Patents

Literature

49results about How to "High work hardening rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-density ultrahigh-strength steel and preparation method thereof

ActiveCN106244927ALow costIn line with the development concept of energy saving and emission reductionChemical compositionCarbide

The invention relates to low-density ultrahigh-strength steel and a preparation method thereof, and belongs to the field of metal materials. The steel comprises the following chemical components in percentage by mass: 0.6 to 1.6 percent of C, 5 to 10 percent of Al, 15 to 30 percent of Mn, 0.01 to 0.2 percent of Nb, 0.1 to 3 percent of Mo, less than or equal to 5 percent of Cr, less than or equal to 0.5 percent of Ti, less than or equal to 2 percent of Si, less than or equal to 0.6 percent of B, and the balance of Fe and unavoidable impurity elements. According to the low-density ultrahigh-strength steel and the preparation method thereof, a NbMoC phase which is finely dispersed precipitates by compounding and adding the Nb and the Mo; precipitation is strengthened by cooperating with a kappa-carbide; the tensile strength reaches over 1,350 MPa, the elongation reaches over 10 percent and the density is 6.8 to 7.0 g / cm<3>; the low-density ultrahigh-strength steel is low in cost, is suitable for light weight of traffic transportation tools, such as vehicles and airplanes, and meets the development concept of energy conservation and emission reduction.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

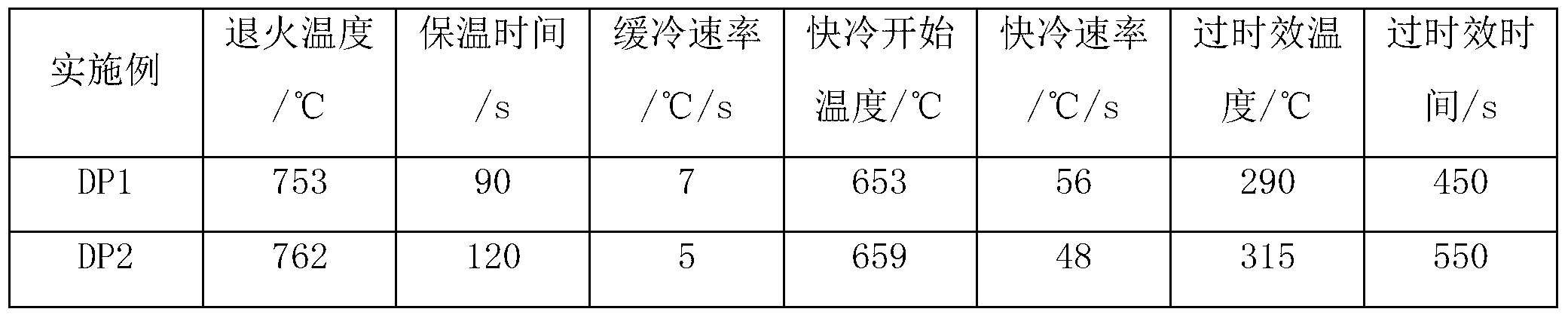

Ultralow-yield-ratio cold-rolled dual-phase steel and manufacturing method thereof

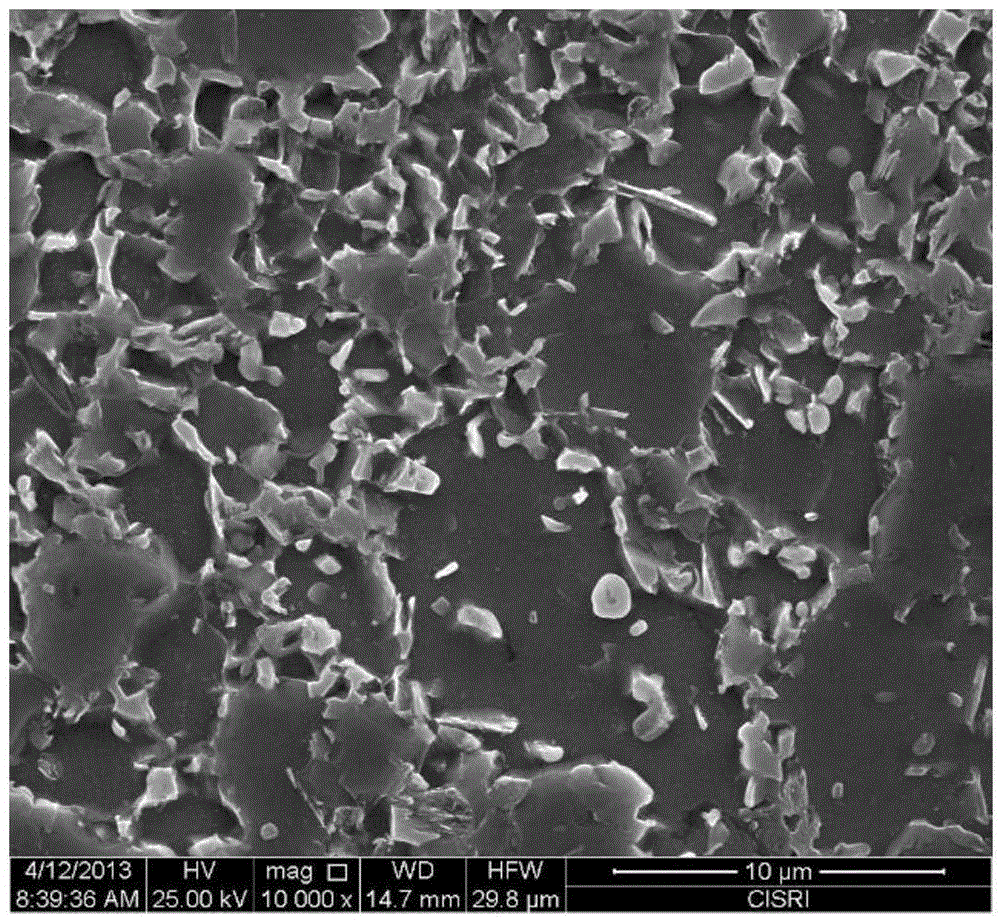

InactiveCN105420605AHigh work hardening rateUltra-low yield ratioChemical compositionDual-phase steel

The invention belongs to the technical field of steel materials, and relates to an ultralow-yield-ratio cold-rolled dual-phase steel and a manufacturing method thereof. Internal control chemical components of the dual-phase steel comprise 0.13%-0.18% of C, 0.30%-0.60% of Si, 1.7%-2.0% of Mn, 0.02%-0.070% of Al, 0.02%-0.05% of Nb and the balance Fe and other inevitable impurities. Simple chemical component design is adopted, the hot-rolling deformation heat treatment TMCP and the flexible continuous annealing process are combined to obtain a microscopic structure with fine grain ferrite, island martensite and 5%-7% of retained austenite, and therefore the uniform deformation capacity of materials is increased while the strong plasticity of the cold-rolled dual-phase steel is improved. The ultralow-yield-ratio cold-rolled dual-phase steel has the beneficial effects that good stamping performance, low process sensitivity and the ultralow yield ratio YS / TS which is smaller than or equal to 0.51 are achieved, springback generated after stamping can be reduced, and later deep machining of the automobile industry is facilitated.

Owner:CENT IRON & STEEL RES INST

Cold-rolled dual-phase sheet steel with 400MPa-level tensile strength and preparation method thereof

The invention discloses a cold-rolled high-strength dual-phase sheet steel with 400MPa-level tensile strength for a car and a preparation method thereof, and belongs to the field of steel materials. The double-phase sheet steel adopts a ferrite-martensite dual-phase structure serving as the main structure and contains 4 to 9% of martensite and comprises the following chemical components by mass percent: 0.01 to 0.05% of C, 0.1 to 0.4% of Si, 1.2 to 1.6% of Mn, 0.1 to 0.4% of Cr, 0.02 to 0.05% of Als, not greater than 0.005% of N, not greater than 0.02% of P, not greater than 0.01% of S, and the balance of Fe and inevitable residual impurity elements. The preparation method comprises the steps of hot rolling, acid pickling, cold rolling and heat treating. The produced cold-rolled double-phase sheet steel has the yield strength of 200 to 250MPa, tensile strength of 400 to 450MPa and percentage of elongation of 30 to 35%.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

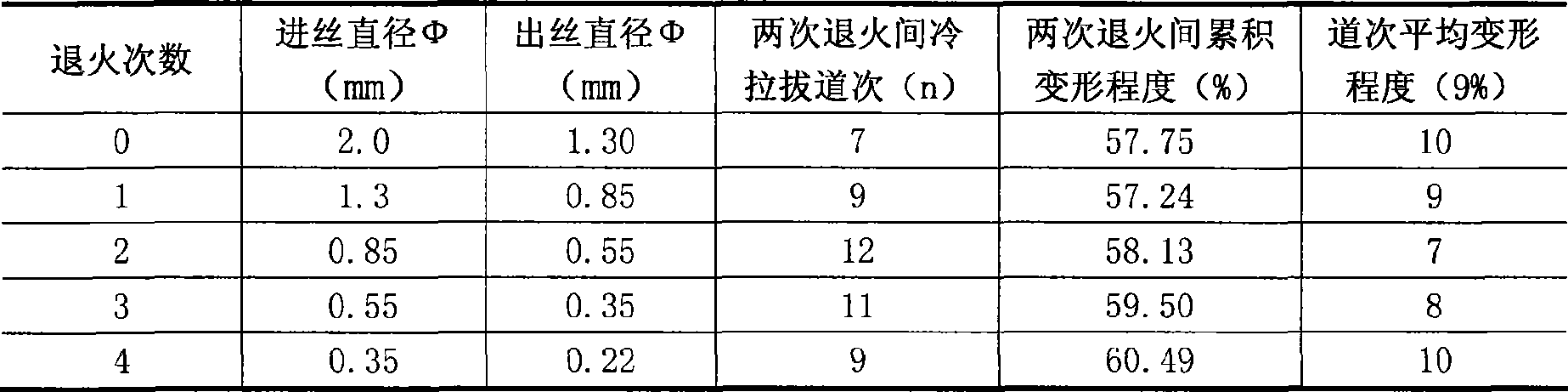

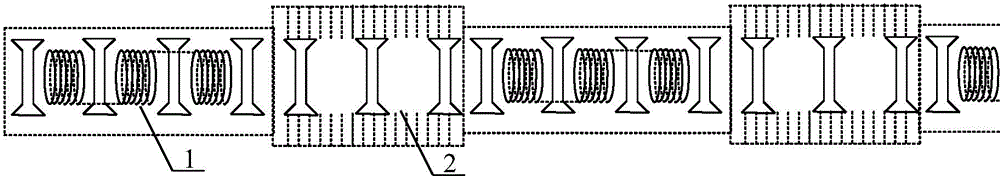

Multi-pass drawing technological process for manufacturing magnesium and magnesium alloy filament

InactiveCN101468363AHigh work hardening rateEasy to implementFurnace typesHeat treatment process controlMagnesium alloyLubricant

The invention relates to a multi-pass drawing process method for manufacturing magnesium and magnesium alloy filaments. The prior production method has many middle annealing times, low production efficiency, low yield of a finished product, and high cost. The multi-pass drawing process method for manufacturing the magnesium and the magnesium alloy filaments comprises: a raw material of a fine crystal magnesium or magnesium alloy wire material with diameter of between phi 2 and 3 is selected; the raw material and a wire drawing mould are lubricated through a grease-type lube and are subjected to cold drawing for 5 to 12 times, and the cold drawing speed is between 120 and 150 mm / s; the raw material is recrystallized and annealed, the annealing temperature is between 400 and 420 DEG C, and the annealing time is between 1 and 3 minutes; and the process is repeated till the process is finished. The method is used for manufacturing the magnesium and the magnesium alloy filaments.

Owner:HARBIN INST OF TECH

Super-hard austenitic stainless steel and preparation method thereof

The invention discloses a super-hard austenitic stainless steel and a preparation method thereof. The super-hard austenitic stainless steel comprises the following chemical components by weight percent: 0.08-0.13% of C, 0.3-1.0% of Si, less than 2.0% and greater than or equal to 0.5% of Mn, 16.5-17.5% of Cr, 6.5-7.5% of Ni, 0.03-0.08% of N, 0.5-0.8% of Mo, greater than or equal to 0.040% of P, greater than or equal to 0.01% of S, Fe and unavoidable impurities; the temperature of Md30 is 30-60 DEG C. By controlling the tempering and cold rolling reduction rate to 35-45%, controlling the rolling speed to less than or equal to 5m / s and the rolling temperature to less than or equal to 30 DEG C, the transformation from the austenite to the deformation martensite is created and the hardness of the material is greatly increased under the same deformation; when the tempering and cold-rolling reduction rate is 35%, the hardness HV is greater than 550 and the anisotropy of the super-hard state steel is reduced.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

