Low-Sc high-strength high-toughness high-hardenability aluminum-zinc-magnesium alloy and preparation method thereof

A high-strength, high-toughness, and high-hardenability technology, applied in the field of aluminum alloy preparation, can solve the problems of reduced alloy hardenability, low limit of hardenability, and high price, so as to reduce adverse effects, reduce manufacturing costs, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) The chemical composition of the alloy is shown in Table 1.

[0041] Chemical composition (mass fraction, %) of table 1 alloy

[0042]

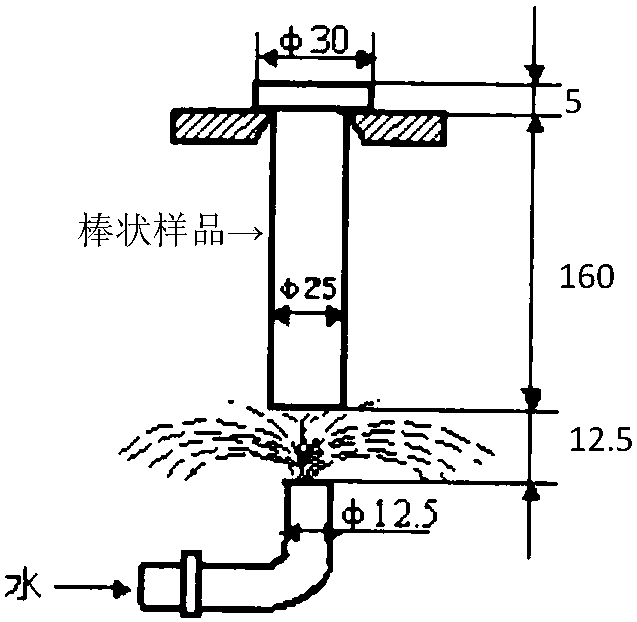

[0043] (2) Add aluminum ingots, Al-Cu, Al-Mn, Al-Zr, Al-Cr into the melting furnace at a temperature of 720-740 ° C to melt according to the content required in Table 1; when the temperature of the molten aluminum rises to 800 ° C, add Al-Sc master alloy, stirring, heat preservation; when the melt is 720°C, add Zn, Al-Ti, and Mg; slag removal, stirring, composition adjustment, refining; stand still for 30 minutes.

[0044] (3) The melt is refined and degassed and left to stand for semi-continuous casting into ingots. The casting temperature is 720°C, the water pressure is 0.14MPa, and the casting speed is 35mm / min.

[0045] (4) Homogenize the above-mentioned ingot for 8 hours at a temperature of 340° C., and air-cool; then homogenize the ingot for 20 hours at a temperature of 465° C. After the homogenization treatment, the ingot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com