Patents

Literature

44 results about "Texture orientation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

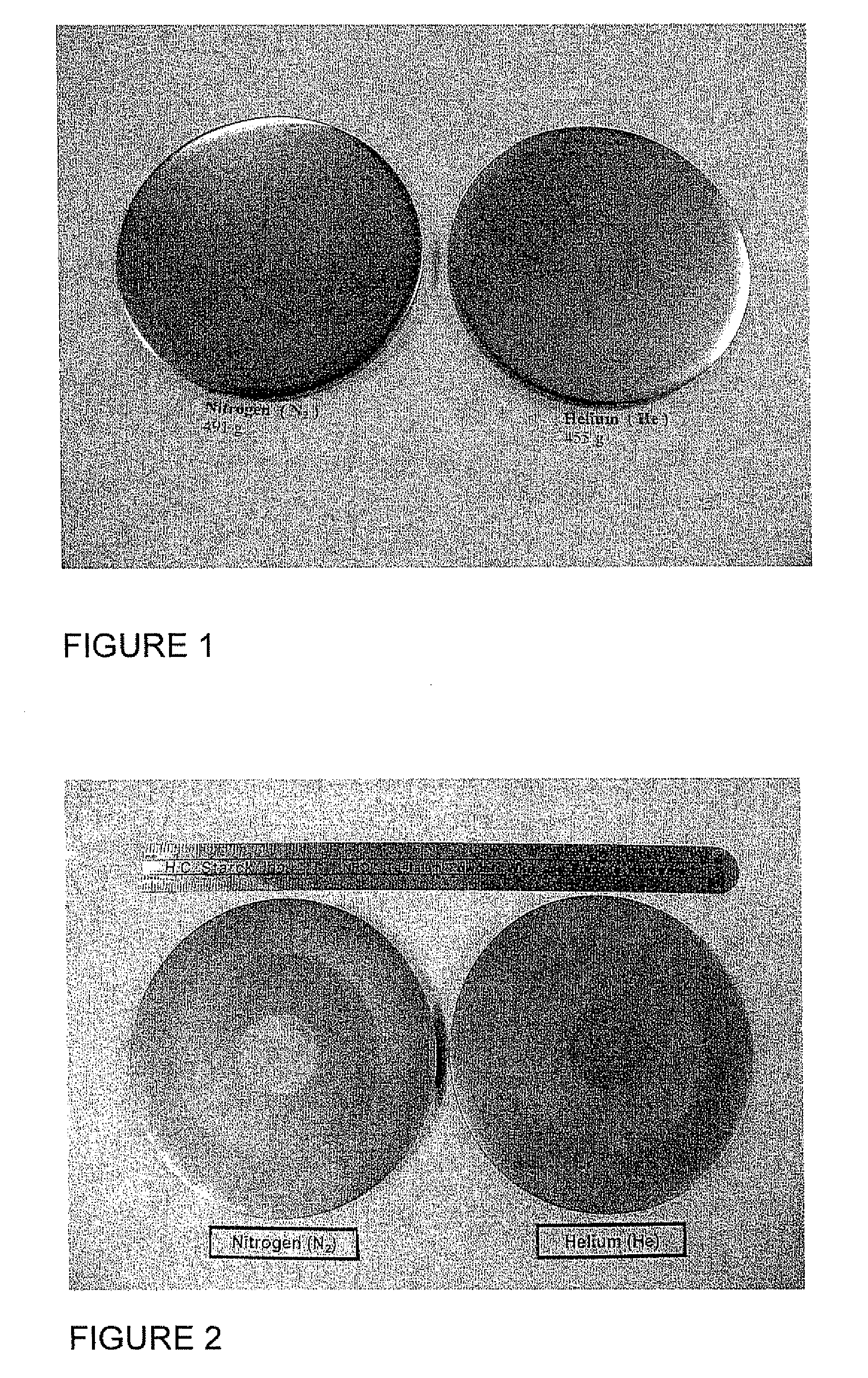

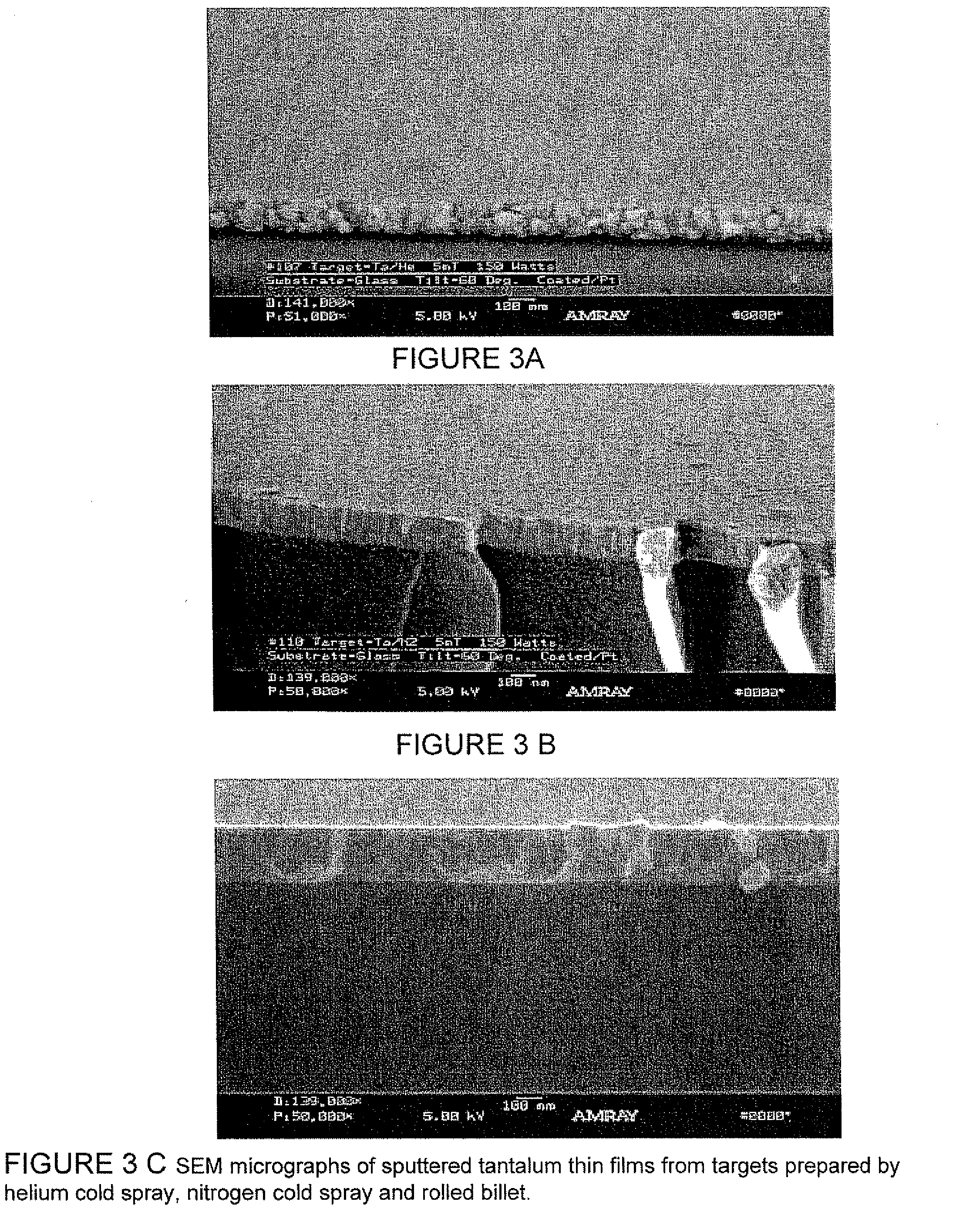

Fine Grained, Non Banded, Refractory Metal Sputtering Targets with a Uniformly Random Crystallographic Orientation, Method for Making Such Film, and Thin Film Based Devices and Products Made Therefrom

ActiveUS20080271779A1Cost-effectively createCost effectiveLiquid surface applicatorsMolten spray coatingFilm baseThermal expansion

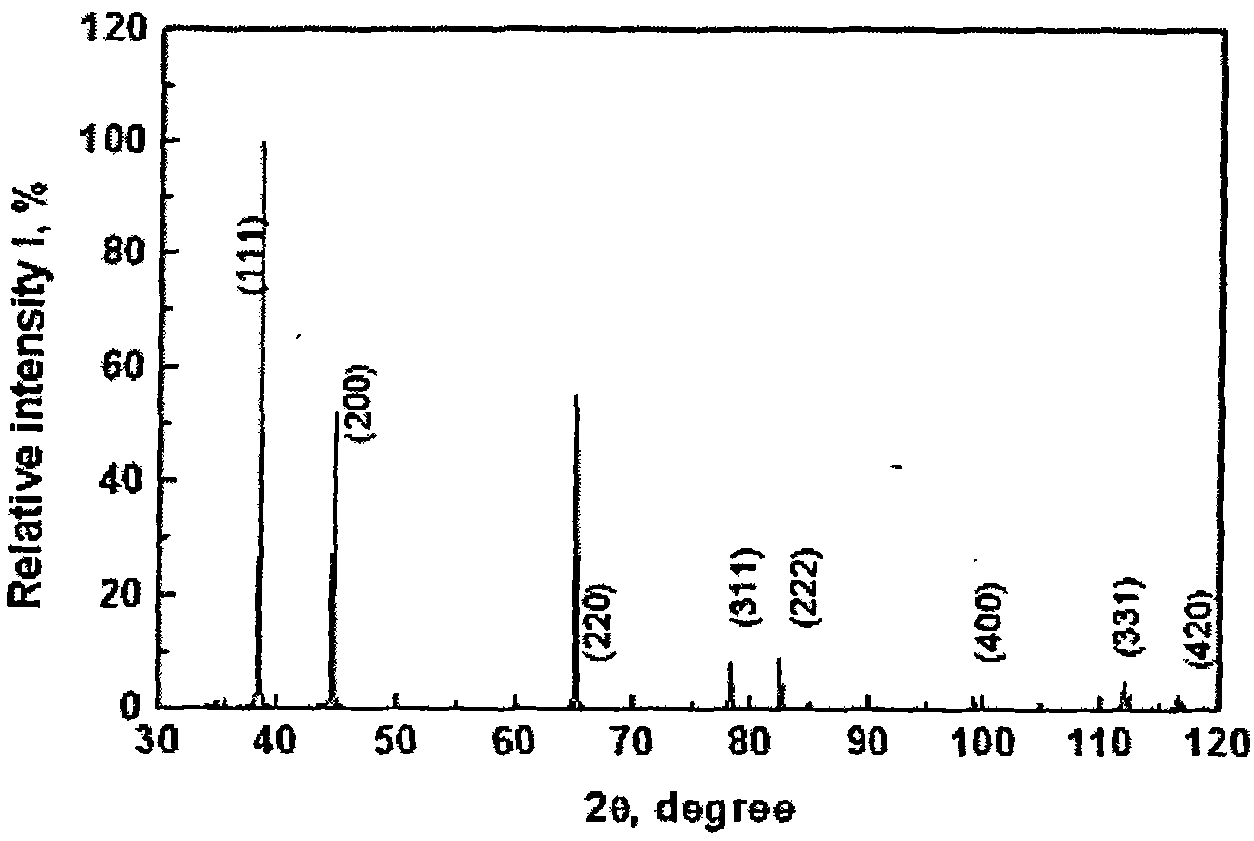

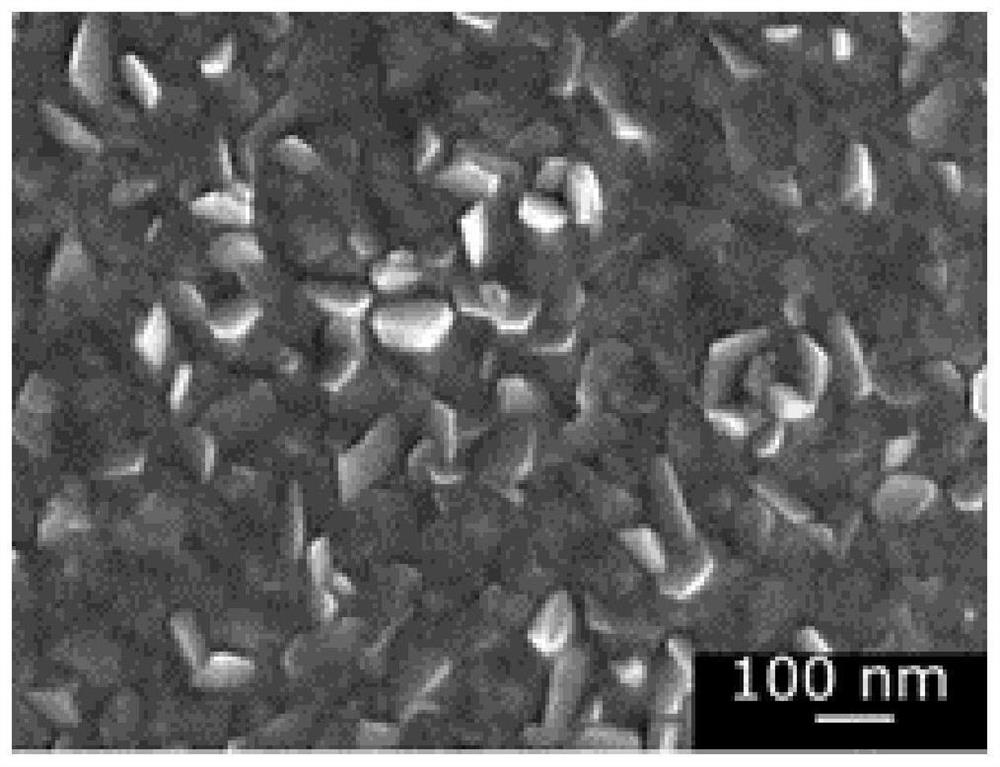

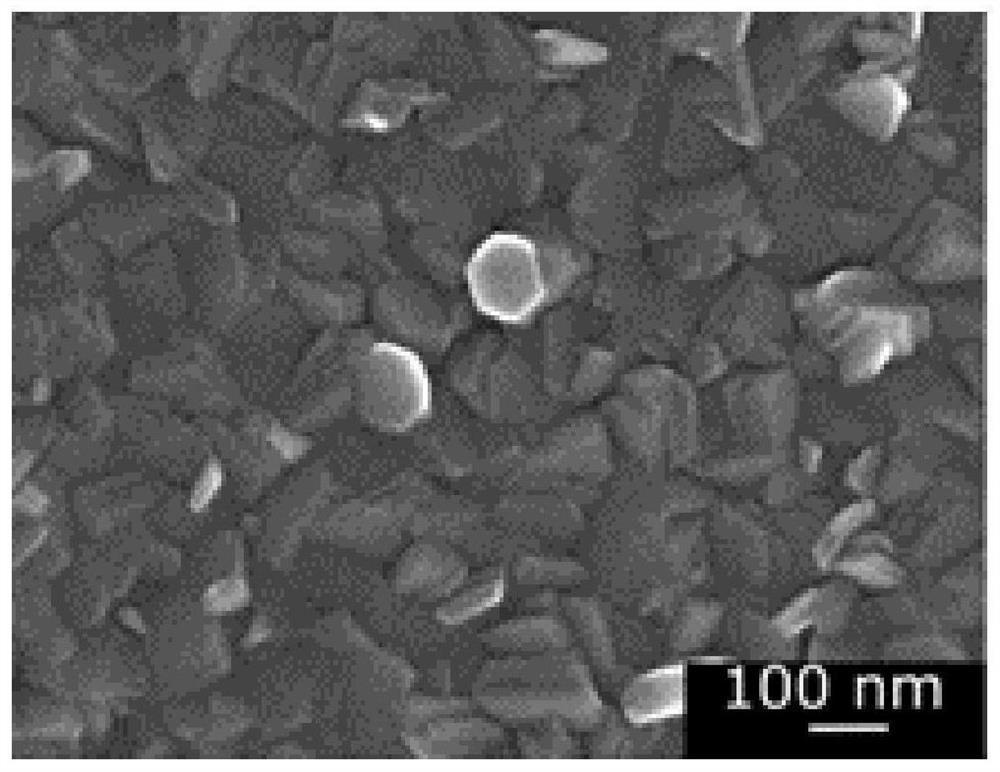

The invention relates to a sputtering target which has a fine uniform equiaxed grain structure of less than 44 microns, no preferred texture orientation as measured by electron back scattered diffraction (“EBSD”) and that displays no grain size banding or texture banding throughout the body of the target. The invention relates a sputtering target with a lenticular or flattened grain structure, no preferred texture orientation as measured by EBSD and that displays no grain size or texture banding throughout the body of the target and where the target has a layered structure incorporating a layer of the sputtering material and at least one additional layer at the backing plate interface, said layer has a coefficient of thermal expansion (“CTE”) value between the CTE of the backing plate and the CTE of the layer of sputtering material. The invention also relates to thin films and their use of using the sputtering target and other applications, such as coatings, solar devices, semiconductor devices etc. The invention further relates to a process to repair or rejuvenate a sputtering target.

Owner:H C STARCK GMBH +1

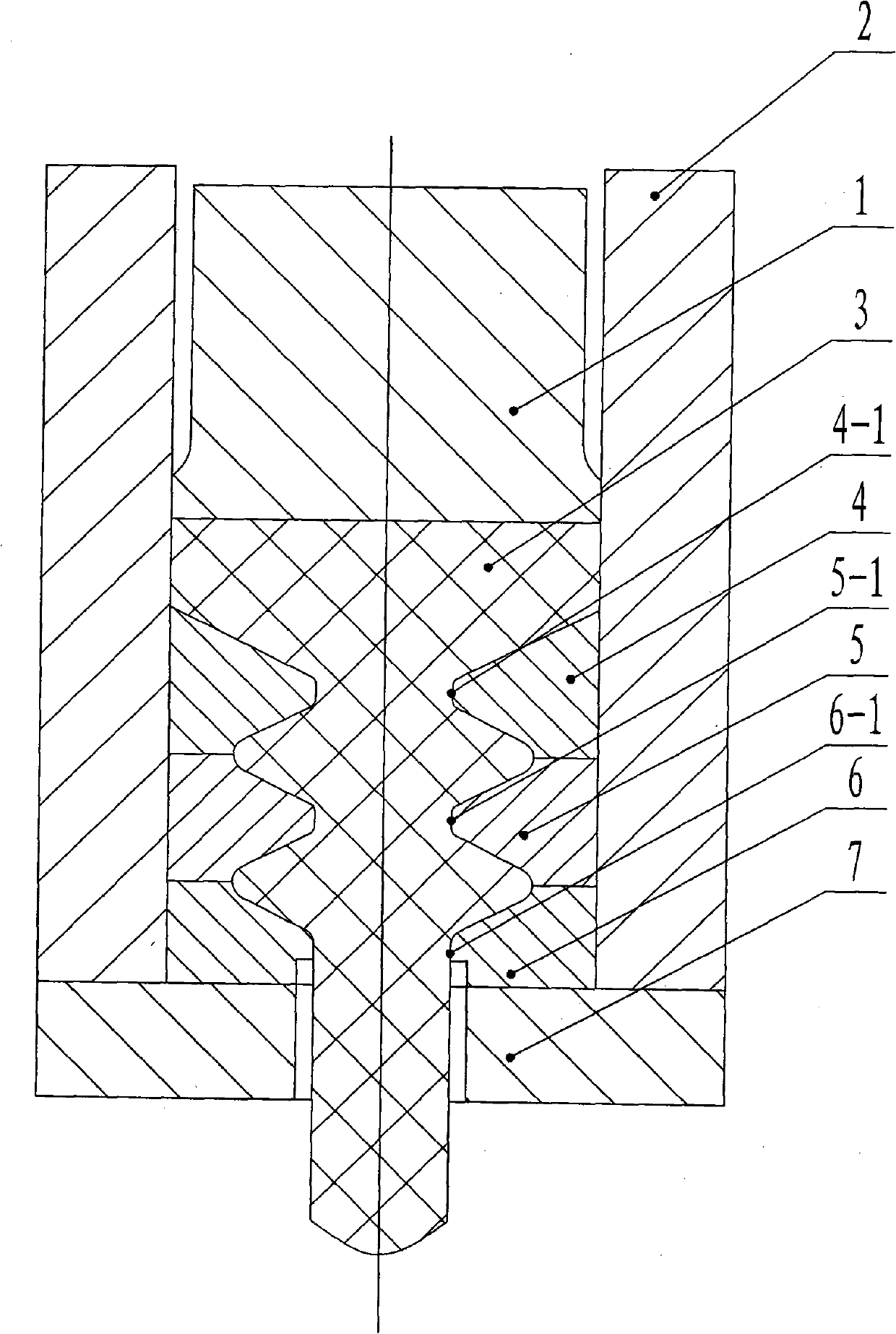

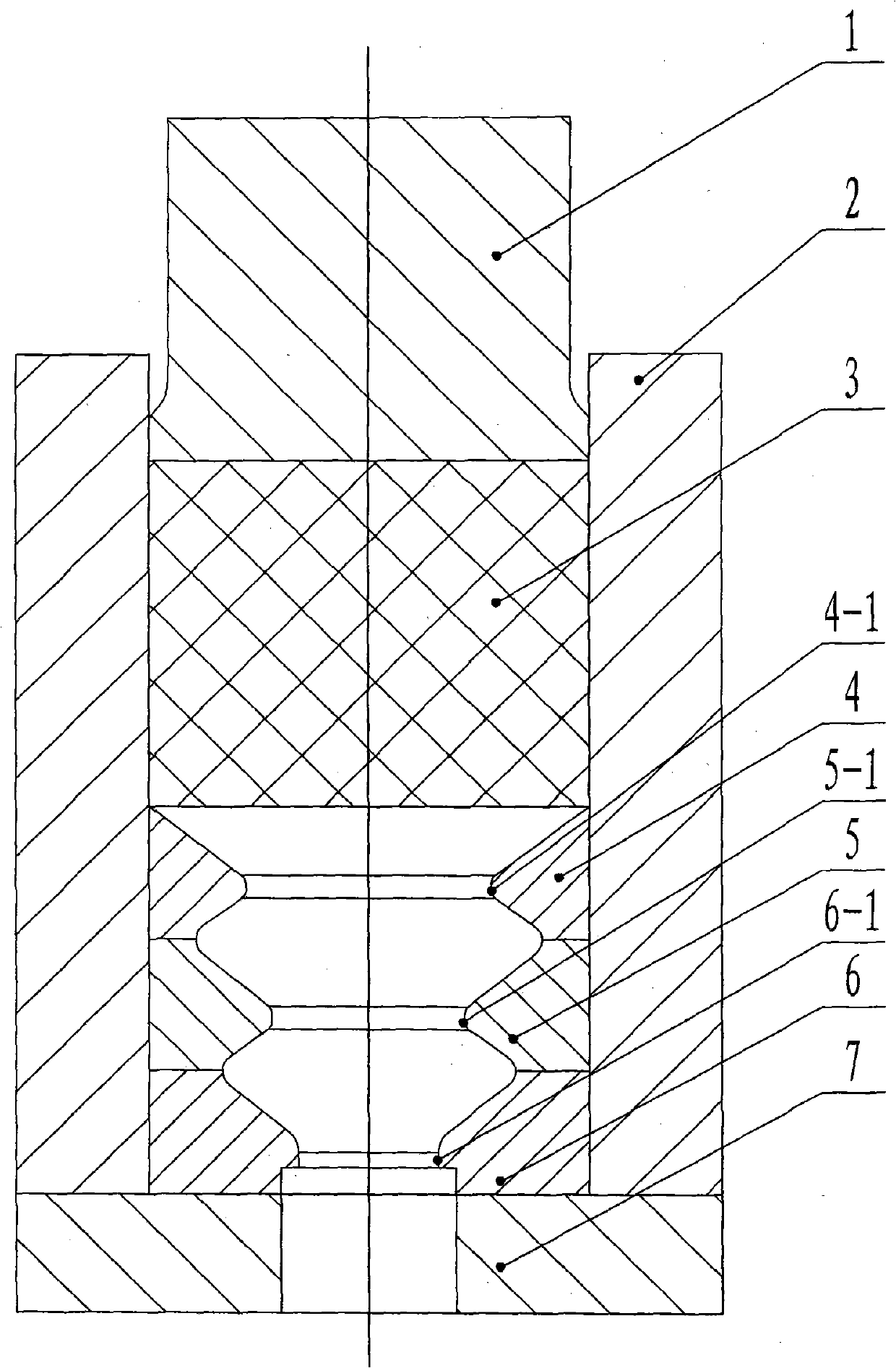

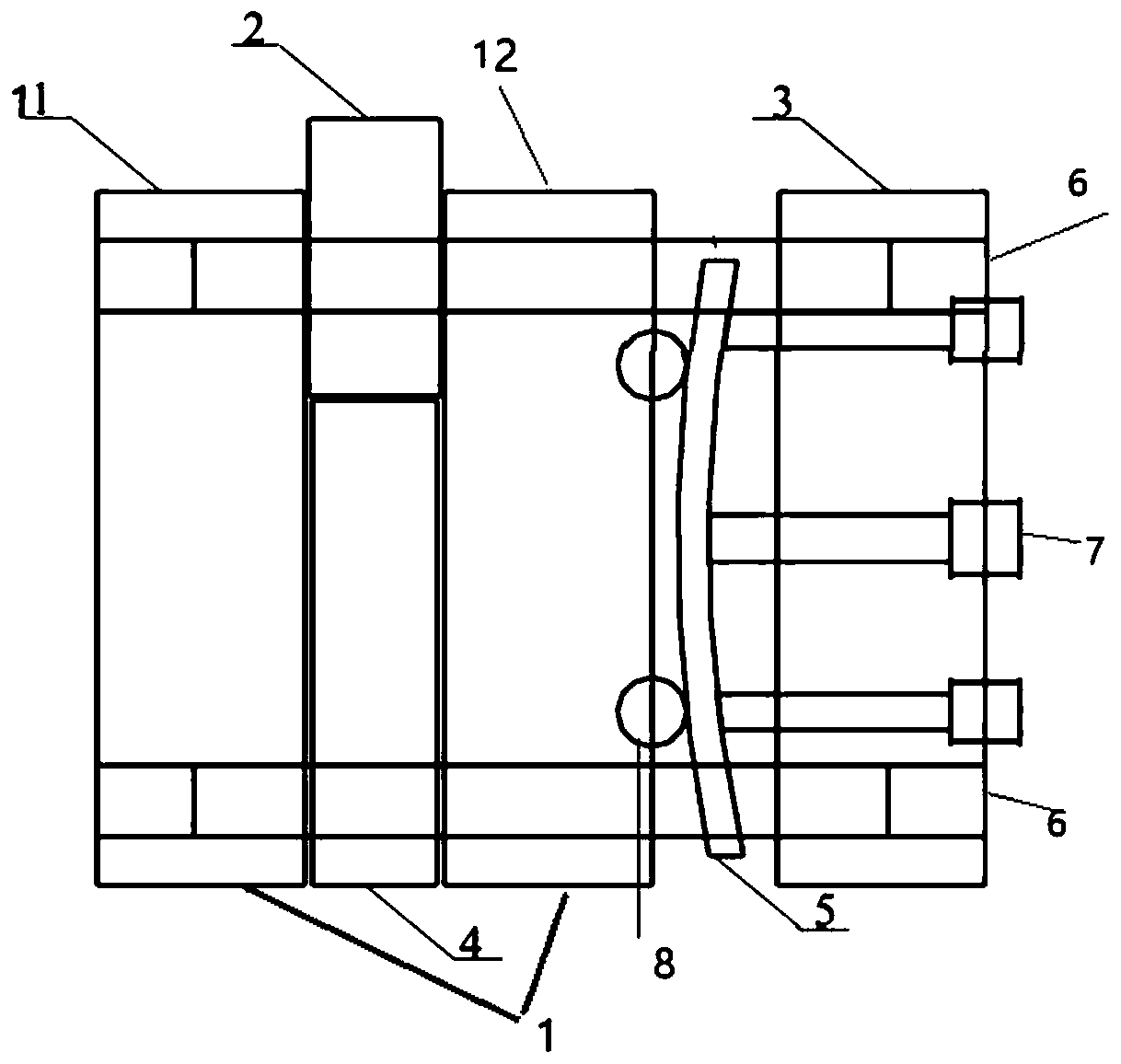

Device and method for preparing fine-grained material by directly extruding continuous variable cross section

