Patents

Literature

623results about How to "Uniform hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

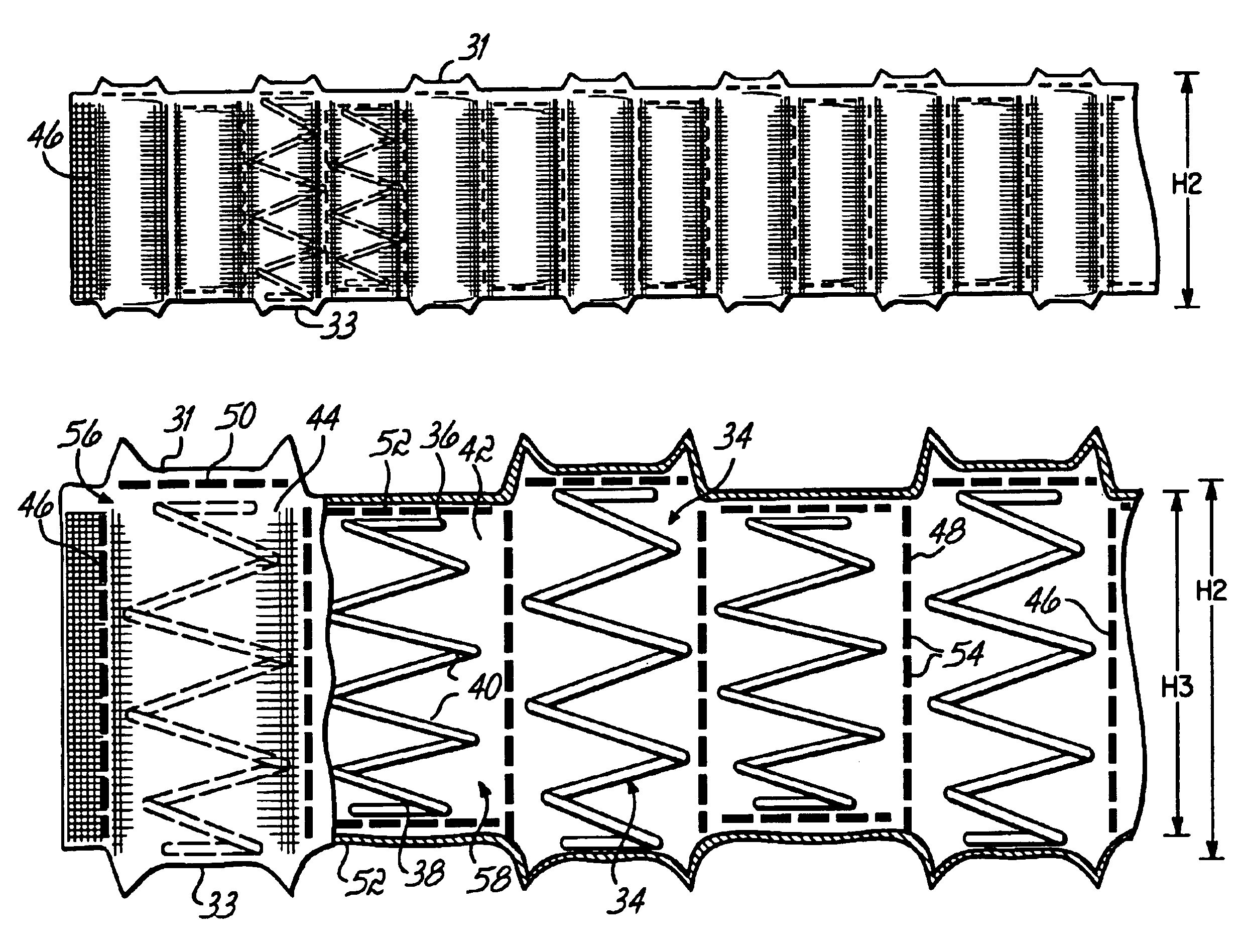

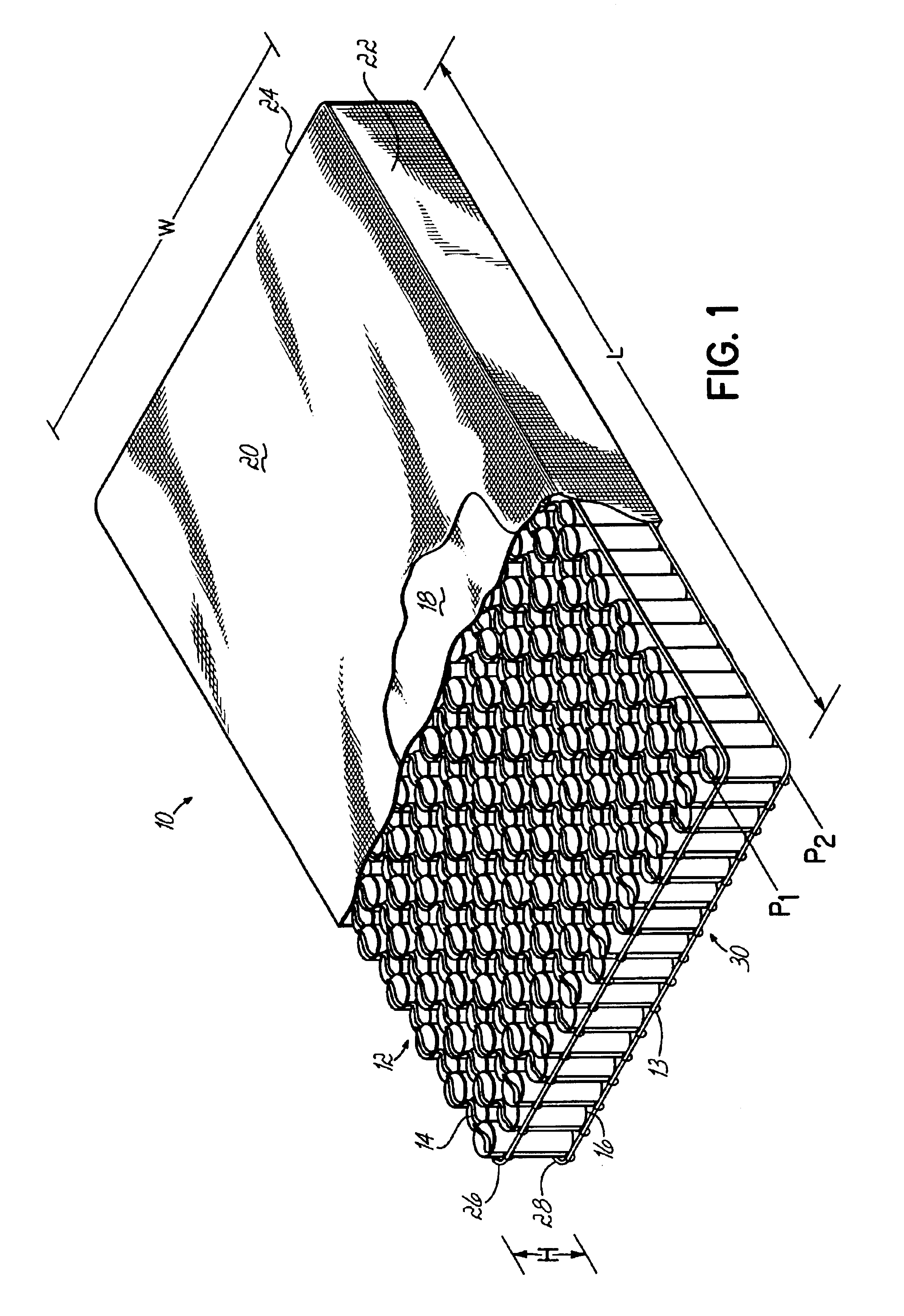

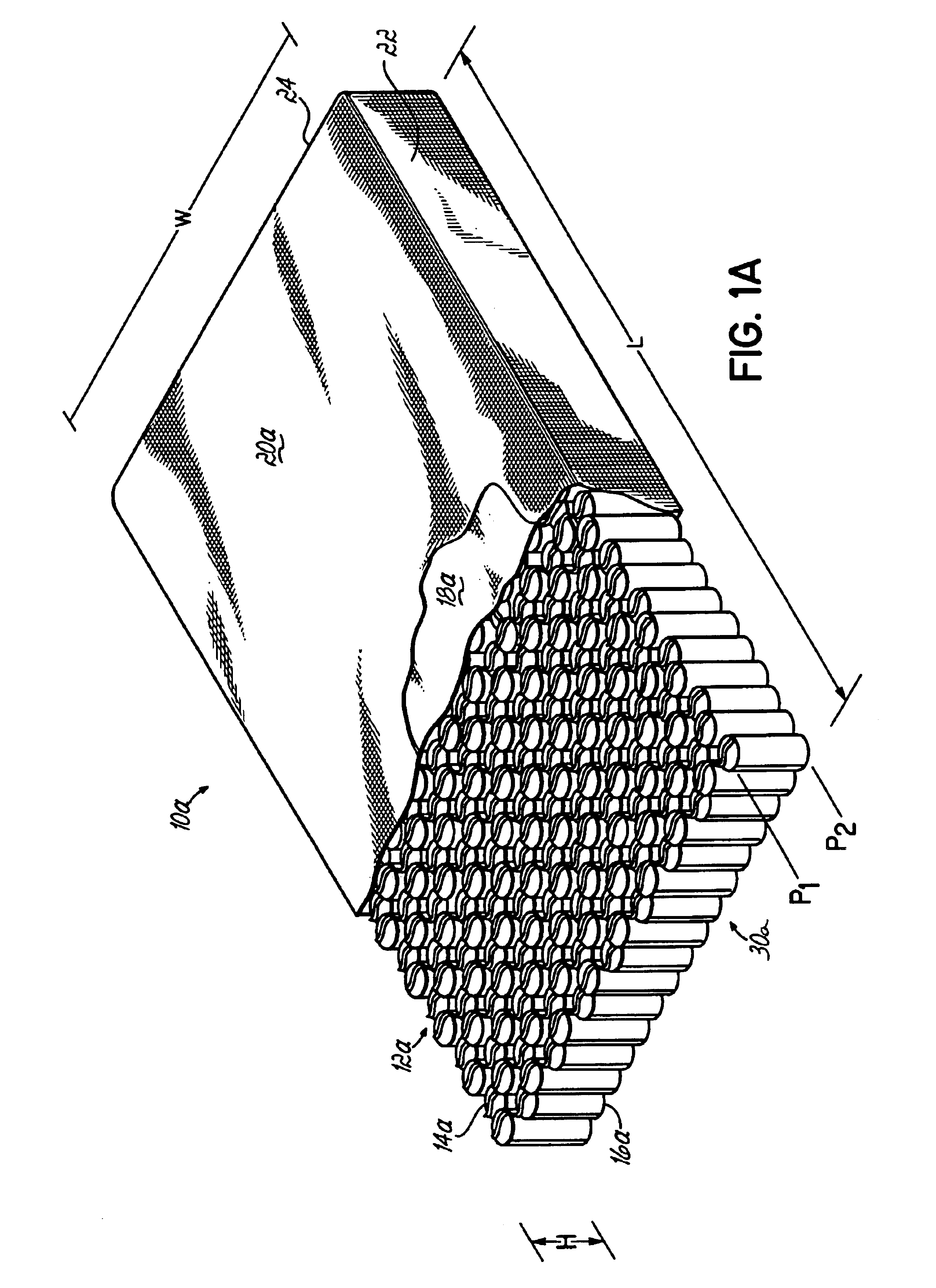

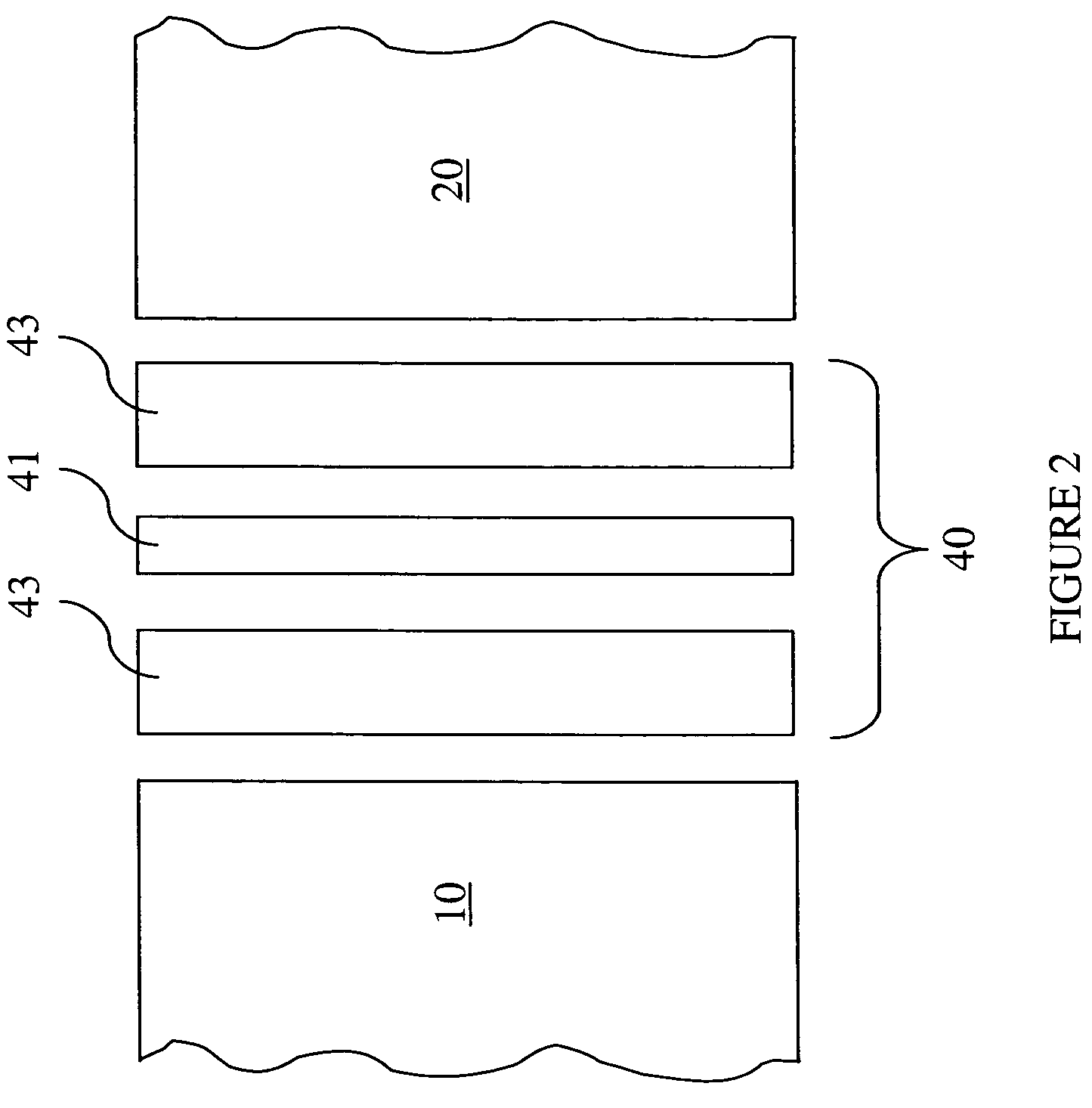

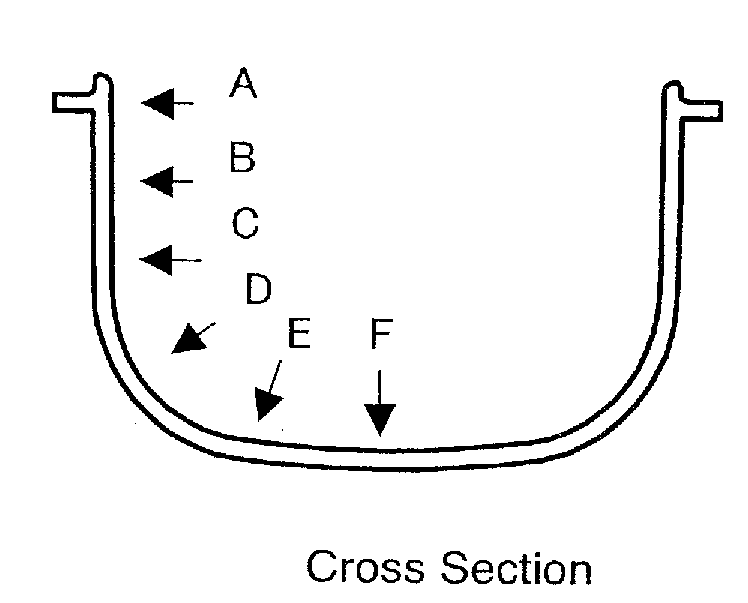

Pocketed bedding or seating product having pockets of differing heights

InactiveUS6862763B2Impart different firmnessUniform hardnessUpholstery manufactureStuffed mattressesEngineeringCoil spring

A bedding or seating product comprising a spring assembly made up of a plurality of parallel strings of springs joined to each other. Each of the strings of springs comprises a row of interconnected pocketed coil springs. Selected pockets of fabric are shorter than adjacent pockets, so coil springs in the selected pockets are under a greater load than adjacent coil springs. In one preferred embodiment, every other pocket is under a greater load than the adjacent pockets, resulting in a checkerboard arrangement in at least one area of the product.

Owner:L & P PROPERTY MANAGEMENT CO

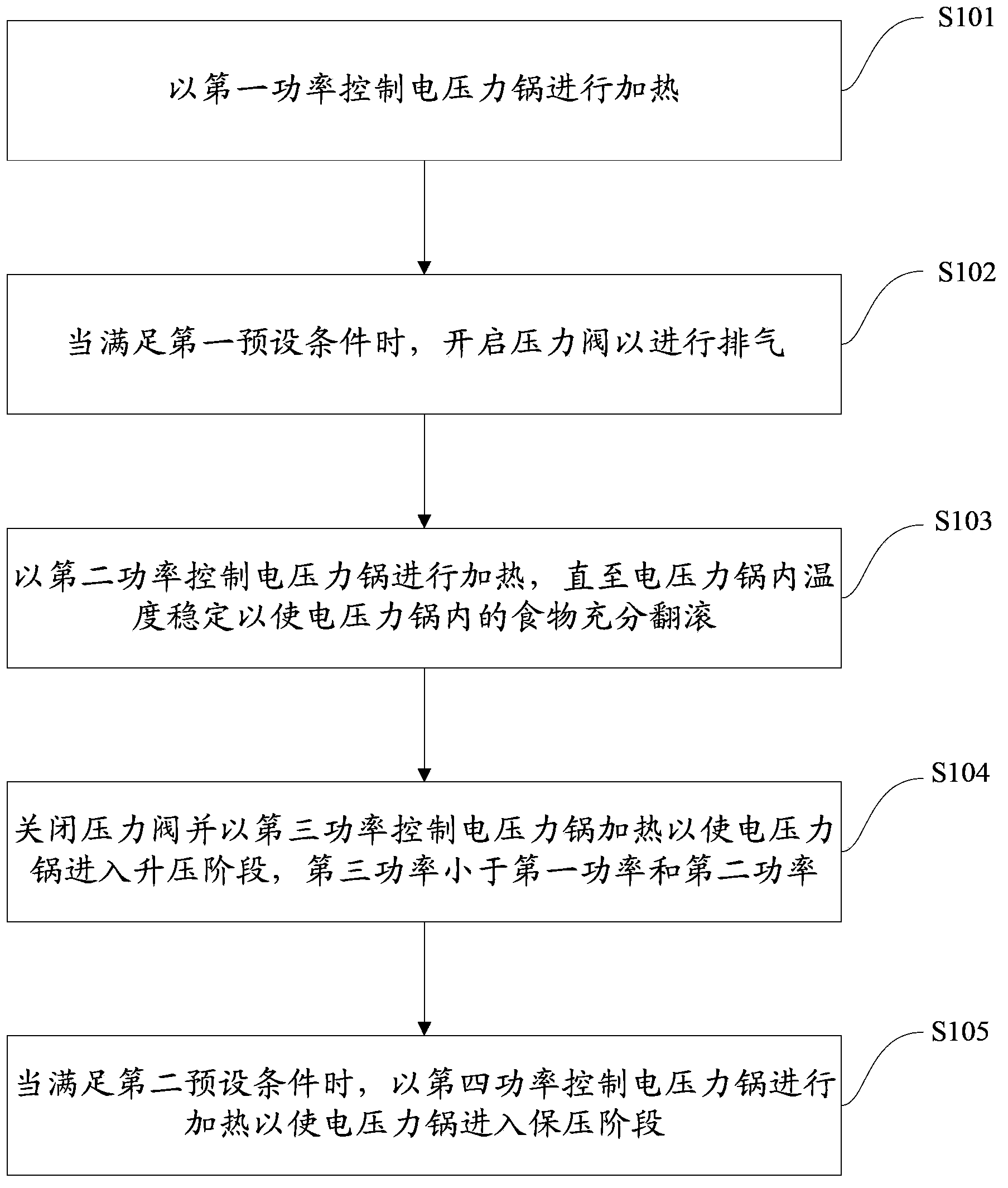

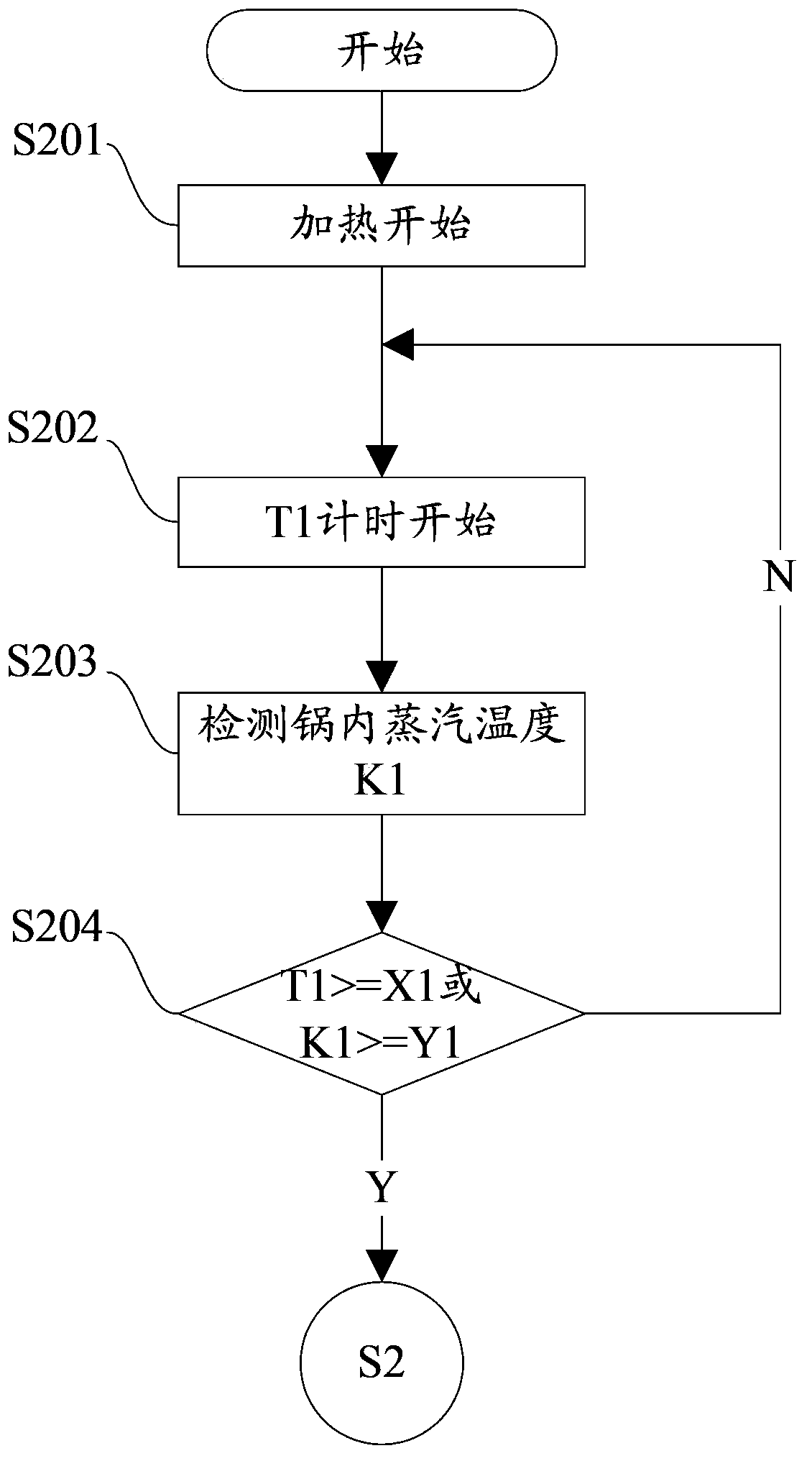

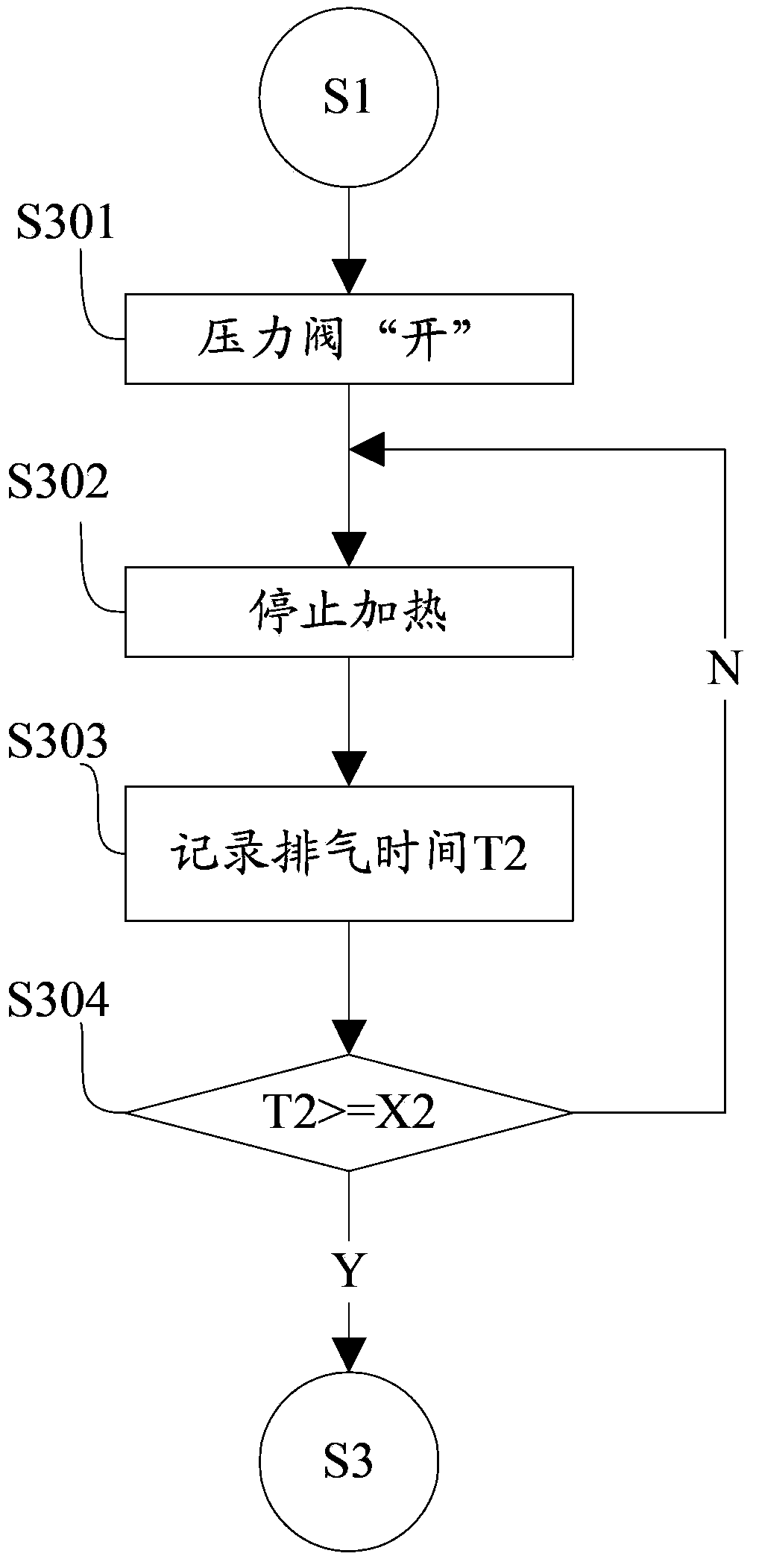

Electric pressure cooker control method and electric pressure cooker

ActiveCN103654373AUniform surface hardnessSufficient flexibilityPressure-cookersEngineeringCooked food

The invention provides an electric pressure cooker control method which comprises the following steps that an electric pressure cooker is controlled to heat with first power; when a first preset condition is met, a pressure valve is opened, so that air is discharged; the electric pressure cooker is controlled to heat with second power until the temperature in the electric pressure cooker is stable and food in the electric pressure cooker is made to be turned over completely; the pressure valve is closed and the electric pressure cooker is controlled to heat with third power, so that the electric pressure cooker enters a boosting stage, and the third power is smaller than the first power and the second power; when a second preset condition is met, the electric pressure cooker is controlled to heat with fourth power, so that the electric pressure cooker enters a pressure maintaining stage. According to the electric pressure cooker control method, the cooked food is complete, moisture is sufficient, the hardness is even, the taste is good, and the cooked food is prevented from pasting the bottom of the cooker and overflowing out of the cooker. The invention further provides the electric pressure cooker.

