Preparation method and extrusion die of bismuth telluride-based thermoelectric material

A technology of extrusion dies and thermoelectric materials, which is applied in the direction of metal extrusion dies, the manufacture/processing of thermoelectric devices, and the material of lead wires of thermoelectric devices, which can solve the problems of easy dissociation and cracks on the surface of extruded ingots , performance degradation and other issues, to achieve the effect of enhancing the degree of plastic deformation and deformation uniformity, realizing thermoelectric properties and mechanical properties, and enhancing mechanical strength and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

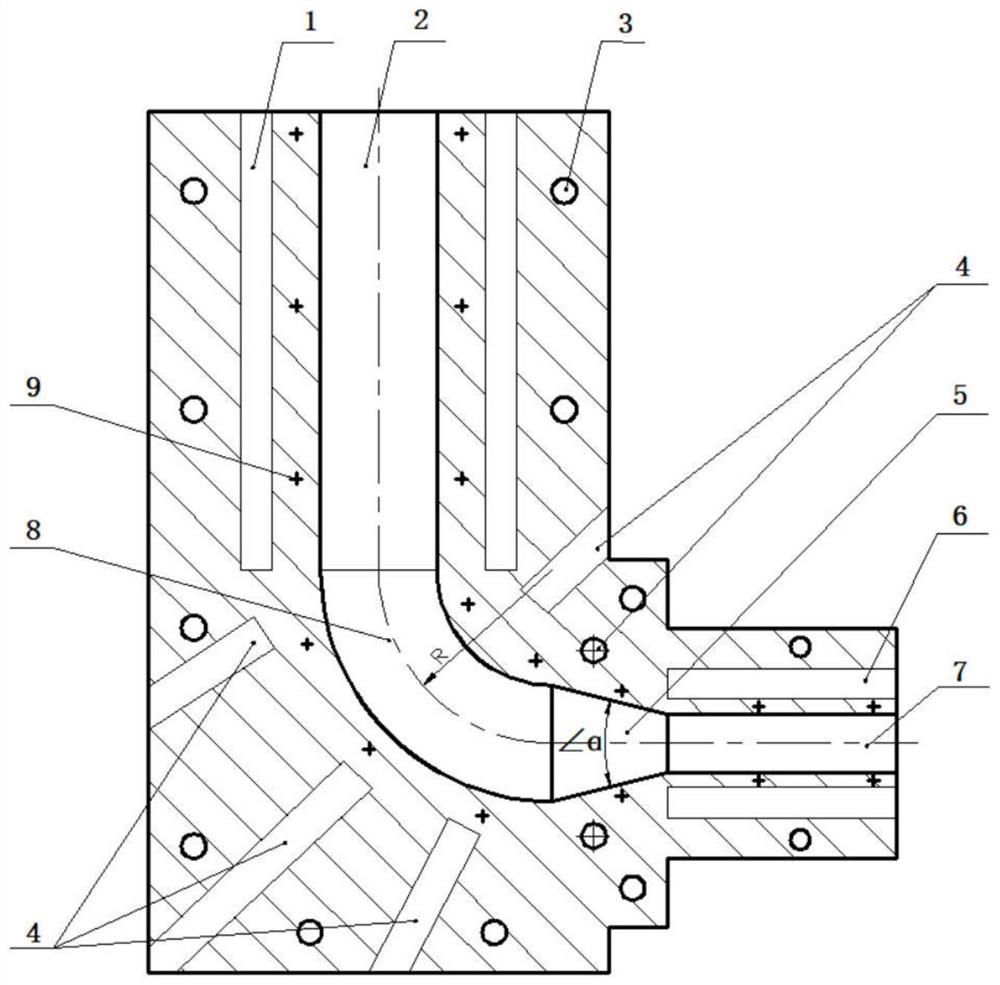

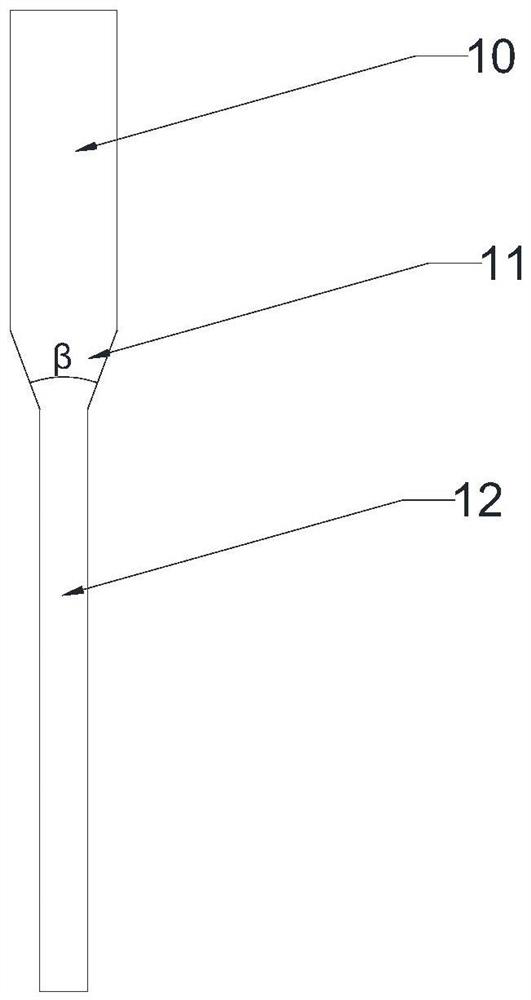

[0048] This embodiment provides an extrusion die, such as figure 1 As shown in the figure, the extrusion die is composed of two processing structural parts with symmetrical semi-cylindrical channels that are fixedly connected by fastening bolts 3, and the two pieces with symmetrical semi-cylindrical channels form a die groove including an inlet section 2, a connecting section and an outlet. Section 7, the inlet section 2 and the outlet section 7 are located at both ends of the connecting section; the connecting section includes the equal-diameter elbow section 8 and the variable-diameter section 5; the equal-diameter elbow section 8 connects the inlet section 2 and the variable-diameter section 5; The diameter section 5 connects the outlet section 7 and the equal-diameter elbow section 8; the diameter of the outlet section 7 is smaller than the diameter of the inlet section 2.

