High-strength and high-plasticity Mg-Al-Ce-(Nd) wrought magnesium alloy and preparation method thereof

A mg-al-ce-, wrought magnesium alloy technology, applied in the field of high-strength and high-plasticity Mg-Al-Ce-wrought magnesium alloy and its preparation, can solve the problems of limiting application, increasing alloy cost and density, and achieving a promotional position Effects of mis-nucleation, increase in work hardening rate, and improvement in alloy formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the above-mentioned Al, Ce and Nd composite strengthened high-strength and high-plastic deformation magnesium alloy comprises the following steps:

[0039] Step 1, preheating industrial pure magnesium ingots, pure aluminum ingots, pure cerium and Mg-25% Nd master alloy (by mass percentage, Nd 25%, Mg balance) at 100-200° C. for 30-60 minutes;

[0040] Step 2: Melt the preheated industrial pure magnesium ingot in a protective atmosphere at a temperature of 760°C±10°C; put the preheated pure aluminum ingot, pure cerium and Mg-25%Nd master alloy in turn into complete melting Keep it warm in the pure magnesium melt for 10-30 minutes; after the pure aluminum ingot, pure cerium and Mg-25% Nd intermediate alloy are completely melted, mechanically stir for 1-3 minutes; For the degassing effect of the body, stand at this temperature for 5-15 minutes to make the inclusions in the melt float or settle; finally, cool the melt to 710°C ± 10°C, skim off the ...

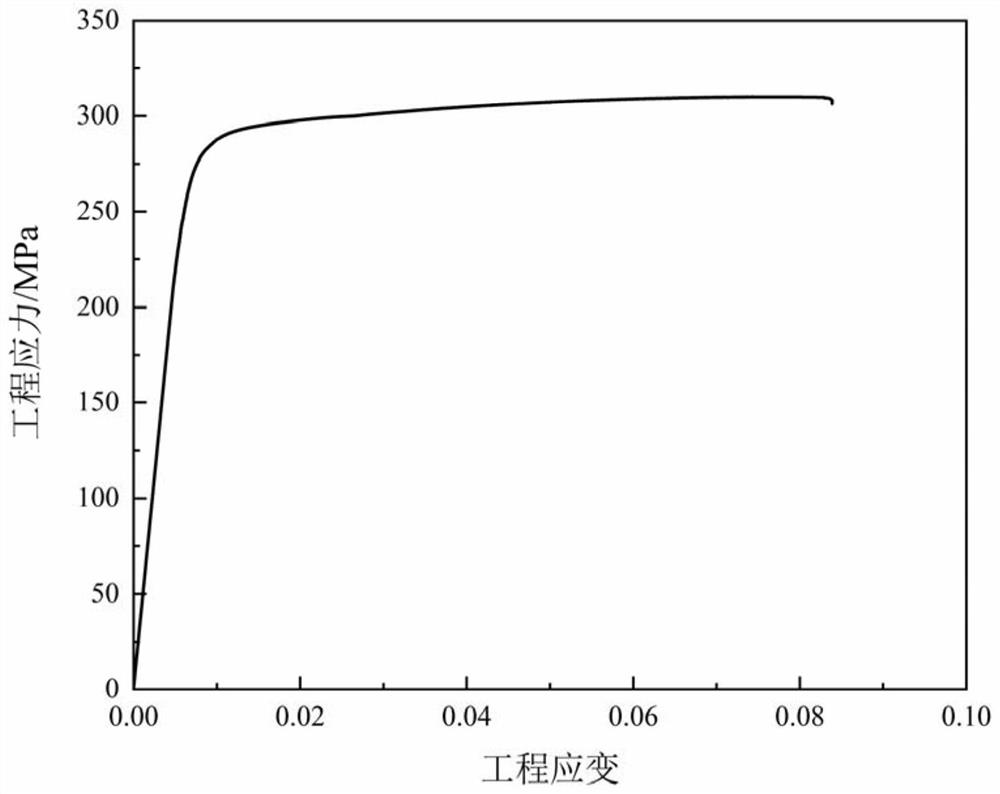

Embodiment 1

[0048] In this embodiment, the high-strength plastic magnesium alloy reinforced by Al, Ce and Nd contains the following components in mass percentage: Al 1.0wt%, Ce 0.3wt%, Nd0.2wt%, the rest are Mg and unavoidable impurities, Impurity content≤0.04wt%.

