Patents

Literature

43results about How to "Weakened texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Large reduction rolling method for magnesium alloy

ActiveCN103962376AIncrease single pass reductionReduce rolling passesAuxillary arrangementsMetal rolling arrangementsThermal insulationManganese

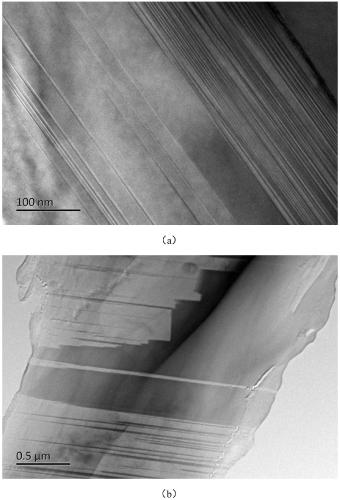

The invention relates to a large reduction rolling method for magnesium alloy. According to the rolling method, a hard alloy lining plate is additionally arranged on the upper surface or the lower surface of the magnesium alloy, or two hard alloy lining plates are additionally arranged on the upper surface and the lower surface of the magnesium alloy at the same time, and the added hard alloy lining plates are rolled synchronously together with the magnesium alloy. The rolling method includes the steps that after a high temperature lubricating agent is evenly smeared on the surfaces of the lining plates and the surface of the magnesium alloy, the high temperature lubricating agent, the lining plates and the magnesium alloy are simultaneously placed into a heating box to be heated, after the temperature rises to a preset temperature, standing and thermal insulation are performed for a certain period of time, one hard alloy lining plate is placed on the upper surface or the lower surface of magnesium alloy blank, or the two hard alloy lining plates are placed on the upper surface and the lower surface of the magnesium alloy at the same time, and the hard alloy lining plates and the magnesium alloy are simultaneously fed into the position between rollers so that rolling can be completed. Through the method, the single pass reduction of the magnesium alloy can be greatly increased in the rolling process, the number of rolling passes is decreased, magnesium alloy crystalline grains are thinned, the texture is weakened, magnesium alloy plates with high strength and plasticity are prepared, and the large reduction rolling method for the magnesium alloy is also suitable for the large deformation rolling process of titanium, manganese and metal-matrix composite materials.

Owner:JILIN UNIV

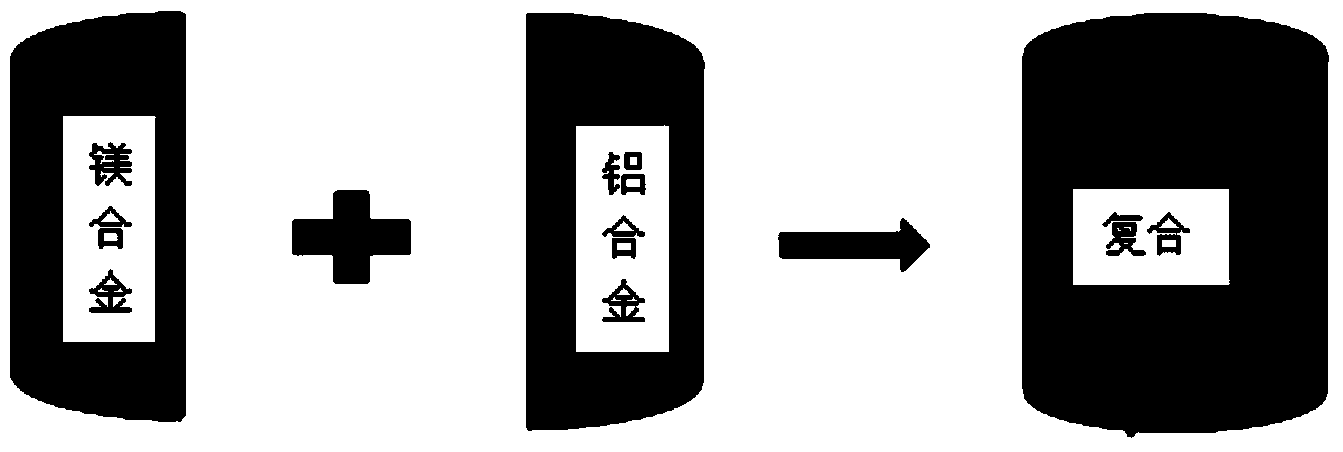

Method for extruding high-performance light alloy sheet materials

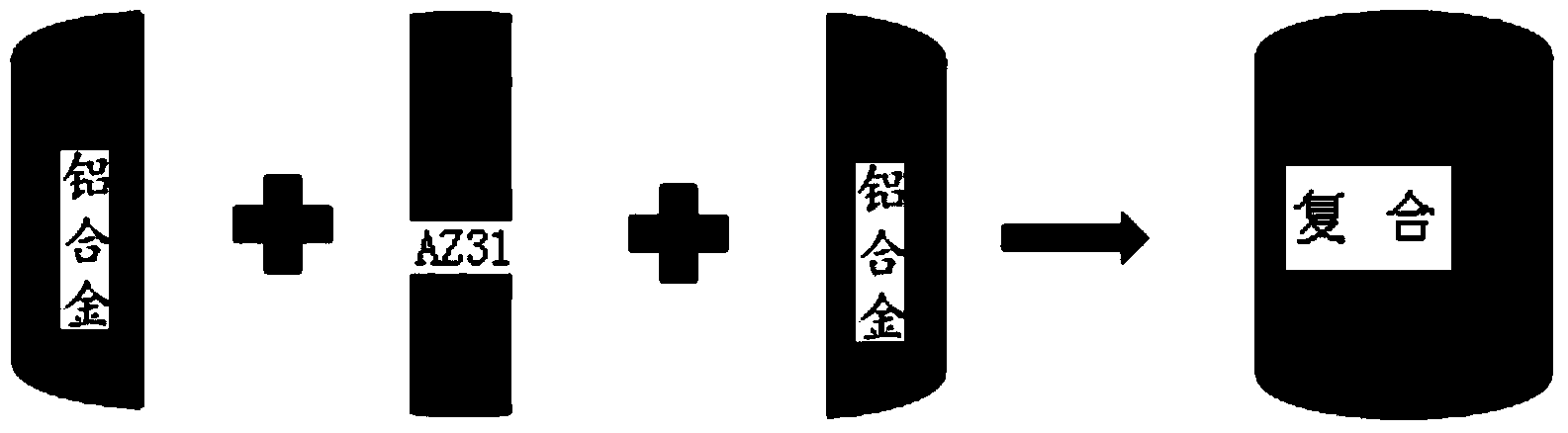

The invention discloses a method for extruding high-performance light alloy sheet materials. The method comprises the following steps: 1) respectively taking at least one block of magnesium alloy and at least one block of aluminium alloy, and overlapping and fixing the magnesium alloy and the aluminium alloy; 2) putting a magnesium-aluminium composite block which is obtained in the step 1) into an extrusion mould to extrude the magnesium-aluminium composite block, and at the same time extruding the magnesium-aluminium composite block from the extrusion mould to obtain the composite extrusion sheet materials. According to the method for extruding the high-performance light alloy sheet materials, disclosed by the invention, greater shear stress is introduced in the same metal block, and metal mixing does not occur among all the metal sheet materials, so that crystal grains can be refined, and the texture can be weakened; for the method for extruding the high-performance light alloy sheet materials, which disclosed by the invention, only the extruding and compositing manner needs to be changed, and the extrusion mould does not need to be redesigned, so that the method has a greater production and research value.

Owner:CHONGQING UNIV

Method for preparing fine-grained magnesium alloy with superplastic deformability

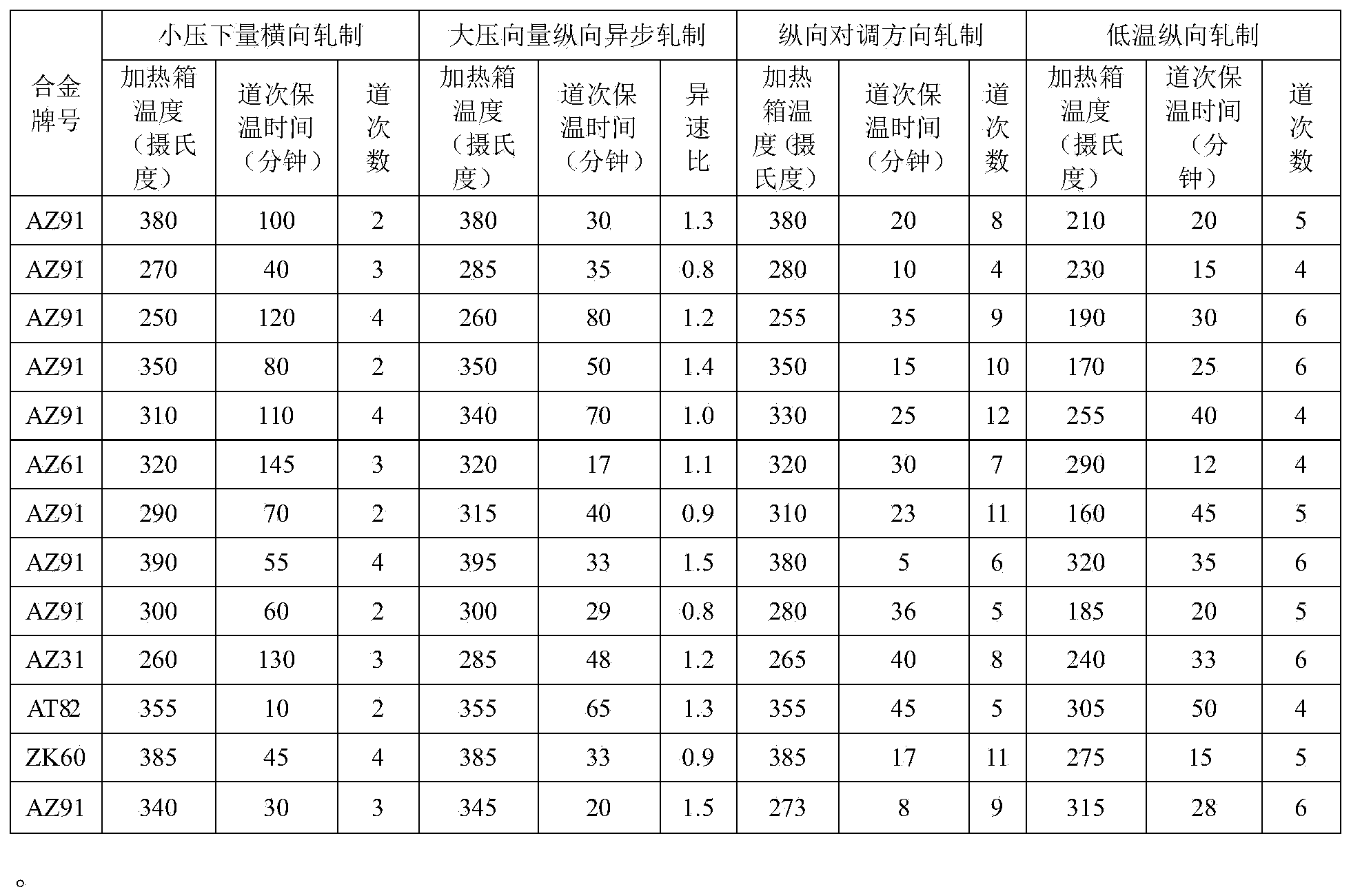

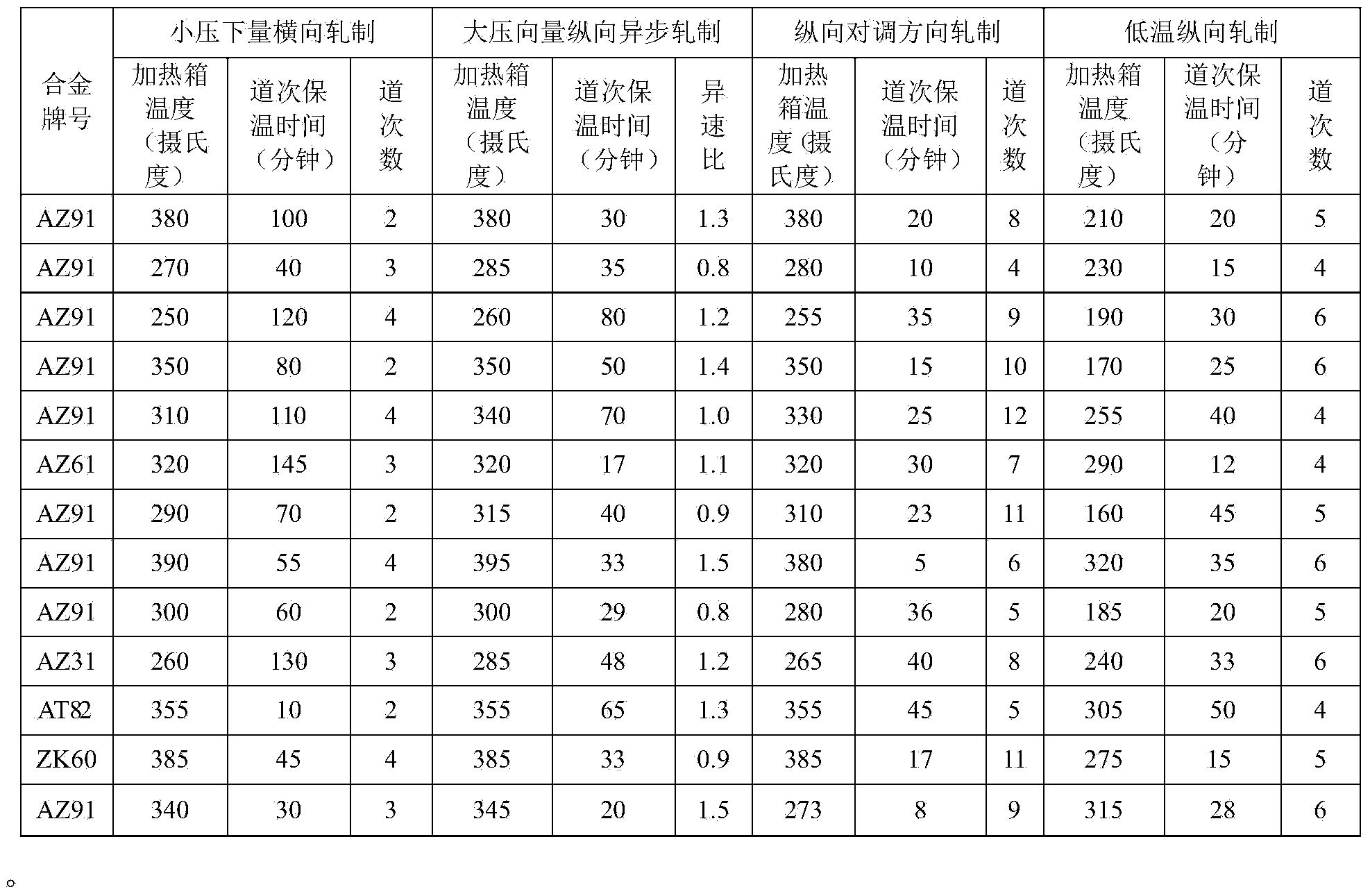

The invention relates to a method for rolling fine-grained magnesium alloy with superplastic deformability. The method comprises the steps of low-rolling-reduction transverse rolling, high-rolling-reduction longitudinal asynchronous rolling, longitudinal reversed-direction rolling, low-temperature longitudinal rolling and annealing, and comprises the specific steps of heating a commercial magnesium alloy blank in a heating box, standing to preserve heat for a period of time after heating to a preset temperature, firstly pushing the magnesium alloy blank to an entrance of a rolling roller along the transverse direction, carrying out transverse rolling firstly, then, carrying out high-rolling-reduction longitudinal asynchronous rolling, then, carrying out longitudinal 180-degree-reversed rolling, then, carrying out low-temperature longitudinal rolling, and finally, carrying out low-temperature long-time annealing treatment or high-temperature short-time annealing treatment. According to the method, cracking during the rolling of the magnesium alloy can be reduced, the crystal grain of the magnesium alloy is refined, the texture is weakened, and the high-temperature plasticity of the magnesium alloy is improved; moreover, the process is simple and easy to operate, large-sized wide-width sheet materials can be prepared, and the formability of the magnesium alloy is improved remarkably, so that the method is applicable to the mass production of superplastic magnesium alloy and is prone to popularization and application.