InactiveCN101767120AUniform refinementImprove mechanical propertiesExtrusion diesExtrusion mandrelsMaterials preparationIngot

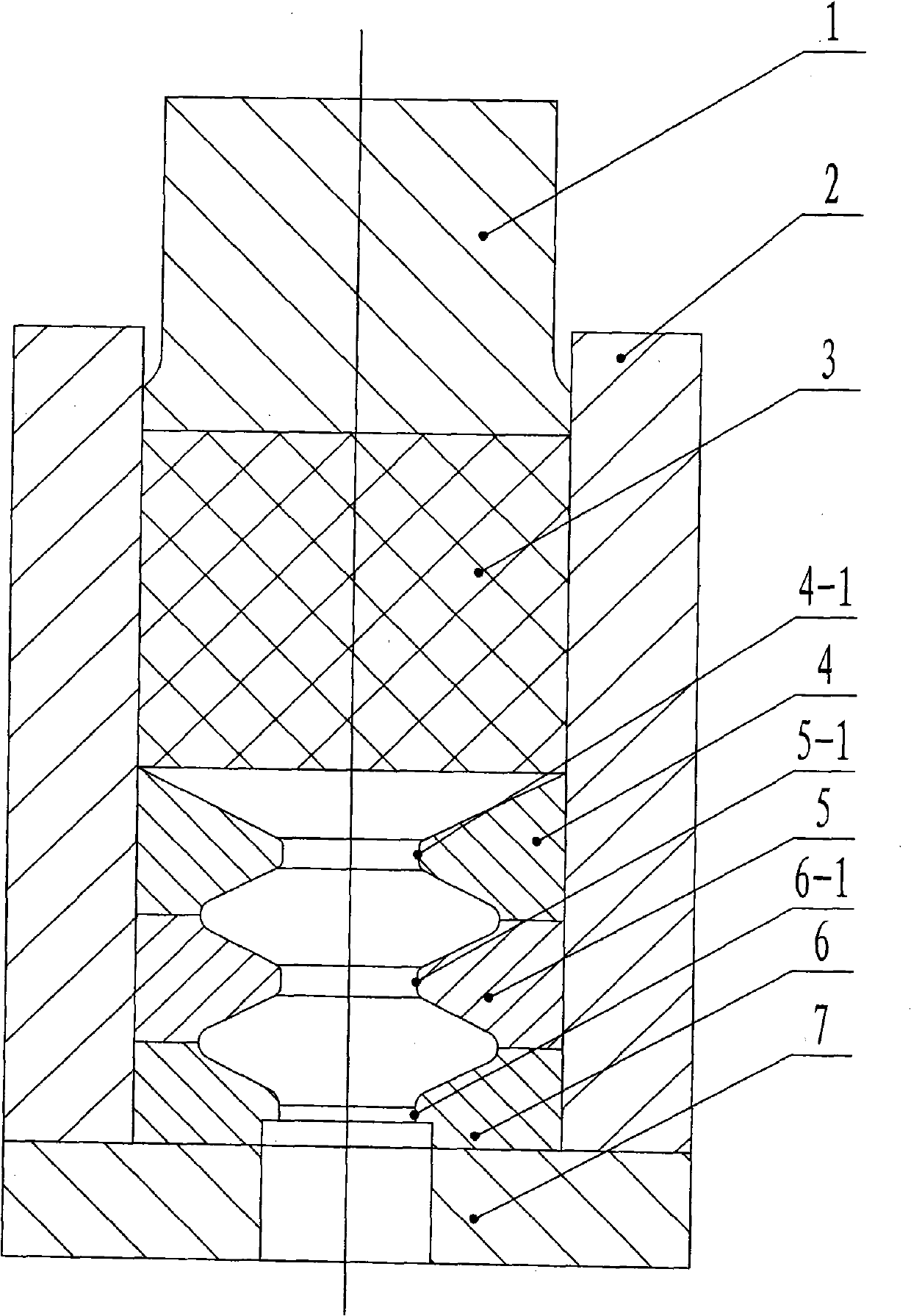

The invention relates to a device and a method for preparing fine-grained material by directly extruding a continuous variable cross section, which relate to a device and a method for preparing fine-grained material. The invention solves the problems of the traditional fine-grained material preparation methods that the procedures are complicated, the process requirements are high, the texture orientation is significant, the defects of folds and material interface superposition are easy to occur in processing and preparation and the preparation methods are difficult to be implemented in production. A primary transition die cavity, a secondary transition die cavity and a core die cavity of the preparation device of the invention are combined to form an axial corrugated extrusion cavity of the continuous variable cross section; the preparation method of the invention comprises the following steps: the preparation device is assembled; an ingot is arranged in a female die, a punch head is put it, a punch head is put in, the die orifice on a core die extrusion end is closed, the punch head descends, the ingot is extruded form a primary transition die orifice and a secondary transition die orifice, the punch head continues to descend, and the ingot is upset and deforms; and the closure is removed, the punch head continues to descend, and the ingot is extruded and formed. The invention requires simple equipment and few production procedures, and is easy to be implemented and popularized in production.

Owner:HARBIN UNIV OF SCI & TECH

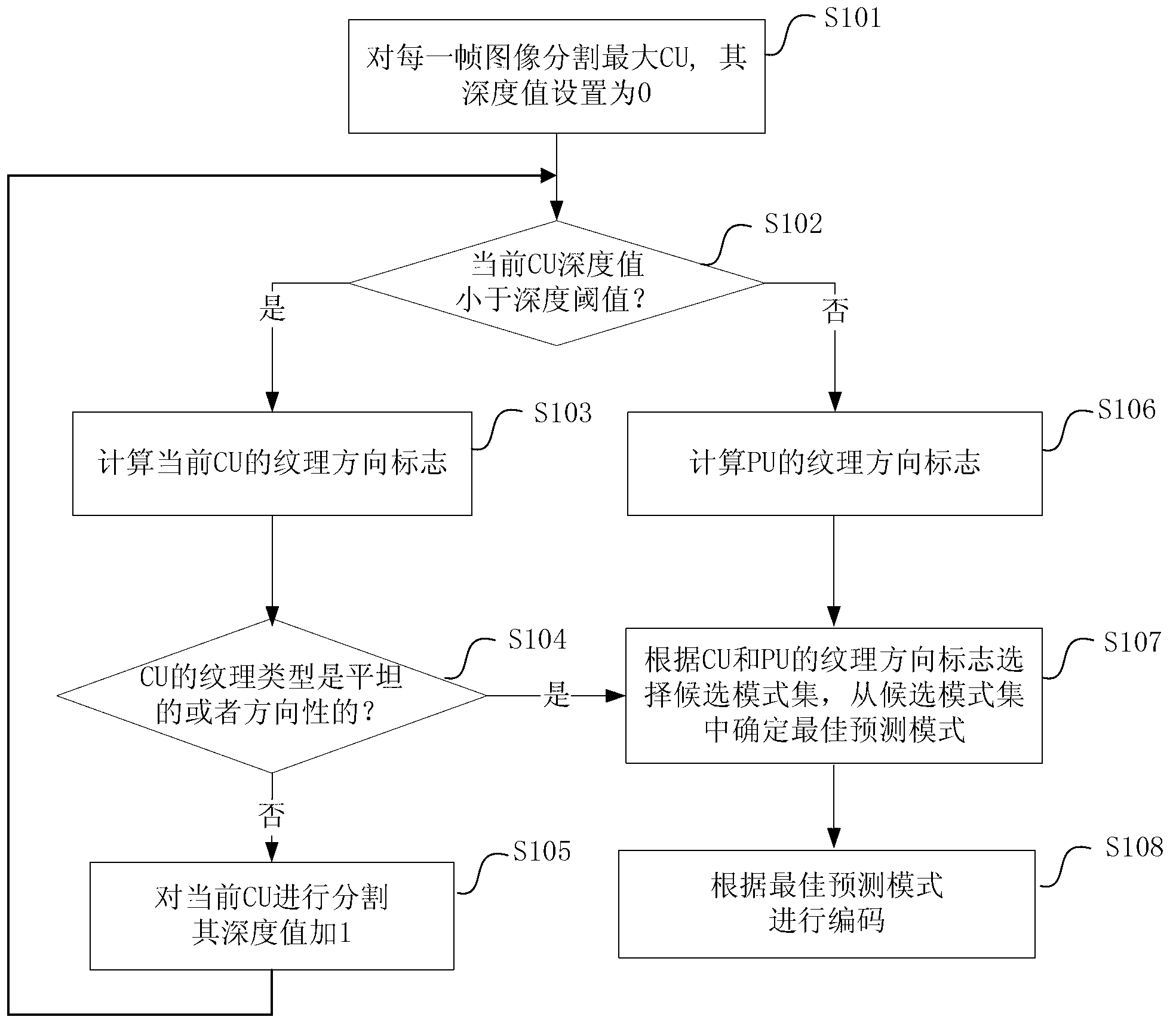

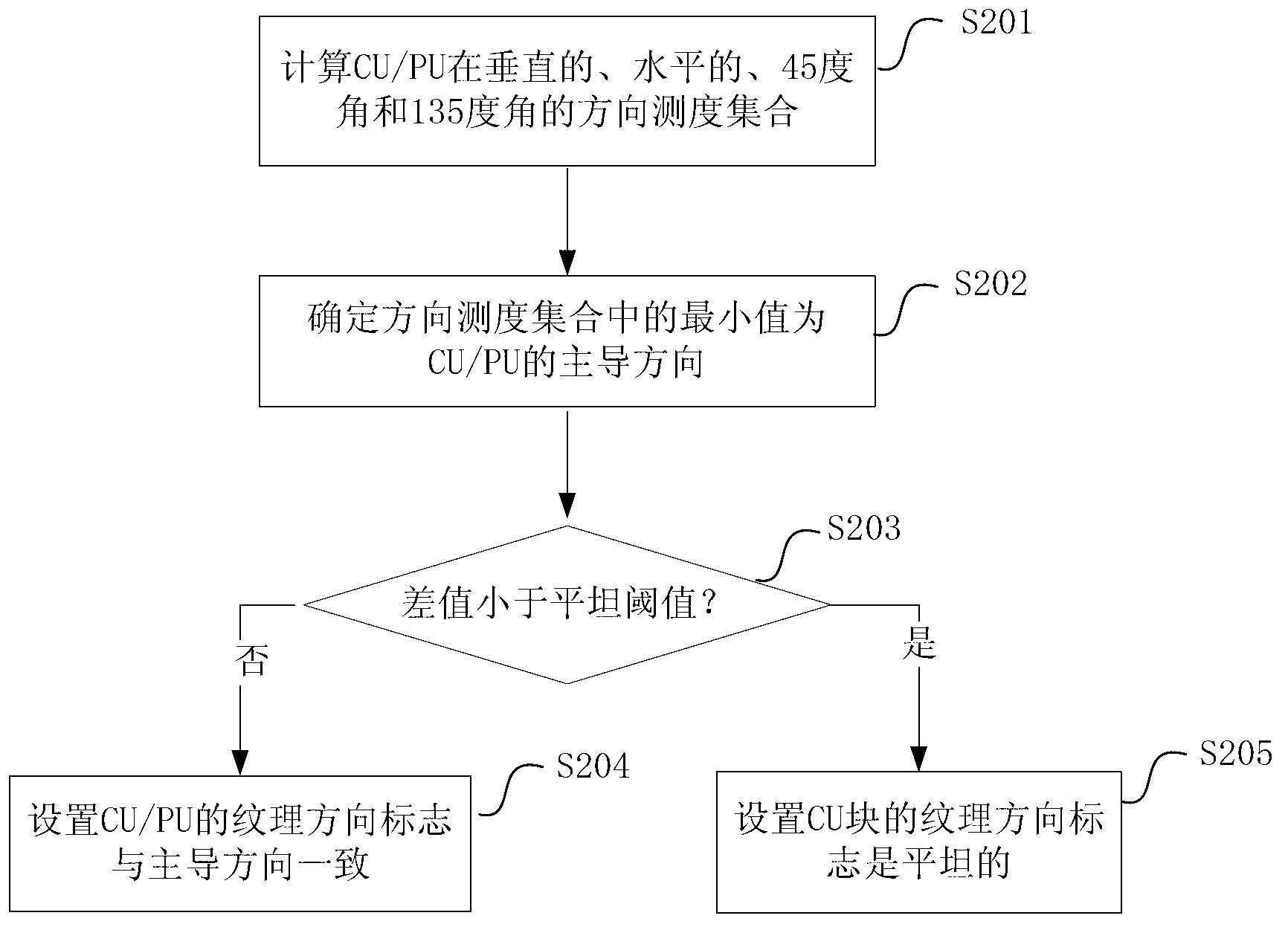

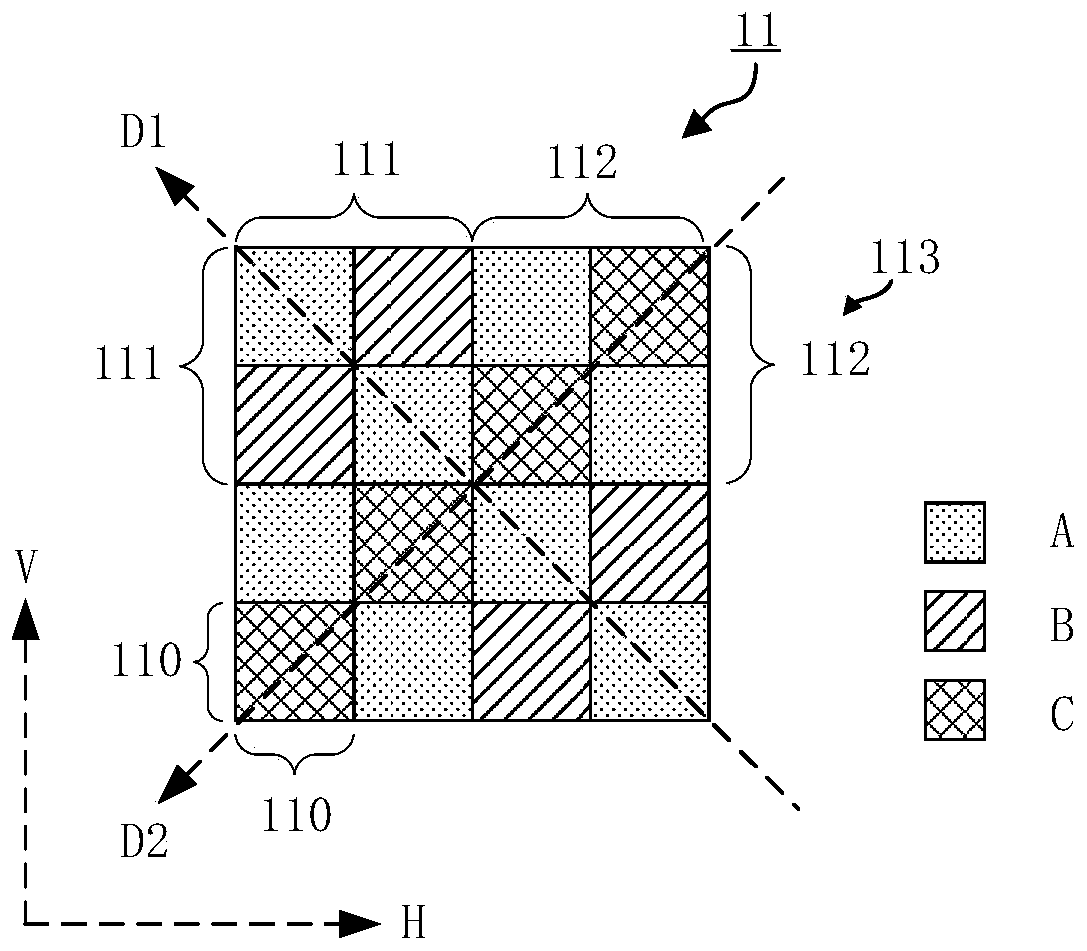

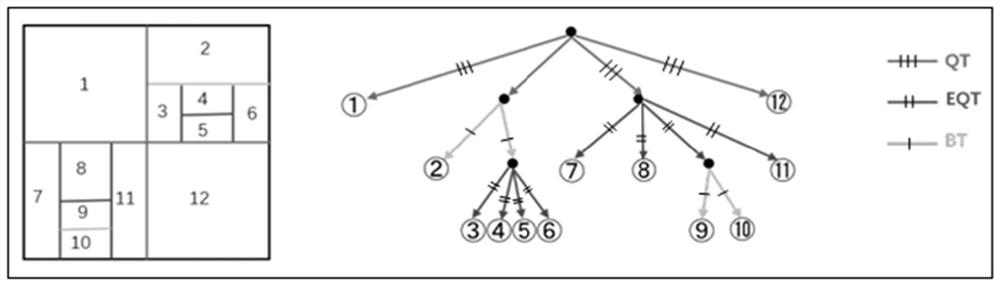

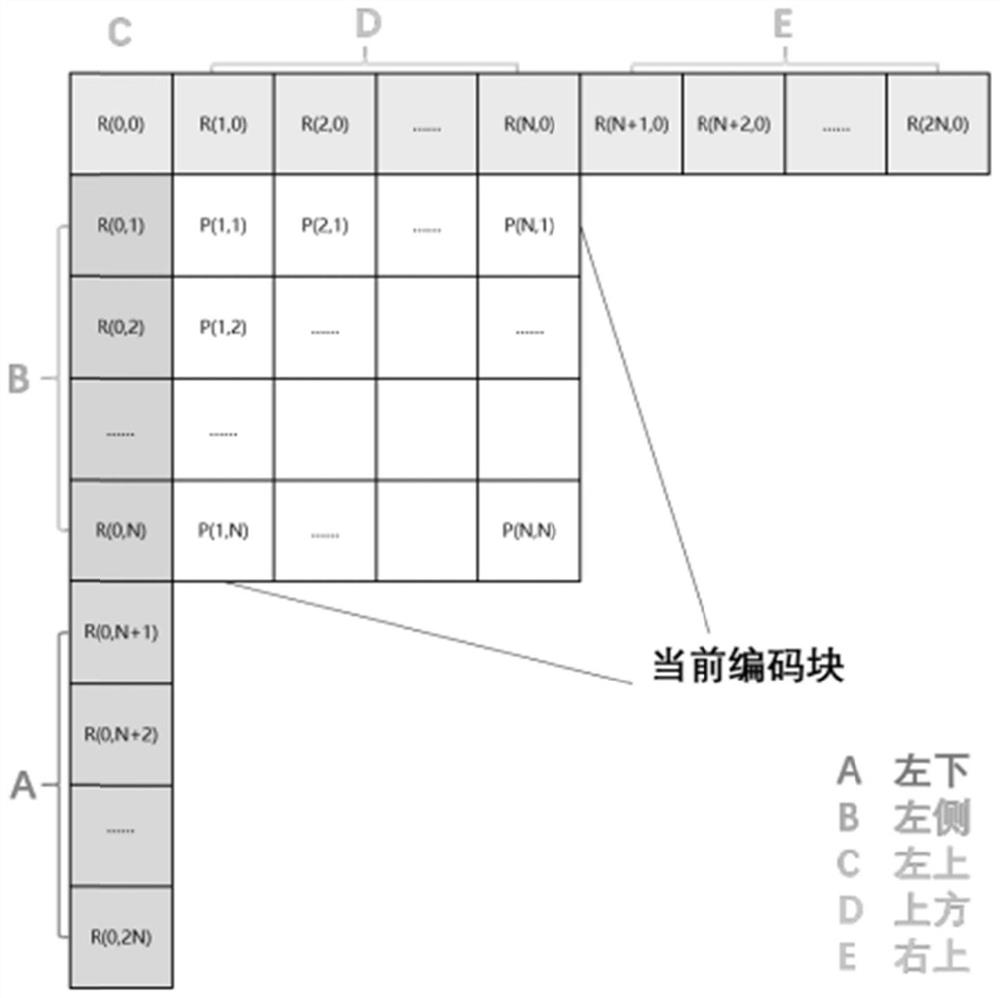

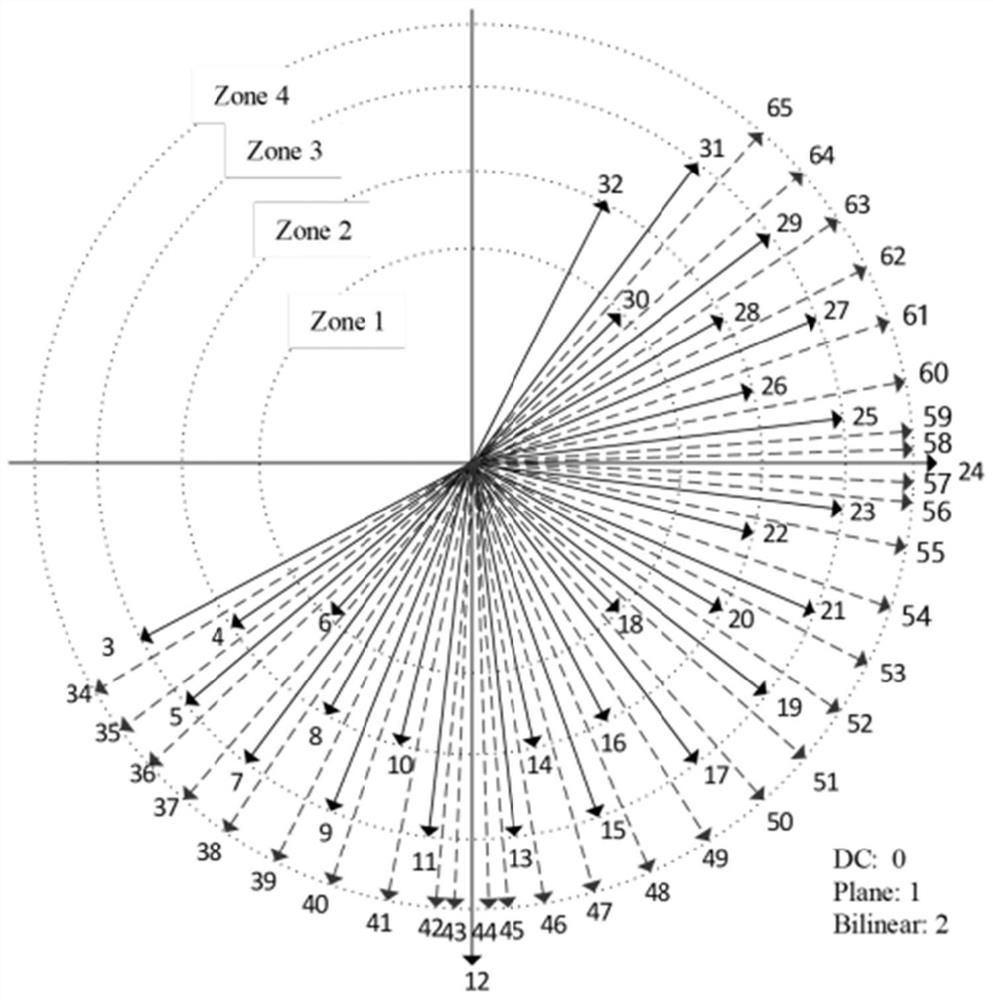

High efficiency video coding (HEVC) intraframe coding method, device and system based on texture direction