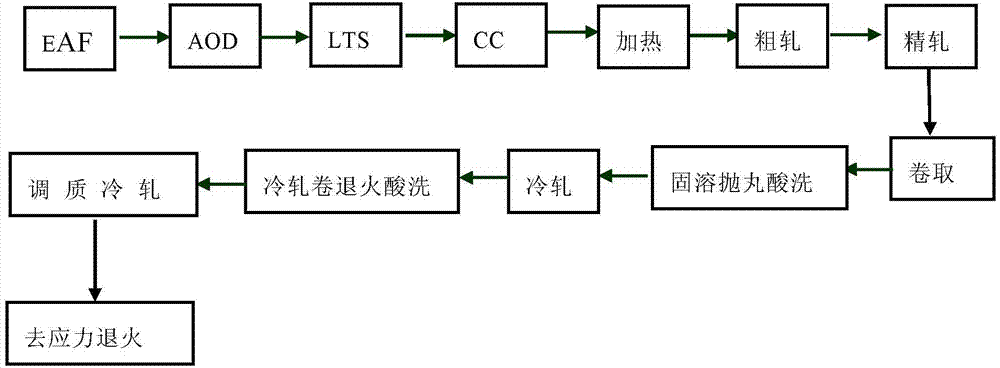

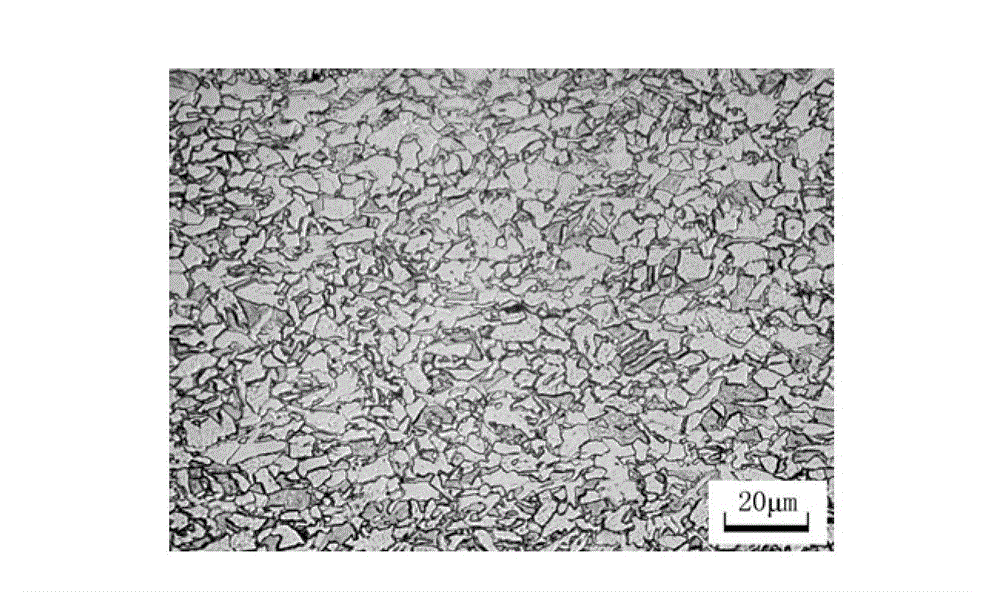

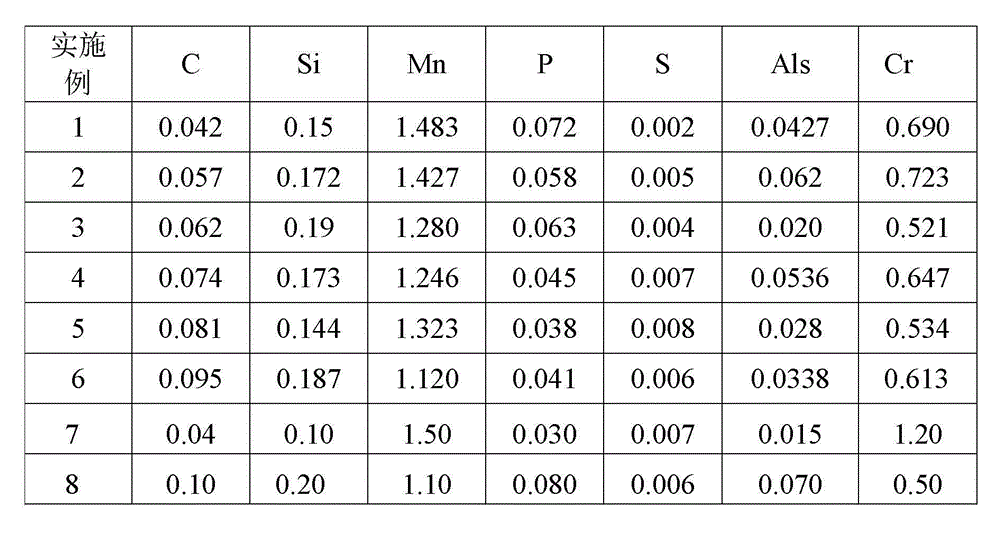

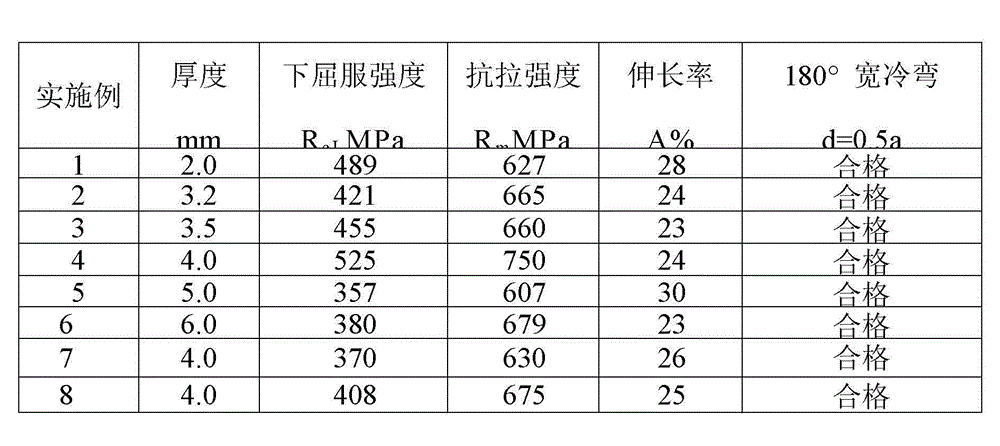

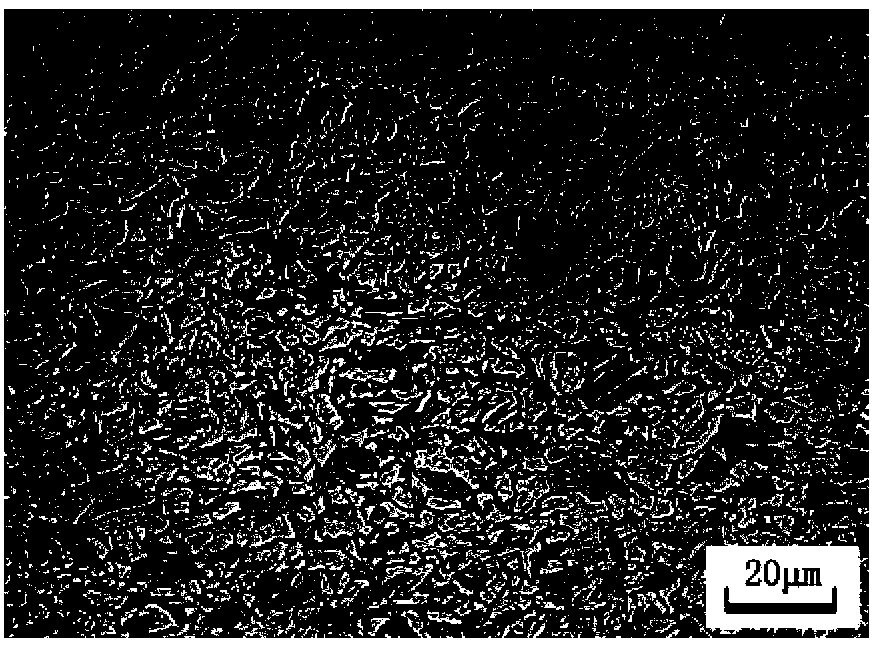

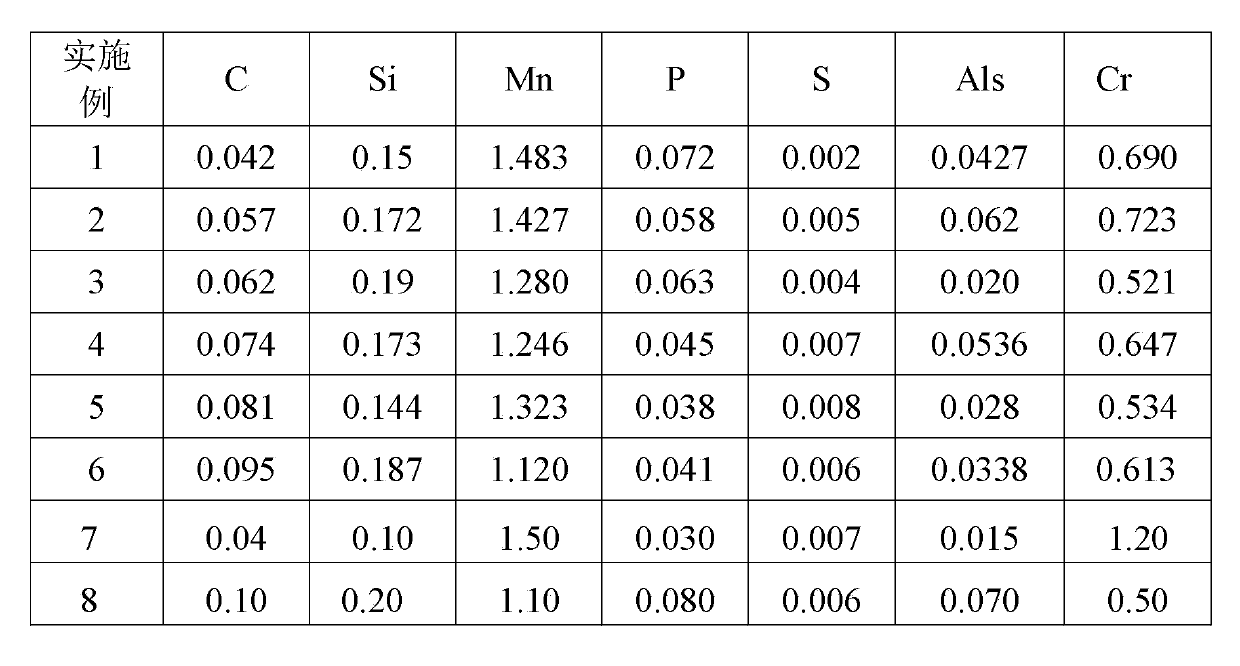

Hot-rolled dual-phase steel in 590MPa tensile strength grade and method for manufacturing hot-rolled dual-phase steel

The invention discloses hot-rolled dual-phase steel in the 590MPa tensile strength grade and a method for manufacturing the hot-rolled dual-phase steel. The steel comprises, by weight, from 0.04% to 0.10% of C, from 1.10% to 1.50% of Mn, from 0.10% to 0.20% of Si, from 0.015% to 0.070% of Als, from 0.03% to 0.08% of P, lower than or equal to 0.008% of S, from 0.5% to 1.2% of Cr, the balance Fe and inevitable impurities. The method for manufacturing the steel includes molten iron desulfurization, converter smelting, vacuum treatment, continuous casting, sizing, plate blank heating, hot continuous rolling, laminar cooling and reeling. As proved by practice, the steel is high in tensile strength, low in yield ratio and excellent in cold stamping forming performance and fatigue resistance, a technological process of the method is simple, and the production cost is low.

Owner:武汉钢铁有限公司

Low-density Ti3Al strengthened super-strength steel and preparing method thereof

The invention relates to low-density Ti3Al strengthened super-strength steel and a preparing method thereof, and belongs to the field of metal materials. The chemical components of the steel comprise, by mass percent, 0.5% to 1.5% of C, 15% to 30% of Mn, 5% to 10% of Al, 5% to 20% of Ti, not larger than 5% of Cr, not larger than 0.2% of Nb, not larger than 2% of Si, not larger than 0.6% of B and the balance Fe and inevitable impurities. Through adding of Ti, Ti3Al is formed, the Ti3Al and k-carbide can jointly generate precipitation strengthening, the steel has the super-high strength and the good plasticity while the density is effectively reduced, the tensile strength reaches above 1350MPa, the ductility reaches above 10%, the density ranges from 6.5 g / cm<3> to 6.9 g / cm / <3>, and the manufacturing requirement of automobile structural parts is met.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

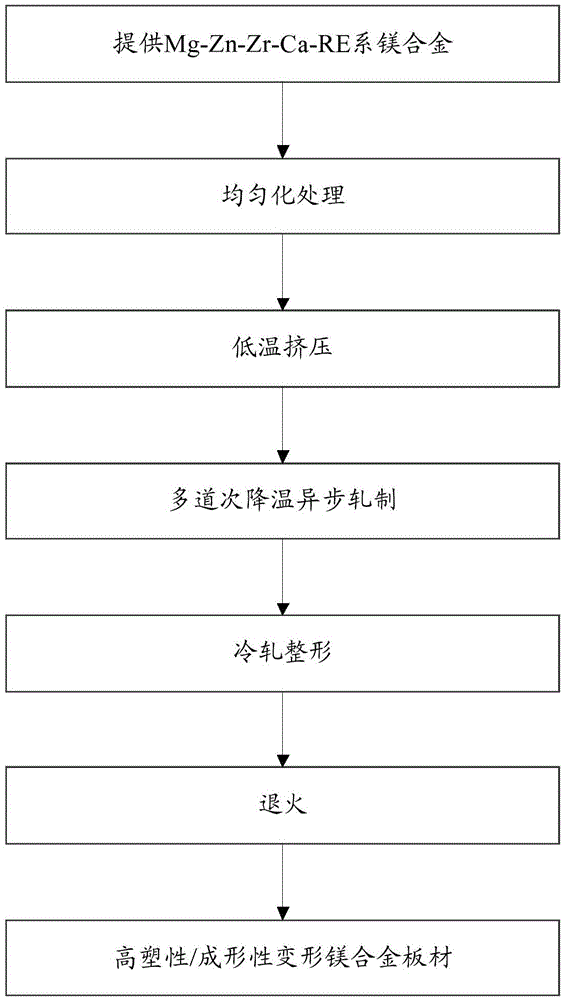

Method for manufacturing high-plasticity/formability deforming magnesium alloy plate

The invention discloses a method for manufacturing a high-plasticity / formability deforming magnesium alloy plate. The method comprises the following steps: a) providing a magnesium alloy composed of 2.5-4.5 wt.% of Zn, 0-0.5 wt.% of Zr, 0-0.3 wt.% of Ca, 0-1.6 wt.% of RE, less than 0.02 wt.% of total impurity elements and the balance of Mg, wherein the RE is selected from one or more of Y, Gd and Nd; b) carrying out low-temperature extrusion on the magnesium alloy, wherein the initial temperature of the magnesium alloy is room temperature to 200 DEG C; c) carrying out multipass cooling asynchronous rolling on the pre-extruded magnesium alloy, wherein the accumulated strain amount is 0.8-3.0; carrying out one-pass cold rolling reshaping; and d) directly carrying out annealing treatment on the rolled magnesium alloy plate, thereby obtaining the high-plasticity / formability deforming magnesium alloy plate.

Owner:HARBIN INST OF TECH AT WEIHAI

Method for producing tough iron-chromium-aluminium ferritic electrothermal alloy

The invention discloses a method for producing tough iron-chromium-aluminium ferritic electrothermal alloy, which comprises the following steps: 1) raw material selection; 2) technological processes: a, vacuum melting; b, high-temperature vacuum refining; c, reductive slagging; d, temperature reduction and solidification; e, temperature rise and deoxidation; f, quenching and tempering and homogenization; and g, casting ingots. The product produced by the method has excellent corrosion resistance as well as good toughness, and is as applied to the material of a heating wire; and the heating wire has lower cost, the used temperature 300 DEG C higher, and longer service life than a nickel-chromium heating wire.

Owner:JIANGSU XIHU SPECIAL STEEL

High manganese steel containing tungsten

The invention discloses a high manganese steel which contains tungsten, and the high manganese steel contains chemical constituents in the following mass percent: C: 1.05%-1.35%, Si: 0.3%-0.9%, Mn: 11%-19%, W: 0.5%-1.5%, P<=0.070% and S<=0.045%, and the rest is Fe, furthermore, the high manganese steel also can contain a rare earth element RE, and the content of the RE is 0.01%-0.3%. The high manganese steel also can contain Cr and the content of the Cr is 1.2-2.5%. The high manganese steel which contains the tungsten of the invention is added with the elements of tungsten, rare earth element RE and chrome in particular when the content of the Mn is 16%-19%, which enables the whole high manganese steel to have the advantages of good toughness, high yield strength, high work hardening degree, better abrasive resistance and the like compared with the existing steel, and thereby the application range of the high manganese steel is enlarged. The high manganese steel of the invention is suitable for preparing fitting parts which are used in the working condition of abrasion and in particular to impact abrasion.

Owner:JINAN UNIVERSITY

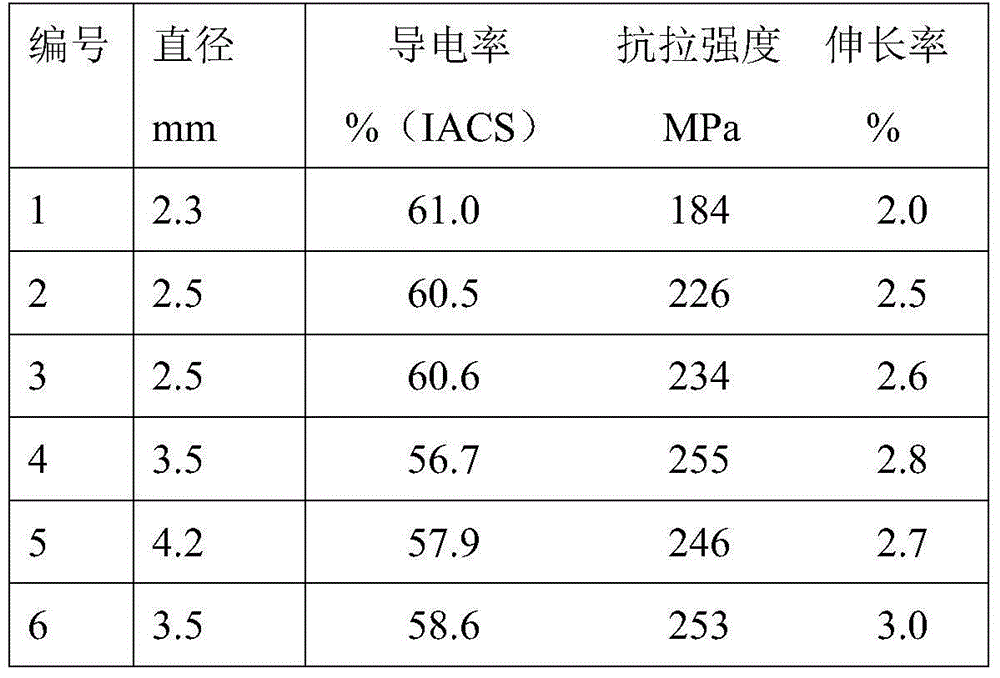

Non-heat treatment medium-strength aluminum alloy conductor material and preparation method thereof

InactiveCN104532067AHigh work hardening rateImprove conductivityMetal/alloy conductorsCable/conductor manufactureElectrical conductorRare earth

The invention relates to a non-heat treatment medium-strength aluminum alloy conductor material and a preparation method thereof, and belongs to the technical field of electrotechnical materials. The non-heat treatment medium-strength aluminum alloy conductor material comprises the following elements in percentage by weight: 0.35%-0.50% of iron, 0.10%-0.25% of copper, 0.01%-0.04% of magnesium, 0.001%-0.002% of boron, 0.02%-0.04% of rare earth (lanthanum or yttrium), impurity element silicon less than or equal to 0.11%, s(chromium+manganese+vanadium+titanium) less than or equal to 0.015%, less than or equal to 0.03% of each of other impurity elements and the balance of aluminum. The non-heat treatment medium-strength aluminum alloy conductor material disclosed by the invention can be used for enhancing the processing hardening rate of an aluminum alloy material to enhance the strength through an iron-containing second phase, copper and magnesium atom enrichment regions and dislocation interaction and enhancing the conductivity and elongation of an aluminum alloy through the matching of the iron, the copper, the magnesium, the rare earth lanthanum or yttrium and the boron. A medium-strength aluminum alloy wire manufactured by adopting the non-heat treatment medium-strength aluminum alloy conductor material can be used for solving the problem of continuous production bottleneck generated due to heat treatment, saving the power consumption and time consumption of heat treatment and reducing the cost and achieves the outstanding economic benefit.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