Owner:JILIN UNIV

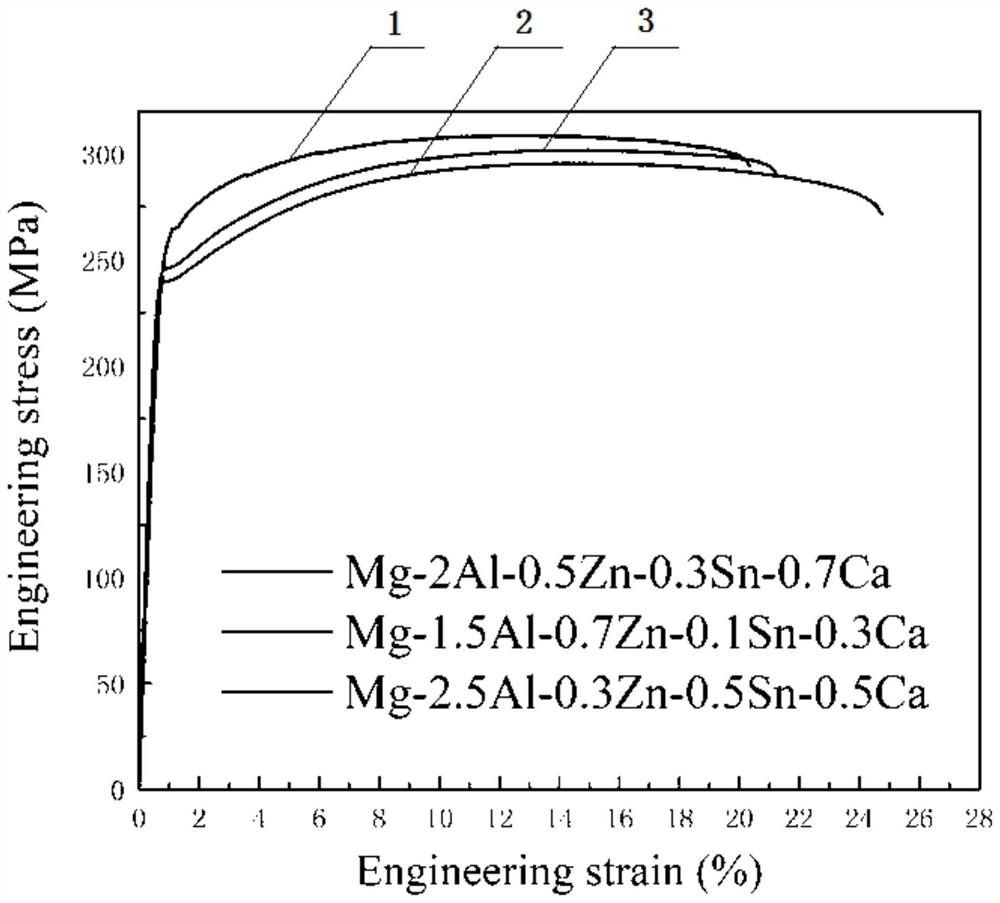

Low-cost high-compression-strength wrought magnesium alloy and preparation method thereof

InactiveCN108118225ANo significant increase in preparation costsRich varietyElemental compositionCu element

The invention relates to a low-cost high-compression-strength wrought magnesium alloy and a preparation method thereof. The magnesium alloy material is composed of six elements, namely Mg, Zn, Mn, Sn,Ca and Cu, wherein the content of the Zn element is 4.0%-8.5%, the content of the Mn element is 0.1%-0.4%, the content of the Sn element is 0.1%-0.4%, the content of the Ca element is 0.1%-0.4%, thecontent of the Cu element is 0.1%-0.4%, the content of inevitable impurities is less than or equal to 0.15%, and the balance is the Mg; and compared with a traditional commercial grade magnesium alloymaterial, high compressive yield strength can be obtained after the magnesium alloy material is subjected to a conventional extrusion treatment, and the compressive yield strength of the alloy is obviously higher than tensile yield strength. The magnesium alloy material does not contain precious alloy elements, and is simple in preparation process and low in cost, has very important practical value for manufacturing a pressed magnesium alloy component.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Extrusion method of metal composite board

The invention discloses an extrusion method of a metal composite board. The extrusion method of metal composite board comprises the following steps: firstly, laminating and fixing homogeneous or heterogeneous metal blocks together; secondly, adding the raw material into an extruding barrel for extruding, and extruding the homogeneous or heterogeneous metal blocks from an extruding mould port simultaneously in the extruding process to obtain an extruded composite board, wherein in the extruding process, macroscopic sliding between the metal blocks on the two sides of each contact interface between the metal blocks does not exist, and extruding flow velocity difference of the same metal block between a position near the contact interface and a position far away from the contact interface exists. According to the extrusion method of the metal composite board, relatively large shear stress is introduced into the same metal block, so that grains can be significantly refined and the texture can be significantly weakened; according to the extrusion method of the metal composite board, only an extruding composite way is required to be changed and the extruding barrel is not required to be redesigned, so that the extrusion method of the metal composite board has relatively high production and research values.

Owner:CHONGQING UNIV

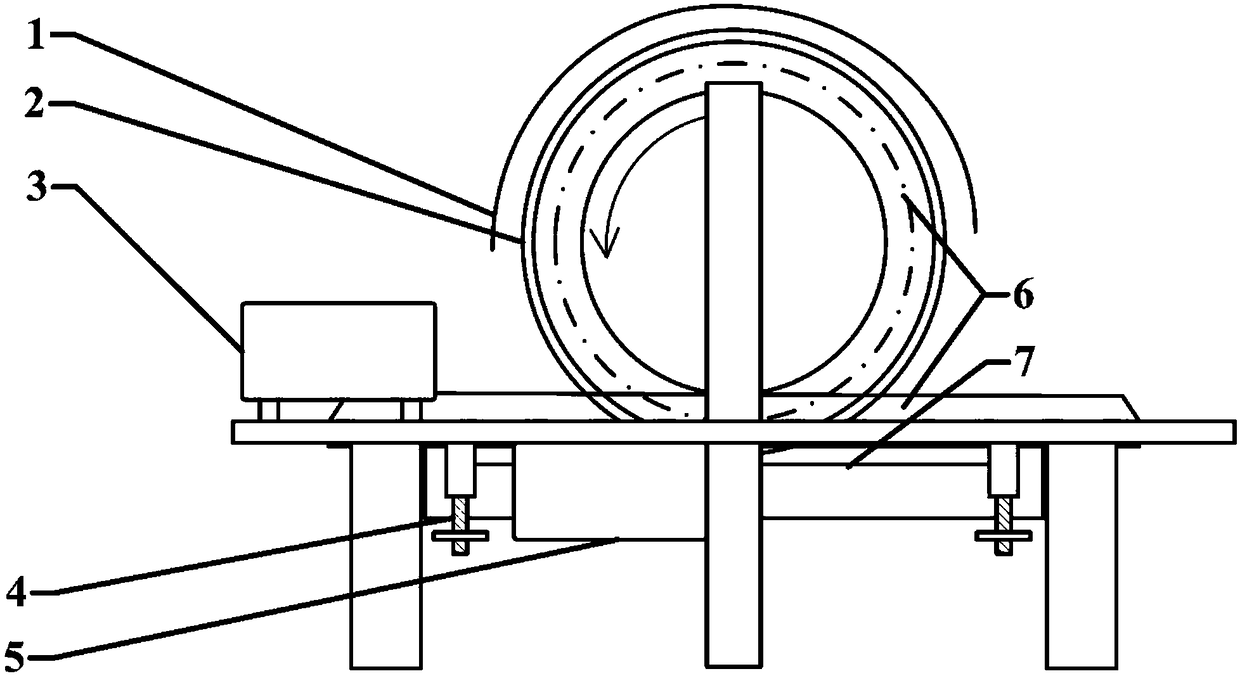

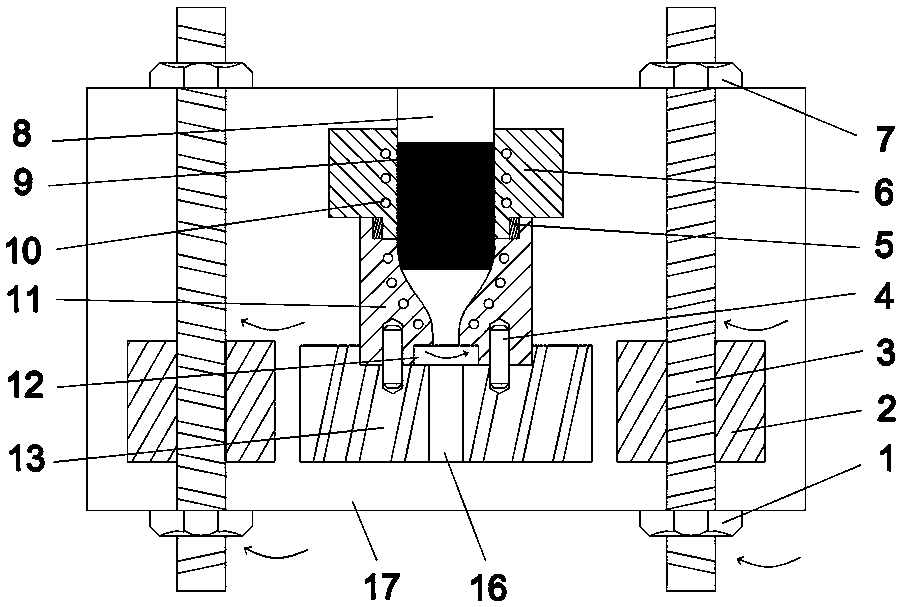

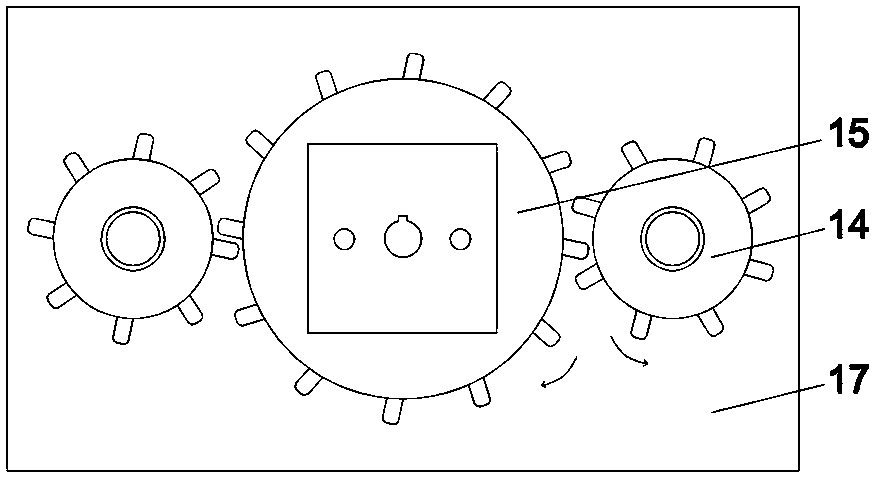

Large-deformation rolling technology based on asymmetric rolling equipment

ActiveCN108126981AMeet different shape forming requirementsWeakened textureMetal rolling arrangementsGear wheelThree-phase

The invention relates to a large-deformation rolling technology based on asymmetric rolling equipment. According to the large-deformation rolling technology based on the asymmetric rolling equipment,a detachable bottom plate is replaced with a shaping demand bottom plate, a hydraulic adjustment device is adopted to adjust spacing between a roller and the bottom plate, the rolling temperature is adjusted through a roller heating plate and a bottom plate heating device, before rolling, a sample is placed into a sample heating device to be preheated to reach a preset deformation temperature, thesample is pushed into a feeding opening, a transmission unit is driven by a three-phase motor to make the roller rotate, and a gear-rack transmission device makes the roller and the bottom plate linked to complete rolling. By the adoption of the large-deformation rolling technology based on the asymmetric rolling equipment, after rolling, recrystallization and annealing treatment are combined tocarry out synergistic regulation to obtain fine-grain superplastic structure, multi-grade structure structure in which large and small crystal particles are mixed can also be obtained, and the strength and the plasticity are greatly improved at the same time; the grain size of plates is reduced, the texture of rolled plates is weakened, the performance of the rolled plates is improved, through cooperation of the roller and the work bottom plate, different kinds of plates can be prepared, technological processes are reduced, the machining cost is reduced, and the production efficiency is improved.