Owner:MIDEA GRP CO LTD

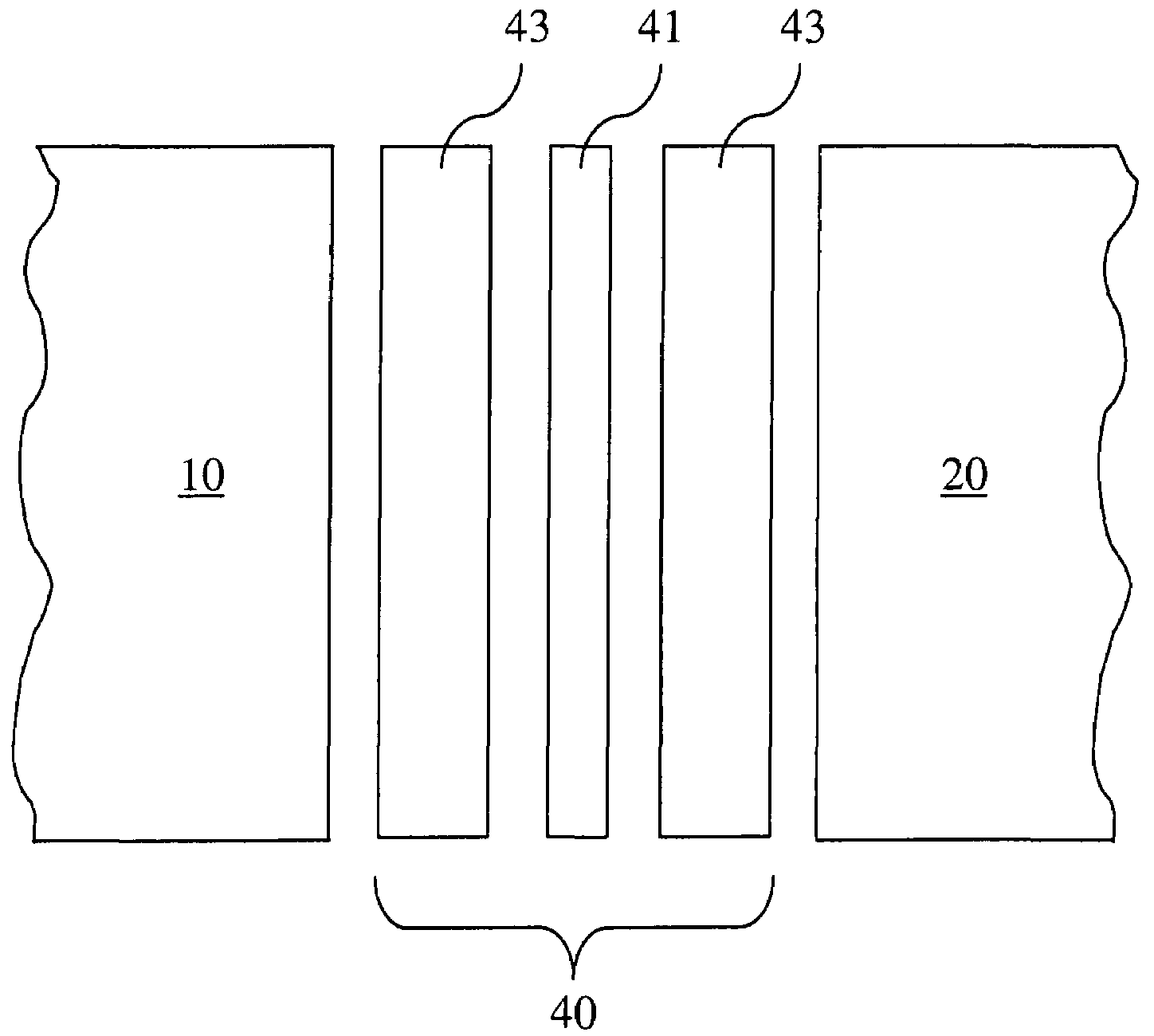

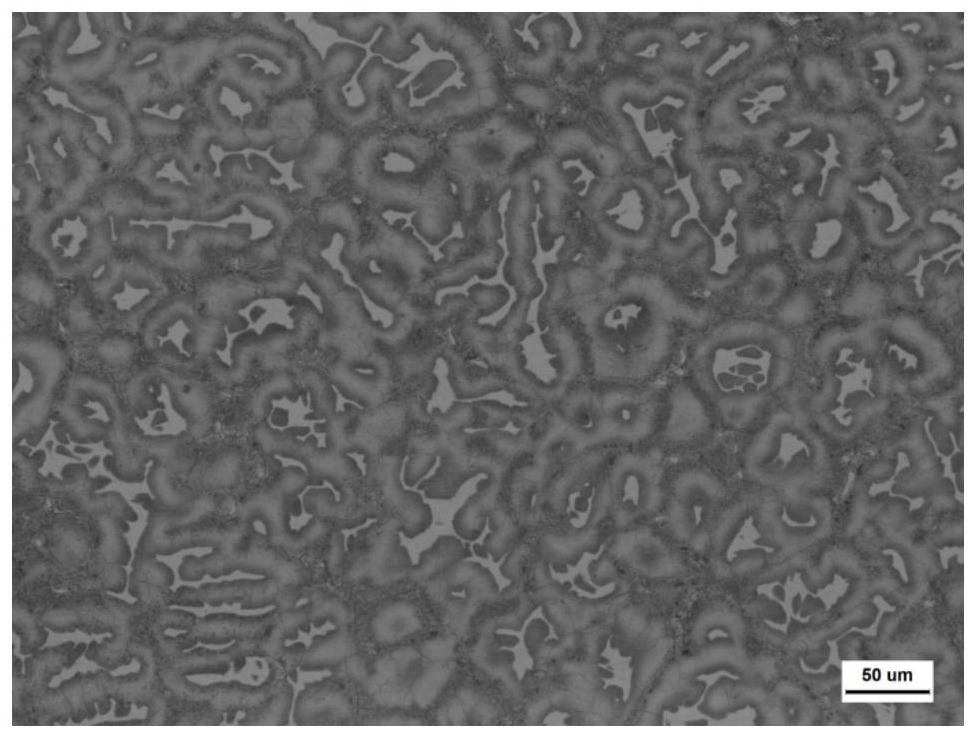

Transient liquid phase bonding using sandwich interlayers

ActiveUS7565996B2Strong and more bondFiner microstructuresTurbinesWelding/cutting media/materialsEngineeringSingle crystal

Systems and methods for transient liquid phase bonding are described herein. Embodiments of these systems and methods utilize sandwich interlayers to produce stronger, more homogeneous bonds than currently possible. These sandwich interlayers have a middle bonding layer sandwiched between two outer bonding layers. The middle bonding layer is a different composition, and may even be a different form, than the outer bonding layers. In embodiments, these sandwich interlayers may be used to join a single crystal material to a polycrystalline material to make a gas turbine engine component, such as an integrally bladed rotor.

Owner:RTX CORP

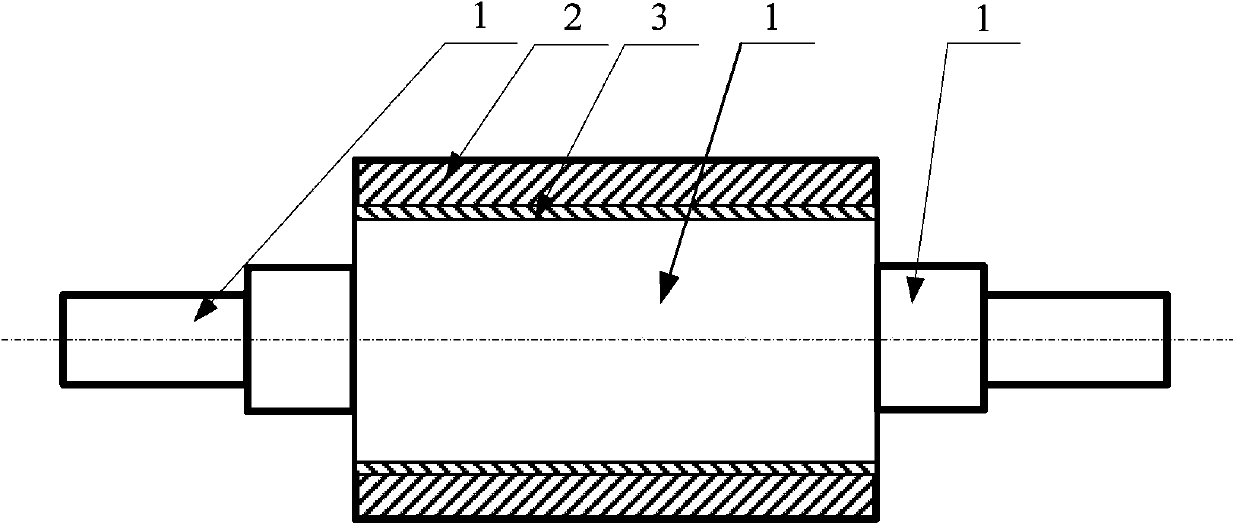

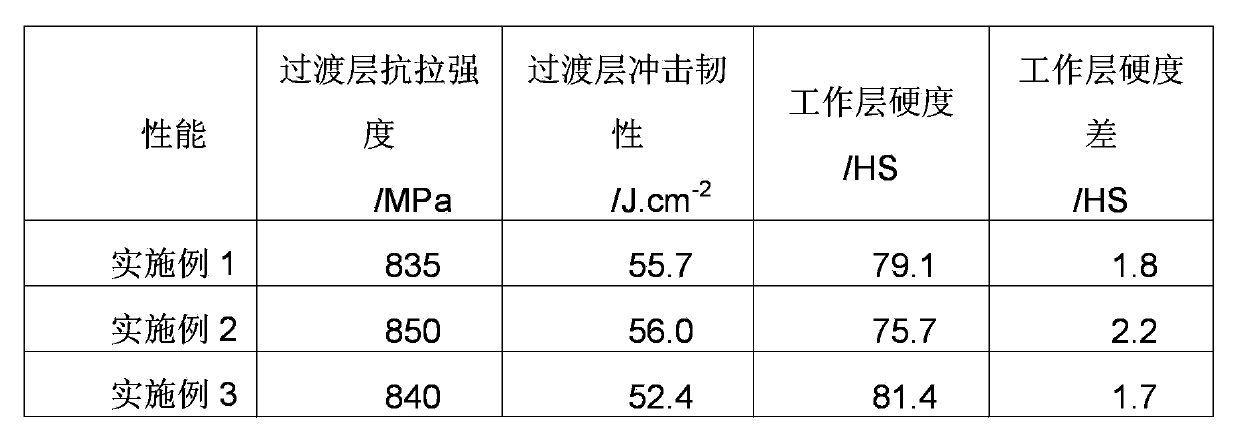

Overlaying repair method for worn roller

InactiveCN103418923AUniform hardnessHigh hardnessWelding/cutting media/materialsSoldering mediaWear resistantToughness

The invention discloses an overlaying repair method for a worn roller. The method is characterized by comprising the following process steps of turning the worn surface of the worn roller; overlaying a high-toughness transition layer on the turned surface; overlaying a wear-resistant working layer on the transition layer; performing heat treatment on the roller subjected to overlaying repair; and performing finish machining on the roller to enable the roller to reach the specified dimension and precision. Compared with the past production and manufacture process and production method, the production and manufacture cost is relatively low, the production and manufacture period is relatively short, and the roller subjected to overlaying repair is long in service life.