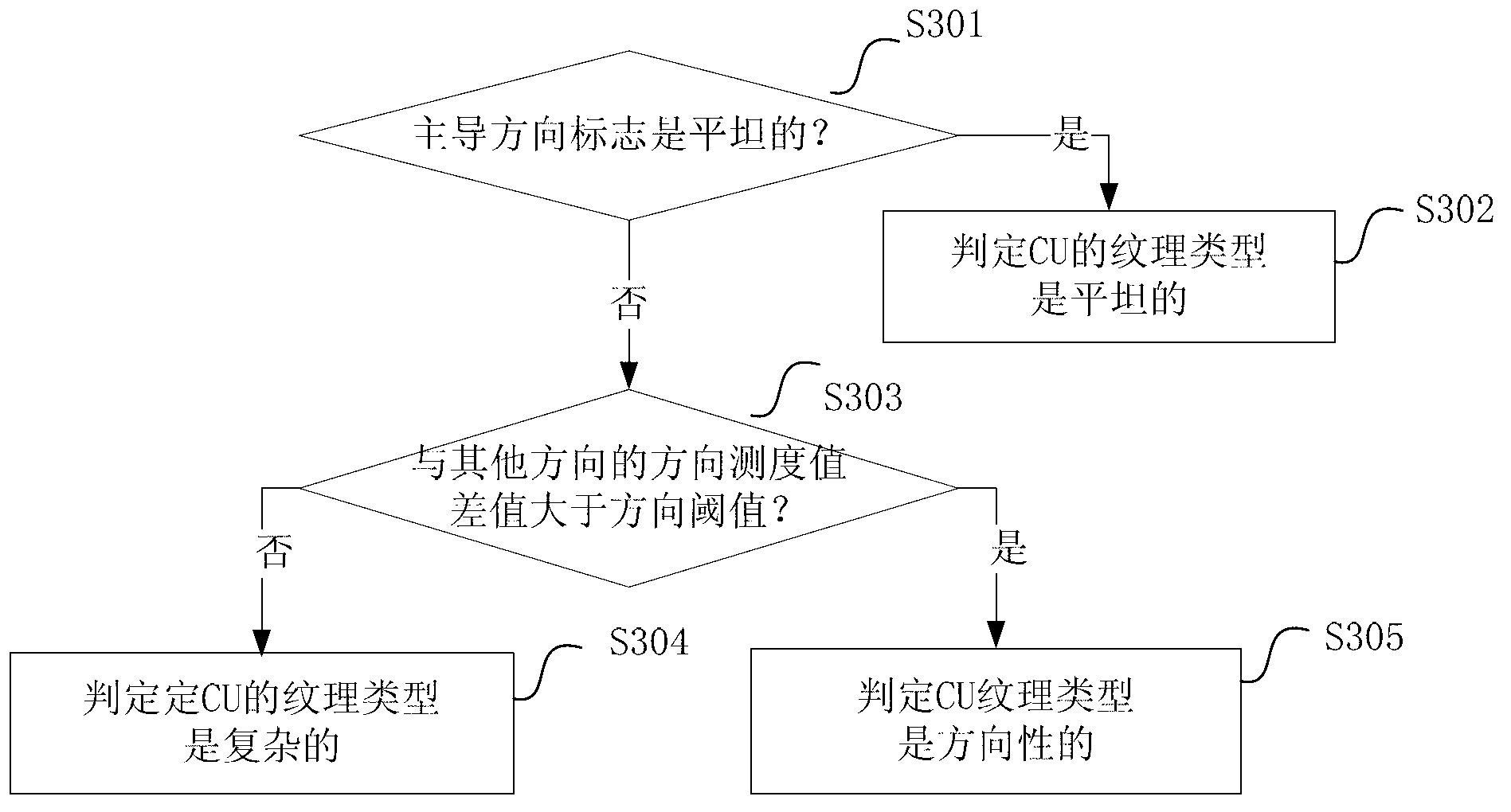

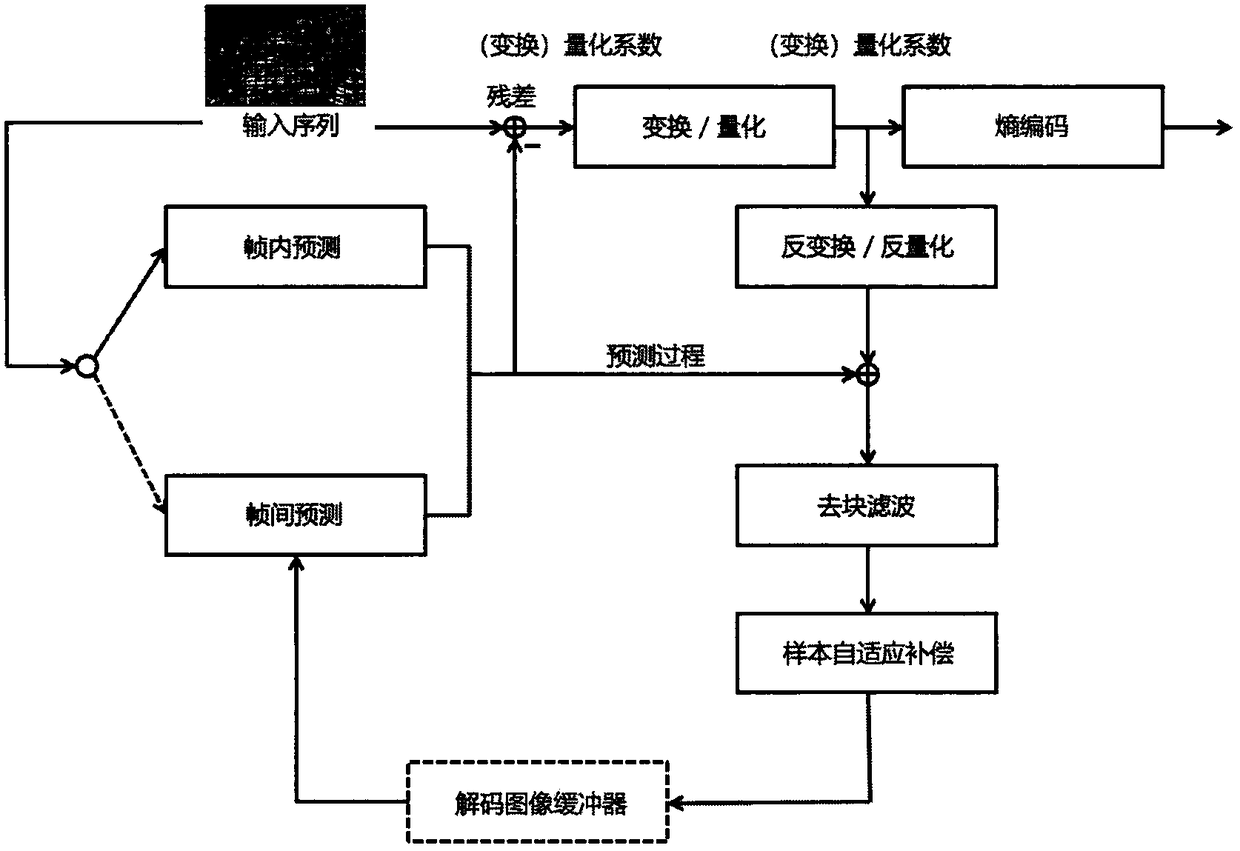

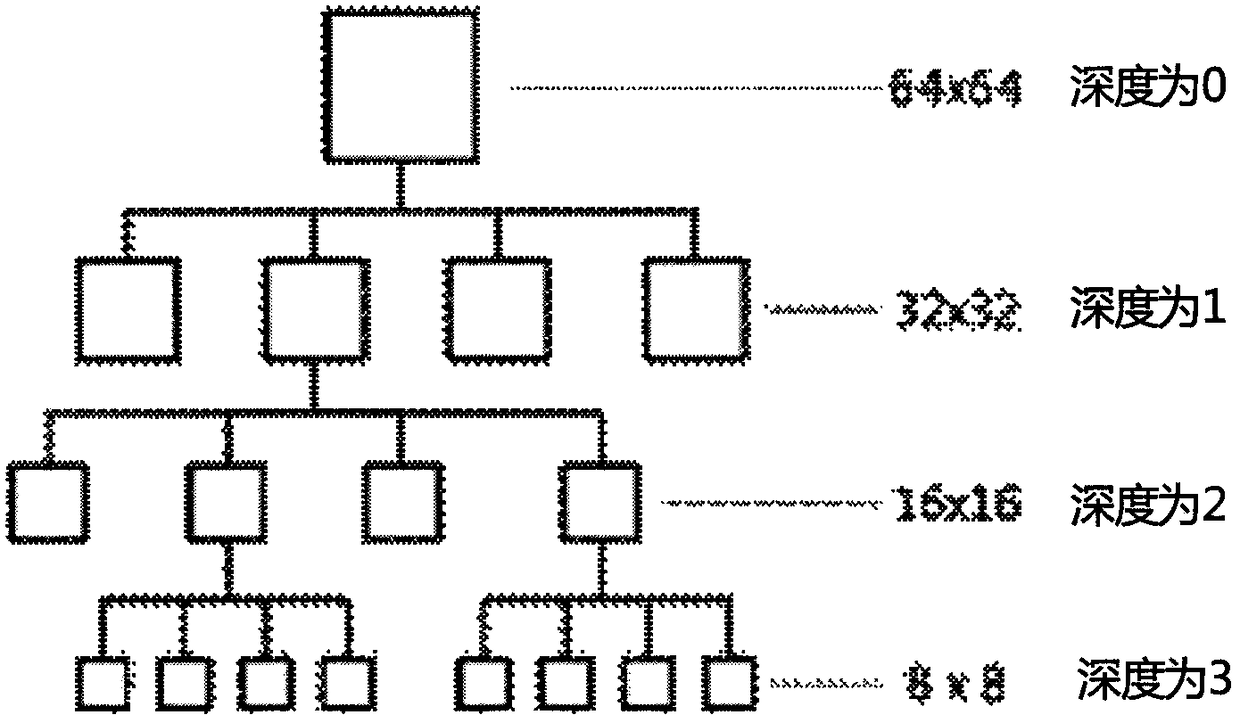

InactiveCN103297781AReduce complexityGood for real-time coding applicationsTelevision systemsPattern recognitionCoding block

The invention discloses a high efficiency video coding (HEVC) intraframe coding method, device and system based on a texture direction. The method comprises the steps of segmenting every frame of image into maximum coding units (CUs), enabling depth values of the maximum CUs to be set as 0; obtaining a depth value of a current CU; when the depth value is smaller than a depth threshold, calculating texture direction signs of the current CU, judging whether a texture type of the current CU is flat or directional, and if the texture type of the current CU is not flat or directional, segmenting the current CU, and adding 1 to the depth value of the current CU; when the depth value reaches the depth threshold, calculating texture direction signs of a prediction unit (PU); selecting a candidate mode set of prediction modes according to the texture direction signs of the CU and / or the PU, and determining an optimum prediction mode from the candidate mode set to perform coding. According to the HEVC intraframe coding method, device and system based on the texture direction, CU layer block segmentation optimization and PU layer prediction mode optimization are performed through texture direction signs of coding blocks, and accordingly coding complexity and coding time are greatly reduced.

Owner:ANKE SMART CITY TECH PRC +2

Aluminium alloy wire with high strength and high electrical conductivity, and preparation method thereof

InactiveCN102719709AHigh strengthImprove conductivityMetal/alloy conductorsCable/conductor manufactureFiberRoom temperature

The invention relates to a wire material of an aluminium alloy wire, and a preparation method thereof. An aluminium alloy wire with high strength and high electrical conductivity which has a high fiber texture degree is obtained through an ultra-low temperature rapid drawing process, and the aluminium alloy wire has a fiber texture degree of more than 60%, a tensile strength of more than 130Mpa, and an electrical conductivity of more than 63% IACS. According to the invention, a micro alloying design is performed by using composites of ferrum, scandium and the like which can form Al3Me type eutectic compound particles; a certain fiber texture is obtained through a drawing process by controlling a continuous casting and rolling process; the fiber texture degree is greatly increased and the distortion caused by room temperature deformation is reduced through the ultra-low temperature rapid drawing process; and the texture orientation and the texture degree of the aluminium wire after the drawing process are adjusted through an annealing treatment, the drawing stress is relaxed, the plasticity of the wire is recovered, the resistance of the wire is reduced and the electrical conductivity of the wire is increased. Compared with the prior art, the aluminium alloy wire and the preparation method of the invention can control the deformation process in micro alloying conditions to greatly increase the strength and the electrical conductivity of the wire.

Owner:SHENZHEN ZHAOFANG VENTURE TECH

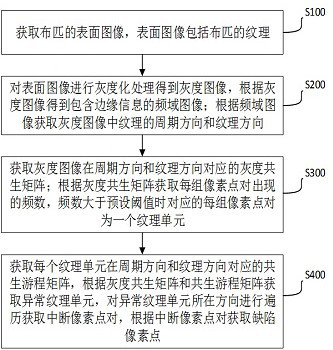

Cloth defect marking method and system based on machine vision

ActiveCN114529549AImprove accuracyImprove detection efficiencyImage enhancementImage analysisMachine visionGray level

The invention relates to the technical field of artificial intelligence, in particular to a cloth defect marking method and system based on machine vision. Obtaining a surface image including the texture of the cloth, obtaining a gray level image corresponding to the surface image, and obtaining a frequency domain image including edge information according to the gray level image; further obtaining the periodic direction and the texture direction of the texture in the gray level image; according to a gray level co-occurrence matrix corresponding to the period direction and the texture direction; selecting each group of corresponding pixel point pairs in the gray level co-occurrence matrix when the occurrence frequency is greater than a preset threshold value as a texture unit; and obtaining a symbiotic run matrix corresponding to each texture unit in the period direction and the texture direction, obtaining an abnormal texture unit according to the gray level co-occurrence matrix and the symbiotic run matrix, obtaining an interruption pixel point pair according to the abnormal texture unit, and obtaining a defect pixel point according to the interruption pixel point pair. Errors caused by noise points of the image are avoided, and efficiency and accuracy of cloth defect detection are improved.