Owner:JILIN UNIV

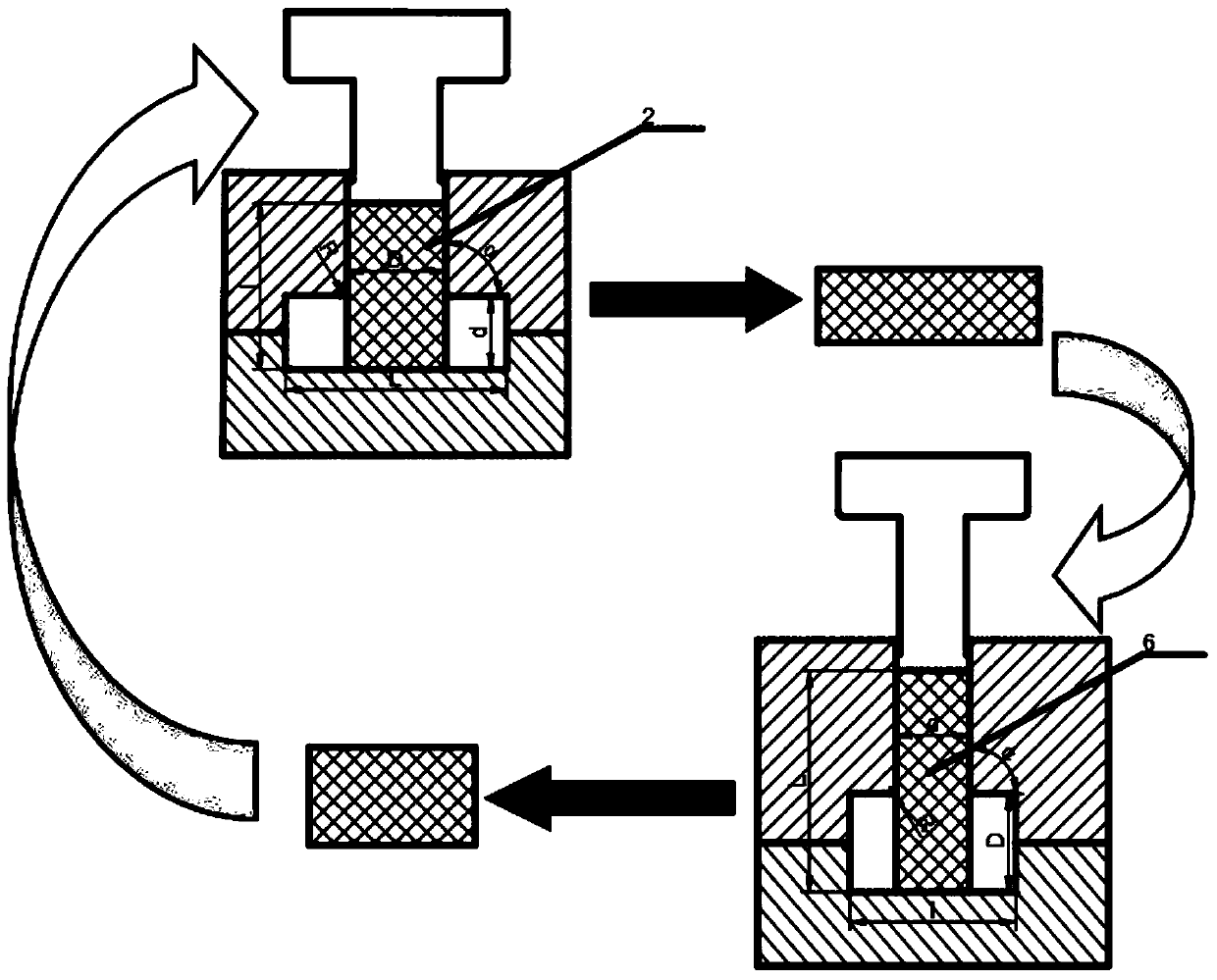

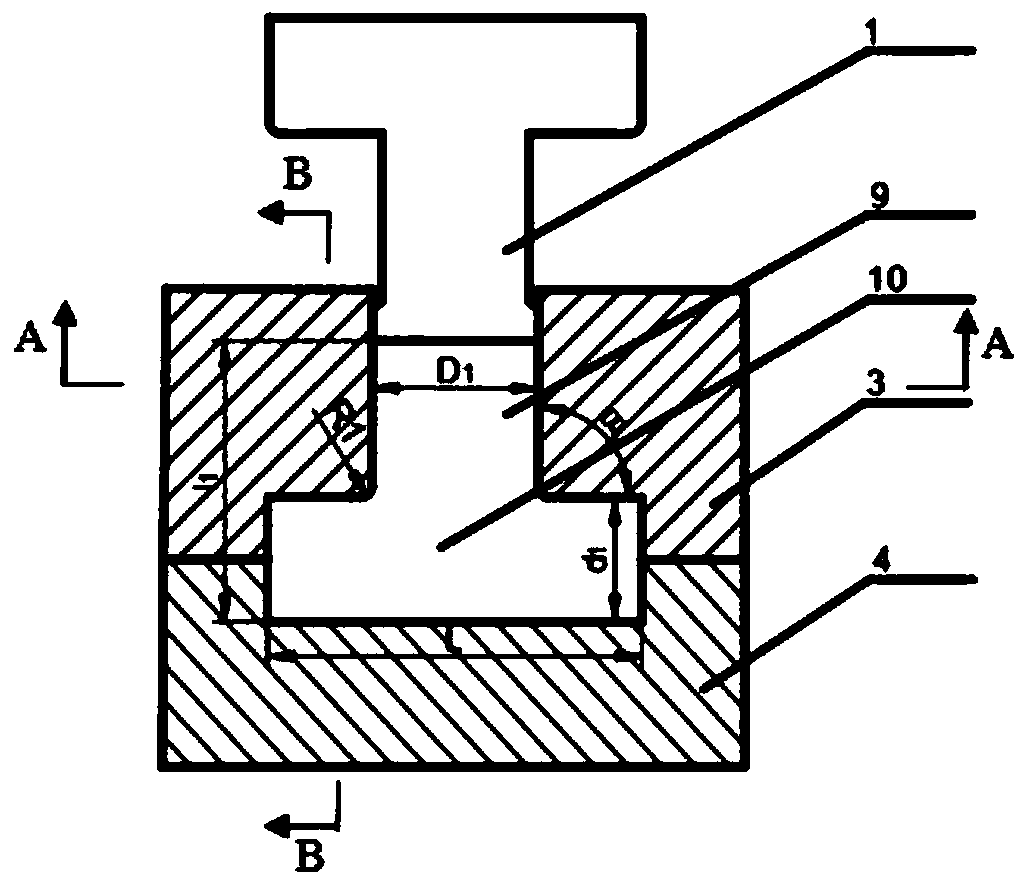

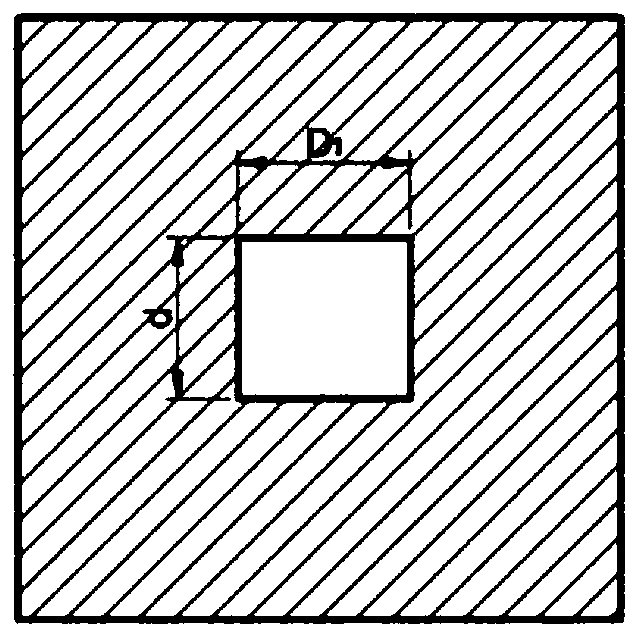

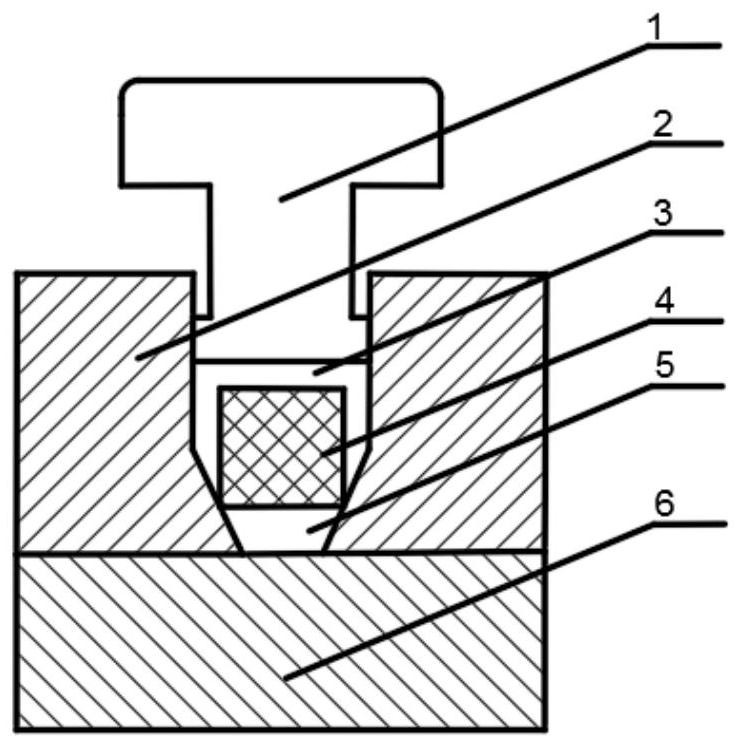

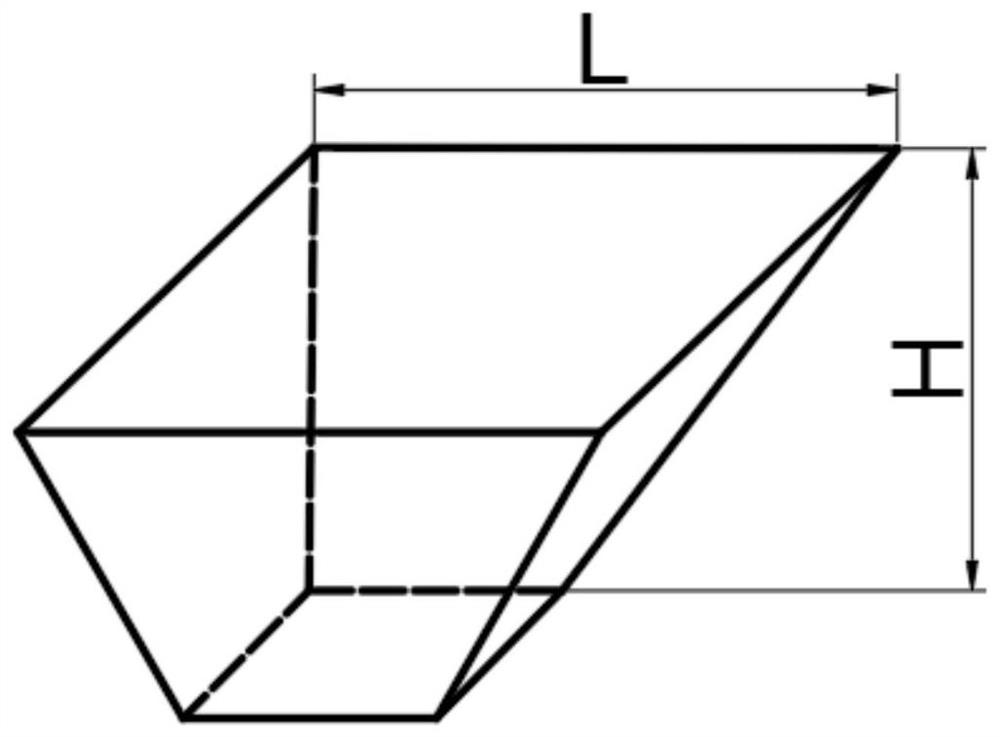

Device for preparing high-performance magnesium alloy through large plastic deformation and preparation method

ActiveCN110000322AControl upsetting deformationSmall machining allowanceExtrusion diesForging/hammering/pressing machinesCrystal structurePlastic property

The invention discloses a device for preparing a high-performance magnesium alloy through large plastic deformation and a preparation method. The device comprises a die I and a die II which have the same structure; each die comprises a male die, an upper female die and a lower female die; a cuboid-shaped extrusion channel is horizontally formed between each upper female die and the corresponding lower female die; the upper female die is vertically penetrated to be provided with a male die channel; the male die channel communicates with the extrusion channel and is matched with the male die; the width of the male die channel of the die I is equal to the height of the extrusion channel of the die II, and the width of the male die channel of the die II is equal to the height of the extrusionchannel of the die I; and the thicknesses of the male die channels and the extrusion channels are equal. According to the device for preparing the high-performance magnesium alloy through the large plastic deformation and the preparation method, the magnesium alloy is repeatedly upset and extruded by replacing the dies to continuously accumulate strain, so that mass points of the magnesium alloy are expected to uniformly generate corner shearing, expansion and upsetting deformation, and finally a texture is weakened while forming a uniform fine crystal structure so as to prepare the high-performance magnesium alloy.

Owner:HUNAN UNIV OF SCI & TECH

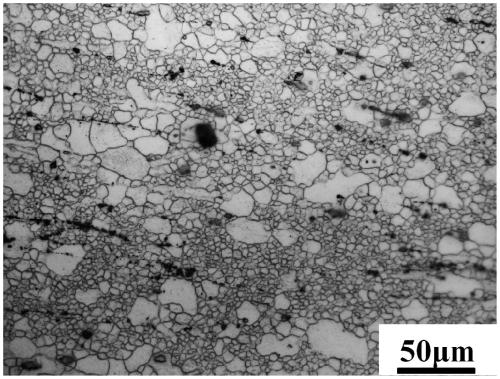

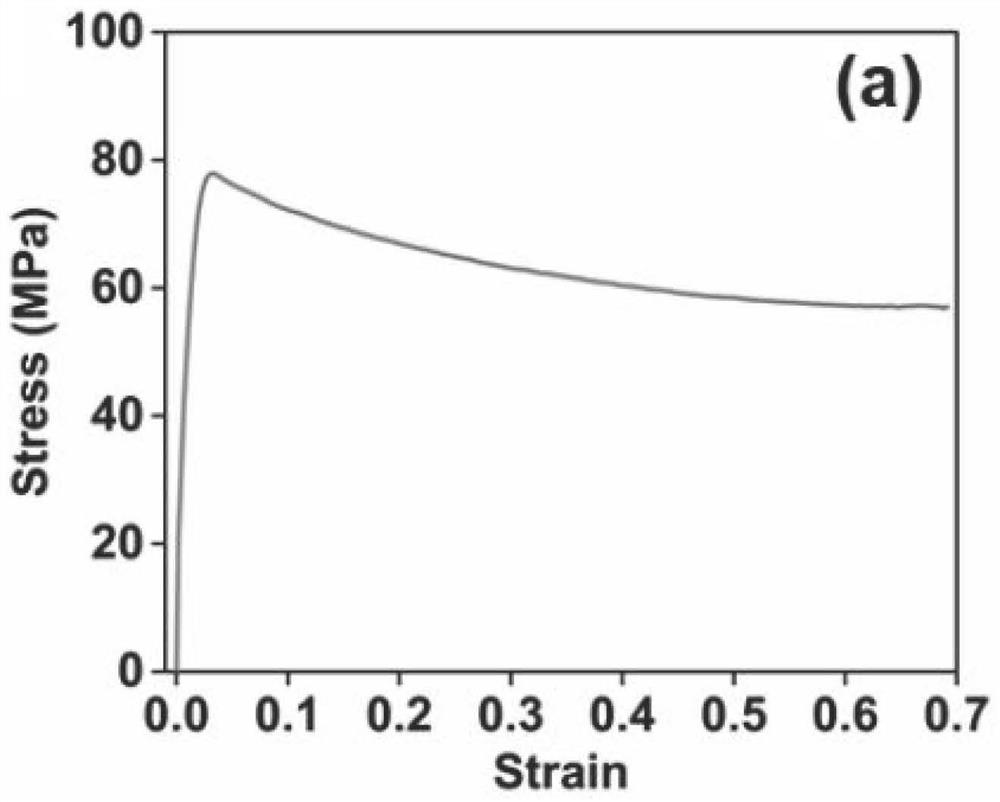

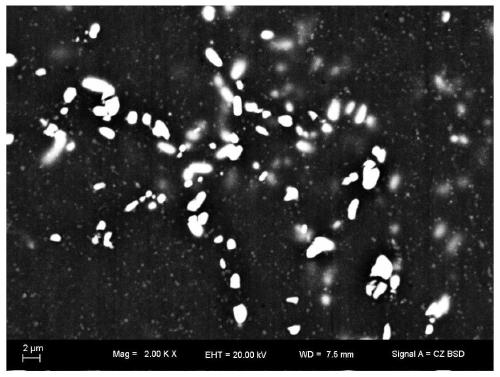

Low-cost high-plastic-deformation magnesium alloy

The invention discloses a low-cost high-plastic-deformation magnesium alloy. The magnesium alloy comprises the following components in percentage by mass: 0.5-4.0% of Mn, 0.1-0.5% of Al and the balance of magnesium and inevitable impurities. In an Mg-Al-Mn ternary system, elements manganese and aluminum define an aluminum-manganese phase, and a rich manganese element defines an elemental manganesephase. In a preparation process, an extrusion process at a relatively low temperature is adopted to prepare a high-plasticity magnesium alloy material which is suitable for 3C product shells, bearingstructures for leisure goods as well as aerospace parts and the like; and the material is simple in preparation process, is low in cost, and has a very good industrialized prospect.

Owner:CHONGQING UNIV

Screw-driven synchronous extruding and twisting composite device for fine-grain magnesium alloy and processing method

ActiveCN110560500AImprove mechanical propertiesGuaranteed deformation uniformityExtrusion diesExtrusion cleaning devicesFine grainSevere plastic deformation

The invention discloses a screw-driven synchronous extruding and twisting composite device for a fine-grain magnesium alloy and a processing method, and relates to the technical field of magnesium alloy application. The device comprises a base and a magnesium alloy blank, wherein a concave extrusion die is arranged at the upper end of the middle part of the inner side of the base, and the lower end of the concave extrusion die is in rotating connection with a variable-section concave extruding and twisting die through a roller bearing; the magnesium alloy blank is arranged in the concave extrusion die and the variable-section concave extruding die; a convex extrusion die is glidingly connected with the upper end of the inner side of the concave extrusion die and is positioned right above the magnesium alloy blank; a discharging port is formed in the middle part of the lower end of the inner side of the variable-section concave extruding and twisting die; and a synchronous twisting device is fixedly connected to the bottom part of the variable-section concave extruding and twisting die. According to the device, a severe plastic deformation process in which extruding and twisting aresynchronously carried out is achieved, and thus the deformation uniformity of the magnesium alloy blank is ensured in the process of fully refining grains.

Owner:TAIYUAN UNIV OF TECH

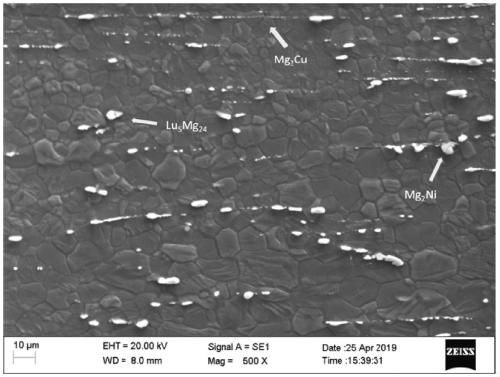

Heat-resistant soluble magnesium alloy and preparation method and application thereof

ActiveCN110129644ARefine the grain sizeHigh elongationSealing/packingElemental compositionMechanical property

The invention relates to a heat-resistant soluble magnesium alloy and a preparation method and application of the heat-resistant soluble magnesium alloy. The heat-resistant soluble magnesium alloy isprepared from the following elements comprising by atom, 0.10%-8.00% of Lu, 0.001-0.05% of Ce, 0.10%-0.60% of Al, 0.001%-0.50% of Ca, 0.01%-1.00% of Cu, 0.01%-1.00% of Ni, less than 0.30% of impurityelements and the balance Mg. Lu5Mg24, Mg2Cu, Mg2Ni, Mg12Ce, Al11Ce3 and (Mg, Al) 2Ca high-temperature phases and long period orderly-stacked LPSO phase Mg-Lu-Al and Mg-Ce-Al are formed in the magnesium alloy. The magnesium alloy has good mechanical properties at 150 DEG C, and the dissolution rate of the magnesium alloy in the 3% KCl solution at 93 DEG C is 30-100mg.cm<-2>h<-1>.

Owner:重庆昱华新材料科技有限公司

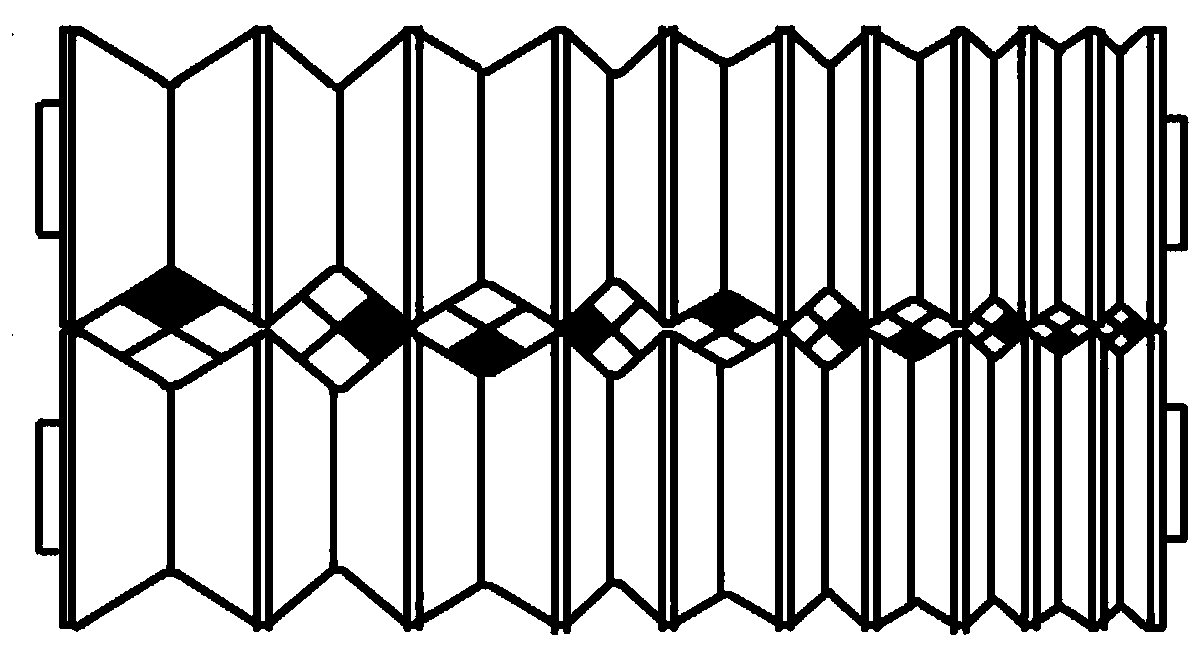

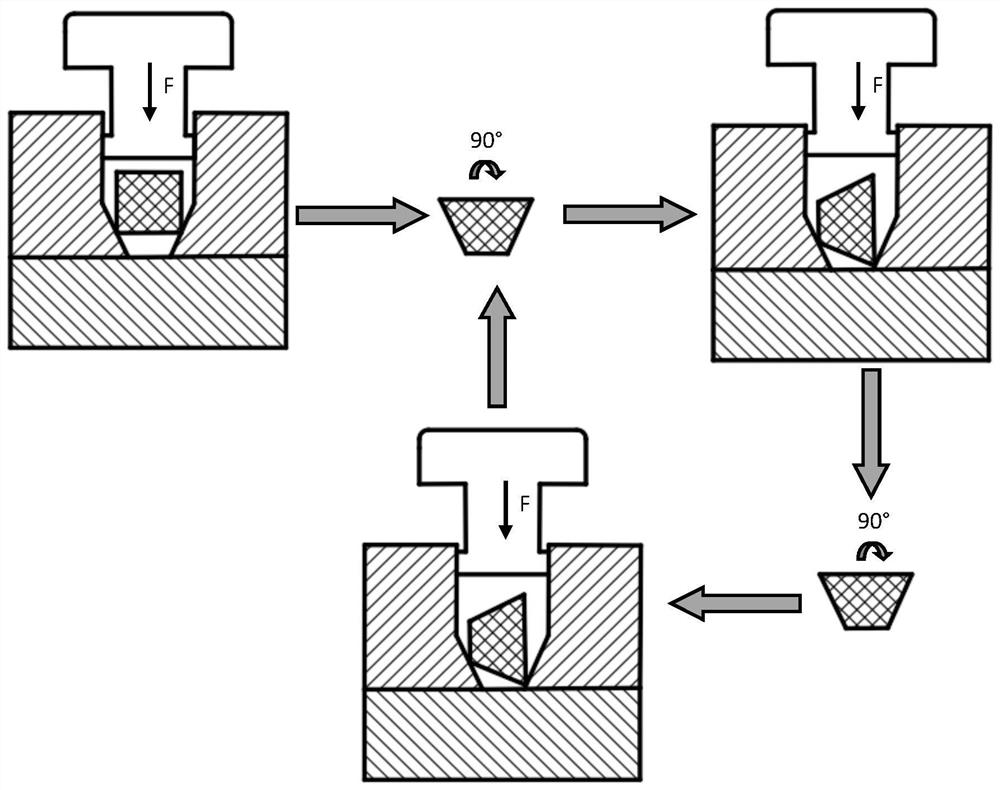

Manufacturing method of magnesium alloy bar

ActiveCN110802125AImprove mechanical propertiesReduce texture strengthRollsMetal rolling arrangementsMetallurgyRolling speed

The invention discloses a manufacturing method of a magnesium alloy bar. The manufacturing method of the magnesium alloy bar comprises the following steps that a raw blank is machined, so that the baris obtained; the bar is extruded; the bar is preheated; and the obtained magnesium alloy bar is subjected to hole pattern rolling operation, the rolling operation is conducted in sequence according to the diamond-square mode, 1-4 passes are conducted through the rolling operation, the rolling speed is 0.1m / s-0.5m / s, the bar is rotated by 90 degrees when each pass is changed in the rolling process, finally the square hole serves as the final rolling pass, the correction is conducted for one time, and therefore the final form of the bar can be guaranteed. By the adoption of the manufacturing method of the magnesium alloy bar, the anisotropy of the bar which is extruded to deform can be remarkably improved, and the toughness of the bar can be further improved.

