Patents

Literature

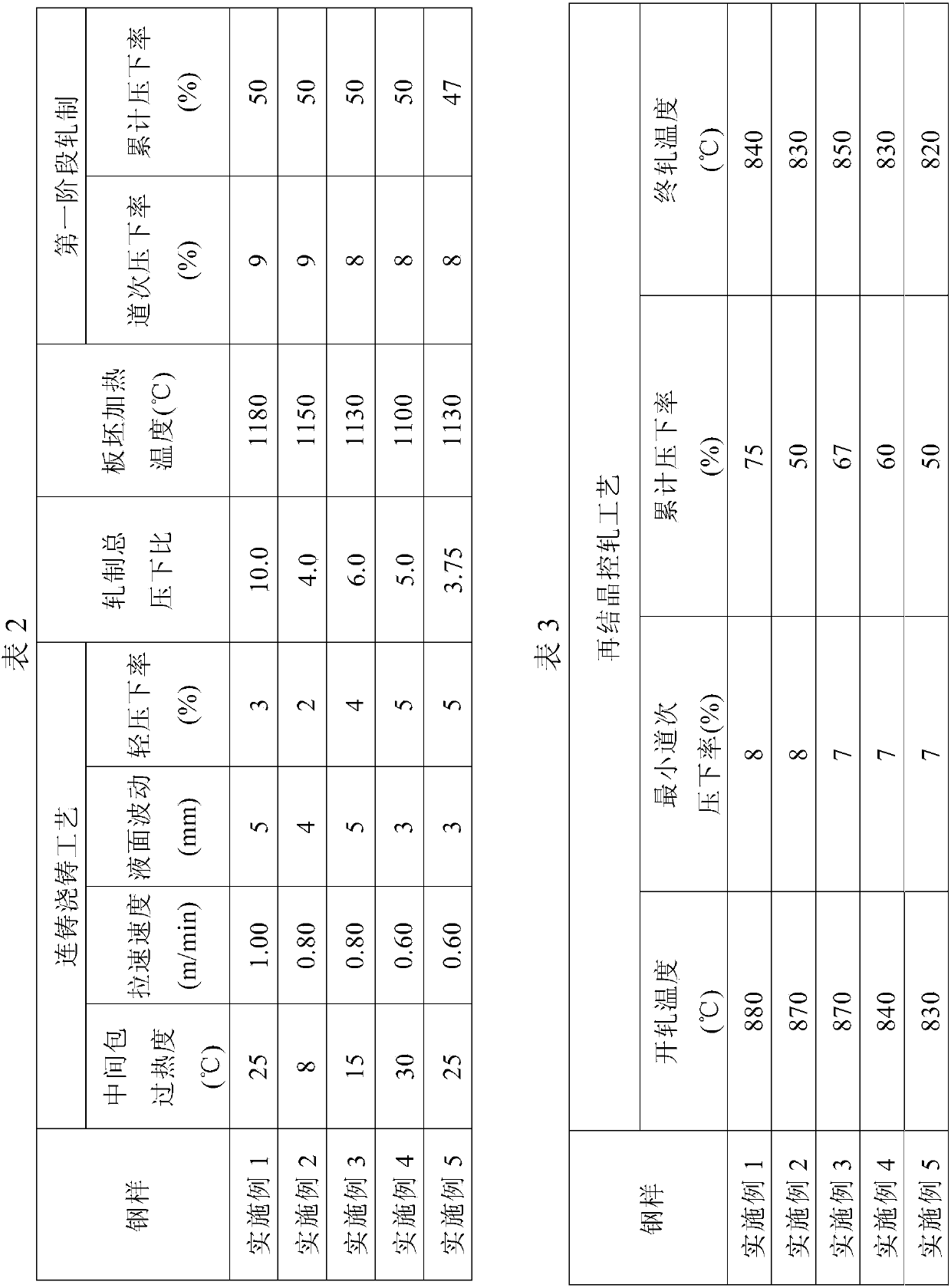

93results about How to "Reduce hardenability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High toughness steel material and method of producing steel pipes using same

InactiveUS6958099B2Improve toughnessReduce hardenabilityFurnace typesHeat treatment furnacesProduction rateAustenite grain

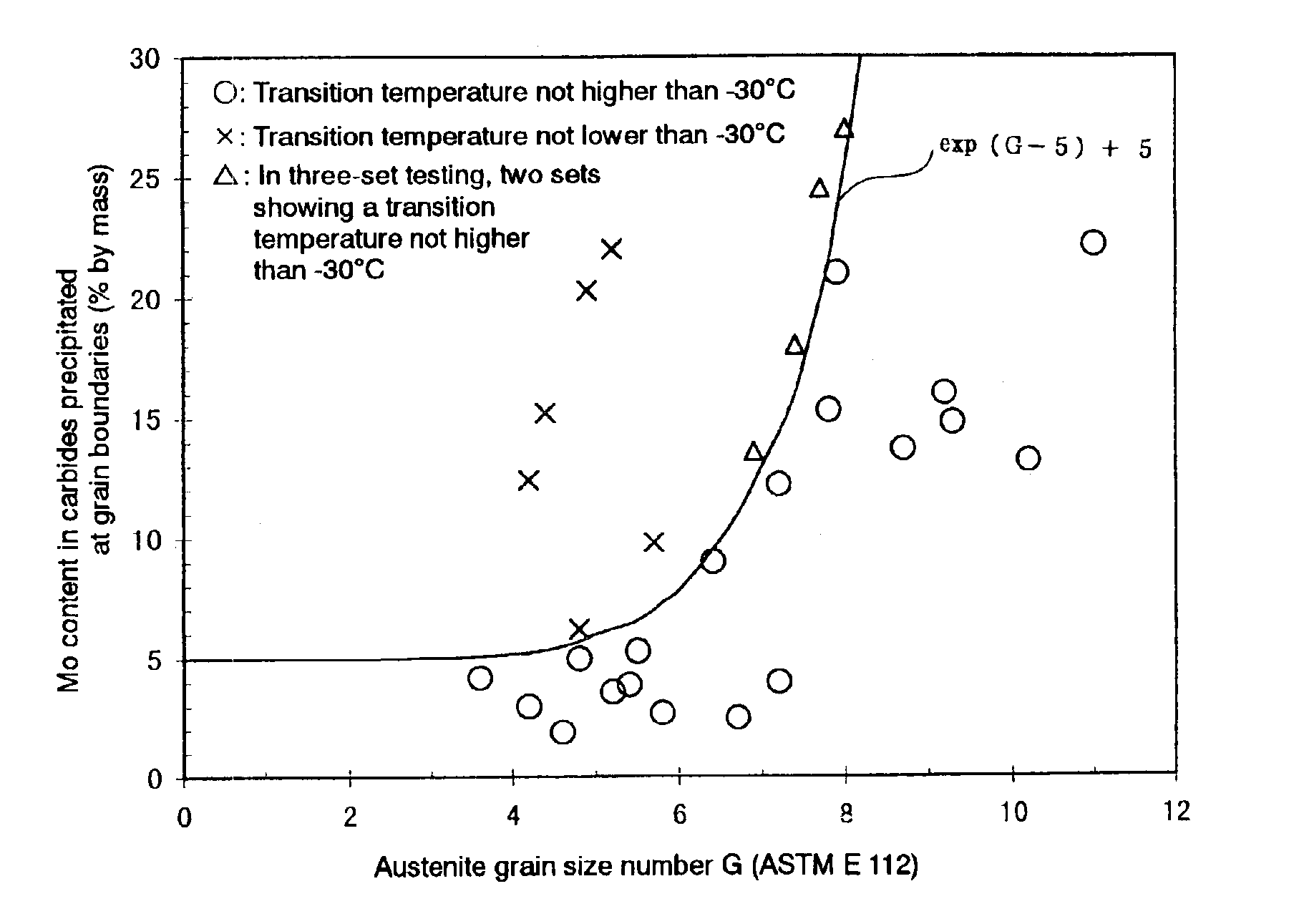

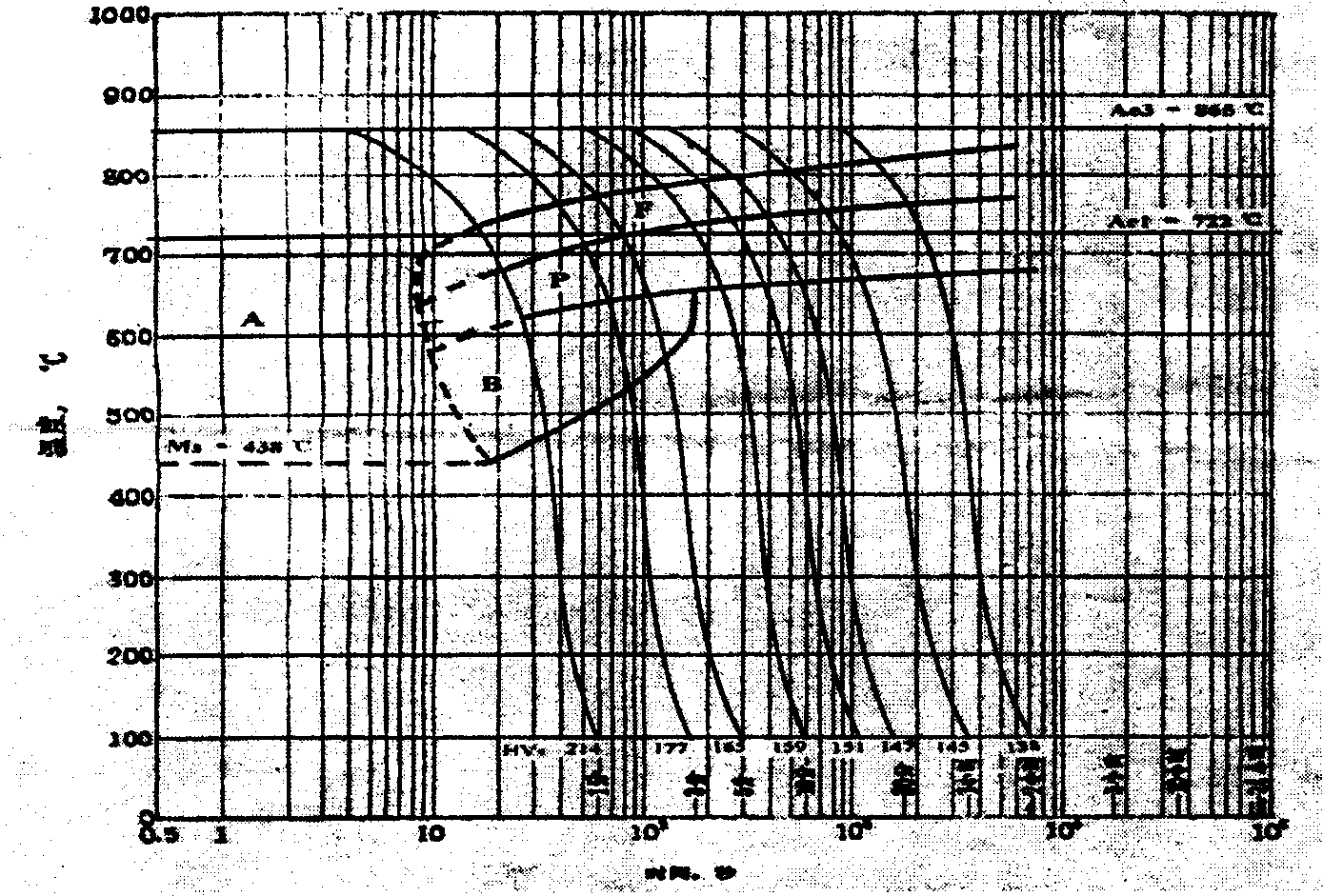

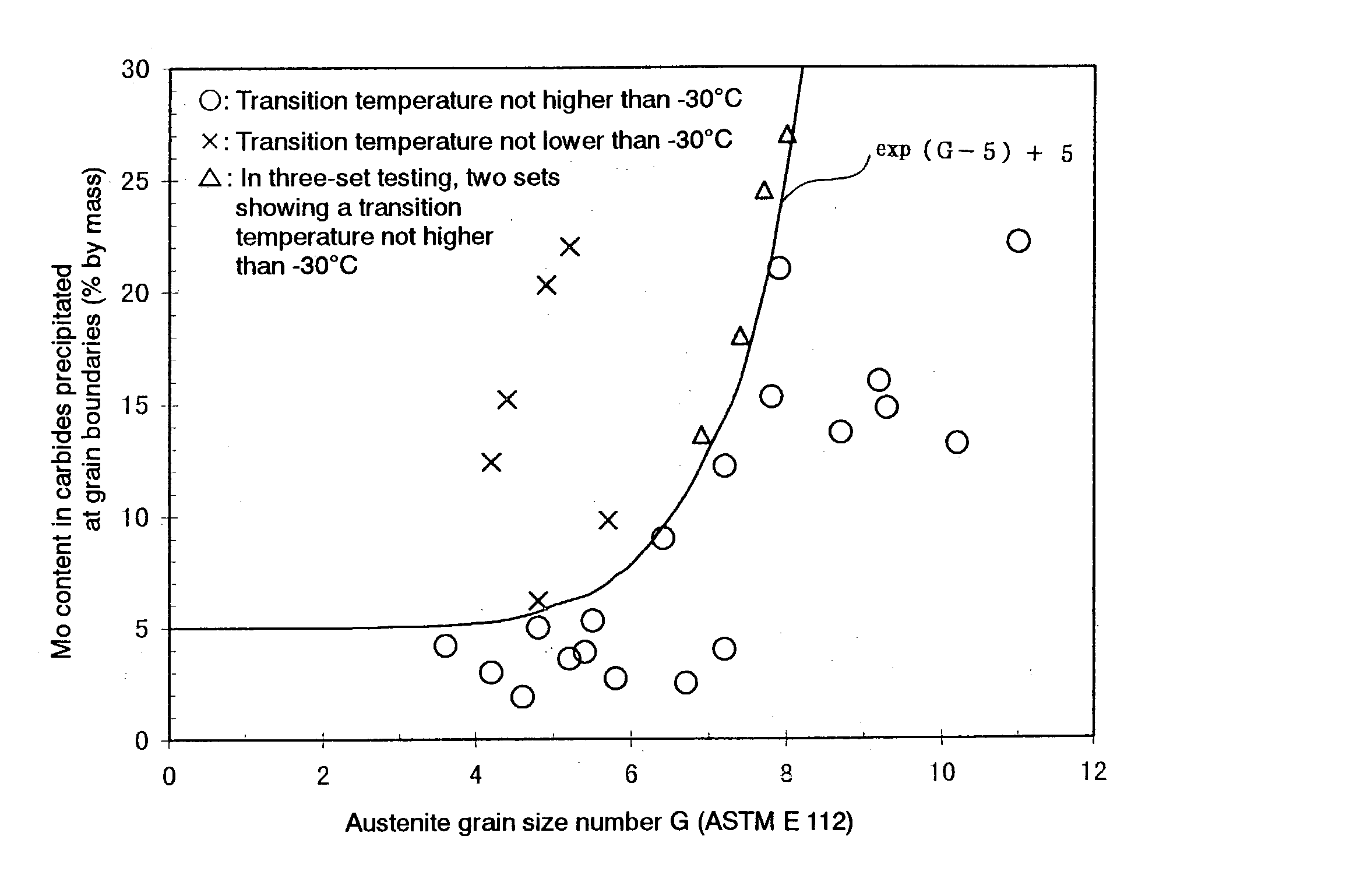

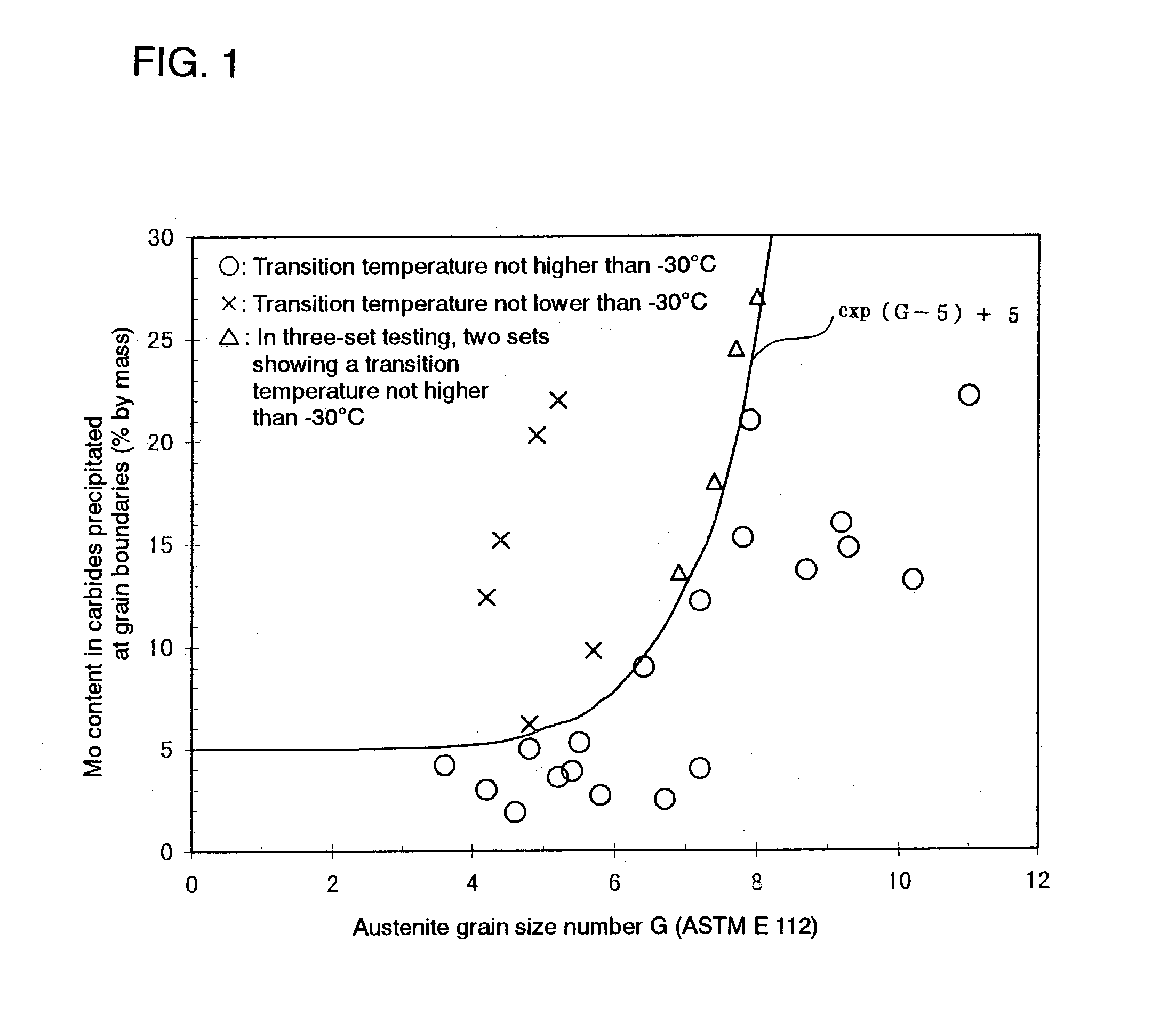

A steel material and a steel pipe made by using the same are provided which are to be used in severe oil well environments. Such a highly tough oil well steel pipe can be produced by rolling the base material, quenching the rolling product from the austenite region and tempering the same so that the relationship between the content of Mo [Mo] in the carbides precipitated at austenite grain boundaries and the austenite grain size (according to ASTM E 112) can be defined by the formula (a) given below. In this manner, steel pipes suited for use even under oil well environments becoming more and more severe can be produced while satisfying the requirements that the cost should be rationalized, the productivity improved and energy saved.[Mo]≦exp(G−5)+5 (a)

Owner:NIPPON STEEL CORP

Seamless steel tube which is intended to be used as a guide pipe and production method thereof