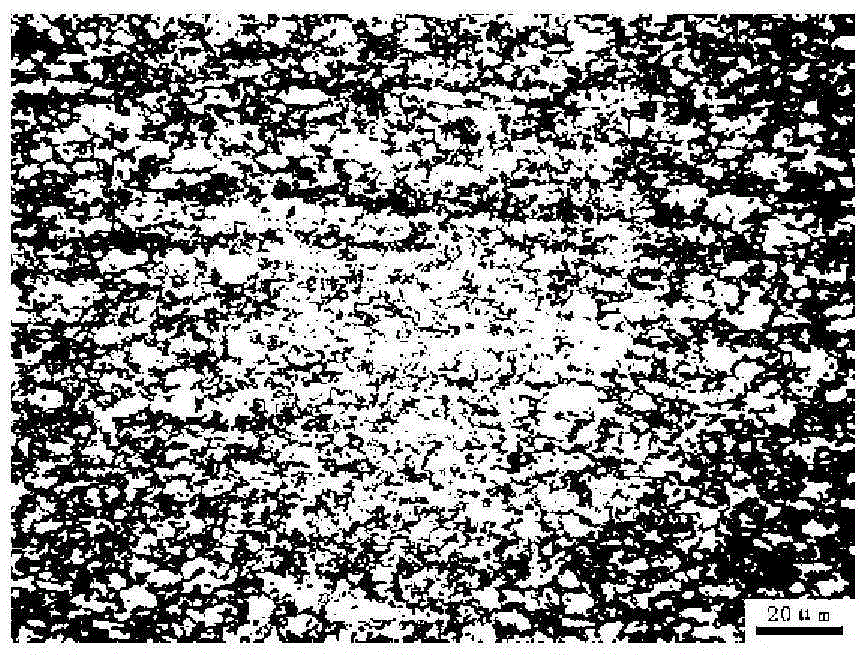

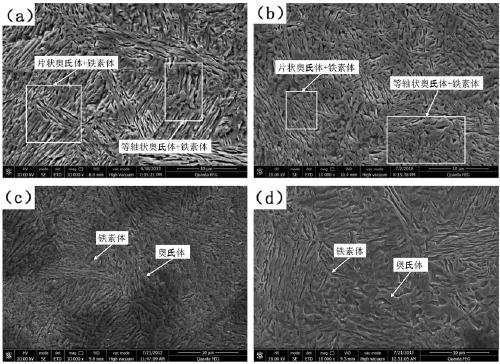

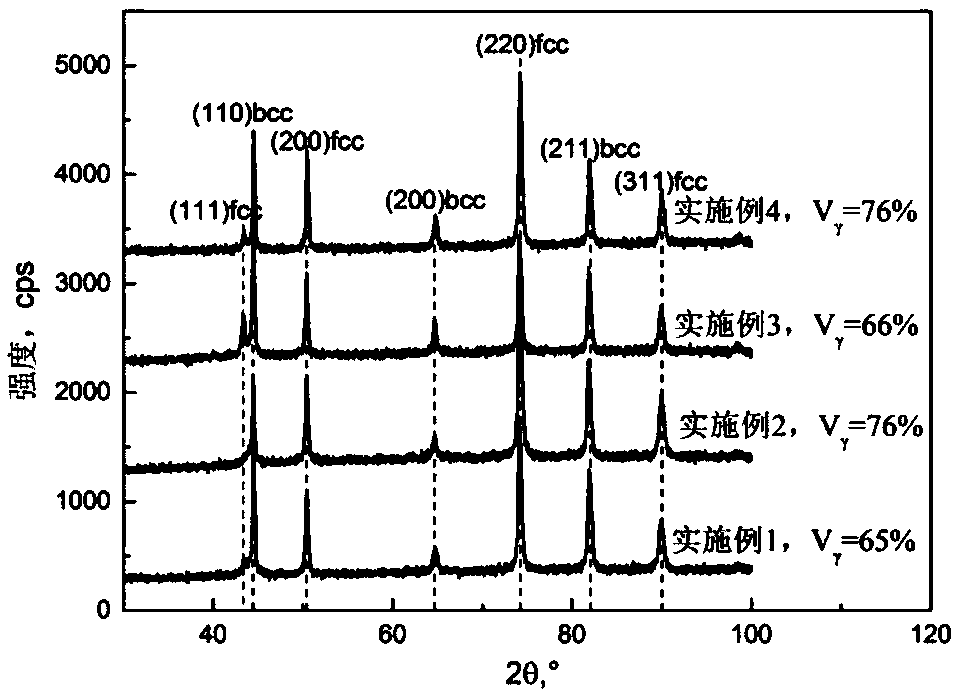

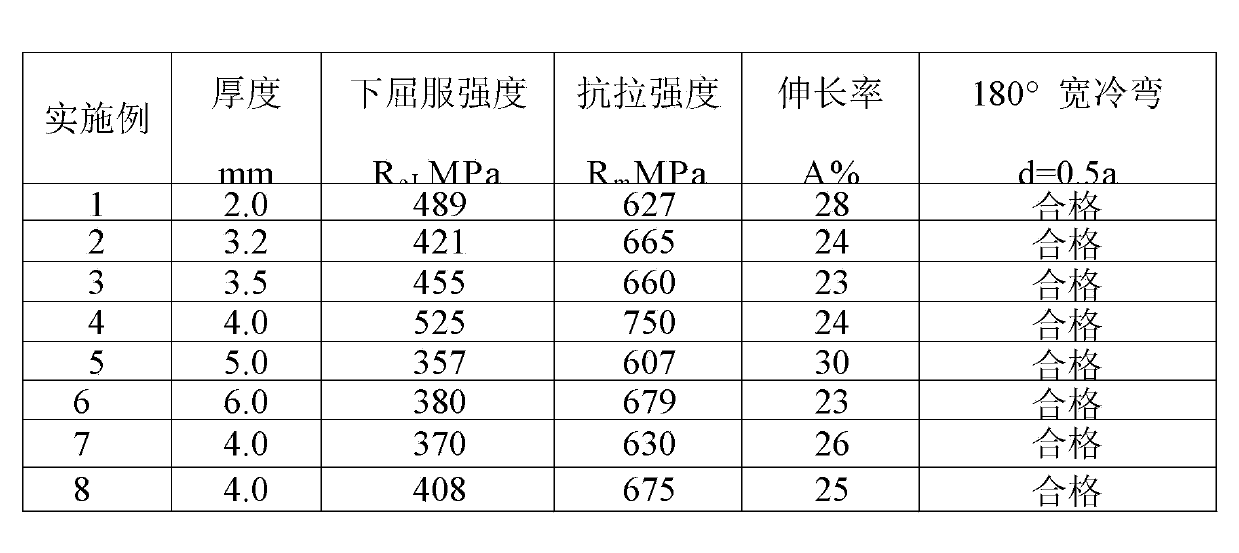

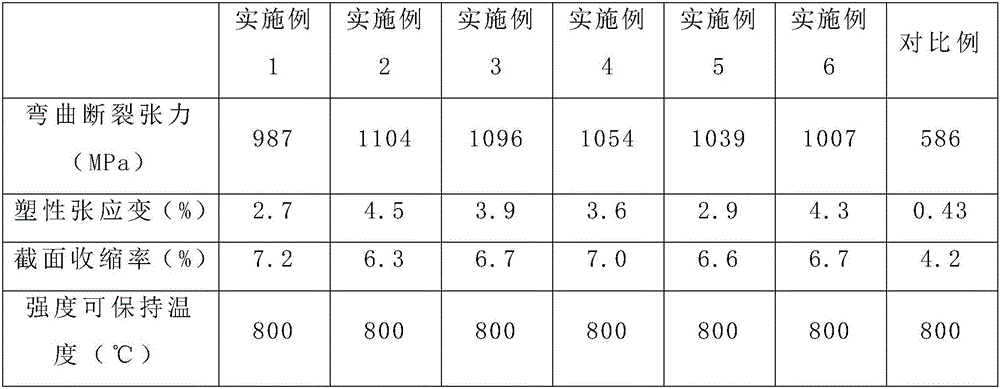

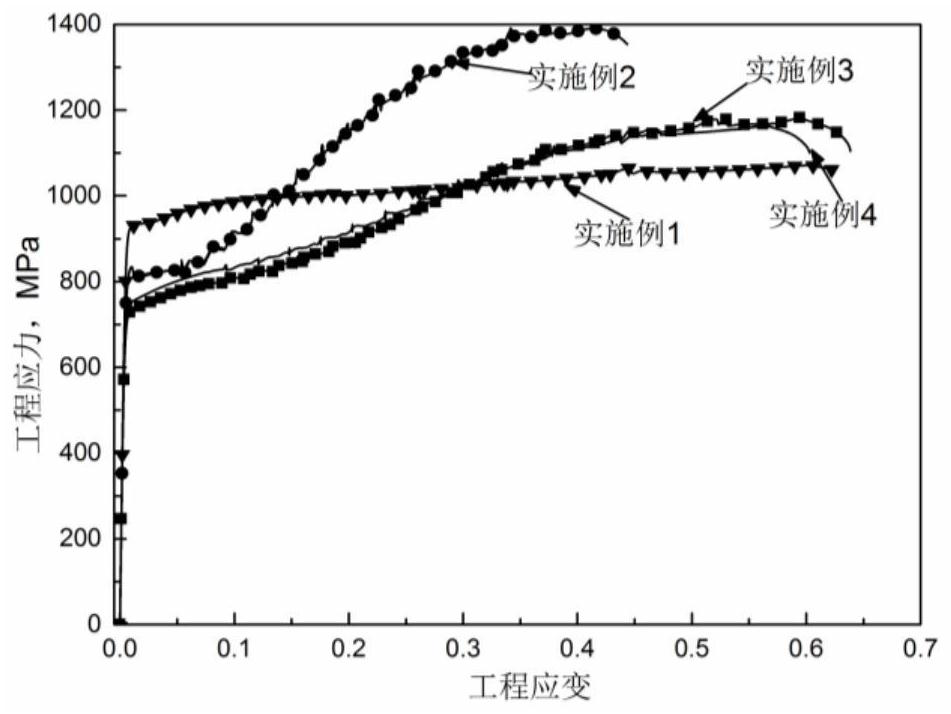

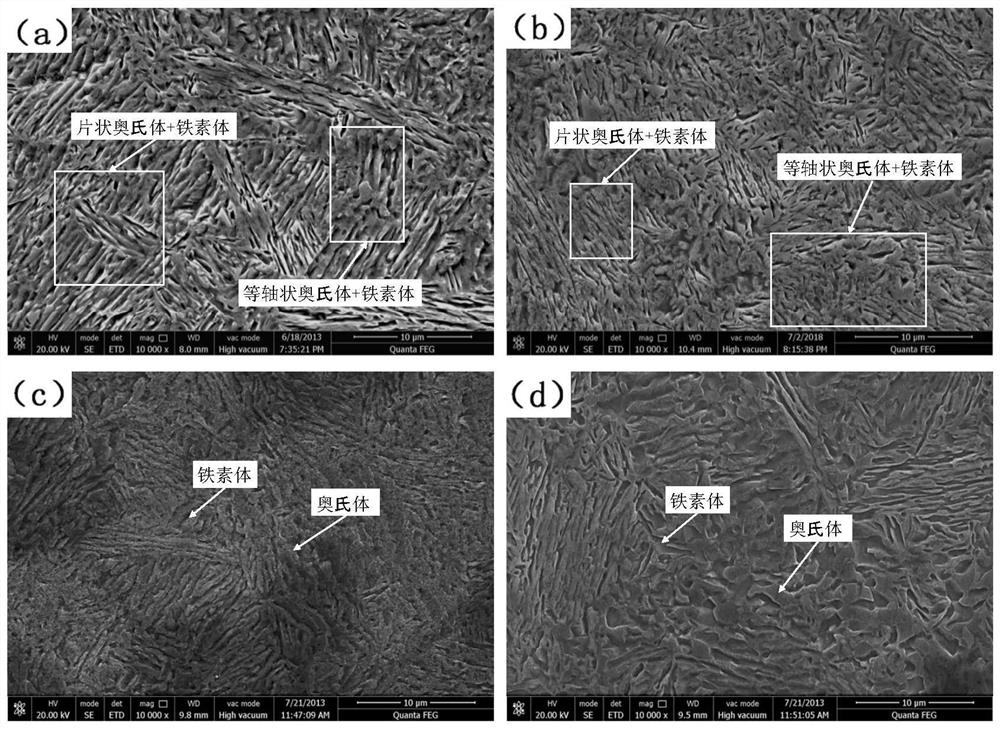

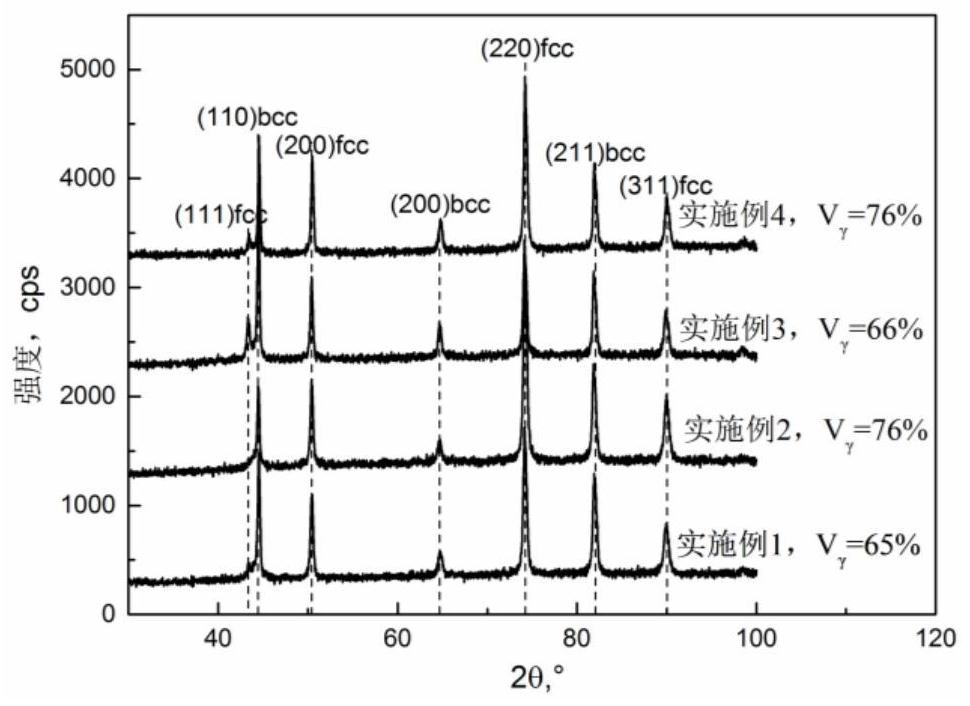

High-toughness hot-rolled medium manganese steel with strength-ductility balance greater than 60 GPa.% and preparation method

ActiveCN109666862AHigh work hardening rateIncreased strength and plasticityChemical compositionPerformance index

The invention discloses high-toughness hot-rolled medium manganese steel with strength-ductility balance greater than 60 GPa.% and a preparation method, and belongs to the field of high-toughness automobile steel. The steel comprises the following chemical components of, in percentage by weight, 0.35-0.40% of C, 6.00 -6.30% of Mn, 2.20-2.35% of Al, 0-0.027% of Nb, 0.030 -0.074% of Si, 0.05% of P,0.02% of S, and the balance Fe and inevitable impurities. The preparation method comprises the steps of raw material preparation, smelting, casting, forging, hot rolling and two-phase region annealing. According to the high-toughness hot-rolled medium manganese steel, strength of extension is 1039-1183 MPa, after-fracture elongation rate is 43.5-64.8%, strength-ductility balance can reach more than 60 GPa.%, but not greater than 72GPa.%. Through reasonable component proportion and optimized two-phase region annealing process, morphology and proportion of a two-phase structure are controlled, TRIP and TWIP effects are effectively simulated to reach a high work hardening rate, the strength and the toughness of the medium manganese steel are greatly improved, and performance indexes of different components of an automobile are met.