Owner:BEIJING UNIV OF TECH

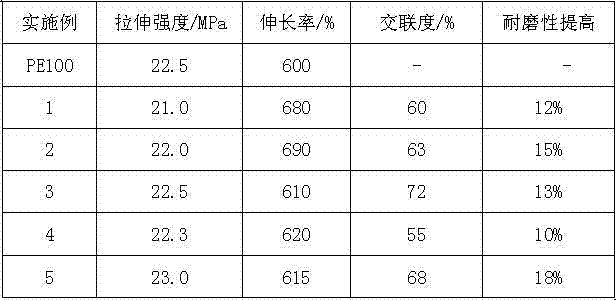

Wear-resistant crosslinked PE (Polyethylene) composite pipe and manufacturing method thereof

The invention relates to a wear-resistant crosslinked PE (Polyethylene) composite pipe and a manufacturing method thereof, belonging to the technical field of PE pipes. The composite pipe is obtained by fusing, extruding and pelletizing 100 parts of PE, 1-3 parts of scratch-resisting agent, 0-10 parts of carbon fiber, 0-5 parts of elastomer, 0.05-0.2 part of antioxidant, 0.2-1 part of crosslinkedaccelerating agent and 0.5-1 part of lubricating agent with double screws, performing vacuum drying, spraying a silane crosslinking agent and extruding by an extruder. By adopting a chemical modification method, the connection of a PE molecular chain is enhanced, a three-dimensional network structure is formed, and the creep resistance and surface solid particle impact resistance of a material are enhanced. By adopting a physical modification technology, the scratch-resisting agent and a reinforcing agent are compounded in a PE material, a PE crosslinked composite material with balanced toughness, strength and hardness is obtained, the wear resistance, heat resistance, tensile strength and elongation percentage of PE are enhanced, and the PE pipe is suitable for conveying powder, solid particles and slurry and has wide market prospect.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD

Preparation method of wear-resistant coating for high-accuracy roller piece

The invention relates to a preparation method of a wear-resistant coating for a high-accuracy roller piece. In the invention, a nickel-based (or cobalt-based) prefabricated layer is prepared by using a supersonic flame spraying process, and the prefabricated layer is treated by adopting an induction heating method, so that the bonding intensity between the coating and a substrate is enhanced. Thewear-resistant coating is prepared by adopting a composite surface treatment technology, so that a workpiece is prevented from being deformed in the machining process, the prepared coating is dense and crackless and has uniform hardness and high binding intensity, and the surface wear resistance and impact resistance of the workpiece are enhanced; and moreover, a preparation technology has the advantages of simple process, high cladding efficiency, low machining cost and the like. After machining, the binding intensity between the coating and the substrate is more than or equal to 70 MPa, andthe hardness of the coating can be up to HRB 55-70 by adjusting the adding amount of solid-phase wolfram carbide (WC) in spraying powder. The preparation method can be widely applied to the preparation of surface reinforced layers for industrial components with severe working conditions, such as high-frequency friction pairs, papermaking rollers, pumping rods, loops and the like.

Owner:BGRIMM ADVANCED MATERIALS SCI & TECH +1

Wearproof and tough quasi bainite points and rails and their production

A high-strength and high-toughness antiwear quasi-bainite rail for switch contains C (0.1-0.4 wt.%), Si (0.8-2.0), Mn (0.8-3.3), Cr (0-2.0), Mo (0.1-0.8), N (10-150 ppm), Al (0-0.005) and Fe (rest), and is made up through smelting in converter, reinfing, treating with RE, vacuum degassing, conticasting, rolling, air cooling to 400 deg.C, slow cooling to 200 deg.C and natural cooling. Its advantages are uniform hardness in cross section, high strength, toughness and stability, and high antiwear performance.

Owner:ANGANG STEEL CO LTD +1

CO2 gas protection welding process of 800 MPa high-strength steel

InactiveCN102179601AUniform strengthUniform hardnessArc welding apparatusWelding/cutting media/materialsThumb oppositionOperability

The invention discloses a CO2 gas protection welding process of 800 MPa high-strength steel. The CO2 protection welding process is characterized by comprising the following steps of: (1) machining a joint: machining an X-shaped groove on the joint; (2) using a solid welding wire with the diameter of 1.2 mm and the tensile strength of 800 MPa, wherein the solid welding wire comprises the following chemical components in percentage by weight: 0.04-0.10% of C, 0.30-0.80% of Si, 1.30-2.0% of Mn, 0.40-1.0% of Ni, 0.20-0.50% of Cr, 0.20-0.60% of Mo, 0.30-0.80% of Cu, 0.05-0.20% of Ti, 0.002-0.010% of B, less than and equal to 0.020% of P, less than and equal to 0.015% of S, less than and equal to 0.03% of Als, and the balance of Fe and inevitable impurities; (3) setting a welding mode: adopting CO2 gas protection welding and a DC power supply opposition method; and (4) welding: carrying out one-side welding with back formation on a first welding line, and then carrying out multilayer multipass welding, wherein interlayer temperature is less than and equal to 160 DEG C. The invention has the advantages of simple process, high operability and low welding energy consumption and welding cost and can be widely used for the technical fields of the gas protection welding of the high-strength steel.

Owner:武钢集团有限公司

Steel with excellent processing performance for gardening tool and production method thereof

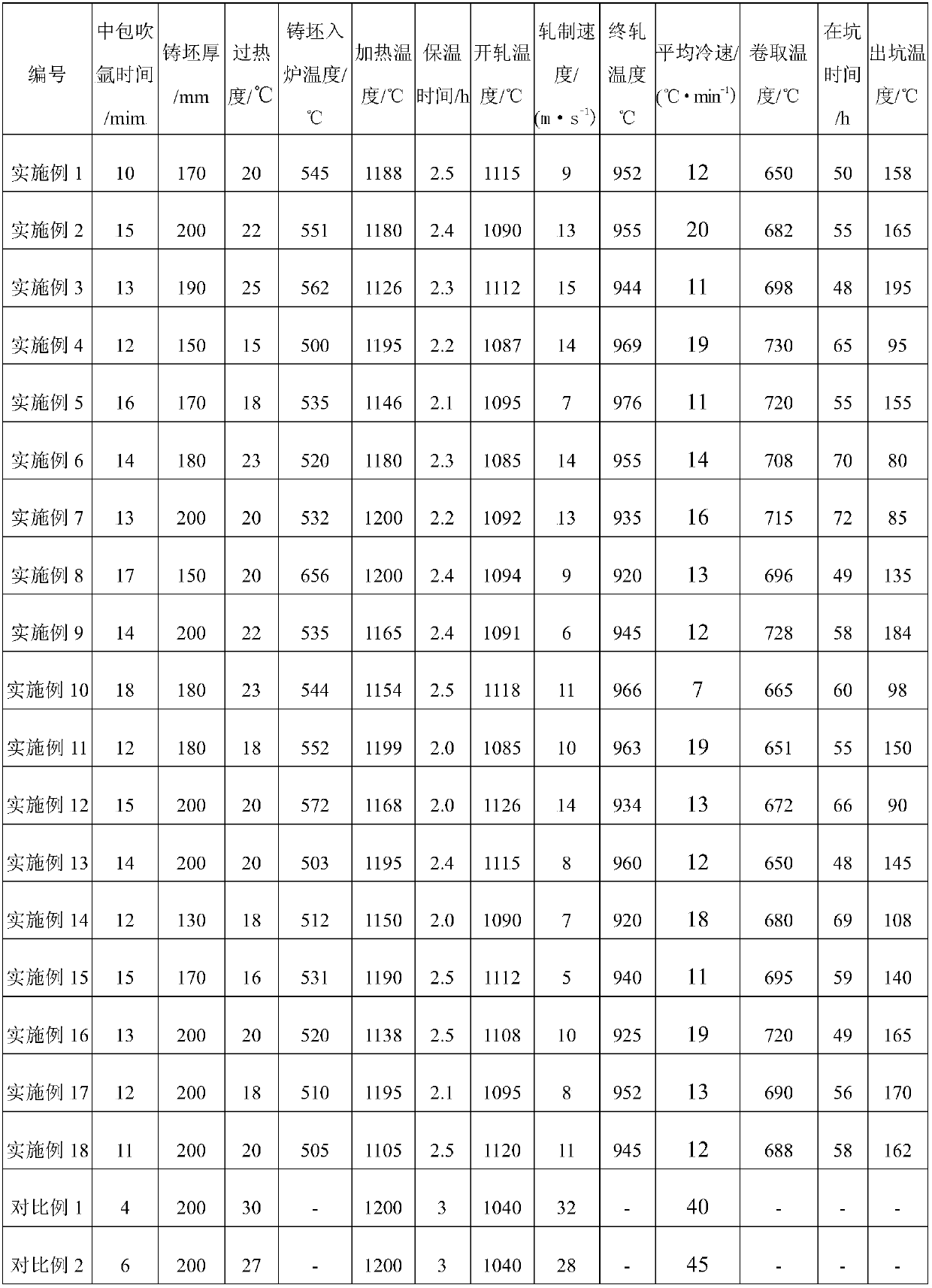

The invention discloses steel with excellent processing performances for a gardening tool and a production method thereof. The steel comprises the following components of, by weight, 0.45%-0.65% of C,0.1%-0.40% of Si, 0.5%-1.5% of Mn, 0.1%-0.5% of Cr, 0.02%-0.05% of Al, less than or equal to 0.4% of Ni, less than or equal to 0.5% of Cu, less than or equal to 0.020% of P, less than or equal to 0.010% of S and the balance Fe and inevitable impurities. The production method comprises the following steps that deoxidation is carried out by adopting Al, and time of argon blowing in tundish is larger than or equal to 10 minutes, the casting superheat degree is less than or equal to 25 DEG C, the thickness of a casting blank is 130-200 mm; charing temperature of the casting blank is larger than or equal to 500 DEG C; heating temperature is 1100-1200 DEG C, the temperature is kept for 2-5 hours, the rolling speed is 5-15 m per second, rolling start temperature is larger than or equal to 1080 DEG C, and rolling finish temperature is larger than or equal to 920 DEG C; and the cold speed is less than or equal to 20 DEG C per second, the casting blank is coiled at the temperature of 650-730 DEG C, then is put into a slow cooling pit for heat preservation and slow cooling for more than or equal to 48 hours, is cooled to below 200 DEG C, and then is air-cooled to the room temperature. According to steel with the excellent processing performances for the gardening tool and the production method thereof, the steel plate has excellent formability and wear resistance.

Owner:ANGANG STEEL CO LTD

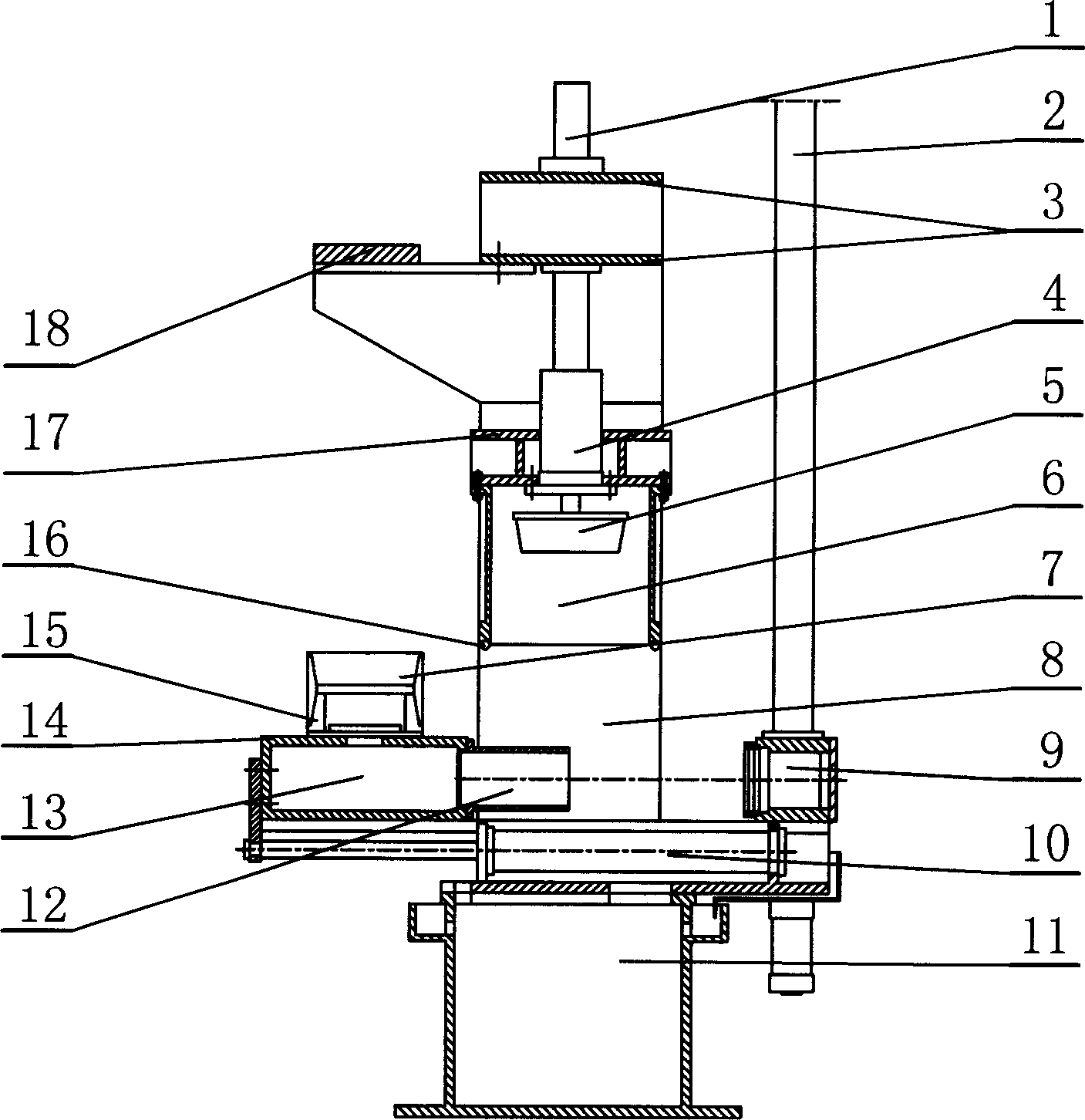

Quenching process and its quenching device for bearing internal and external rings

ActiveCN1858268ASimple structureImprove work efficiencyFurnace typesHeat treatment furnacesSmall footprintManipulator

The present invention relates to heat treatment, and is especially internal and external bearing ring quenching process and quenching press. The quenching process includes the steps of mounting and heating, feeding quenching material, simultaneous quenching of the internal bearing ring and the external bearing ring, and discharging. The special quenching apparatus includes internal bearing ring quenching apparatus, external bearing ring quenching apparatus and manipulator for grabbing the outer bearing ring. The external bearing ring quenching press is provided with fixing mold, the internal bearing ring quenching apparatus is provided with expanding mold, and the quenching process is one closed immersing process. The present invention has homogeneous quenching and is suitable for batch heat treatment.