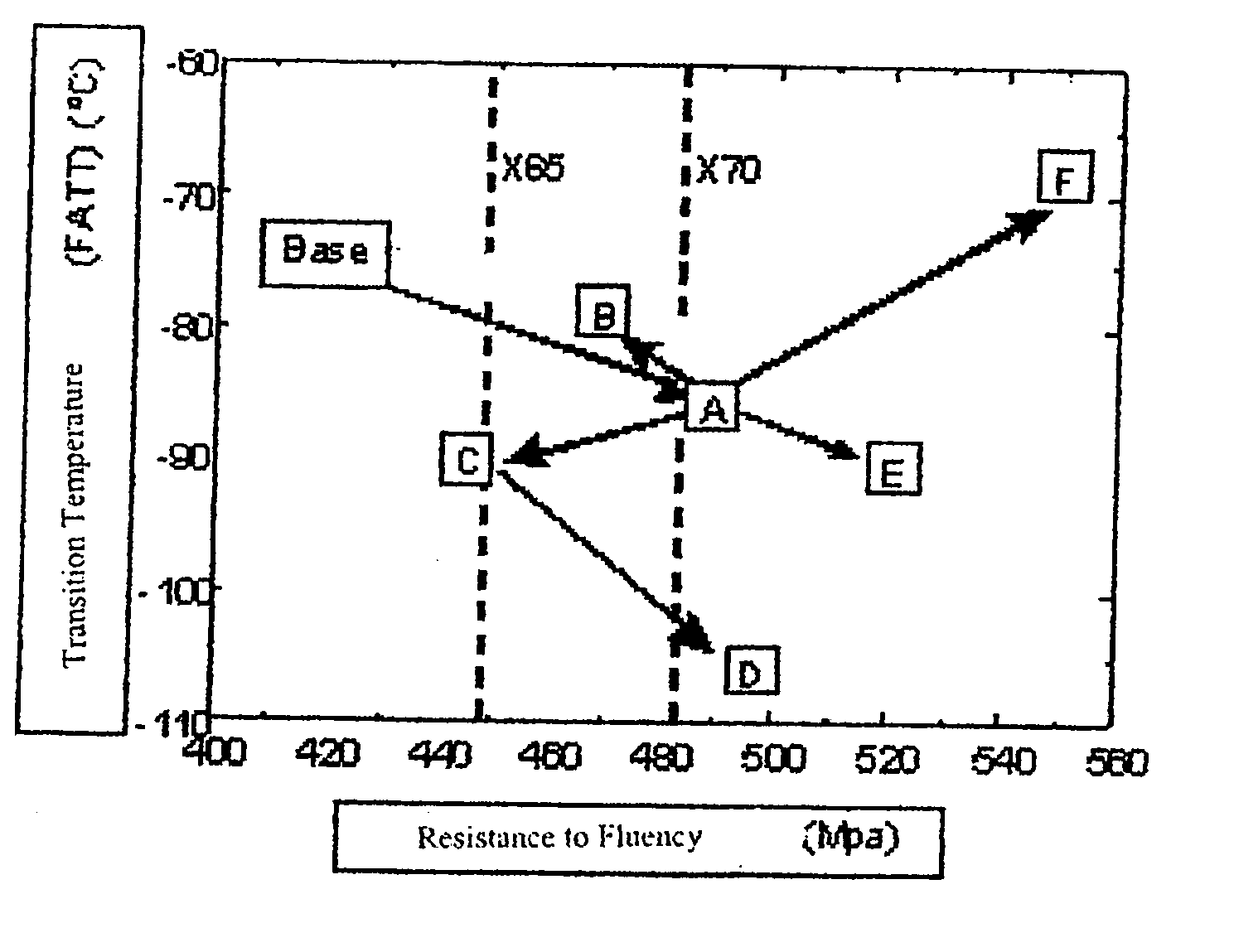

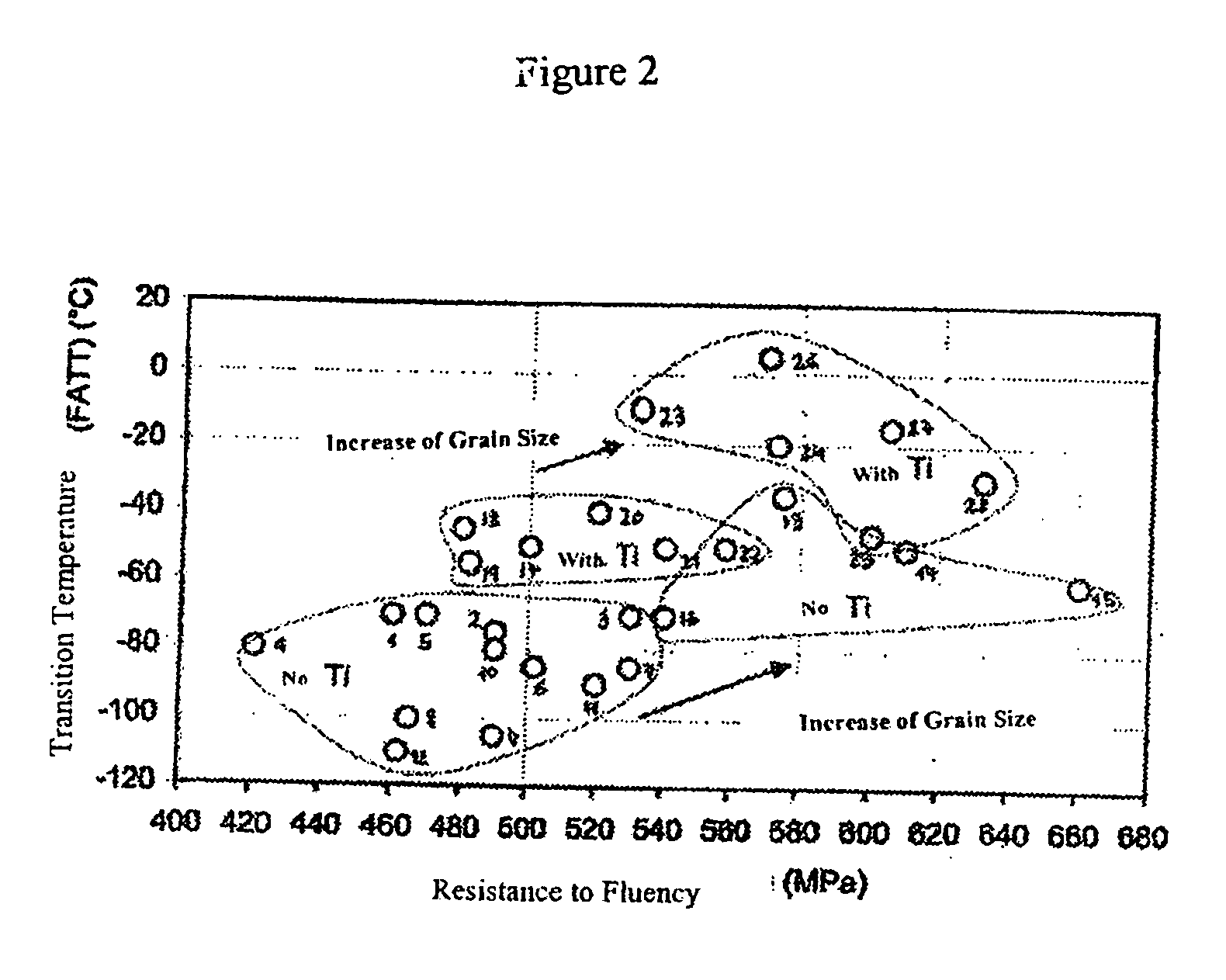

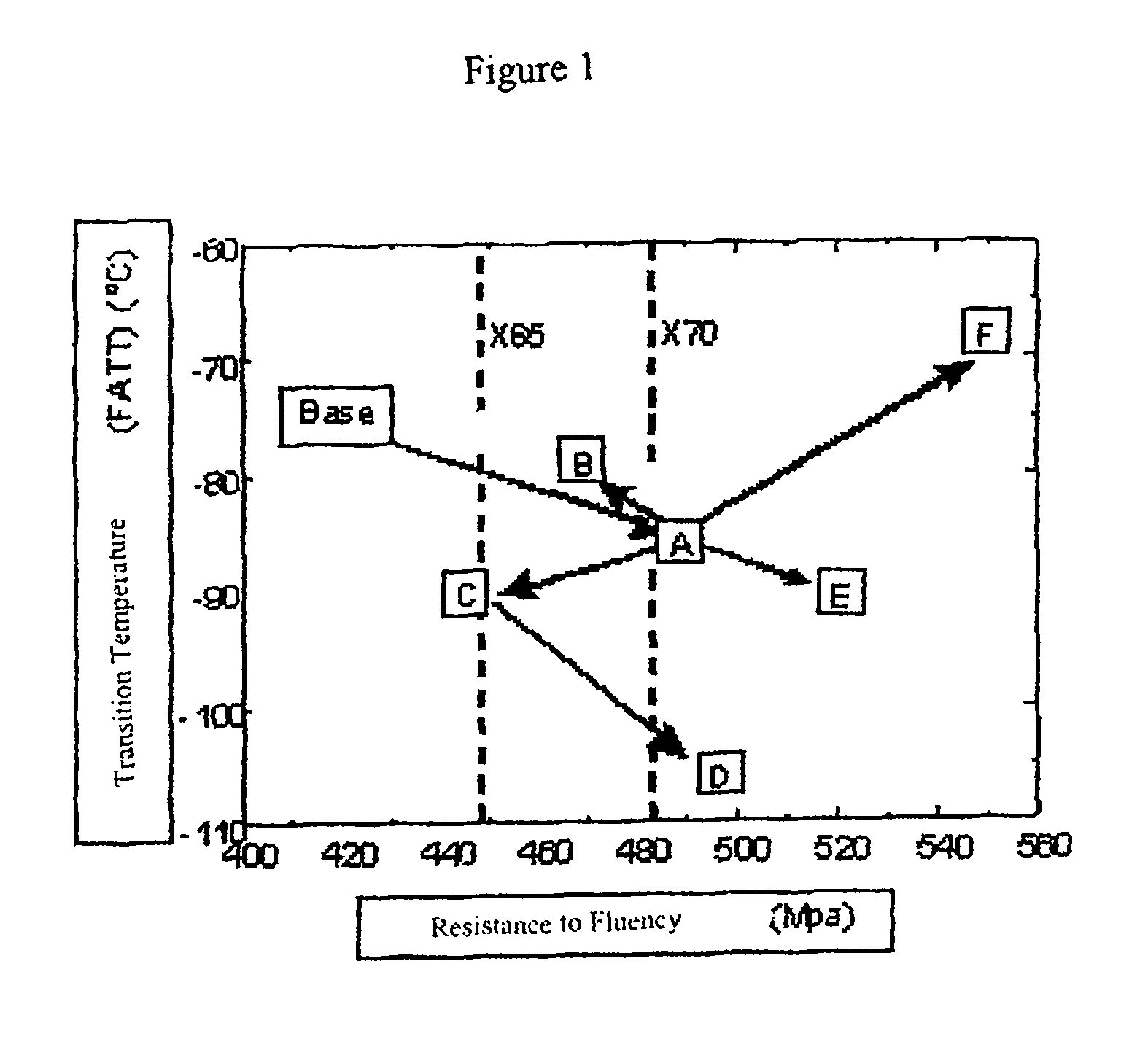

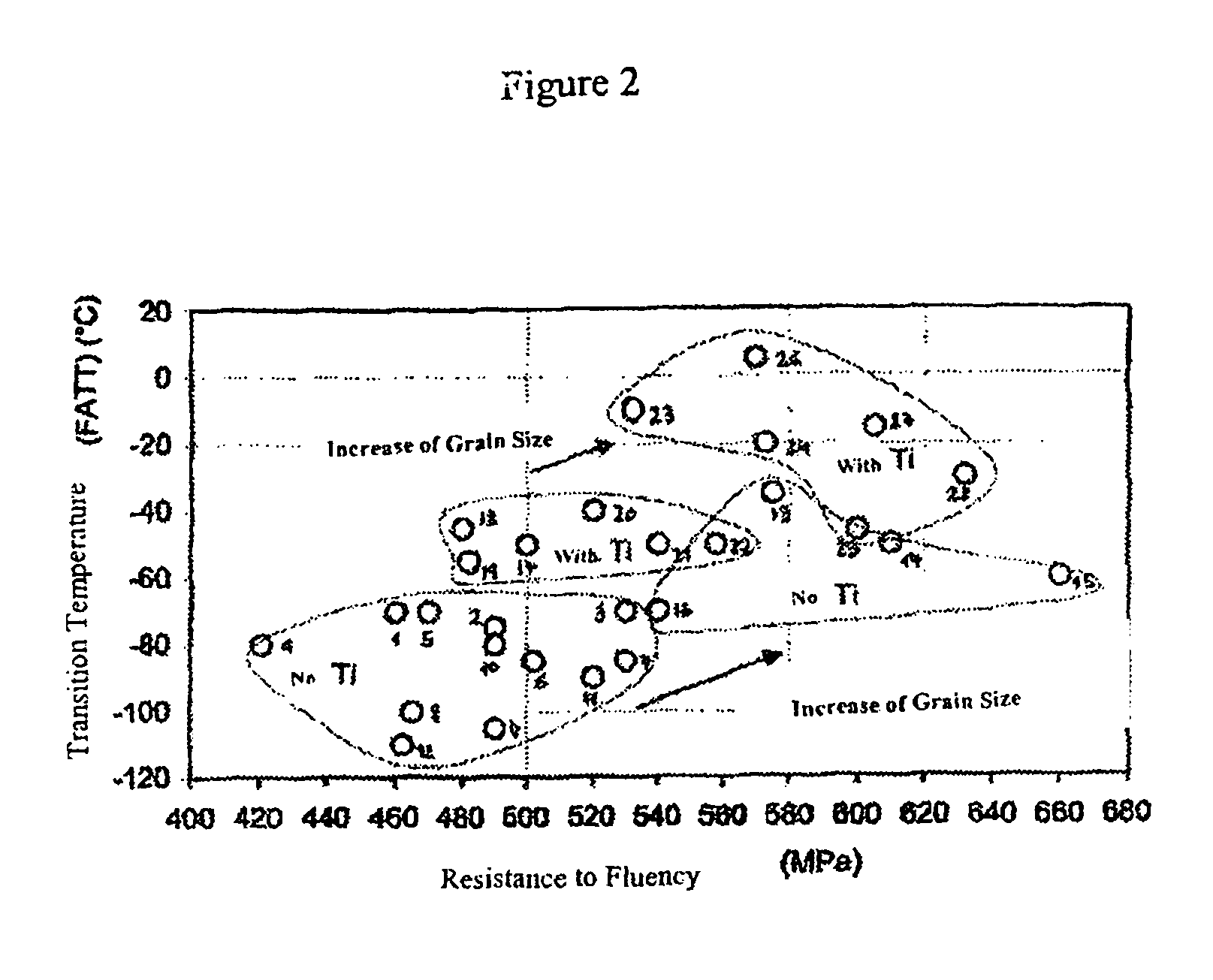

ActiveUS20070089813A1High mechanical resistanceHardenability is lowFurnace typesHeat treatment furnacesSteel tubeCorrosion

The present invention pertains to steel with high mechanical resistance at room temperature and up to 130° C., good toughness and good corrosion resistance in the metal base as well as good resistance to cracking in the heat affected zones (HAZ) once the tubing is welded together, and more specifically to heavy gauge seamless steel tubing with high mechanical resistance, good toughness and good corrosion resistance called catenary conduit. The advantages of the present invention with respect to those of the state of technology reside in providing a chemical composition for steel used to manufacture heavy gauge seamless steel tubing with high mechanical resistance, good toughness, good fissure resistance in the HAZ and good corrosion resistance and a process for manufacturing this product. These advantages are obtained by using a composition made up basically of Fe and a specific chemical composition.

Owner:TUBOS DE ACERO DE MEXICO +1

Low-carbon low-alloy steel and pipe

The present invention relates to one kind of low-carbon and low-alloy steel and produced pipe and aims at raising strength, toughness, hardness penetration and welding performance of alloy steel. The low-carbon and low-alloy steel of the present invention includes the following elements: C, Si, Mn, Al, V, Ni, B, P, S, Mo, co and Nb except Fe and impurity. The low-carbon and low-alloy steel may be used in producing conduit line pipe and other pipe of steel grade X60-X80.

Owner:BAOSHAN IRON & STEEL CO LTD

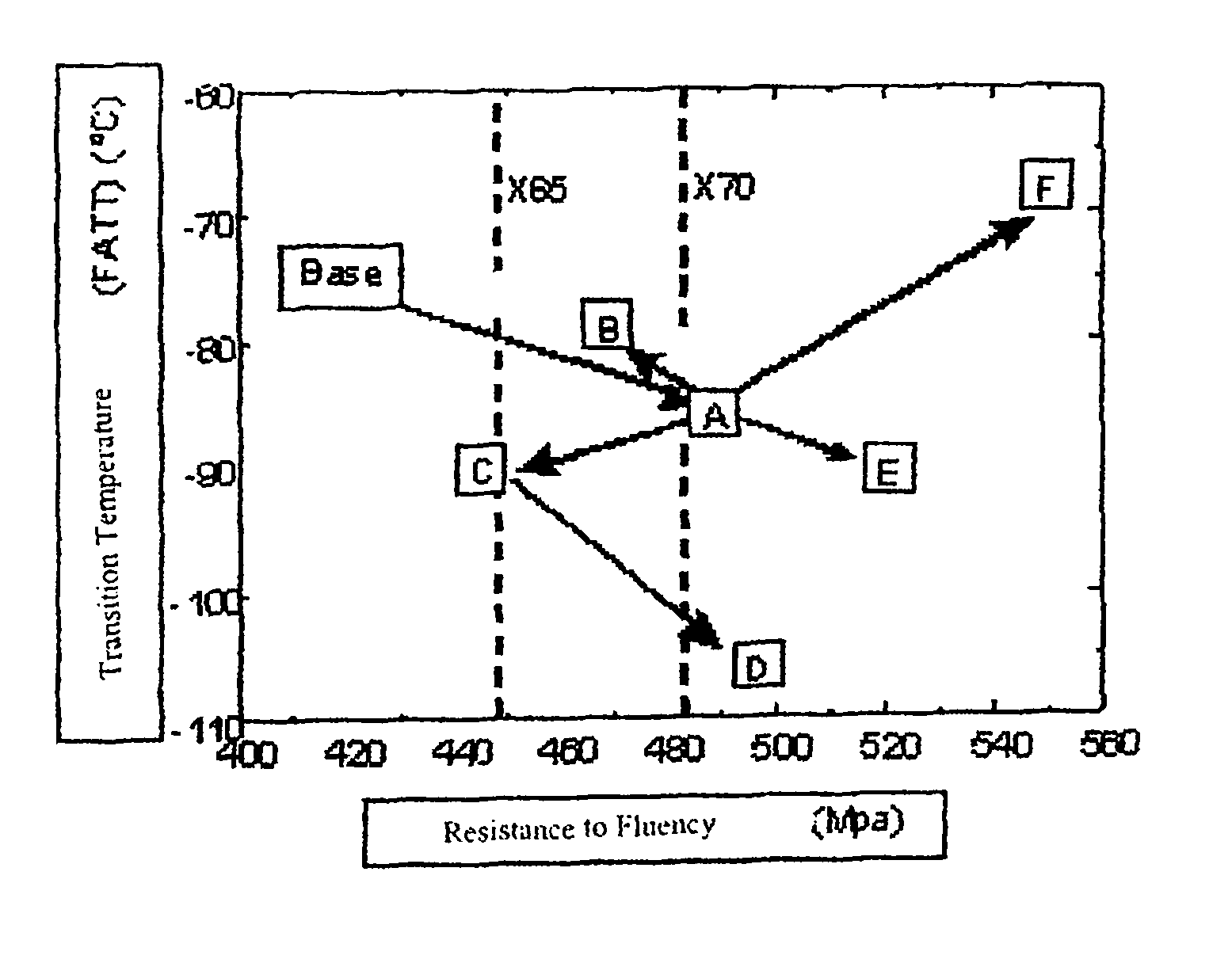

High crack-arresting toughness steel plate with yield strength of 500MPa and production method thereof

ActiveCN102994874APromote productionIncrease the lengthHeat treatment process controlReduction rateChemical composition

The invention provides a high crack-arresting toughness steel plate with yield strength of 500MPa and a production method thereof. The chemical components of steel comprises the following components in percentage by weight: 0.04-0.08% of C, 0.10-0.5% of Si, 0.8-1.6% of Mn, not more than 0.02% of P, not more than 0.01% of S, 0.03-0.065% of Al, not more than 0.005% of N, 0.005-0.05% of Nb, 0.005-0.03% of Ti, 0.0005-0.003% of B, not more than 0.004% of Ca, and the balance of Fe and avoidless impurities. The preparation method comprises the steps of roughing in an austenite re-crystalline region in a first stage, wherein the rolling temperature is 1000-1130 DEG C, the total reduction rate in the re-crystalline region is greater than or equal to 50%; cooling a rolled steel plate quickly to 580-530 DEG C at a rate of 10 DEG C / s; rolling in a non-re-crystalline region in a second stage when the temperature of the surface of the steel plate is 720-770 DEG C, wherein the accumulated deformation is greater than or equal to 50%, the finish rolling temperature is 700-740 DEG C; and water-cooling after rolling, wherein the cooling rate is 5-15 DEG C / s, and the final cooling temperature is 460-560 DEG C. The high crack-arresting toughness steel plate provided by the invention has the characteristics of high strength, high toughness, inhibition of crack formation and expansion and the like, and meets the performance requirements of special part members of large container ships.

