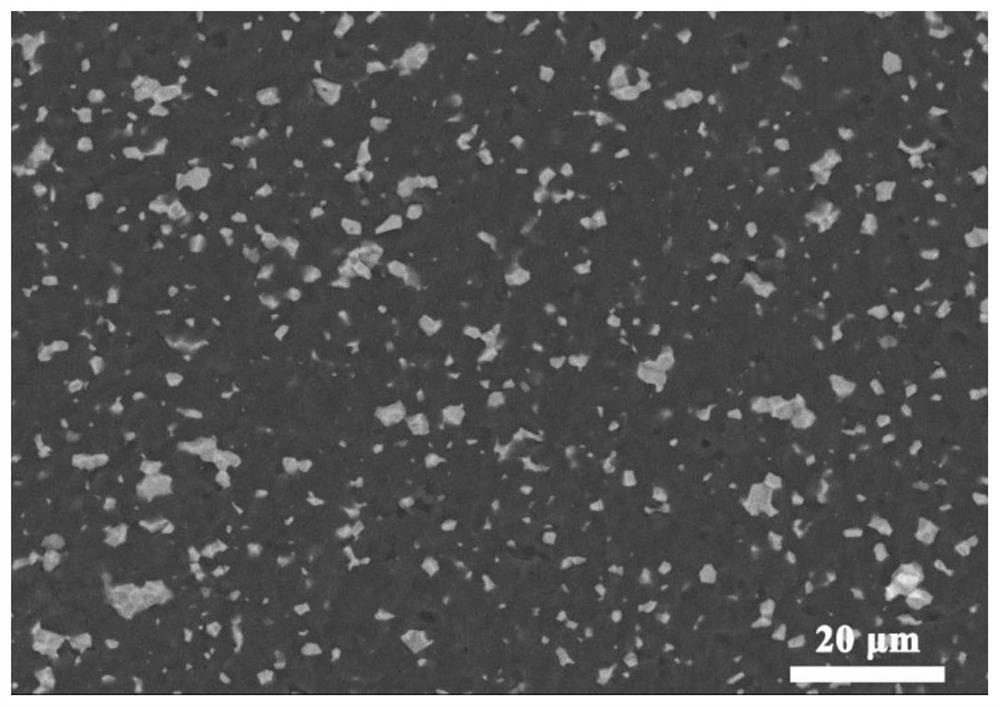

The invention relates to a nano-structured boron-bearing hexagonal diamond polycrystalline superhard composite and a preparation method and application thereof, and belongs to the field of superhard materials. The preparation method of the nano-structured boron-bearing hexagonal diamond polycrystalline superhard composite includes: mixing well carbon powder having different crystal structures andan amorphous boron powder initial material, subjecting the mixture to vacuum thermal treatment, adding the initial material subjected to vacuum treatment into a high-temperature high-pressure chamber,and carrying out solid-phase reaction / sintering under the pressure of 21-27 GPa and the temperature of 1000-1600 DEG C. The nano-structured boron-bearing hexagonal diamond polycrystalline superhard composite formed under high temperature and high pressure may form tightly-combined high-strength D-D and B-C chemical bonds between grains, and accordingly, has excellent mechanical properties / hardness, high thermal stability, and good heat conductivity, electrical conductivity / electrical properties; therefore, the composite herein is effectively applicable to electrical devices, tool materials and anvil materials.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Boron carbide-titanium boride lightweight high-strength composite ceramic material and preparation method thereof