Owner:NINGXIA MACHINERY RES INST

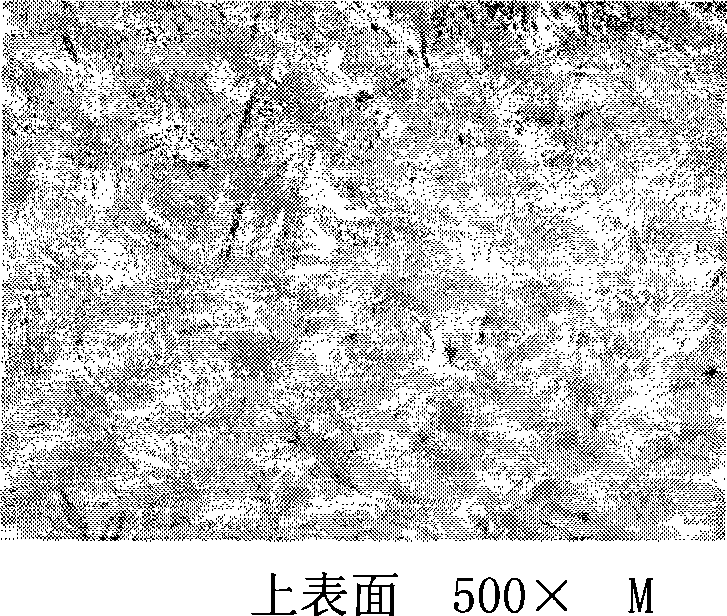

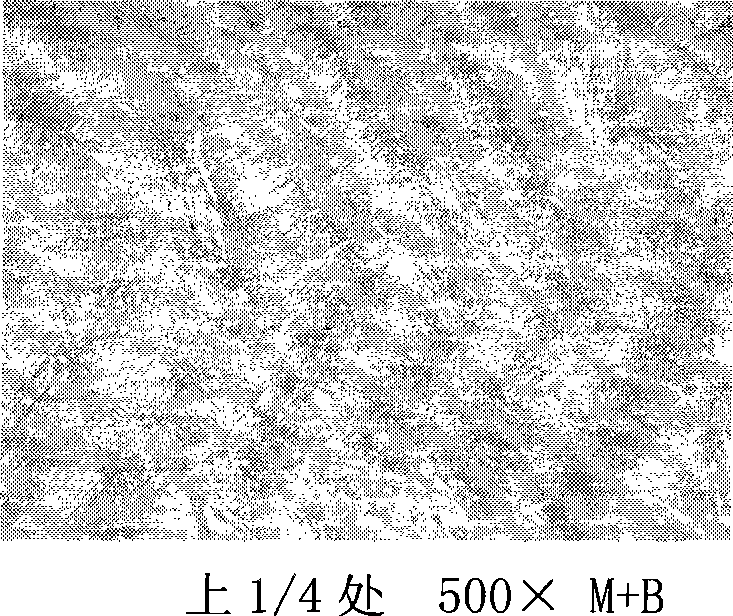

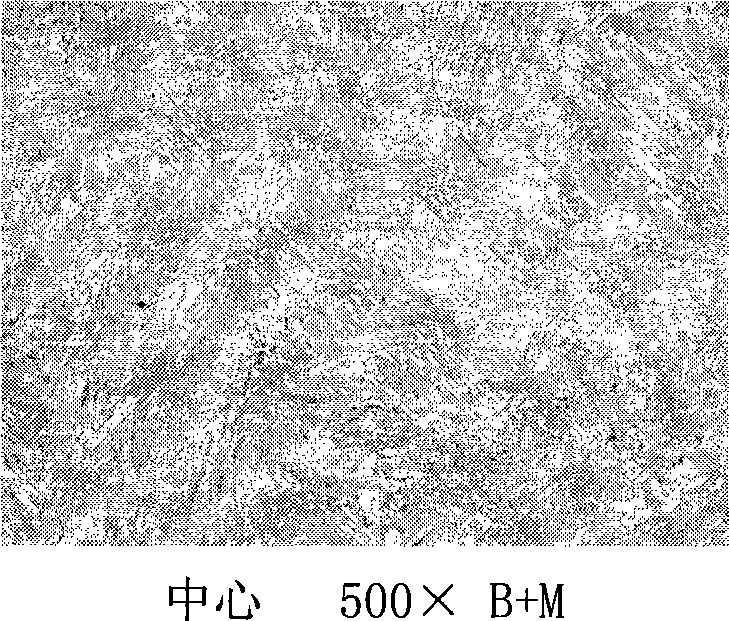

Quenching and tempering type abrasion resistant steel and heat treating method thereof

InactiveCN101451218AReasonable toughness matchingModerate hardnessHeat treatment process controlChemical compositionWear resistant

The invention relates to quenching and tempering type wear resistant steel and a heat treatment method thereof. The steel comprises the following chemical components by weight percentage: less than or equal to 0.22 percent of C, less than or equal to 0.80 percent of Si, less than or equal to 1.60 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.60 percent of Ni, less than or equal to 1.00 percent of Cr, less than or equal to 0.50 percent of Mo, 0.02 to 0.03 percent of Nb,0.04 to 0.06 percent of V, 0.020 to 0.045 percent of Al, 0.015 to 0.030 percent of Ti, less than or equal to 0.004 percent of B, and the balance being Fe and unavoidable impurities. The steel plate has reasonable obdurability matching, proper hardness, even full-thickness hardness and the mechanical properties reaching the expected design requirements. The steel plate production process has easy operation and high adaptability. The steel plates of various batches have stable and even performance and can reach the requirements for volume production. As the tempering time in a quenching machine is longer, the tempering time can be appropriately shortened in the subsequent production through tests, thereby reducing the cost.

Owner:WUYANG IRON & STEEL

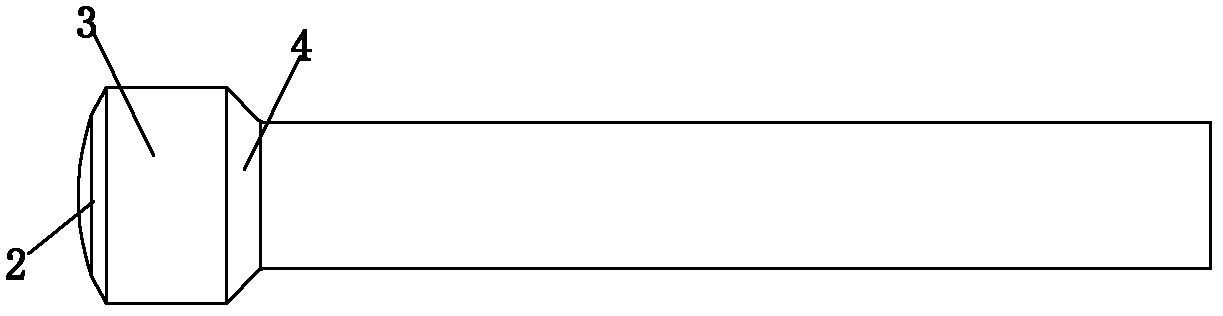

Fabrication process of hexagonal flange toothed bolt

The invention discloses a fabrication process of hexagonal flange toothed bolt. In the fabrication process, medium carbon cold heading steel wires are used. The fabrication process mainly comprises the steps of: (1) shearing blanking; (2) preliminarily heading; (3) pressing to form a circular top; (4) pulling to produce a hexagonal product; (5) molding; (6) thread rolling; (7) heating; and (8) electroplating. In the fabrication process of hexagonal flange toothed bolt disclosed by the invention, the cold heading forming technology is adopted to carry out processing, thus the material utilization rate is over 98%, the material is saved, the cost is reduced; by the use of multi-position extrusion, the volumetric deformation and metal flow are more reasonable, fins produced in deformation process are removed, and the resistance to deformation is reduced; by undergoing thermal processing, the bolt has uniform grain and hardness, and is free of cracks; the qualification rate is up to 100%; by electroplating cadmium and titanium, the strength of the bolt is greatly improved, as well as the safety in use.

Owner:苏州新凌电炉有限公司

Multipurpose all-austenite low-density steel and preparation method thereof

The invention relates to a multipurpose all-austenite low-density steel and a preparation method thereof, and belongs to the technical field of metal materials and preparation thereof. The steel comprises the following chemical components of, by weight, 0.40%-0.90% of C, 15.0%-25.0% of Mn, 3.0%-6.0% of Al, 0.3%-0.80% of Mo, 0.3%-0.90% of V, 0.01%-0.04% of Ti, 0.02%-0.10% of Nb, less than or equalto 0.3% of Si, less than or equal to 0.03% of P, less than or equal to 0.002% of S, less than or equal to 0.006% N (60 ppm), and the balance Fe and inevitable impurities; the density is 7.0-7.4 g / cm<3>, and the structure type is a total austenite + nano-scale VC and an MoC precipitation phase; and the composition system is characterized in that uniform and stable all-austenite steady-state structure can be obtained through casting and controlled rolling and controlled cooling technologies. The steel and the method are suitable for various fields of automobiles, buildings, mechanical structuresand the like.

Owner:CENT IRON & STEEL RES INST

Corrosion-resistant steel for chain plates and manufacturing method of corrosion-resistant steel

The invention provides corrosion-resistant steel for chain plates and a manufacturing method of the corrosion-resistant steel. The corrosion-resistant steel for the chain plates is prepared from the following components in percentage by weight: 0.40%-0.70% of C, 0.1%-0.40% of Si, 0.50%-1.0% of Mn, 0.1%-0.5% of Cr, 0.1%-0.5% of Cu, 0.03% -0.2% of Sb, 0.015%-0.050% of Al, 0.02%-0.3% of Sn, less thanor equal to 0.035% of impurity element P, less than or equal to 0.010% of S, the balance of Fe and inevitable impurities. The manufacturing method of the corrosion-resistant steel comprises the stepsof smelting, continuous casting, rolling and cold rolling. The stamping yield of the corrosion-resistant steel for the chain plates is as high as over 98%, the depth of a decarburized layer on the surface of the steel plate is less than or equal to 0.02 mm, the hardness is uniform after heat treatment, the performances of fatigue and impact resistance and the like meet the requirements, the corrosion resistance is obviously improved, and the average corrosion rate is less than 25g / m<2>.h.