Owner:HEBEI UNIV OF TECH

Magnesium alloy thick plate and preparation method thereof

ActiveCN112481536ASolve rolling difficultiesSolve the mechanical propertiesThick plateMagnesium alloy

The invention aims to provide a preparation method of a novel magnesium alloy thick plate. The alloy comprises, by mass, 3.5-5.0% of Al, 2.0-3.5% of Zn, 0.1-0.8% of Mn, 0.01-0.80% of RE, 0.001-0.090%of Ca, less than or equal to 0.005% of Fe, less than or equal to 0.05% of Si, less than or equal to 0.005% of Cu, less than or equal to 0.005% of Ni and the balance Mg, and the total content of impurities does not exceed 0.1%, wherein the sum of the Al content and the Zn content satisfies the condition that Al+Zn is greater than or equal to 6% and less than or equal to 8%. Aiming at a novel Mg-Al-Zn alloy system, a forming process for preparing the large-size magnesium alloy thick plate with low anisotropy and high strength is developed to satisfy urgent demands of such fields as aerospace, weaponry and automobiles on the magnesium alloy thick plate with low cost and high performance.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

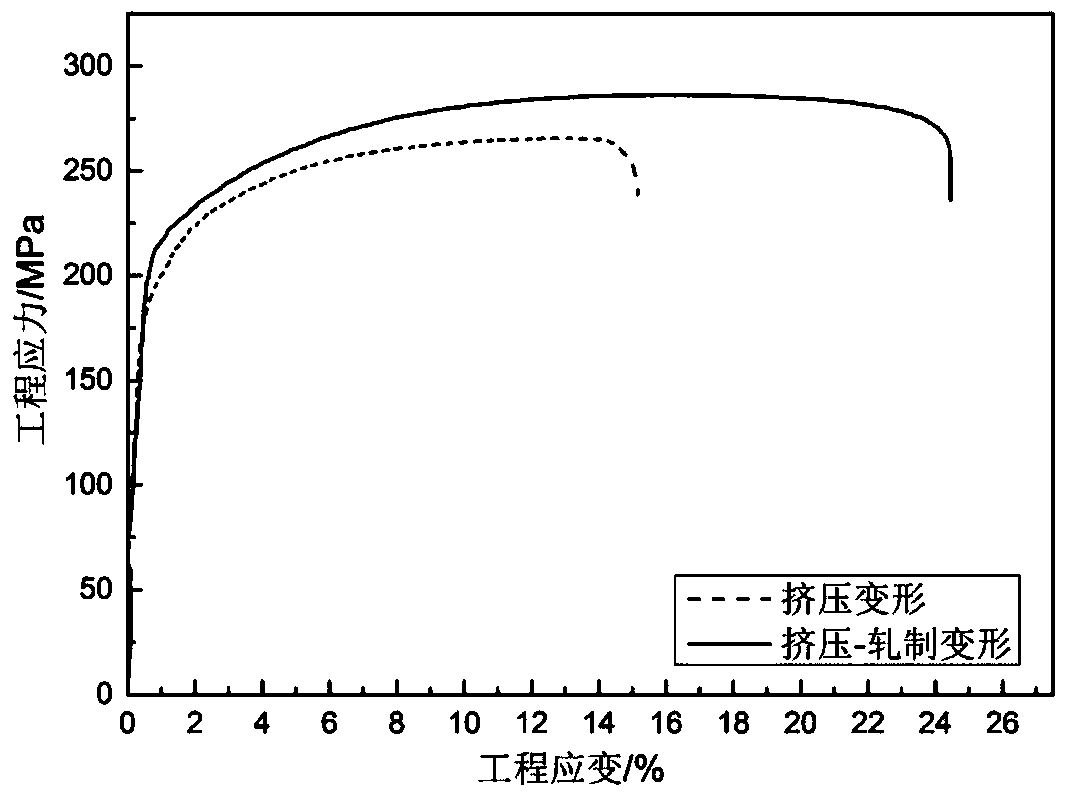

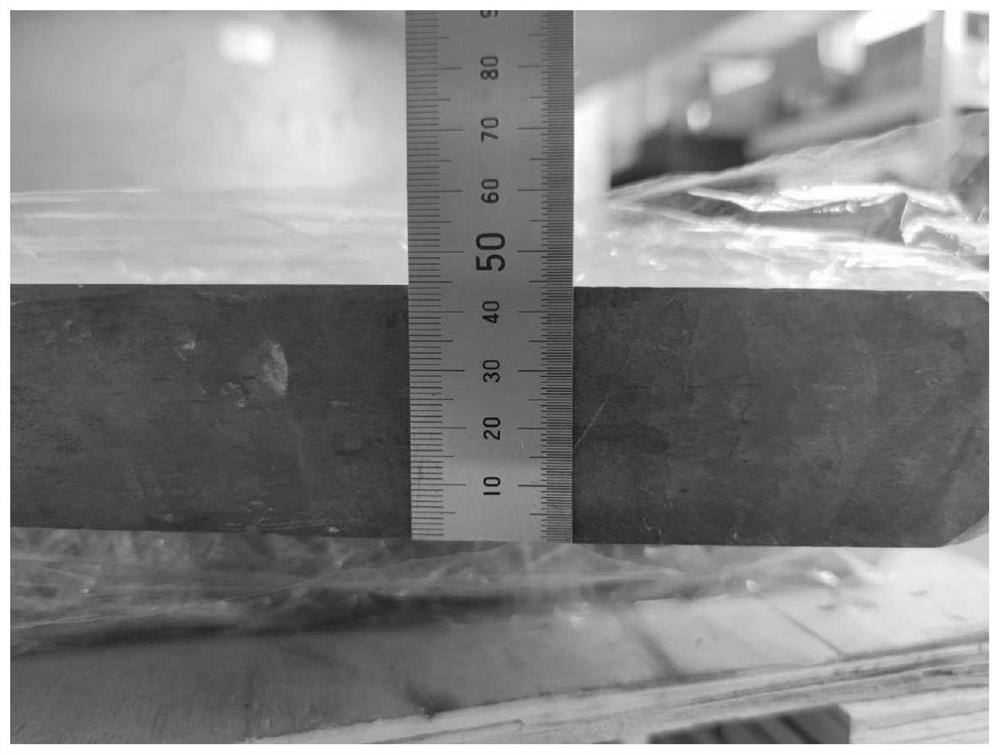

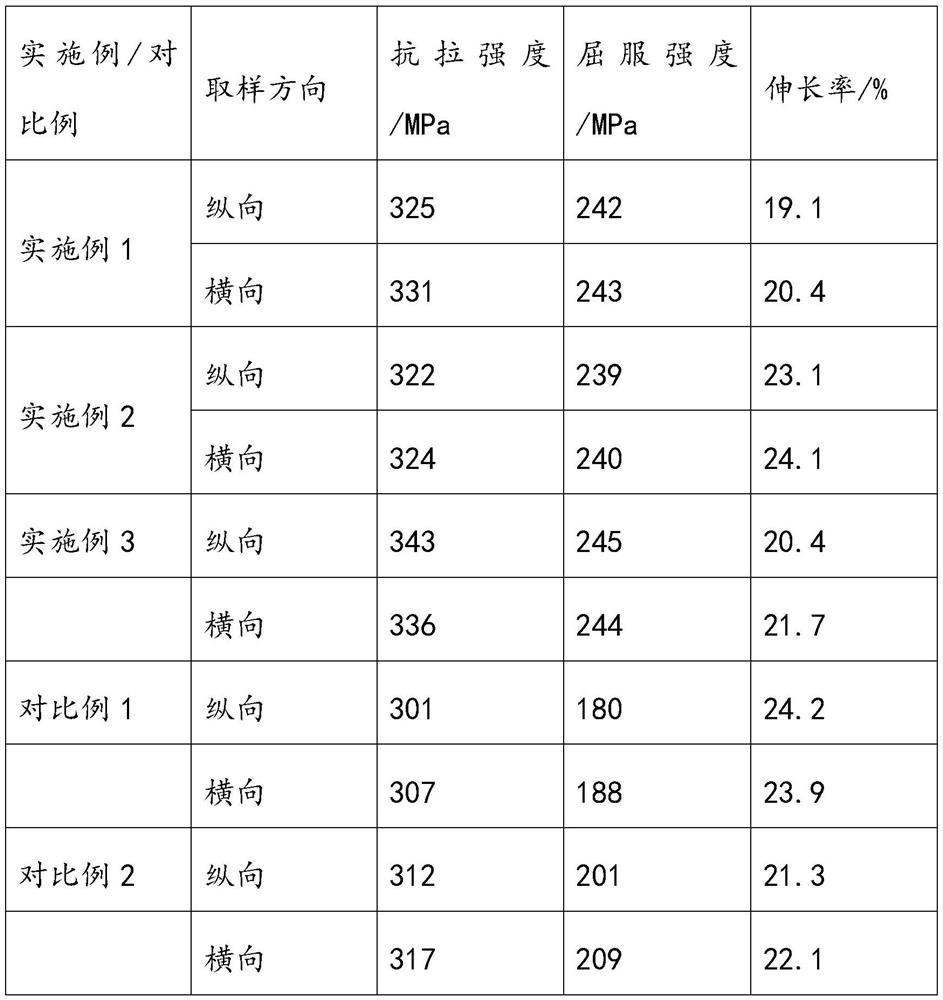

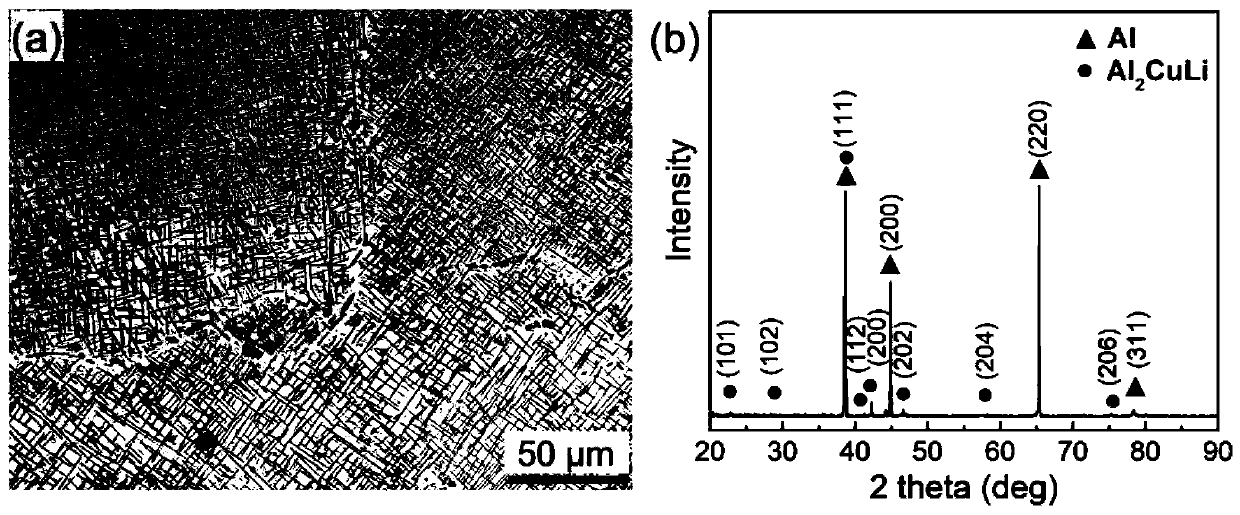

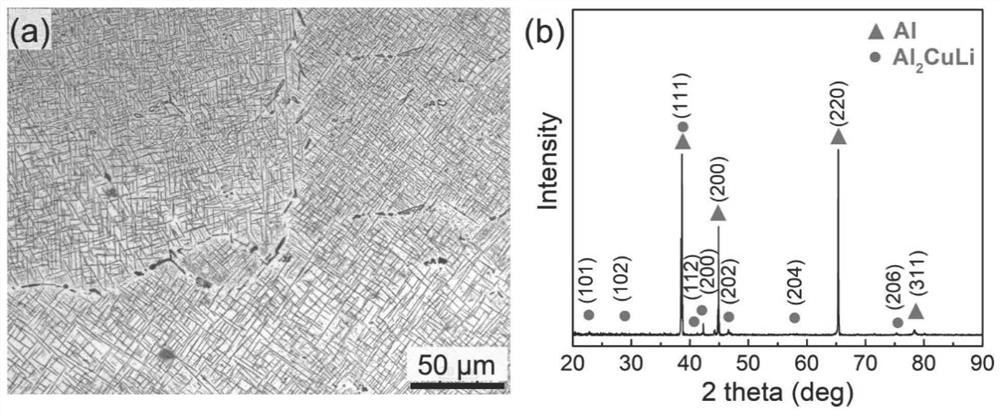

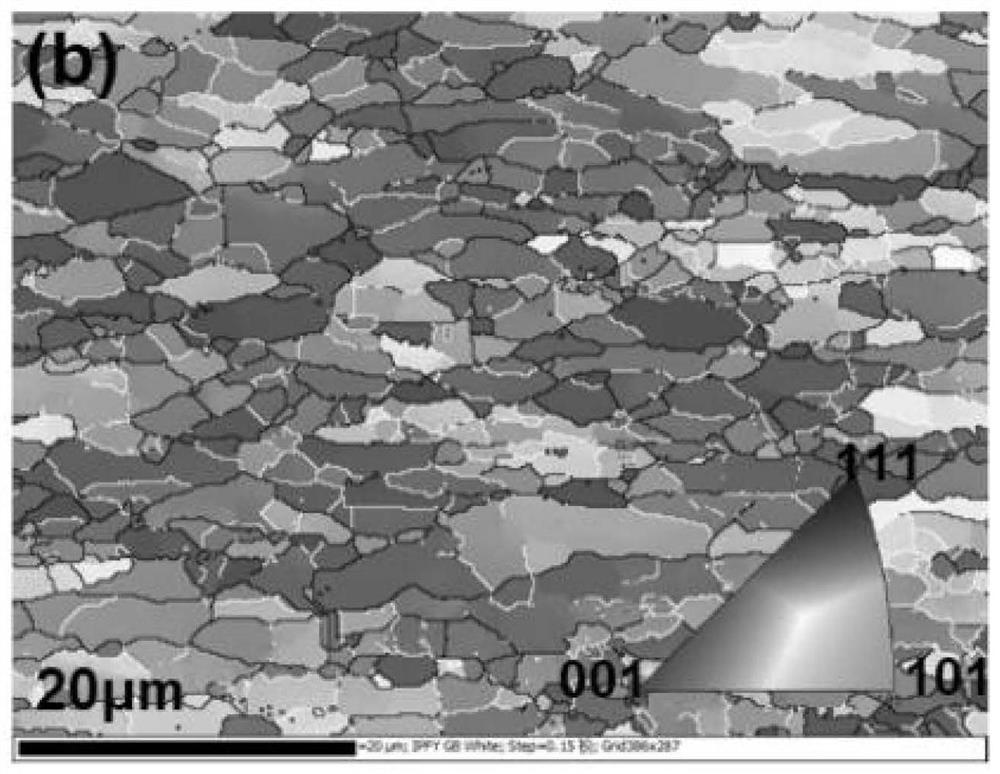

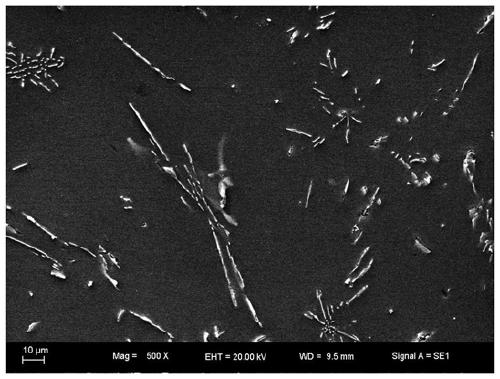

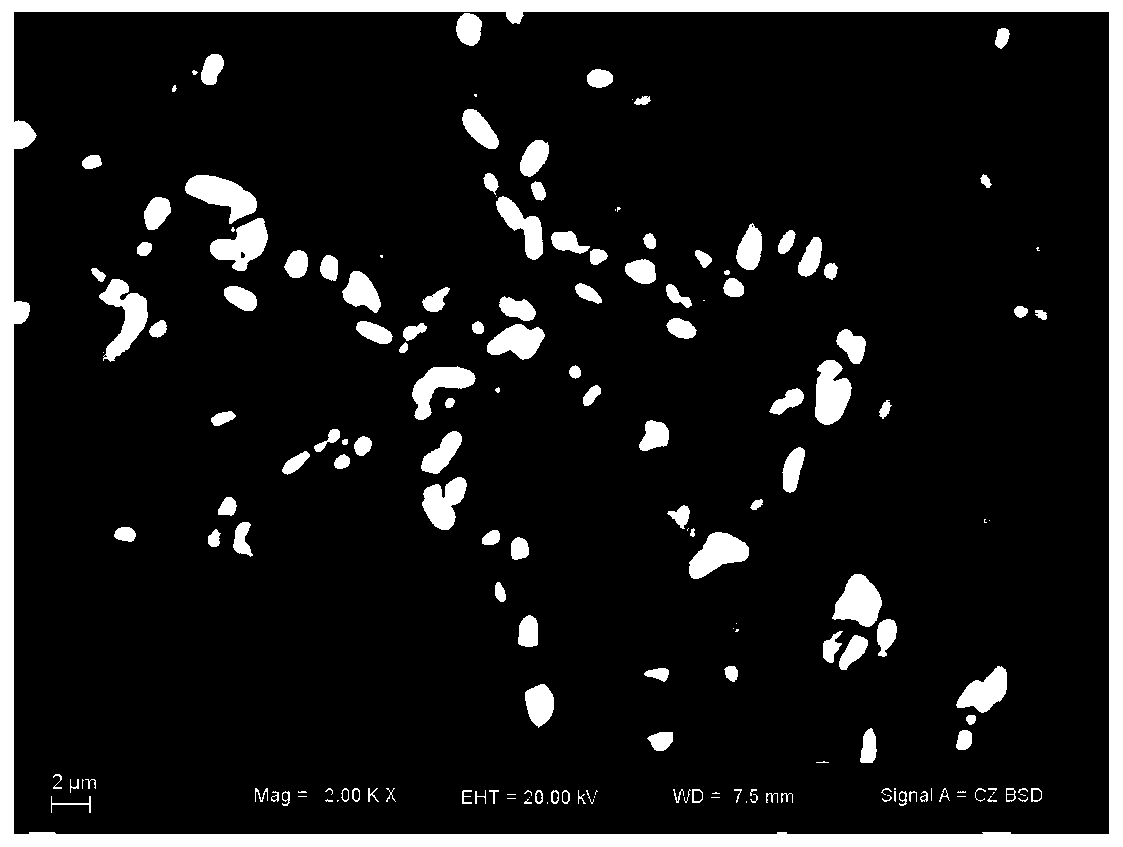

Al-Cu-Li alloy deformation heat treatment process based on particle stimulated nucleation

