Low-cost, high-toughness and excellent-weldability 800 MPa-grade quenched and tempered steel plate and manufacturing method thereof

A technology of quenched and tempered steel plate and manufacturing method, which is applied in the field of high-strength steel plate, and can solve the problems of narrow range of welding heat input, increased manufacturing cost, high manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

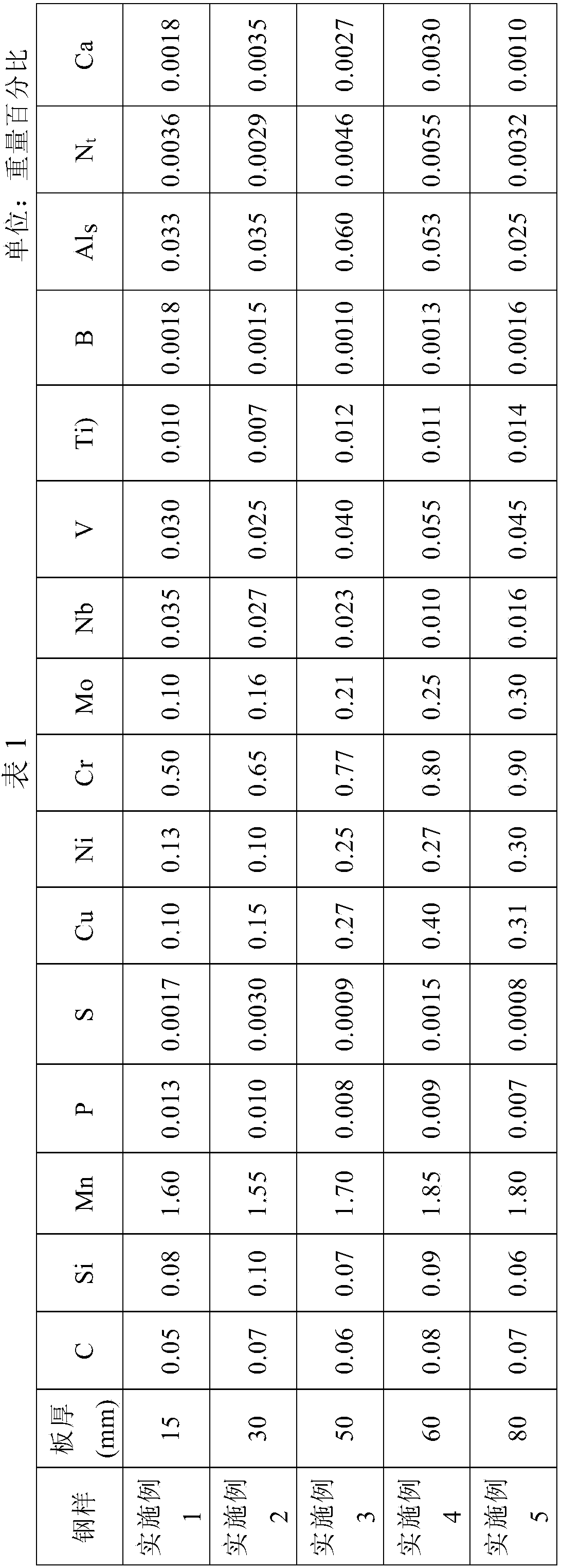

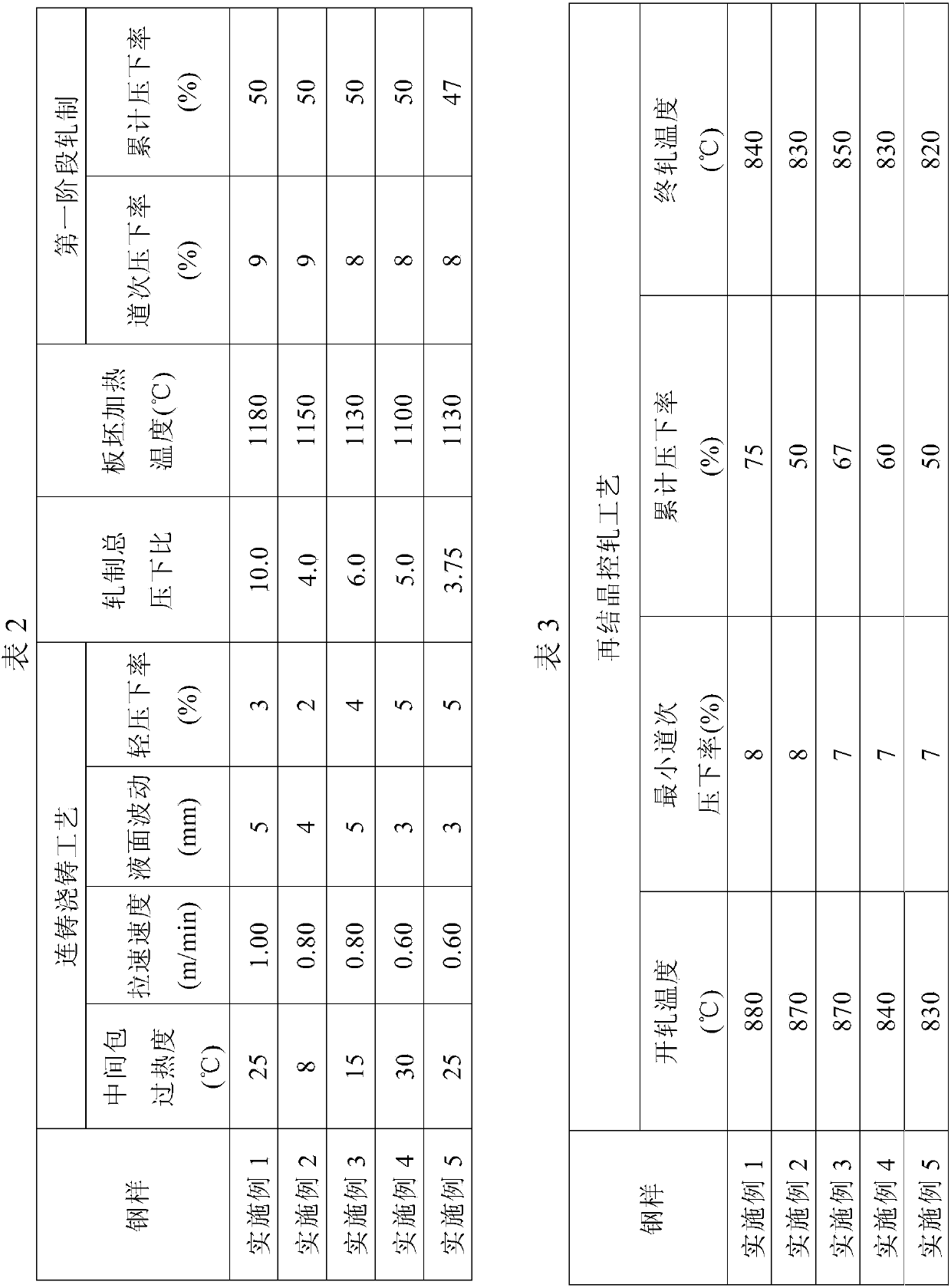

[0077] Refer to Table 1 for the steel composition of the embodiment of the present invention, Table 2 to Table 5 are the process parameters of the embodiment of the present invention, and Table 6 is the performance parameter of the steel of the embodiment of the present invention.

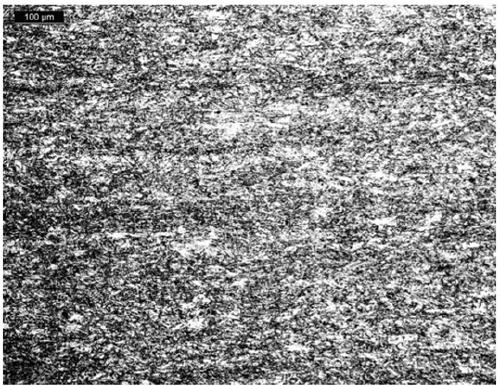

[0078] Depend on figure 1 It can be seen that, through the combination of composition optimization design, TMCP and subsequent tempering process in the present invention, the microstructure of the steel plate is uniform and fine lower bainite + lath martensite, and the average grain size is below 20 μm.

[0079] The present invention combines the combined design of steel plate alloy elements with controlled rolling CR+on-line quenching DQ+off-line tempering T process, while obtaining an excellent 800MPa high-strength quenched and tempered steel plate, the strength, toughness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com