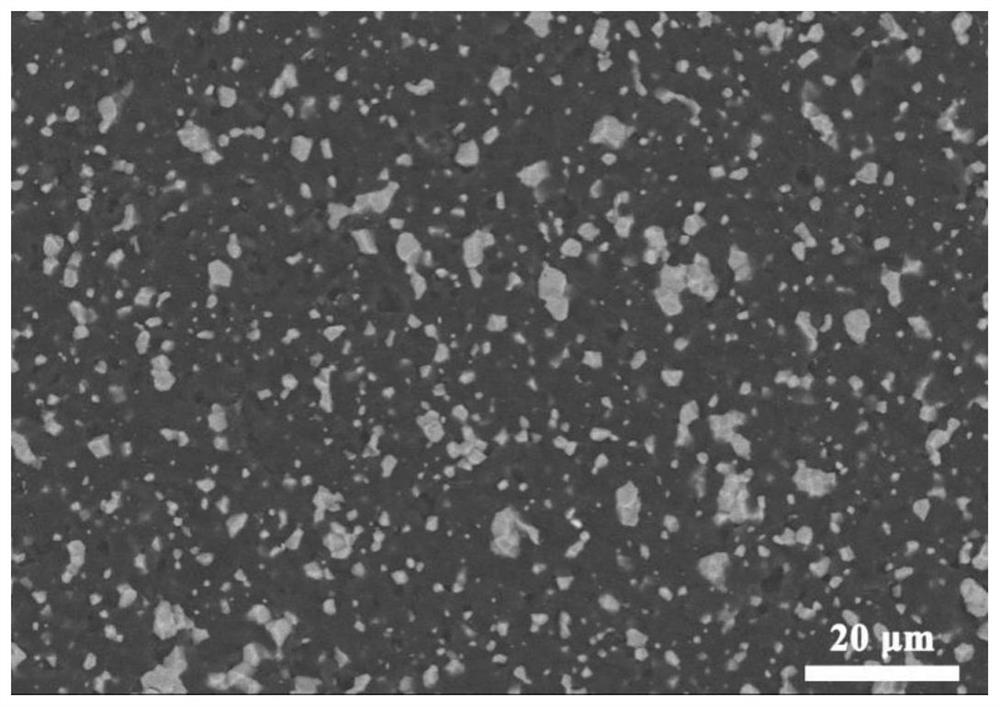

The invention provides a boron carbide-titanium boride lightweight high-strength composite ceramic material and a preparation method thereof. The boron carbide-titanium boride lightweight high-strength composite ceramic material is prepared from, by mass, 28.20-82.05% of boron carbide (B4C) powder, 8.20-32.75% of titanium carbide (TiC) powder and 9.75-39.05% of amorphous boron (B) powder through the following steps: weighing the titanium carbide powder and the amorphous boron powder, mixing the titanium carbide powder and the amorphous boron powder through a roller mixer, carrying out rotary evaporation, drying and sieving to obtain TiC-B mixed powder, placing the TiC-B mixed powder in a hot pressing sintering furnace, carrying out heat treatment to obtain primary B4C-TiB2 composite powder, weighing the primary B4C-TiB2 composite powder and boron carbide powder, carrying out ball-milling mixing on the powder through a planetary ball mill, carrying out rotary evaporation, drying and sieving to obtain B4C-TiB2 composite powder, placing the B4C-TiB2 composite powder in a graphite mold, and carrying out hot pressing sintering in a hot pressing furnace. According to the invention, the product has the advantages of good sinterability, fracture toughness and conductivity, capability of being processed through electric sparks, uniform TiB2 aggregate dispersion, controllable components, high bending strength and the like.

Owner:WUHAN UNIV OF TECH

Non-toxic and non-corrosive ignition mixture

InactiveUS6964287B1High sensitivityEasy feedingLoomsNitroparaffin explosive compositionsNitrocellulosePolyvinyl alcohol

A non-toxic and non-corrosive ignition mixture is created by combining the energy system and the pyrotechnic system. The energy system comprises a high explosive from the groups of nitroesters and nitramines and a senzibiliser of the type of tetrazene or derivatives of tetrazoles for its activation. The pyrotechnic system comprises an oxidizing agent from the group of oxides and peroxides of metals, from the group of salts of inorganic oxygen-containing acids, and a fuel which is amorphous boron. The mixture is supplemented with a friction agent which is preferably ground glass. Nitrocellulose, polyvinyl alcohol and acacia gum are used as bonding agents. Mixtures are utilizable in the field of ammunition production for the production of primers, especially for central ignition cartridges.

