Manufacture and measuring of automotive components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

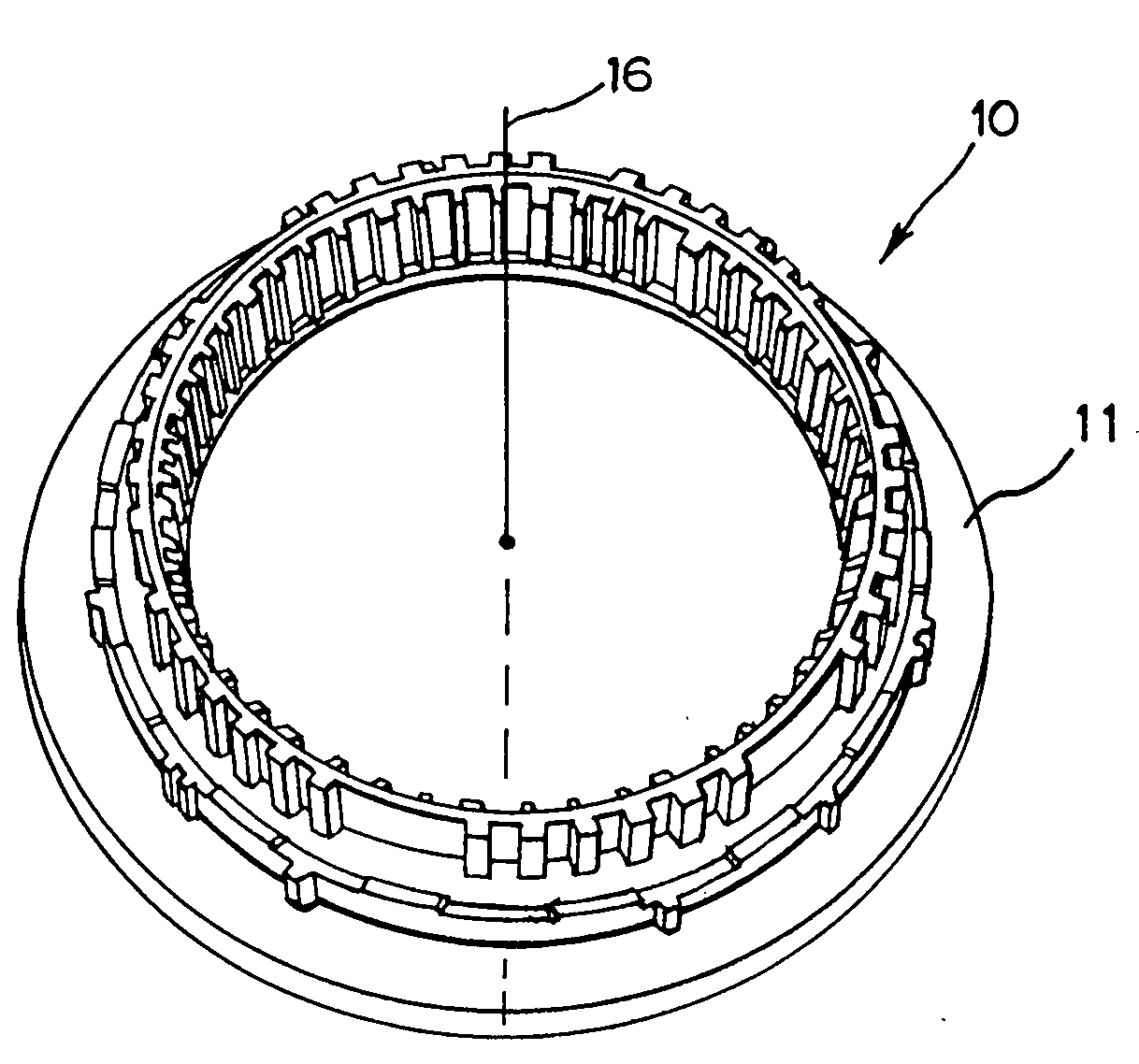

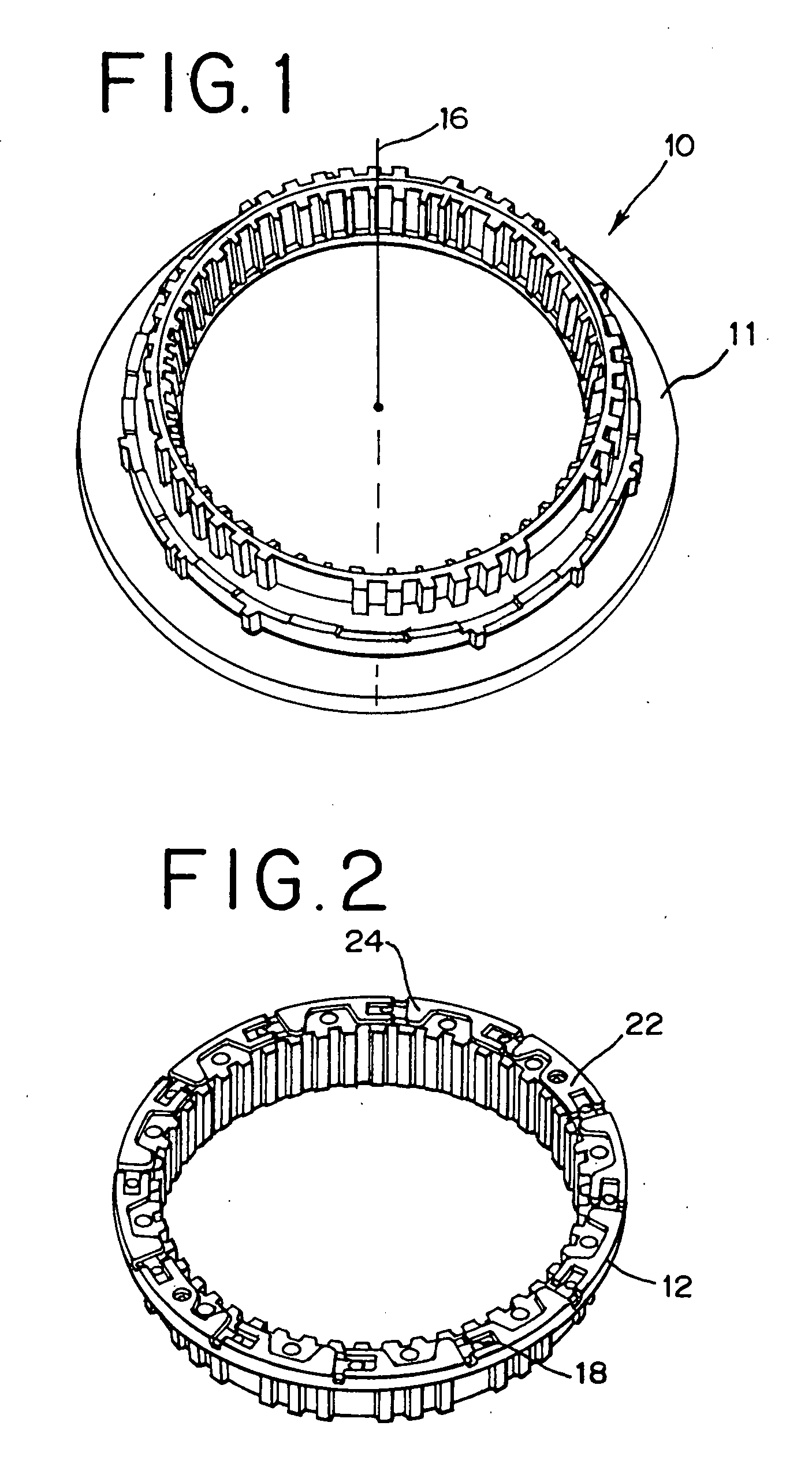

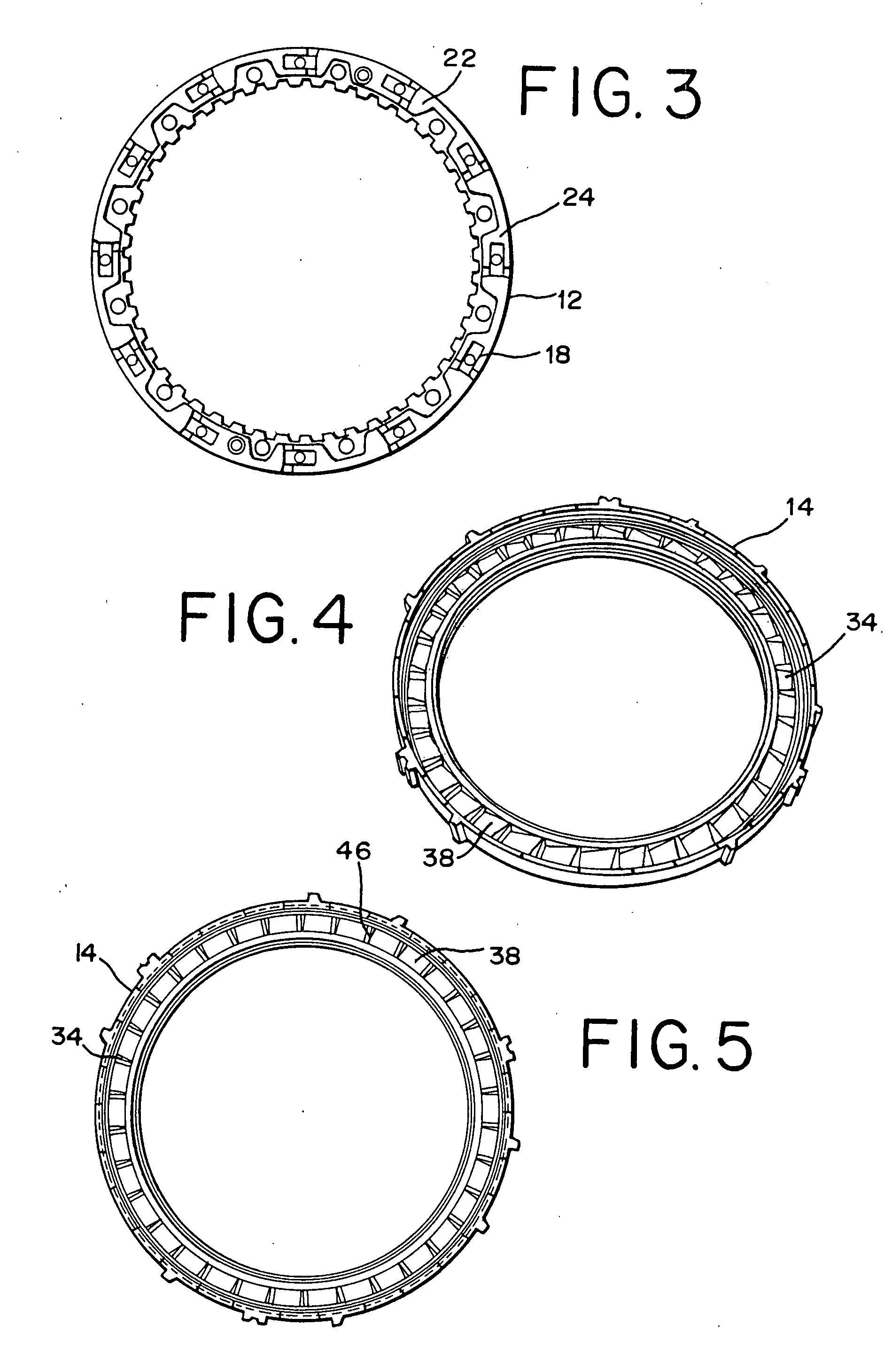

Image

Examples

example 1

[0033]In a method of manufacturing an automotive clutch component, an initial pre alloy metal powder of particle sizes between 250 and 1 micron was provided comprising, by weight, 0.45% nickel, 0.65% molybdenum, with the balance essentially iron.

[0034]An additional 0.7% graphite, and 1.75% copper metal powder of particle sizes between 150 and 1 micron, by weight, were admixed to form an admixed metal powder.

[0035]0.5% EBS was added as a lubricant to form a lubricated admixed metal powder.

[0036]The lubricated, admixed metal powder was compacted at a pressure of 45 tons per square inch.

[0037]The die compacted metal blank was then placed on a machined flat ceramic support and sintered at a temperature 2050° F. for 15 minutes.

