Copper alloy sheet material and method of producing the same

a technology of copper alloy sheet and alloy sheet, which is applied in the direction of conductive materials, metal/alloy conductors, and conductors, etc., can solve the problems of copper alloy sheet materials having problems, temperature elevation in the use environment, and thinness reduction of substrate materials in progress, and achieve excellent mechanical strength excellent bending properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0077]As shown with the respective composition in the column of alloying elements in Table 1-1, an alloy containing at least one or both of Ni and Co in an amount of 0.5 to 5.0 mass % in total, and Si in an amount of 0.1 to 1.5 mass %, with the balance being Cu and unavoidable impurities, was melted in a high-frequency melting furnace, followed by casting, to obtain an ingot. The resultant ingots in this state were used as test materials, and test specimens of copper alloy sheet materials of Examples 1-1 to 1-19 according to the present invention and Comparative Examples 1-1 to 1-9 were produced in any of the following A to F.

(Step A)

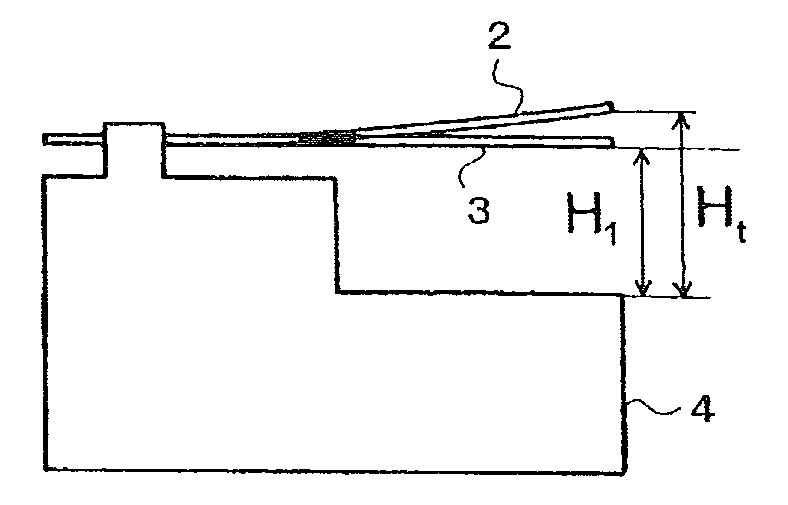

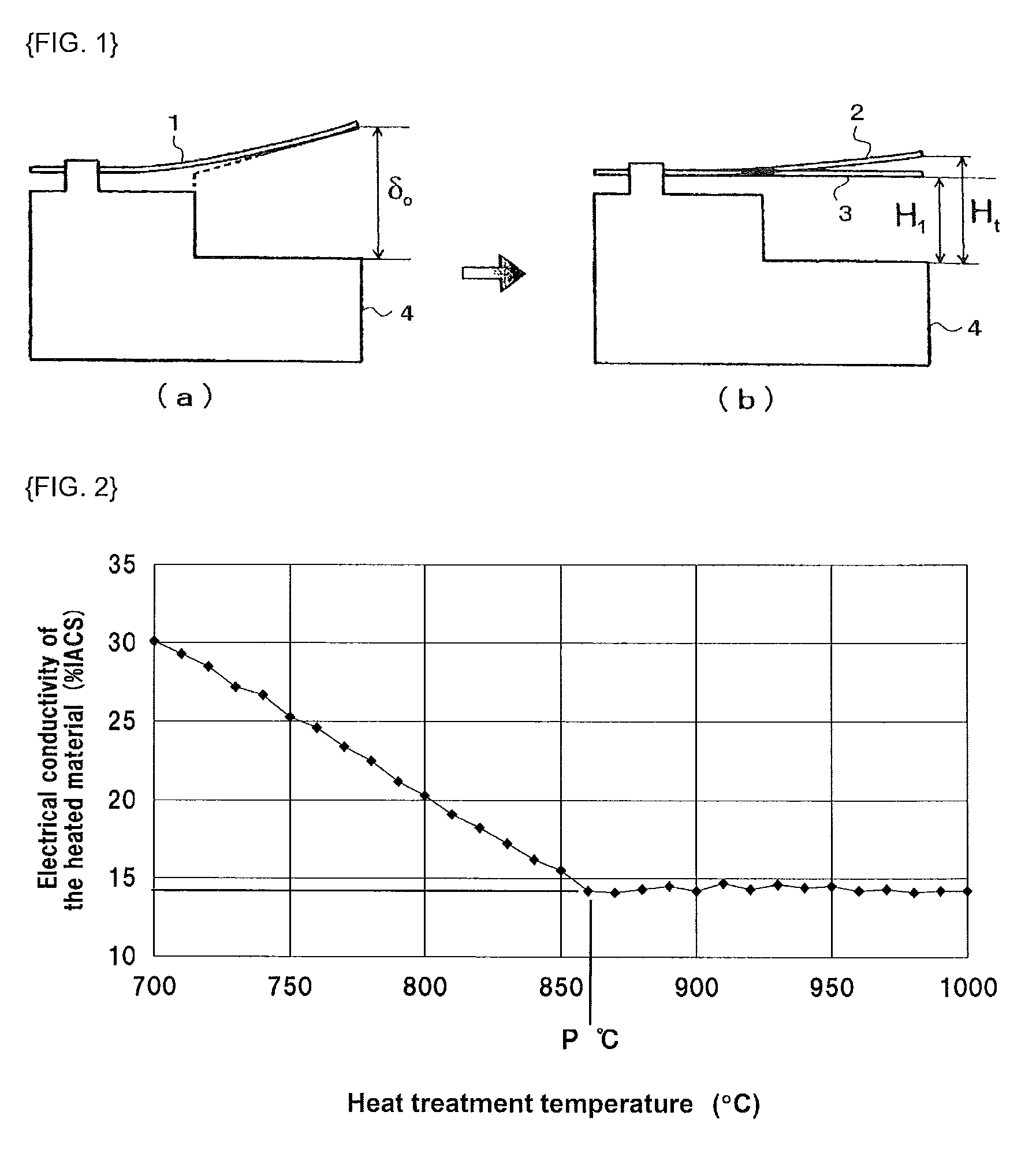

[0078]Each of the test specimens was produced in the following manner. The respective test material was subjected to a homogenization heat treatment at 1,020 to 700° C. for 10 minutes to 10 hours; three passes of hot-rolling at a working ratio of 25% or higher at a temperature in the range of 1,020° C. to (P+30)° C.; air cooling; three passes of hot-rol...

example 2