Owner:SELLIER & BELLOT

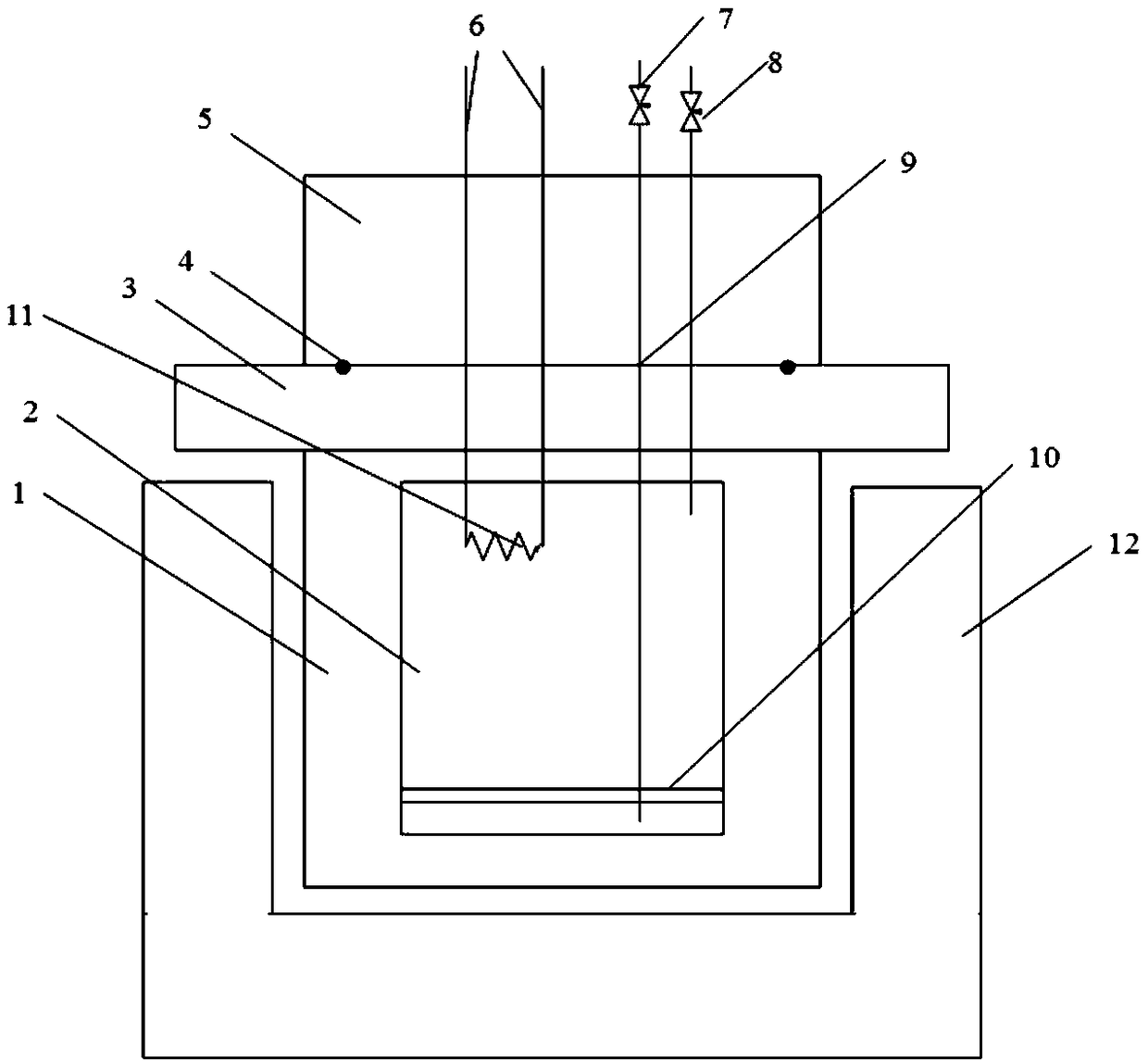

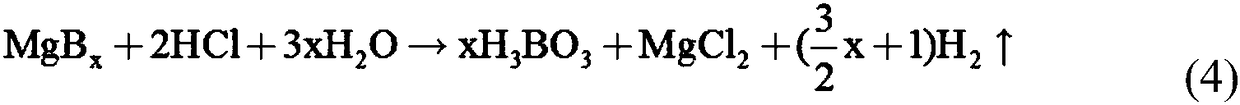

Amorphous boron powder preparation device and method of device for preparing amorphous boron powder

The invention relates to an amorphous boron powder preparation device. The device comprises a sealing body, a reactor (2), a self-propagating reaction initiation assembly, an air inflation valve (7),an air release valve (8), an air guide pipe (9) and a heating body (12); the reactor (2) is used for containing reaction raw materials; the sealing body is used for placing the reactor (2), and the reaction raw materials in the reactor are subjected to heat insulation from the exterior and located in a sealing space in a reaction process; the self-propagating reaction initiation assembly is used for initiating a self-propagating reaction of the reaction raw materials; two air through holes are formed in the sealing body, the air guide pipe (9) penetrates through the air through holes and is connected with the interior and the exterior of the sealing body, and the air inflation valve (7) and the air release valve (8) are arranged on the air guide pipe (9) of the exterior of the sealing body; the heating body (12) is used for heating the sealing body, and accordingly the reaction raw materials in the reactor (2) are pre-heated.

