Die and method for regulating and controlling formability of magnesium alloy plate through gradient strain

A sheet forming and magnesium alloy technology, which is applied in the field of magnesium alloy processing, can solve the problems of weakened texture and low formability of magnesium alloy sheets, and achieve the effect of improving sheet formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

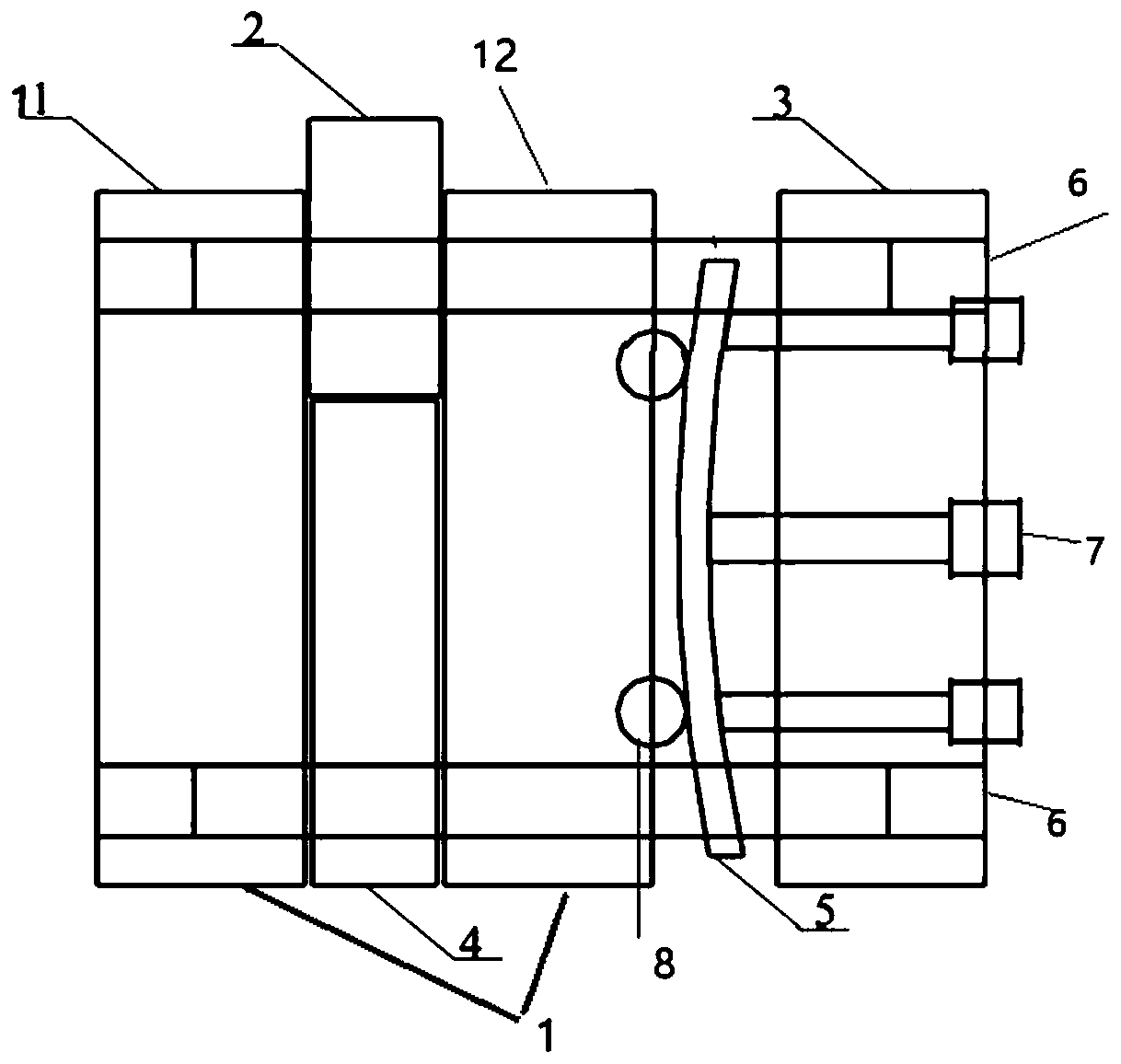

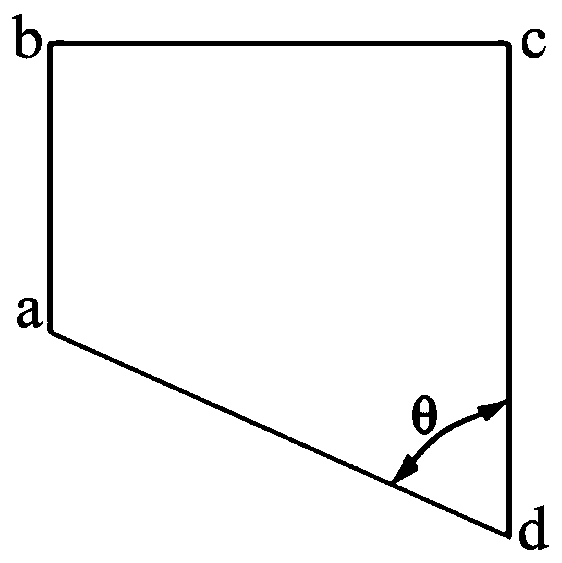

[0029] (1) Take an AZ31 magnesium alloy plate with a hypotenuse at an angle of 5° and a size of 100mm (width)×100mm (length)×1mm (thickness), and a gasket with an angle of 5° at the hypotenuse, place the magnesium alloy plate on Homogenized annealing treatment at 300°C for 60 minutes, then place the gasket and magnesium alloy plate along the inclined sheet in the strain area of the mold; then place the mold on a hydraulic or electronic universal testing machine

[0030] (2) Adjust the fastening bolt 7, the splint 3 makes the support block 8 evenly squeeze the plate B12 to move to the plate A11 through the elastic support piece 5 to fix the gasket 2 and the magnesium alloy plate 4; through the hydraulic or electronic universal testing machine along the parallel The length direction of the magnesium alloy plate is pre-deformed and compressed, and the deformation rate is 0.1mm / s;

[0031] (3) The deformed and compressed magnesium alloy sheet is kept at 300°C for 90 minutes to c...

Embodiment 2

[0036] (1) Take an AZ31 magnesium alloy plate with a hypotenuse at an angle of 10° and a size of 100mm (width)×100mm (length)×1mm (thickness), and a gasket with an angle of 10° at the hypotenuse, place the magnesium alloy plate on Homogenized annealing treatment at 300°C for 60 minutes, then place the gasket and magnesium alloy plate along the inclined sheet in the strain area of the mold; then place the mold on a hydraulic or electronic universal testing machine.

[0037] (2) Adjust the fastening bolt 7, the splint 3 makes the support block 8 evenly squeeze the plate B12 to move to the plate A11 through the elastic support piece 5 to fix the gasket 2 and the magnesium alloy plate 4; through the hydraulic or electronic universal testing machine along the parallel The length direction of the magnesium alloy plate is pre-deformed and compressed, and the deformation rate is 1mm / s;

[0038] (3) The deformed and compressed magnesium alloy sheet is kept at 300°C for 120 minutes to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com