Owner:UNIV OF SCI & TECH BEIJING

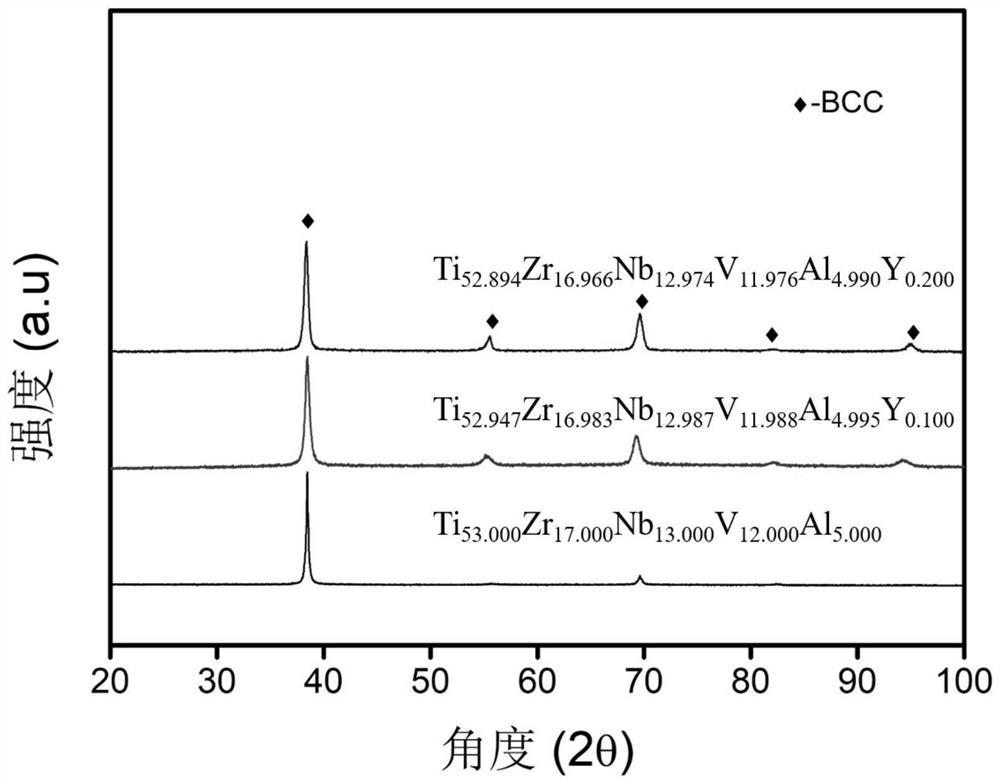

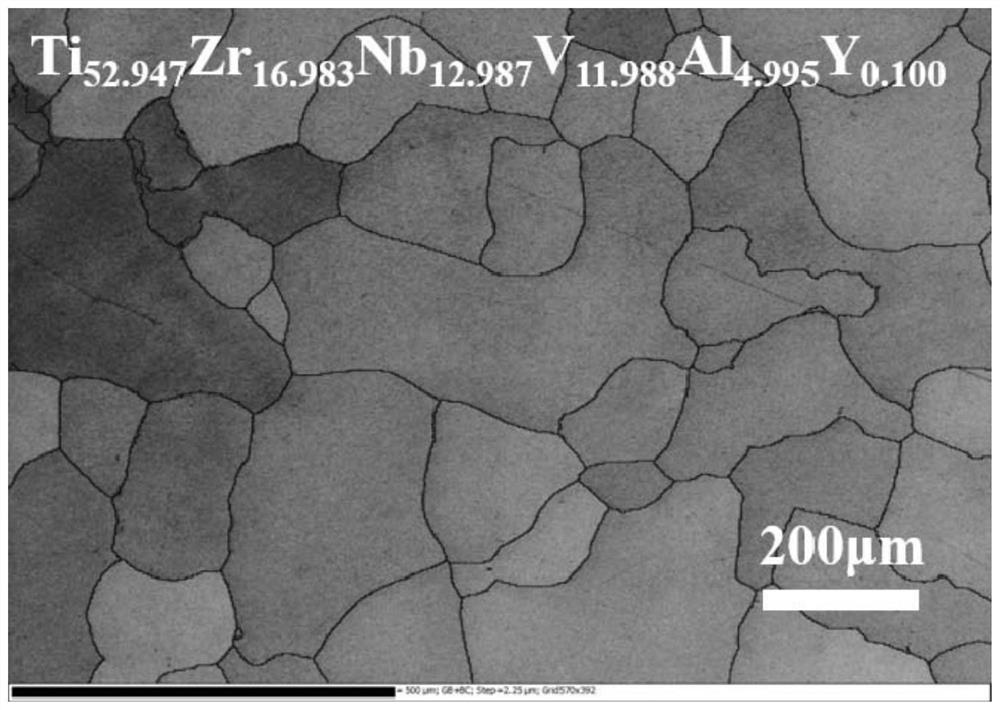

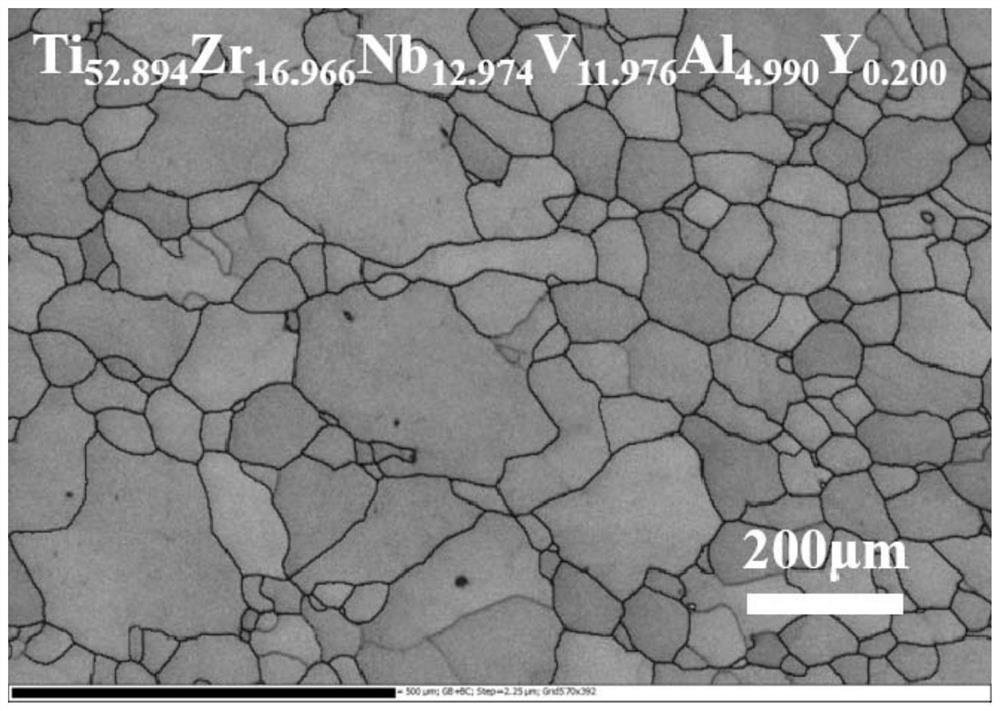

TiZrVNb-based high-entropy alloy containing rare earth elements and preparation method thereof

ActiveCN113667877AReduce critical nucleiIncrease nucleation rateRare-earth elementHigh entropy alloys

The invention relates to a TiZrVNb-based high-entropy alloy containing rare earth elements and a preparation method thereof, and belongs to the technical field of TiZrVNb-system high-entropy alloys. The chemical formula of the high-entropy alloy is briefly named as TiaZrbNbcVdMeAf according to the atomic ratio, M is at least one of Al, Hf, Ta, W, Mn, Cu, Cr, Fe, Mg, Be, Li, Mo, Co, Ni, Si, B, O and N, A is at least one of Y, La, Er, Sc, Nd, Gd and Ce. According to the TiZrVNb-based high-entropy alloy containing the rare earth elements and the preparation method thereof, grain refinement under a common smelting technology is achieved mainly by adding the rare earth elements to increase component supercooling, reduce a critical nucleation radius and form a rare earth oxide pinning grain boundary. On the basis of keeping high strength and high plasticity of the TiZrVNb-based high-entropy alloy, the work hardening rate of the TiZrVNb-based high-entropy alloy is obviously increased. In addition, the high-entropy alloy can be prepared by adopting a smelting technology, subsequent deformation and heat treatment are not needed, the preparation process is simple, the production efficiency is high, and the preparation method is suitable for industrial production.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

High-strength plastic vanadium microalloyed dual-phase steel seamless pipe and preparation method thereof

ActiveCN104018067AImprove mechanical propertiesHigh strengthFurnace typesIncreasing energy efficiencySolid componentHigh rate

The invention discloses a high-strength plastic vanadium microalloyed dual-phase steel seamless pipe and an on-line preparation method thereof. The seamless pipe is composed of the following chemical components in percentage by mass: 0.10-0.18% of C, 0.1-0.6% of Si, 1.1-1.6% of Mn, 0.16-0.20% of V, 0.01-0.03% of N, at most 0.006% of P, at most 0.005% of S, and the balance of Fe and other inevitable impurities. The intermediate-frequency induction heat treatment device of the thin-wall steel pipe is utilized and assisted by the vanadium microalloyed component design to produce the dual-phase steel seamless pipe with favorable comprehensive mechanical properties; the advantages of low yield-tensile ratio, high rate of work hardening, favorable strength and favorable elongation percentage of the dual-phase steel are matched and successfully applied to the field of production of steel pipes to efficiently substitute solid components with hollow components, thereby implementing light weight of the automobile; and meanwhile, the seamless pipe promotes further development of the internal high-pressure forming technique, and has wide application prospects.

Owner:LAIWU IRON & STEEL GRP

Multi-pass drawing technological process for manufacturing magnesium and magnesium alloy filament

InactiveCN101468363BHigh work hardening rateEasy to set upFurnace typesHeat treatment process controlMaterials scienceLubricant

The invention relates to a multi-pass drawing process method for manufacturing magnesium and magnesium alloy filaments. The prior production method has many middle annealing times, low production efficiency, low yield of a finished product, and high cost. The multi-pass drawing process method for manufacturing the magnesium and the magnesium alloy filaments comprises: a raw material of a fine crystal magnesium or magnesium alloy wire material with diameter of between phi 2 and 3 is selected; the raw material and a wire drawing mould are lubricated through a grease-type lube and are subjected to cold drawing for 5 to 12 times, and the cold drawing speed is between 120 and 150 mm / s; the raw material is recrystallized and annealed, the annealing temperature is between 400 and 420 DEG C, and the annealing time is between 1 and 3 minutes; and the process is repeated till the process is finished. The method is used for manufacturing the magnesium and the magnesium alloy filaments.

Owner:HARBIN INST OF TECH

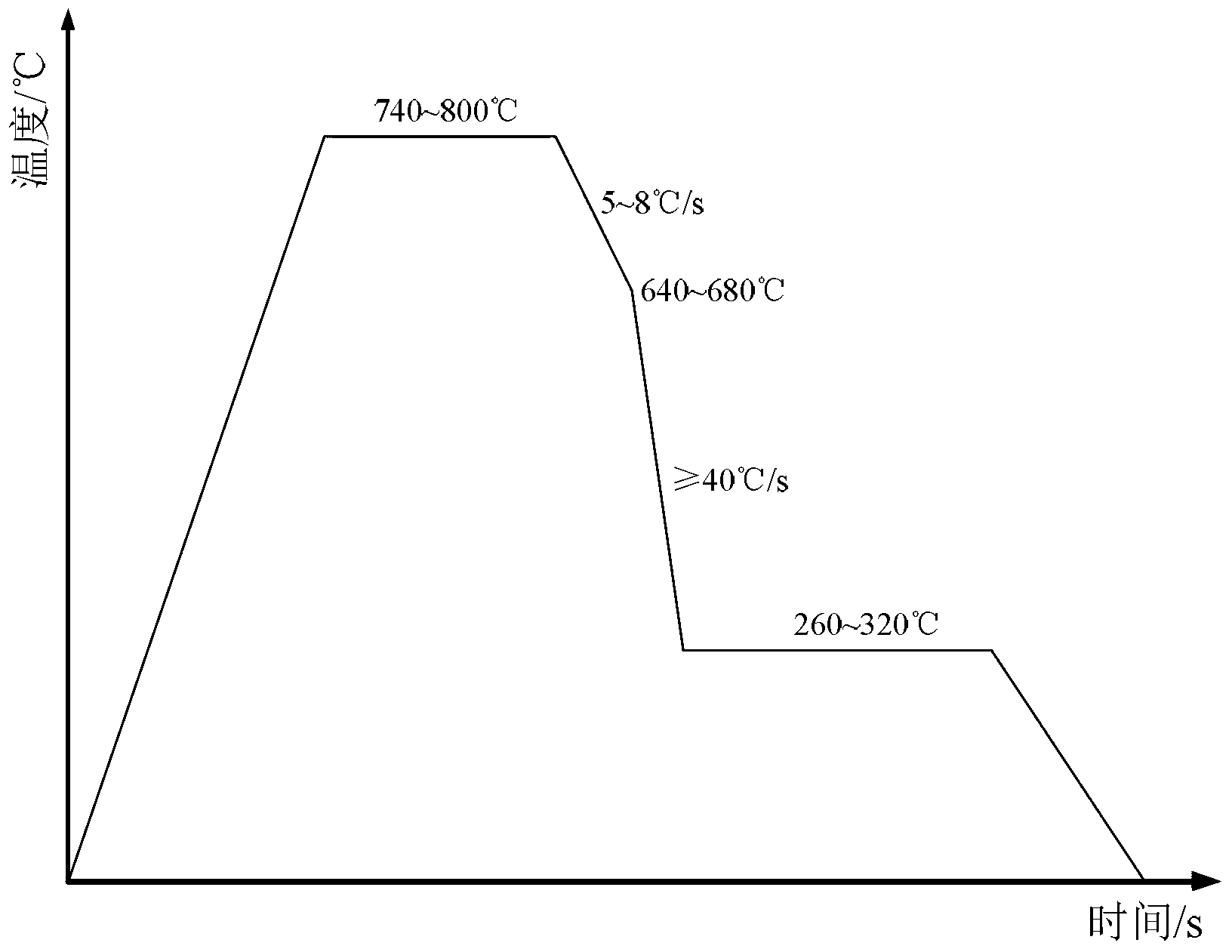

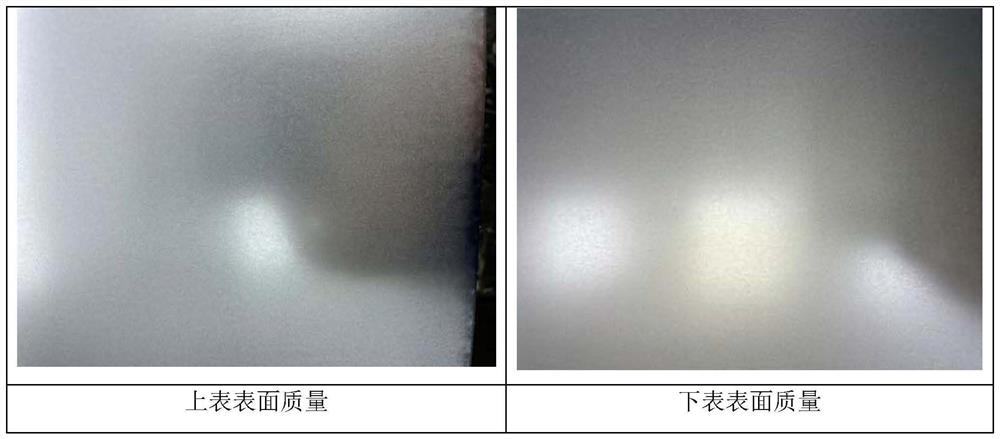

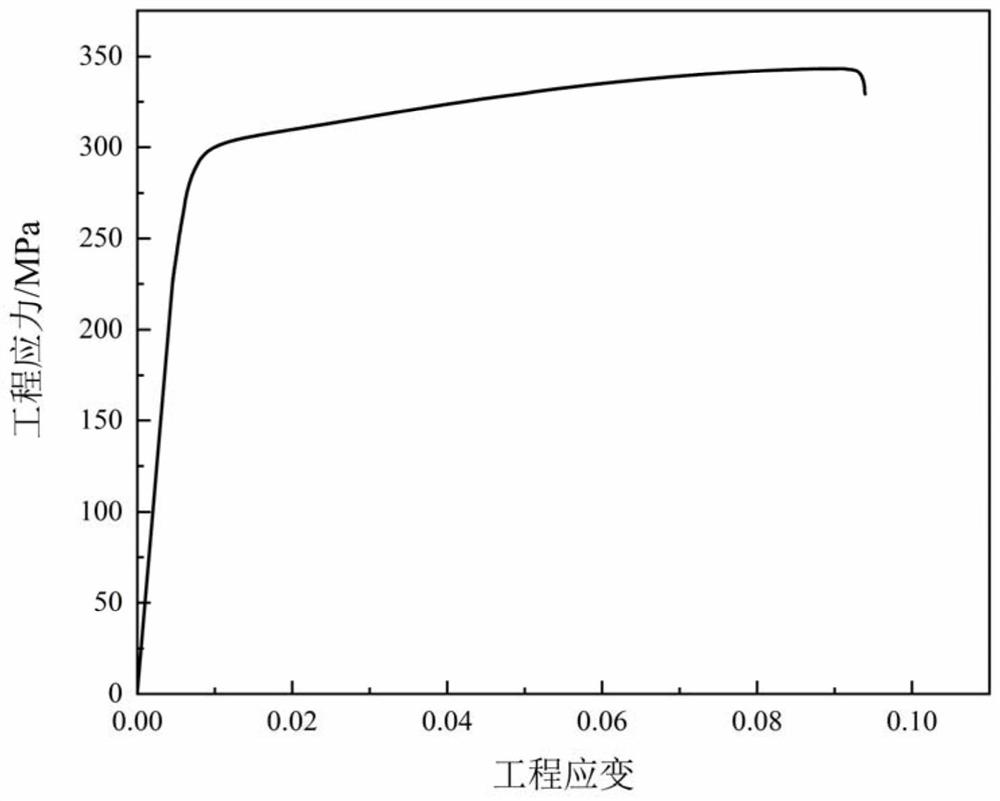

450MPa-grade hot-dip galvanized dual-phase steel with high work hardening rate and surface quality and production method of 450MPa-grade hot-dip galvanized dual-phase steel

PendingCN114107806AExcellent surface coating qualityImprove strong plasticityHot-dipping/immersion processesManganeseSlow cooling

The invention discloses 450MPa-grade hot-dip galvanized dual-phase steel and a production method thereof, and belongs to the field of galvanized automobile steel manufacturing, the 450MPa-grade hot-dip galvanized dual-phase steel adopts a low-carbon-low-manganese component design of trace Si, low Mo and high Cr, processes of coiling at a low temperature of 520-560 DEG C, slow cooling at a temperature of 640-660 DEG C and rapid cooling at a temperature of more than or equal to 10 DEG C are carried out, and the 450MPa-grade hot-dip galvanized dual-phase steel is prepared by matching a dew point in a furnace at a temperature of less than or equal to-40 DEG C and an oxygen content of less than or equal to 5ppm. And obtaining the 450MPa-grade hot-dip galvanized dual-phase steel under the atmosphere that the dew point of a furnace nose is not more than-20 DEG C. According to the produced hot-dip galvanized dual-phase steel with the tensile strength of 450 MPa, the uniform elongation is 18%-23%, the work hardening rate n value is not lower than 0.19, the after-fracture elongation A80 reaches up to 28%-33%, and the hot-dip galvanized dual-phase steel is suitable for being used as a high-drawing and high-flanging complex forming automobile part.