Owner:南通东德纺织科技有限公司

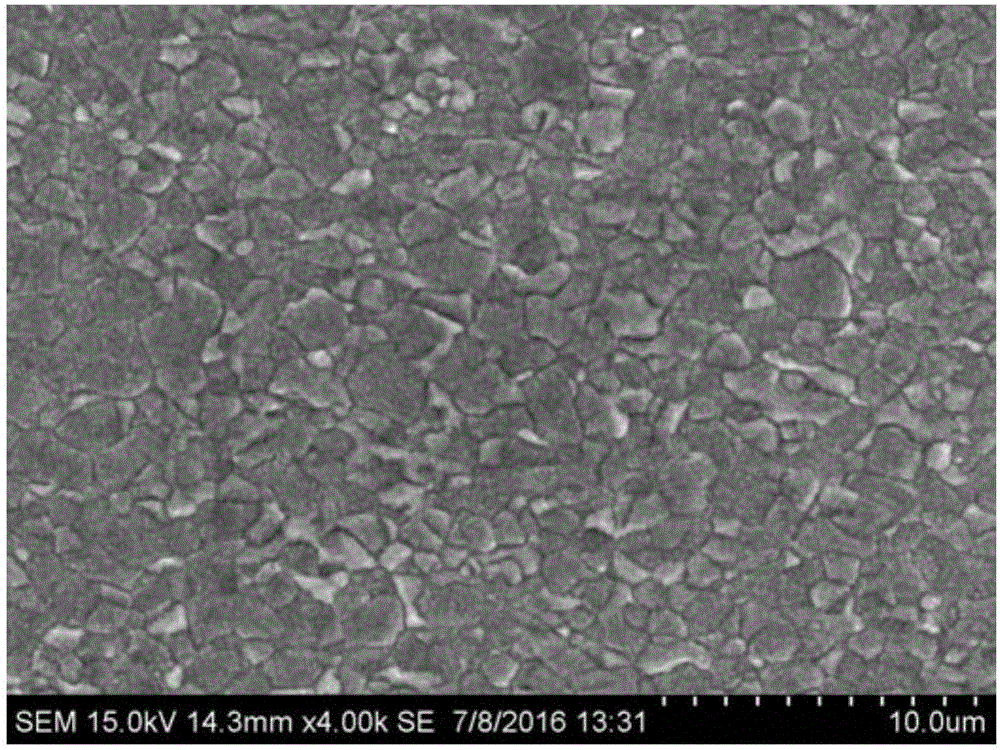

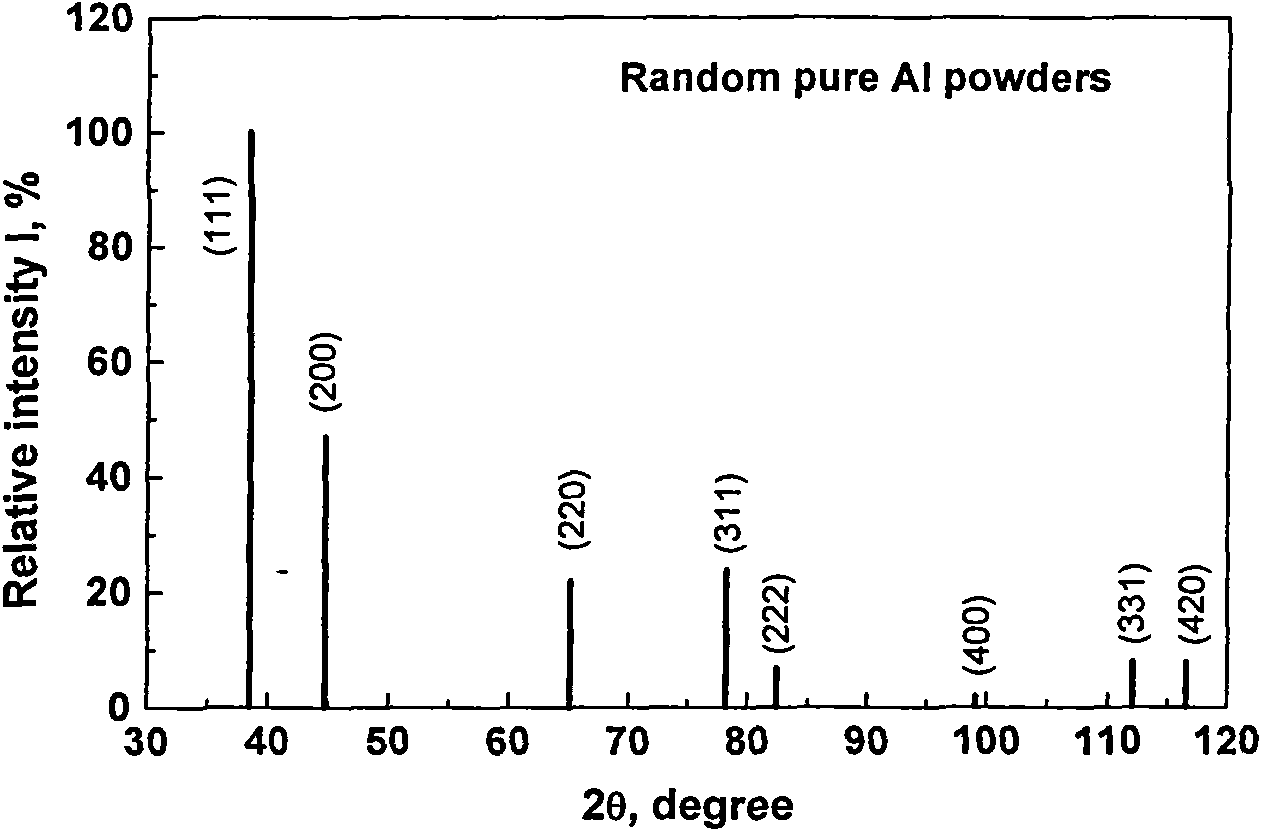

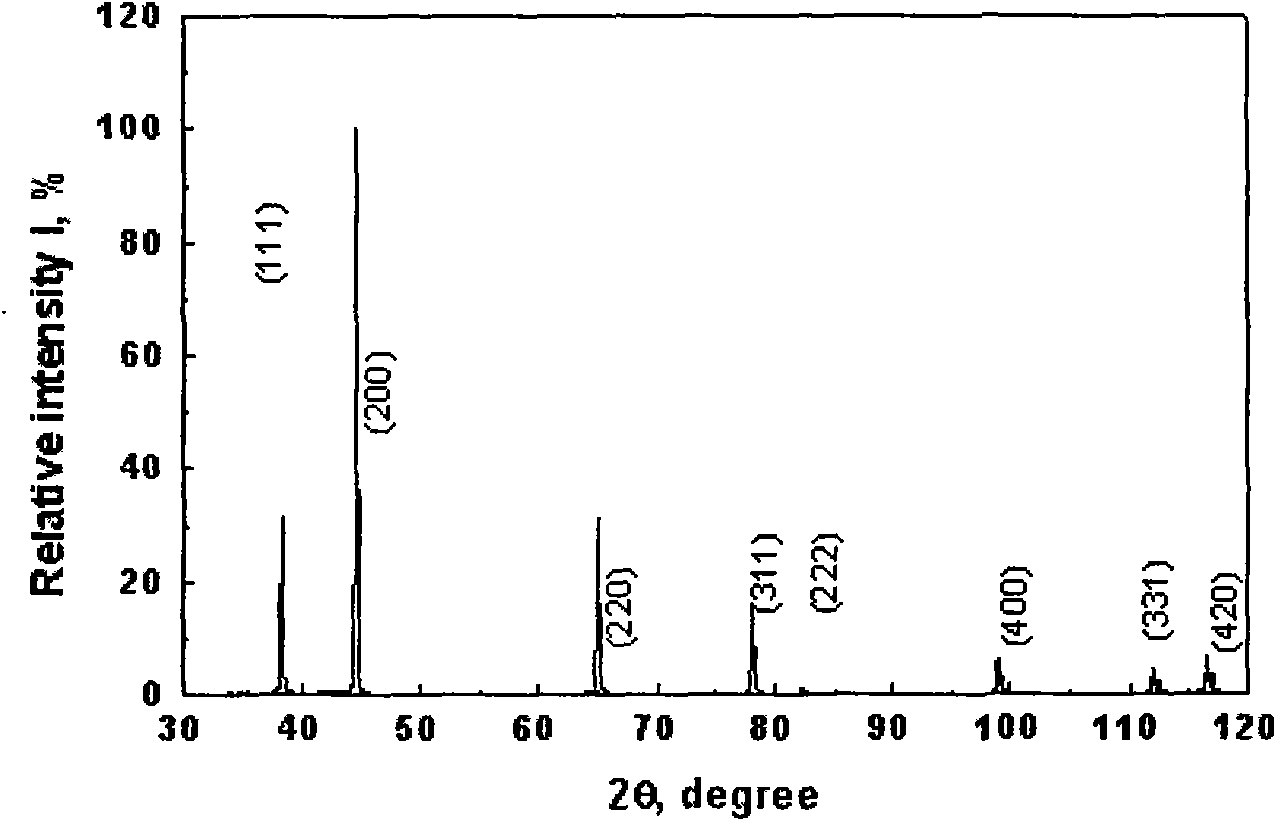

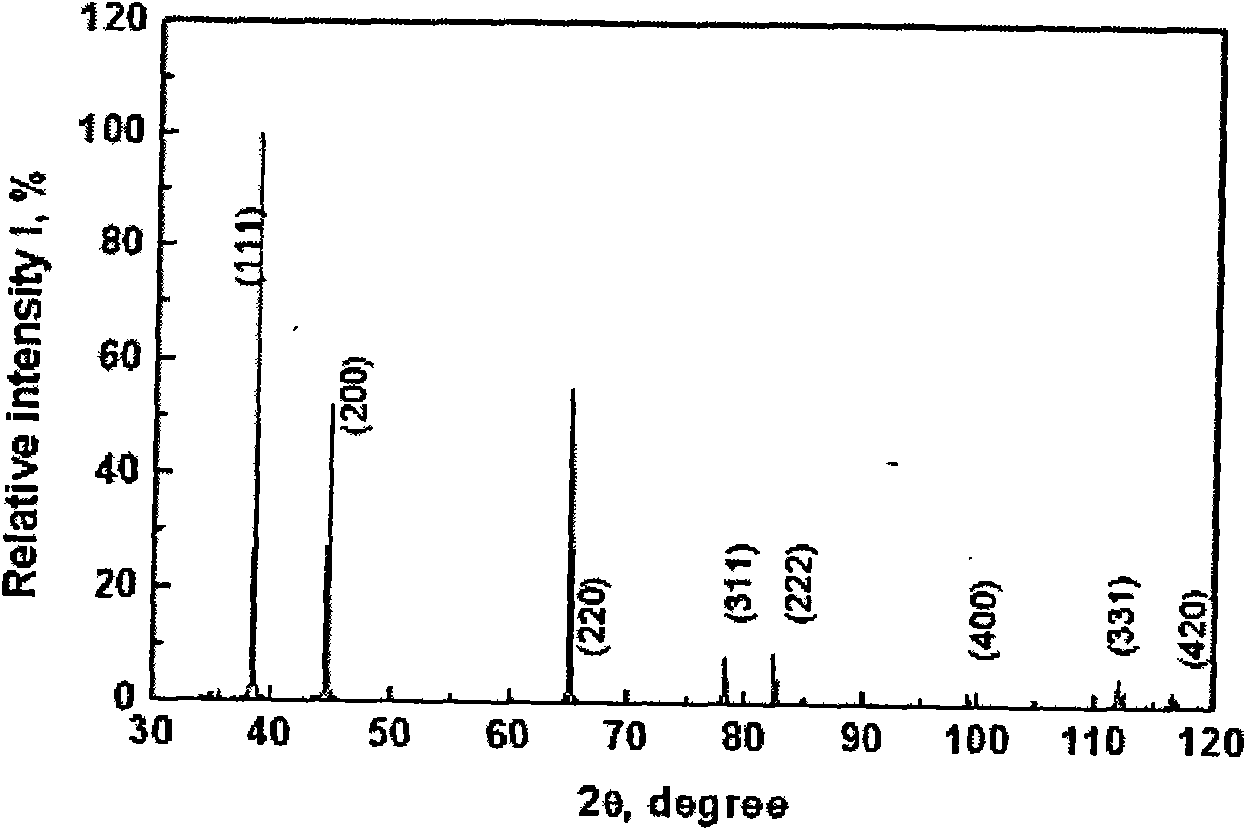

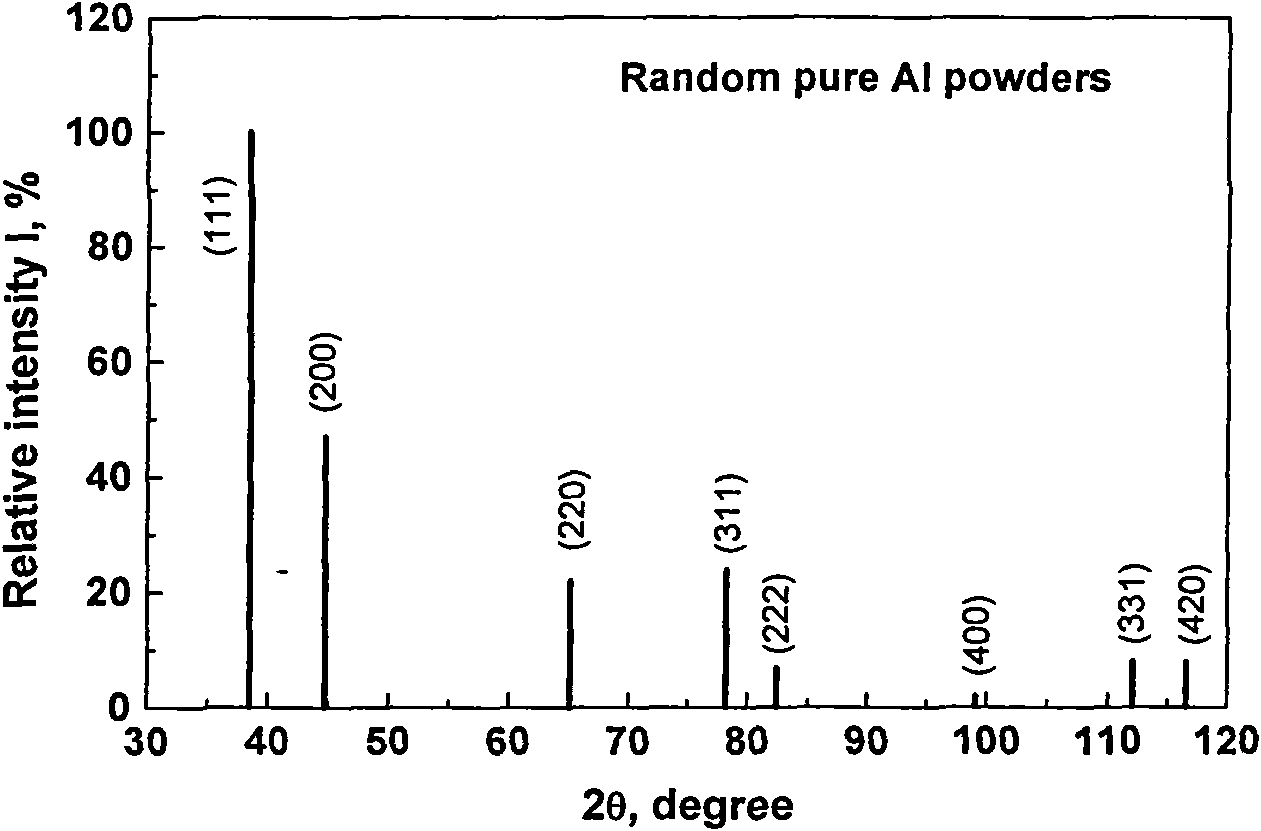

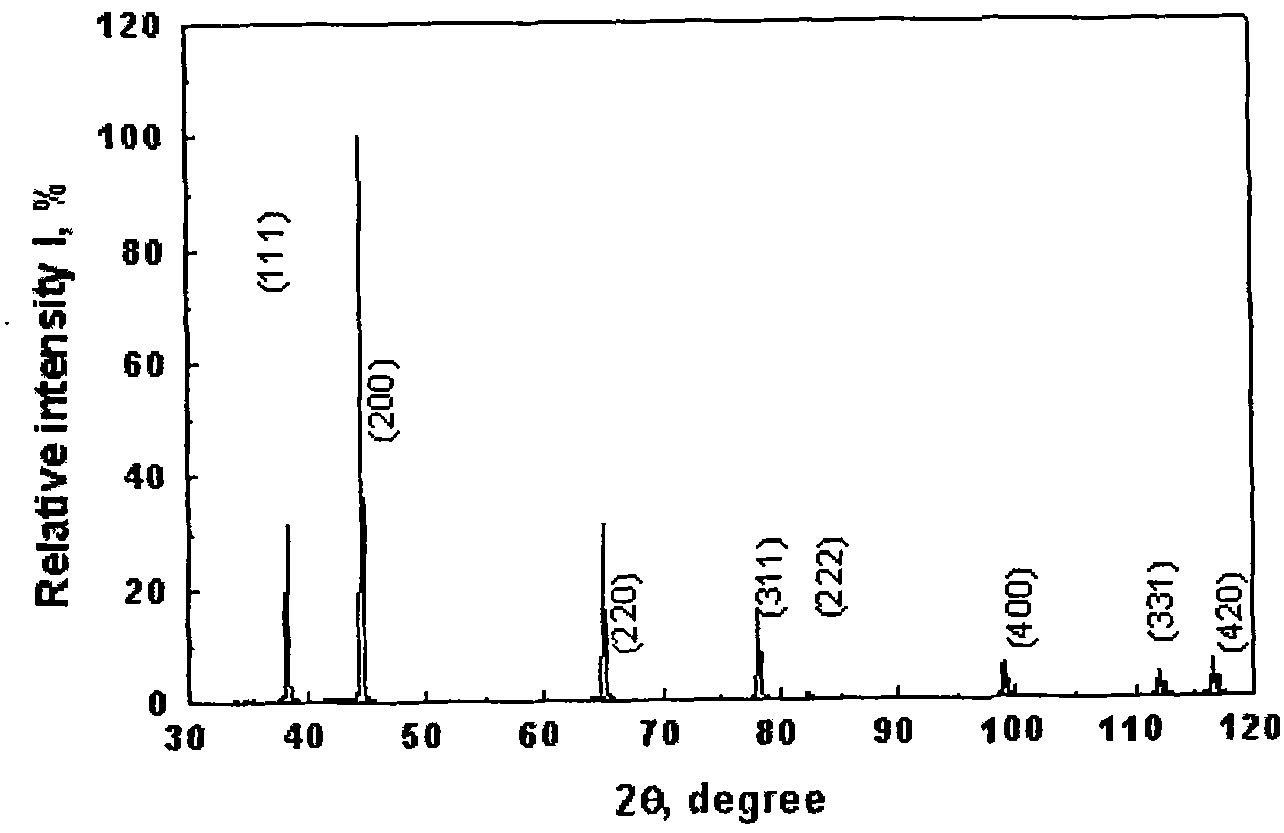

Preparation method of ultrahigh-purity aluminum target

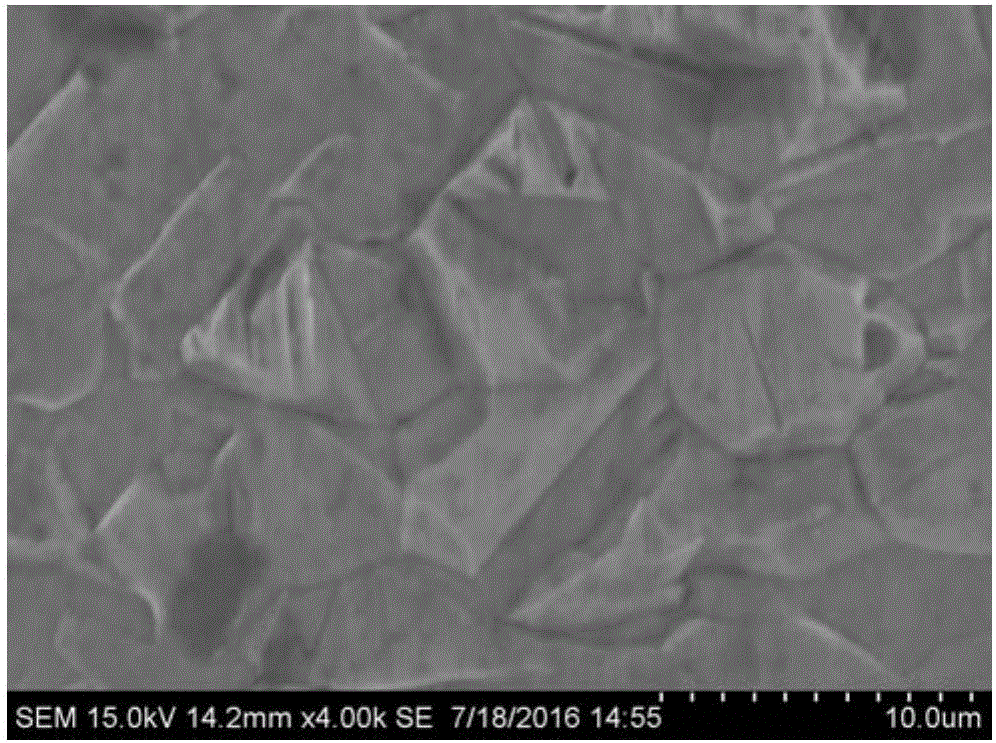

ActiveCN106282945AHigh purityFine and uniform grainVacuum evaporation coatingSputtering coatingIngotEnergy consumption

The invention relates to a preparation method of an ultrahigh-purity aluminum target. The preparation method comprises the following steps: (1) the surface of an ultrahigh-purity aluminum ingot with a purity of higher than 99.999 wt% is milled to remove an oxide layer thereof; (2) the ingot is heated to 230-400 DEG C; (3) the hot rolling of 10-20 passes is performed for the heated ingot; the single-pass reduction is controlled within 20-60 mm; and the final rolling temperature in final pass is controlled below 350 DEG C; (4) the annealing treatment with a temperature of 200-300 DEG C and an insulation time of 1-2 h is performed for a hot-rolled aluminum plate; and (5) the plate is straightened for milling to obtain the ultrahigh-purity aluminum target with average grains of 80-150 microns. The preparation method can prepare the target with high purity, fine and uniform grains and consistent texture orientation to satisfy the use requirements of PVD; and meanwhile, the preparation method is simple in process, easy to operate and convenient for large-scale industrial production, effectively reduces the energy consumption, and reduces the cost.

Owner:CHINALCO RUIMIN

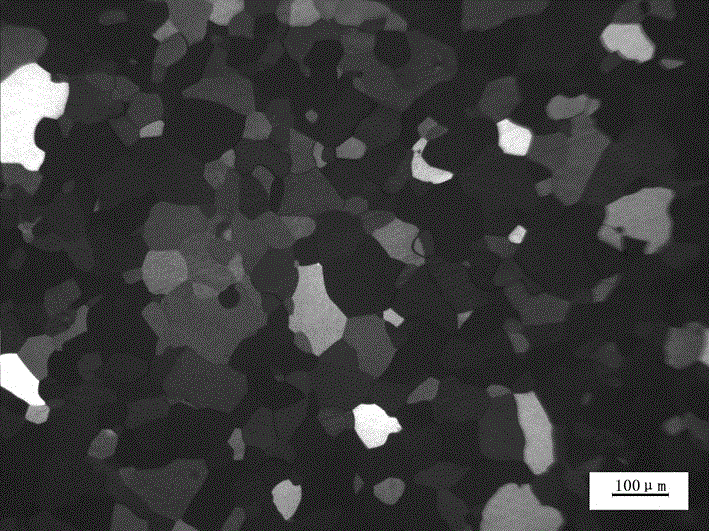

Surface-modified coated cutting tool and preparation method thereof

ActiveCN103205728AImprove and optimize texture orientationTexture Orientation ObviousTurning toolsChemical vapor deposition coatingDeposition temperatureCoated surface

The invention discloses a surface-modified coated cutting tool and a preparation method thereof. The cutting tool comprises a tool substrate and a coating which is coated on the substrate. The coating comprises an Al(Zr)2O3 modification coating. The modification coating has obvious texture orientations on both (110) and (300) crystal planes, and has columnar structures with smooth surfaces. The preparation method provided by the invention comprises the steps that: a TiN layer, a TiCN layer, a TiCO layer, and an alpha-Al2O3 layer are sequentially deposited on the tool substrate by using an existing CVD process; and the following process conditions are used for depositing the modification coating: multiple gases are adopted as a deposition atmosphere system; deposition temperature and pressure are controlled, and atmosphere concentrations of specific gases are adjusted; deposition thickness is controlled; and coating surface post-treatment is not carried out after deposition is finished, and the coated cutting tool is directly obtained. The cutting tool provided by the invention has uniform surface thickness, extremely smooth coating surface, and improved microstructure and coating crystal plane orientation.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

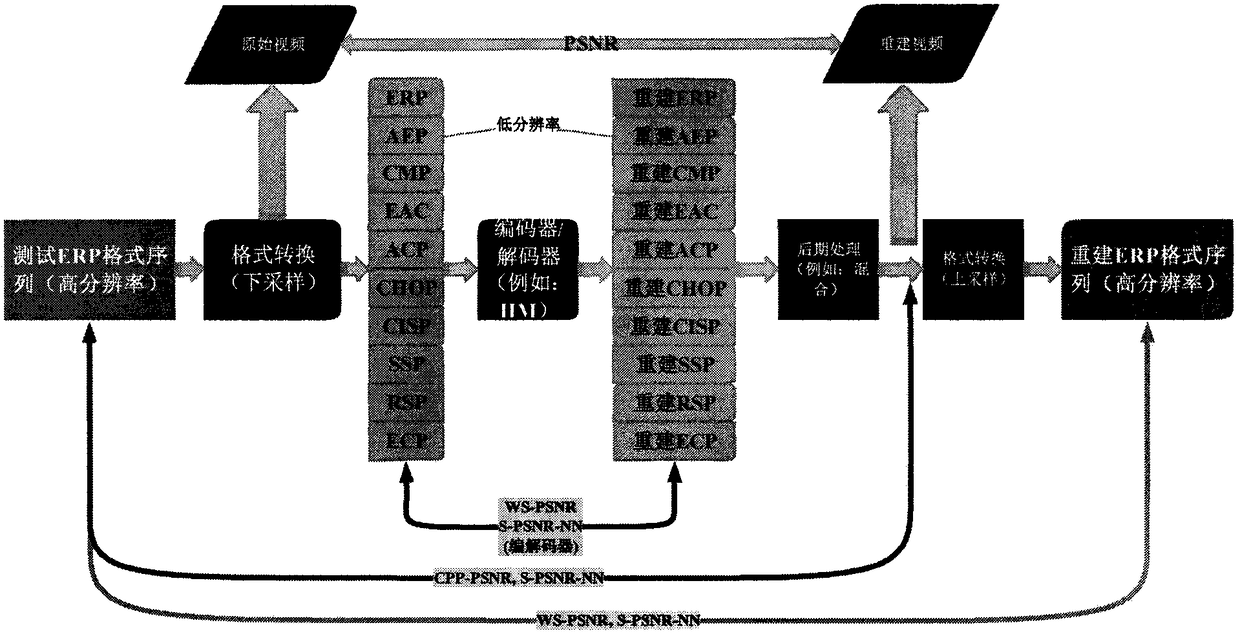

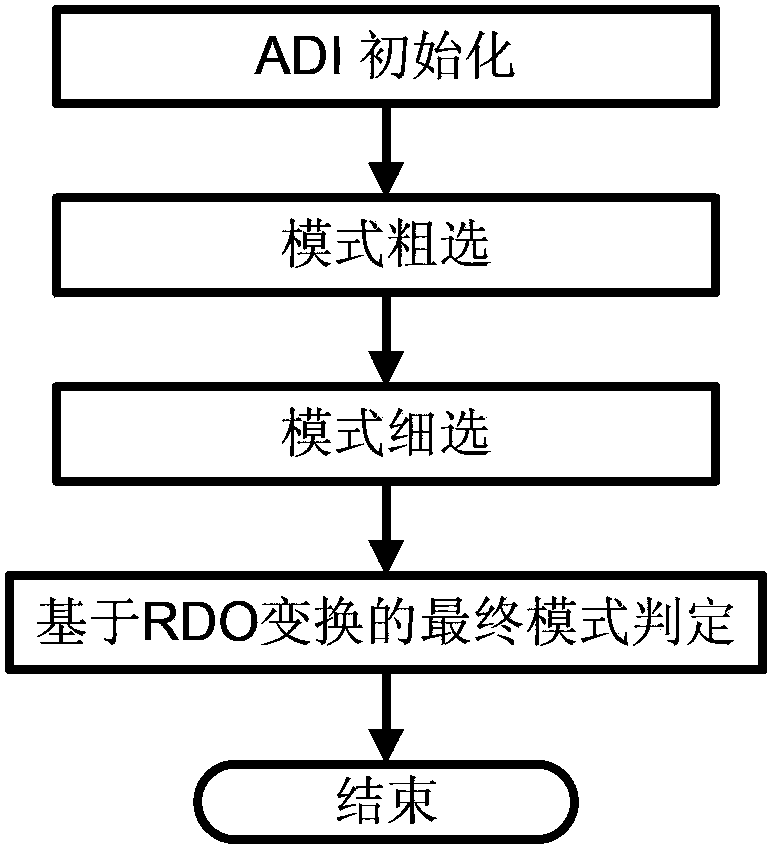

Fast decision of 360-degree video intra-frame prediction based on texture features

360-degree video has ultra-high resolution (usually 4K to 8K), resulting in a significant increase in encoding time. In order to reduce the coding complexity, a 360-degree video intra-frame predictionfast decision-making device based on texture features is designed. On one hand, the proposed decision method is based on the texture complexity to determine whether to terminate the coding unit partition as soon as possible; on the other hand, the proposed method reduces the number of candidate patterns according to the texture directionality. The two methods can be used simultaneously or separately.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

