450MPa-grade hot-dip galvanized dual-phase steel with high work hardening rate and surface quality and production method of 450MPa-grade hot-dip galvanized dual-phase steel

A production method and 450mpa technology, applied in hot dip plating process, metal material coating process, coating and other directions, can solve the problem of low work hardening rate of 450Mpa hot-dip galvanized dual-phase steel, and improve the initial work hardening rate , the effect of reducing yield strength and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

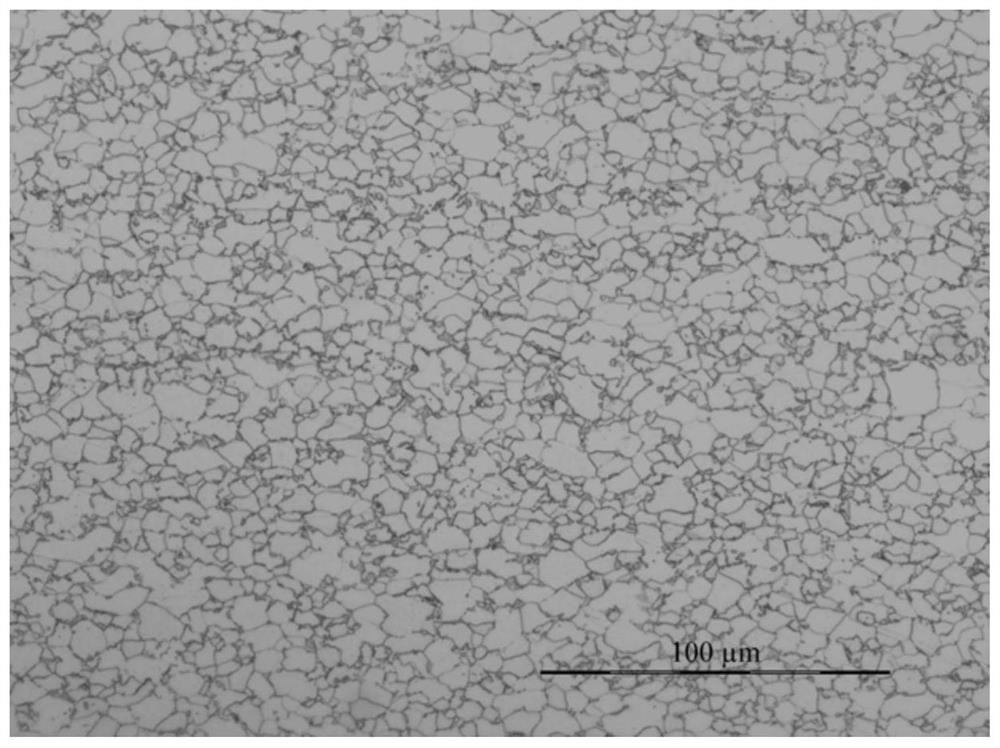

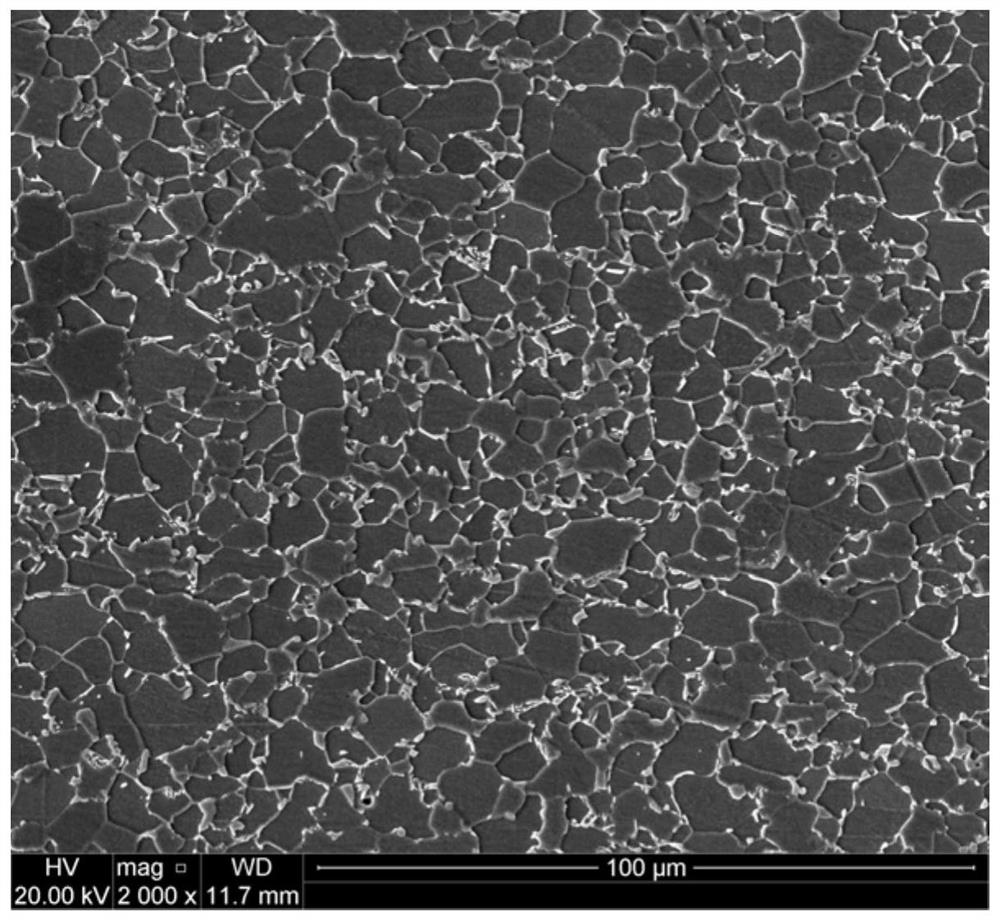

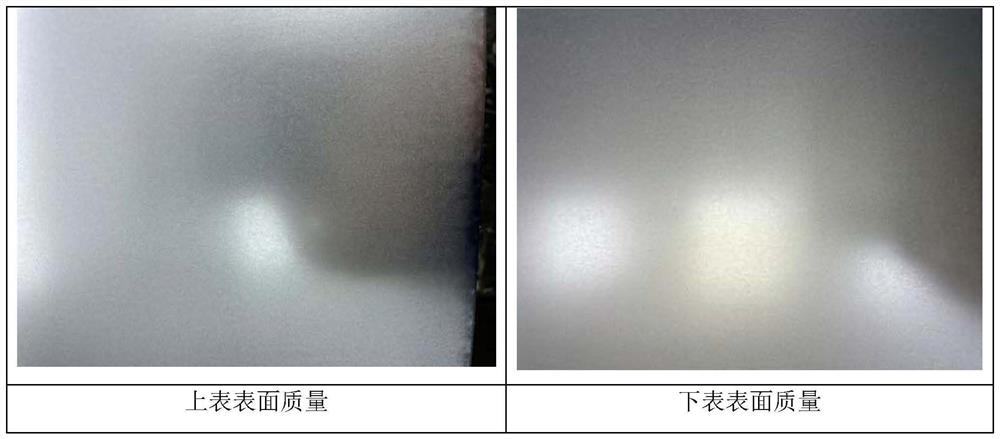

Examples

Embodiment 1

[0050] Technical scheme implementation steps of the present invention are as follows:

[0051] (1) Smelting and pouring into slabs according to the process route of molten iron pretreatment→converter smelting→alloy fine-tuning→LF furnace refining→continuous casting;

[0052] (2) The slab is heated to 1210-1250°C, after dephosphorization and 6 passes of rough rolling, and 7 passes of finish rolling, the start temperature of finish rolling is 1000-1080°C, and the outlet temperature is 860-900°C, Laminar cooling to 520-560°C to obtain a hot-rolled sheet, which is then coiled and naturally cooled in the air;

[0053] (3) Cold rolling after normal pickling, the cold rolling reduction rate is 55% to 80%;

[0054] (4) Carry out continuous annealing + hot-dip galvanizing, heat the steel coil to 770-790°C, dew point in the furnace ≤ -40°C, oxygen content ≤ 5ppm, slow cooling after heat preservation, and cool at a cooling rate of 3-6°C / s to 640-660°C, and then cooled to 470-490°C at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com