ActiveCN110541131AImprove the degree of recrystallizationFine grainMicron scaleManufacturing technology

The invention discloses an Al-Cu-Li alloy deformation heat treatment process based on particle stimulated nucleation, and belongs to the technical field of aerospace component manufacturing. Accordingto the process, an Al-Cu-Li alloy can be remarkably promoted to be subject to thermal deformation and recrystallization to obtain an isometric fine crystal structure. The process comprises the following steps of carrying out homogenizing annealing on an alloy ingot to obtain a uniformly-distributed micron-scale T1 phase (Al2CuLi), then performing hot-pressing deformation, and annealing at a hightemperature. According to the process, the high-stability recrystallization structure in the Al-Cu-Li alloy can be obtained controllably, the recrystallization degree is high, the fine crystal effectis obvious, the structure is stable, the alloy texture can be remarkably weakened, the alloy anisotropy is reduced, and therefore the multi-directional bearing performance and the corrosion resistanceof the alloy are improved, the comprehensive service performance of the Al-Cu-Li alloy can be greatly improved, the application range of the Al-Cu-Li alloy in aerospace components can be extended, and the competitiveness of products such as materials / components can be improved

Owner:HARBIN INST OF TECH

High-strength and high-plasticity Mg-Al-Ce-(Nd) wrought magnesium alloy and preparation method thereof

The invention belongs to the field of nonferrous metal materials and machining thereof, and particularly relates to a high-strength and high-plasticity Mg-Al-Ce-(Nd) wrought magnesium alloy and a preparation method thereof. The high-strength and high-plasticity wrought magnesium alloy comprises the following components of, in percentage by mass, 0.1wt%-6.0 wt% of Al, 0.1wt%-3.0 wt% of Ce, 0wt%-3.0 wt% of Nd and the balance Mg and inevitable impurities, and the content of the impurities is less than or equal to 0.04 wt%. The high-strength and high-plasticity wrought magnesium alloy is prepared through a series of means such as melting, casting, homogenization treatment and backward extrusion. The wrought magnesium alloy with the submicron grain size is obtained by compositely adding Al, Ce and Nd elements and combining a backward extrusion process. In the extrusion process, high-density Mg17Al12, Al2Ce and Mg12Nd nano precipitated phases are dynamically precipitated and are partially dispersed and distributed on dislocation and grain boundaries (including small-angle grain boundaries), a remarkable precipitation strengthening effect is obtained, and the room-temperature mechanical property of the alloy is further improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

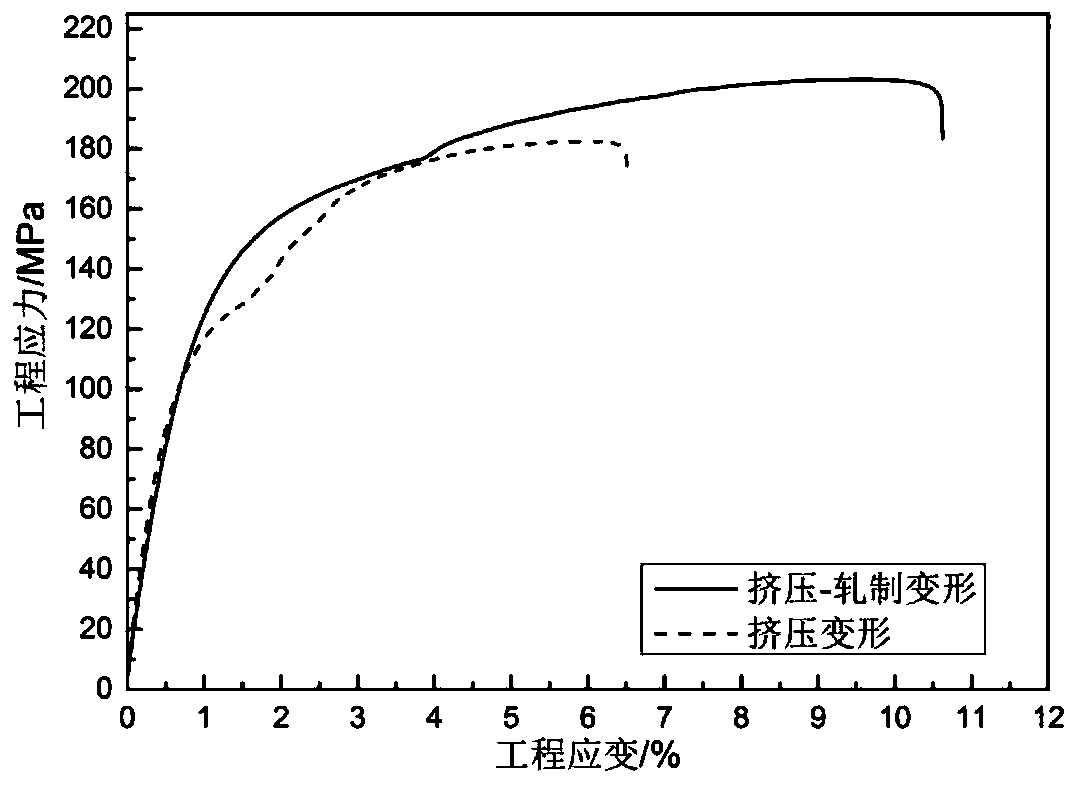

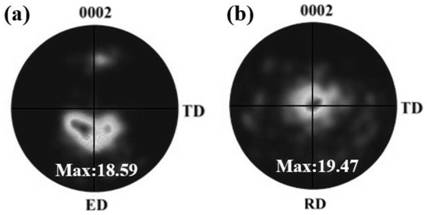

Method for achieving ATX series magnesium alloy plate texture weakening through asymmetric extrusion

ActiveCN112570480ACumulative strain increasesGood for solid solution strengtheningExtrusion diesIngotMachining

The invention discloses a method for achieving ATX series magnesium alloy plate texture weakening through asymmetric extrusion, and belongs to the technical field of magnesium alloy extrusion machining. The method comprises the following steps that an ATX series magnesium alloy ingot blank is homogenized, then a magnesium alloy plate is prepared by conventional extrusion, and the extruded plate ispreheated and put in an asymmetric extrusion die for being extruded. The central axis of a forming channel hole of the asymmetric extrusion die does not coincide with the central axis of an extrusiondie cavity, the proportions of blanks located on the left side and the right side of the forming channel hole in the die cavity are different, extra upsetting deformation is generated in the extrusion process of part of the blanks, the whole extrusion deformation process can be regarded as upsetting and extrusion deformation composite superposition, and therefore, the texture of the finally obtained asymmetric extrusion plate is obviously weakened compared with that of an initial extrusion plate. The asymmetric extrusion die is simple and convenient to manufacture, simple in technological operation and easy to implement, and has a good industrial application prospect.

Owner:JILIN UNIV

High-plasticity rapidly-degradable Mg-Li-Gd-Ni alloy and preparation method thereof

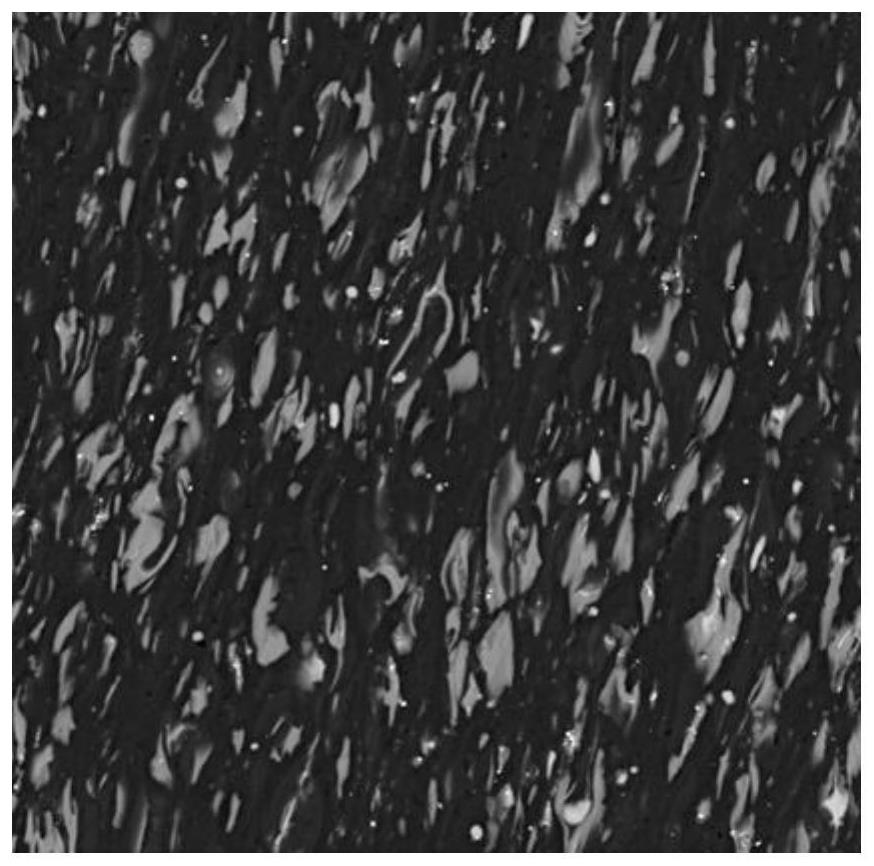

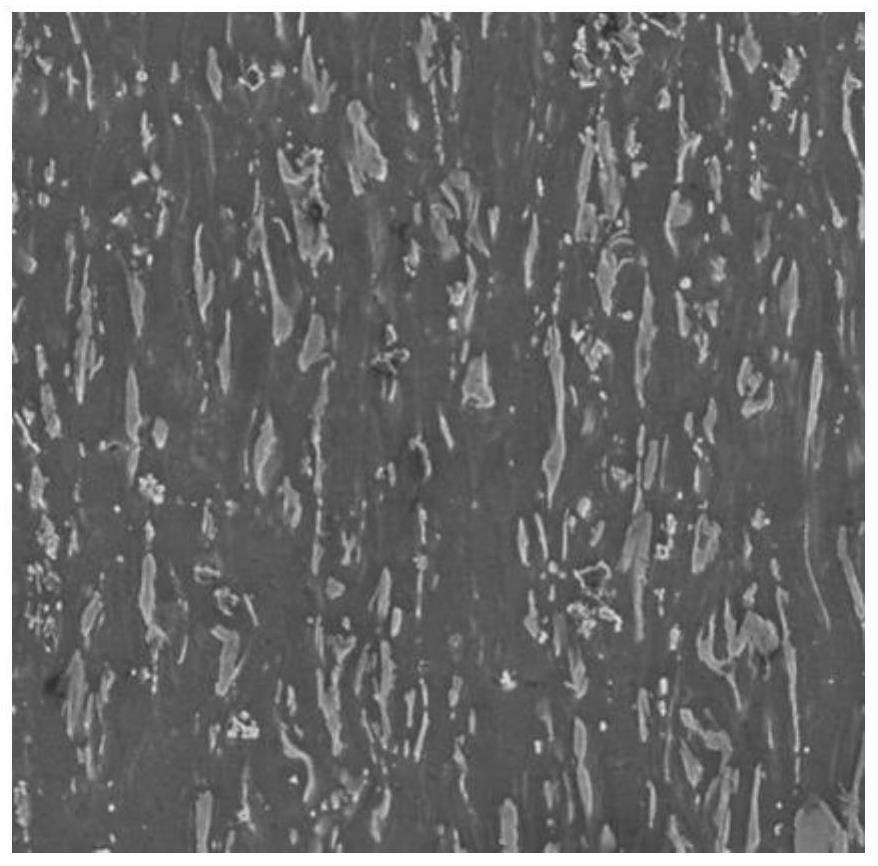

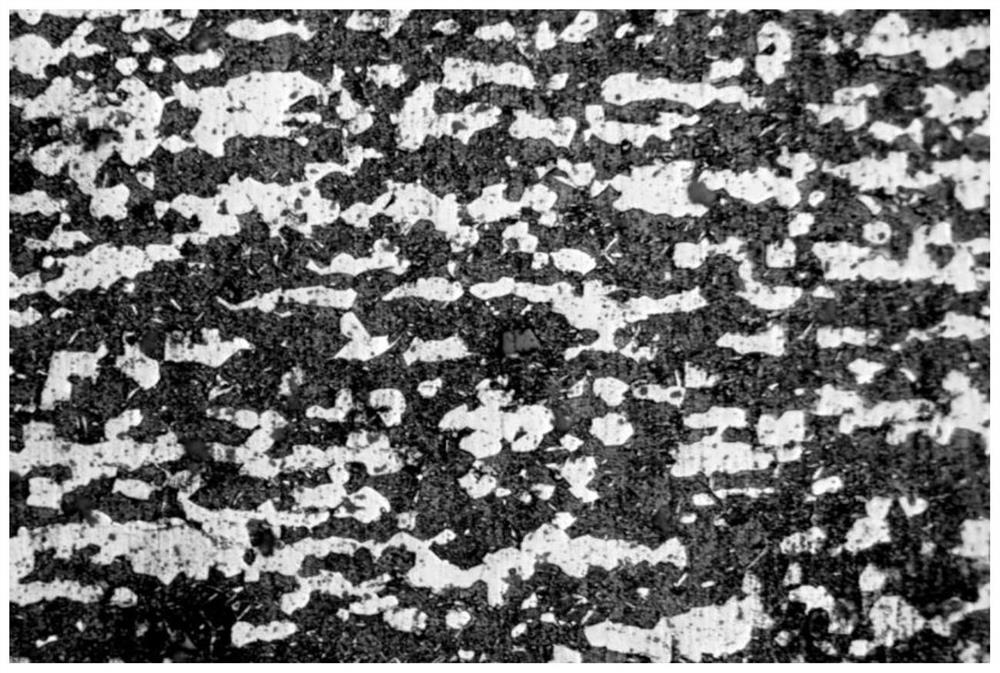

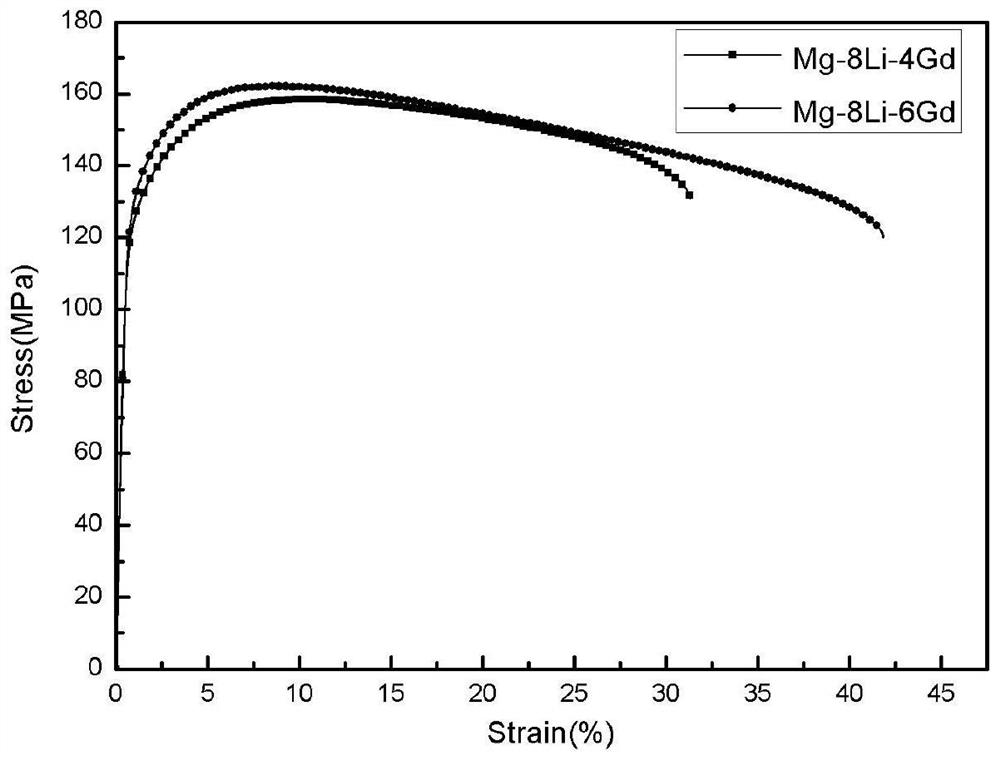

The invention discloses a high-plasticity rapidly-degraded Mg-Li-Gd-Ni alloy which comprises the following chemical elements in percentage by mass: 1.0-10.0% of Gd, 0.2-2.0% of Ni, 5.5-10% of Li and the balance of Mg and inevitable impurities, and the total content of the impurities is less than or equal to 0.3%. The invention further discloses a preparation method of the Mg-Li-Gd-Ni alloy with high plasticity and capable of being rapidly degraded. According to the high-plasticity rapidly-degraded Mg-Li-Gd-Ni alloy provided by the invention, beta-Li of a BCC structure with more slippage systems is introduced into alpha-Mg, so that an alpha-Mg + beta-Li dual-phase matrix structure is constructed, and the plasticity of the alloy is improved; then a certain amount of Gd element is added into the Mg-Li alloy, the texture is weakened, and non-basal plane slippage is promoted; the plasticity of the alloy is improved by compounding a beta-Li phase with good plasticity and a plurality of plasticizing methods for generating LPSO toughness and the like; and moreover, a high-potential Ni-LPSO-containing phase is introduced, a large potential difference is formed between the Ni-LPSO-containing phase and alpha-Mg and beta-Li, galvanic corrosion is accelerated, and the degradation performance of the alloy is improved.

Owner:CHONGQING UNIV

Weak-basal-texture high-strength magnesium-lithium alloy and preparation method thereof

ActiveCN114277295AGuaranteed StrengthHigh strengthFurnace typesHeat treatment furnacesUltimate tensile strengthHeat treating

The invention discloses a weak-basal-texture high-strength magnesium-lithium alloy and a preparation method thereof. The weak-basal-texture high-strength magnesium-lithium alloy is prepared from the following components in percentage by mass: 1-5% of Li, 0.3-0.6% of Ca, 0.1-0.2% of Ce, 0.1-0.2% of Y, less than or equal to 0.2% of total impurity elements and the balance of Mg. Through alloying, rolling and heat treatment, the strength of the magnesium-lithium alloy can be improved while the basal texture of the magnesium-lithium alloy is weakened.