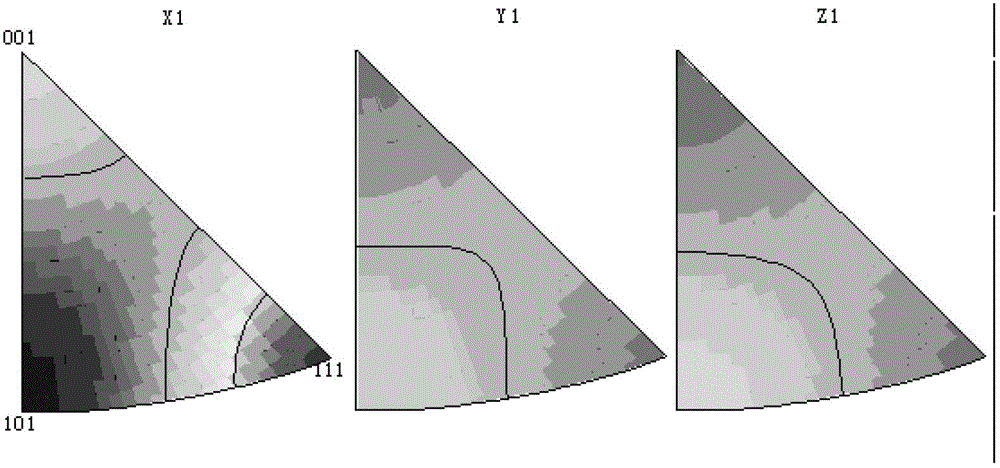

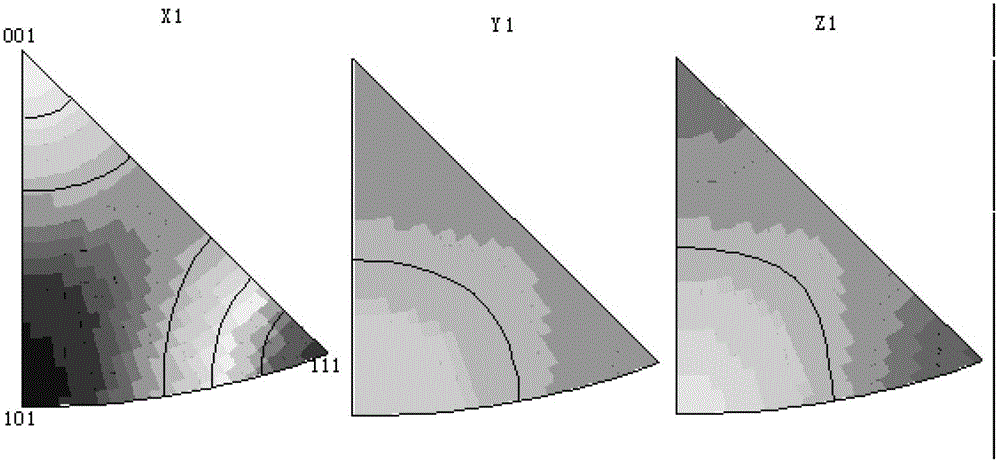

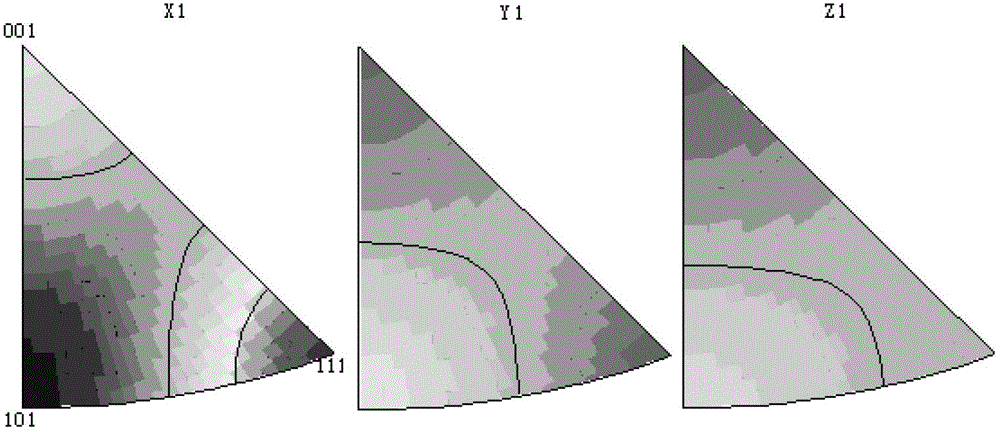

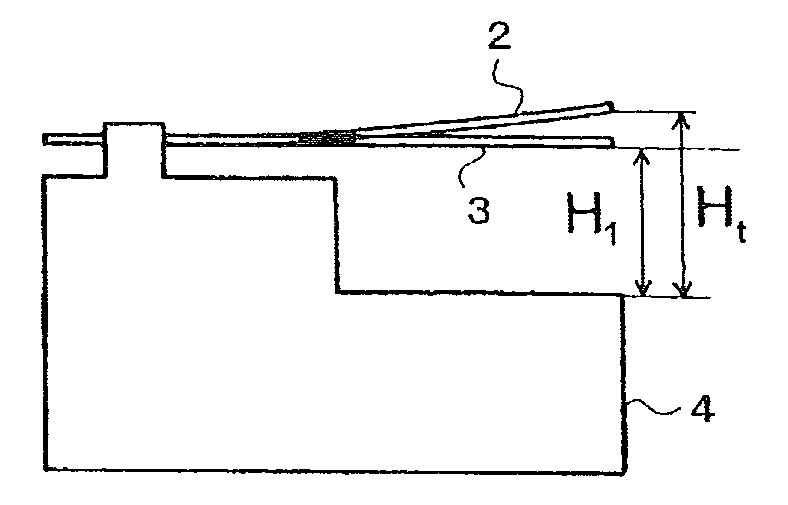

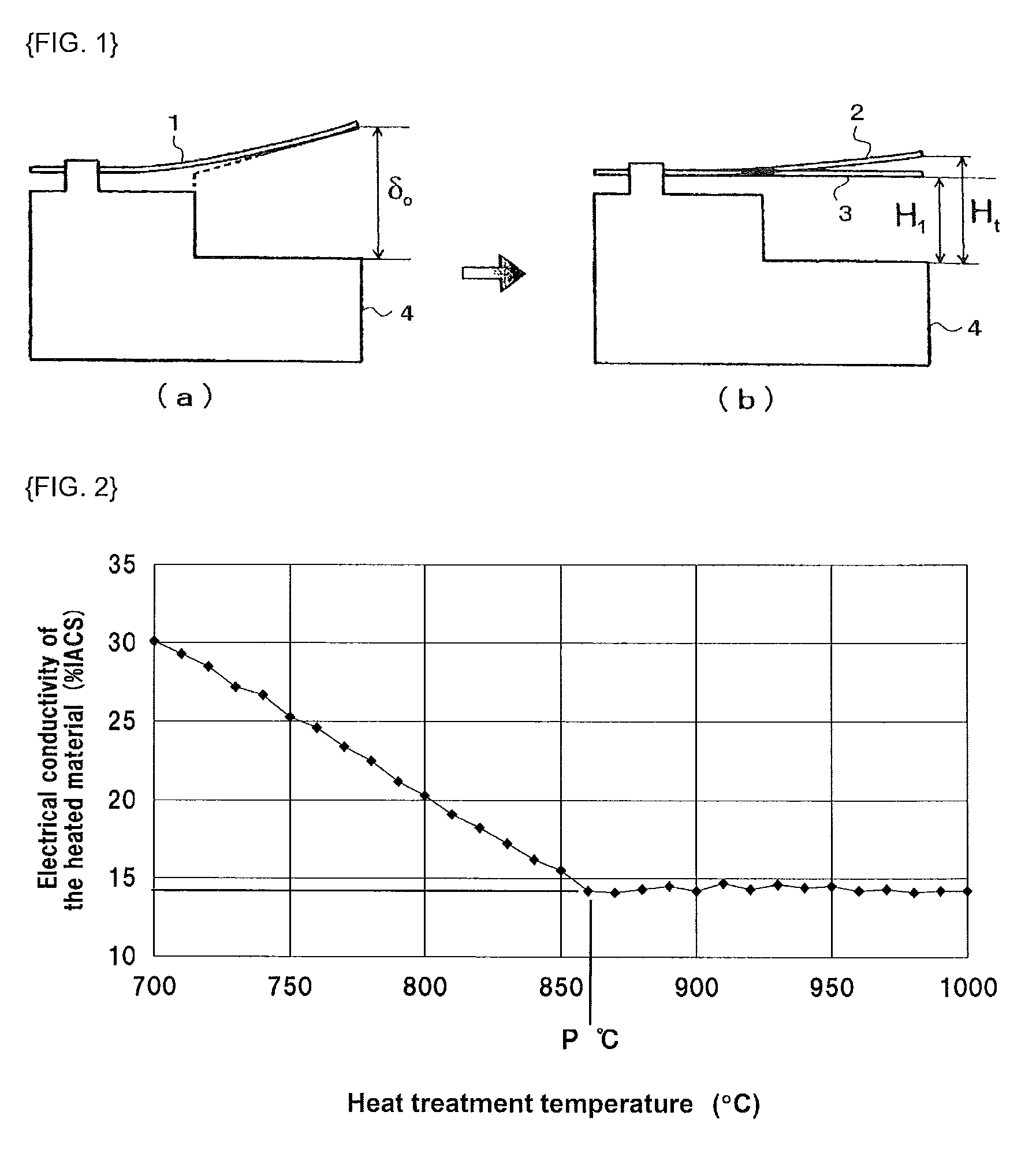

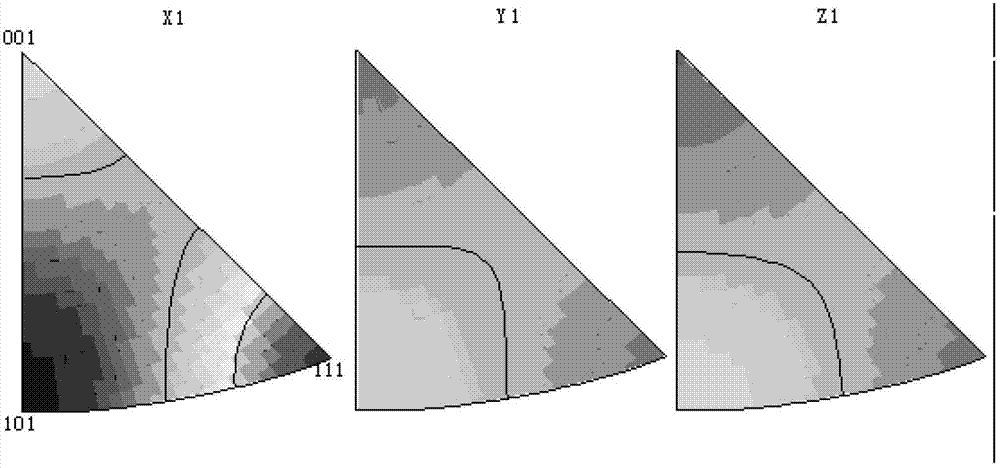

Copper alloy sheet material and method of producing the same

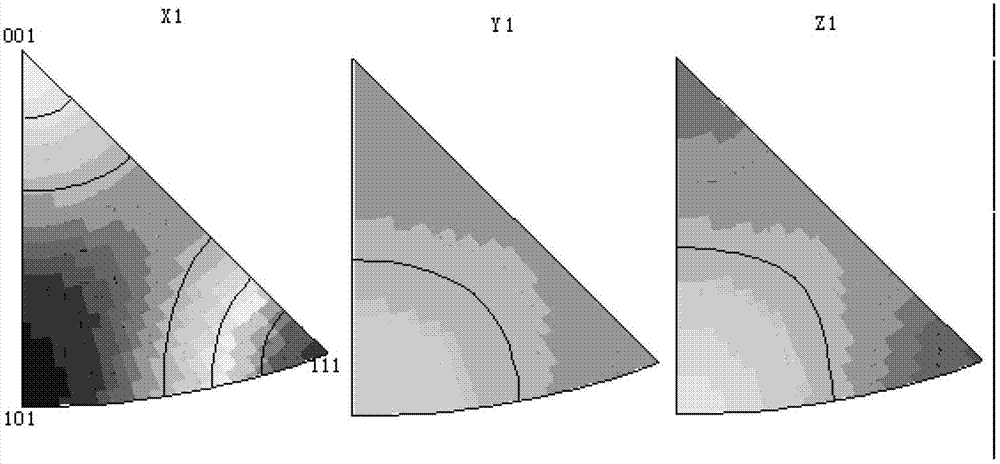

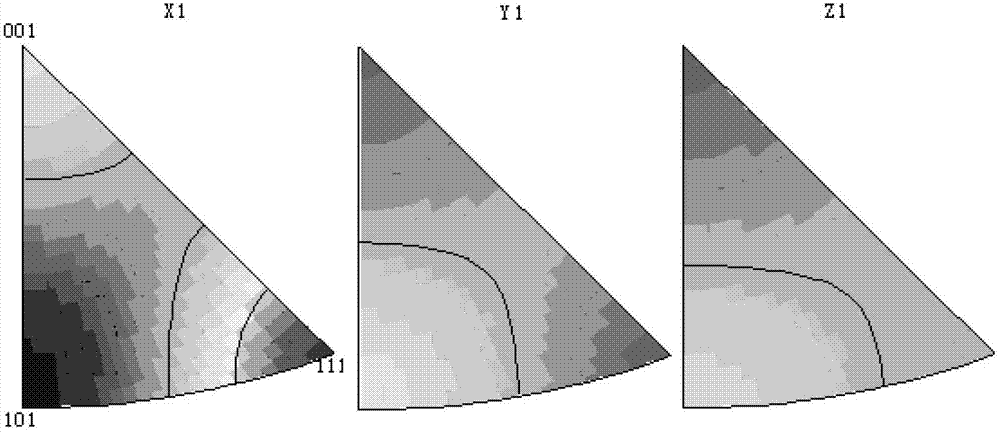

InactiveUS20120267013A1High mechanical strengthConductive materialMetal/alloy conductorsCrystal orientationArea ratio

A copper alloy sheet material, having an R value of 1 or greater, which is defined by:R=([BR]+[RDW]+[W]) / ([C]+[S]+[B])wherein [BR], [RDW], [W], [C], [S], and [B] represent an area ratio of crystal texture orientation component of BR orientation {3 6 2}<8 5 3>, RD-rotated-cube orientation {0 1 2}<1 0 0>, cube orientation {1 0 0}<0 0 1>, copper orientation {1 2 1}<1 1 1>, S-orientation {2 3 1}<3 4 6>, and brass orientation {1 1 0}<1 1 2>, respectively, in crystal orientation analysis in an EBSD (electron back scatter diffraction) analysis, and having a proof stress of 500 MPa or greater, and an electrical conductivity of 30%IACS or higher; and a production method of the same.

Owner:FURUKAWA ELECTRIC CO LTD

Processing method of long-service-life copper manganese alloy target material

InactiveCN106399954AExtend your lifeIncrease profitVacuum evaporation coatingSputtering coatingManufacturing technologyManganese

The invention discloses a processing method of a long-service-life copper manganese alloy target material, and belongs to the technical field of sputtering target material manufacturing. The method mainly comprises the steps that a copper manganese alloy cast ingot is processed by a conventional heat mechanical treatment method to obtain an original blank; the original blank is subjected to grain refinement through stirring and friction processing; the preparation of the long-service-life copper manganese alloy target material is realized; the service life of the target material can be effectively prolonged; and the utilization rate of the target material is improved. The obtained long-service-life copper manganese alloy target material has the advantages that the average grain size is less than 5 [mu]m; the service life can reach 3000kwh; and the texture orientation is in random distribution, so that the requirement of the technical process of 45nm or lower of an integrated circuit can be met.

Owner:GRIKIN ADVANCED MATERIALS

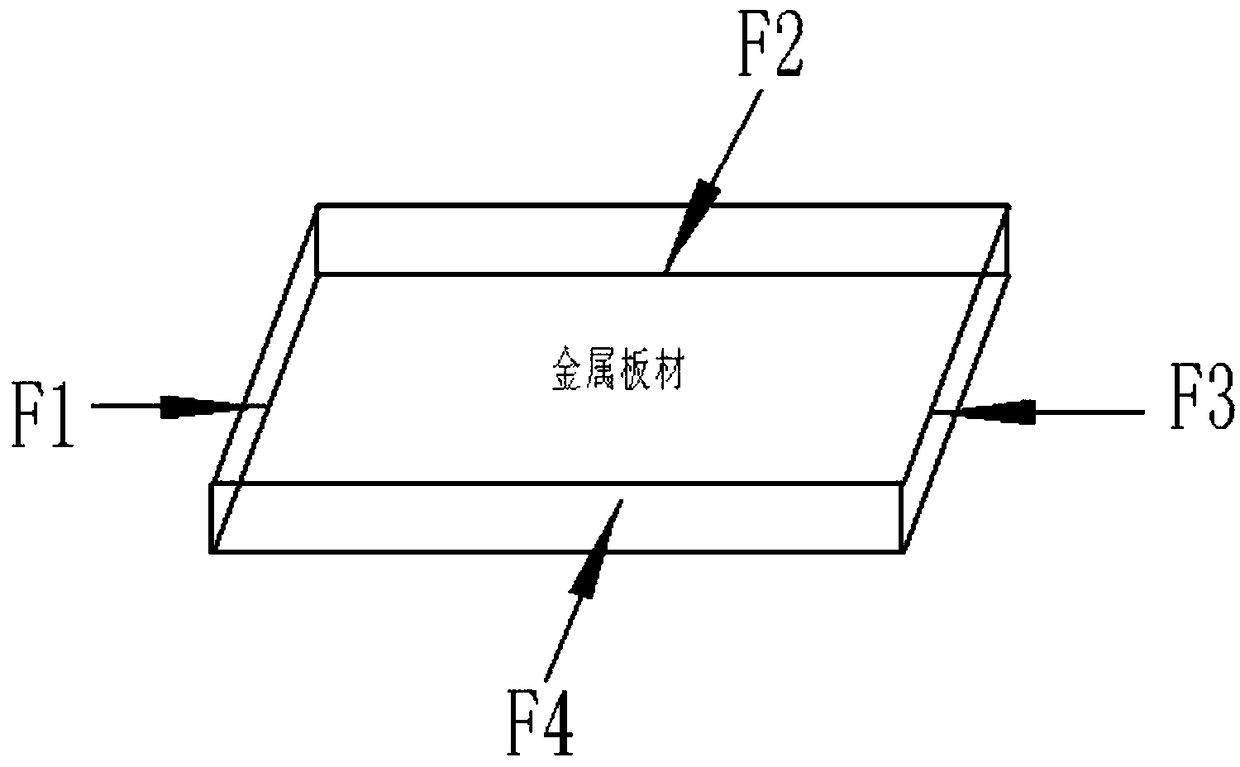

Rolling method of sheet metal

ActiveCN102000695AImprove roll formabilityReduce edge crackingMetal rolling arrangementsCrystal structureTransverse compression

The invention relates to a rolling method of the sheet metal and the method comprises the steps of pretreatment and rolling. In the pretreatment step, a transverse compression stress or normal tensile stress is applied on the sheet material before the rolling step to ensure the sheet material to generate plastic strain. In the method of invention, the sheet material is pretreated before rolled, namely the special stress is applied on the sheet material to change the texture orientation of the sheet material, thus weakening or eliminating basal texture and increasing the rolling formability ofthe sheet material to a great extent, namely cracks can not appear under a large reduction. Therefore, the edge cracks of the sheet material which are generated in the rolling process can be reduced,the rolling efficiency can be increased and the production cost can be reduced; and the rolling method is suitable for the rolling of the metals with dense-hexagonal crystal structure such as magnesium alloy, the rolling reduction of magnesium alloy per pass is more than 60%, and the edge cracks can not be generated.

Owner:深圳市怡康乐科技有限公司

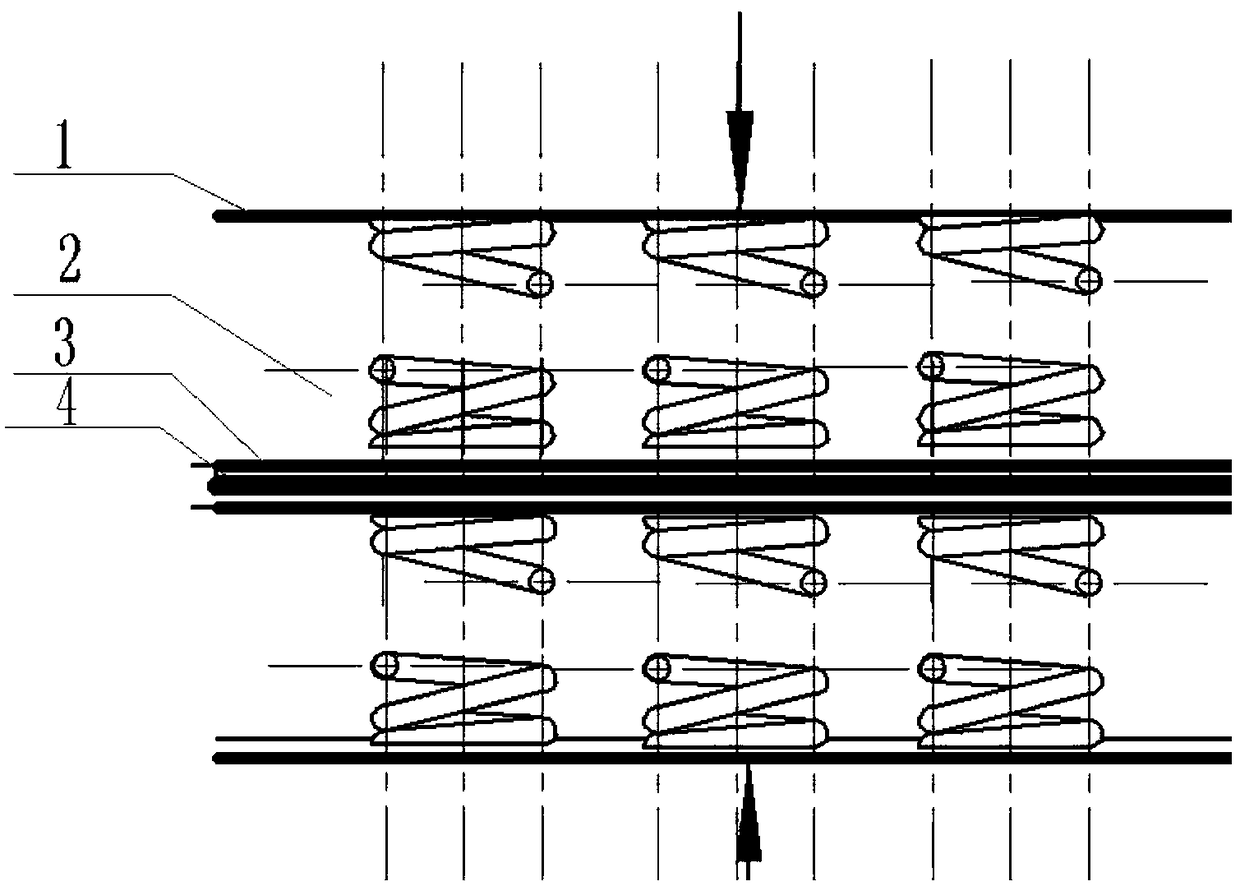

Preparation method of texture controllable fine grain metal material based on large strain deformation and recrystallization

ActiveCN101660034AUniform continuous large strain pre-deformationReduce energy consumptionHardnessThermal treatment

A preparation method of texture controllable fine grain metal material based on large strain deformation and recrystallization includes large strain predeformation and recrystallization heat treatment. The preparation method is characterized in that the large strain predeformation includes that blanks are firstly subject to rolling by multi-pair rolling wheels, so that the blanks get thinner and deformation degree of the blanks rolled by multi-pair rolling wheels is not less than 50%; secondly an equal channel angular pressing mould is arranged at the outlet of the last pair of rolling wheel,so that the thinner blanks after rolling carry out ECAP deformation; and the recrystallization heat treatment includes that the blanks after the large strain deformation are fed into a thermal treatment furnace, temperature is maintained to be 150-500 DEG C for 0.5-2h, and then air cooling is carried out. The invention combines the advantages of the multi-pair wheel rolling technology and the equal channel angular pressing technology and can realize energy-saving, high-efficiency, continuous and uniform large strain deformation processing of metal material; and the prepared metal material hasthe characteristics of small grain crystal, strength and hardness far higher than supply state and wonderful texture orientation and the like.

Owner:JIANGYIN HENGYE FORGING

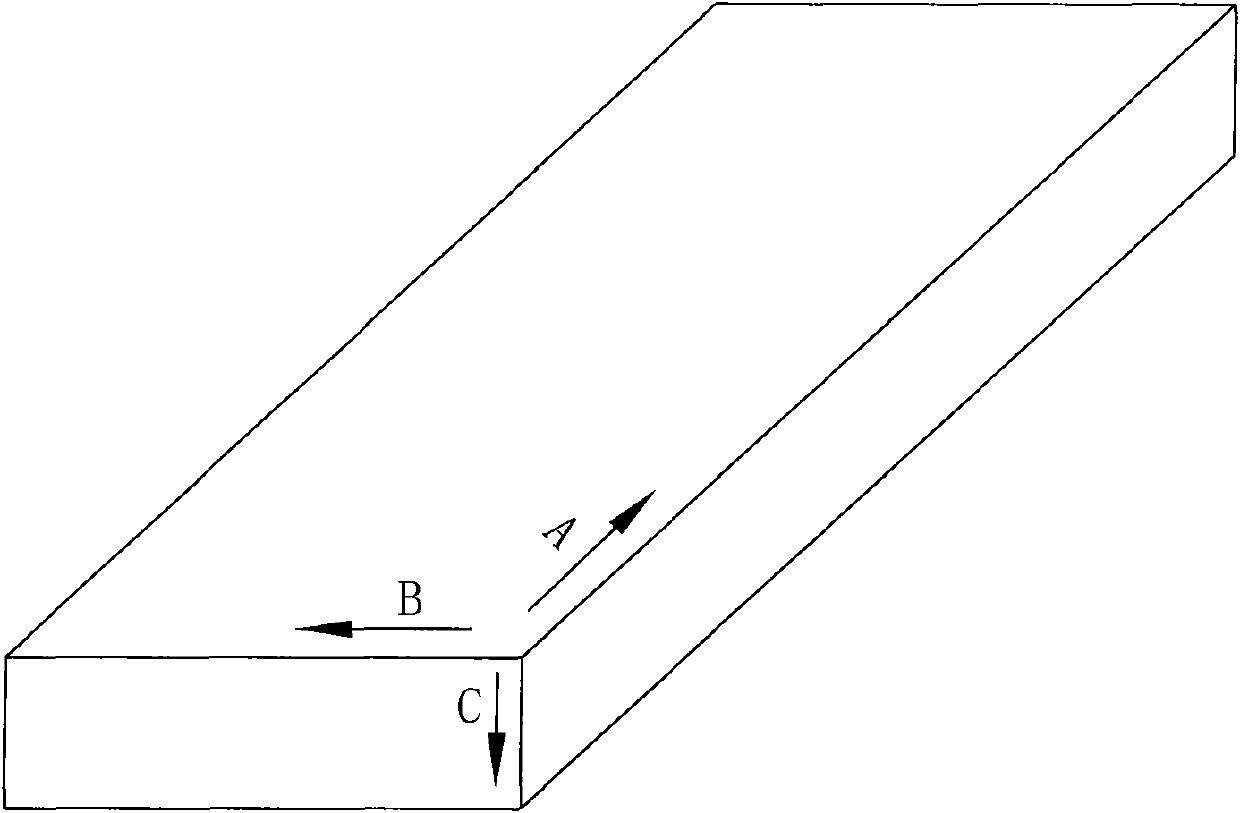

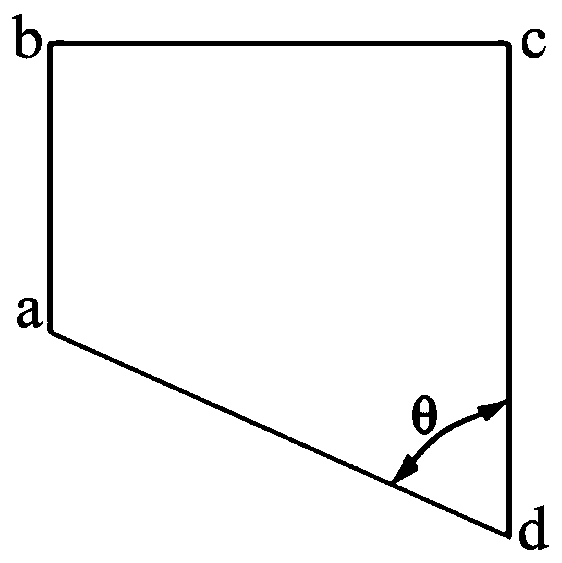

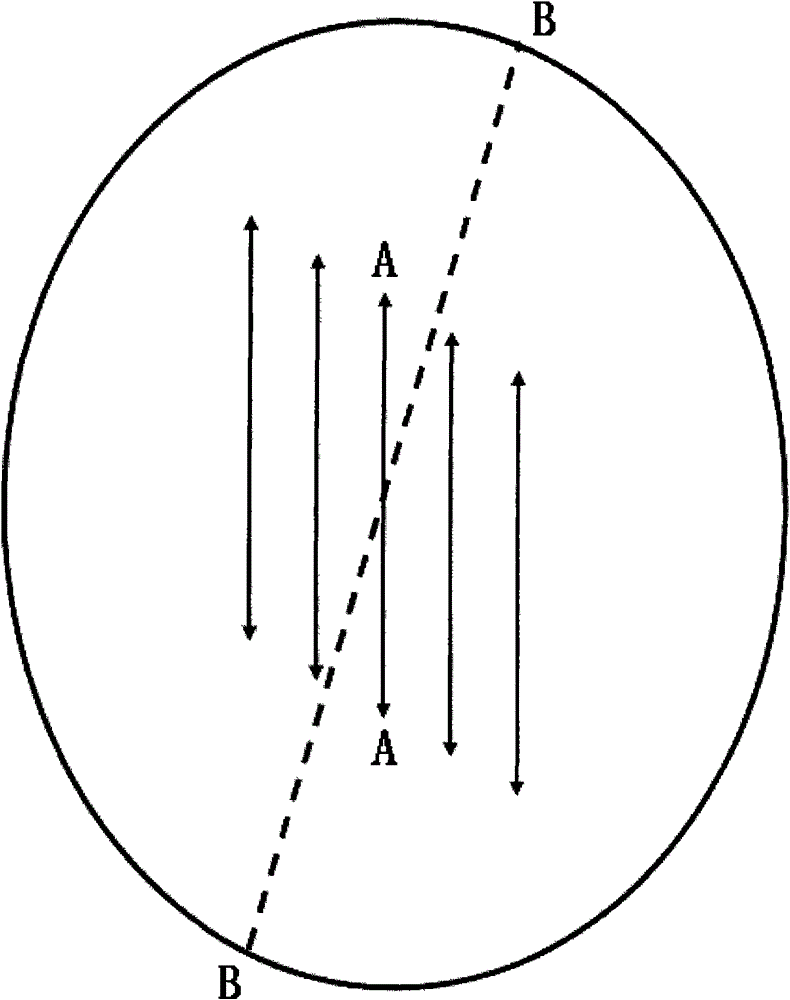

Die and method for regulating and controlling formability of magnesium alloy plate through gradient strain

ActiveCN109940094AGood formabilityWeakened textureShaping toolsFurnace typesMaterials scienceMagnesium alloy

The invention discloses a die and method for regulating and controlling formability of a magnesium alloy plate through gradient strain. The die comprises a fixing plate and a clamping plate, wherein the fixing plate is connected with the clamping plate through a connecting plate; the fixing plate consists of a plate A and a plate B, wherein the plate A is fixed with the connecting plate, and the plate B can freely slide along the connecting plate; a strain area for storing a gasket and the magnesium alloy plate is arranged between the plate A and the plate B; the gasket and the magnesium alloyplate are both provided with inclined edges with an angle theta; the gasket and the magnesium alloy plate are superposed along the inclined edges; and the clamping plate is provided with fastening bolts for enabling the clamping plate to press the plate B to move towards the plate A so as to fix the gasket and the magnesium alloy plate. According to the die and the method, the gradient strain ofthe magnesium alloy plate is achieved by designing the compression gasket with a certain angle, so that the texture orientation of the magnesium alloy plate is further regulated and controlled, the texture is weakened, and finally, the formability of the magnesium alloy plate is improved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