[0049] In the present embodiment, the preparation method of the high-strength plasticity magnesium alloy strengthened by Al, Ce and Nd, comprises the following steps:

[0050] 1) Preheat industrial pure magnesium ingots, pure aluminum ingots, pure cerium and Mg-25% Nd master alloy at 150°C for 1 hour;

[0051] 2) Put the preheated industrial pure magnesium ingot in SF 6 / CO 2 Melt in a protective atmosphere at a temperature of 760°C; put the preheated pure aluminum ingot, pure cerium and Mg-25% Nd master alloy into the completely melted pure magnesium melt for 20 minutes; wait for the pure aluminum ingot, pure cerium After the Mg-25% Nd master alloy is completely melted, stir it mechanically for 2 minutes; then pass in argo...

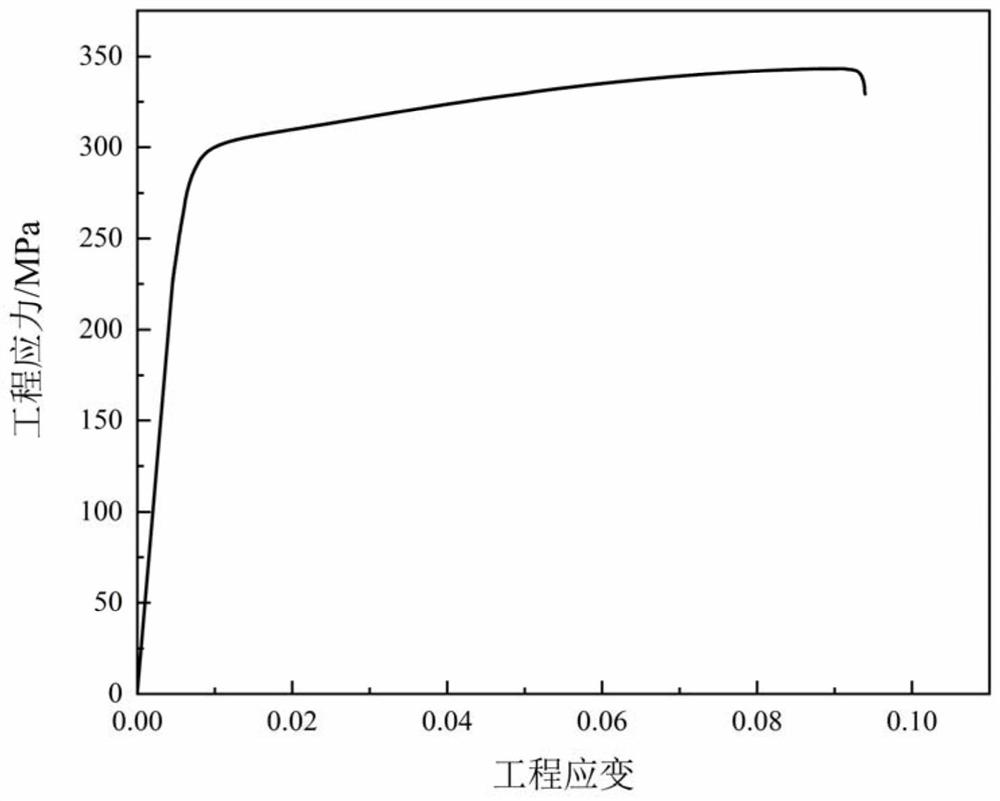

Embodiment 2

[0056] In this embodiment, the high-strength plastic magnesium alloy strengthened by Al, Ce and Nd contains the following components in mass percentage: Al 1.0wt%, Ce 1.0wt%, Nd 1.0wt%, the rest are Mg and unavoidable impurities, Impurity content≤0.04wt%.

[0057] In the present embodiment, the preparation method of the high-strength plasticity magnesium alloy strengthened by Al, Ce and Nd, comprises the following steps:

[0058] 1) Preheat industrial pure magnesium ingots, pure aluminum ingots, pure cerium and Mg-25% Nd master alloy at 150°C for 1 hour;

[0059] 2) Put the preheated industrial pure magnesium ingot in SF 6 / CO 2 Melt in a protective atmosphere at a temperature of 760°C; put the preheated pure aluminum ingot, pure cerium and Mg-25% Nd master alloy into the completely melted pure magnesium melt for 20 minutes; wait for the pure aluminum ingot, pure cerium After the Mg-25% Nd master alloy is completely melted, stir it mechanically for 2 minutes; then pass in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com