Owner:ANGANG STEEL CO LTD

Seamless steel tube which is intended to be used as a guide pipe and production method thereof

ActiveUS8002910B2Good mechanical resistanceImprove toughnessFurnace typesHeat treatment furnacesHeat-affected zoneCrack resistance

The present invention pertains to steel with high mechanical resistance at room temperature and up to 130° C., good toughness and good corrosion resistance in the metal base as well as good resistance to cracking in the heat affected zones (HAZ) once the tubing is welded together, and more specifically to heavy gauge seamless steel tubing with high mechanical resistance, good toughness and good corrosion resistance called catenary conduit. The advantages of the present invention with respect to those of an the state of technology reside in providing a chemical composition for steel used to manufacture heavy gauge seamless steel tubing with high mechanical resistance, good toughness, good fissure resistance in the HAZ and good corrosion resistance and a process for manufacturing this product. These advantages are obtained by using a composition made up basically of Fe and a specific chemical composition.

Owner:TUBOS DE ACERO DE MEXICO +1

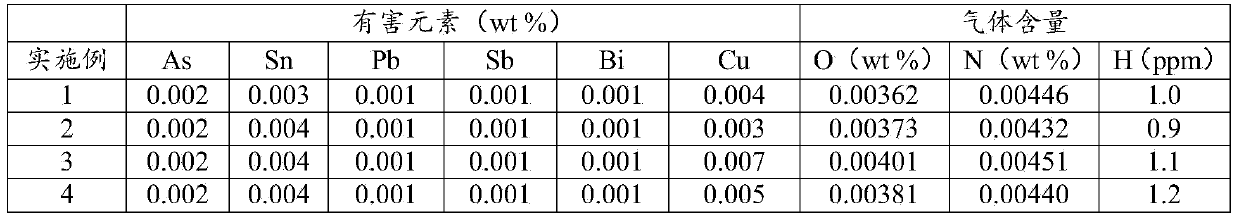

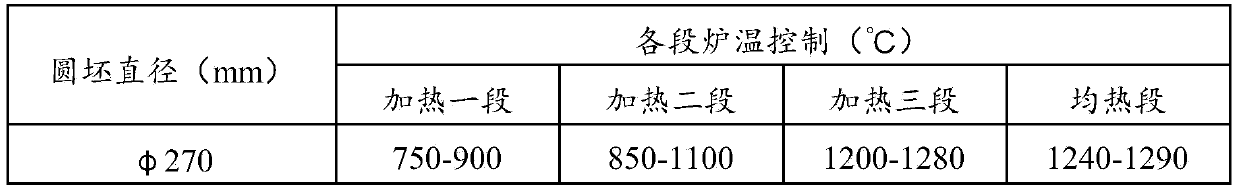

Aluminum alloy for 480 MPa-class aluminum alloy oil pipe and pipe manufacturing method thereof

The invention discloses an aluminum alloy for a 480 MPa-class aluminum alloy oil pipe. The aluminum alloy comprises the following components by weight percent: 5.10-6.90% of Zn, 1.10-1.80% of Mg, 0.05-0.20% of Cu, 0.10-0.30% of Mn, 0.10-0.30% of Cr, 0.01-0.02% of Ti, 0.15-0.2% of Zr and the balance of Al and unavoidable impurities, wherein in the unavoidable impurities, the content of the Si is not greater than 0.15 of the total weight of the aluminum alloy and the content of Fe is not greater than 0.15 of the total weight of the aluminum alloy. The manufacture method of the aluminum alloy pipe comprises the following steps: (1) smelting the raw materials according to the weight percentage, performing external refining and casting to obtain a pipe blank; (2) performing three-stage homogenization treatment; (3) squeezing under high temperature; (4) performing twin-stage solid solution treatment, quenching and cooling; (5) prestretching and deforming; and (6) performing twin-stage artificial aging treatment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

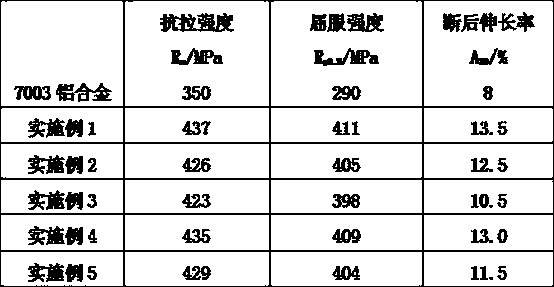

Aluminium alloy used for automobile anti-collision beam, and manufacturing method for product thereof

The invention relates to an aluminum alloy used for an automobile anti-collision beam, and a manufacturing method for a product thereof. The aluminum alloy comprises, by mass, 6.50%-6.80% of Zn, 0.90%-1.10% of Mg, 0.2-0.30% of Cu, 0.15%-0.20% of Zr, 0.10%-0.15% of Mn, 0.01-0.02% of Ti, less than or equal to 0.05% of Cr, less than or equal to 0.25% of Fe, less than or equal to 0.20% of Si, and the balance being Al. The tensile strength of the automobile anti-collision beam obtained by the aluminum alloy can reach over 420 MPa; yield strength can be stably controlled between 390 MPa and 420 MPa; percentage elongation after fracture is larger than 10%; and weldability and corrosion resistance are increased to different degrees than an automobile anti-collision beam obtained by adopting an original alloy system. The aluminum alloy can meet anti-collision and energy absorption requirements of the automobile, and retains the low quenching sensitivity of 7003 alloy, and can be used for producing high performance automobile anti-collision beams.

Owner:GUANGDONG HAOMEI ALUMINUM

Carburizing steel and steel products manufactured making use of the carburizing steel

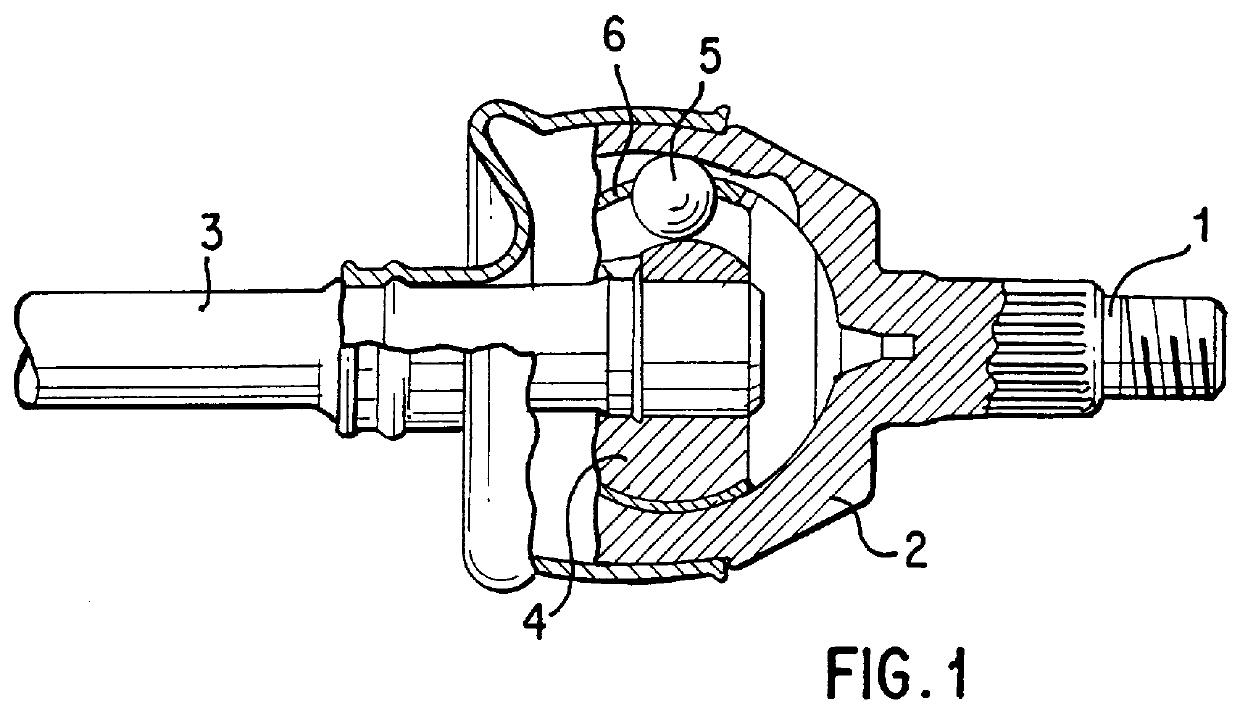

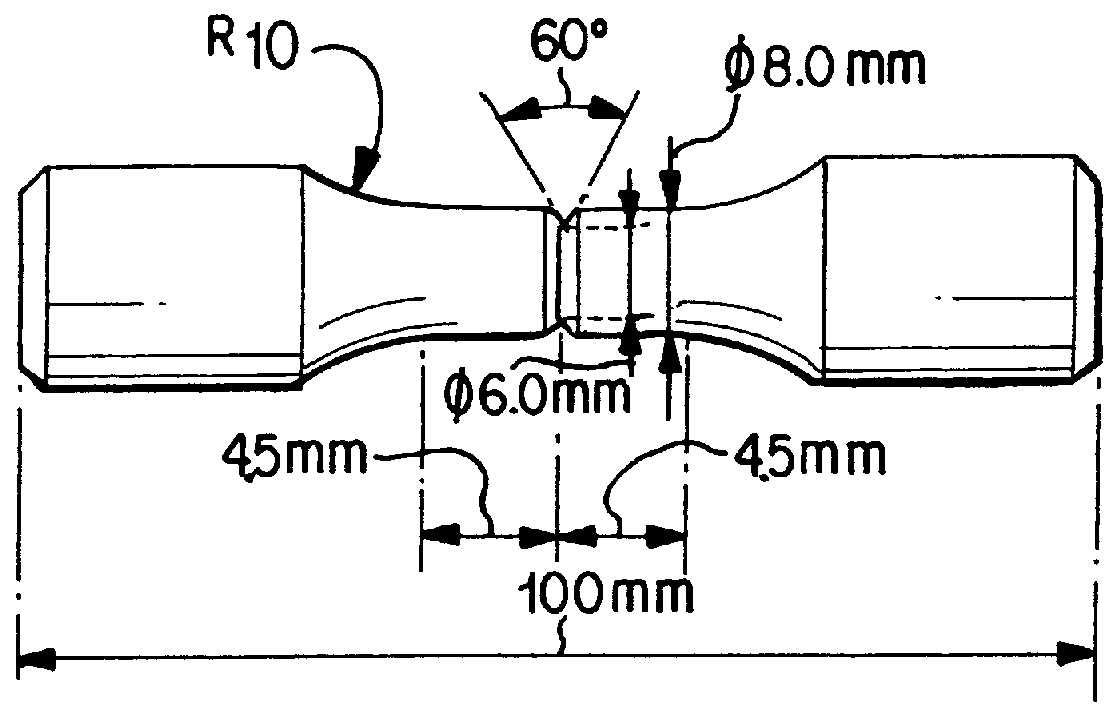

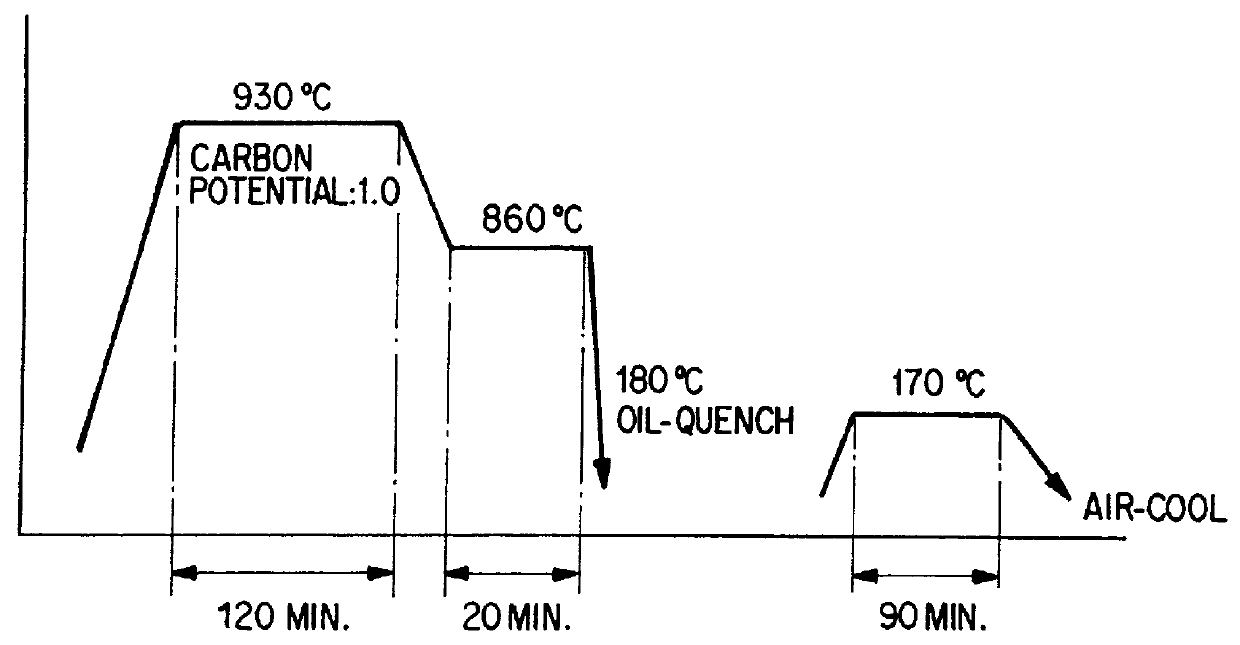

InactiveUS6126897AImproving rolling contact fatigue resistanceHigh strengthYielding couplingSolid state diffusion coatingChemical compositionUniversal joint

A carburizing steel having the following chemical composition: C: 0.1 to 0.25%, Si: 0.2 to 0.4%, Mn: 0.3 to 0.9%, P: 0.02% or less, S: 0.001 to 0.15%, Cr: 0.5 to 0.9%, Mo: 0.15 to 1%, Al: 0.01 to 0.1%, B: 0.0005 to 0.009%, N: less than 0.006%, and the balance of Fe and incidental impurities, wherein % is on a weight basis. Also disclosed are a method for the manufacture of the carburizing steel, parts of constant velocity universal joints for drive shafts made of the carburizing steel, as well as a method for the manufacture of such parts. The carburizing steel may further contain Ni: 0.3-4.0%, and one or more elements selected from the group consisting of Ti, Nb, V and Zr: 0.01-0.3% for each. The parts of constant velocity universal joints for drive shafts are manufactured using the carburizing steel of the present invention as a material. When they are carburized and quenched, they exhibit a surface hardness (Hv) of 650-800, core hardness (Hv) of 250-450, and carburized case depth of 0.2-1.2 mm.

Owner:SUMITOMO METAL IND LTD +1

High-strength atmospheric corrosion-resistant cold heading steel and preparation method thereof

The invention relates to the technical field of cold heading steel, and particularly discloses high-strength atmospheric corrosion-resistant cold heading steel and a preparation method thereof. The high-strength atmospheric corrosion-resistant cold heading steel comprises, by weight, 0.28%-0.40% of C, 0.15%-0.30% of Si, 0.60%-0.90% of Mn, smaller than or equal to 0.025% of P, smaller than or equalto 0.020% of S, 0.60%-1.00% of Cr, 0.20%-0.50% of Ni, 0.20%-0.45% of Cu, 0.005%-0.050% of Ti, any one or more elements of 0.15%-0.35% of Mo, 0.09%-0.12% of V and 0.005%-0.015% of Nb, the balance Fe and unavoidable impurities. The cold heading steel prepared through the method has the high strength and hardness, has the good hardenability, meets the requirements of the hardenability of large-sizebolts, has the certain delayed fracture resistance, is low in production cost and has the characteristics of being good in corrosion resistance, high in tensile strength, good in surface quality and excellent in performance.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