Owner:ANGANG STEEL CO LTD

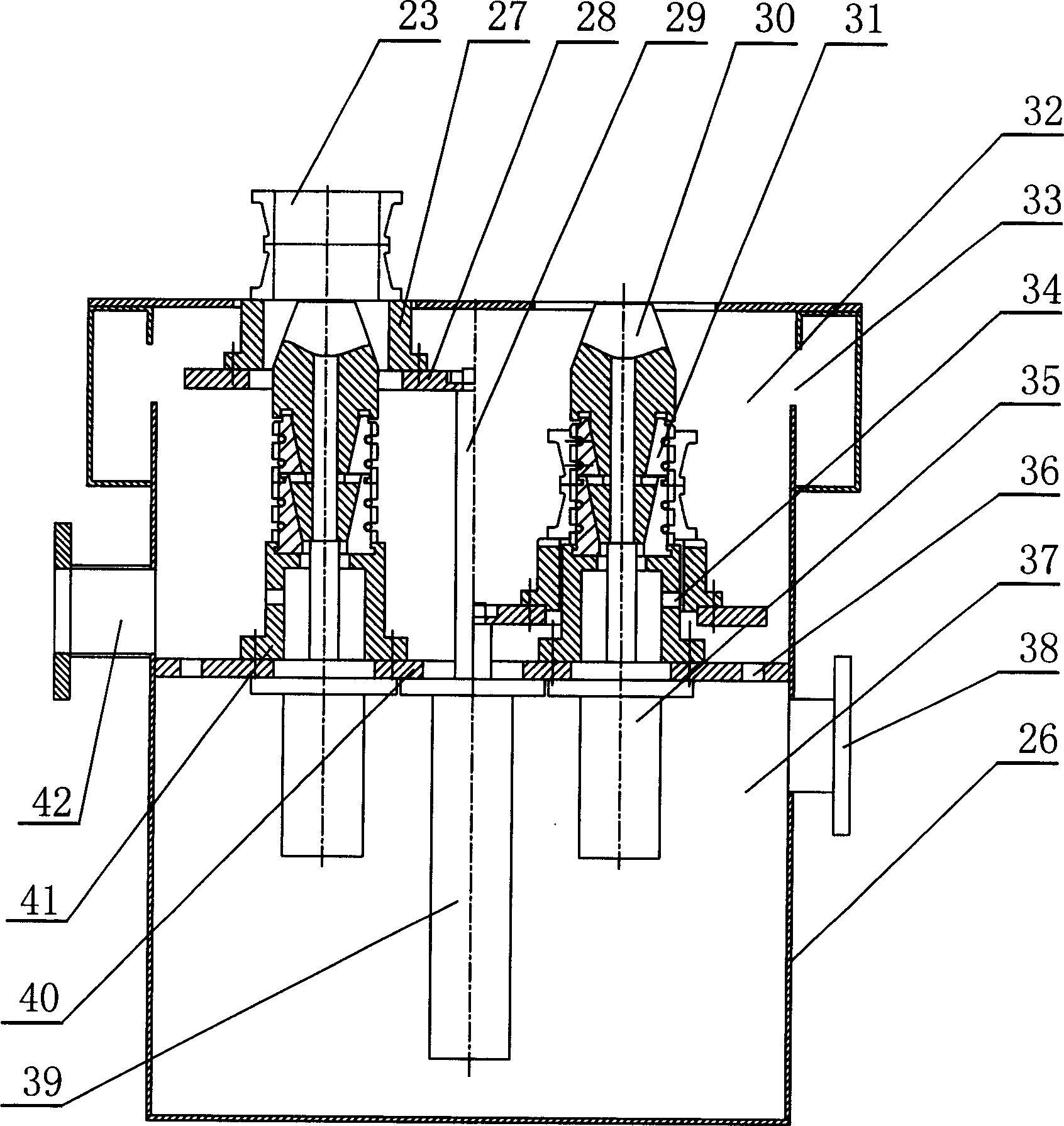

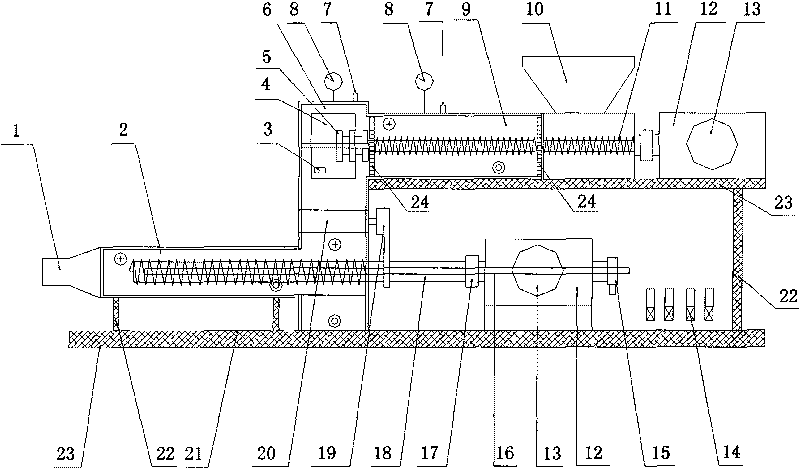

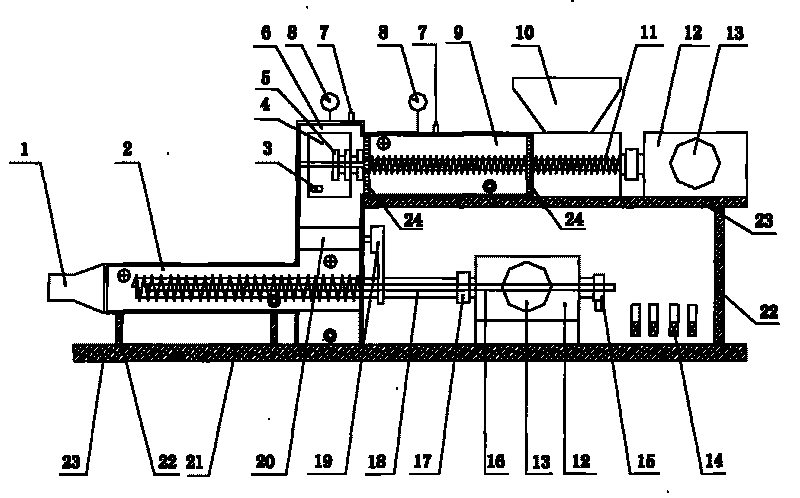

Honeycombed ceramic slurry water cooling vacuum refiner

The invention provides a honeycombed ceramic slurry water cooling vacuum refiner, comprising a slurry feed cylinder, slurry stirring shafts with helical blades, a vacuum chamber, a pumping hole, two kneading rollers, a photoelectric control device, a transmission mechanism, a hollow extruding shaft with helical blades, a slurry discharge cylinder, a fence which has section area close to and slightly smaller than the slurry feed cylinder, a cooling water device, a frame, a speed reducer and a variable-frequency motor, wherein the front end of the slurry stirring shafts with helical blades is provided with a slurry scraping knife. The slurry feed cylinder consists of two cylinders which are communicated, the section plane of the slurry feed cylinder is in a shape of a lying 8, and is communicated in the middle; the outlet end of the slurry feed cylinder is provided with the fence and the pumping port to form primary vacuum area; one slurry stirring shaft with the helical blade extends into each single cylinder, and is supported by a bearing with a seal ring; a bearing at the front end of the slurry stirring shaft is provided with a plurality of slurry scraping knives consisting of crossed blades; the fence is arranged at the outlet of the slurry feed cylinder; the upper end of the vacuum chamber is provided with the pumping port to ensure the vacuum chamber and the slurry discharge cylinder to form a secondary vacuum area; the lower part of the vacuum chamber is provided with two kneading rollers which are engaged with each other; the slurry outlet on the front part of the slurry discharge cylinder is a cone with narrowing opening.

Owner:NANJING KERUI SPECIAL CERAMICS +1

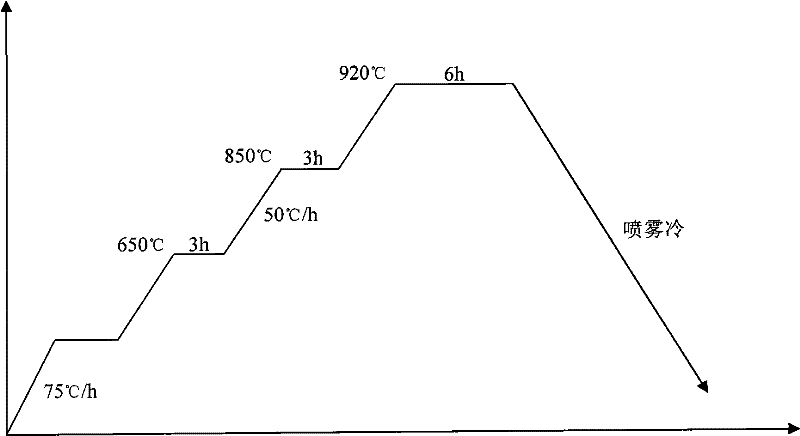

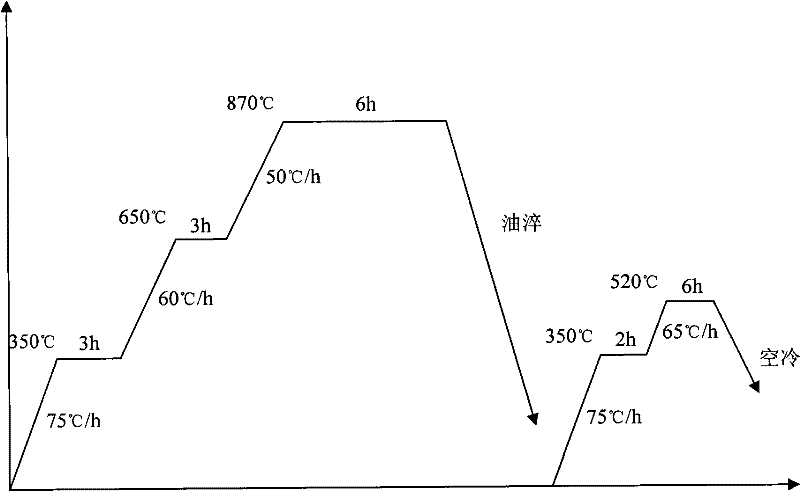

High speed steel composite roller heat treatment method

InactiveCN101215628AIncrease productivityReduce energy consumptionFurnace typesHeat treatment furnacesSocial benefitsInduction hardening

A compound rolling heat treatment process of rapid-steel belongs to the steel rolling technology field. The invention comprises conducting annealing treatment for roller with 870-890 DEG C of annealing temperature, warming up for 6-10 hours, proceeding induction quenching on a 50Hz / 250Hz double-frequency quenching machine, preheating the roller before the induction quenching with 280-350 DEG C of preheating temperature for 6-10 hours of preheating warming. The roller is need being rotated and shifted down perpendicularly along axial direction when in quenching heating. The roller is water-cooled fast after heated up, then is conducted the first tempering treatment with 520-560 DEG C, and is insulated tempering for 4-6 hours, and then is cooled down in air. The roller is reheated to 500-540 DEG C to finish the second tempering treatment, and is insulated tempering for 6-8 hours, and is cooled down when the temperature of furnace is cooled smaller than 200 DEG C. The heat treatment technology of the invention treats high speed steel compound rolling, has simple technology, low energy consumption, short production cycle, high rolling strength and excellent use effect, and has excellent economic and social benefits after being popularized and applied.

Owner:BEIJING UNIV OF TECH

QT600-3 ductile iron casting and method for producing the same

ActiveCN101418414AImprove mechanical propertiesUniform hardnessProcess efficiency improvementDuctile ironCopper

The invention discloses a QT600-3 nodular iron casting and a manufacturing method thereof. The hardness range of the nodular iron casting is between 180 and 220 HB, and the tensile strength of the nodular iron casting is more than or equal to 600 MPa. The nodular iron casting comprises 3.3 to 3.8 percent of C, 2.2 to 2.5 percent of Si, 0.2 to 0.4 percent of Mn, 0.06 to 0.08 percent of rare-earth RE, 0.03 to 0.06 percent of Mg, 0.33 to 0.4 percent of Cu, less than or equal to 0.15 percent of P, less than or equal to 0.02 percent of S, other trace impurity, and the balance being Fe. The manufacturing method thereof comprises the following steps: heating a raw material containing iron into molten iron and smelting the molten iron, and pouring the molten iron into a foundry ladle to cool; pouring the molten iron into the foundry ladle comprising nodulizing agent and copper blocks, and standing; pouring the molten iron into a mold, adding nucleating agent, and cooling the mixture; and finally obtaining the nodular iron casting through opening a box, cleaning, drawing temper, cooling, blasting ball, painting. The tensile strength of the nodular iron casting is high, and the hardness of the nodular iron casting is even.

Owner:CRRC QISHUYAN CO LTD

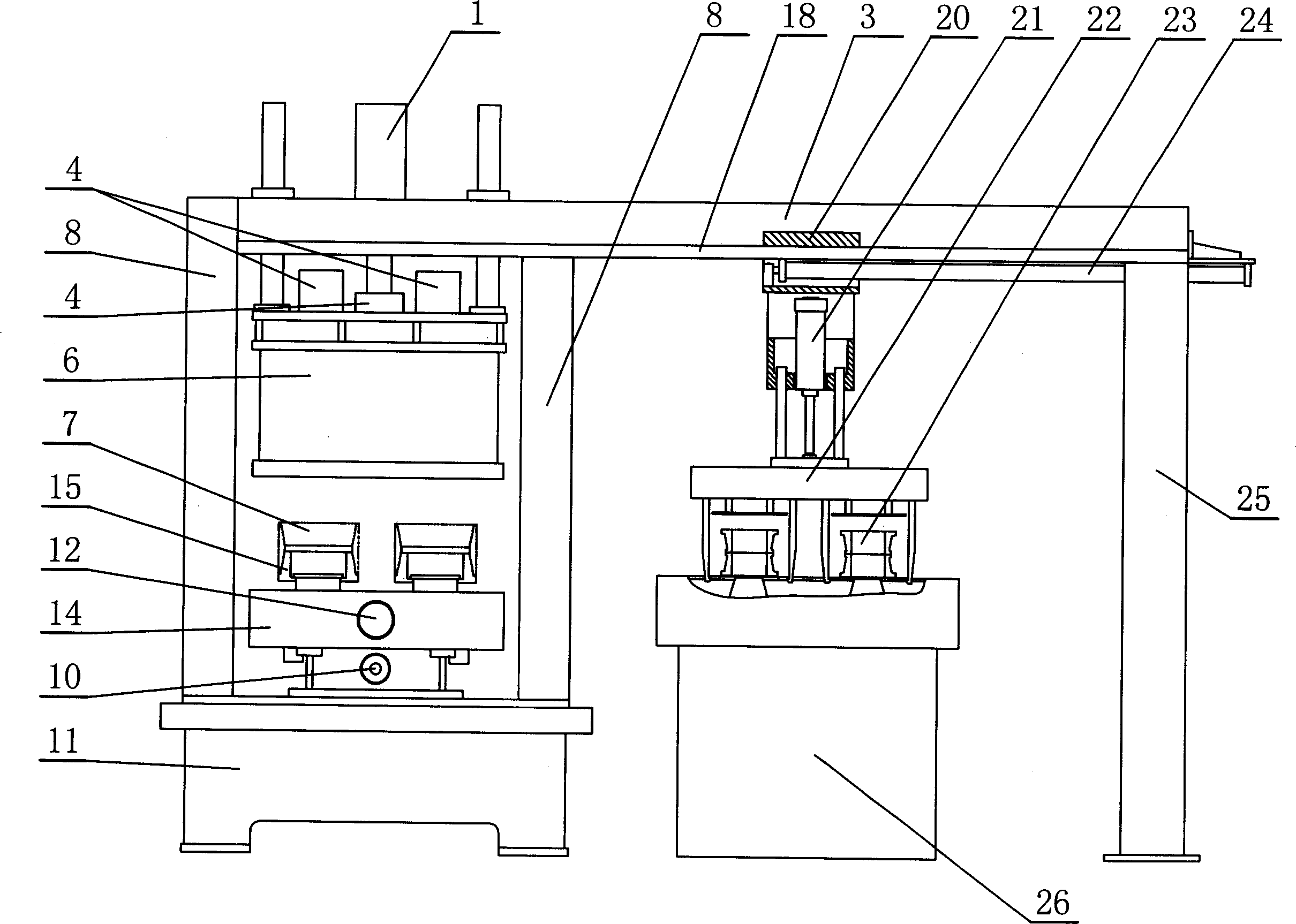

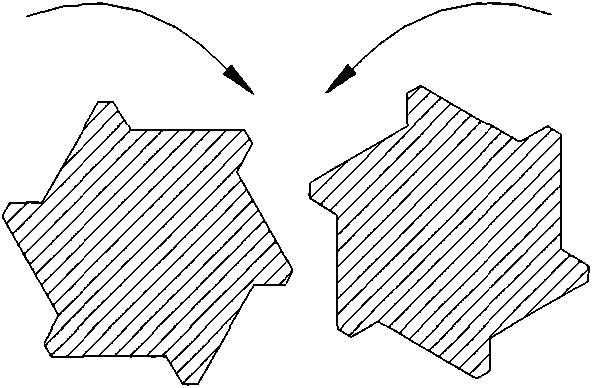

Manufacturing technology and device for improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller

ActiveCN105401059AEasy feedingOvercome the defect of prone to tissue segregationFurnace typesProcess efficiency improvementManufacturing technologyFerrosilicon

The invention discloses a manufacturing technology and device for an improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller. The roller comprises, by mass percent, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, not larger than 0.05% of P, not larger than 0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable micro elements. Yttrium base rare-earth nodulizing and Ba, Ca, and silicon iron composite inoculation are adopted, Nb, Ti, V, B and Sb are added for modification, and the mechanical performance of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved, an induction heater is adopted to carry out in-mold whole heating casting on a core stick, a water cooled crystallizer is molded, a composite layer interface can be dynamically controlled, the technology is simple, the efficiency is high, power consumption is small, the cost is low, no composition segregation exists, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