Owner:NAT UNIV OF DEFENSE TECH

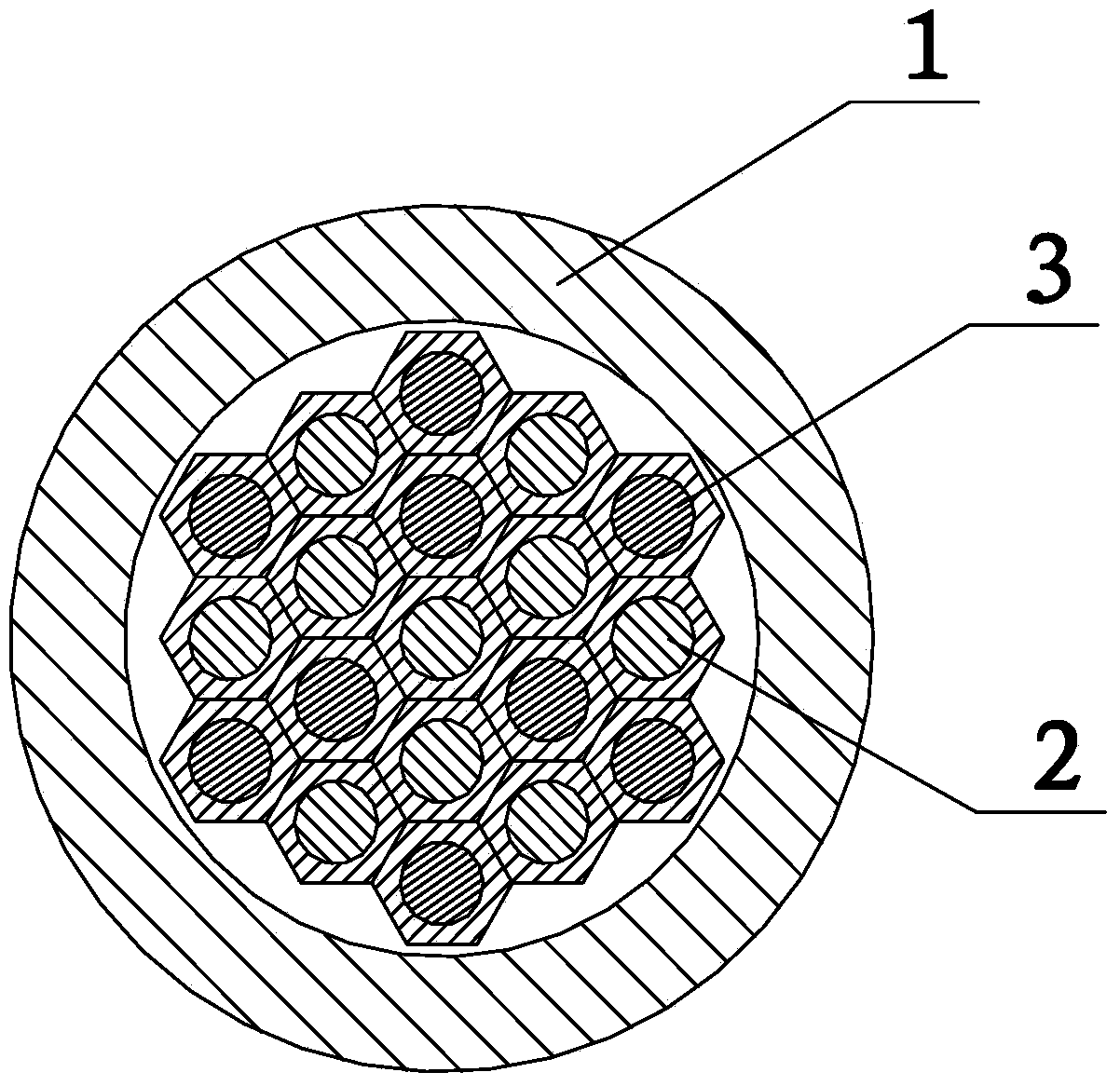

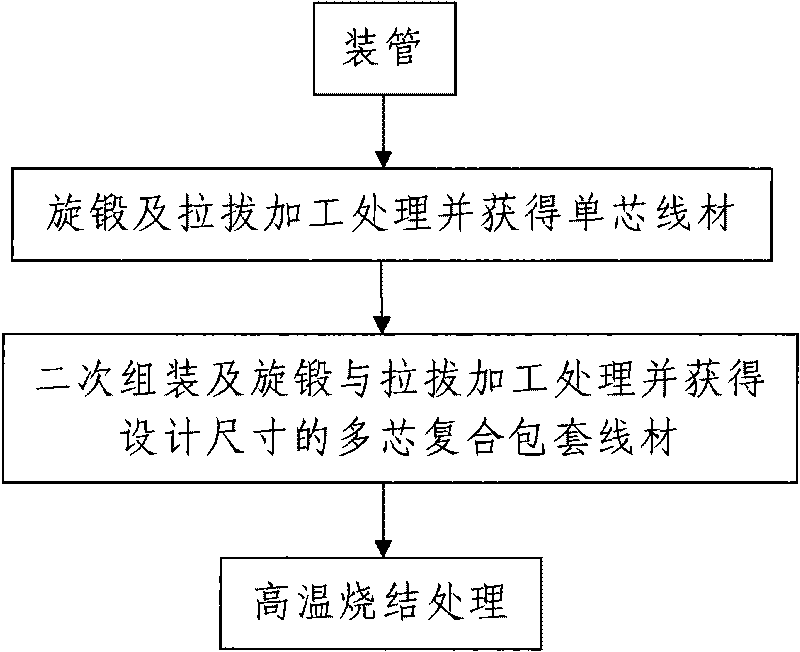

Method for preparing multicore C doped with MgB2 superconductive material by in situ method