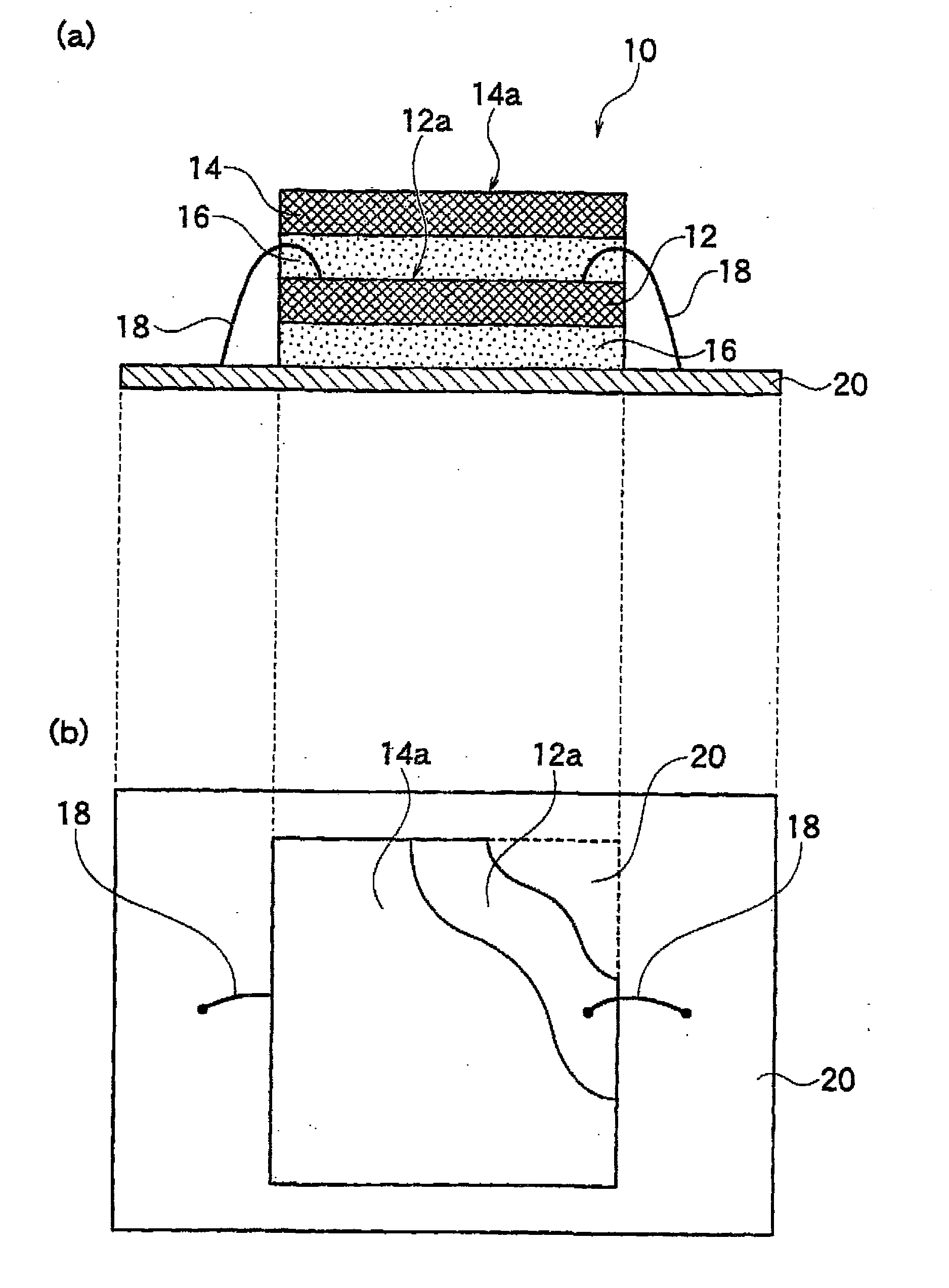

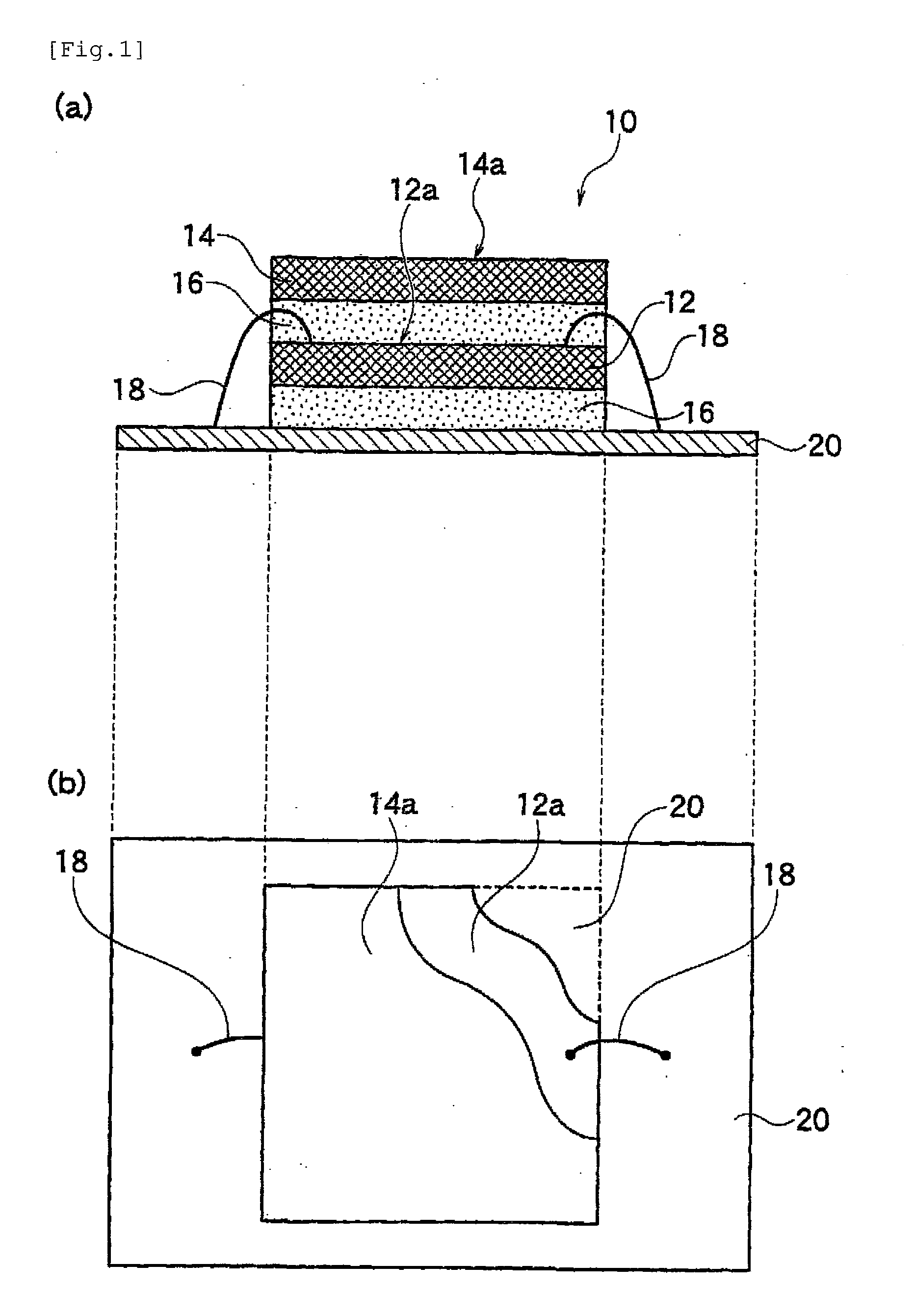

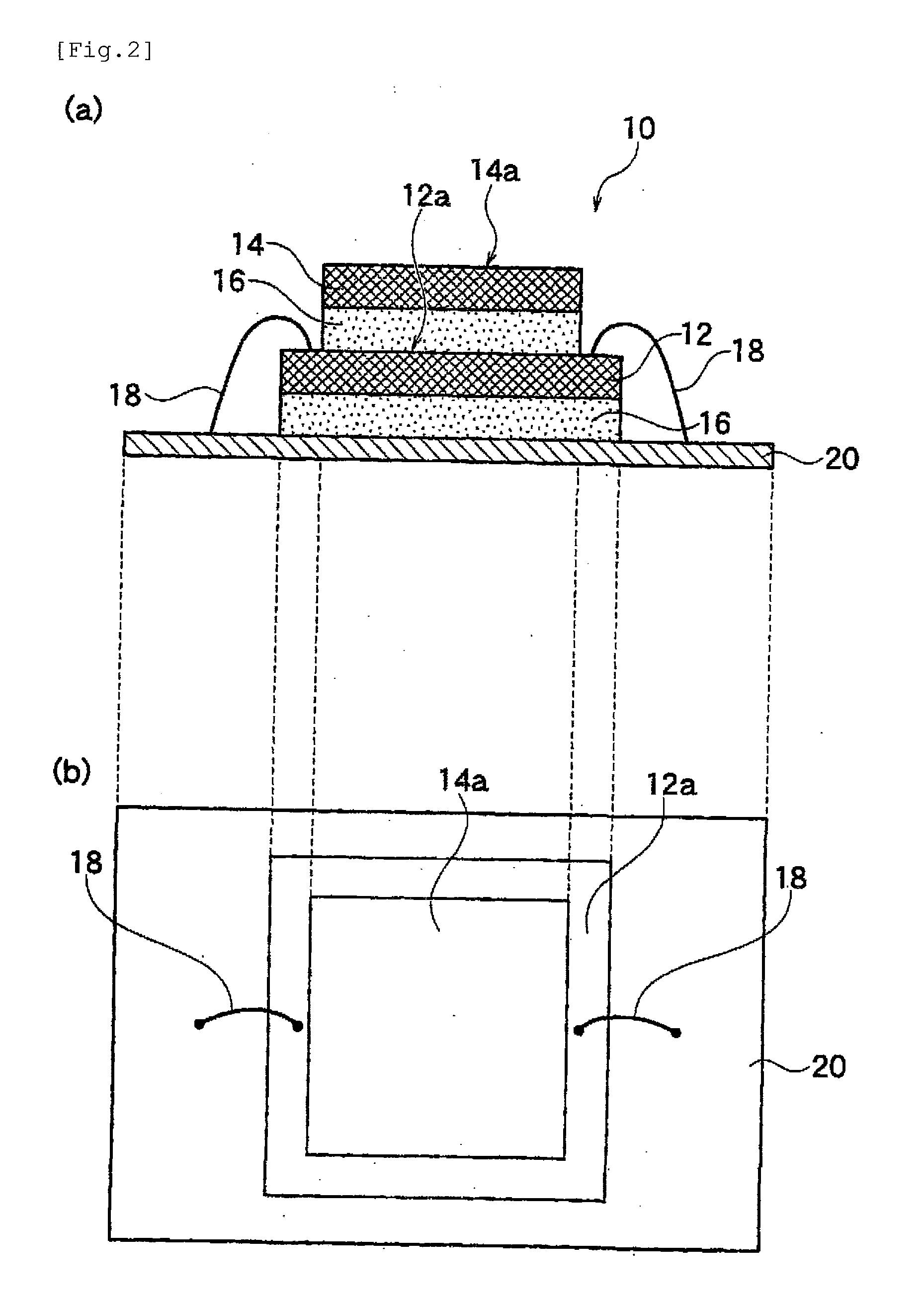

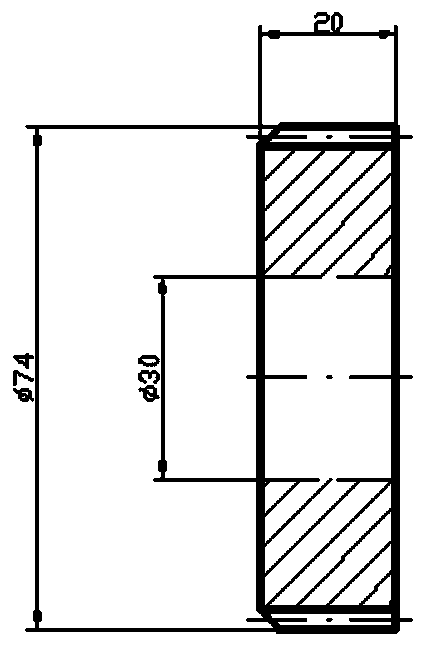

Semiconductor Chip Laminate and Adhesive Composition for Semiconductor Chip Lamination

ActiveUS20100133703A1Good package reliabilityHigh efficiencyPlastic/resin/waxes insulatorsSemiconductor/solid-state device detailsChemistryAcrylic polymer

A semiconductor chip laminate comprises a plurality of semiconductor chips and an adhesive layer through which the plurality of semiconductor chips are laminated, wherein the adhesive layer is composed of an adhesive composition comprising an acrylic polymer (A); an epoxy resin (B); a thermal curing agent (C); and a certain organic phosphine compound (D) as a thermal curing accelerator, and the content of the organic phosphine compound (D) relative to 100 parts by weight in total of the epoxy resin (B) and the thermal curing agent (C) is 0.001 to 15 parts by weight.

Owner:LINTEC CORP

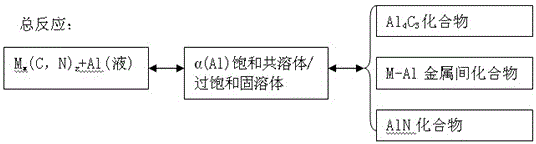

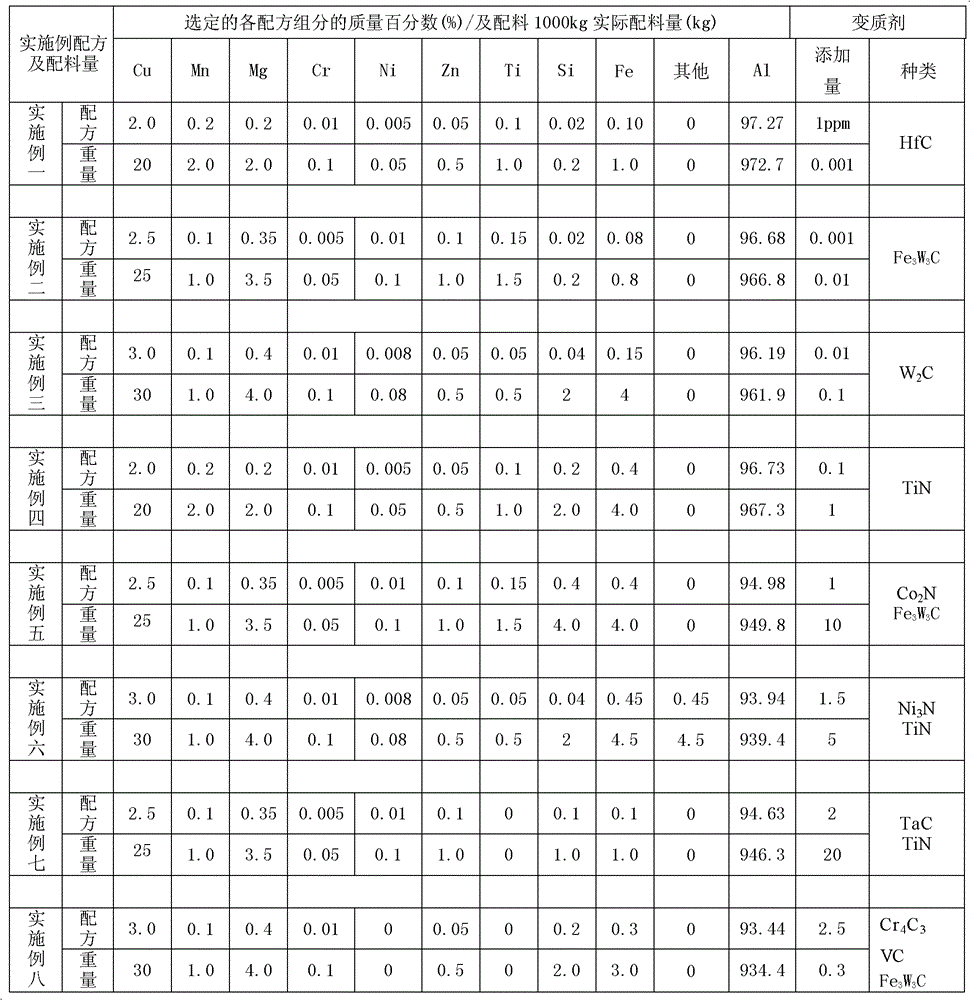

High-strength aluminum alloy subjected to carbonitride complex treatment and preparation method thereof

The invention discloses a high-strength aluminum alloy subjected to carbonitride complex treatment and a preparation method thereof. The alloy comprises the following components in percentage by weight: 2.0-3.2 percent of Cu, less than or equal to 0.2 percent of Mn, 0.2-0.5 percent of Mg, less than or equal to 0.01 percent of Cr, less than or equal to 0.01 percent of Ni, less than or equal to 0.1 percent of Zn, less than or equal to 0.15 percent of Ti, less than or equal to 0.5 percent of Si, less than or equal to 0.5 percent of Fe, and the balance of Al and inevitable trace impurities, wherein the carbonitride MX(C,N)Y is 0.05-2.5 percent of total mass of the furnace burden. The aluminum alloy has the characteristics of high strength and good casting performance.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Low-Sc high-strength high-toughness high-hardenability aluminum-zinc-magnesium alloy and preparation method thereof

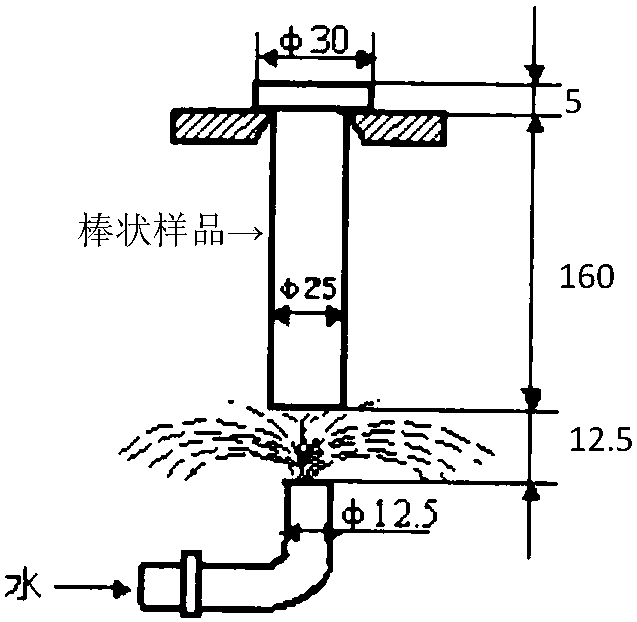

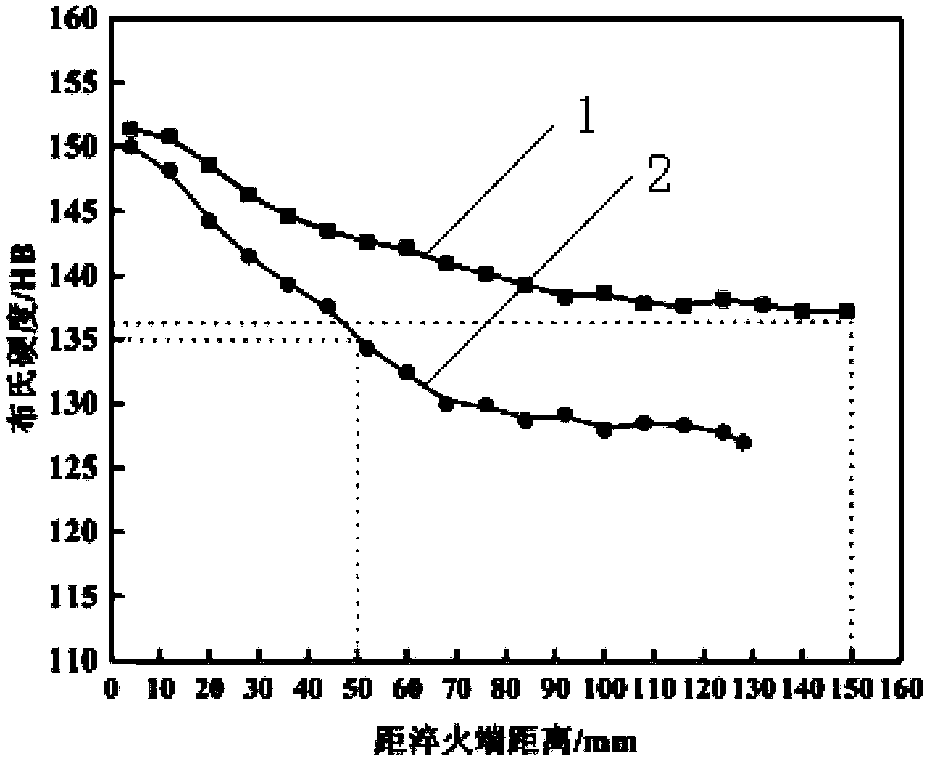

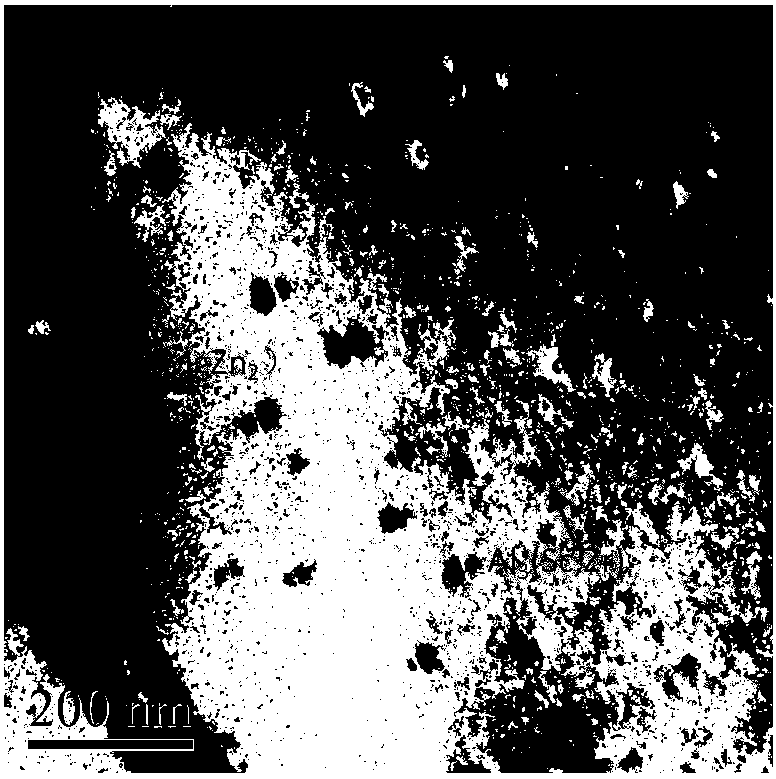

The invention discloses a low-Sc high-strength high-toughness high-hardenability aluminum-zinc-magnesium alloy and a preparation method thereof. The alloy is prepared from the following components inpercentage by mass: 5.5-6.0% of Zn, 1.8-2.2% of Mg, 0.3-0.4% of Cu, 0.2-0.4% of Mn, 0.05-0.12% of Sc, 0.06-0.12% of Zr, 0.05-0.20% of Cr, 0.03-0.06% of Ti and the balance of Al, wherein total contentof impurities such as Fe and Si is not greater than 0.15%. The preparation method comprises the following steps: adopting semi-continuous chilling and casting, and cast ingot two-stage homogenizing treatment to obtain nano-scale Al3(Sc, Zr), sub-micron A17Cr and A16Mn precipitated phase; and obtaining sub-structure reinforcing, precipitation reinforcing and diffusion reinforcing in a follow-up thermal processing process and a thermal treatment process. The low-Sc high-strength high-toughness high-hardenability aluminum-zinc-magnesium alloy adopts Cr and Mn to cooperatively add and partially substitute Sc; compared with an existing Al-Zn-Mg-Sc-Zr Alloy, the alloy has slightly improved in single alloy tensile strength, yield strength and elongation in case of reducing Sc content of the alloyby 60%; and full quenching depth is increased to 150 mm from 50 mm, and manufacturing cost is reduced by 45%.

