Method for preparing texturing boride super-high-temperature ceramic

An ultra-high temperature ceramic and boride technology, which is applied in the field of preparation of non-oxide composite ceramic materials, can solve problems such as no obvious improvement in mechanical properties, and achieve the effects of improved performance, obvious thermal conductivity and high degree of texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

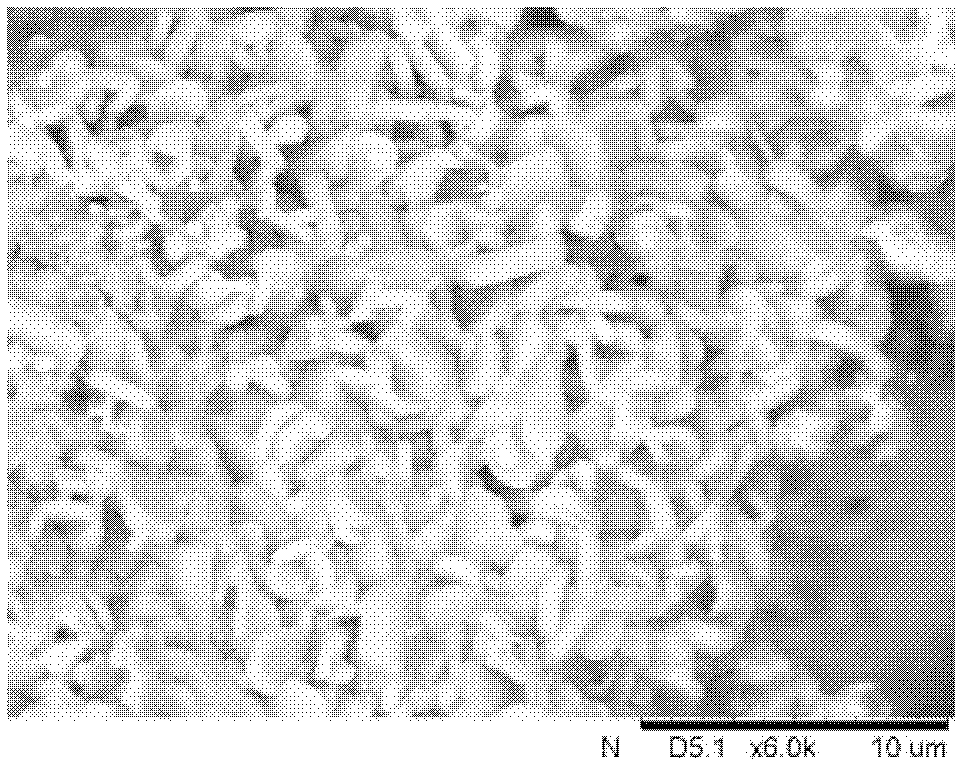

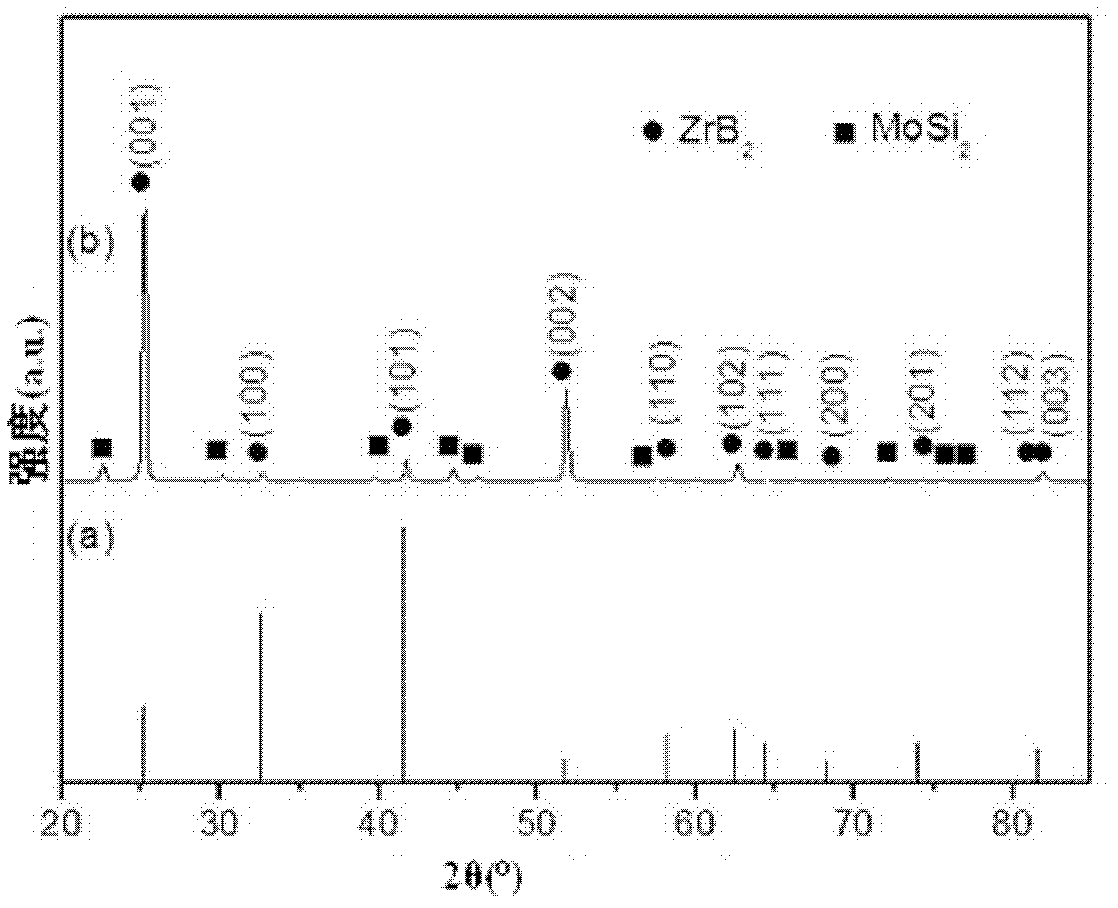

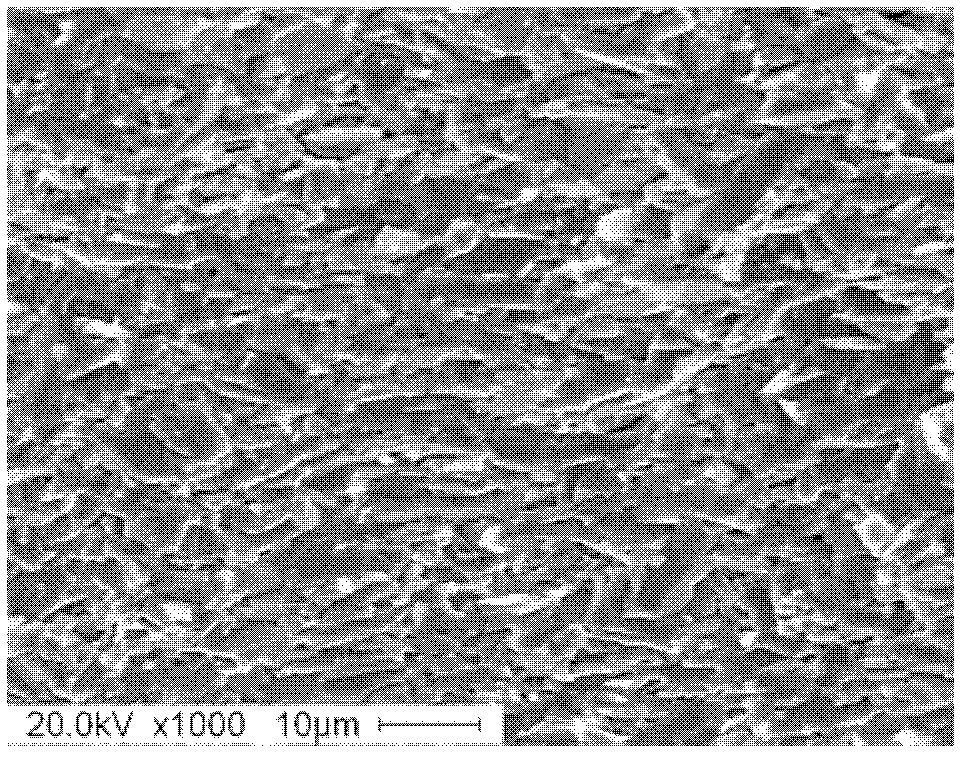

[0036] Weighing according to the stoichiometric ratio: 45.612 grams of Zr powder, 10.811 grams of B powder, 2.399 grams of Mo powder and 1.404 grams of Si powder, mixed; with acetone as solvent, at a speed of 560 rpm, with ZrO 2 The ball and planet ball milled for 8 hours, and the resulting slurry was dried by rotary evaporation to obtain a uniformly mixed powder; the uniformly mixed powder was compacted with a dry press, placed in a graphite mold, and reacted and synthesized in a vacuum, and the temperature was raised The rate is 10°C / min, the temperature is raised to 1400°C and kept for 1 hour; after the heat preservation is completed, the multiphase powder containing boride seed crystals is obtained by natural cooling; the prepared multiphase powder containing boride seed crystals is mixed with boride After the ceramic powder is mixed in a molar ratio of 1:9, it is added to a mixed solution of ethanol and butanone (ethanol: butanone=1:2, volume ratio), and a dispersant (glyc...

Embodiment 2

[0042] Weigh according to the stoichiometric ratio: Zr powder 45.612 grams, B powder 10.811 grams, Mo powder 9.114 grams and Si powder 5.336 grams, mix.

[0043] All the other contents are the same as those described in Example 1.

[0044] It is found from the test that the relative density of the prepared textured boride-based ultra-high temperature ceramics is 98.7%; the Lotgering orientation factor f(00l) is 0.92; the bending strength of the sample: vertical to the hot pressing direction, 913 MPa; parallel to the hot pressing direction , 759MPa.

Embodiment 3

[0046] Weigh according to the stoichiometric ratio: Zr powder 45.612 grams, B powder 10.811 grams, Mo powder 23.985 grams and Si powder 14.043 grams, mix.

[0047] All the other contents are the same as those described in Example 1.

[0048] It is found from the test that the relative density of the prepared textured boride-based ultra-high temperature ceramics is 99.0%; the Lotgering orientation factor f(00l) is 0.95; the bending strength of the sample: vertical to the hot pressing direction, 882 MPa; parallel to the hot pressing direction , 746MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com