[0038]The sintered metal blank was then quenched while on the ceramic support metal blank at a rate of 5.4° F. (3.00° C.) per second from an initial temperature of (2000° F.) (1090° C.) to a temperature of (500° F.) (260° C.) per use. The quenched was then tempered...

example 2

[0041]In a method of manufacturing an automotive clutch component, an initial pre alloy metal powder of particle sizes between 250 and 1 microns was provided comprising, by weight, 0.45% nickel, 0.65% molybdenum, with the balance essentially iron.

[0042]An additional 0.9% graphite, and 1.75% copper metal powder of particle size between 150 and 1 micron, by weight, were admixed to form an admixed metal powder.

[0043]0.5% EBS was added as a lubricant to form a lubricated admixed metal powder.

[0044]The lubricated, admixed metal powder was compacted at a pressure of 45 tons per square inch.

[0045]The die compacted metal blank was then placed on a ceramic support and sintered at a temperature 2050° F. for 15 minutes.

[0046]The sintered metal blank was then quenched while on the ceramic support at a rate of 1.9° F. (1.05° C.) per second from an initial temperature of (2000° F.) (1090° C.) to a temperature of (500° F.) (260° C.) per use. The quenched metal blank was then tempered at a temperat...

example 3

[0049]In a method of manufacturing an automotive clutch component, an initial pre alloy metal powder of particle size between 250 and 1 micron was provided comprising, by weight, 0.45% nickel, 0.65% molybdenum, with the balance essentially iron.

[0050]An additional 0.9% carbon, and 1.75% copper metal powder of particle size between 150 and 1 micron, by weight, were admixed to form an admixed metal powder.

[0051]0.5% EBS was added as a lubricant to form a lubricated admixed metal powder.

[0052]The lubricated, admixed metal powder was compacted at a pressure of 45 tons per square inch.

[0053]The die compacted metal blank was then placed on a machined flat ceramic support and sintered at a temperature 2050 for 15 minutes.

[0054]The sintered metal blank was then quenched while on the ceramic support at a rate of 1.9° F. (1.0° C.) per second from an initial temperature of (2000° F.) (1090° C.) to a temperature of (500 ° F.) (260° C.) per use. The quenched metal blank was then tempered at a te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com