Owner:CENT SOUTH UNIV

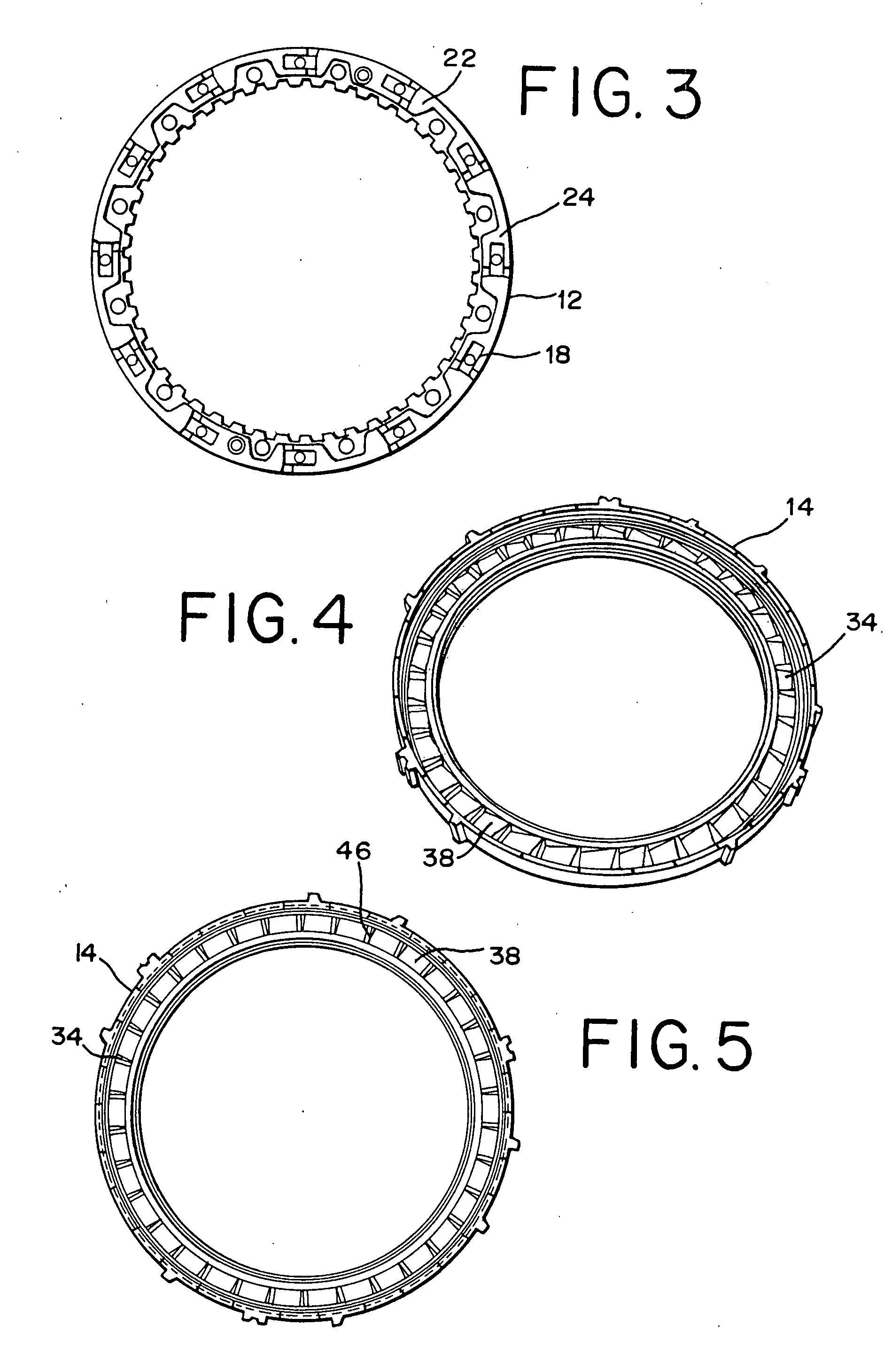

Nitratable steel piston rings and steel cylindrical sleeves, and casting method for the production thereof

InactiveUS20120090462A1Good nitridabilityEasy transitionPiston ringsBraking action transmissionCast ironSteel cylinder

A steel piston ring and a steel cylinder liner are described which comprise as the main body a steel composition which has good nitridability. The steel composition consists of the following elements: 0-0.5 weight % B, 0.5-1.2 weight % C, 4.0-20.0 weight % Cr, 0-2.0 weight % Cu, 45.30-91.25 weight % Fe, 0.1-3.0 weight % Mn, 0.1-3.0 weight % Mo, 0-0.05 weight % Nb, 2.0-12.0 weight % Ni, 0-0.1 weight % P, 0-0.05 weight % Pb, 0-0.05 weight % S, 2.0-10.0 weight % Si, 0-0.05 weight % Sn, 0.05-2.0 weight % V, 0-0.2 weight % Ti and 0-0.5 weight % W. The steel piston ring and the steel cylinder liner can be manufactured in a casting process using the machinery and technology employed for the manufacture of cast iron parts.

Owner:FEDERAL MOGUL BURSCHEID

Nitrogen-added 20MnCr5 gear steel and production method thereof

The invention relates to nitrogen-added 20MnCr5 gear steel. The gear steel comprises, by weight, 0.18-0.21% of C, Si with the amount smaller than or equal to 0.12%, 1.25-1.35% of Mn, 1.16-1.24% of Cr, P with the amount smaller than or equal to 0.020%, 0.020-0.030% of S, 0.025-0.045% of Al and 0.0060-0.0100% of N. The gear steel further comprises, by weight, Ni with the amount smaller than or equal to 0.10%, Cu with the amount smaller than or equal to 0.10%, B with the amount smaller than or equal to 0.0003%, O with the amount smaller than or equal to 15*10-6, and the balance Fe and other trace residual elements. The gear steel has the advantages of being stable in performance, small in heat treatment deformation and good in surface quality, and achieving hardenability band narrowing.

Owner:SGIS SONGSHAN CO LTD

Aluminum alloy for anti-chloridion-corrosion type aluminum alloy oil pipe and pipe manufacturing method of aluminum alloy

The invention discloses aluminum alloy for an anti-chloridion-corrosion type aluminum alloy oil pipe and a pipe manufacturing method of the aluminum alloy. The aluminum alloy comprises, by weight, 6.90%-7.49% of Zn, 2.10%-2.30% of Mg, 0.05%-0.10% of Cu, 0.10%-0.30% of Mn, 0.10%-0.30% of Cr, 0.01%-0.02% of Ti, 0.15%-0.2% of Zr, 0.05%-0.1% of Sc, and the balance Al and inevitable impurities. The strength performance of the aluminum alloy is improved significantly through matching of the high-content Zn and the low-content Mg. The strength and the repeated loading resistance of the aluminum alloy are improved through the appropriate-content Mn and the appropriate-content Cr, and the good plasticity and toughness of the aluminum alloy are ensured. The micro-content Ti, the micro-content Zr and the micro-content Sc serve as supplement and improvement. The structure stability and the performance reliability of the aluminum alloy are ensured through grain refinement and precipitation strengthening. The aluminum alloy for the anti-chloridion-corrosion type aluminum alloy oil pipe is high in overall specific strength, good in corrosion resistance, low in cost, good in processability and high in qualified product ratio.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Low-cost, high-toughness and excellent-weldability 800 MPa-grade quenched and tempered steel plate and manufacturing method thereof

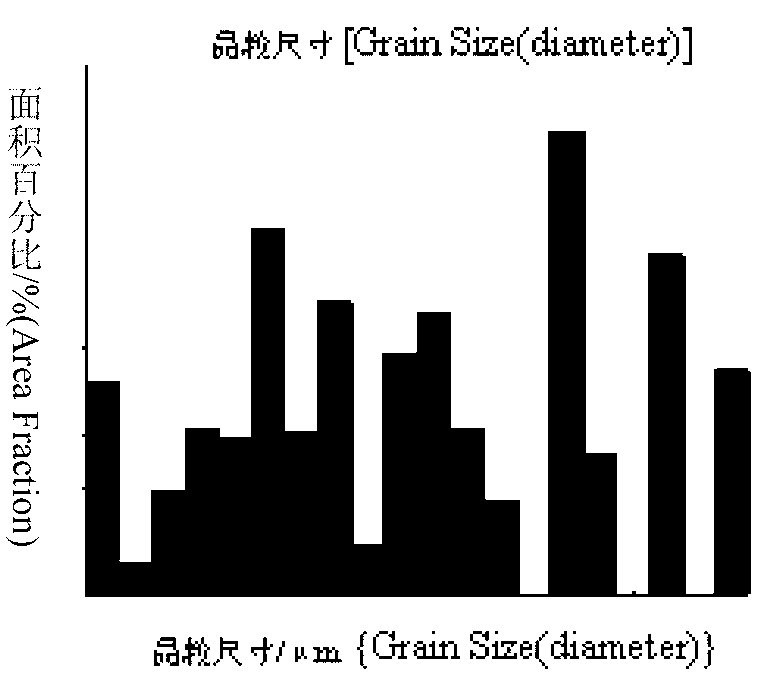

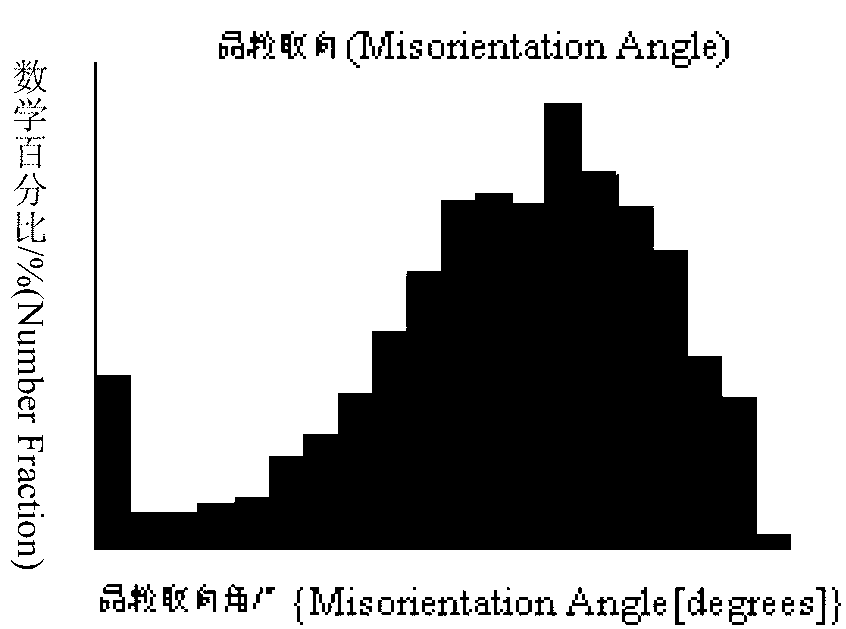

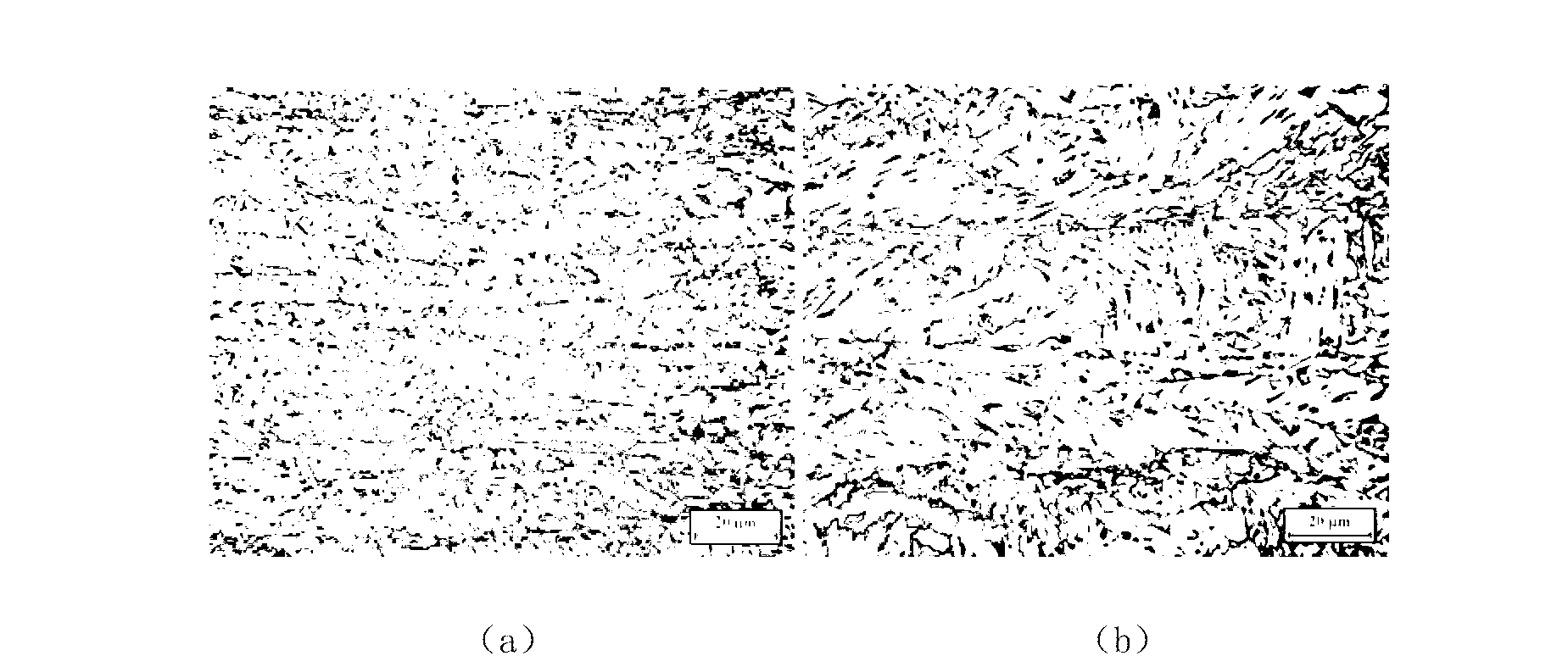

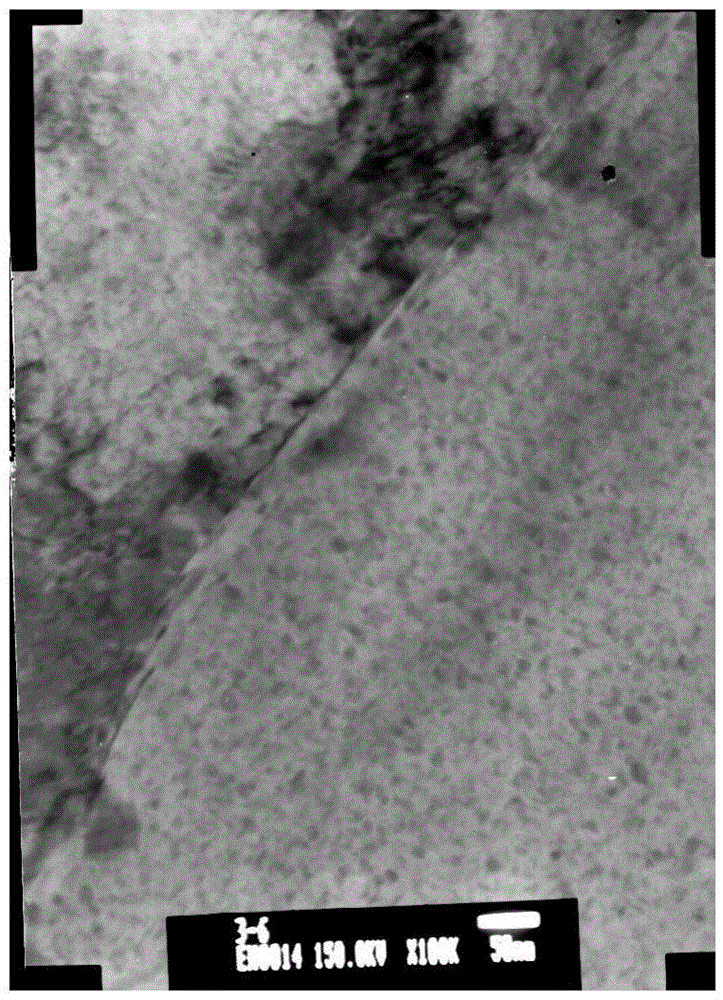

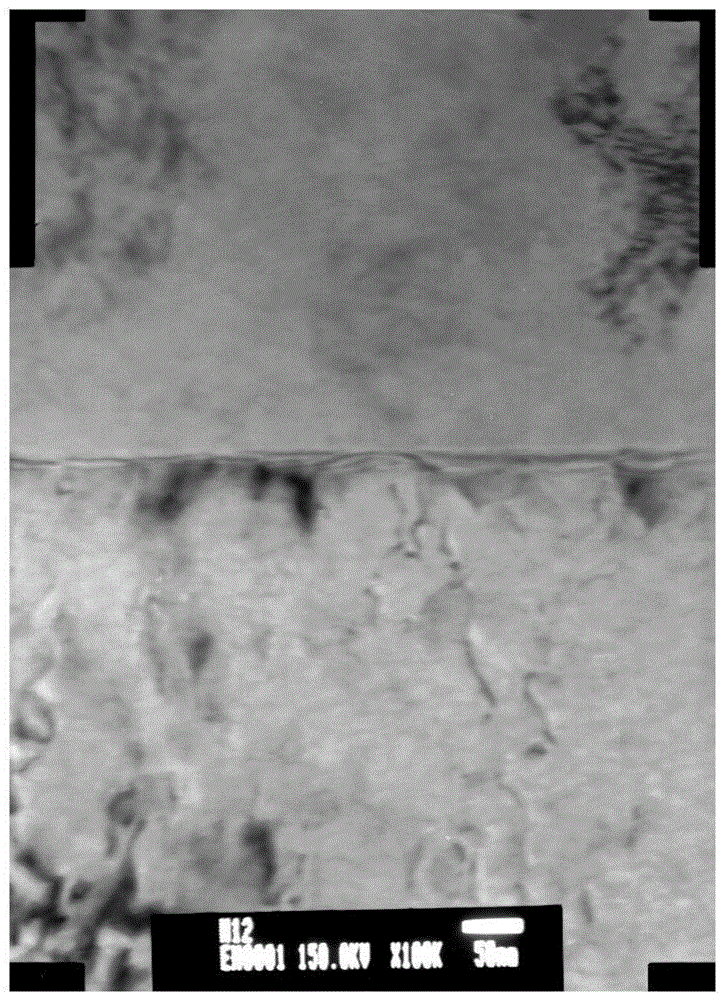

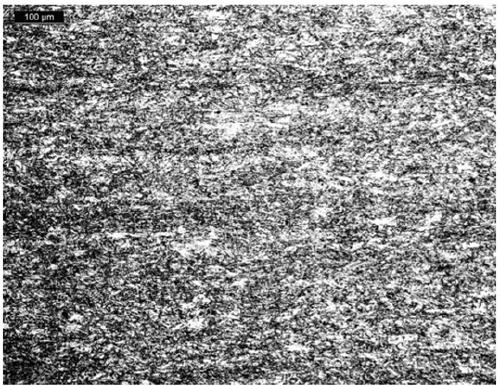

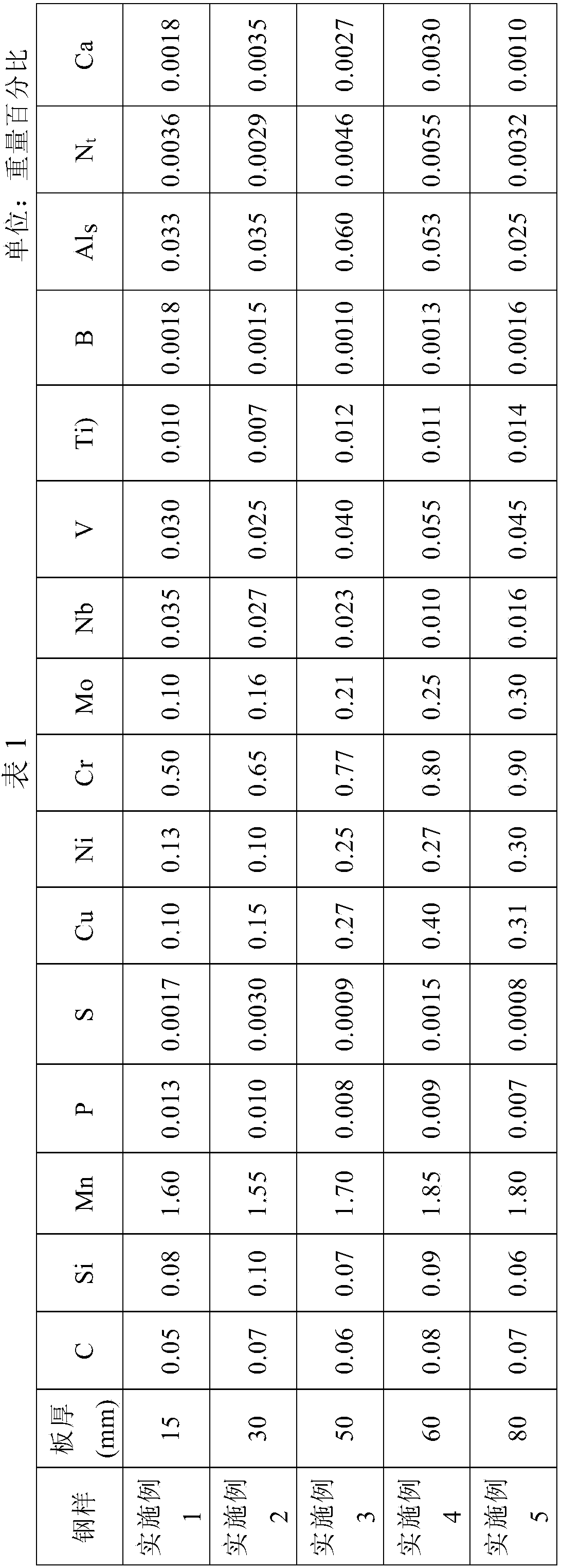

The invention discloses a low-cost, high-toughness and excellent-weldability 800 MPa-grade quenched and tempered steel plate and a manufacturing method thereof. An ultra-low C- ultra-low Si-high Mn (Cu + Ni + Mo + high Cr) alloying-(Ti + V + B) micro-alloyed component system is taken as a foundation, the content of acid-soluble Als in steel is properly improved, and (% Als) is larger than or equalto 10 * [(% Nt)-0.292 (% Ti)], metallurgy technology control measures are adopted, specifically, a large-angle bainite lath / a martensite lath grain boundary forming index chi is controlled to be larger than or equal to 2.1, (% C) * [(% Si) +0.83 (% Mo) +1.12 (% Nb) +0.89 (% Als) +0.45 (% V)] is controlled to be less than or equal to 0. 031, a Di index * zeta * T cooling acceleration start temperature * [(T cooling acceleration start temperature-T cooling acceleration stop temperature) / (T cooling acceleration start temperature +T cooling acceleration stop temperature)] / t is controlled to be larger than or equal to 1535, Ca is treated and the Ca / S ratio is within 1.00-3.00, and CR + DQ + an off-line tempering process T is optimized, so that the microscopic structure of a finished steel plate is composed of uniform and fine lower bainite and lath martensite, the average size of eutectic cells is 20 micrometers or below, and excellent strong plasticity and high toughness are obtained.