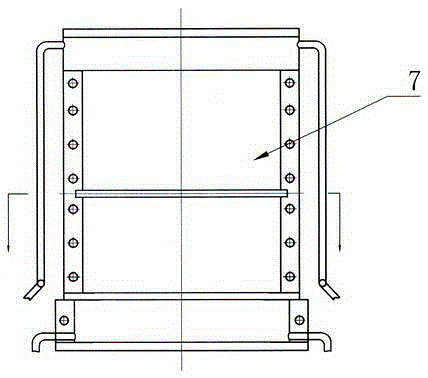

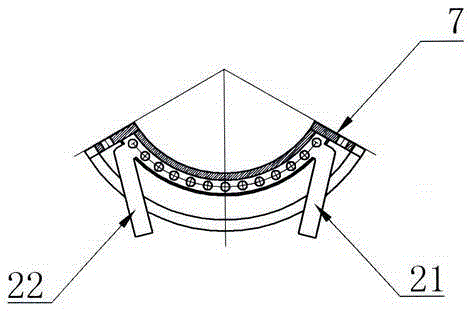

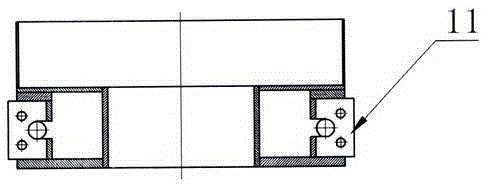

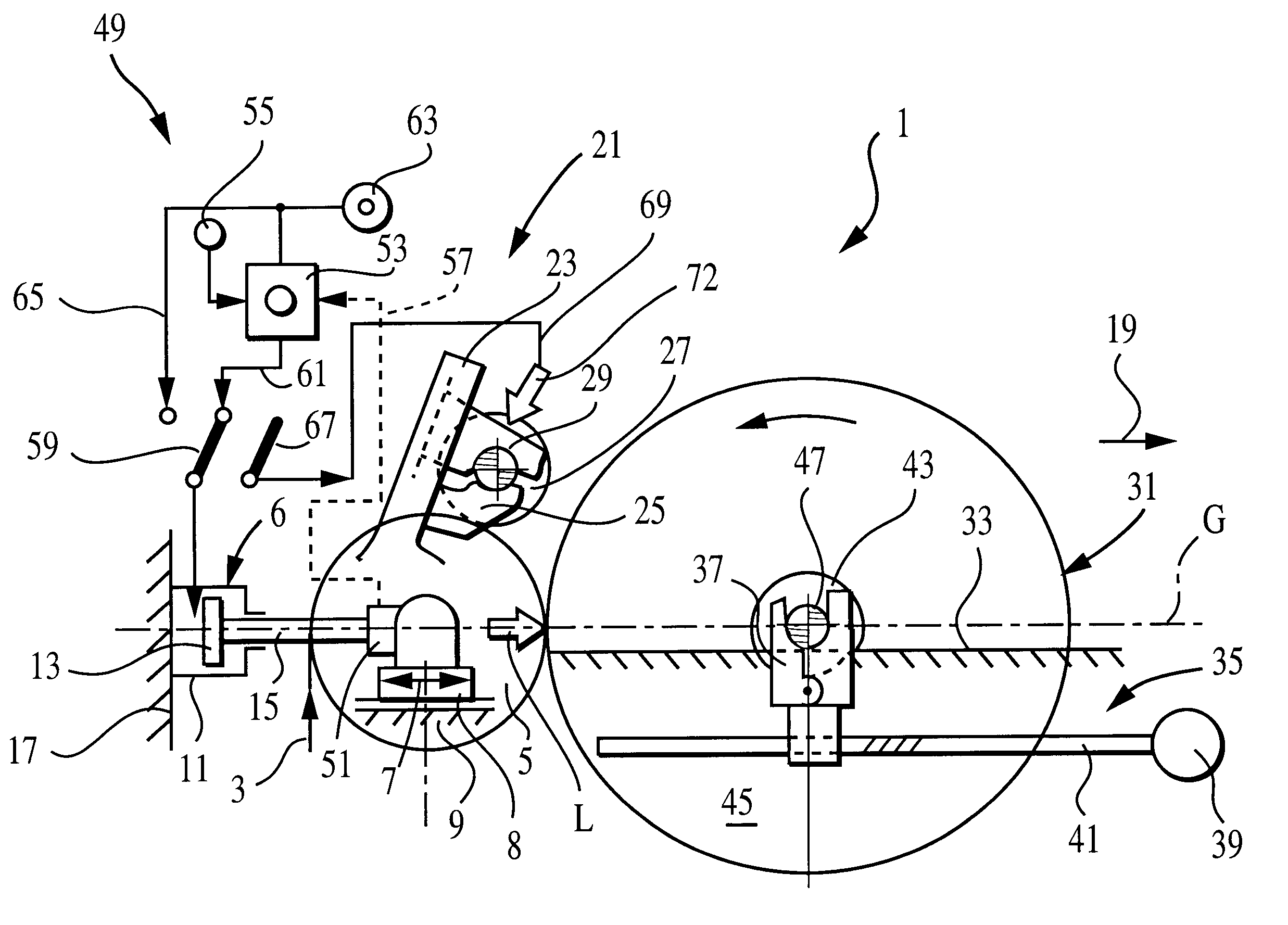

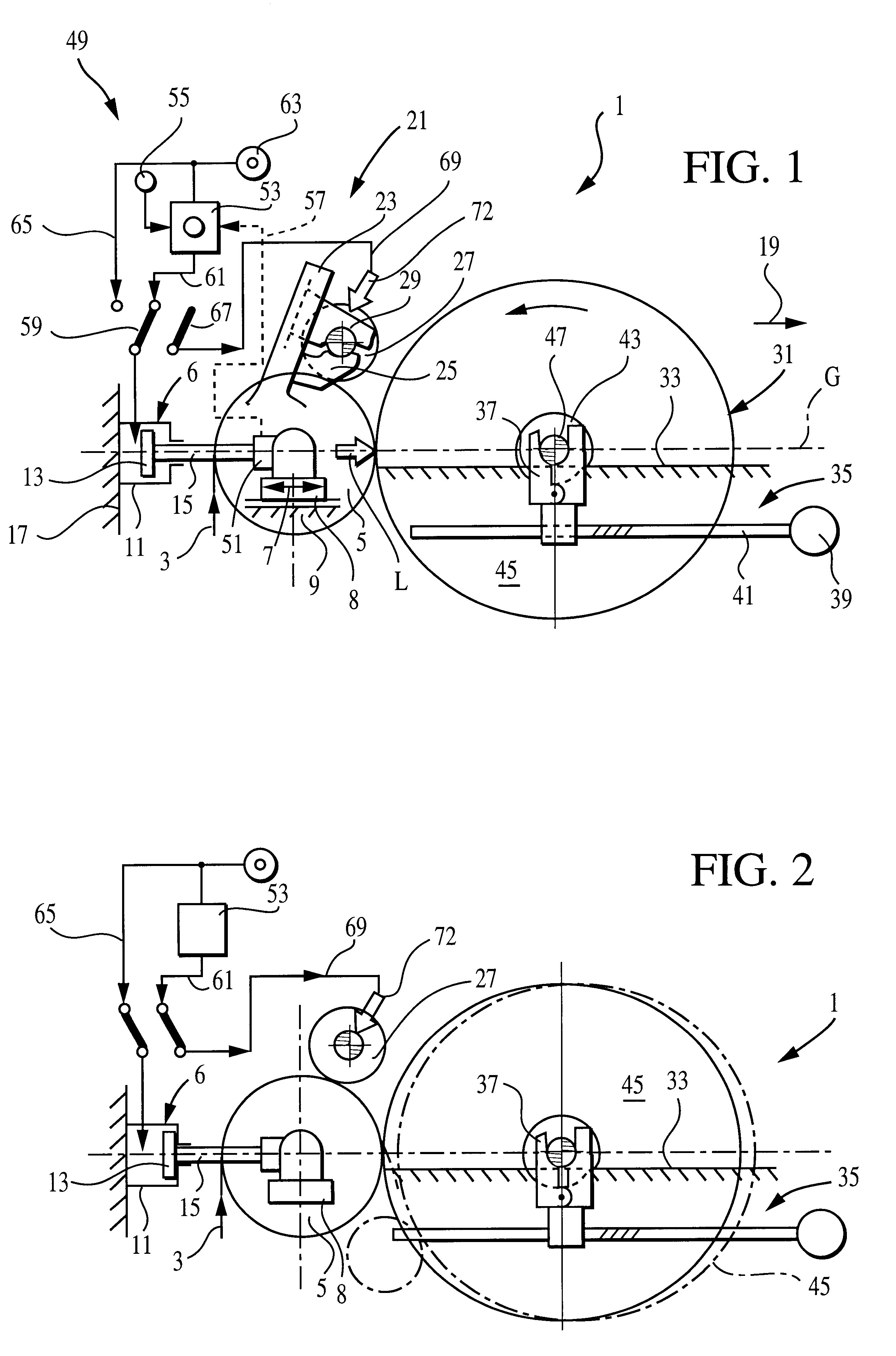

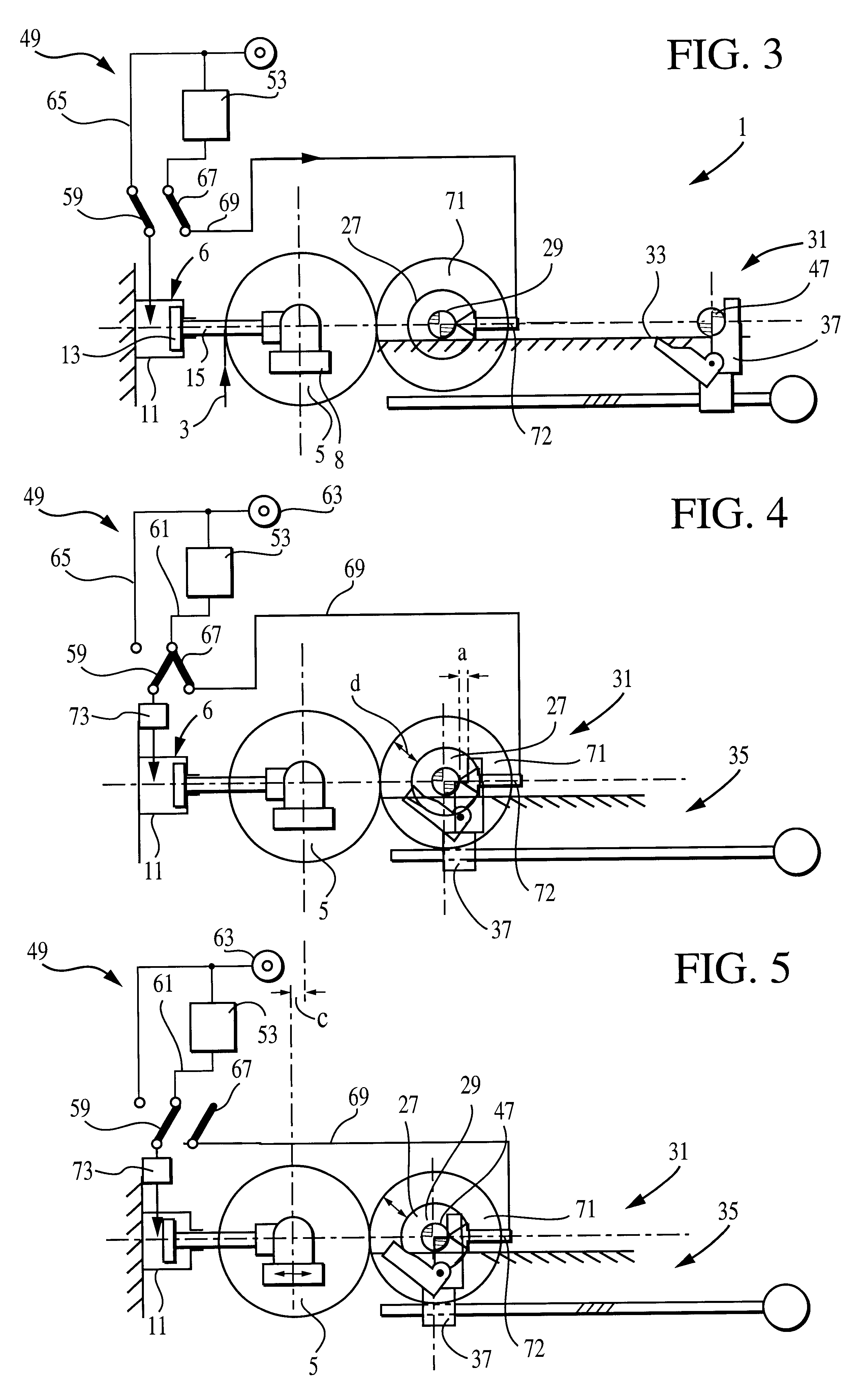

Method and apparatus for continuous winding of a web of material

InactiveUS6250580B1Sensitive adjustmentOptimal core windingFilament handlingWebs handlingWinding machineEngineering

Process and winding machine for the continuous winding of a web of material onto a reel spool to form a reel. The process includes forming a winding nip between a peripheral zone of a reel drum the reel, guiding the material web over the peripheral zone of the reel drum, positioning the reel in a secondary zone, and displacing and pressing the reel drum against the reel in the secondary zone. In this manner, one of control and regulation of a linear force in the winding nip occurs through the displacement of the reel drum. Upon obtaining a completed reel having a desired reel diameter, the process includes moving the reel drum into a temporarily fixed position, introducing a new, empty reel spool into a primary zone, forming another winding nip between the new spool and the reel drum through a relative movement of the new reel spool with respect to the reel drum in the temporarily fixed position, cutting the material web, winding the material web onto the new reel spool to form a new reel, and removing the completed reel. The process also includes transferring the new reel spool from the primary zone to the secondary zone, releasing the reel drum from the temporarily fixed position, and displacing the reel drum for one of the control and regulation of the linear force in the winding nip between the reel drum and the new reel spool in the secondary zone. The winding machine includes a reel drum arranged to form a winding nip with the reel, a primary mount adapted to hold a new reel spool, wherein the primary mount is further adapted to displace the new reel spool along a first guide path substantially radially to the reel drum, and a secondary mount coupled to the reel spool. The machine also includes a pressure device coupled to the reel drum, which is adapted to move the reel drum at least substantially horizontally when the reel spool is in the secondary mount, and which is further adapted to at least temporarily fix a position of the reel drum when the new reel spool is in the primary mount.