Owner:MAANSHAN IRON & STEEL CO LTD

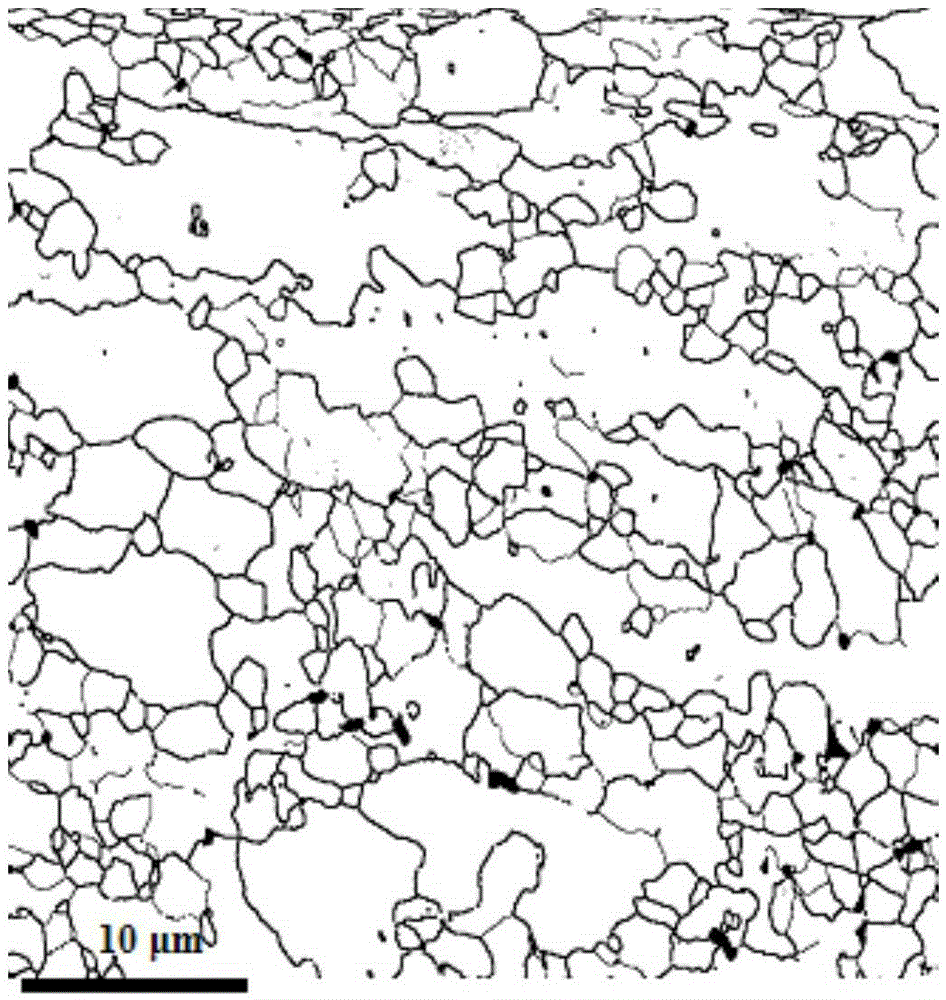

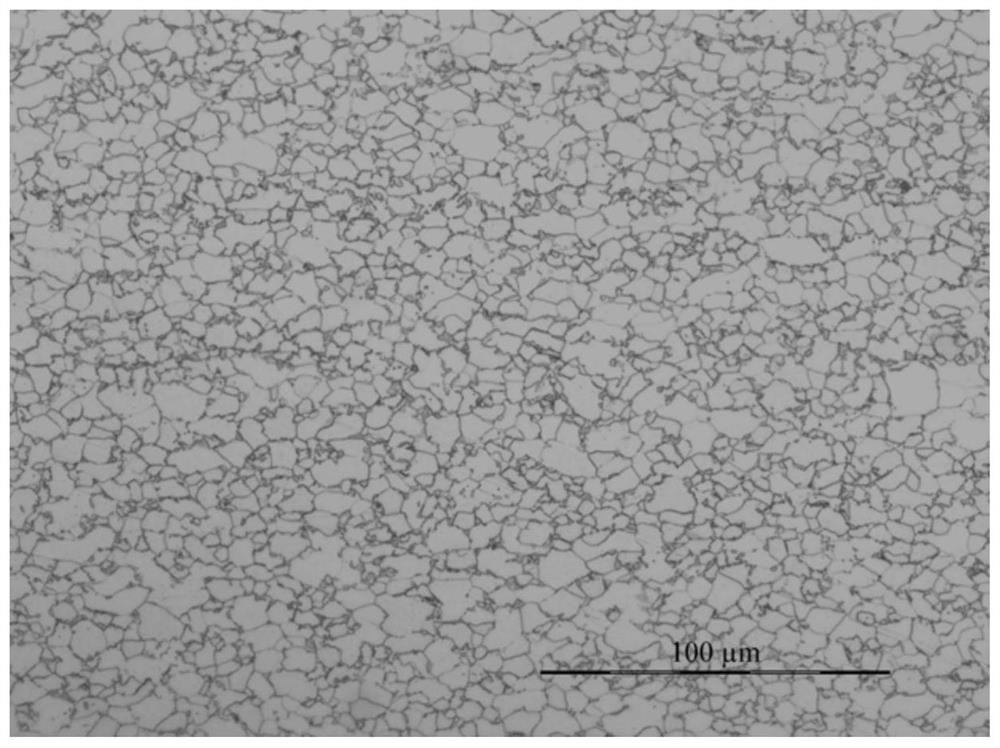

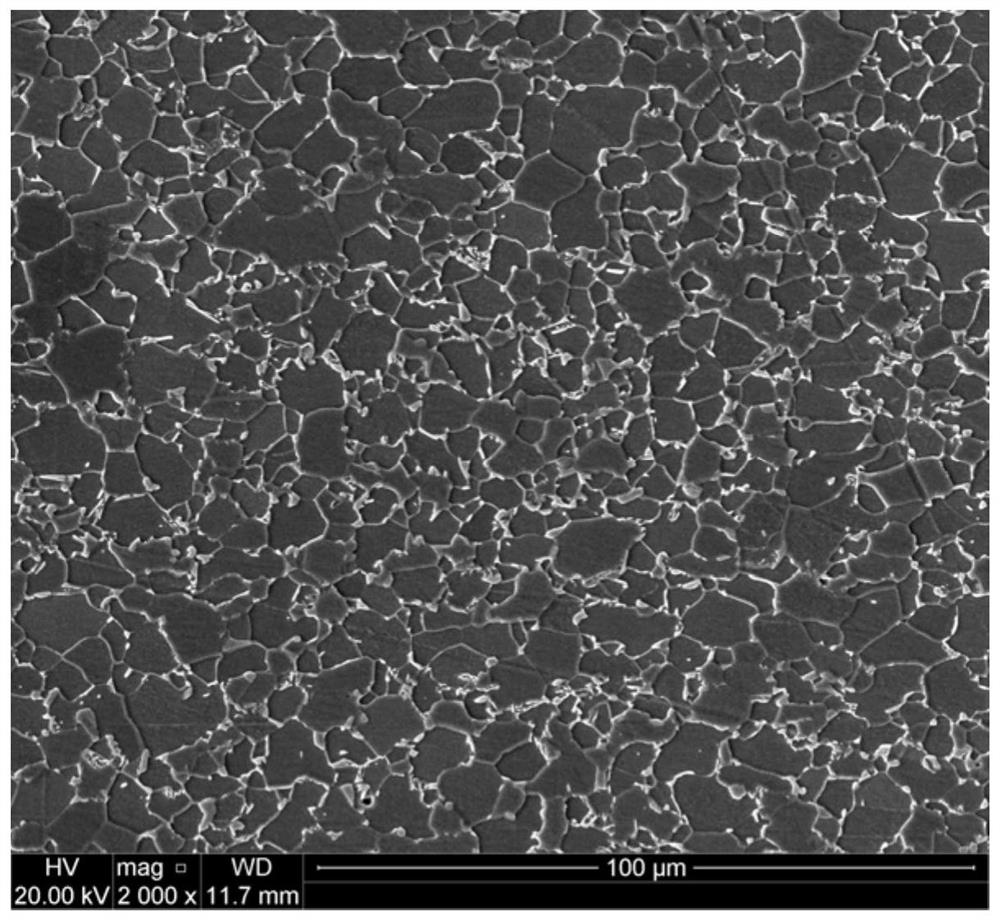

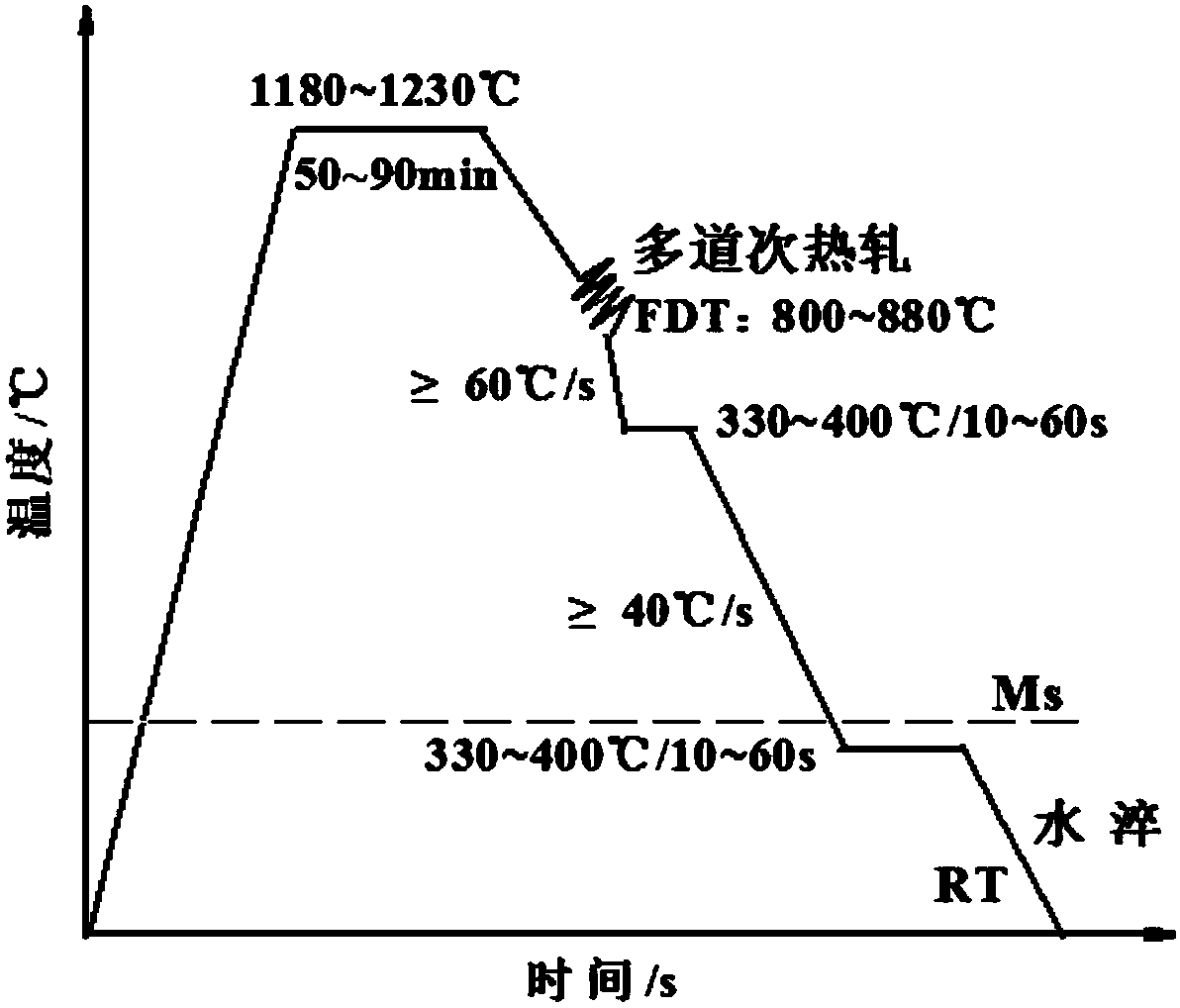

High-work-hardening-ratio hot rolling Q&P steel plate and preparing method thereof

The invention relates to a high-work-hardening-ratio hot rolling Q&P steel plate and a preparing method thereof. According to the technical scheme, the high-work-hardening-ratio hot rolling Q&P steelplate comprises chemical components including, by weight percent, 0.15 to 0.20% of C, 0.60 to 1.0% of Si, 1.2 to 2.0% of Mn, 0.03 to 0.06% of Al, 0.03 to 0.06% of Nb, not larger than 0.020% of P, notlarger than 0.005% of S and the balance Fe and inevitable impurities. A casting blank is placed in a heating furnace, the charging temperature ranges from 700 DEG C to 900 DEG C, heating to 1180 DEG Cto 1230 DEG C is achieved, heat preservation is carried out for 50 to 90 min, heavy reduction is carried out in the first three passes, the reduction rate ranges from 40 to 60%, the final rolling temperature ranges from 800 DEG C to 880 DEG C, cooling to 650 DEG C to 720 DEG C is achieved, air cooling relaxation is carried out for 4 to 8 s, ferrite is precipitated, cooling to 340 DEG C to 400 DEGC is achieved, partition treatment is carried out, the partition treatment time is 10 to 60 s, water quenching to the room temperature is achieved, and the high-work-hardening-ratio hot rolling Q&P steel plate is obtained. The process is simple, the cost is low, and the made product is high in work hardening rate, good in mechanical property, high in strength and ductility product and excellent in forming performance.

Owner:WUHAN UNIV OF SCI & TECH

Malleable iron-chromium-aluminum ferritic electrothermal alloy

The invention discloses a malleable iron-chromium-aluminum ferritic electrothermal alloy, which comprises the following chemical compositions in percentage by mass: less than or equal to 0.01 percent of C, less than or equal to 0.05 percent of N, less than or equal to 0.1 percent of Si, less than or equal to 0.08 percent of Mn, 21.5 to 31 percent of Cr, less than or equal to 3.0 to 6.0 percent of Al, less than or equal to 0.030 percent of P, less than or equal to 0.030 percent of S, and the balance of Fe and inevitable impurities. The malleable iron-chromium-aluminum ferritic electrothermal alloy not only has excellent corrosion resistance, but also has good toughness, lower cost than a nickel-chromium electric stove wire, service temperature 300 DEG C higher than the nickel-chromium electric stove wire and long service life.