Owner:ZHENGZHOU UNIV

High-plasticity magnesium alloy and preparation method thereof

PendingCN114411030AImprove plasticityEasy to slideExtrusion diesFurnace typesDouble phaseChemical element

The invention discloses a high-plasticity magnesium alloy which comprises the following chemical elements in percentage by mass: 1.0-8.0% of Gd, 5.5-10% of Li and the balance of Mg and inevitable impurities, and the total content of the impurities is less than or equal to 0.3%. The invention further discloses a preparation method of the high-plasticity magnesium alloy. According to the high-plasticity magnesium alloy provided by the invention, the beta-Li phase of the BCC structure with more slippage systems is introduced into the alpha-Mg phase, so that a double-phase structure is constructed, and the plasticity of the magnesium alloy is improved; a certain amount of Gd element is added into the Mg-Li alloy, so that the texture is weakened, and non-basal plane slippage is promoted; plasticizing methods of introducing a beta-Li phase with good plasticity, weakening a texture and the like are combined, and the plasticity of the magnesium alloy is improved through compounding.

Owner:CHONGQING UNIV

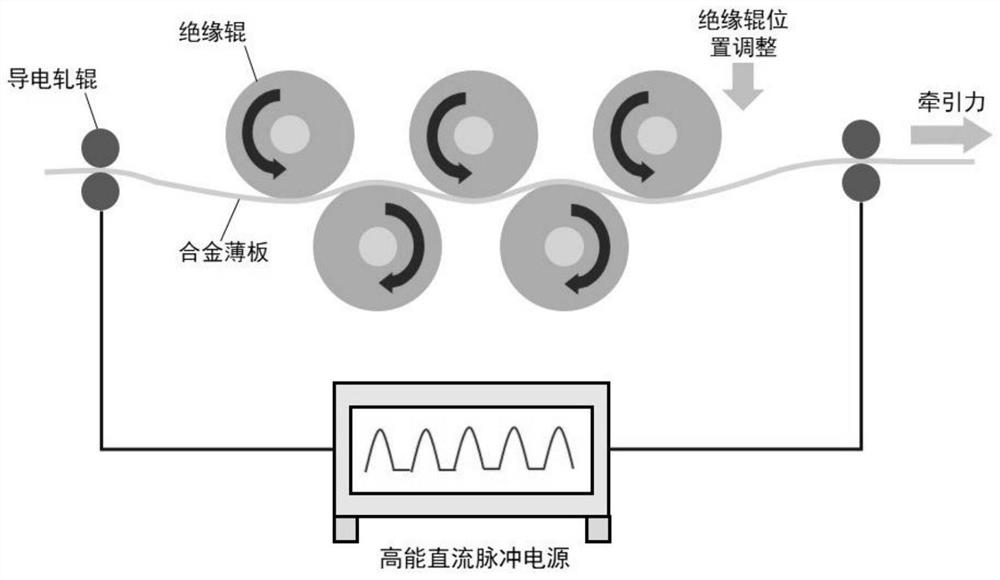

Novel sheet metal modification system and method based on current energy field assistance

The invention discloses a novel sheet metal modification system and method based on current energy field assistance. The system comprises a sheet metal modification loading platform, a load platform, a first conductive roller group, a second conductive roller group and a power supply, wherein the sheet metal modification loading platform comprises an upper-layer insulating roller group and a lower-layer insulating roller group, the upper-layer insulating roller group comprises a plurality of upper-layer insulating rollers, and the lower-layer insulating roller group comprises a plurality of lower-layer insulating rollers; the upper-layer insulating rollers and the lower-layer insulating rollers are alternately distributed and linearly arranged; sheet metal is bent between the upper-layer insulating roller group and the lower-layer insulating roller group; the relative positions of the upper-layer insulating roller group and the lower-layer insulating roller group are adjusted through the load platform; and the sheet metal penetrates through the first conductive roller group, the sheet metal modification loading platform and the second conductive roller group, and the sheet metal, the first conductive roller group, the second conductive roller group and the power supply form a current heating circuit. The system and the method solve the problems of high energy consumption, high cost and low efficiency in the prior art.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

A Method for Realizing Texture Weakening of Atx Series Magnesium Alloy Sheets Using Asymmetric Extrusion

The invention discloses a method for realizing the weakening of the texture of an ATX series magnesium alloy plate by adopting asymmetric extrusion, and belongs to the technical field of magnesium alloy extrusion processing. In the invention, the ATX series magnesium alloy ingot is homogenized firstly, then the magnesium alloy plate is prepared by conventional extrusion, and finally the extruded plate is preheated and put into an asymmetric extrusion die for extrusion. Since the central axis of the forming channel hole of the asymmetric extrusion die does not coincide with the central axis of the extrusion die cavity, the proportion of the billets on the left and right sides of the forming channel hole in the mold cavity is different, and extra parts of the billet will be upset during the extrusion process. Coarse deformation, the entire extrusion deformation process can be regarded as the combined superposition of upsetting and extrusion deformation, so the texture of the finally obtained asymmetric extruded sheet is obviously weaker than that of the initial extruded sheet. The asymmetric extrusion die is easy to manufacture, simple to operate and easy to implement, and has good industrial application prospects.

Owner:JILIN UNIV

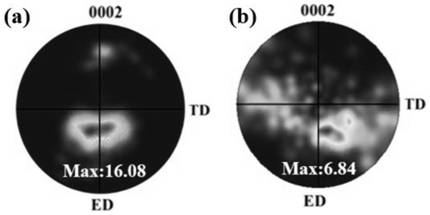

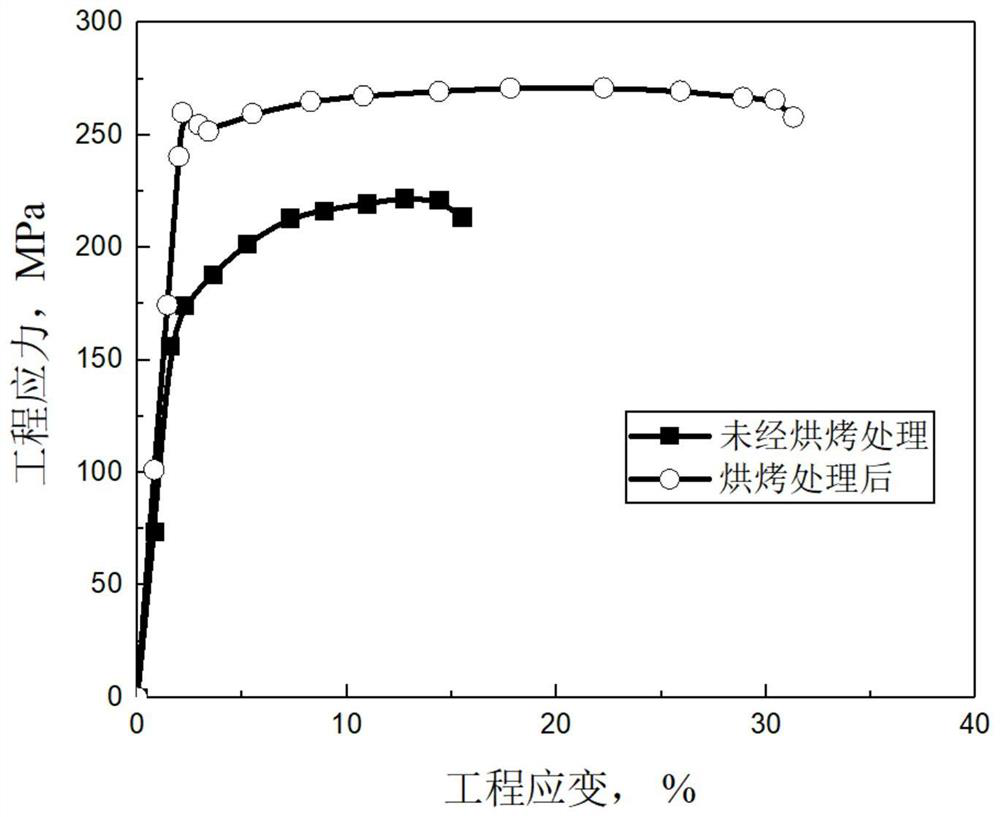

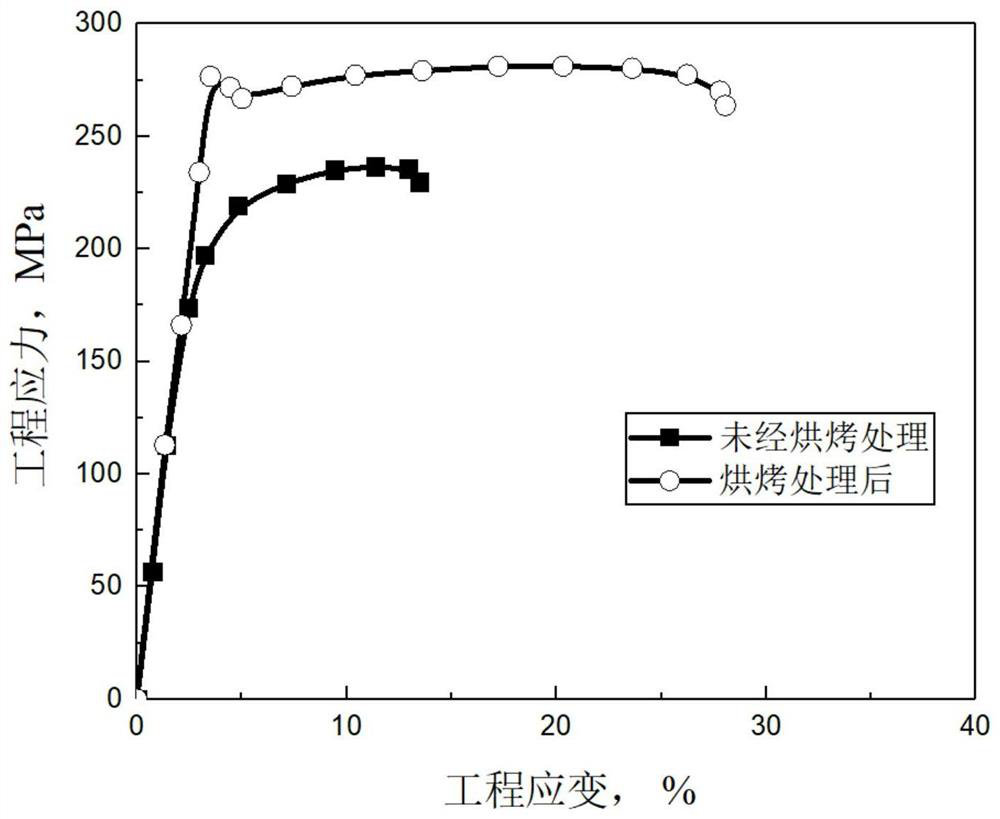

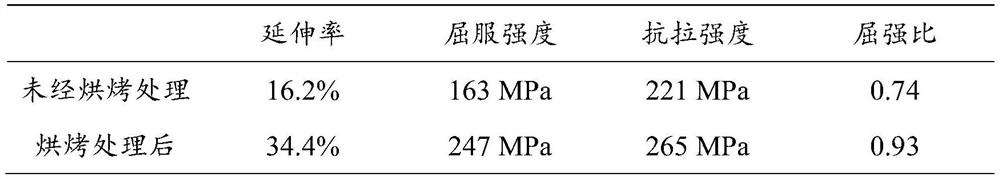

A method of preparing high-strength and toughness magnesium alloy wire by baking

The invention discloses a method for preparing high-strength and high-toughness magnesium alloy wires by means of roasting. Alloys include one or more of calcium, zinc, tin and bismuth and include yttrium and the balance magnesium, the atomic percentage of one or more of calcium, zinc, tin and bismuth ranges from 0.3% to 1.5%, and the atomic percentage of yttrium ranges from 0.03% to 0.3%. Cylindrical magnesium alloy ingot blanks with the diameters ranging from 3 mm to 6 mm are prepared with the semi-continuous casting method, repeated drawing is performed after solid solution treatment, the working rate per pass does not exceed 15%, intermediate annealing and water quenching are performed after each pass of drawing, wires are subjected to roasting and water quenching at 100-220 DEG C for10-120 min finally, and the wires are obtained. Compared with magnesium alloys which are not subjected to roasting treatment, the magnesium alloy subjected to roasting treatment under equivalent service conditions has the advantages that the yield strength, the yield ratio and the toughness are synchronously and remarkably improved. The method is simple in equipment requirement, low in cost, highin efficiency, wide in application range and capable of stably improving the comprehensive mechanical performance of the magnesium alloy wires.

Owner:天津市金镁轮科技有限公司

A thermomechanical treatment process for al-cu-li alloy based on particle-induced nucleation

The invention discloses an Al-Cu-Li alloy deformation heat treatment process based on particle-induced nucleation, and belongs to the technical field of aerospace component manufacturing. The invention can significantly promote the thermal deformation recrystallization of the Al-Cu-Li alloy and obtain equiaxed fine-grained structure. The method of the present invention is as follows: the alloy ingot is obtained by homogenizing annealing to obtain uniformly distributed, micron-scale T 1 Phase (Al 2 CuLi), then hot-pressed and deformed, and then annealed at high temperature. The invention realizes controllable acquisition of high-stability recrystallization structure in Al-Cu-Li alloy, high degree of recrystallization, remarkable fine-grain effect, stable structure, can significantly weaken alloy texture, reduce alloy anisotropy, thereby improving alloy multi- bearing capacity and corrosion resistance. The application of the present invention can greatly improve the comprehensive service performance of the Al-Cu-Li alloy, expand its application range in aerospace components, and enhance the competitiveness of products such as materials / components.

Owner:HARBIN INST OF TECH

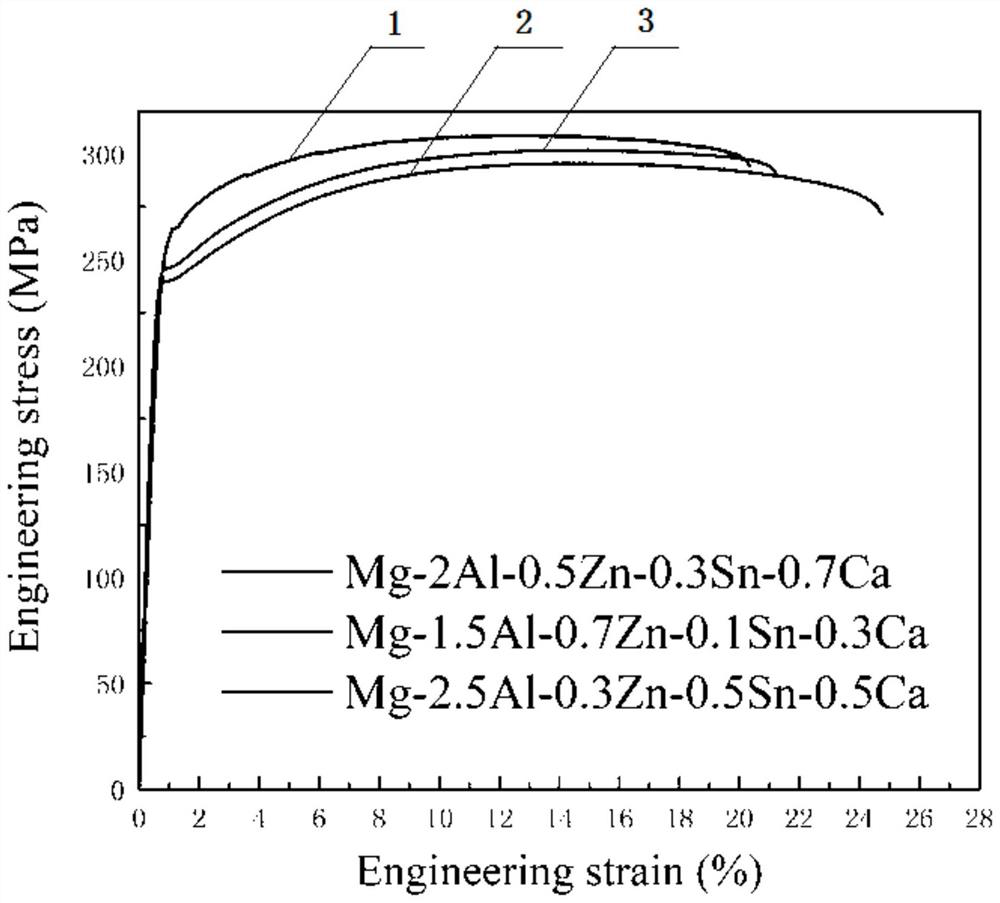

Novel high-strength plastic magnesium alloy plate and preparation process thereof

ActiveCN113953320AHigh strengthLow mobilityAuxillary arrangementsMetal rolling arrangementsComposite plateUltimate tensile strength

The invention provides a novel high-strength plastic magnesium alloy plate. On the basis of a traditional AT-series magnesium alloy, Zn and Ca elements are added at the same time, the grain boundary energy is further reduced through the separation eutectic of Zn and Ca at the grain boundary, the pinning effect of the grain boundary is induced, the mobility of the grain boundary is reduced, growth of grains is restrained, and therefore the grains are further refined, the strength of the magnesium alloy is improved, the texture of the AT-series magnesium alloy is weakened, and the forming performance of the alloy is improved. The magnesium alloy plate subjected to double-roller cast rolling is subjected to asynchronous rolling, and different deformation amounts are generated on the upper surface and the lower surface of the magnesium alloy plate through the difference of the roller speed. Finally, through accumulated stack rolling, through the difference of the grain size and the microstructure of the plate, asymmetric deformation is generated in the rolling process, a lamellar structure is formed, and the center segregation phenomenon of the cast rolling plate and the separation and recycling problem generated after a heterogeneous composite plate is used are solved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