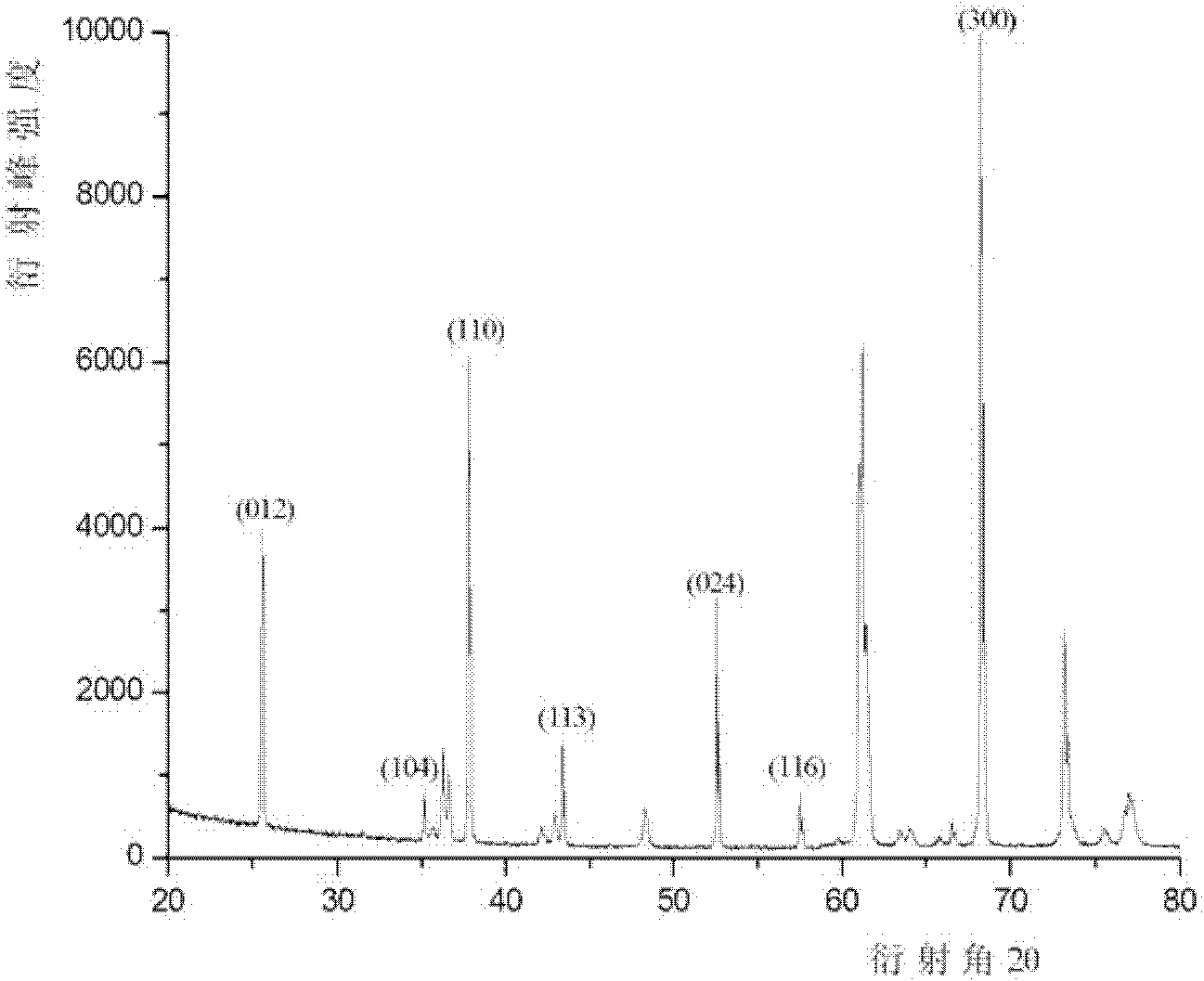

Surface modified coating cutting blade and preparation method thereof

ActiveCN105506580AImprove antioxidant capacityReduce residual stressLayered productsChemical vapor deposition coatingHeat resistanceUltimate tensile strength

The invention discloses a surface modified coating cutting blade and a preparation method thereof. The cutting blade comprises a blade matrix and a coating deposited on the blade matrix, the coating contains an MT-TiZrCN coating and an outermost Al(Zr)2O3 modified coating with a corundum structure; the Al(Zr)2O3 modified coating has (300) crystal face strong texture orientation, and the strength ratio I(300) / I(110) of the orientation crystal surface is 0.5-2.5. The preparation method includes: sequentially depositing a TiN layer, an MT-TiZrCN coating, a TiCxNyOz layer, an alpha-Al2O3 layer and an Al(Zr)2O3 modified coating on the blade matrix, thus obtaining the surface modified coating cutting blade. The surface modified coating cutting blade provided by the invention has excellent heat resistance, anti-tipping performance and anti-adhesion performance, and is suitable for general milling processing and other aspects of steel and stainless steel.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

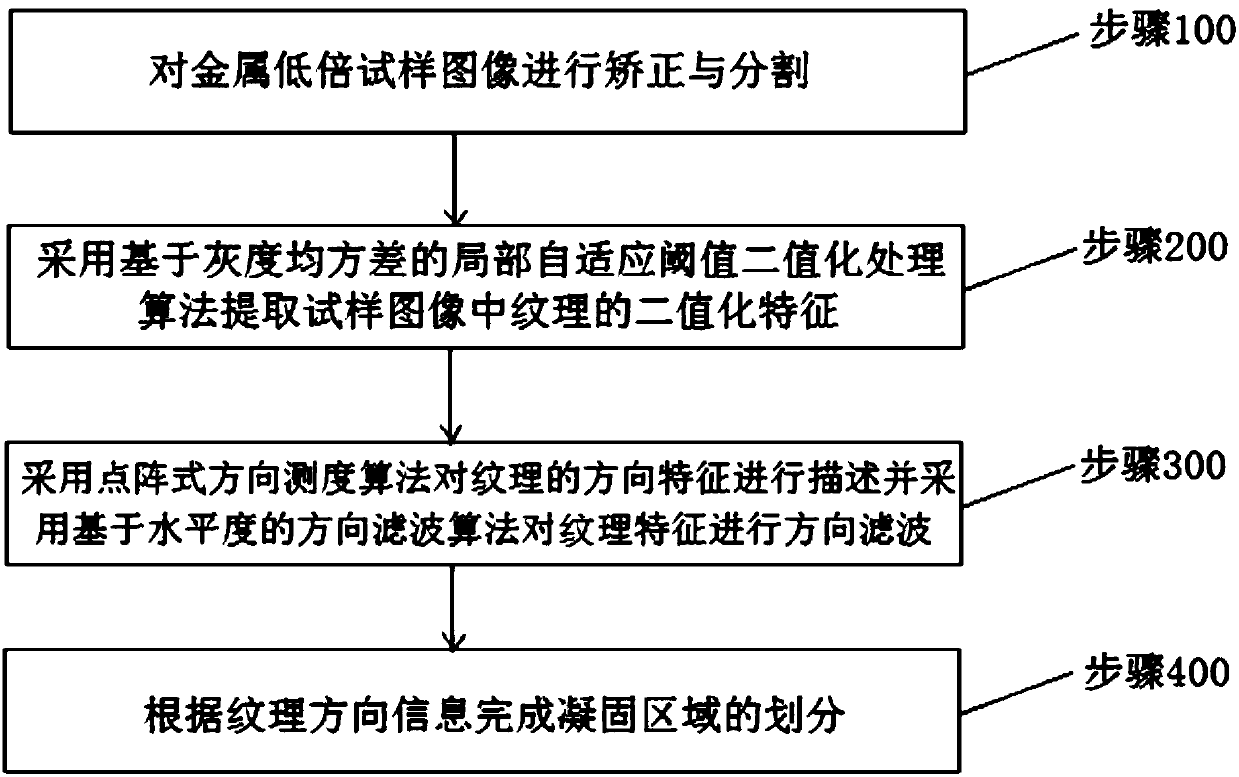

Method and system for identifying metal solidification area with texture

ActiveCN107657620AEliminate distractionsImprove detection accuracyImage enhancementImage analysisDot matrixFeature extraction

The invention discloses a method for identifying a metal solidification area with a texture. The method is characterized by comprising the following steps of: Step 100, correcting and segmenting a metal low-magnification sample image; Step 200, adopting a local self-adaptive threshold binaryzation processing algorithm based on grayscale mean square difference to extract binarization features of the texture in the sample image; Step 300, describing the direction characteristics of the texture by adopting a dot matrix type direction measurement algorithm, and carrying out direction filtering onthe texture features by adopting a direction filtering algorithm based on the levelness; Step 400, dividing the solidification area according to the texture direction information. According to the invention, a digital image processing technology is used to perform preprocessing, feature extraction, pattern recognition and the like on a solidification area image of a casting blank macrostructure soas to realize automatic recognition and quantization and improve the detection precision. Meanwhile, the labor intensity is reduced and the production efficiency is improved.

Owner:NORTHEASTERN UNIV

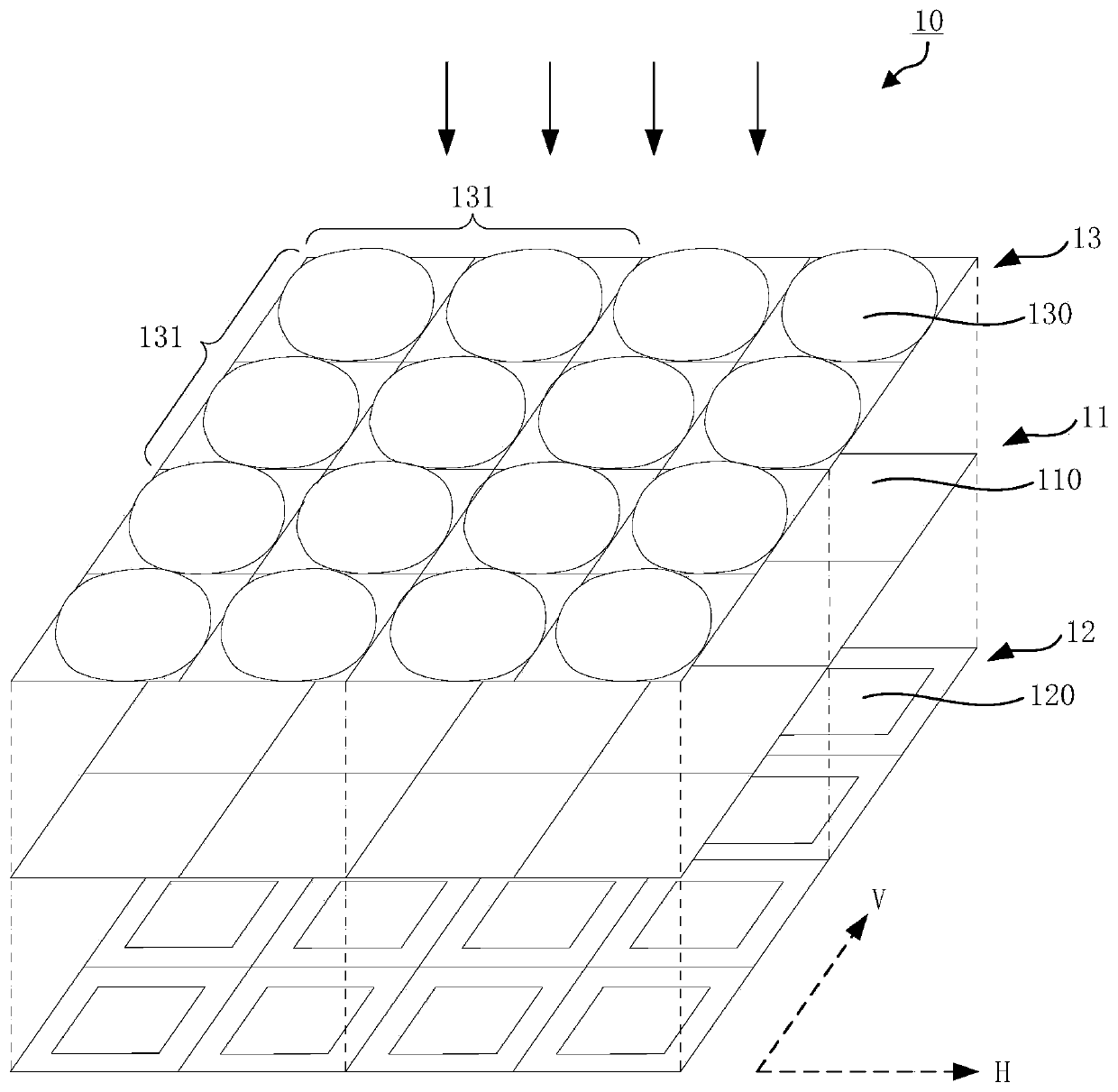

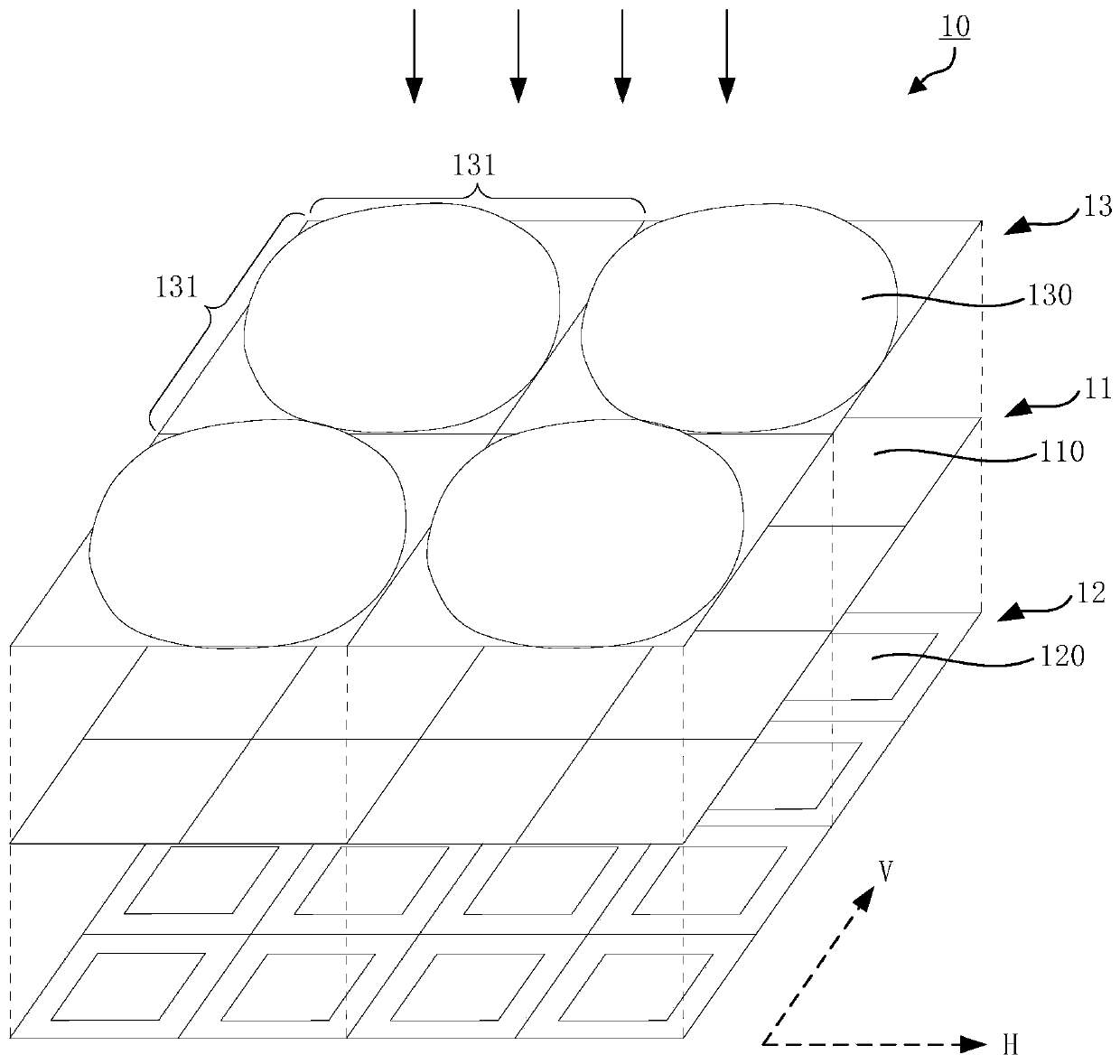

Image sensor, imaging device, electronic apparatus, image processing system, and signal processing method

ActiveCN111225135AAccurate interpolationHigh color reproductionTelevision system detailsPicture signal generatorsColor imageIntermediate image

The invention discloses an image sensor, an imaging device, electronic equipment, an image processing system and a signal processing method. The image sensor is configured to: generate a texture imagesignal, wherein a plurality of texture pixel signals in the texture image signal each have a value of a first color channel; and process the texture image signal to obtain a target texture directionfor indicating an interpolation direction of a pixel signal in an intermediate image signal output to the processor by the image sensor. According to the image sensor, the imaging device, the electronic equipment, the image processing system and the signal processing method provided by the embodiment of the invention, the pixel signal in the intermediate image signal is interpolated based on the interpolation direction indicated by the target texture direction; the interpolation of the pixel signal in the intermediate image signal is more accurate, the color restoration effect of the finally obtained color image is better, and the consistency of the texture in the color image and the texture of the shooting scene is higher.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

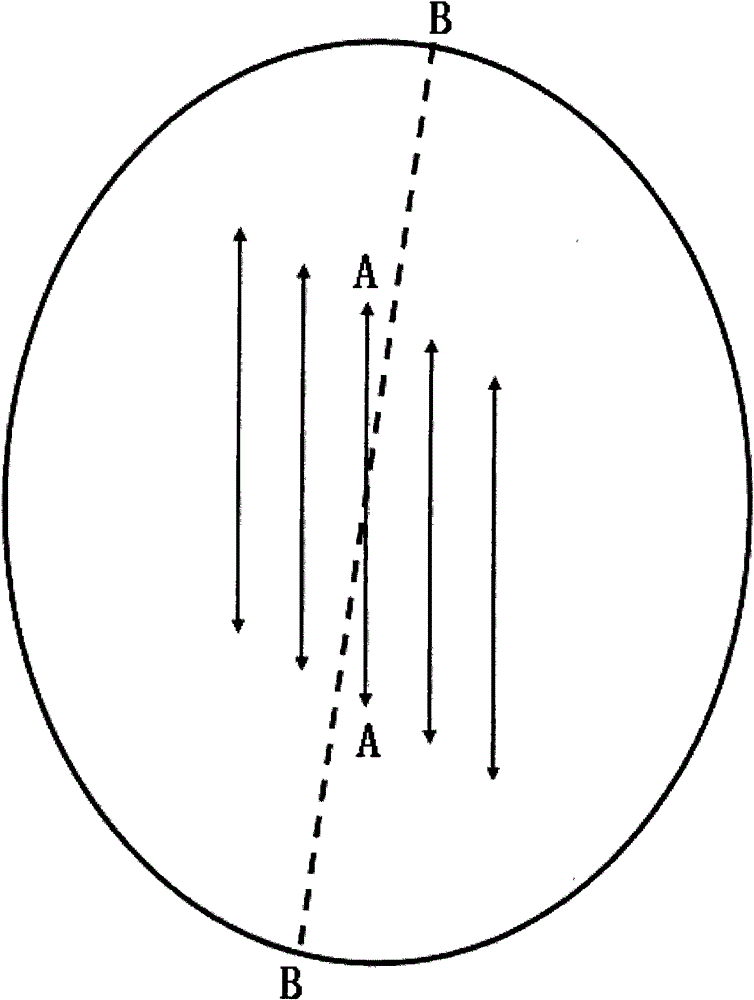

Metal plate texture adjusting and control method

The invention discloses a metal plate texture adjusting and control method. The metal plate texture adjusting and control method comprises the following steps that firstly, the upper surface and the lower surface of a metal plate are clamped and fixed, the metal plate bears force along the thickness direction of the metal plate, and thus, different orientations of the metal plate texture are achieved, wherein it is further limited that a metal plate fixing device is used to clamp and fix the upper surface and the lower surface of the metal plate, and the device is characterized in that throughupper loading force and lower loading force and with the cooperation of intermediate elastic materials, a crease phenomenon of the metal plate during compression deformation can be prevented, and theflatness and deformation uniformity of the metal plate are guaranteed; and then deformation of different degrees in the aspects such as speed, angle and deformation amount is carried out in the thickness direction of the plate, the grain orientation of the metal plate is adjusted and controlled, preferential texture orientation of the plate is achieved, and thus the plate adapting to different environments with comprehensive performance is obtained. The method is especially applicable to wide metal plates, operation is easy, complex auxiliary technology means such as edge trimming are not needed, and the indoor-temperature stamping property of stamped parts of large specification and size can be greatly improved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Aluminium alloy wire with high strength and high electrical conductivity, and preparation method thereof

InactiveCN102719709BHigh strengthImprove conductivityMetal/alloy conductorsCable/conductor manufactureFiberRoom temperature

The invention relates to a wire material of an aluminium alloy wire, and a preparation method thereof. An aluminium alloy wire with high strength and high electrical conductivity which has a high fiber texture degree is obtained through an ultra-low temperature rapid drawing process, and the aluminium alloy wire has a fiber texture degree of more than 60%, a tensile strength of more than 130Mpa, and an electrical conductivity of more than 63% IACS. According to the invention, a micro alloying design is performed by using composites of ferrum, scandium and the like which can form Al3Me type eutectic compound particles; a certain fiber texture is obtained through a drawing process by controlling a continuous casting and rolling process; the fiber texture degree is greatly increased and the distortion caused by room temperature deformation is reduced through the ultra-low temperature rapid drawing process; and the texture orientation and the texture degree of the aluminium wire after the drawing process are adjusted through an annealing treatment, the drawing stress is relaxed, the plasticity of the wire is recovered, the resistance of the wire is reduced and the electrical conductivity of the wire is increased. Compared with the prior art, the aluminium alloy wire and the preparation method of the invention can control the deformation process in micro alloying conditions to greatly increase the strength and the electrical conductivity of the wire.

Owner:SHENZHEN ZHAOFANG VENTURE TECH

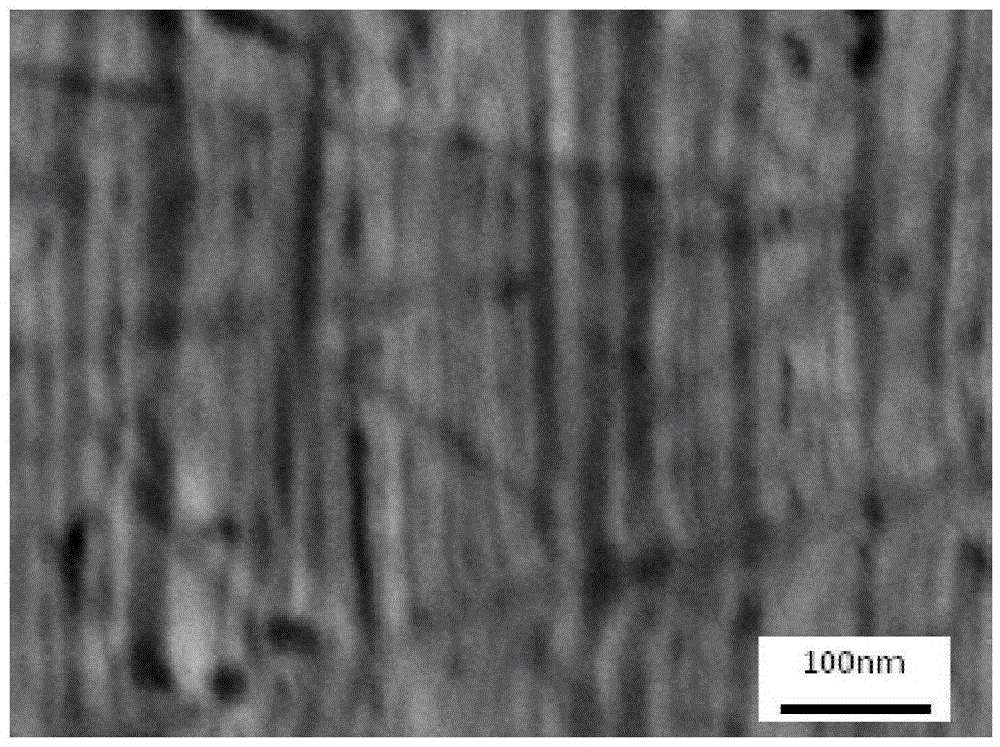

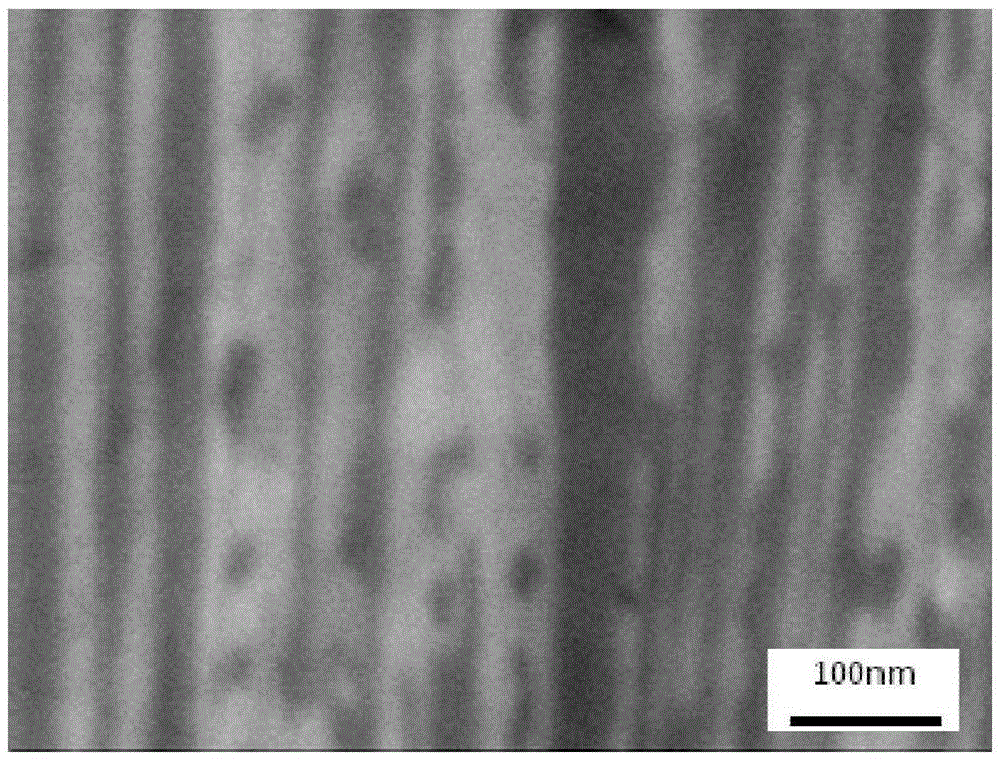

Method for manufacturing nanoscale multilayer metal matrix composite with combination of magnetic field heat treatment

ActiveCN105478520AEnhanced texture orientationHigh hardnessMetal rolling arrangementsElectrical resistance and conductanceHardness

The invention discloses a method for manufacturing a nanoscale multilayer metal matrix composite with combination of magnetic field heat treatment and belongs to the field of metal material manufacturing. The method includes the following steps that firstly, substrates are pretreated, wherein after the substrates are selected, annealing, cutting and stacking are conducted; secondly, a plate is formed through pressing, wherein the stacked substrates are put into a stainless steel sleeve to be pressed; thirdly, rolling is conducted; fourthly, heat treatment is conducted; the multilayer metal matrix composite in stainless steel is taken out, and whether heat treatment and a static magnetic field are combined for the process of heat treatment or not is judged according to the thickness of a ferromagnetic element layer of the multilayer metal matrix composite; and fifthly, the ending condition of the process is judged according to the thickness of the ferromagnetic element layer of the multilayer metal matrix composite. According to the manufacturing method, roughening of a nanophase is inhibited through the strong magnetic field, and texture orientation of the nanophase is strengthened; the average thickness of nanolayers of the manufactured nanoscale multilayer metal matrix composite is smaller than 20 nm; and compared with the prior art, hardness is improved by 10-35% or so, and resistance is also improved by 10-35% or so.