Owner:JIANGSU XIHU SPECIAL STEEL

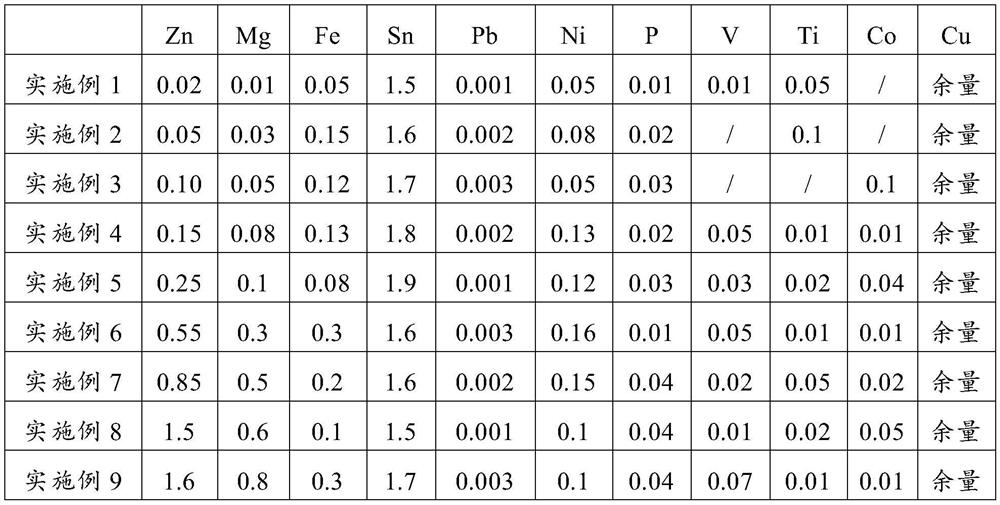

High-strength,high-elasticity and bending-resistant copper alloy as well as preparation method and application thereof

ActiveCN112853148AHigh work hardening rateHigh strengthMetal rolling arrangementsCopper alloyElastic modulus

The invention belongs to the technical field of alloys, and particularly relates to a high-strength, high-elasticity and bending-resistant copper alloy as well as a preparation method and application thereof. The high-strength, high-elasticity and bending-resistant copper alloy is prepared from the following elements in percentage by mass: 0.02-3.2% of Zn, 0.01-2.2% of Mg, 1.5-2.0% of Sn, 0.05-0.3% of Fe, 0.05-0.19% of Ni, 0.001-0.003% of Pb, 0.01-0.05% of P, 0.01-0.1% of strengthening elements and the balance of Cu, wherein the strengthening element is one or more of Ti, Co and V. The embodiment shows that the high-strength, high-elasticity and bending-resistant copper alloy has the tensile strength of 280-680 MPa, the ductility of 3-40%, the conductivity of 30-35% IACS, the elastic modulus of 108-113 GPa, and is bending-resistant.

Owner:浙江惟精新材料股份有限公司

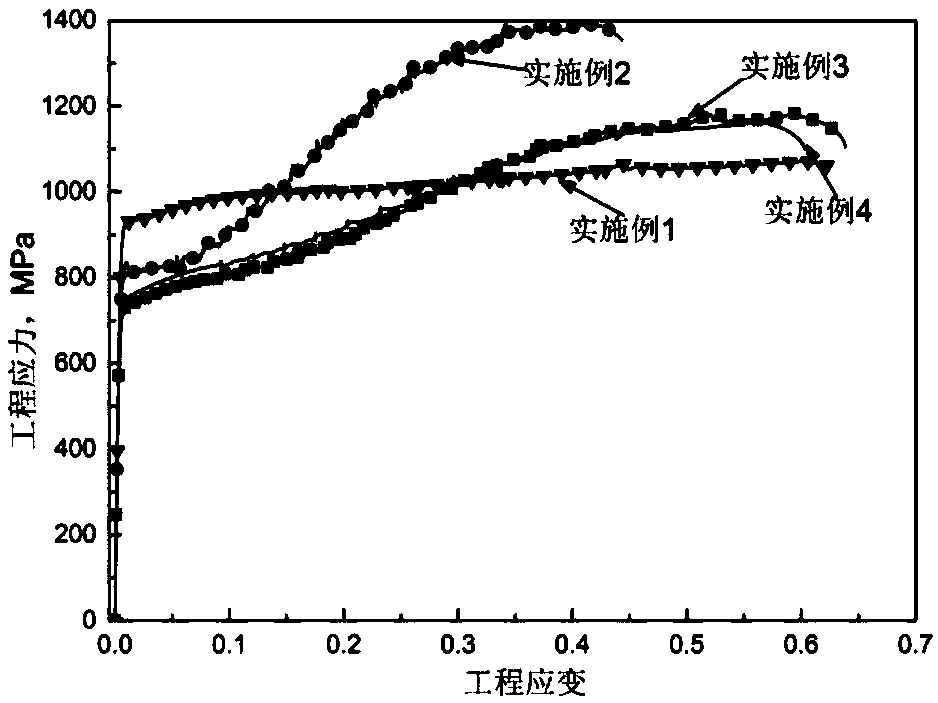

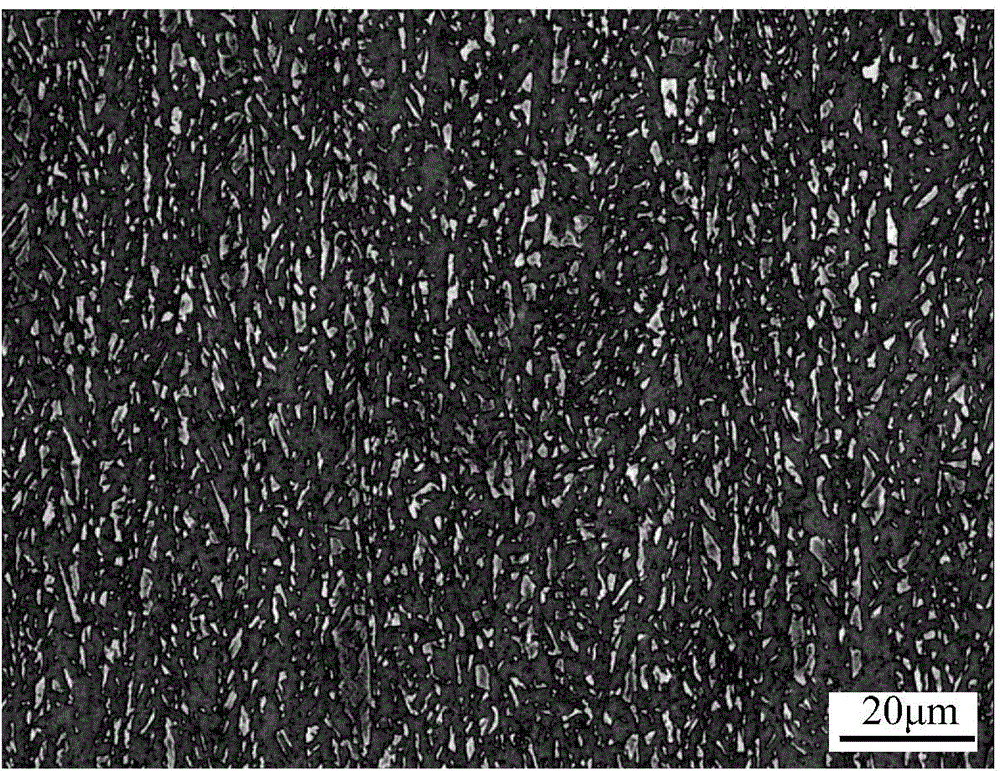

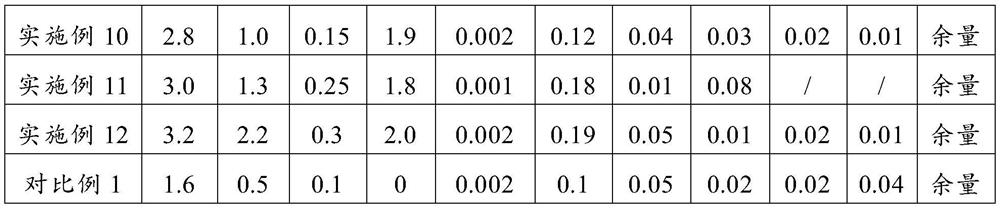

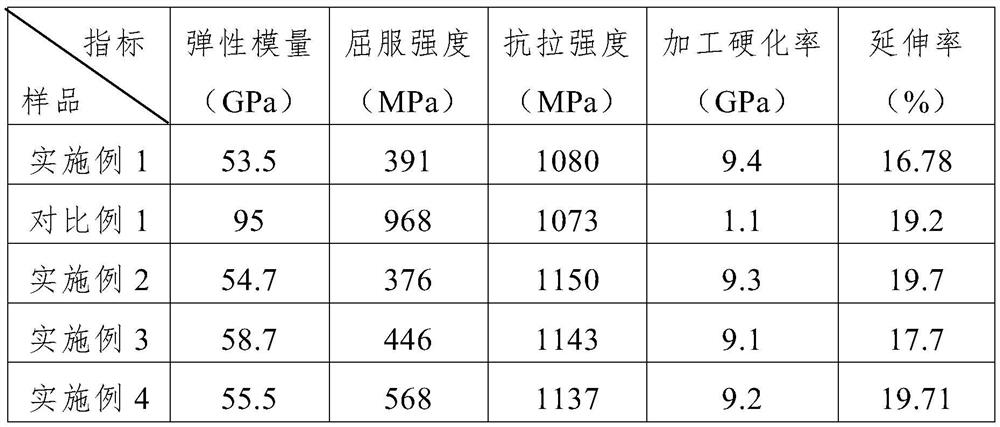

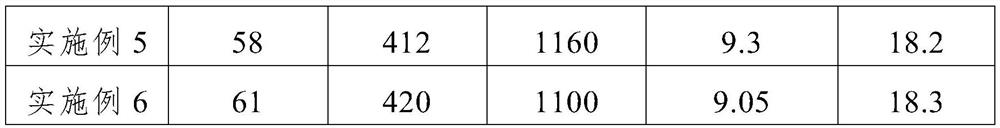

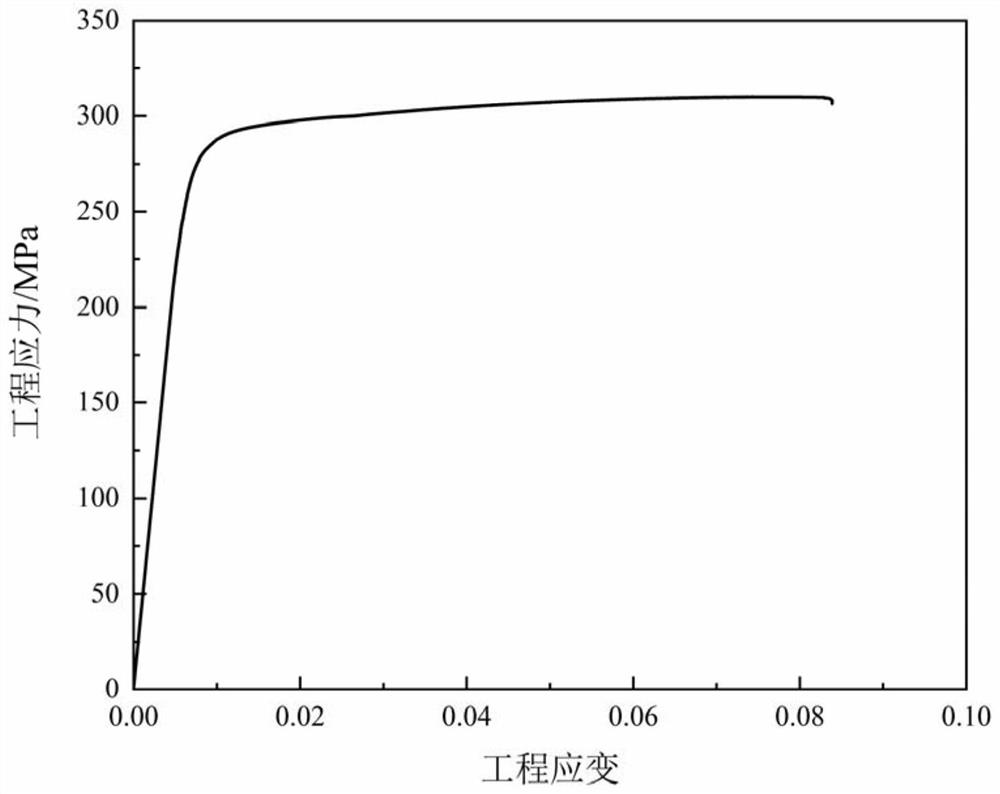

Ti-Al-Mo-Cr series beta titanium alloy with ultralow elastic modulus and ultrahigh work hardening rate and heat treatment process thereof

The invention discloses a Ti-Al-Mo-Cr series beta titanium alloy with the ultralow elastic modulus and the ultrahigh work hardening rate. The Ti-Al-Mo-Cr series beta titanium alloy is composed of the following components of, in percentage by mass, 4.5%-5.5% of Al, 6.0%-7.0% of Mo, 2.5%-3.5% of Cr and the balance Ti and inevitable impurity elements. The invention further discloses a heat treatment process for carrying out solution treatment on the Ti-Al-Mo-Cr series beta titanium alloy at the temperature of (T-50 DEG C) to (T + 50 DEG C). According to the Ti-Al-Mo-Cr series beta titanium alloy with the ultralow elastic modulus and the ultrahigh work hardening rate, by designing the components and content of the titanium alloy, martensite phase transformation is easily induced when the titanium alloy deforms at room temperature, so that the elastic modulus of the alloy is reduced, and the ultrahigh work hardening rate is achieved; and according to the Ti-Al-Mo-Cr series beta titanium alloy with the ultralow elastic modulus and the ultrahigh work hardening rate, the solution treatment temperature of the Ti-Al-Mo-Cr series beta titanium alloy is controlled, so that the Ti-Al-Mo-Cr series beta titanium alloy is in an easily unstable state within a large temperature range, and the ultralow modulus and the ultrahigh work hardening rate performance of the Ti-Al-Mo-Cr series beta titanium alloy are guaranteed.

Owner:西安稀有金属材料研究院有限公司

High-strength and high-plasticity Mg-Al-Ce-(Nd) wrought magnesium alloy and preparation method thereof

The invention belongs to the field of nonferrous metal materials and machining thereof, and particularly relates to a high-strength and high-plasticity Mg-Al-Ce-(Nd) wrought magnesium alloy and a preparation method thereof. The high-strength and high-plasticity wrought magnesium alloy comprises the following components of, in percentage by mass, 0.1wt%-6.0 wt% of Al, 0.1wt%-3.0 wt% of Ce, 0wt%-3.0 wt% of Nd and the balance Mg and inevitable impurities, and the content of the impurities is less than or equal to 0.04 wt%. The high-strength and high-plasticity wrought magnesium alloy is prepared through a series of means such as melting, casting, homogenization treatment and backward extrusion. The wrought magnesium alloy with the submicron grain size is obtained by compositely adding Al, Ce and Nd elements and combining a backward extrusion process. In the extrusion process, high-density Mg17Al12, Al2Ce and Mg12Nd nano precipitated phases are dynamically precipitated and are partially dispersed and distributed on dislocation and grain boundaries (including small-angle grain boundaries), a remarkable precipitation strengthening effect is obtained, and the room-temperature mechanical property of the alloy is further improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Spinning deformation preparation method for particle reinforced aluminum-based composite pipe

ActiveCN106799421AIncrease temperatureGuaranteed not to crackMetal matrix compositeMaterials science

The invention discloses a spinning deformation preparation method for a particle reinforced aluminum-based composite pipe, and belongs to the technical field of metal-based composite processing. A spinning blank prepared by adopting a powder metallurgy method is subjected to the hot-spinning and cogging operation and the warm-spinning finished product preparing operation to obtain the composite pipe, wherein the deformation temperature of the hot-spinning and cogging operation is 290-450 DEG C, the number of the spinning passes is five, and on-line annealing treatment is carried out between every two spinning passes. According to the method, the deformation of the first two spinning passes is small, and the inner surface of the blank is prevented from cracking; and a wire annealing process is adopted between the spinning passes, and machining hardening is eliminated. The particle reinforced aluminum-based composite large-diameter and thin-wall pipe prepared through the spinning method can be widely applied to aerospace vehicles.