Owner:BAOSHAN IRON & STEEL CO LTD

High toughness steel material and method of producing steel pipes using same

InactiveUS20030178111A1Improve toughnessReduce hardenabilityFurnace typesHeat treatment furnacesProduction rateAustenite grain

A steel material and a steel pipe made by using the same are provided which are to be used in severe oil well environments. Such a highly tough oil well steel pipe can be produced by rolling the base material, quenching the rolling product from the austenite region and tempering the same so that the relationship between the content of Mo [Mo] in the carbides precipitated at austenite grain boundaries and the austenite grain size (according to ASTM E 112) can be defined by the formula (a) given below. In this manner, steel pipes suited for use even under oil well environments becoming more and more severe can be produced while satisfying the requirements that the cost should be rationalized, the productivity improved and energy saved.[Mo]<=exp(G-5)+5 (a)

Owner:NIPPON STEEL CORP

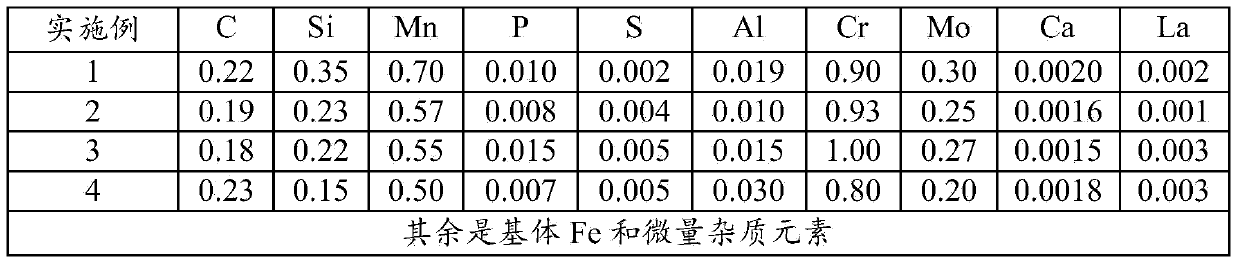

Low-cost rare earth-containing anti-H2S corrosion petroleum casing pipe material and production method thereof

InactiveCN103436787AStrong enoughImprove resistance to H

<sub>2</sub>

S corrosion performanceChemical compositionRare earth

The invention discloses a low-cost rare earth-containing anti-H2S corrosion petroleum casing pipe material. The low-cost rare earth-containing anti-H2S corrosion petroleum casing pipe material comprises the following chemical components in percentage by mass: 0.18-0.23% of C, 0.15-0.23% of Si, 0.50-0.70% of Mn, less than or equal to 0.015% of P, less than or equal to 0.05% of S, 0.010-0.030% of Al, 0.80-1.00% of Cr, 0.20-0.30% of Mn, 0.0015-0.0020% of Ca, less than or equal to 0.03% of La and the balance of matrix Fe and impurity elements. The invention also discloses a production method of the low-cost rare earth-containing anti-H2S corrosion petroleum casing pipe material. The low-cost rare earth-containing anti-H2S corrosion petroleum casing pipe material has the advantages of relatively low cost, good plasticity, low crack sensitivity, low residual stress, good hardenability, stable performance and relatively high percentage of elongation.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

1200MPa-grade ultra-fast cold-rolled double-phase steel plate and preparation method thereof

The invention discloses a 1200MPa-grade ultra-fast cold-rolled double-phase steel plate and a preparation method thereof. The steel plate comprises the chemical components of, by mass, 0.12-0.17% of C, 0.3-0.6% of Si, 2.0-2.4% of Mn, less than or equal to 0.015% of P, less than or equal to 0.008% of S, 0.03-0.06% of Als, 0.03-0.06% of Ti, less than or equal to 0.005% of N, and the balance being Feand unavoidable impurities. The preparation method includes smelting, continuous casting, hot rolling, cold rolling, annealing, and leveling processes. By adoption of the design of Ti-microalloying and low-alloying composition, the continuous retreating process is utilized; the water-cooling is ultra-fast; the hardenability of the steel plate is improved; a cold-rolled dual-phase steel with ferrite and martensite biphasic structure morphology is obtained; the structure is uniform; the strength of extension reaches 1200 MPa or more; and the mechanical properties are excellent.

Owner:HANDAN IRON & STEEL GROUP +1

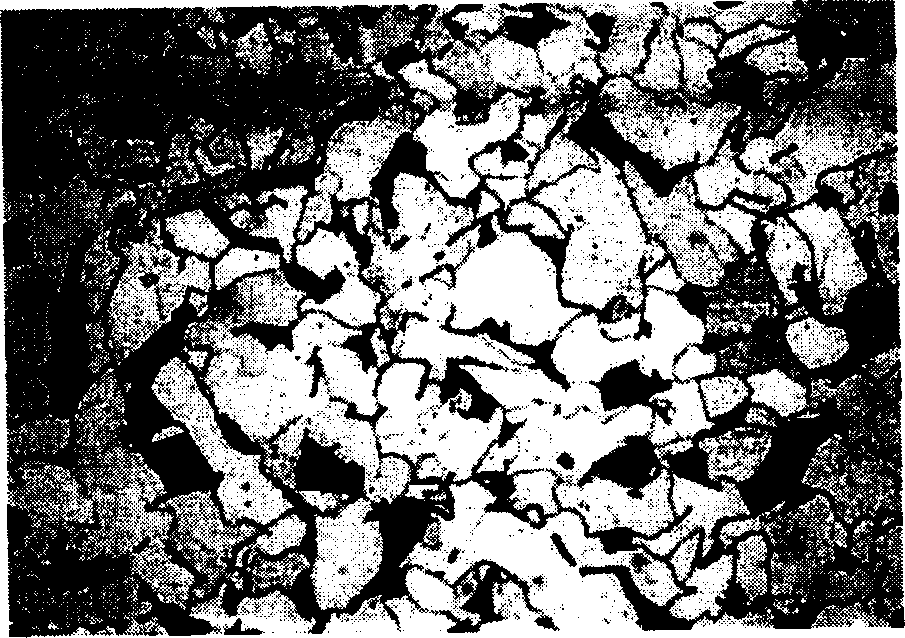

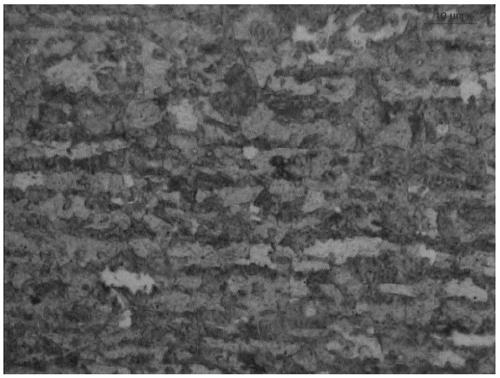

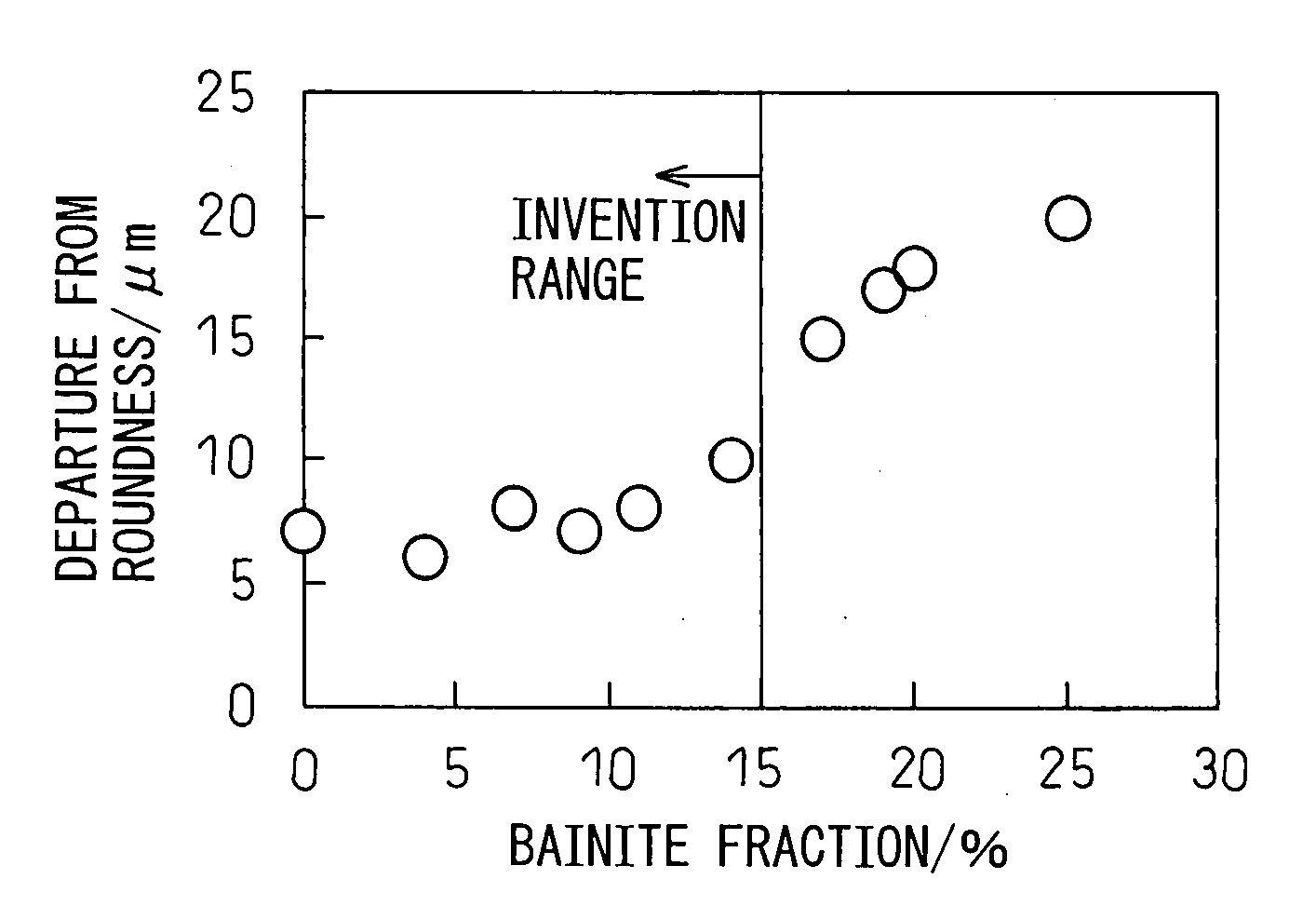

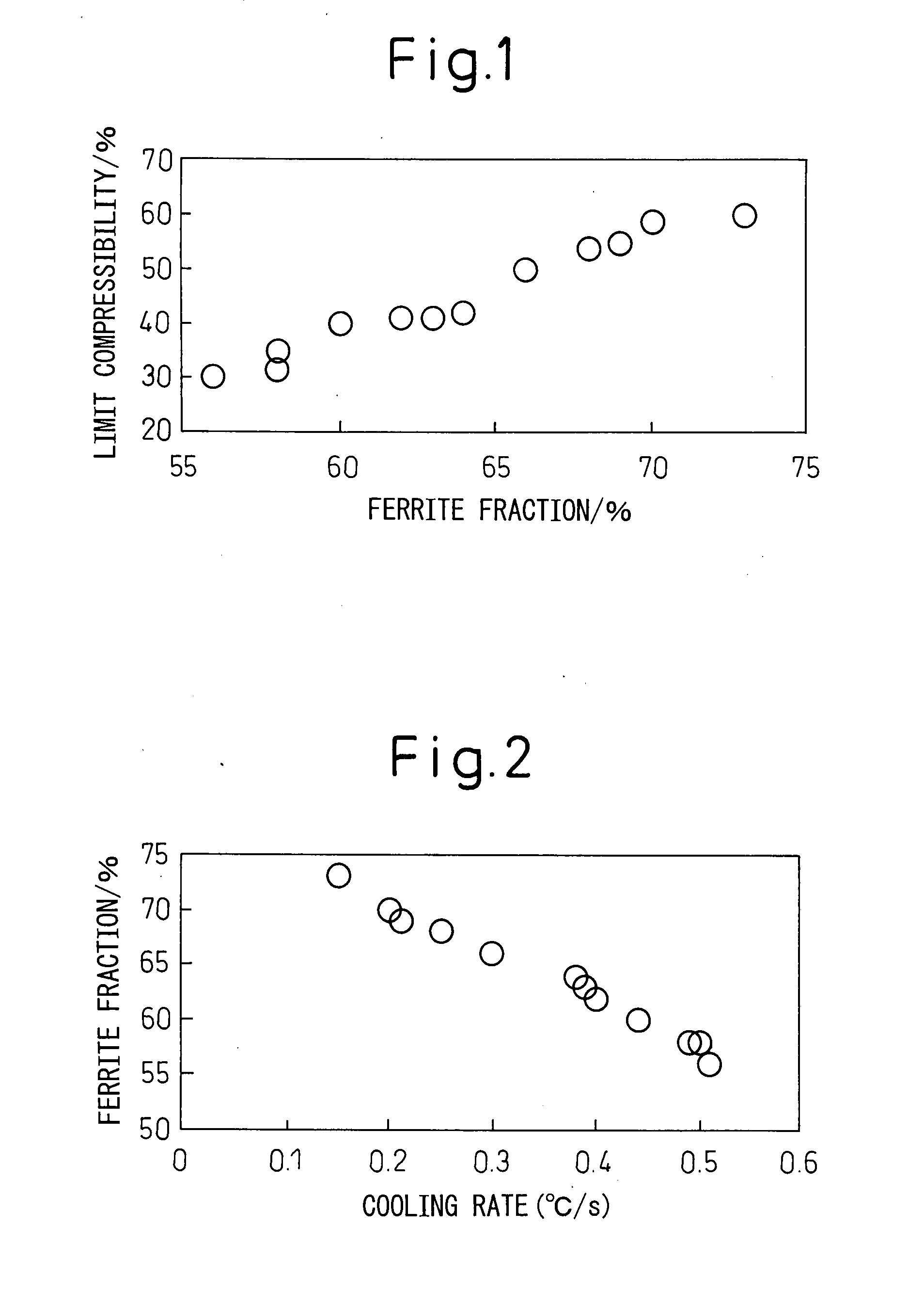

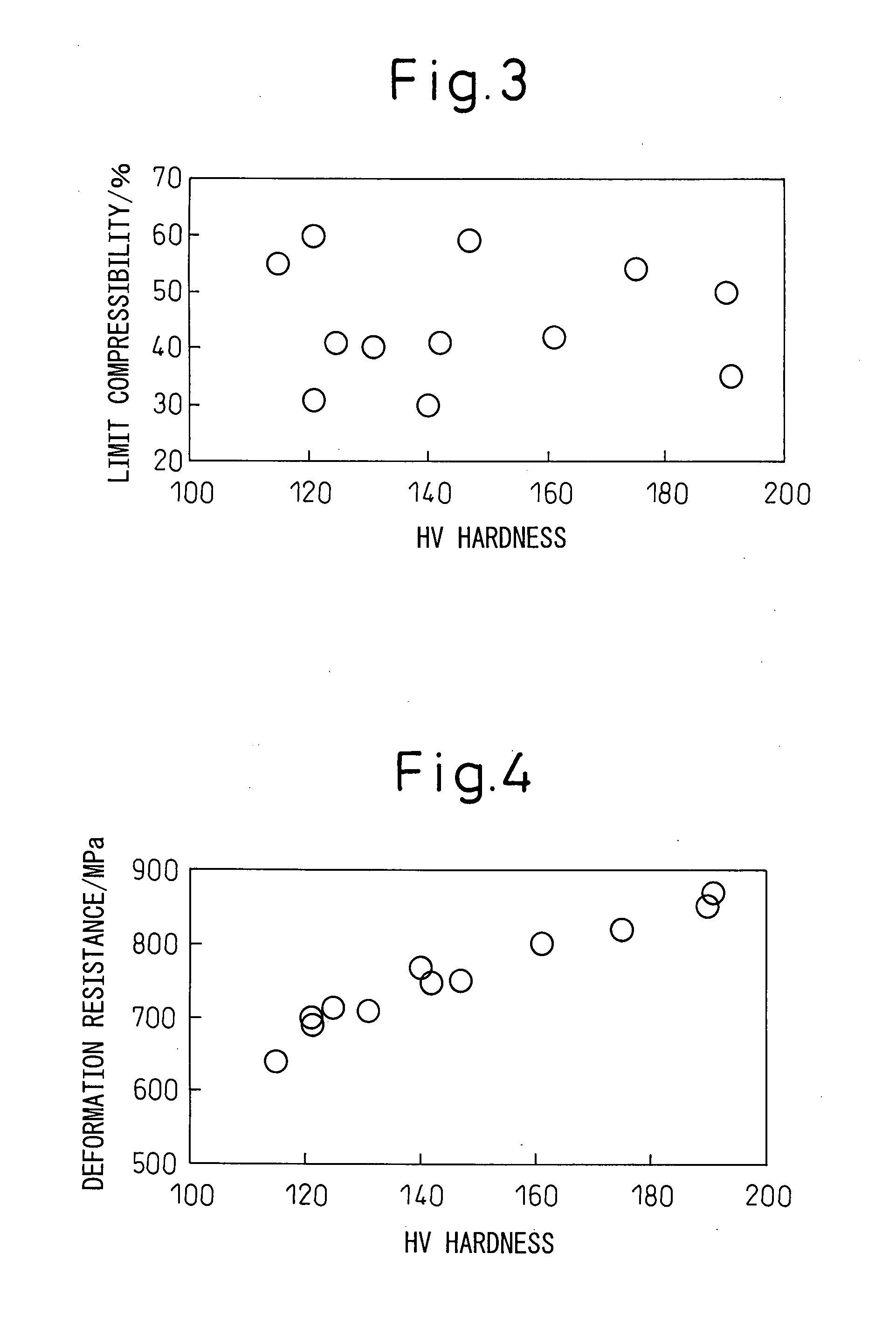

Case-hardening steel excellent in cold forgeability and low carburization distortion property

This invention provides a case-hardening steel excellent in cold forgeability and low carburization distortion property that exhibits low deformation resistance and high limit compressibility when cold, namely, a case-hardening steel excellent in cold forgeability and low carburization distortion property comprising, in mass %, C: 0.07% to 0.3%, Si: 0.01% to 0.15%, Mn: 0.1% to 0.7%, P: 0.03% or less, S: 0.002% to 0.10%, Al: 0.01% to 0.08%, Cr: 0.7% to 1.5%, Ti: 0.01% to 0.15%, B: 0.0005% to 0.005%, N: 0.008% or less, and the balance of Fe and unavoidable impurities, and having a metallographic structure comprising 65% or greater of ferrite and 15% or less of bainite.

Owner:NIPPON STEEL CORP

Aluminum alloy capable of digesting high-hardness compounds and smelting method of aluminum alloy

The invention discloses an aluminum alloy capable of digesting high-hardness compounds and a smelting method of the aluminum alloy. The method comprises the following steps of: heating aluminum ingots or molten aluminum till complete melting; adding Si, Fe, Cu, Mn, Mg, Cr, Zn and Ti, and completely dissolving and melting the elements; preserving the heat at the temperature of between 700 and 1,000 DEG C after refining, and obtaining an alloy melt; performing degassing purification operation on the alloy melt by using nitrogen or inert gas or mixed gas of the nitrogen and the inert gas in a random ratio, and continuously introducing the gas till the reaction is finished; adding LaH3 powder into the alloy melt in a fluidized form together with the gas; stirring to make the LaH3 distributed uniformly in the alloy melt and fully reacted with the alloy melt; and standing, regulating the temperature to 680-730 DEG C, and discharging the molten alloy for casting. By the method, the defects of the properties of the conventional aluminum alloy can be overcome, the toughness, the forming property and the hardening capacity of the aluminum alloy are improved, and a high-end base material is provided for efficient deep processing.