[0049] Preferably, the bending angle of the equal diameter elbow section 8 is 90°;

[0050] Prefer...

Embodiment 2

[0062] (1) According to the chemical formula Bi 0.5 Sb 1.5 Te 3.10 , Weigh the elemental raw materials Bi, Sb and Te (the purity of each element is ≥99.99%) according to the stoichiometric ratio, load the weighed raw materials into a quartz tube with a diameter of 50.8mm, and carry out crystallisation in a district furnace after vacuum packaging Zone melting growth, the growth rate is 3-5mm / min;

[0063] (2) after the crystal obtained in step (1) is polished on the surface, a crystal rod with a length of 100 mm is intercepted, and it is loaded into the inlet section of the hot extrusion die in Example 1 to carry out hot extrusion;

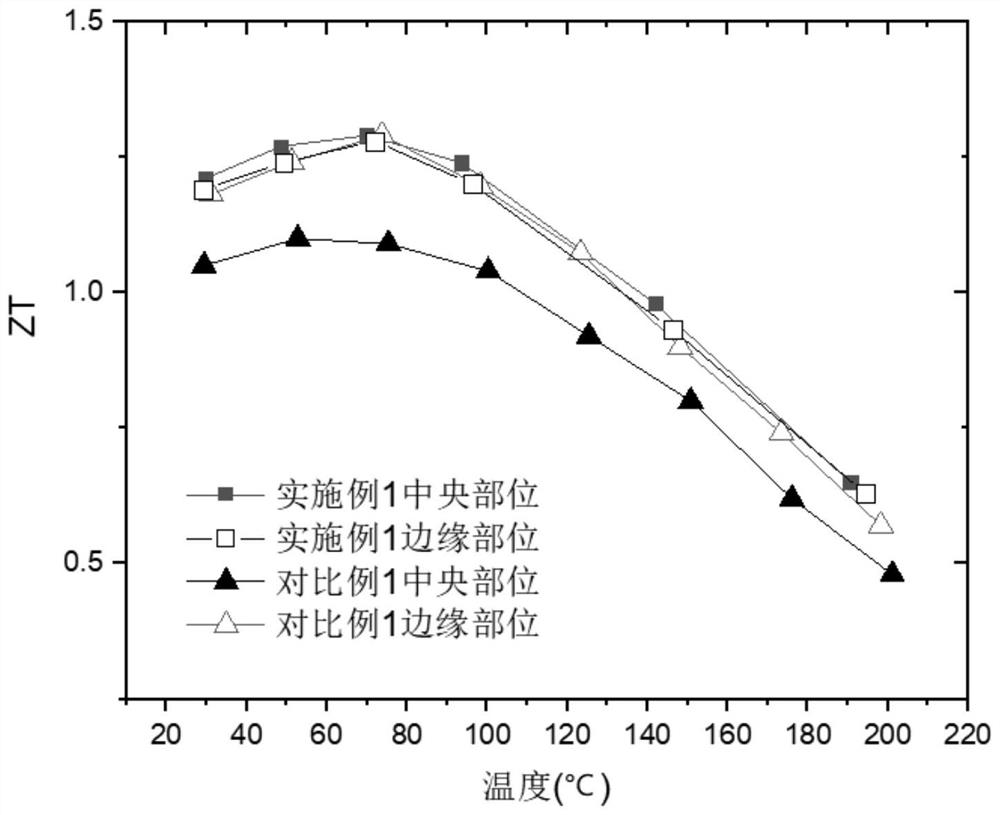

[0064] In this embodiment, the hole diameter of the inlet section is 50.8mm, the centerline turning radius of the equal-diameter elbow section is 60mm, and the bending angle is 90°; The diameter of the hole is 25.4mm; during the hot extrusion process, the temperature of the inlet section is controlled to be 350-400°C, the temperature of the conn...

Embodiment 3

[0066] (1) According to the chemical formula Bi 2 Te 2.7 Se 0.3 / 0.1%SbI 3 , Weigh the elemental raw materials Bi, Sb, Te, Se and I according to the stoichiometric ratio (the purity of each element is all ≥ 99.99%), load the weighed raw materials into a quartz tube with a diameter of 50.8 mm, and place the The melting growth of the crystal region is carried out in the furnace, and the growth rate is 1-3mm / min;

[0067] (2) after the crystal obtained in step (1) is polished on the surface, a crystal rod with a length of 100 mm is intercepted, and it is loaded into the inlet section of the hot extrusion die in Example 1 to carry out hot extrusion;

[0068] In this embodiment, the diameter of the hole in the inlet section is 50.8mm, the centerline turning radius of the equal diameter section is 60mm, and the bending angle is 90°; The diameter is 25.4mm; during the hot extrusion process, the temperature of the inlet section is controlled to be 400-480°C, the temperature of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com