Owner:有研金属复材技术有限公司

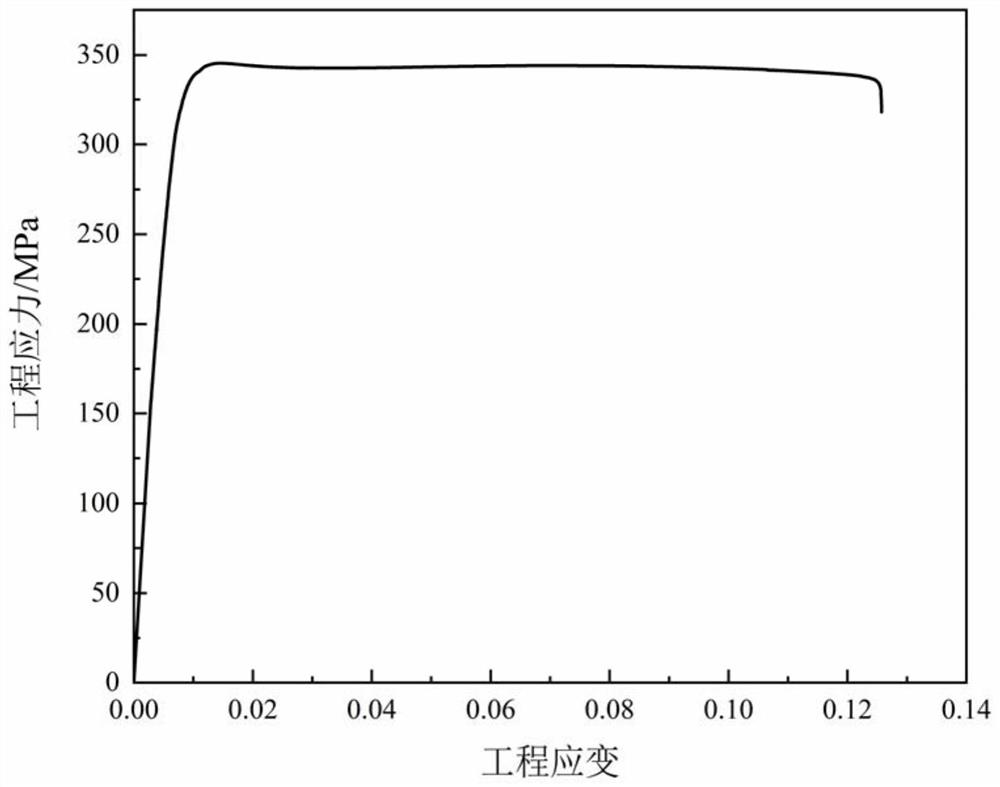

Hot-rolled dual-phase steel in 590MPa tensile strength grade and method for manufacturing hot-rolled dual-phase steel

The invention discloses hot-rolled dual-phase steel in the 590MPa tensile strength grade and a method for manufacturing the hot-rolled dual-phase steel. The steel comprises, by weight, from 0.04% to 0.10% of C, from 1.10% to 1.50% of Mn, from 0.10% to 0.20% of Si, from 0.015% to 0.070% of Als, from 0.03% to 0.08% of P, lower than or equal to 0.008% of S, from 0.5% to 1.2% of Cr, the balance Fe and inevitable impurities. The method for manufacturing the steel includes molten iron desulfurization, converter smelting, vacuum treatment, continuous casting, sizing, plate blank heating, hot continuous rolling, laminar cooling and reeling. As proved by practice, the steel is high in tensile strength, low in yield ratio and excellent in cold stamping forming performance and fatigue resistance, a technological process of the method is simple, and the production cost is low.

Owner:武汉钢铁有限公司

Particle reinforced titanium-aluminum composite based on spinning deformation and preparation method thereof

InactiveCN106583909AHigh strengthHigh strength and plasticityWelding/cutting auxillary devicesAuxillary welding devicesTitaniumTitanium alloy

The invention provides a particle reinforced titanium-aluminum composite based on spinning deformation and a preparation method thereof. The preparation method comprises the following steps that a cold-rolled titanium alloy TA18 plate and an aluminum alloy LY12 plate serve as initial blanks for explosive welding, the cold-rolled titanium alloy TA18 plate is mechanically polished, and the aluminum alloy LY12 plate is subjected to pickling and passivating treatment; and the treated TA18 plate and the treated LY12 plate are subjected to explosive welding, the TA18 plate is arranged below while the LY12 plate is arranged above, the surface of the LY12 plate is coated with heat-resisting grease serving as a protective layer, an ammonium nitrate explosive mixture is adopted for explosive welding, and then the TA18 plate and the LY12 plate are subjected to softening annealing, cold rolling machining, heat treatment strengthening and multi-roller leveling treatment to obtain a titanium-aluminum composite; and a titanium-aluminum composite plate serves as a spinning billet to be installed on a particle reinforcer core film, and the particle reinforced titanium-aluminum composite based on spinning deformation is obtained through a hot spinning blooming forging method. The titanium-aluminum composite prepared through the preparation method is high in strength, low in weight and excellent in comprehensive performance.

Owner:DONGGUAN JIAQIAN NEW MATERIAL TECH CO LTD

A high-strength and tough hot-rolled medium manganese steel with a strength-plasticity product greater than 60gpa% and its preparation method

ActiveCN109666862BHigh work hardening rateIncreased strength and plasticityUltimate tensile strengthToughness

The invention discloses high-toughness hot-rolled medium manganese steel with strength-ductility balance greater than 60 GPa.% and a preparation method, and belongs to the field of high-toughness automobile steel. The steel comprises the following chemical components of, in percentage by weight, 0.35-0.40% of C, 6.00 -6.30% of Mn, 2.20-2.35% of Al, 0-0.027% of Nb, 0.030 -0.074% of Si, 0.05% of P,0.02% of S, and the balance Fe and inevitable impurities. The preparation method comprises the steps of raw material preparation, smelting, casting, forging, hot rolling and two-phase region annealing. According to the high-toughness hot-rolled medium manganese steel, strength of extension is 1039-1183 MPa, after-fracture elongation rate is 43.5-64.8%, strength-ductility balance can reach more than 60 GPa.%, but not greater than 72GPa.%. Through reasonable component proportion and optimized two-phase region annealing process, morphology and proportion of a two-phase structure are controlled, TRIP and TWIP effects are effectively simulated to reach a high work hardening rate, the strength and the toughness of the medium manganese steel are greatly improved, and performance indexes of different components of an automobile are met.

Owner:UNIV OF SCI & TECH BEIJING

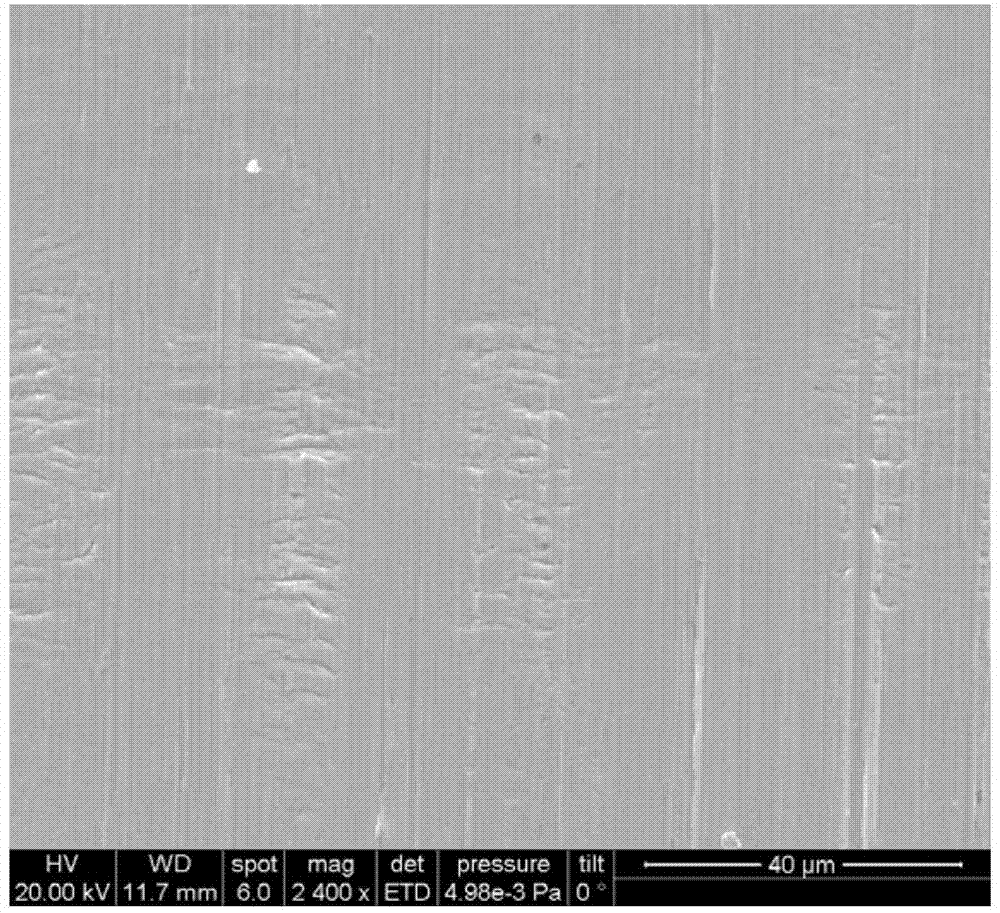

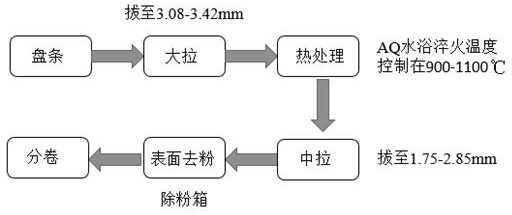

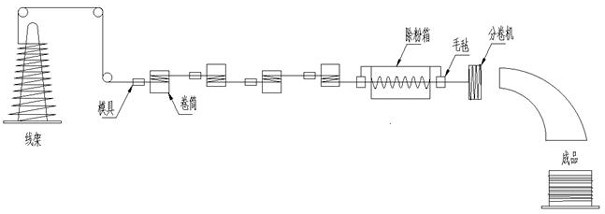

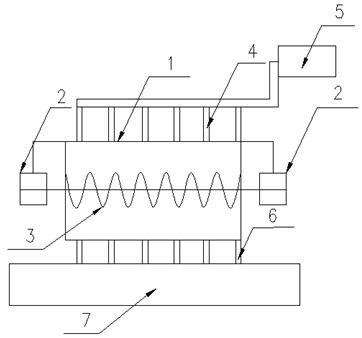

Method for efficiently preparing blind rivet steel

PendingCN112410516AExcellent spacingEliminate abnormal decarburizationFurnace typesProcess efficiency improvementWater bathsIndustrial engineering

The invention discloses a method for efficiently preparing blind rivet steel, and relates to the technical field of preparation of the blind rivet steel. The preparation method comprises the followingsteps of preparation of raw materials; primary drawing; heat treatment, wherein water bath quenching is adopted, the length of a quenching section is changed in the quenching process, staged heatingis adopted in the heat treatment process, steel wires form good oxide skin in the first two stages, and structural transformation is completed in the later four stages; secondary medium drawing, wherein the total drawing compression ratio is controlled within 70%, and the compression ratio of the last pass is controlled within 10%; powder removing, wherein residual soap powder of the drawn steel wires is removed through a powder removing box; and reeling. The method has the advantages that water bath quenching is adopted during heat treatment and is more environmentally friendly, staged heating is adopted during heat treatment, the quenching section length is changed, and the performance of the steel wires is well controlled; it is guaranteed that the surface quality of finished products reaches the standard, and the out-of-tolerance problem of the diameter is effectively reduced; and the content of residual soap powder on the surfaces of the steel wires is effectively reduced, and thepreparation efficiency is high.

Owner:江苏宝钢精密钢丝有限公司 +1

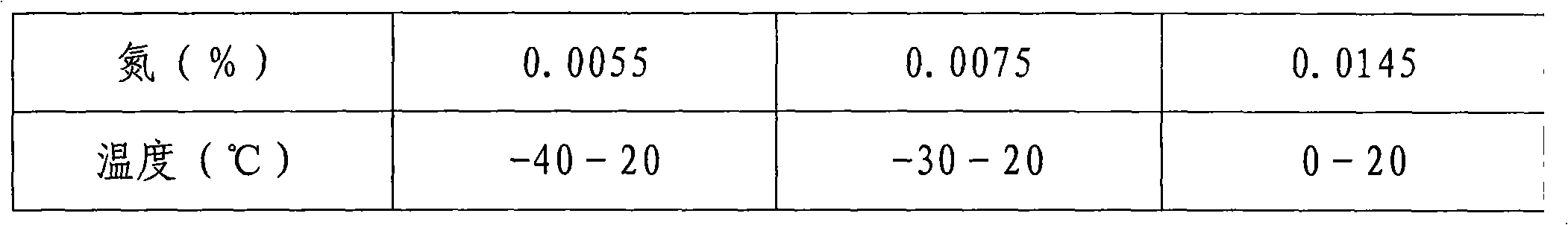

A kind of low-temperature resistant micro-alloyed steel and its production process