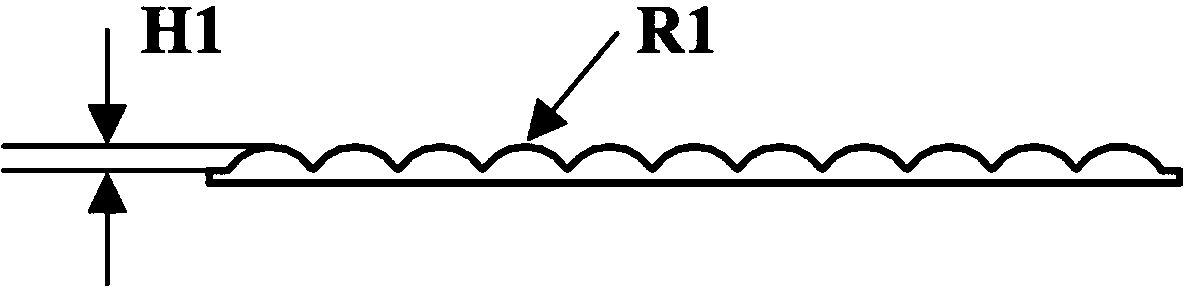

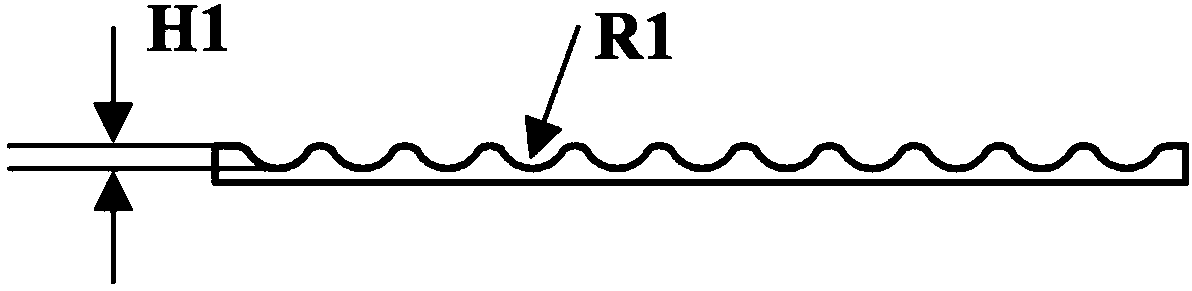

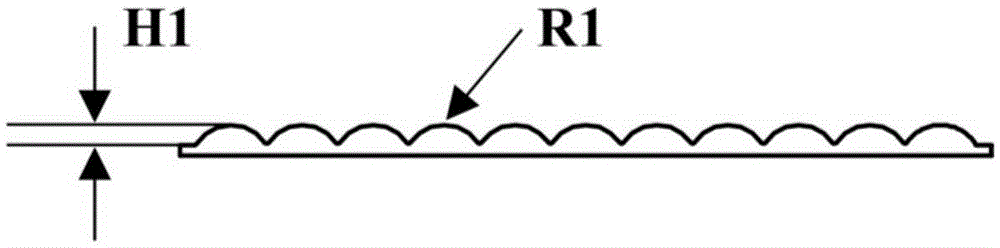

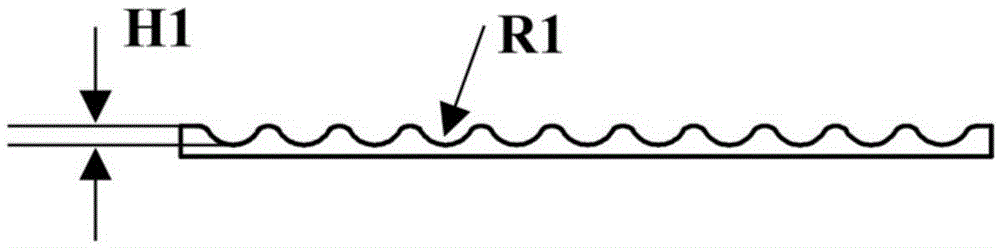

A light alloy rolling composite forming process with controllable edge cracking

ActiveCN112718861BSimple processReliable workmanshipAuxillary arrangementsMetal rolling arrangementsAlloyShearing deformation

The invention discloses a light alloy rolling compound forming process with controllable edge cracking, which belongs to the technical field of light alloy plate compound forming process. Alloy liner, the alloy plate and the hard liner are heated and rolled together. The grooves can effectively control the edge cracks during the rolling process; the protrusions cooperate with the rolls to cause local severe shear deformation of the alloy plate during the rolling process, promote the widening of the plate along the transverse direction, and weaken the texture Effect. The entire liner is the same as the liner rolling in the composite forming process, which can increase the single-pass reduction, reduce the rolling passes, reduce the rolling temperature, and more effectively refine the grain size. Under the premise of controllable edge cracking, the whole deformation process can be regarded as the compound superposition of rolling, shearing and widening deformation of the lining plate. The whole technological process is simple and easy to realize, and has good industrial application prospect.

Owner:JILIN UNIV

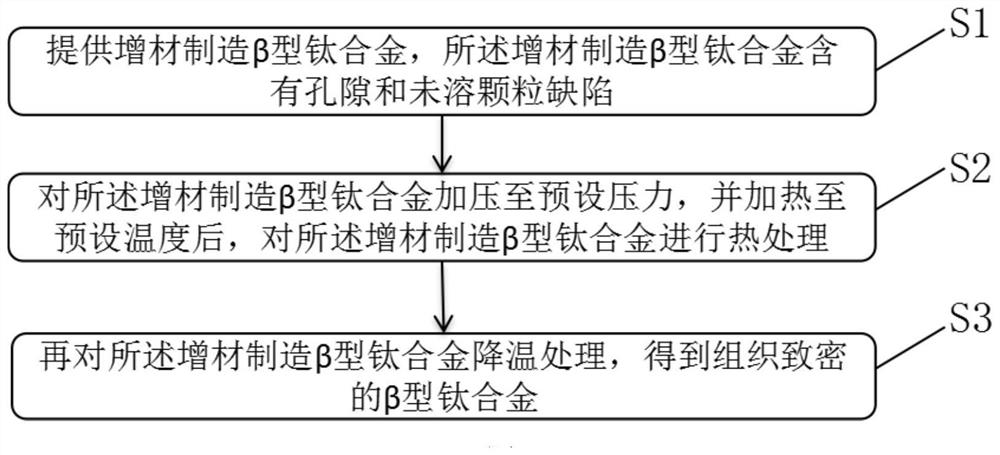

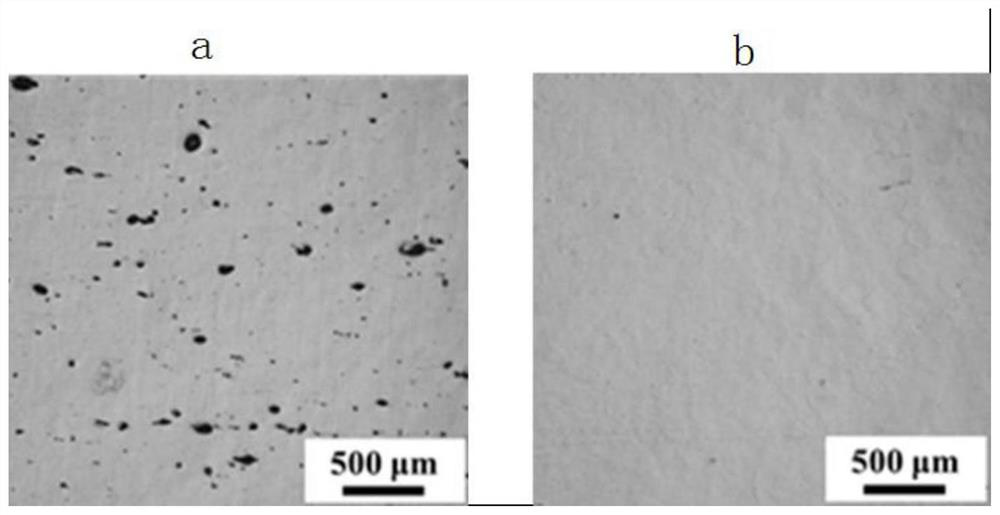

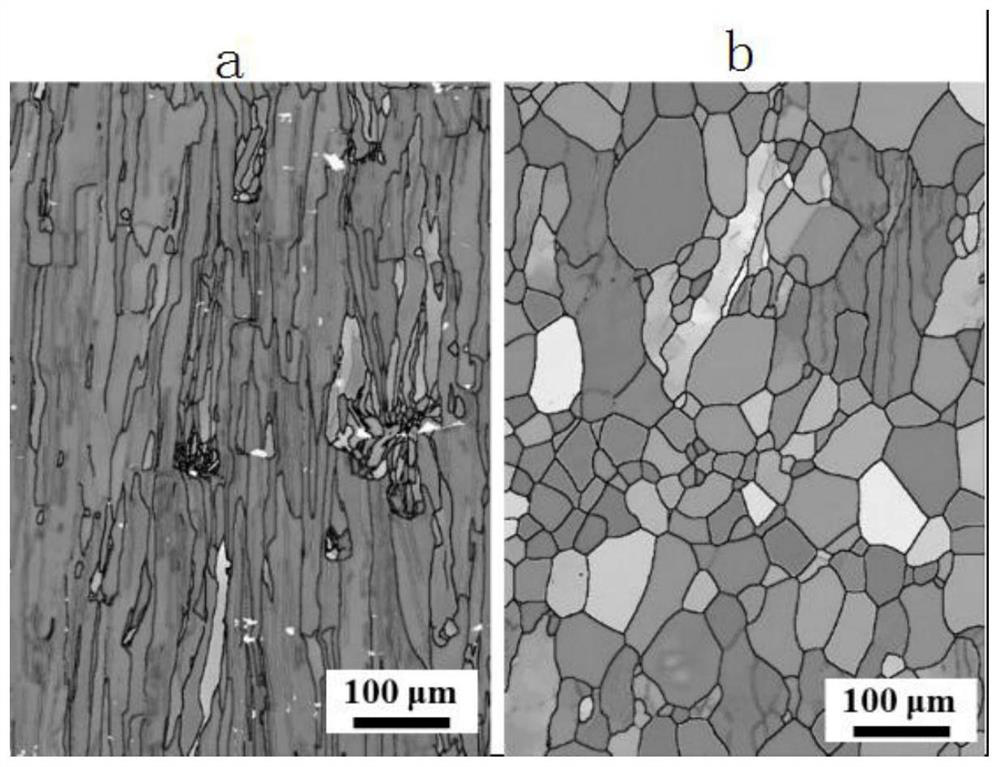

Heat treatment method for improving defects in additive manufacturing of beta-type titanium alloy

PendingCN114411075AImprove defectsImprove performanceAdditive manufacturing apparatusTitanium alloyUltimate tensile strength

The invention provides a heat treatment method for improving defects in an additive manufacturing beta-type titanium alloy, which comprises the following steps: providing the additive manufacturing beta-type titanium alloy, and the additive manufacturing beta-type titanium alloy contains the defects of pores and undissolved particles; the additive manufacturing beta-type titanium alloy is pressurized to preset pressure, and after the additive manufacturing beta-type titanium alloy is heated to preset temperature, the additive manufacturing beta-type titanium alloy is subjected to heat treatment; and cooling treatment is conducted, and the beta-type titanium alloy compact in structure is obtained. The method is simple in technological process, short in period, low in cost and small in subsequent machining allowance, defects are effectively improved on the basis of additive manufacturing of the beta-type titanium alloy, meanwhile, the structure can be improved and weakened through heat treatment, the anisotropy of the material is reduced, and then the strength, plasticity, fatigue resistance and other performance of the beta-type titanium alloy are improved.

Owner:SHANGHAI JIAO TONG UNIV

A large reduction rolling method of magnesium alloy

ActiveCN103962376BSimple processReliable workmanshipAuxillary arrangementsMetal rolling arrangementsThermal insulationManganese

The invention relates to a large reduction rolling method for magnesium alloy. According to the rolling method, a hard alloy lining plate is additionally arranged on the upper surface or the lower surface of the magnesium alloy, or two hard alloy lining plates are additionally arranged on the upper surface and the lower surface of the magnesium alloy at the same time, and the added hard alloy lining plates are rolled synchronously together with the magnesium alloy. The rolling method includes the steps that after a high temperature lubricating agent is evenly smeared on the surfaces of the lining plates and the surface of the magnesium alloy, the high temperature lubricating agent, the lining plates and the magnesium alloy are simultaneously placed into a heating box to be heated, after the temperature rises to a preset temperature, standing and thermal insulation are performed for a certain period of time, one hard alloy lining plate is placed on the upper surface or the lower surface of magnesium alloy blank, or the two hard alloy lining plates are placed on the upper surface and the lower surface of the magnesium alloy at the same time, and the hard alloy lining plates and the magnesium alloy are simultaneously fed into the position between rollers so that rolling can be completed. Through the method, the single pass reduction of the magnesium alloy can be greatly increased in the rolling process, the number of rolling passes is decreased, magnesium alloy crystalline grains are thinned, the texture is weakened, magnesium alloy plates with high strength and plasticity are prepared, and the large reduction rolling method for the magnesium alloy is also suitable for the large deformation rolling process of titanium, manganese and metal-matrix composite materials.