Owner:GUIZHOU ALUMINUM MATERIALS ENG TECHRES CENT

Rolled Rod for Cold-Forged Thermally Refined Article

InactiveUS20180347019A1Improve hydrogen embrittlement resistanceHigh strengthScrewsFurnace typesChemical compositionPearlite

The rolled rod for cold-forged thermally refined articles according to the present invention has a chemical composition consisting, in mass %: C: 0.22 to 0.40%, Si: 0.35 to 1.5%, Mn: 0.20 to 0.40%, P: less than 0.020%, S: less than 0.015%, Cr: 0.70 to 1.45%, Al: 0.005 to 0.060%, Ti: 0.01 to 0.05%, B: 0.0003 to 0.0040%, N: 0.0020 to 0.0080%, and O: 0.0020% or less, with the balance being Fe and impurities, and that satisfies Formula (1) and Formula (2), wherein a total area fraction of pro-eutectoid ferrite and pearlite is 90% or more, an area fraction of the pro-eutectoid ferrite is 30% or more, and the rolled rod has a tensile strength of 700 MPa or less.0.50≤C+Si / 10+Mn / 5+5Cr / 22≤0.85 (1)Si / Mn>1.0 (2)

Owner:NIPPON STEEL CORP

Nodular cast iron for automobile braking disc and preparation method thereof

InactiveCN108441752AReduce hardenabilityImprove hardenabilityProcess efficiency improvementHigh intensityDuctile iron

The invention relates to the technical field of nodular cast iron, and particularly relates to nodular cast iron for an automobile braking disc and a preparation method thereof. The nodular cast ironis prepared from the following elements according to mass percent: 3.2 to 3.6% of C, 2.8 to 3.2% of Si, 0.4 to 0.8% of Cr, 0.2 to 0.6% of Mn, 0.2 to 0.8% of Al, 0.2 to 0.8% of Ni, 0.2 to 0.8% of Mg, 0.2 to 0.6% of Cu, 0.2 to 0.4% of Mo, 0.08 to 0.10% of Ta, 0.04 to 0.06% of Y, 0.02 to 0.03% of Sb, less than or equal to 0.02% of S, less than or equal to 0.04% of P and the balance of Fe and inevitable impurities. The invention provides the nodular cast iron for the automobile braking disc and the preparation method thereof. The elements and the content are reasonably optimized, so that the prepared nodular cast iron has the advantages of high strength, high toughness and wear resistance and high high-temperature resistance, and the service life of the automobile braking disc is prolonged during use.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

Ultralow-carbon austenitic welding wire material for welding of stainless steel

InactiveCN102319965AReduced cold crack susceptibilityReduce sensitivityWelding/cutting media/materialsWelding/soldering/cutting articlesRare-earth elementChemical composition

The invention provides an ultralow-carbon austenitic welding wire material for the welding of stainless steel. According to percentage in weight, the specific chemical components of the welding wire material are as follows: less than or equal to 0.023 percent of C; 3.87 to 4.45 percent of Si; 0.57 to 0.89 percent of Mn; less than or equal to 0.023 percent of P; less than or equal to 0.013 percent of S; 18.59 to 19.32 percent of Cr; 13.57 to 14.87 percent of Ni; less than or equal to 0.33 percent of Mo; less than 0.044 percent of N; 0.09 to 0.29 percent of Cu; and the balance of Fe and inevitable impurities; and the welding wire material also comprises 0.02 to 0.042 percent by weight of rare-earth element Re. The welding wire material has the beneficial effects that: the component design is scientific, the welding wire material is convenient to use, the cold-cracking sensitivity of metal at the weld is low after welding, the performance result of the metal at the weld is near to the performance result of parent metal, and moreover, the welding wire material has high low-temperature impact toughness and corrosion resistance; and in particular, the ultralow-carbon austenitic welding wire material for the welding of stainless steel can resist the corrosion of concentrated nitric acid.

Owner:JIANGSU XINGHAI SPECIAL STEEL

Automotive light gear and manufacturing process thereof

ActiveCN110408885AFast quenchingControllable organizational structurePortable liftingSolid state diffusion coatingWork in processWear resistance

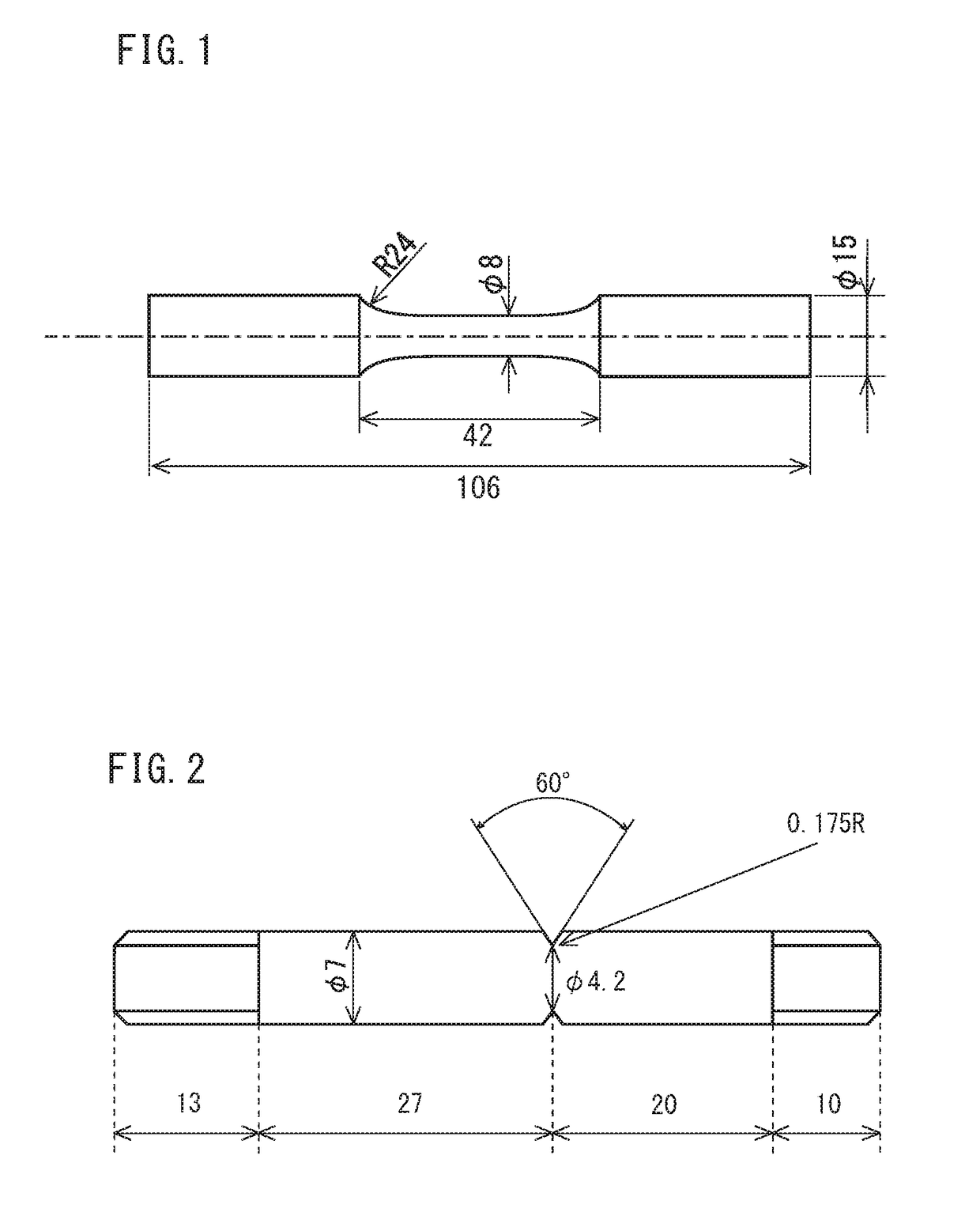

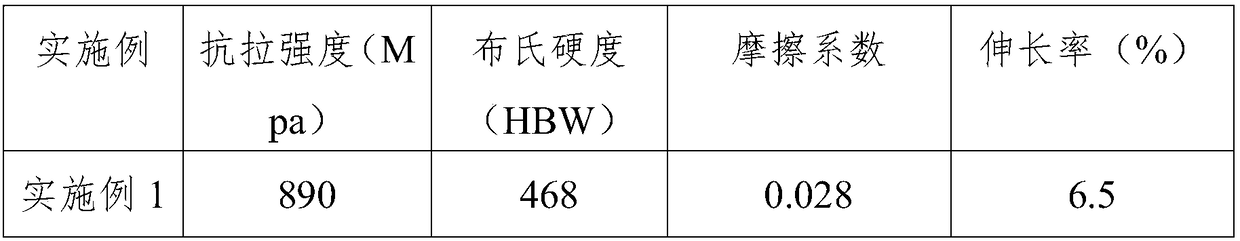

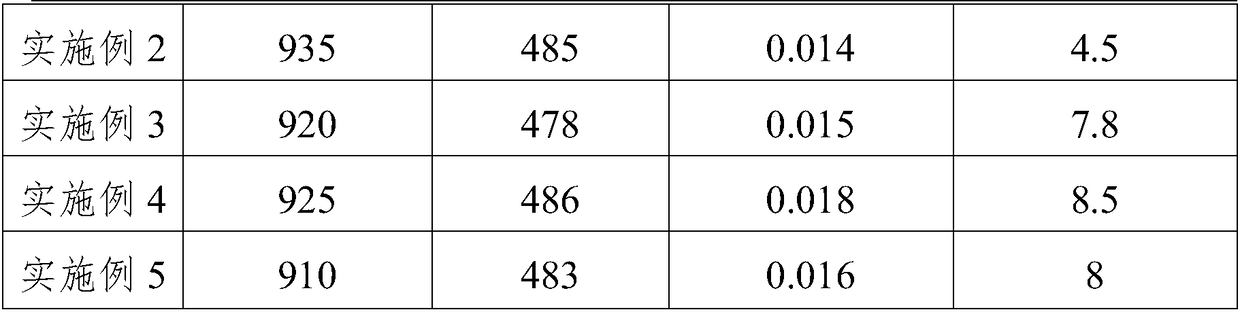

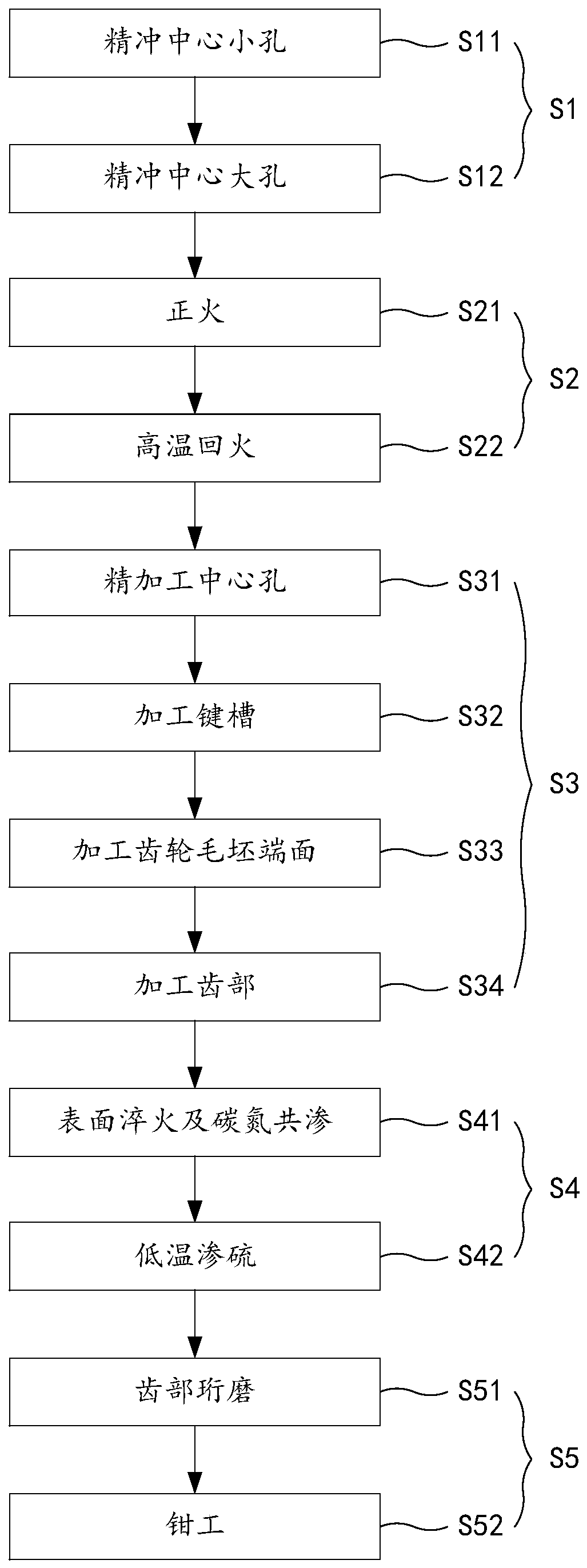

The invention discloses a manufacturing process of an automotive light gear. The manufacturing process of the automotive light gear comprises the following steps of first, carrying out rough machiningon a gear raw material to obtain a gear blank with a central large hole; second, carrying out heat treatment on the gear blank; third, carrying out semifinishing on the gear blank to obtain a semi-finished product of gear with teeth; fourth, carrying out plasma surface hardening carbonitriding treatment and sulfurizing treatment on the semi-finished product of gear; and fifth, carrying out secondary finish machining on the semi-finished product of gear to obtain a finished product of gear. According to the manufacturing process of the automotive light gear, because of the tooth surface hardening carbonitriding treatment and sulfurizing treatment, the hardening time is shortened, energy consumption is reduced, the surface friction coefficient is decreased, and the surface abrasive resistance is improved.

Owner:NANJING INST OF TECH

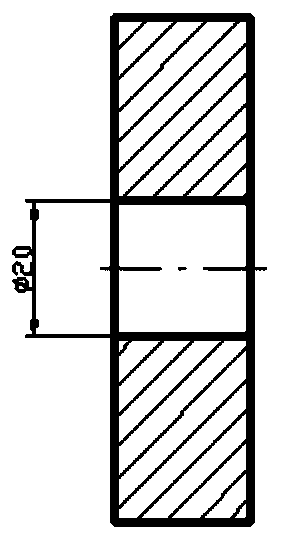

Manufacture and measuring of automotive components

InactiveUS20080193320A1Reduce hardenabilityReduce materialMeasurement devicesTransportation and packagingPearliteClutch

Clutch components for automotive use usually include a pair of clutch members with operative faces. In particular, planar one way clutches include a pair of clutch members whose operative faces are enclosed spaced opposition, with each clutch face including a plurality of recessed defining respective load bearing shoulders. A plurality of struts are disposed between the coupling face of the members, and such struts are moveable between the coupling position and non coupling position. A preferable method of manufacturing such clutch components includes powder metal operations comprising die compacting a metal powder into a metal blank, placing the die compacted metal blank in a machined flat ceramic support, sintering the metal blank to form a sintered metal blank, and cooling the sintered metal blank to form a cooled metal blank. The preferred metallic structure of the cooled metal blank is 50-80% martensite and 20-50% bainite and fine pearlite. The cooled metal blank is then measured for flatness, roundness or perpendicular structure in a measuring devise having supports and probes. Signals from the probes are analyzed to determine whether the parameters of concern are within tolerance.

Owner:BURGESS NORTON MFG

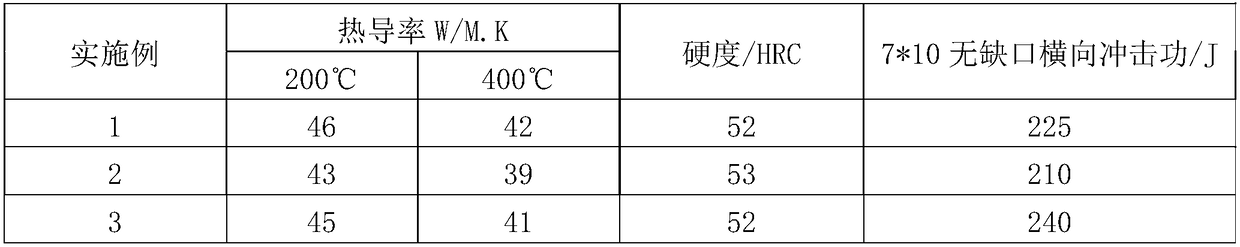

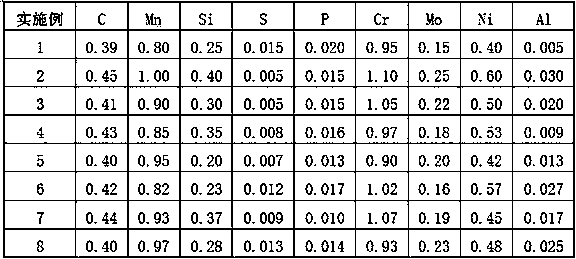

Ultra-high thermal conductivity hot stamping die steel and manufacturing method thereof

InactiveCN108774712AHigh thermal conductivityGuaranteed mechanical propertiesHot stampingStress relief

The invention relates to an ultra-high thermal conductivity hot stamping die steel and a manufacturing method thereof, the ultra-high thermal conductivity hot stamping die steel comprises the following alloy elements by mass: 0.40-0.50% of C;<=0.30% of Si;<=0.30% of Cr; 0.80-1.5% of Mn; 0.80-1.50% of Ni; 1.30-2.0% of Mo; 1.30-2.0% of V; trace amount of B; and balance of Fe and others unavoidable impurities. The manufacturing method comprises electric furnace smelting + vacuum refining + electroslag remelting, electroslag ingots with uniform composition can be smelted, stress relief annealing of the electroslag ingots is performed; forging forming is performed, then water cooling and spheroidizing annealing are performed after the forging forming; and finally, high temperature quenching andmultiple times of high temperature tempering are used to obtain the hot stamping die steel with excellent impact toughness, tempering stability and high thermal conductivity.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

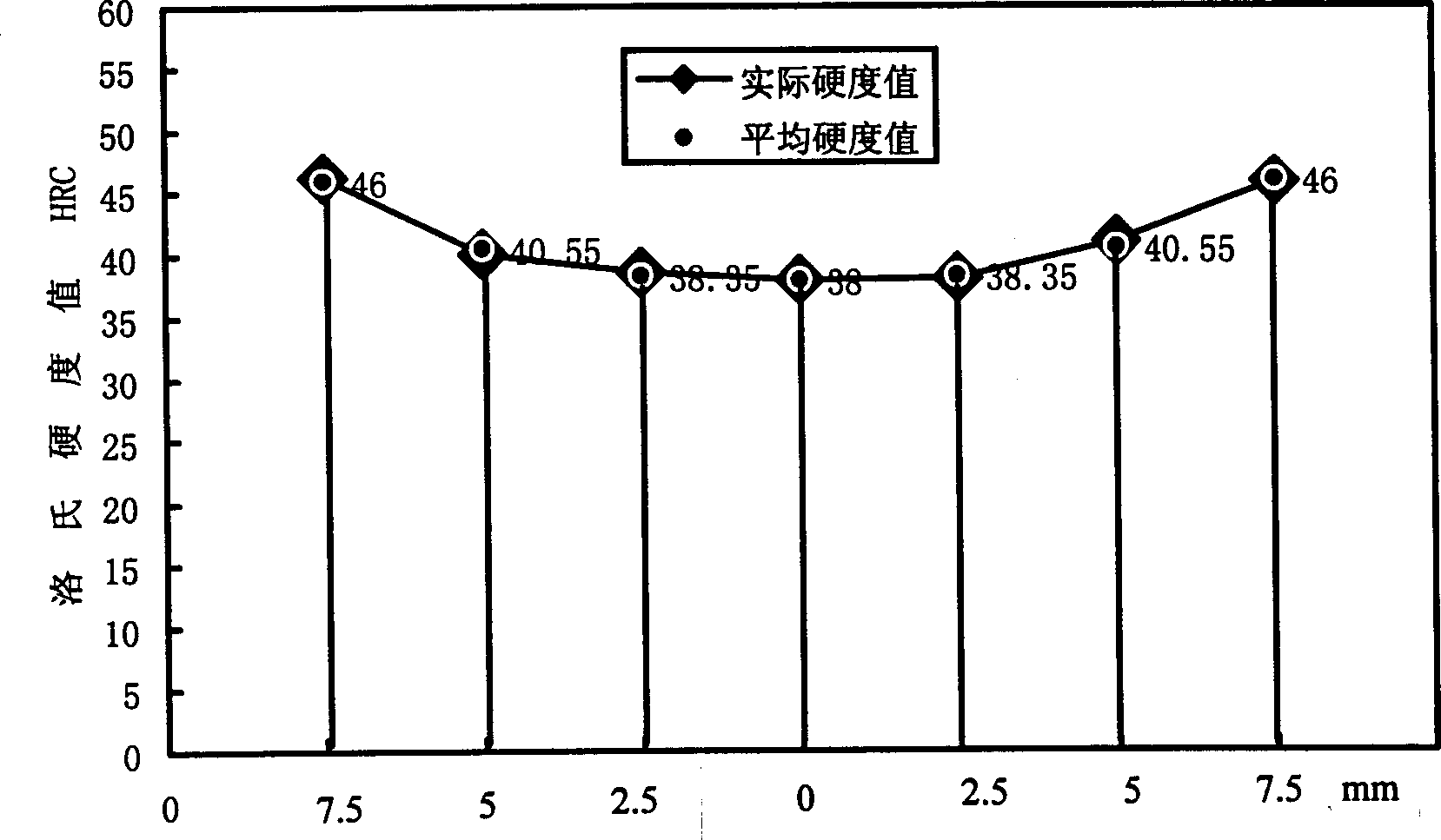

Nickel-added high-polishing pre-hardened plastic mold steel plate and production method thereof

The invention discloses a nickel-added high-polishing pre-hardened plastic mold steel plate and a production method thereof. The steel plate is prepared from the chemical components of, by mass, 0.39-0.45% of C, 0.80-1.00% of Mn, 0.20-0.40% of Si, less than or equal to 0.015% of S, less than or equal to 0.020% of P, 0.90-1.10% of Cr, 0.15-0.25% of Mo, 0.40-0.60% of Ni, 0.005-0.030% of Al, and thebalance being iron and unavoidable impurities. The production method includes the processes of converter smelting, LF furnace refining, RH vacuum refining, continuous casting slab, controlled rollingand controlled cooling and high temperature tempering heat treatment. Through the component design of adding nickel and the processes of controlled rolling and controlled cooling and high temperaturetempering heat treatment, pre-hardened plastic mold steel is obtained, and the steel has the characteristics of excellent polishing performance and simple production processes.