InactiveCN101728027AThe process steps are simpleShort processSuperconductors/hyperconductorsSuperconductor devicesSingle-coreCritical current

The invention discloses a method for preparing multicore C doped with MgB2 superconductive material by in situ method, including the following steps: firstly, tabulation, dry magnesium powder, amorphous boron powder and amorphous carbon powder or nano carbon powder are fully mixed to be uniform and then packed into Nb metal tube subject to acid cleaning, and then an oxygen-free copper tube is sheathed outside the Nb metal tube, thus obtaining a tabulation compound body; secondly, rotary swaging and drawing processing are carried out to obtain single core wire rod; thirdly, secondary packaging and rotary swaging and drawing processing are carried out to obtain multicore compound sheathed wire rod in designed dimension; fourthly, high temperature sintering is carried out. The invention is reasonable in design, simple in technological step and convenient to realize, is applicable to preparing MgB2 superconductive wire rod with high critical current density in any length, reaction between superconducting phase and sheathed material is greatly reduced, and the critical current density is higher.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

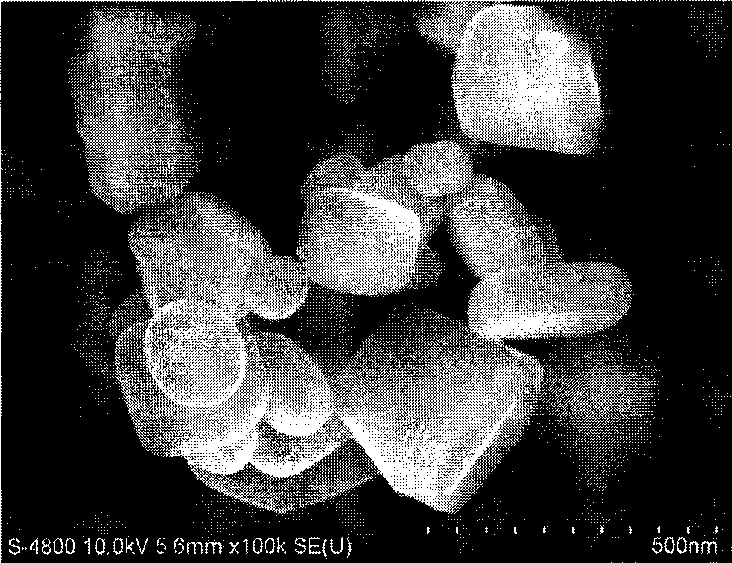

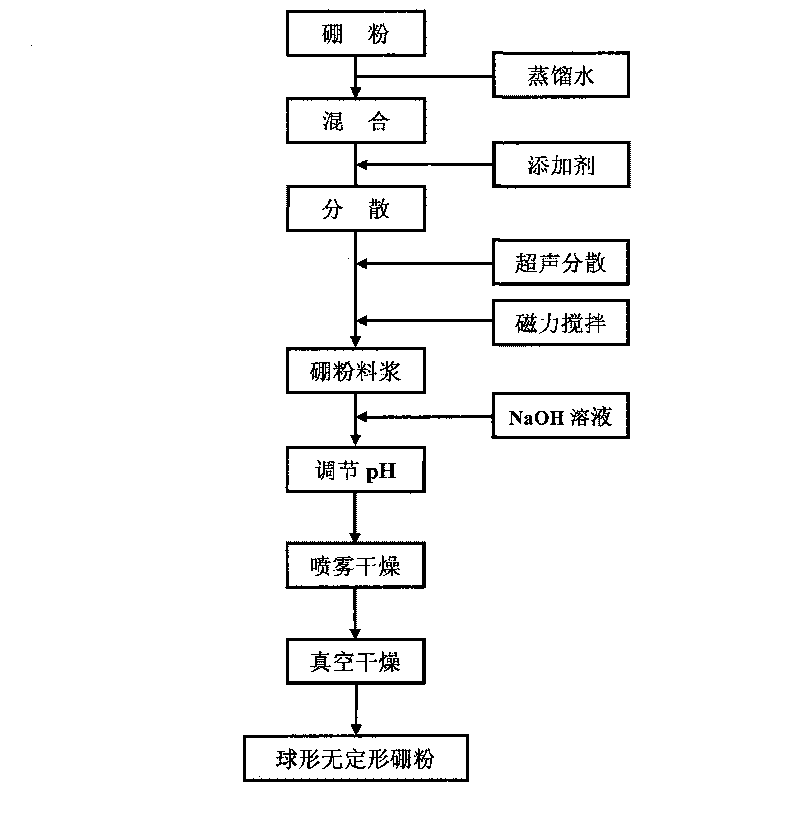