Owner:JILIN UNIV

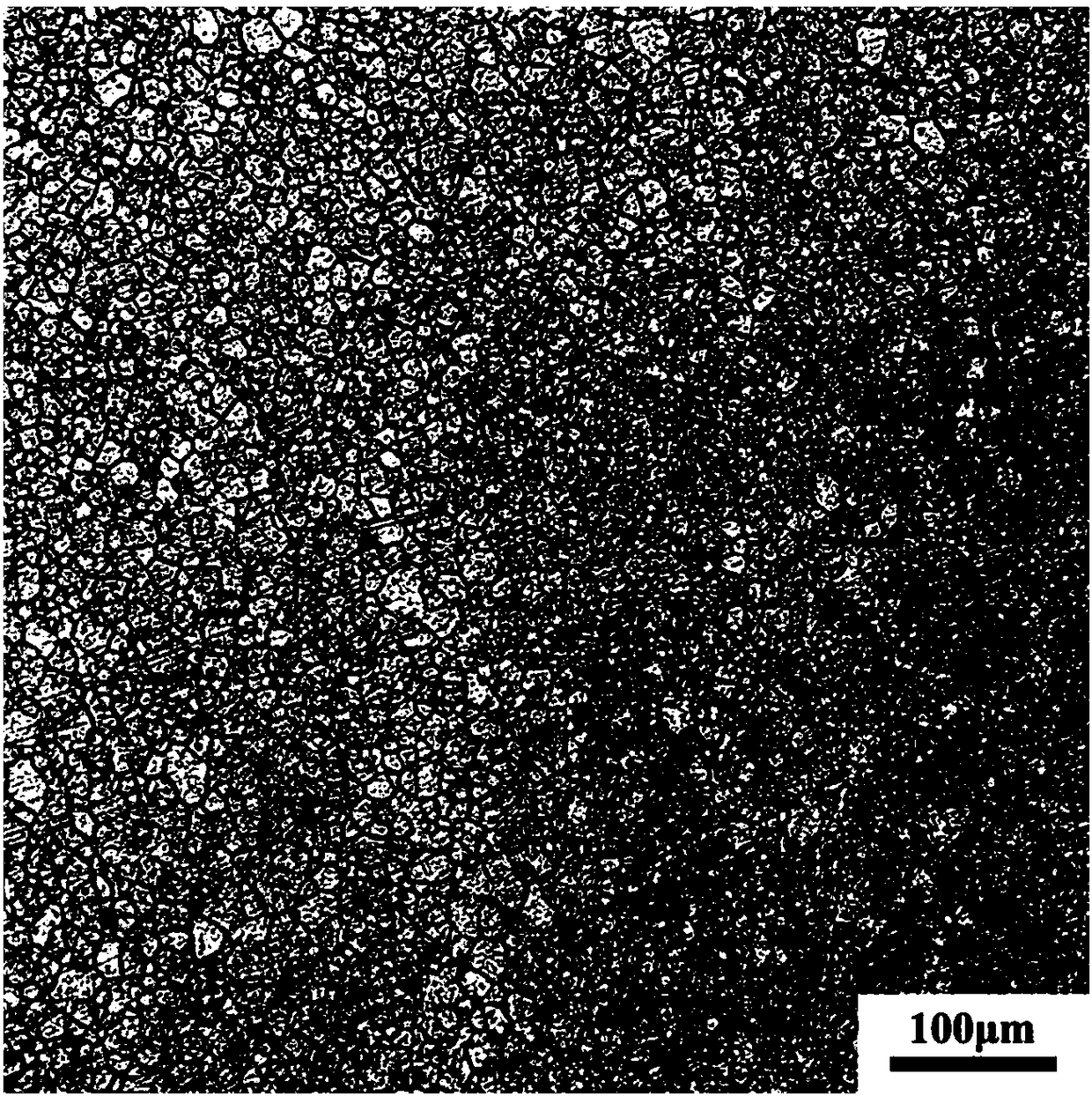

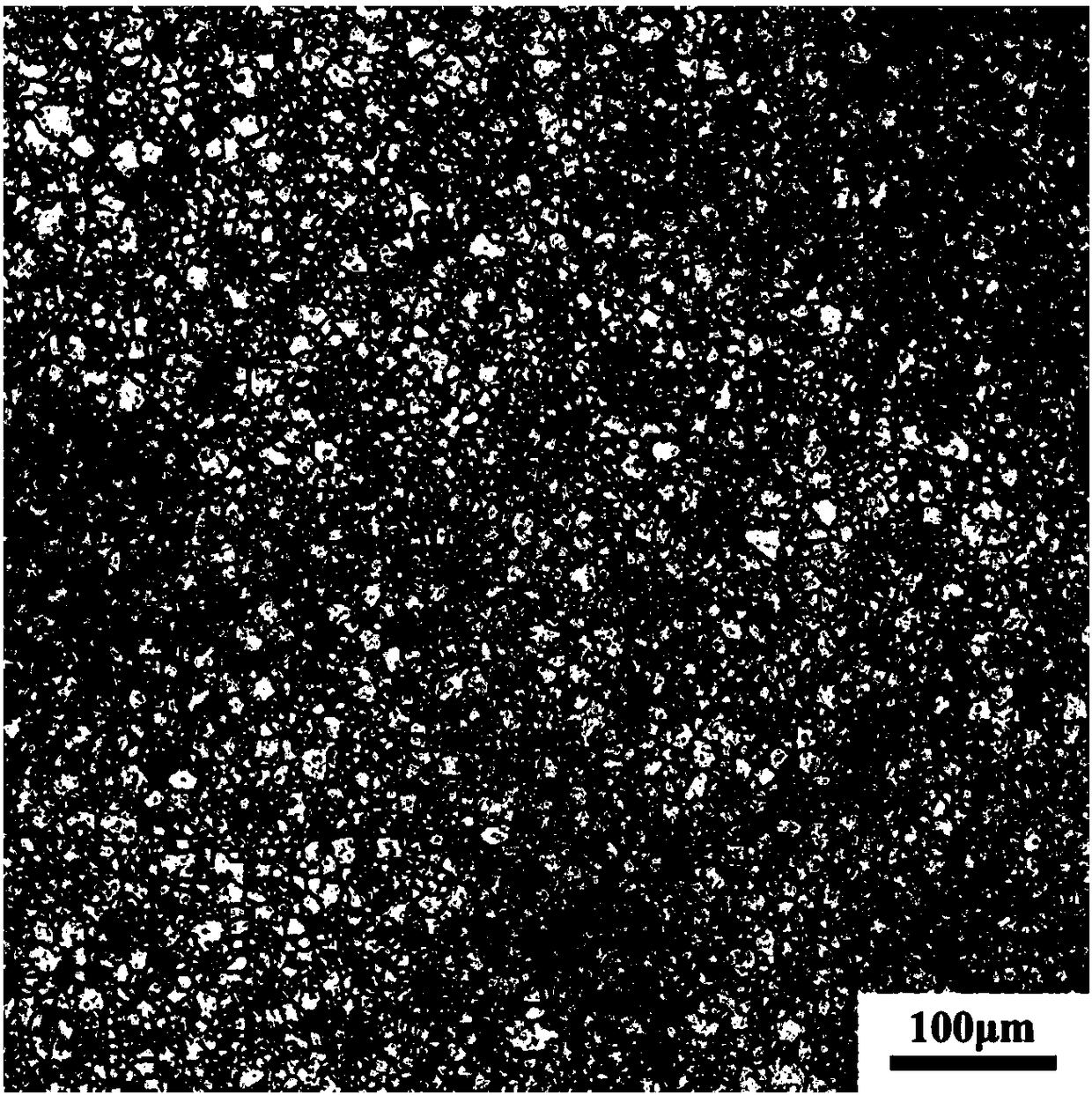

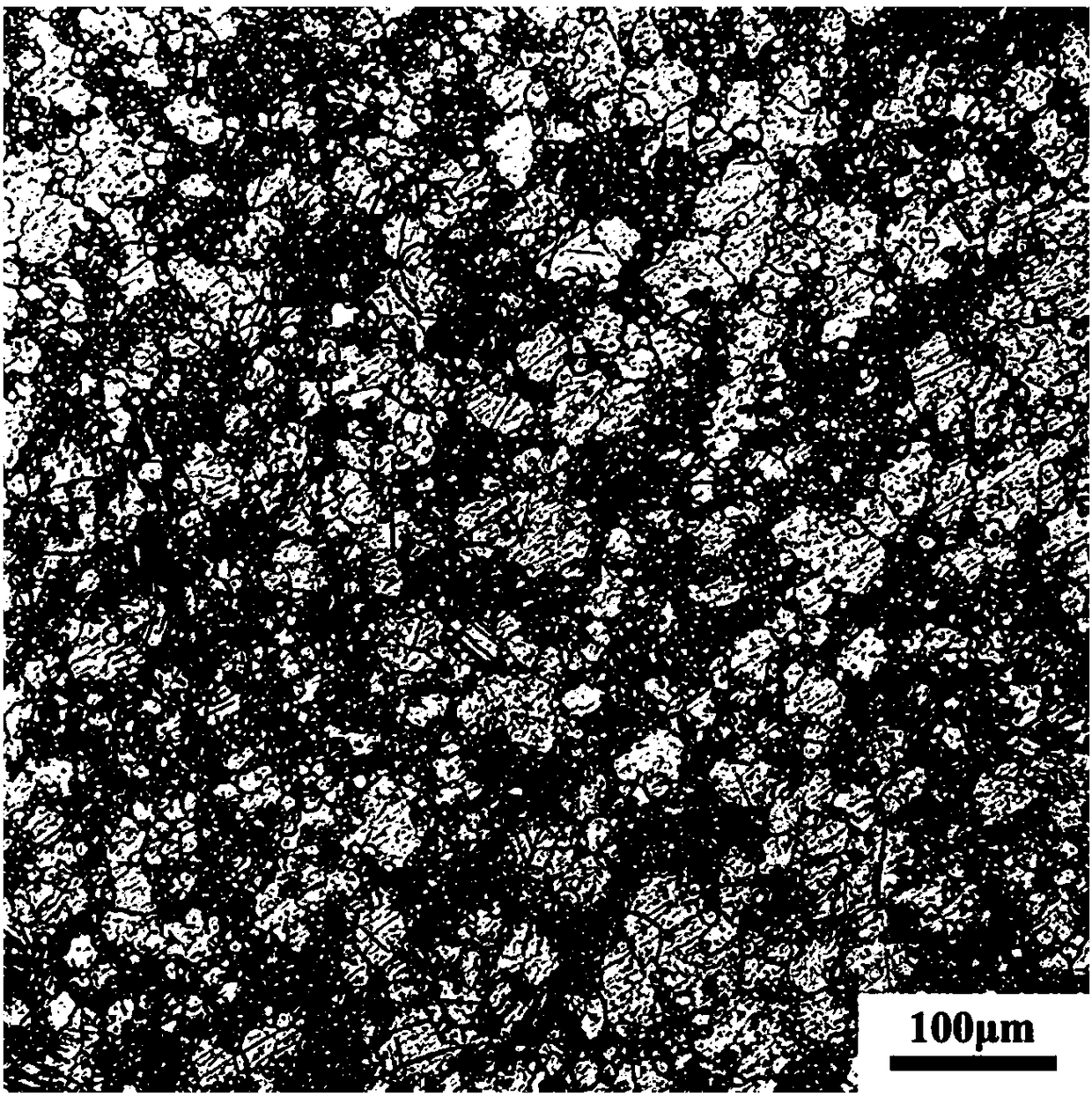

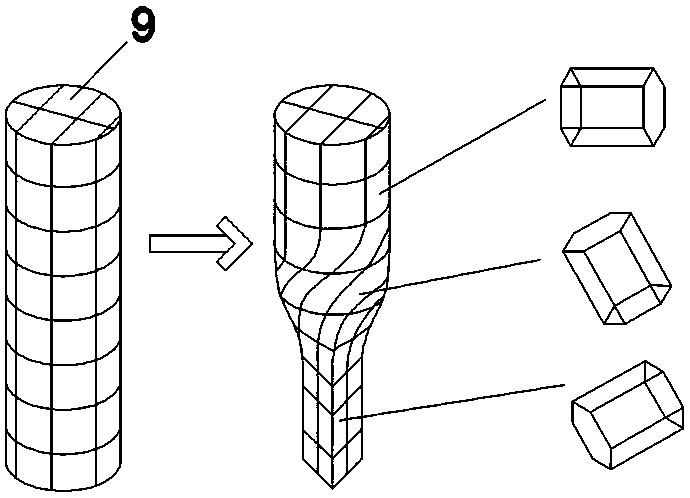

A method for crushing and spheroidizing the second phase in magnesium alloy by heating and rotating rolling

ActiveCN110129697BSolve the problem of easily reacting to form a coarse second phaseExpand the scope of the designHigh densityMetallic materials

The invention relates to the field of metal material rolling processing and particularly discloses a method for carrying out warming, rotary rolling, fragmentation and spheroidization on a second phase in magnesium alloy. The method comprises the following steps: S1, carrying out earlier stage thermal insulating treatment; S2, carrying out single-pass fragmentation on the second phase; and S3, carrying out warming and rotary rolling on the second phase. According to the method, warming four-pass rotary rolling is utilized, and clockwise 90-degree rotation is realized each pass, so that the situation that the second phase is cured in a multidirectional manner is ensured, and submicron order second phase also can separate out dynamically; and in addition, high-density dislocation is introduced during first-pass low temperature rolling to promote dynamic recrystallization and realize the purpose of refining grain during the following warming rolling process; and moreover, the submicron order second phase and fine grain structures improve the strengthening and processing hardening capacity and improve the strength and plasticity simultaneously.

Owner:JILIN UNIV

Multi-directional repeated extrusion deformation processing device and procesisng method for magnesium alloy profile

The invention relates to the technical field of metal material processing equipment, in particular to a multi-directional repeated extrusion deformation processing device and a processing method for amagnesium alloy profile. The processing device comprises a male die, an upper female die and a lower female die; the upper female die is provided with a die cavity; the die cavity is composed of a male die channel and an extrusion channel; the male die channel is in a cuboid shape; the extrusion channel is in an inverted regular quadrangular frustum pyramid shape; the upper female die and the lower female die are connected, positioned and combined into the female die through screws and pins; and the male die is arranged in the male die channel and is matched with the male die channel. The processing device provided by the invention is simple in structure, convenient to operate, beneficial to extrusion sample demolding, capable of preparing a large number of high-performance magnesium alloy products of various sizes, capable of improving the production efficiency and the processing precision, easy to disassemble, convenient to maintain, small in abrasion to the male die under the condition of long-time extrusion production, and the magnesium alloy processed by the device has good strength, plasticity and corrosion resistance.

Owner:HUNAN UNIV OF SCI & TECH

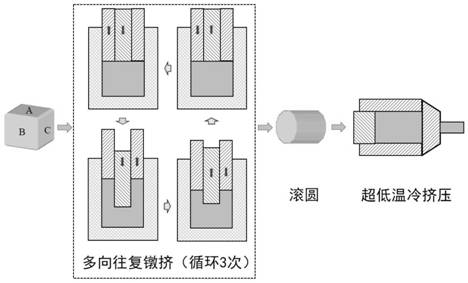

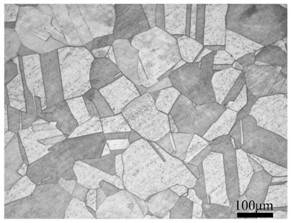

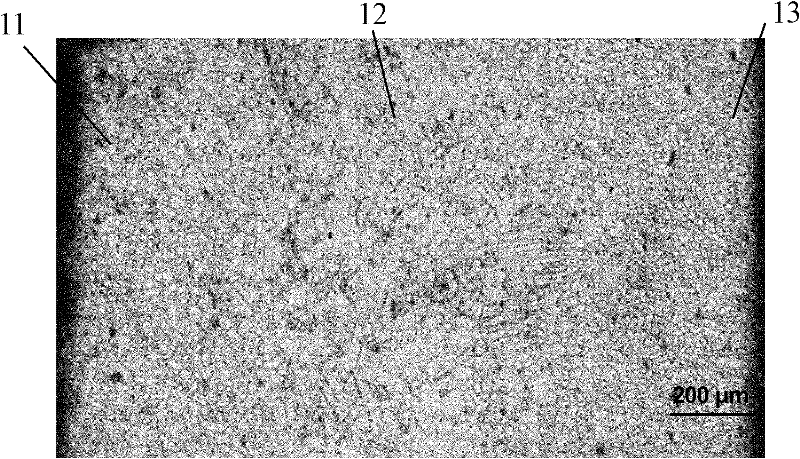

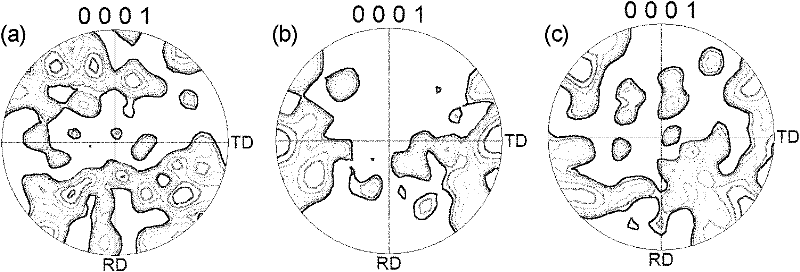

A preparation method of fine-grained and weak-textured blank for medicine-shaped mask

ActiveCN114134438BAchieve purificationTissue weakeningFurnace typesForging/hammering/pressing machinesMedicinePhysical chemistry

The invention provides a method for preparing a billet for a medicine-shaped cover, which sequentially performs multi-directional reciprocating and ultra-low temperature large-deformation extrusion; the multi-directional reciprocating upsetting extrusion is sequentially performed on three faces of the six-sided billet with the same apex Reciprocating upsetting extrusion, single extrusion ratio ≥ 1.5, complete 2 to 4 cycles of multi-directional reciprocating upsetting extrusion; the ultra-low temperature and large deformation extrusion is to subject the billet to cryogenic treatment for 60 to 150 minutes, and extrude the working part of the extrusion die The inner cone angle is 90°~140°, and the extrusion rate is 10~20mm / s. The invention can realize fine-grained and weak texture structure, and improve the isotropy, high yield ratio and high ductility of the liner.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

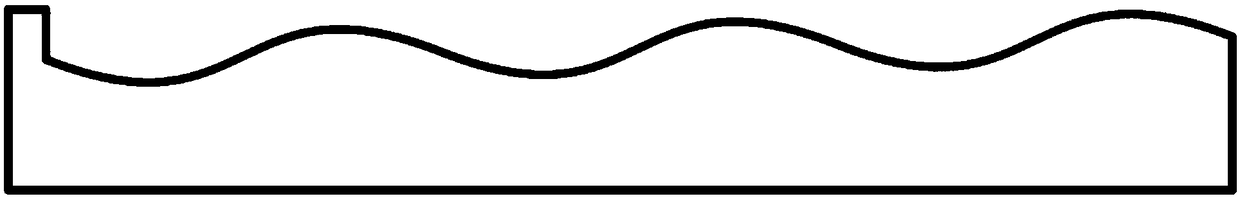

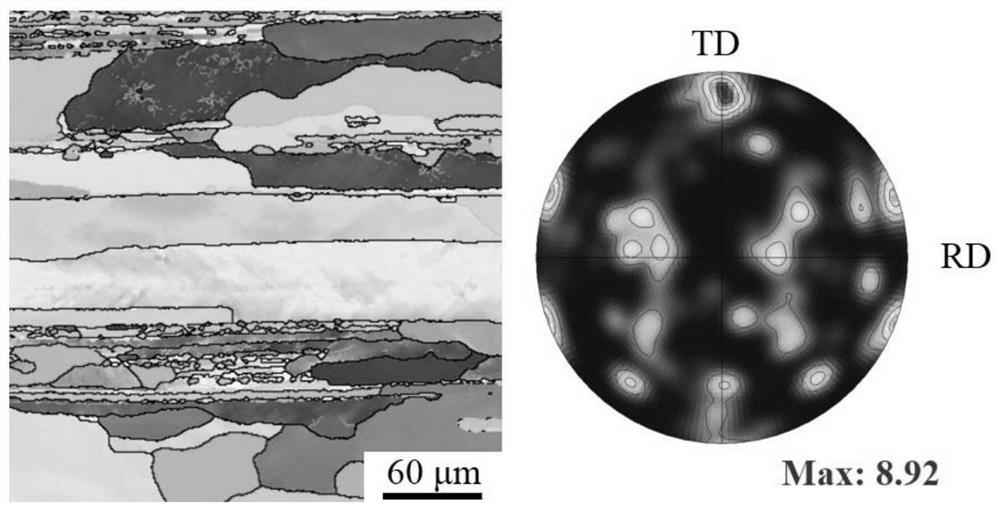

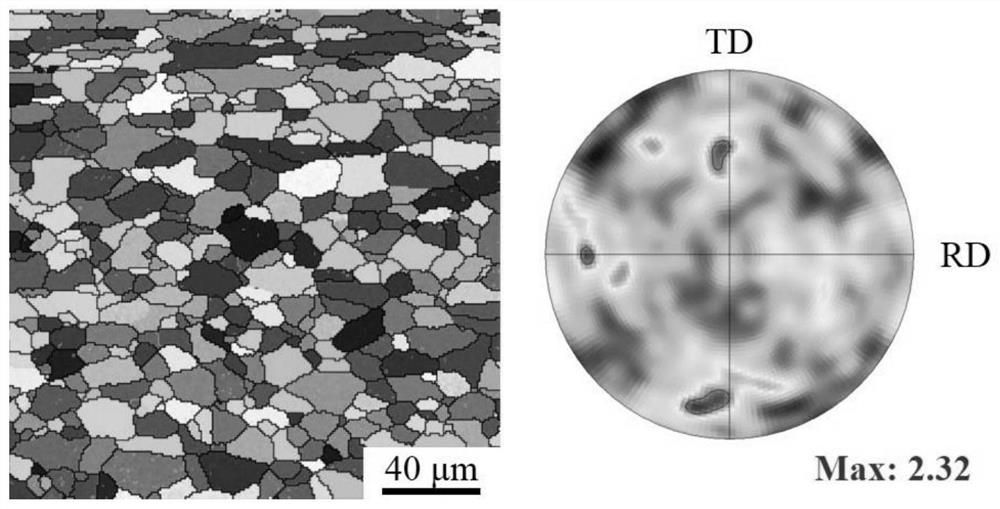

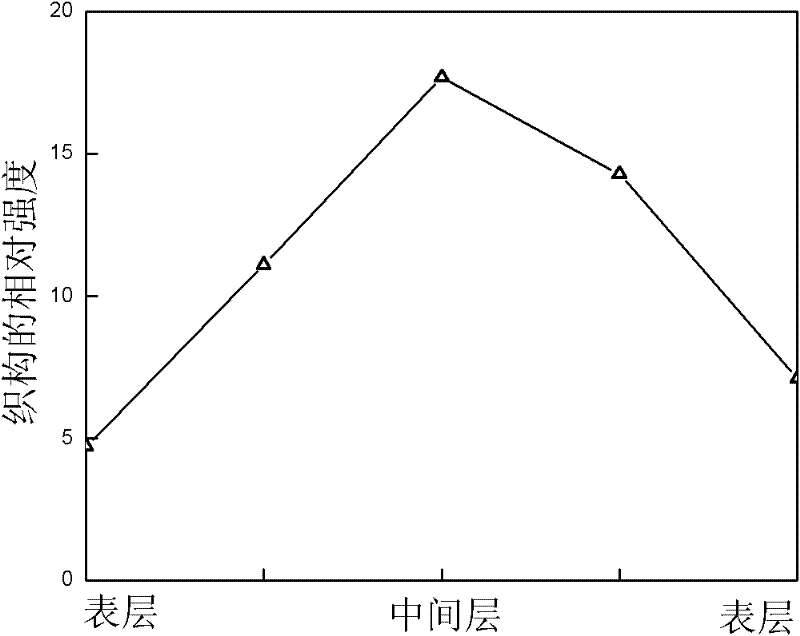

Method for preparing magnesium alloy plate strip with grain size in symmetric gradient distribution along plate thickness direction

The invention relates to a method for preparing a magnesium alloy plate strip with a grain size in symmetric gradient distribution along a plate thickness direction. In the method, the magnesium alloy plate strip is subjected to bidirectional continuous bending deformation and then recrystallization annealing; during deformation, a surface layer is subjected to large twinning deformation, and shear stress applied to the surface layer makes a base surface texture deflected and weakens the original texture; during annealing, the surface layer with large deformation is subjected to static recrystallization so as to refine grains and randomize the texture; and when the deformation is less than or equal to 0.03, the grains on the surface layer are quickly recrystallized and grown to be coarsened due to a low recrystallization nucleation rate. By the method, two gradient materials with refined or coarsened grains on the surface layer can be prepared. The process is reasonable in design and easy to operate, required equipment is realized by modifying and upgrading the conventional straightener, the gradient structure along the plate thickness direction is obtained by coordinating repeated bending with recrystallization annealing, the texture of the magnesium alloy plate strip is weakened, the strength and the ductility of the magnesium alloy plate strip are improved, and the subsequent processability of a magnesium alloy plate is improved.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com