Owner:NORTHEASTERN UNIV

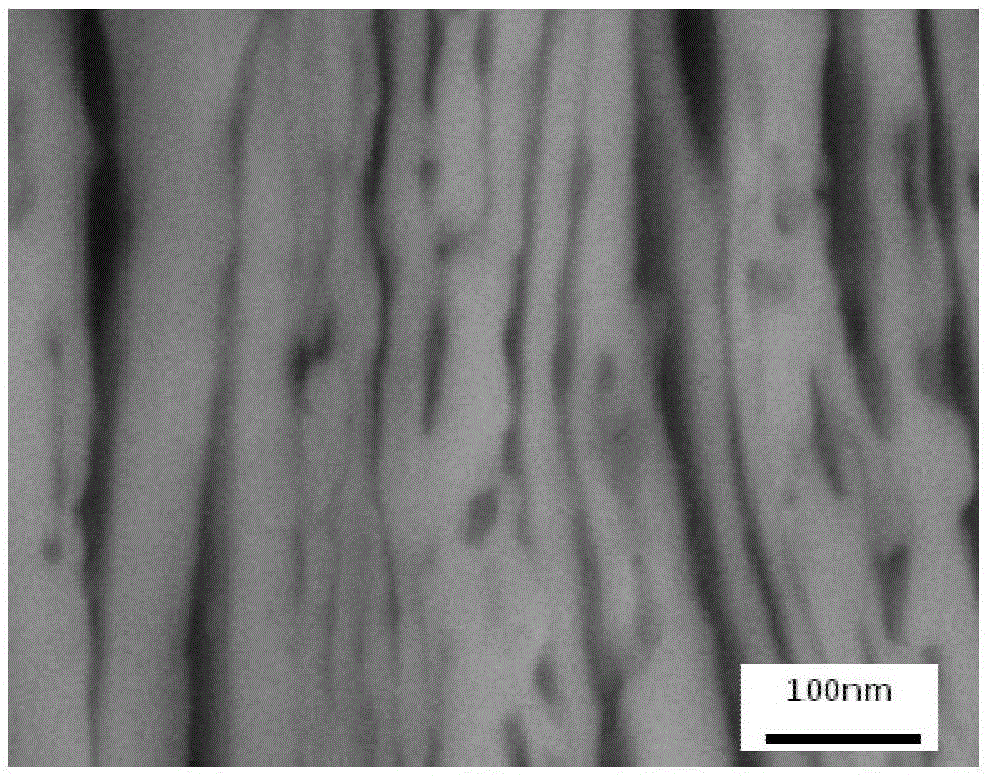

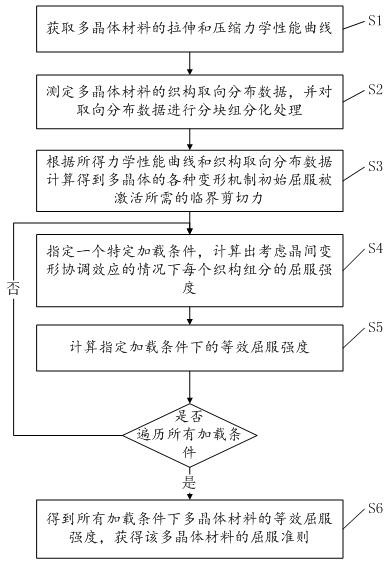

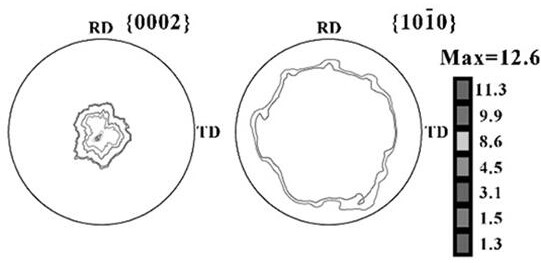

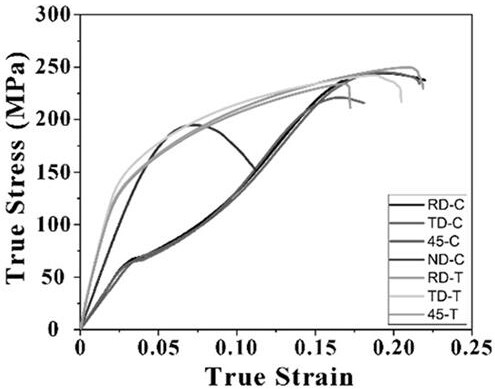

Method for obtaining yield criterion of polycrystalline metal material

ActiveCN111681721APracticalAchievableComputational materials scienceInstrumentsMetallic materialsTexture (crystalline)

The invention provides a method for obtaining a yield criterion of a polycrystalline metal material, comprising the following steps of: S1, obtaining tensile and compressive mechanical property curvesof a polycrystalline material; S2, measuring texture orientation distribution data of the polycrystalline material, and carrying out block component processing on the orientation distribution data; S3, calculating to obtain critical shearing force required by activation of initial yield of various deformation mechanisms of the polycrystal according to the obtained mechanical property curve and texture orientation distribution data; S4, specifying a specific loading condition, and calculating the yield strength of each texture component under the condition of considering the intercrystalline deformation coordination effect; S5, calculating the equivalent yield strength under the specified loading condition; and S6, circularly executing the steps S4 and S5 until all loading conditions are traversed to obtain the equivalent yield strength of the polycrystalline material under all loading conditions and obtain the yield criterion of the polycrystalline material. The method has advantagesof high accuracy of the yield criterion, small calculated amount and strong practicability.

Owner:JIHUA LAB

Oriented Silicon Steel and Method for Manufacturing Same

ActiveUS20150302962A1Low production costHigh potential benefitConductive/insulating/magnetic material on magnetic film applicationInorganic material magnetismWell controlSilicon

The invention discloses an oriented silicon steel with excellent magnetic properties and a manufacturing method thereof. The present invention obtains the oriented silicon steel with excellent magnetic properties by controlling the area ratio of small crystal grains of D<5 mm in an oriented silicon steel finished product to be not more than 3%, and controlling the ratio μ17 / μ15 of the magnetic conductivity under the magnetic induction of 1.7 T and 1.5 T in the oriented silicon steel finished product to be 0.50 or more. In addition, by using a slab of the oriented silicon steel with suitable components and an optimized cold rolling step, the present invention effectively decreases the heating temperature of the slab and the production cost thereof, and simultaneously better controls the size and ratio of the crystal grains in the oriented silicon steel finished product and the magnetic conductivity in a certain range of magnetic induction, ensures that secondary recrystallization has good Goss texture orientation and finally, stably obtains the oriented silicon steel product with excellent magnetic properties.

Owner:BAOSHAN IRON & STEEL CO LTD

AVS3 texture information-based CU block division method and apparatus, and medium

PendingCN114827603AQuick divisionHigh speedDigital video signal modificationRound complexityVideo encoding

The invention discloses a CU block division method based on AVS3 texture information, a computer device and a storage medium, and the method comprises the steps: obtaining a variance, a horizontal gradient and a vertical gradient of a to-be-divided CU block, selecting to skip some division modes according to the relation between the variance, the horizontal gradient and the vertical gradient and a first threshold value, and obtaining candidate division modes, and selecting an optimal division mode from the candidate division modes, and dividing the CU block to be divided in the optimal division mode. According to the method, texture information is extracted based on the variance and the Scharr operator to divide the CU blocks into different categories, the variance with low complexity is used for analyzing a division mode pruning strategy of flat blocks and complex blocks, rapid division of the CU blocks is achieved, the speed of an AVS3 encoder is increased, the Scharr operator is used for considering fine textures and texture directions, and the method is suitable for large-scale popularization and application. The algorithm is balanced between the coding speed and the coding quality; the method is widely applied to the technical field of video coding.

Owner:SUN YAT SEN UNIV

Method and device for quickly selecting HEVC intra prediction mode on basis of texture characteristics

ActiveCN102843559BImprove selection speedGuaranteed coding qualityDigital video signal modificationAlgorithmPattern selection

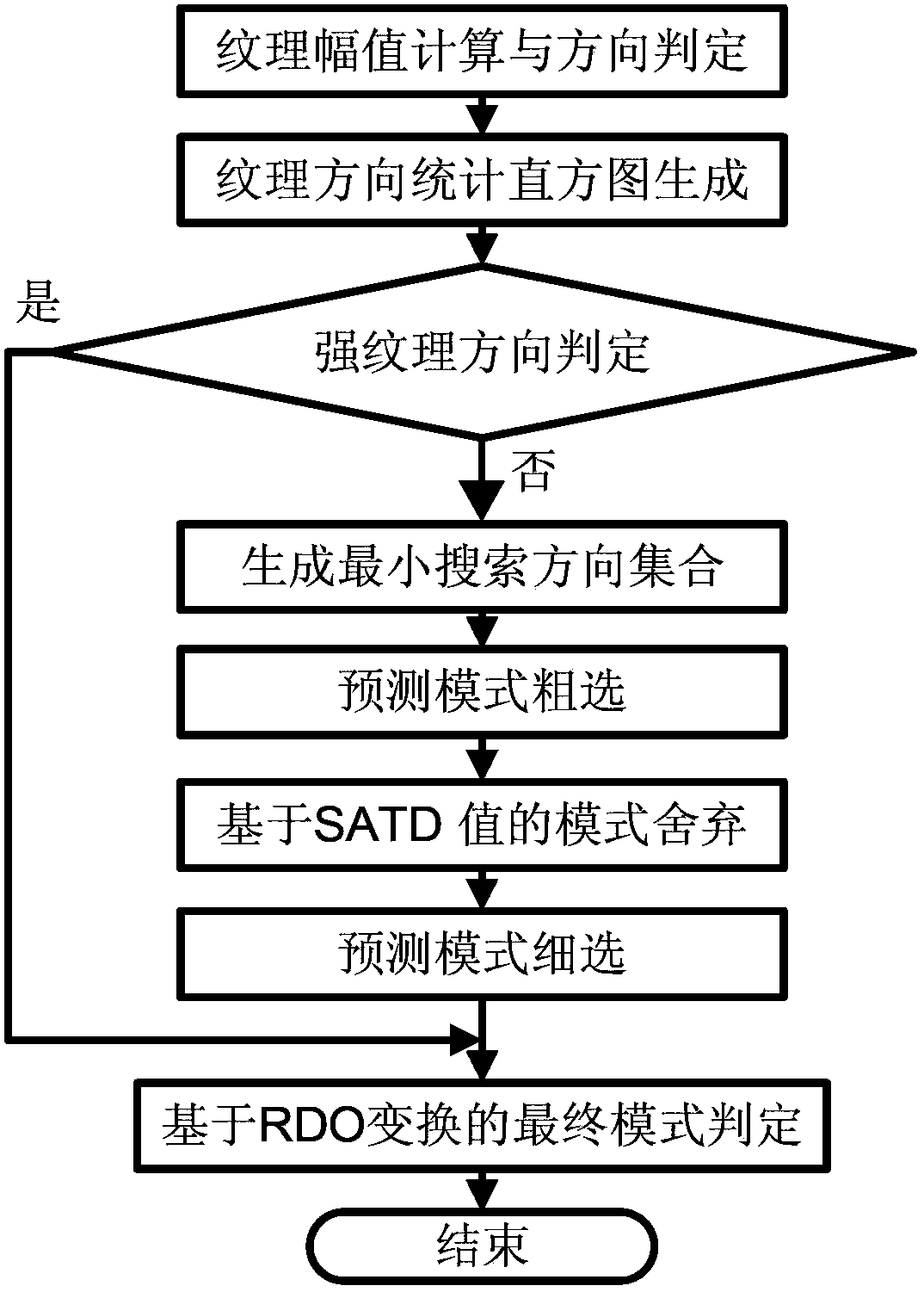

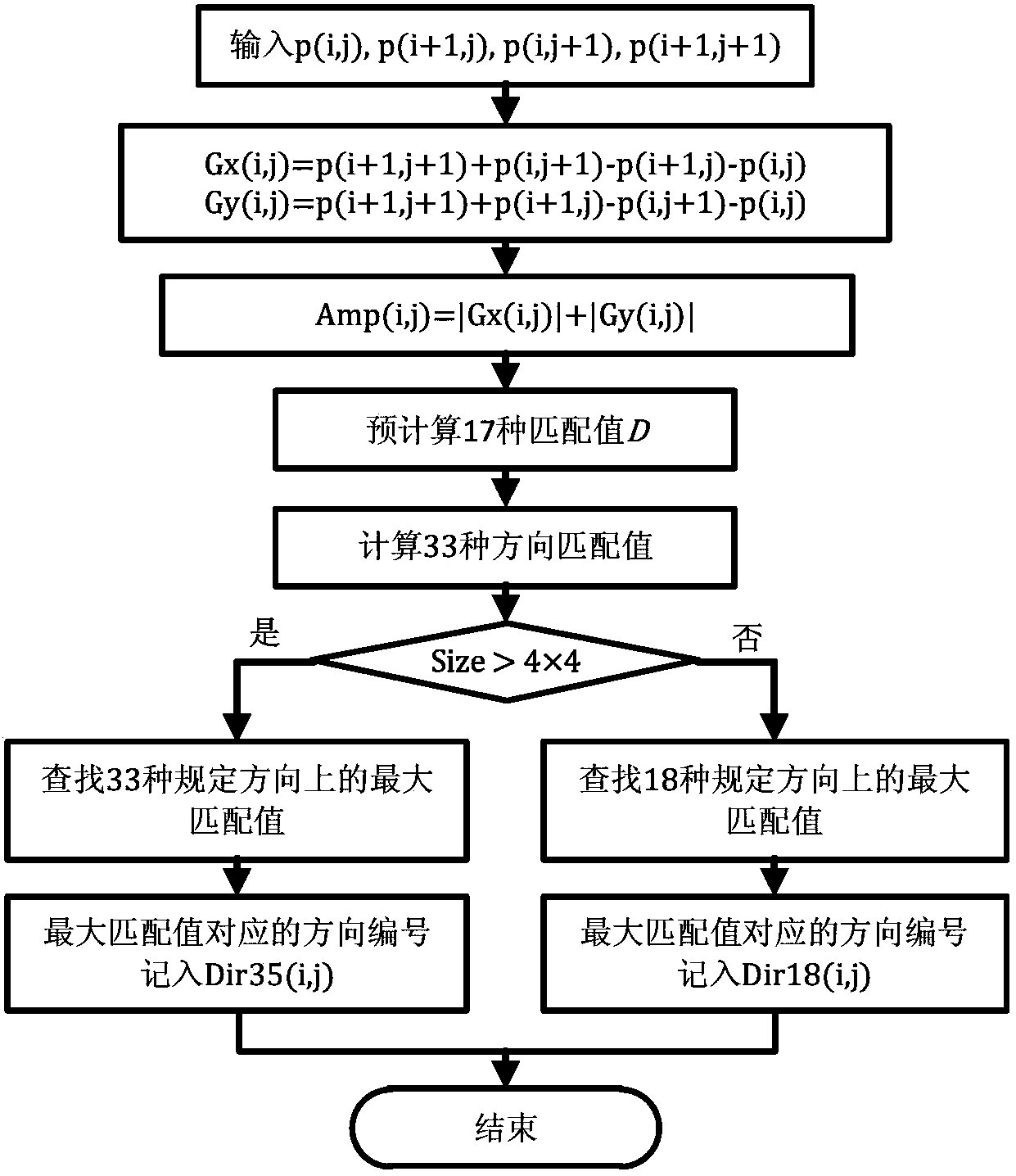

The invention provides a method and a device for quickly selecting high efficiency video coding (HEVC) intra prediction mode on basis of texture characteristics. A texture direction statistical histogram is generated by determining the texture amplitude and the texture direction of each element of an edge texture figure of a to-be-predicted unit (PU), so that the strong texture direction of the PU is judged; and when the PU has the strong texture direction which is matched with a prediction mode direction of any adjacent module, the strong texture direction serves as the final prediction mode direction. By the method and the device, the search times are reduced, the calculation time of mode selection is effectively reduced and the speed of mode selection is obviously increased on the premise of guaranteeing the coding quality.

Owner:TSINGHUA UNIV

Data restoration device and method for original CT projection data, CT imaging system

ActiveCN106910163BRepair the original projection dataImage enhancementReconstruction from projectionRadiologyDirection information

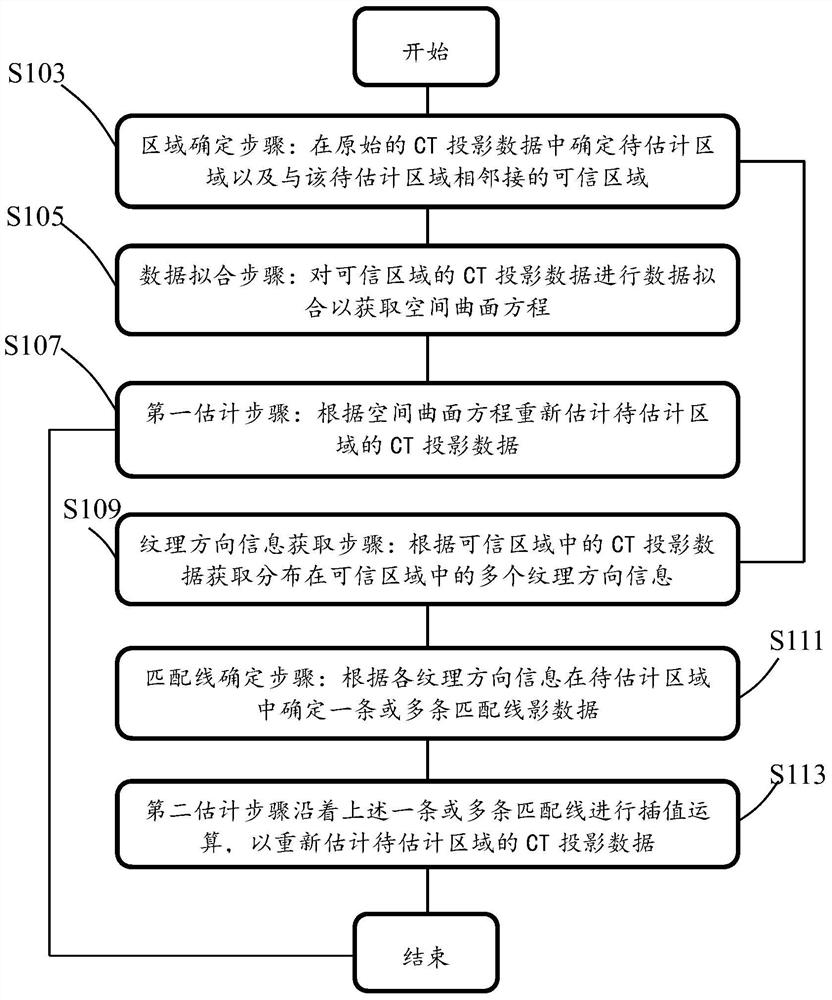

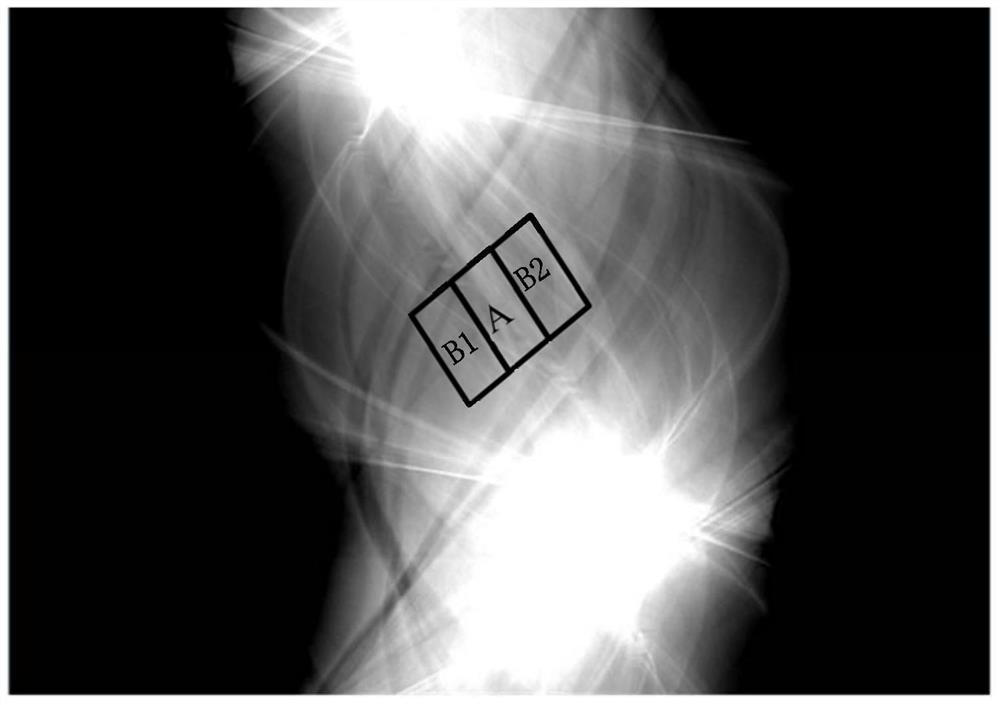

The present invention provides a data restoration method for original CT projection data, including: determining the area to be estimated and the credible area adjacent to the area to be estimated in the original CT projection data; and performing the first processing and the second At least one of the processing. The first processing includes: performing data fitting on the CT projection data of the credible region to obtain a space surface equation; and reestimating the CT projection data of the region to be estimated according to the space surface equation. The second process includes: acquiring a plurality of texture direction information distributed in the credible region according to the CT projection data of the credible region; determining one or more matching lines in the region to be estimated according to each texture direction information, and each matching line The line passes through at least one data point to be estimated and is matched with at least one piece of texture direction information; an interpolation operation is performed along the matching line to re-estimate CT projection data of the area to be estimated.