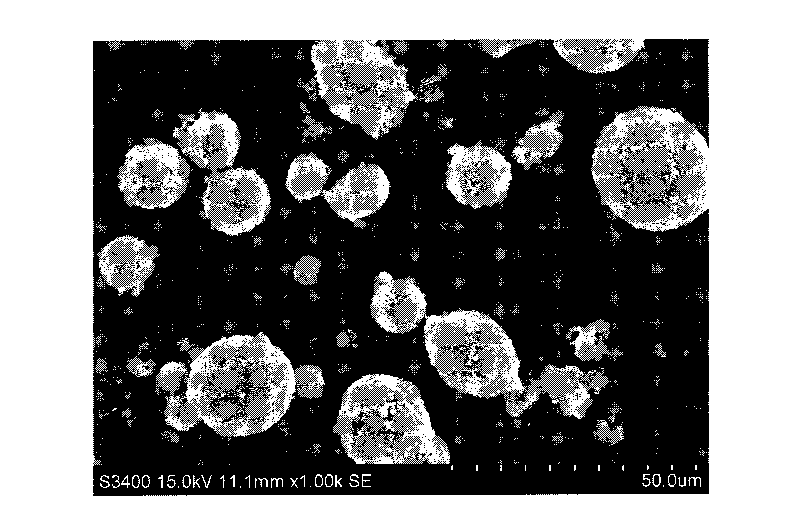

Method for preparing spherical amorphous boron powder by spray drying method

InactiveCN101734680AThe method is simpleShort preparation cycleBoron compoundsMetallurgyDistilled water

The invention relates to a method for preparing spherical amorphous boron powder by a spray drying method, which is characterized by comprising the following steps of: (1) pulping: evenly mixing boron powder and distilled water according to the mass ratio of 30:70 to 40:60, adding additive based on 2-6 percent of the boron powder, firstly, performing ultrasonic dispersion for 15-30 minutes and then stirring magnetically for 15-30 minutes to obtain the boron powder pulp, adding sodium hydroxide solution in the boron powder pulp and adjusting the pH value of the boron powder pulp to 9-12 to obtain the boron powder pulp after adjusting the pH value; (2) spray drying: performing spray drying on the boron powder pulp after adjusting the pH value in the step (1) with a spray dryer; and (3) vacuum drying: placing the spherical boron powder obtained in the step (2) in a vacuum drying box, and drying for 1-2 hours at 70-90 DEG C to obtain the spherical amorphous boron powder. The method is simple and easy to operate, and the spherical amorphous boron powder prepared by the method has excellent sphericity, high boron content and small grain size.