Owner:CENT IRON & STEEL RES INST +1

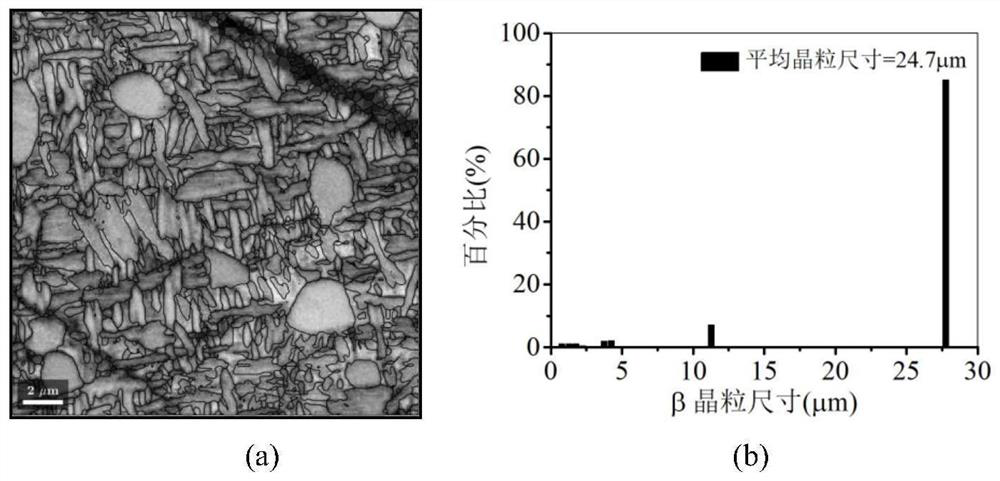

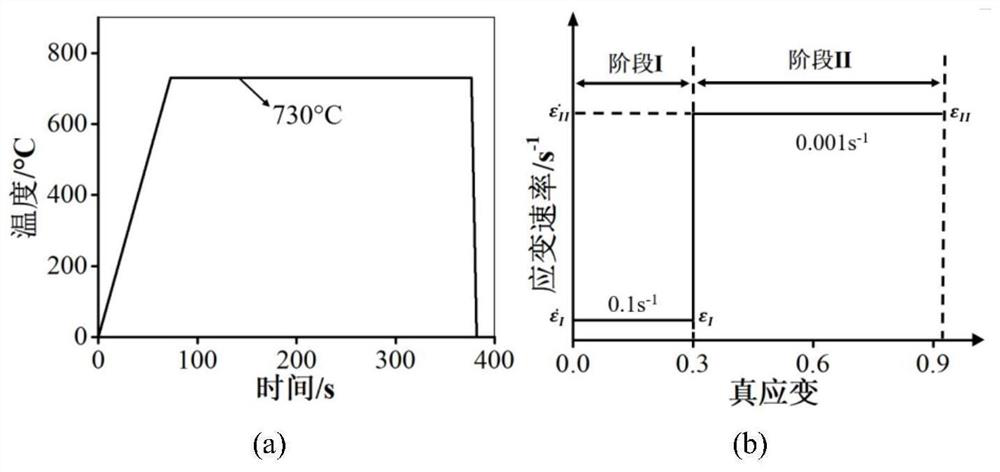

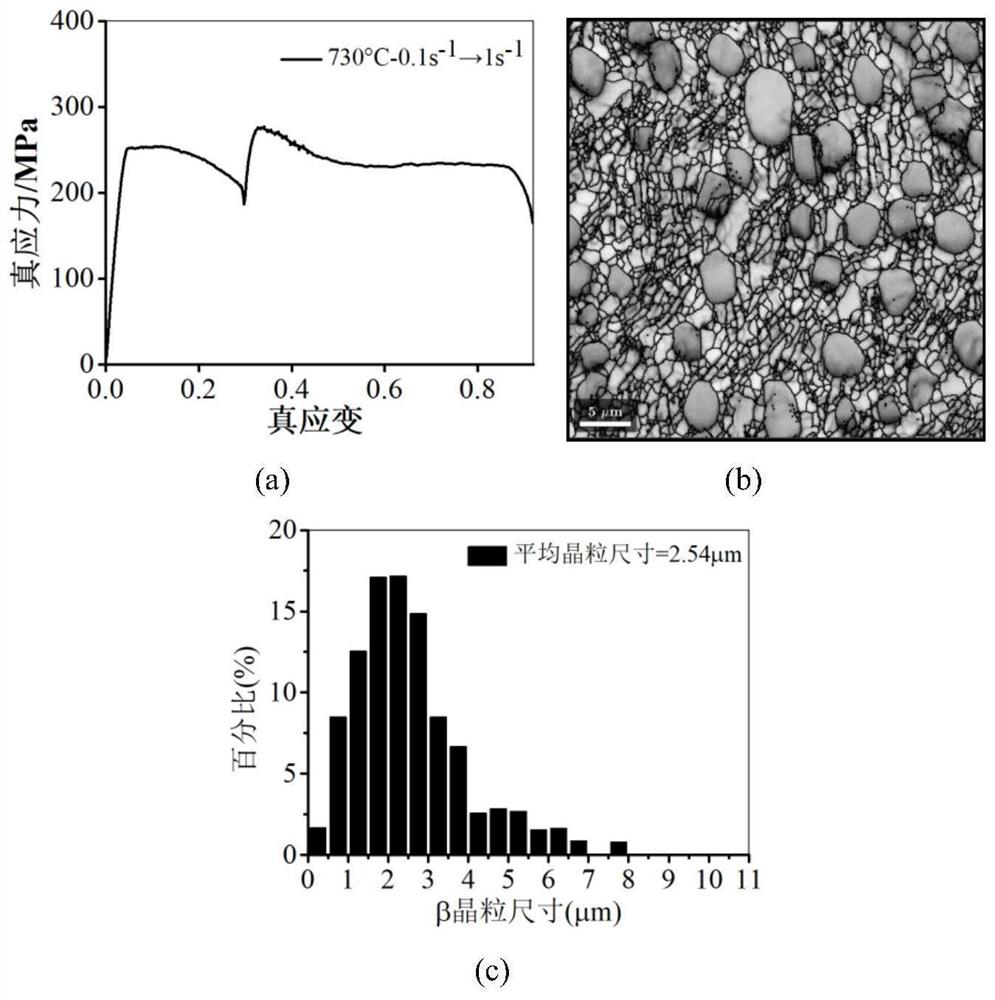

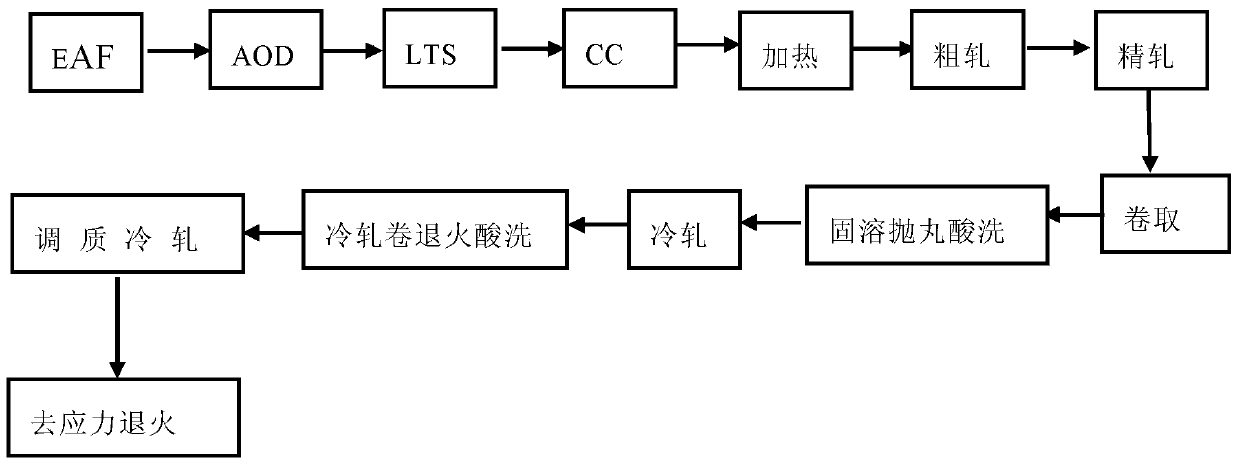

A method for refining β grains of tc18 titanium alloy by step strain rate forging process

The invention provides a method for refining β grains of TC18 titanium alloy by adopting step strain rate forging process. The method comprises the following steps: (1) heating the TC18 titanium alloy forging billet whose initial structure is a two-state structure to the forging temperature in the α+β dual-phase region, and keeping it warm until the temperature of the forging billet is uniform, and then performing two-stage step strain rate forging, The forging temperature is 700-820°C, the strain rate includes two stages, and the strain rate in the first stage is 0.1-0.5s ‑1 , the strain rate in the second stage is 1~5s ‑1 , the amount of deformation in the first stage is 20-40% of the height of the blank, the amount of deformation in the second stage is 30-50% of the height of the blank, the total deformation of the two stages is 50%-70%, and the strain after the deformation in the first stage is The rate changes immediately, without interval holding time; (2) After forging, immediately quench the forging. The invention can achieve the purpose of refining the beta grains of the TC18 titanium alloy with a relatively small amount of deformation.

Owner:CENT SOUTH UNIV

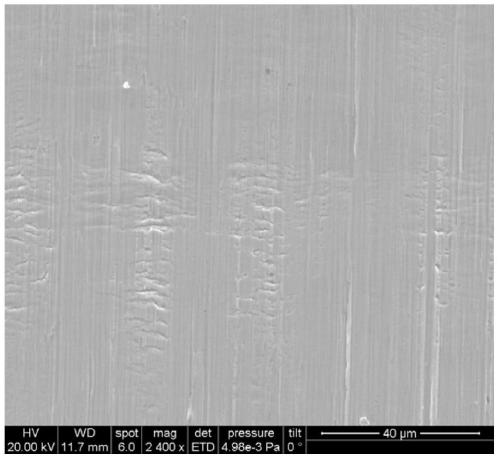

A kind of superhard austenitic stainless steel and its manufacturing method

The invention discloses a super-hard austenitic stainless steel and a preparation method thereof. The super-hard austenitic stainless steel comprises the following chemical components by weight percent: 0.08-0.13% of C, 0.3-1.0% of Si, less than 2.0% and greater than or equal to 0.5% of Mn, 16.5-17.5% of Cr, 6.5-7.5% of Ni, 0.03-0.08% of N, 0.5-0.8% of Mo, greater than or equal to 0.040% of P, greater than or equal to 0.01% of S, Fe and unavoidable impurities; the temperature of Md30 is 30-60 DEG C. By controlling the tempering and cold rolling reduction rate to 35-45%, controlling the rolling speed to less than or equal to 5m / s and the rolling temperature to less than or equal to 30 DEG C, the transformation from the austenite to the deformation martensite is created and the hardness of the material is greatly increased under the same deformation; when the tempering and cold-rolling reduction rate is 35%, the hardness HV is greater than 550 and the anisotropy of the super-hard state steel is reduced.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

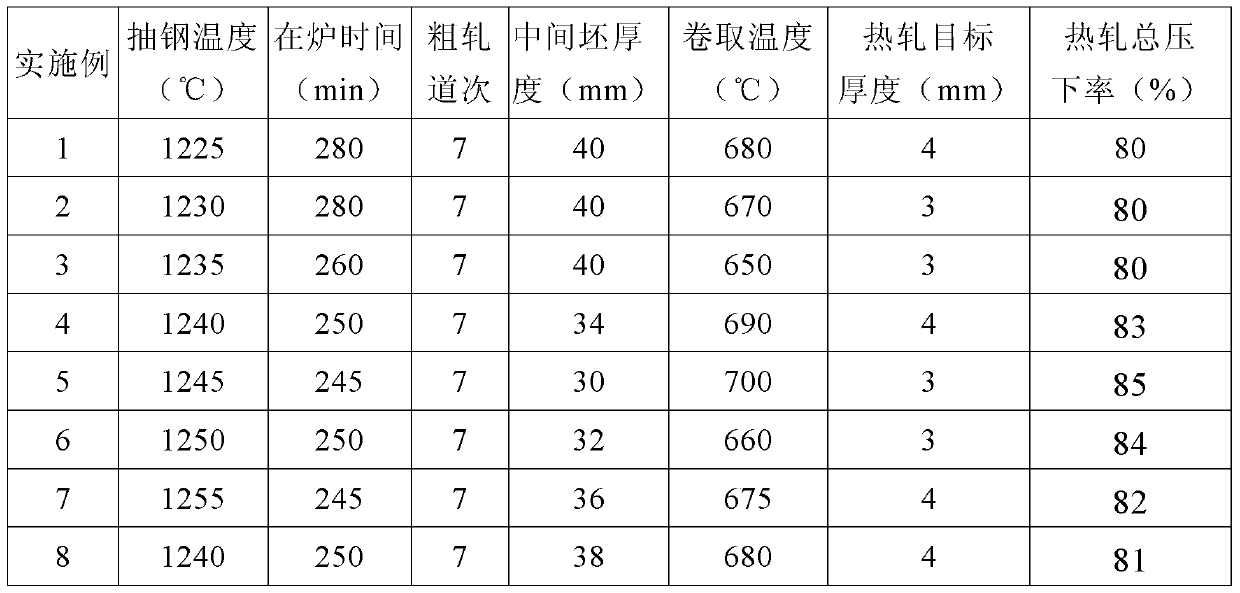

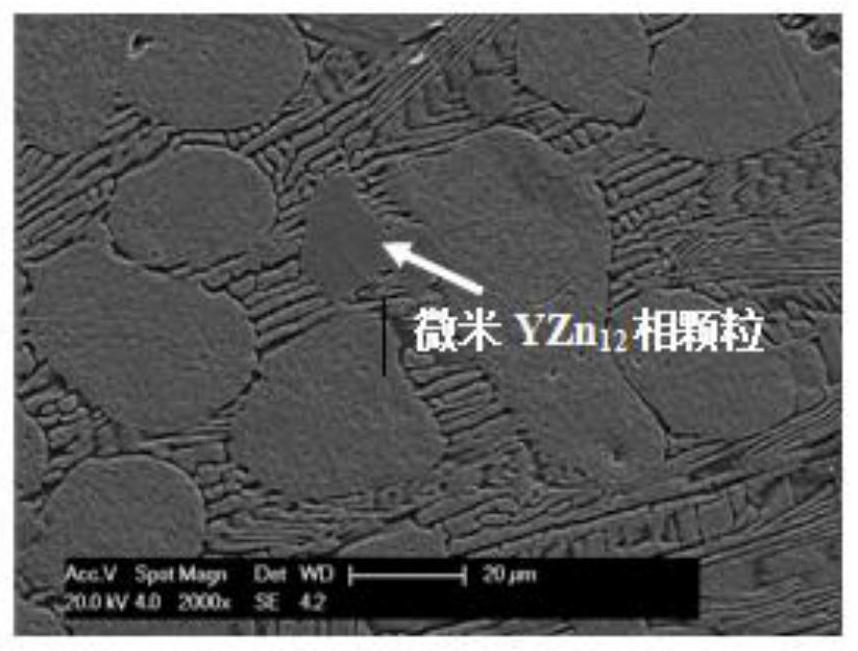

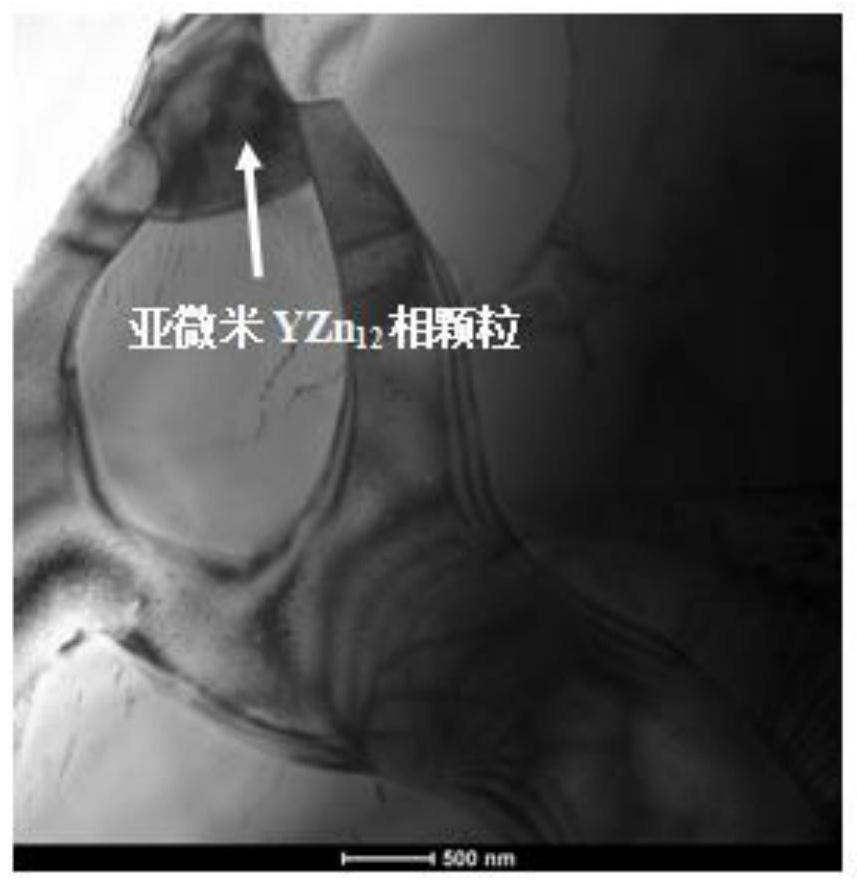

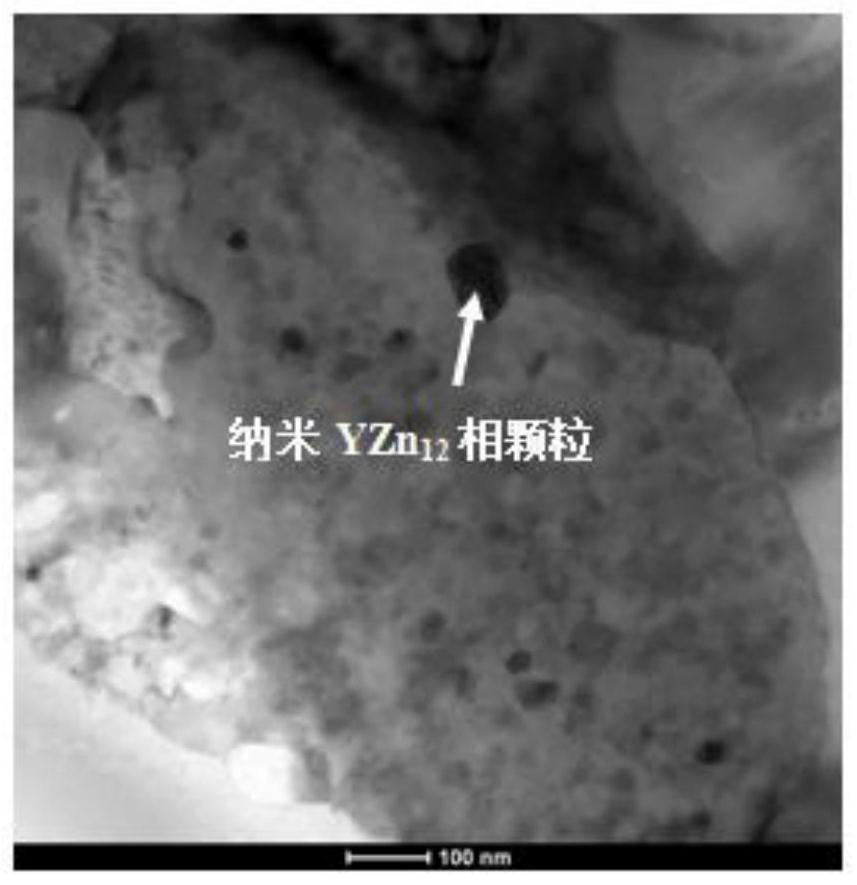

A high strength and toughness degradable zinc alloy with high work hardening rate and its preparation method and application

ActiveCN113186427BHigh work hardening rateHigh uniform elongationSurgeryMicron scaleMetallic materials

The invention discloses a high-strength, tough and degradable zinc alloy with high work hardening rate, including a Zn matrix, Zn+Mg refined and dispersed in the Zn matrix 2 Zn 11 Eutectic structure, micron-sized YZn is also dispersed in the Zn matrix 12 , Zn+Mg 2 Zn 11 Submicron YZn is dispersed in the eutectic structure 12 and nanoscale YZn 12 , submicron YZn 12 and nanoscale YZn 12 The area ratio is not greater than 85:15. The invention also discloses a preparation method of a high-strength and tough degradable zinc alloy with high work hardening rate and its application in biomedical degradable metal materials. The zinc alloy of the invention has both high strength and high toughness, its tensile strength is 340-530MPa, and its elongation is 10-32%, which can meet the requirements of different medical devices on the mechanical properties of the zinc alloy.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com