Owner:GENERAL ELECTRIC CO

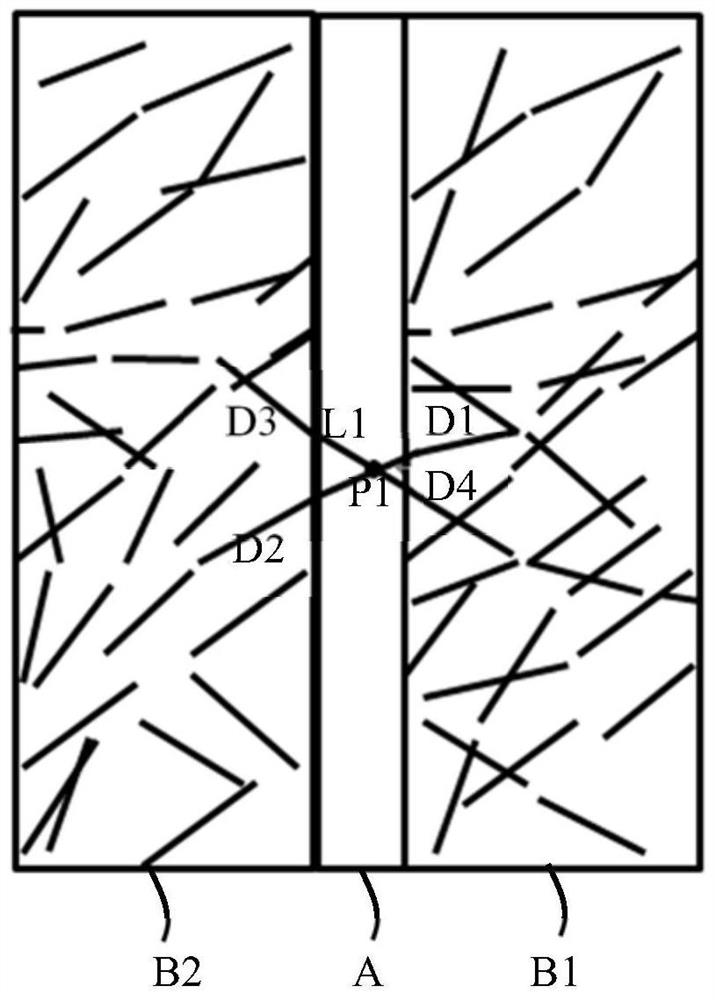

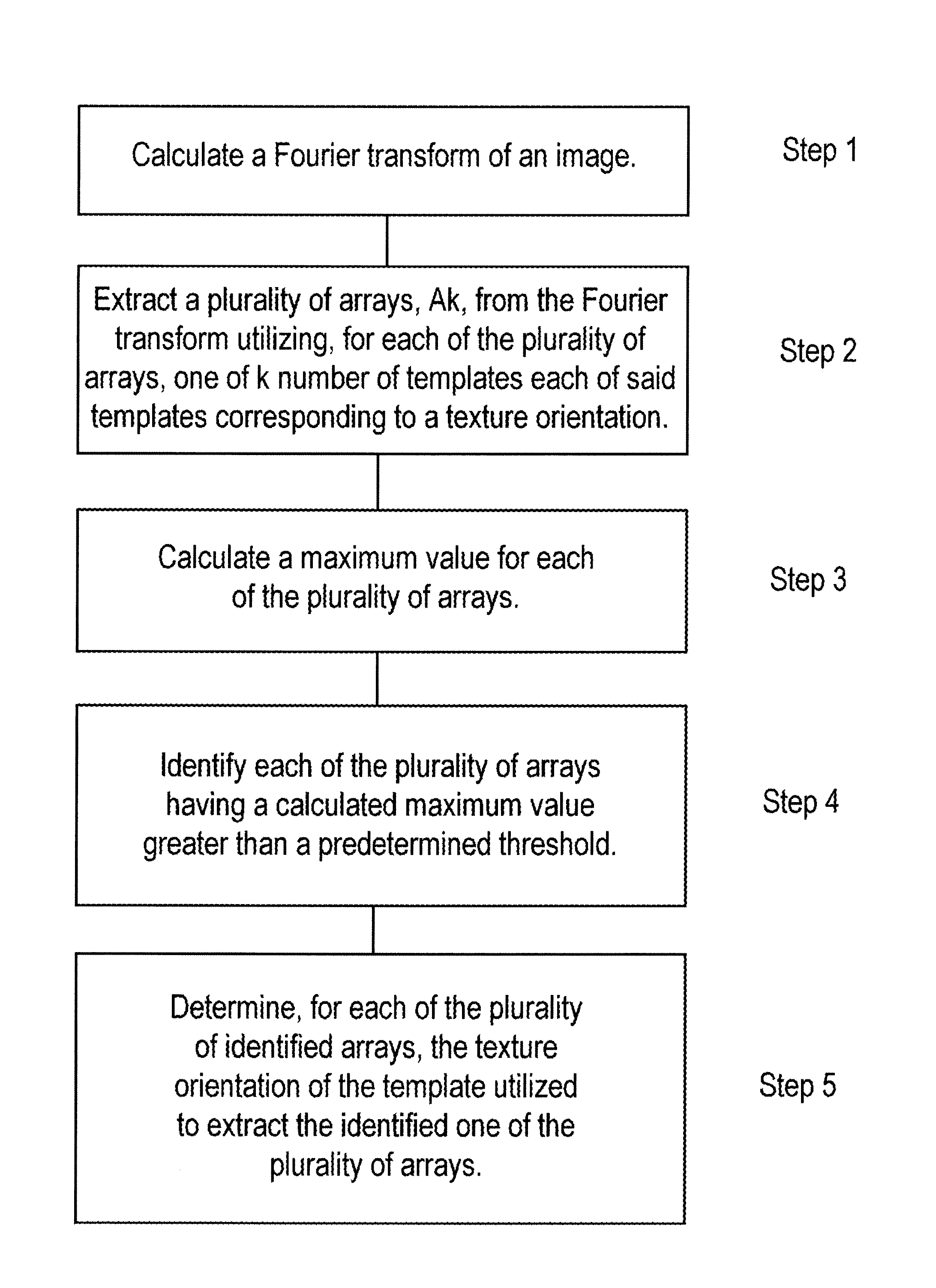

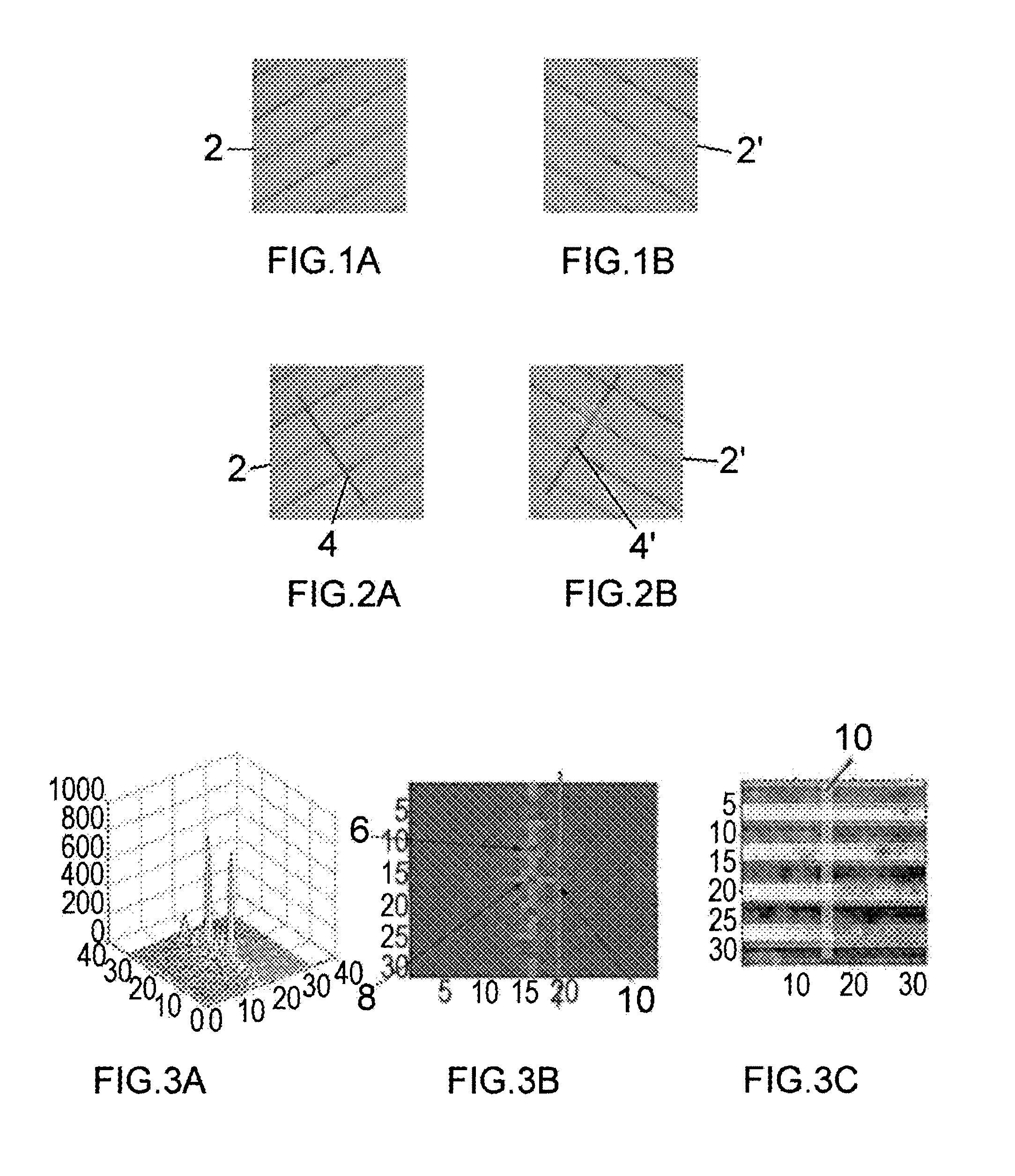

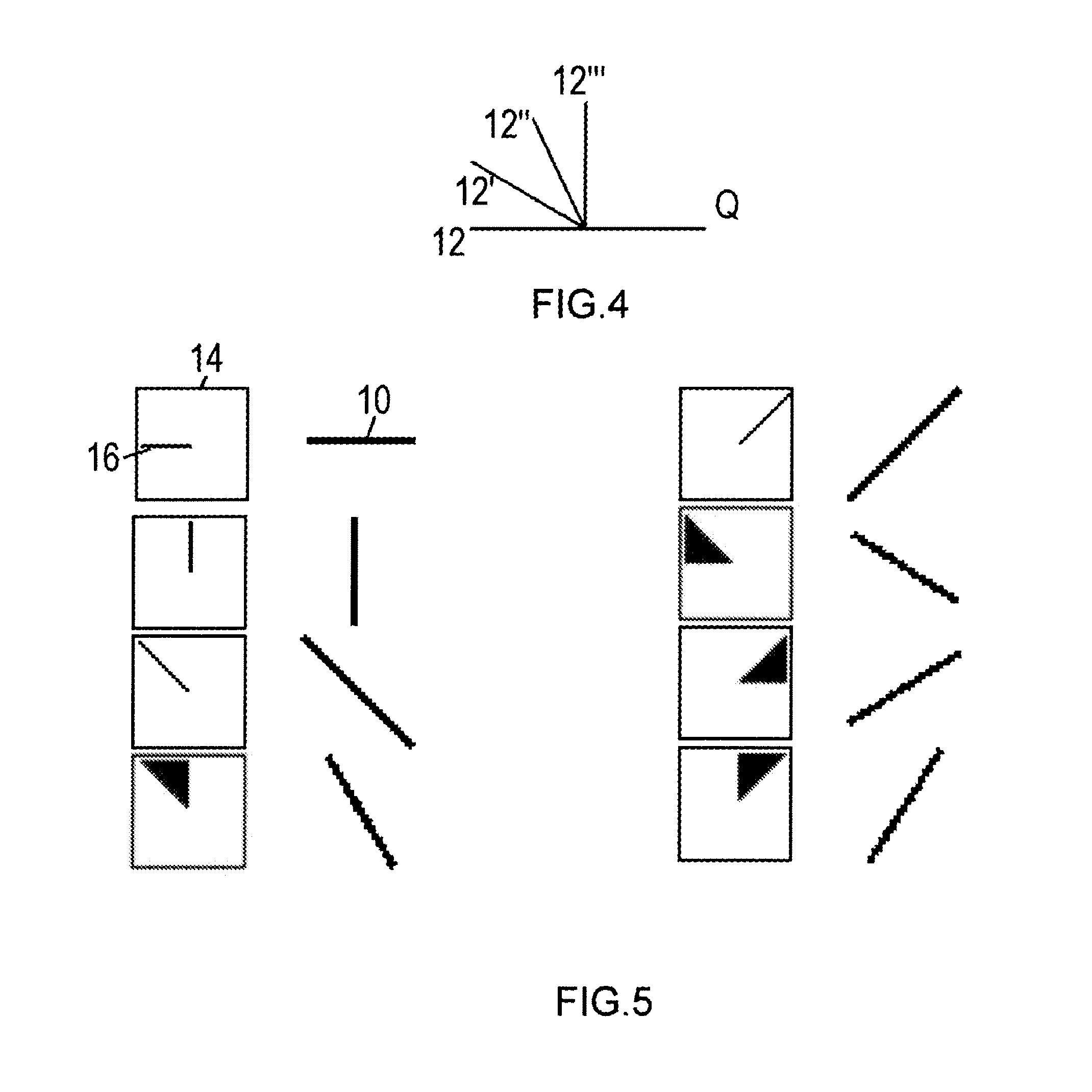

Method of and apparatus for low-complexity detection of periodic textures orientation

ActiveUS9183640B2Image enhancementImage analysisPattern recognitionFourier transform on finite groups

A method includes calculating a Fourier transform of an image, extracting a plurality of arrays, from the Fourier transform utilizing, for each of the plurality of arrays, one of a plurality of templates each of said templates corresponding to a texture orientation, calculating a maximum value for each of the plurality of arrays, identifying each of the plurality of arrays having a calculated maximum value greater than a predetermined threshold and determining, for each of the plurality of identified arrays, the texture orientation of the template utilized to extract the identified one of the plurality of arrays.

Owner:INTEL CORP

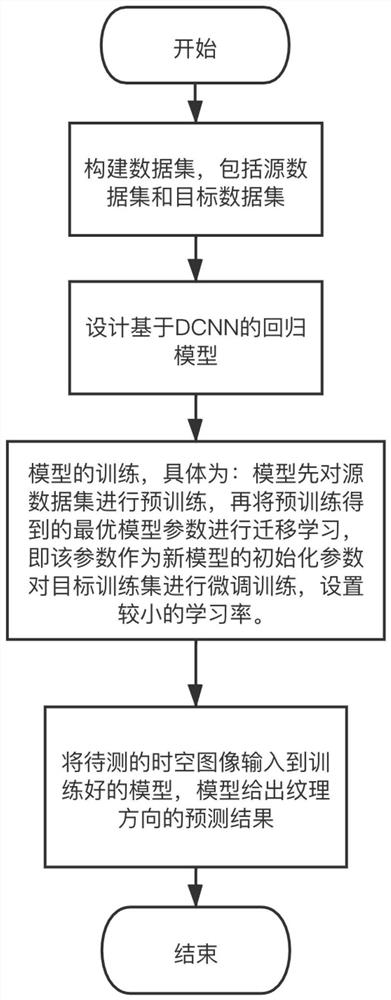

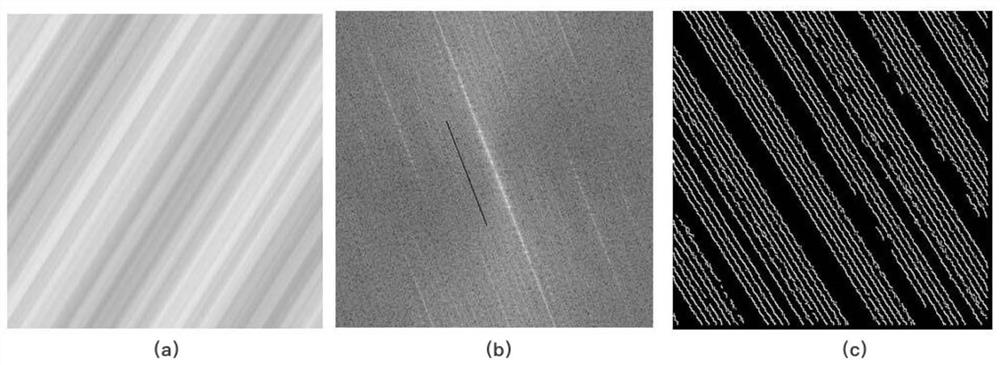

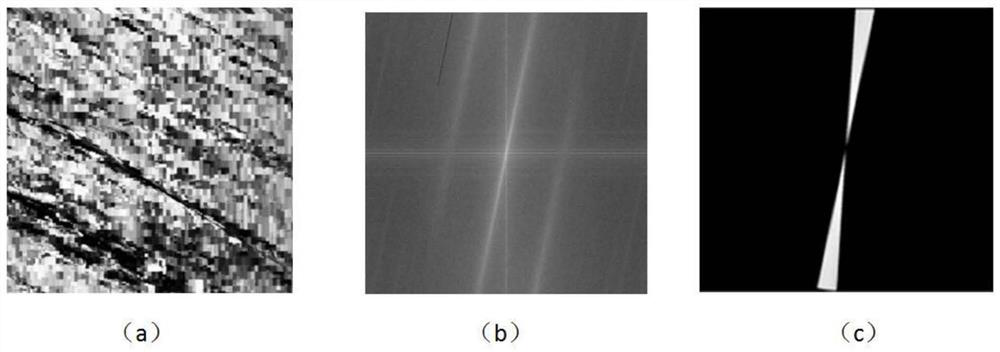

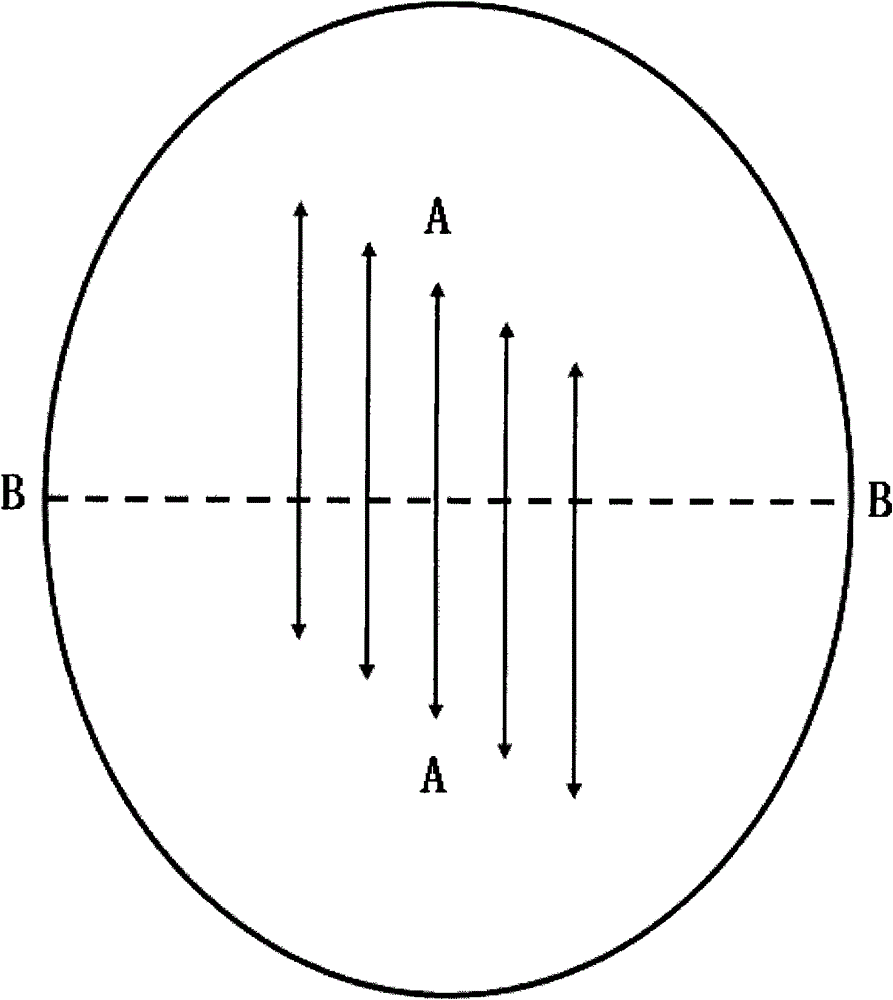

Space-time image texture direction detection method and system based on DCNN and transfer learning

ActiveCN113222976AEasy extractionRemove image noiseImage analysisNeural architecturesDirection detectionNeural network nn

The invention discloses a time-space image texture direction detection method and system based on a DCNN (deep convolutional neural network) and transfer learning in the technical field of time-space image texture direction recognition. The method comprises the following steps: acquiring a time-space image; inputting the collected space-time image into a trained space-time image texture direction prediction model based on a deep convolutional neural network and transfer learning, and obtaining a prediction result of the space-time image texture direction; the image noise is eliminated, and the detection accuracy under the turbulent flow condition with strong flow velocity pulsation is improved.

Owner:HOHAI UNIV

Method and equipment for preparing dumplings

ActiveCN101991052BFull shapeBeautiful appearanceDough shaping and cutting apparatusDough extruding machinesEngineeringTexture orientation

The present invention provides a dumpling producing method and a dumpling producing device. The method comprises the following steps: cutting a mechanically sheeted dough sheet of a unidirectional texture into dumpling wrappers of a pre-defined shape, filling the stuffing into the dumpling sheet, and wrapping the dumpling wrapper along a fold line at an angle of 0 to 20 degrees to the texture orientation of each dumpling wrapper to produce the dumplings. The device comprises: a cutting mechanism consisting of a cutting unit and a rotating unit, wherein the rotating unit is configured to cause an angle formed between the texture orientation of the dumping wrapper and the fold line to be within 0 to 20 degrees.

Owner:GENERAL MILLS MARKETING INC

Preparation method of texture controllable fine grain metal material based on large strain deformation and recrystallization

ActiveCN101660034BUniform continuous large strain pre-deformationReduce energy consumptionHardnessUltimate tensile strength

A preparation method of texture controllable fine grain metal material based on large strain deformation and recrystallization includes large strain predeformation and recrystallization heat treatment. The preparation method is characterized in that the large strain predeformation includes that blanks are firstly subject to rolling by multi-pair rolling wheels, so that the blanks get thinner and deformation degree of the blanks rolled by multi-pair rolling wheels is not less than 50%; secondly an equal channel angular pressing mould is arranged at the outlet of the last pair of rolling wheel,so that the thinner blanks after rolling carry out ECAP deformation; and the recrystallization heat treatment includes that the blanks after the large strain deformation are fed into a thermal treatment furnace, temperature is maintained to be 150-500 DEG C for 0.5-2h, and then air cooling is carried out. The invention combines the advantages of the multi-pair wheel rolling technology and the equal channel angular pressing technology and can realize energy-saving, high-efficiency, continuous and uniform large strain deformation processing of metal material; and the prepared metal material hasthe characteristics of small grain crystal, strength and hardness far higher than supply state and wonderful texture orientation and the like.

Owner:JIANGYIN HENGYE FORGING

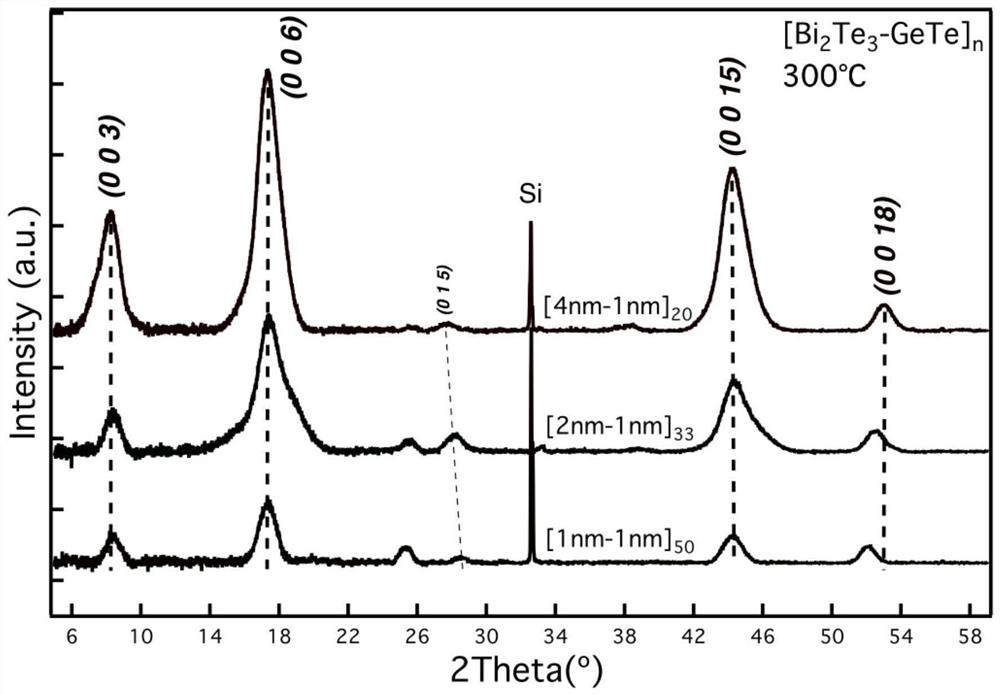

Highly-textured oriented phase change storage material and preparation method thereof

PendingCN113437214AImprove switching efficiencyImprove performancePolycrystalline material growthElectrical apparatusCrystallographyPhase-change memory

The invention relates to a highly-textured oriented phase change storage material and a preparation method thereof. The phase change storage material comprises a Van der Waals structure buffer layer and a nitrogen-sulfur compound-GeTe superlattice structure, and the superlattice structure grows in a layered mode in the direction perpendicular to the surface of the substrate. The nitrogen-sulfur compound phase-change material with continuous component distribution and high texture orientation is realized by using a high-throughput preparation method, and the phase-change storage material has high texture orientation, so that a low-power-consumption and high-performance phase-change storage unit with an interface disordering characteristic can be designed; and the highly-textured oriented phase change storage material is expected to be used in nonvolatile memory devices with high speed, high cycle erase times and low power consumption.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

A kind of preparation method of ultra-high purity aluminum target material

ActiveCN106282945BHigh purityFine and uniform grainVacuum evaporation coatingSputtering coatingIngotUltra high purity

The invention relates to a preparation method of an ultrahigh-purity aluminum target. The preparation method comprises the following steps: (1) the surface of an ultrahigh-purity aluminum ingot with a purity of higher than 99.999 wt% is milled to remove an oxide layer thereof; (2) the ingot is heated to 230-400 DEG C; (3) the hot rolling of 10-20 passes is performed for the heated ingot; the single-pass reduction is controlled within 20-60 mm; and the final rolling temperature in final pass is controlled below 350 DEG C; (4) the annealing treatment with a temperature of 200-300 DEG C and an insulation time of 1-2 h is performed for a hot-rolled aluminum plate; and (5) the plate is straightened for milling to obtain the ultrahigh-purity aluminum target with average grains of 80-150 microns. The preparation method can prepare the target with high purity, fine and uniform grains and consistent texture orientation to satisfy the use requirements of PVD; and meanwhile, the preparation method is simple in process, easy to operate and convenient for large-scale industrial production, effectively reduces the energy consumption, and reduces the cost.

Owner:CHINALCO RUIMIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com