Owner:WUHAN UNIV OF TECH

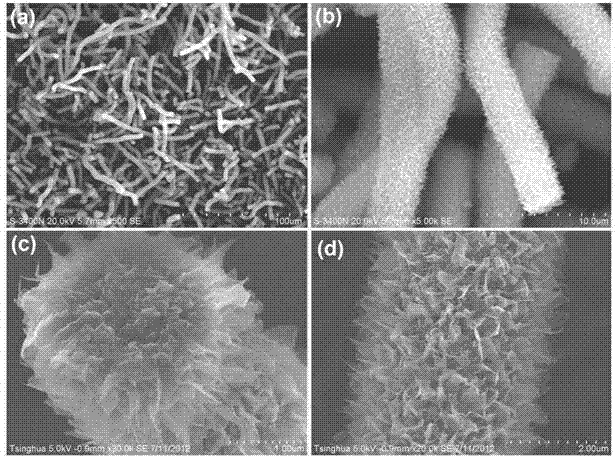

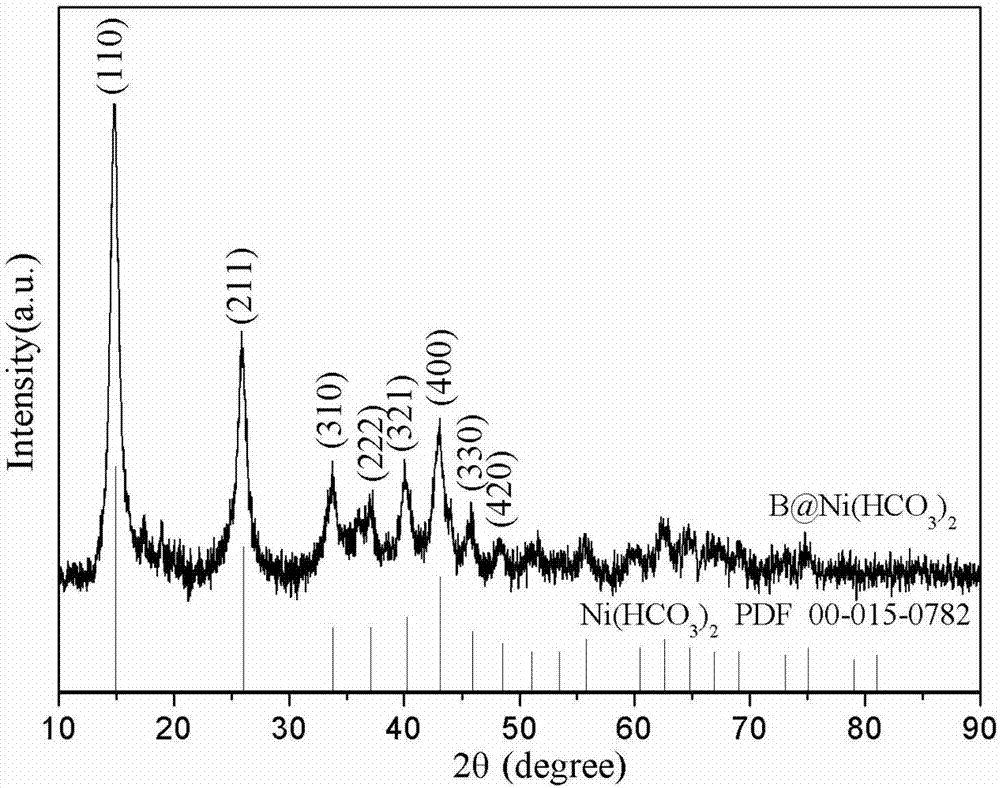

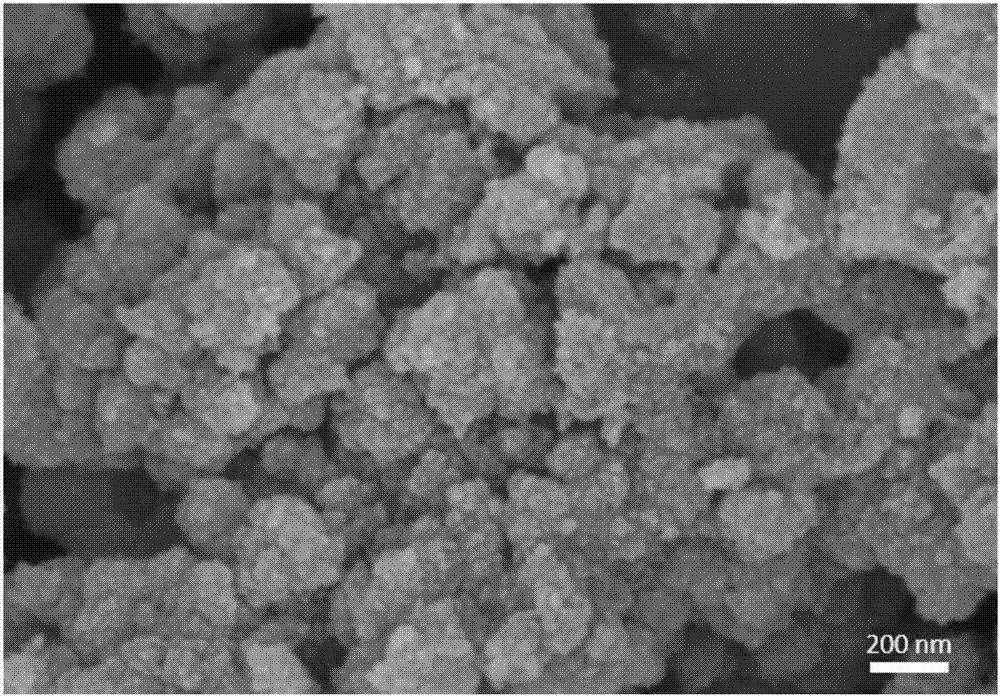

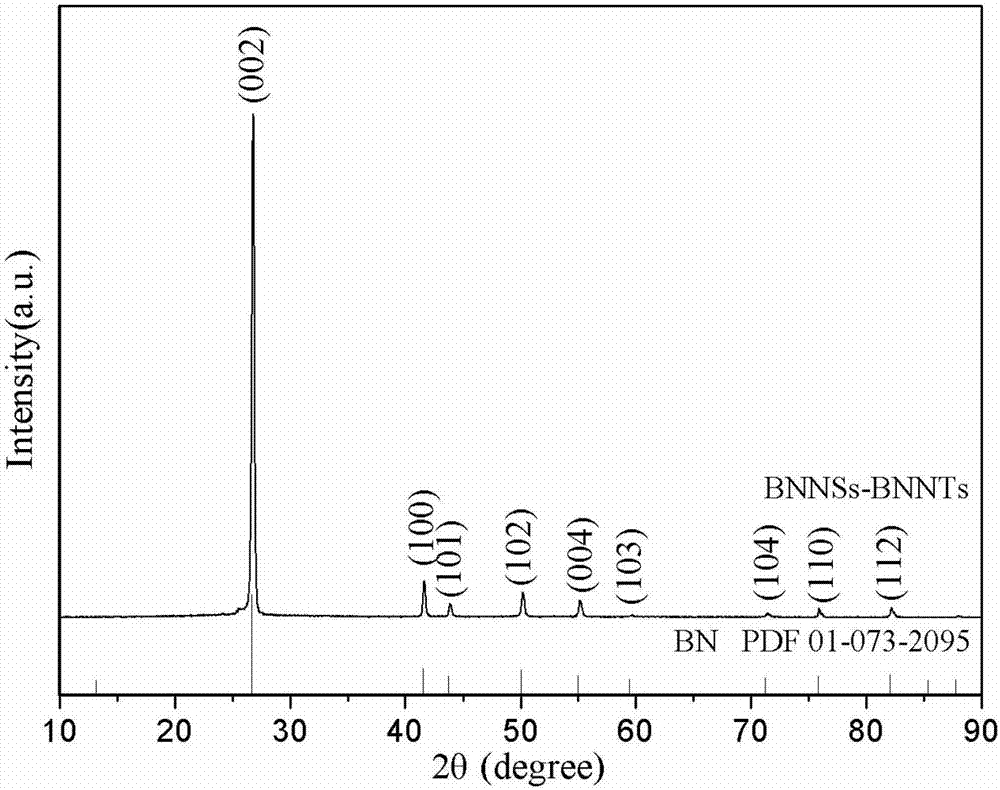

Sea urchin-like boron nitride nanosheet-nanotube hierarchical structure and preparation method thereof

ActiveCN107161961ACover firmlyAvoid reunionMaterial nanotechnologyNitrogen compoundsWater bathsNickel salt

The invention specifically relates to a sea urchin-like boron nitride nanosheet-nanotube hierarchical structure and a preparation method thereof, belonging to the field of inorganic nano-materials. The preparation method comprises the following steps: successively adding a surfactant, amorphous boron powder and a nickel salt, carrying out magnetic stirring and ultrasonic treatment, then adding an ammonium salt, placing the obtained mixture in a constant-temperature water-bath pot for magnetic stirring and filtering and then carrying out washing and vacuum drying so as to obtain a core-shell-structure-like B@Ni(HCO3)2 precursor; placing the obtained precursor in a vacuum tubular furnace, carrying out heating to a certain temperature in an ammonia gas atmosphere for a heat treatment reaction and then carrying out natural cooling to room temperature so as to obtain a solid crude product; and treating the crude product so as to obtain the pure sea urchin-like boron nitride nanosheet-nanotube hierarchical structure. The sea urchin-like boron nitride nanosheet-nanotube hierarchical structure prepared by using the method is formed by assembling of nanosheets and nanotubes and has good crystallinity, uniform morphology, stable structure, good resistance to oxidation and good application prospects in the field of functional composite materials.

Owner:WUHAN UNIV OF TECH

Boron-containing additive for carbide refractory and preparation thereof

The invention provides a boron-containing additive for carbon refractory, which is characterized in that the boron-containing ingredients including metal boride, B4C or amorphous boron powder are directly compounded in spongy basal body of Al2O3 or MgO by the in-situ synthesis technology so as to form Al2O3-base or MgO-base boron-containing additive. The product takes loose sponge shape. The invention adopts the boric anhydride and metal oxide, or the boric anhydride and graphite, or the boric anhydride as raw materials, and adopts the aluminum powder or magnesium powder as a reducing agent; the materials and the reducing agent are mixed, activated and are then placed in a self-spreading reacting furnace; the partial ignition mode is adopted to initiate the combustion synthesis reaction so as to produce the Al2O3-base or MgO-base boron-containing additive. The boron-containing additive for carbon refractory has the advantages of simple technique, low production cost and high product purity and does not have secondary pollution caused by crashing in the traditional production technique.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com