[0096]With respect to the copper alloys having the compositions shown in the column of alloying elements in Table 2, with the balance of Cu and unavoidable impurities, test specimens of copper alloy sheet materials of Examples 2-1 to 2-17 according to the present invention and Comparative Example 2-1 to 2-3 were produced in the same manner as in Example 1, and the test specimens were subjected to examination of the properties in the same manner as in Example 1.

[0097]The results are shown in Table 2.

TABLE 2Alloying elementsBendingIDNiCoSiOther elementspropertyYSECSRnumbermass %mass %mass %mass %StepRGWBWMPa% IACS%Ex 2-10.501.000.360.15Sn, 0.2AgD1.6◯◯67553.423.3Ex 2-21.000.500.380.03Zr, 0.05MnA2.1◯◯73750.220.7Ex 2-3—0.800.450.32Ti, 0.21FeC1.7◯◯71251.721.8Ex 2-40.501.500.350.2Ag, 0.05B, 0.1MgB1.4◯◯74051.223.4Ex 2-50.801.200.420.14Mg, 0.15Sn, 0.3ZnC1.8◯◯73549.919.6Ex 2-61.001.000.480.23Cr, 0.14Mg, 0.10PD1.6◯◯76048.521.8Ex 2-72.32—0.650.2Hf, 0.2ZnB1.9◯◯78539.824.4Ex 2-80.901.700.610.04Zr...

example 3

[0100]By using the copper alloy having the composition shown in Table 3, with the balance being Cu and inevitable impurities, the ingot was subjected to a homogenization heat treatment at 1,020 to 700° C. for 10 minutes to 10 hours, followed by hot-rolling as shown in Table 4, water cooling, face milling, cold-rolling at a working ratio of 50% to 99%, a heat treatment of maintaining at 600 to 900° C. for 10 seconds to 5 minutes, cold-working at a working ratio of 5% to 55%, and a final solution heat treatment of maintaining at 750 to 1,000° C. for 5 seconds to 1 hour. Then, the resultant sheet was subjected to an aging precipitation heat treatment at 350 to 600° C. for 5 minutes to 20 hours, finish rolling at a working ratio of 2 to 45%, and temper annealing of maintaining at 300 to 700° C. for 10 seconds to 2 hours, to produce a test specimen. The properties were examined in the same manner as in Example 1. The results are shown in Table 4.

TABLE 3Additive elementsNiCoSiSnZnMgCrmass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com