Owner:TANGSHAN HEAVY PLATE CO LTD +2

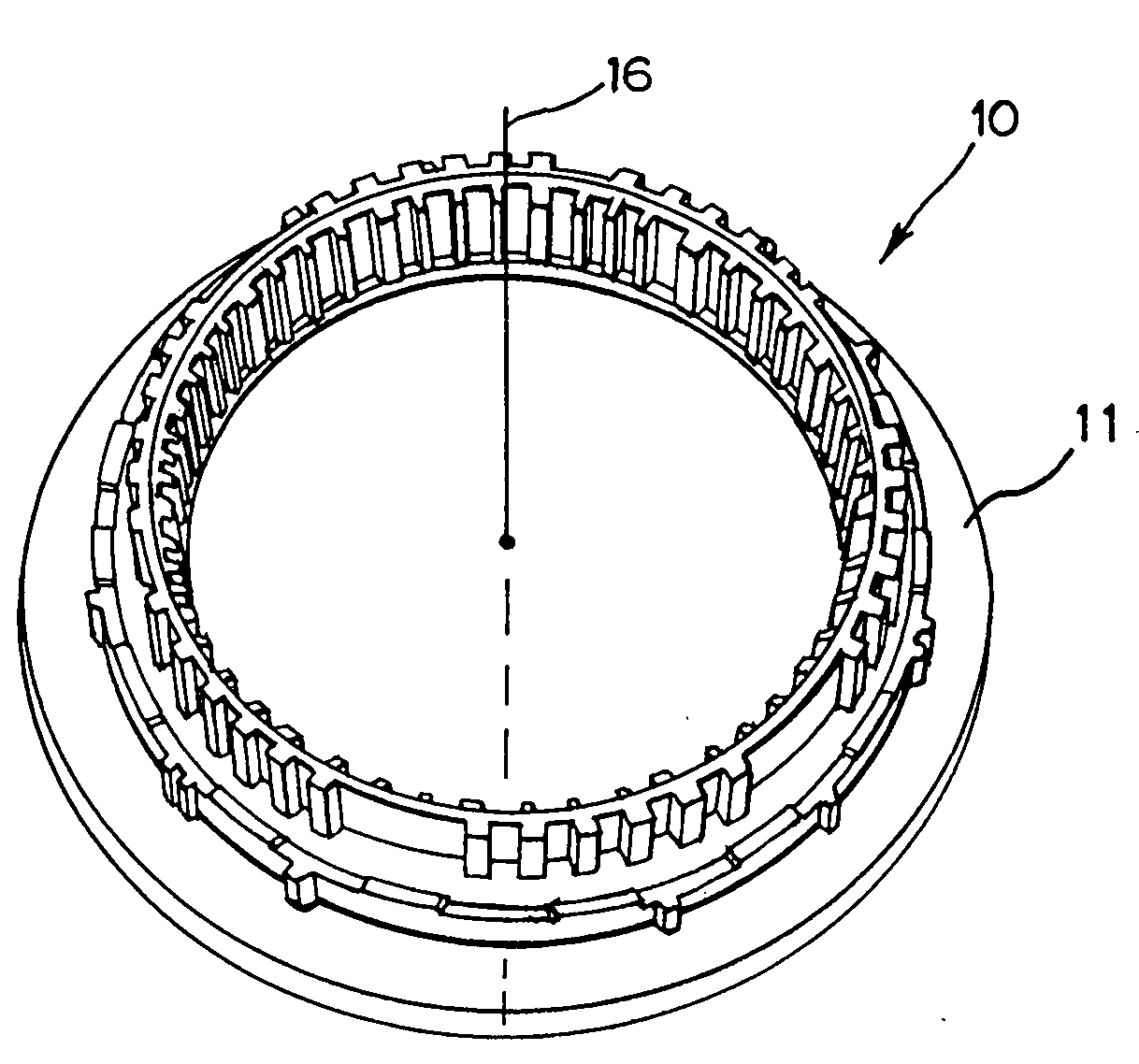

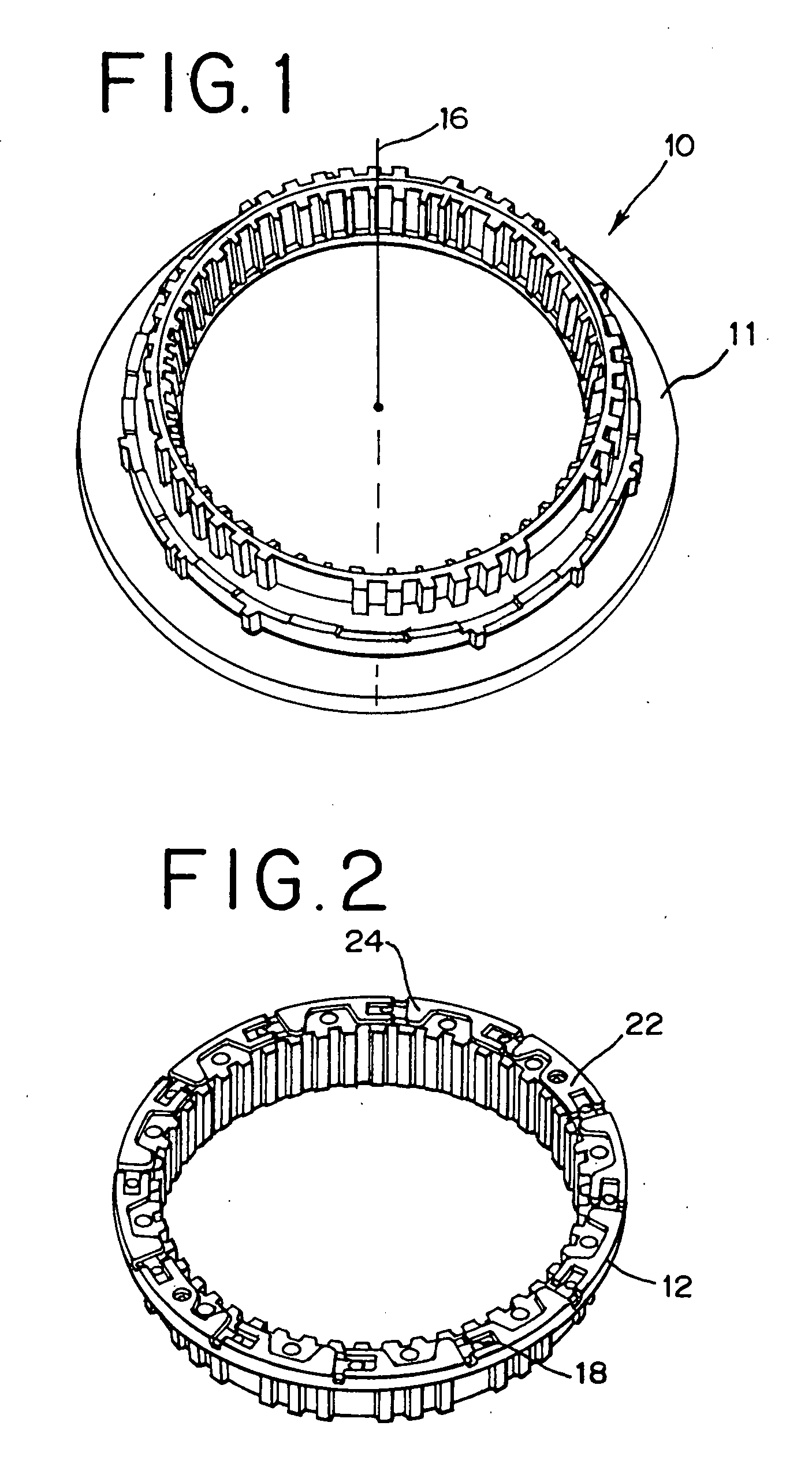

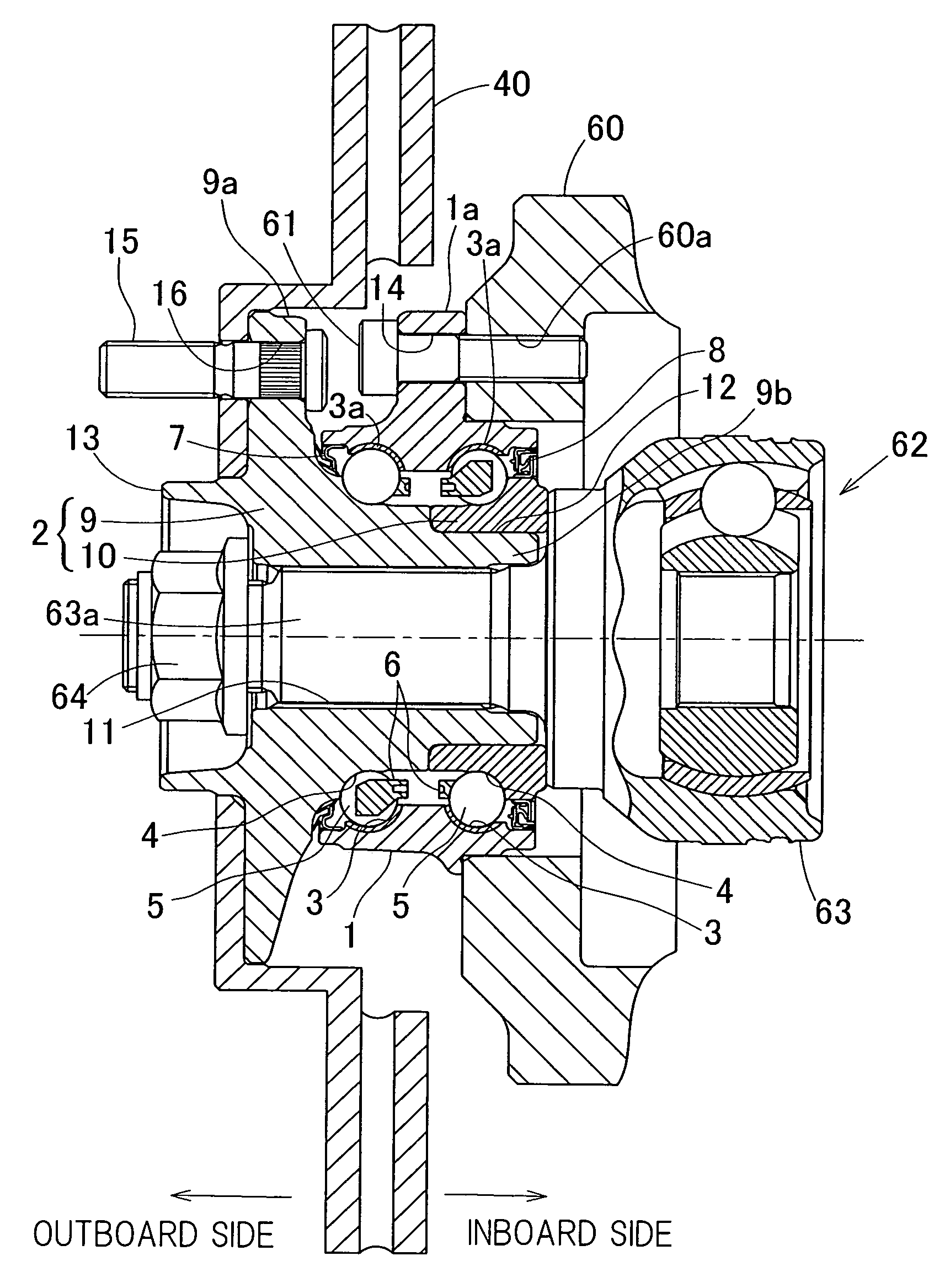

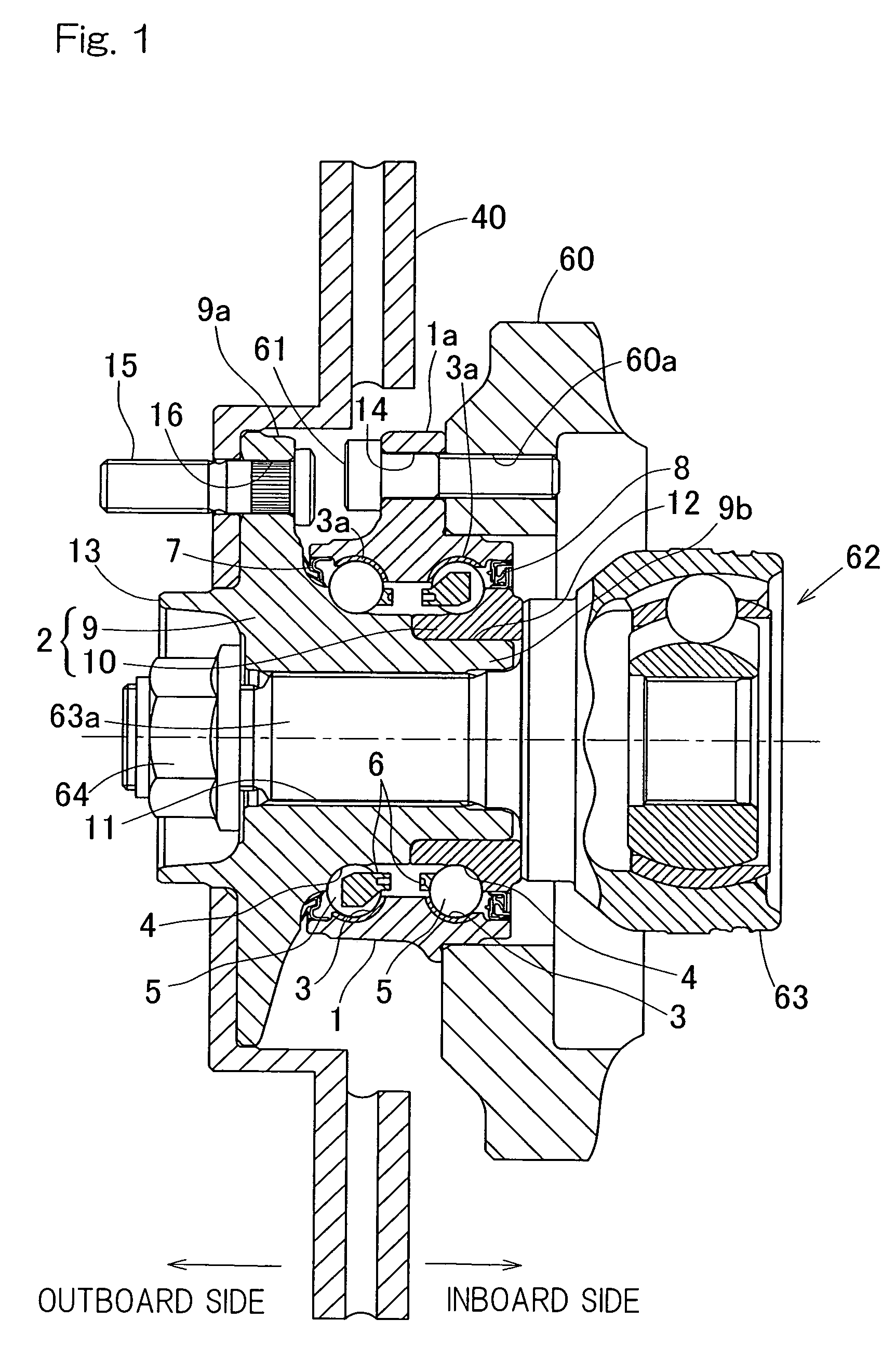

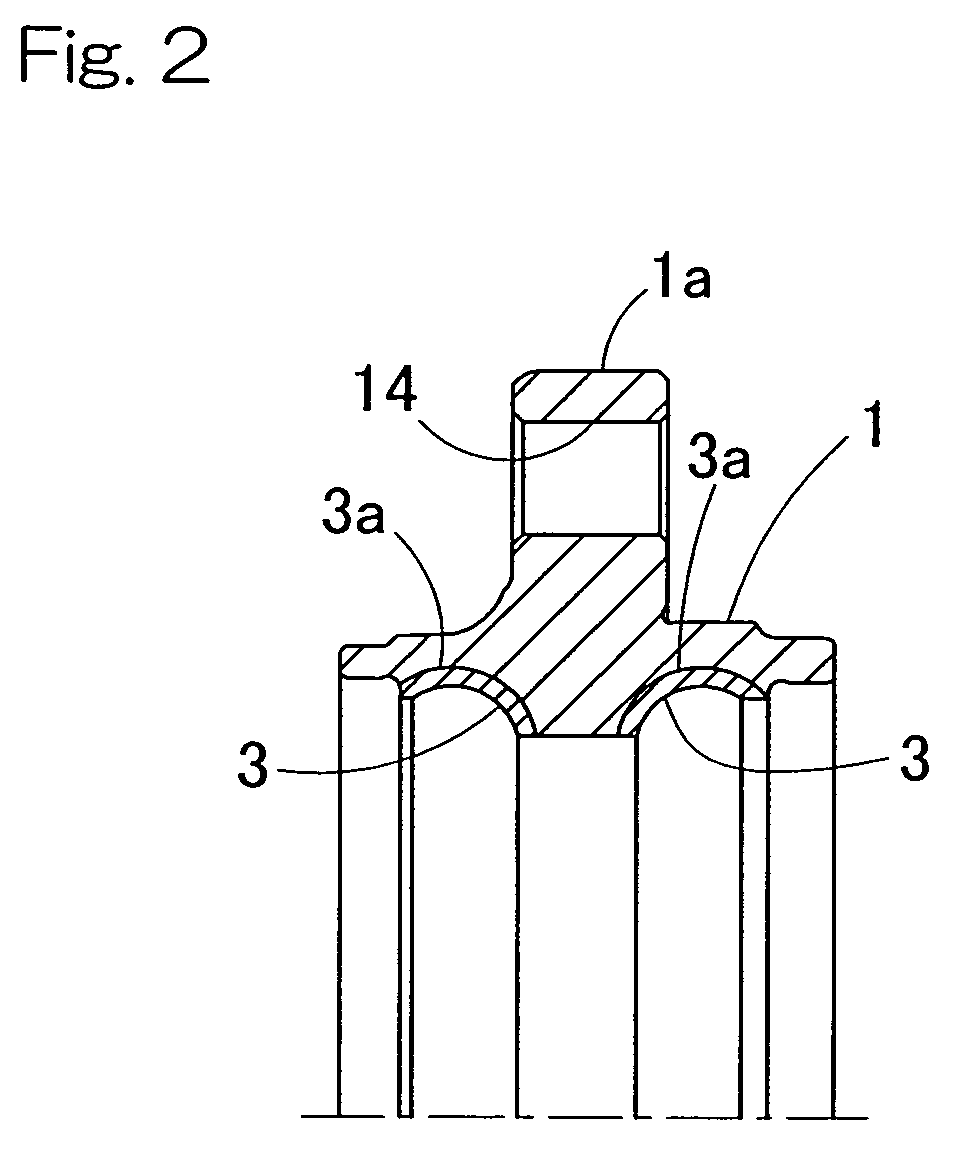

Wheel support bearing assembly

A wheel support bearing assembly includes an outer member (1), which serves as a stationary member and has an inner periphery formed with a plurality of rows of raceway surfaces (3), an inner member (2), which serves as a rotatable member and has an outer periphery formed with respective raceway surfaces (4) opposed to the previously described raceway surfaces (3), and a plurality of rows of rolling elements (5) interposed between the respective opposed raceway surfaces (3, 4). The outer member (1) is thermally refined by means of a quenching and a high temperature tempering process so that a layer of at least 2 mm in depth from a surface of the outer member is rendered to have a micro-pearlite structure.

Owner:NTN CORP

Solder wire material for stainless steel

InactiveCN101318271AReduce hardenabilityImprove the size of inclusionsWelding/cutting media/materialsSoldering mediaChemical compositionWeld seam

The invention discloses a welding wire material for stainless steels and the weight percentage of the concrete chemical compositions of the welding wire material is as follows: C, 0.07 to 0.09; Si, 0.65 to 0.95; Mn, 6.7 to 7.2; P, less than or equal to 0.02; S, less than or equal to 0.015; Cr, 18.5 to 19.5; Ni, 8.0 to 9.5; Mo, less than or equal to 0.4; the remaining is Fe and inevitable impurities. The welding wire material is used for 304 austenitic stainless steels, and welding seams are smooth after the welding is performed and metals at the welding seams have the similar performance as mother metal, no black skin exists and the cost is low.

Owner:JIANGSU XINGHAI SPECIAL STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com