Owner:VOITH PATENT GMBH

High-strength spheroidal graphite cast iron for thick-walled casting die

The invention discloses high-strength spheroidal graphite cast iron for a thick-walled casting die, which comprises the following main components in percentage by mass: 3.20 to 3.50 percent of C, 1.90 to 2.20 percent of Si, 0.20 to 0.50 percent of Mn, 0.40 to 0.60 percent of Cu, 0.40 to 0.80 percent of Mo, 0.60 to 0.80 percent of Ni, less than or equal to 0.06 percent of P, less than or equal to 0.03 percent of S, 0.02 to 0.05 percent of Mg, less than or equal to 0.07 percent of Re and the balance of Fe and other inevitable impurities. The as-cast mechanical properties of the spheroidal graphite cast iron are that: sigma b is more than or equal to 750MPa, sigma 0.2 is more than or equal to 520MPa, delta is more than or equal to 3 percent, and Brinell hardness is 190 to 240; the mechanical properties of the normalized, hardened and tempered spheroidal graphite cast iron are that: the sigma b is more than or equal to 1,000MPa, the sigma 0.2 is more than or equal to 900MPa, the delta is more than or equal to 2 percent, and the Brinell hardness is 260 to 300; and the material has high strength, hardness and elongation, has uniform section hardness and structure after the material is hardened and tempered when used for a large-section die, and can meet the requirement of the actual use working condition of the large-section die with the wall thickness of more than 200mm.

Owner:BAOSHAN IRON & STEEL CO LTD +1

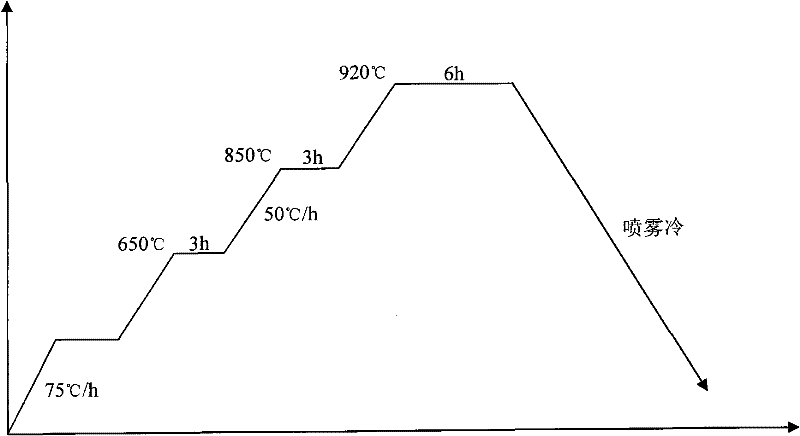

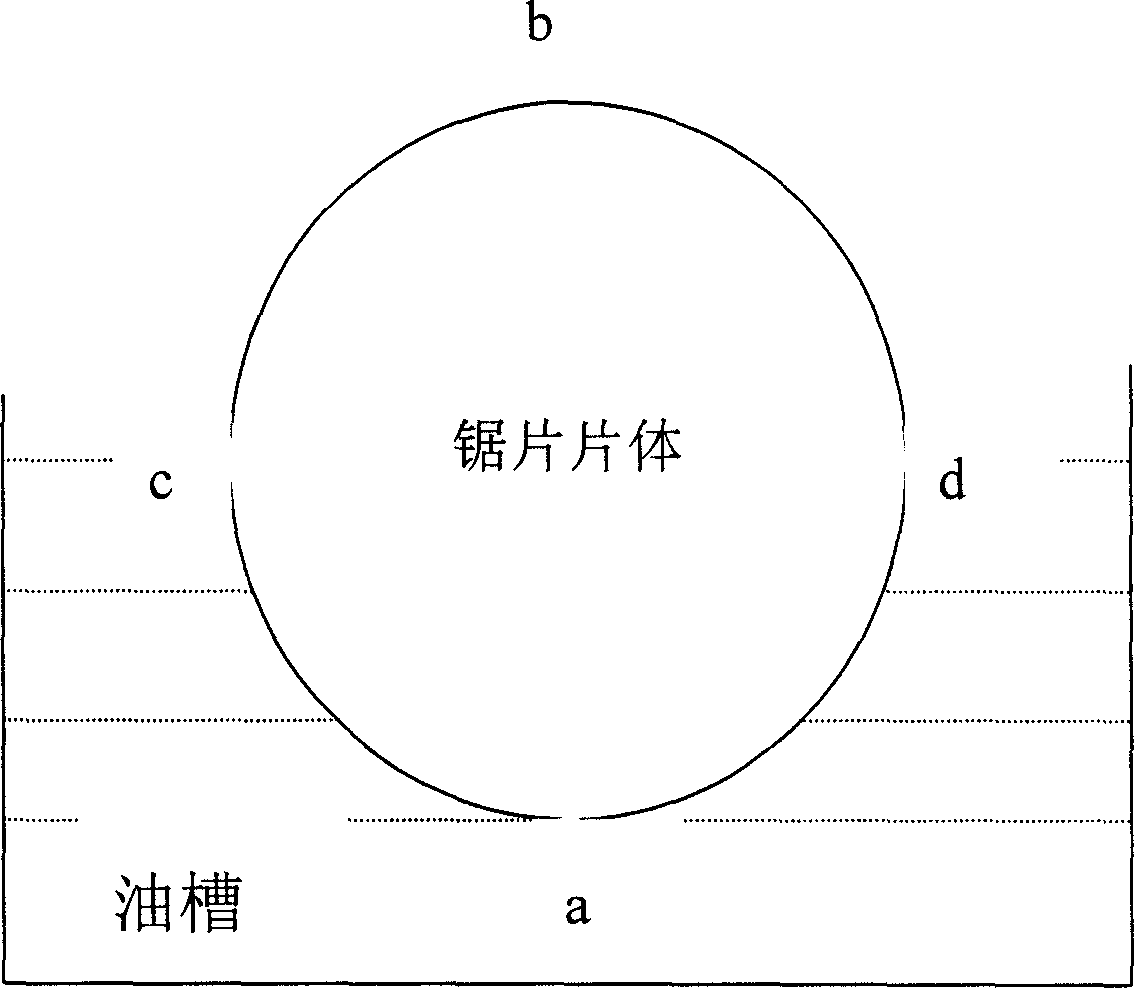

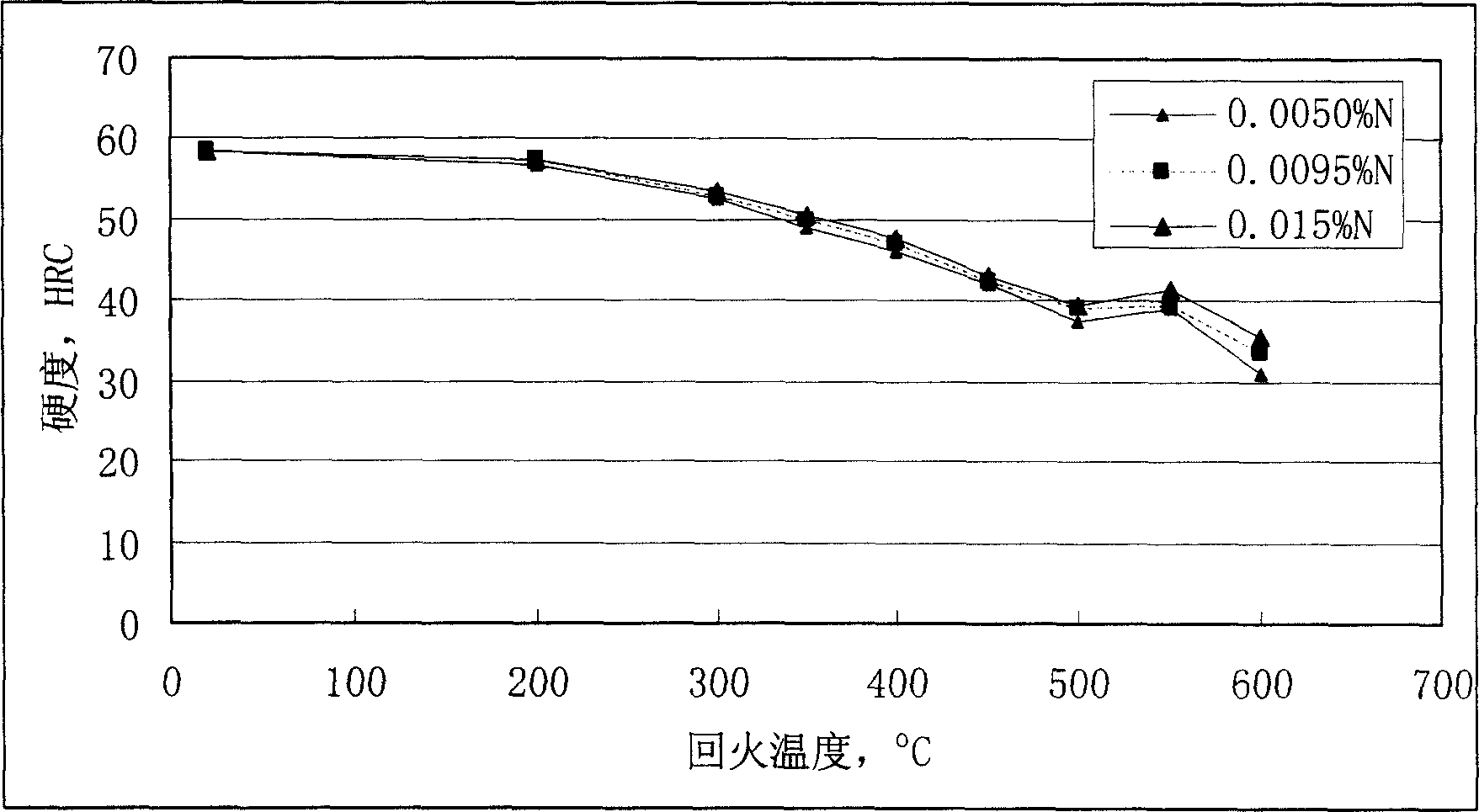

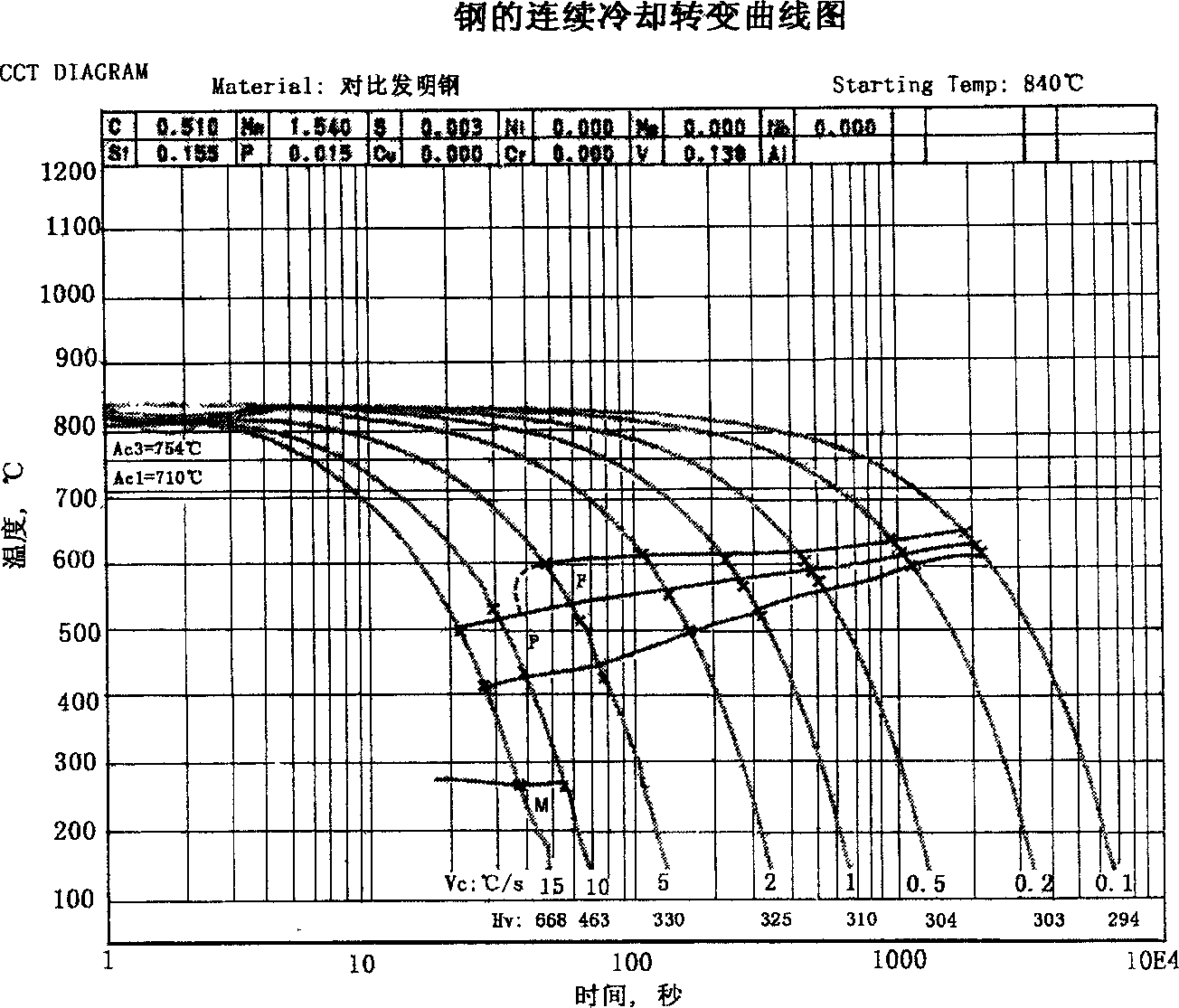

Stone material cutting saw blade steel and its manufacturing method

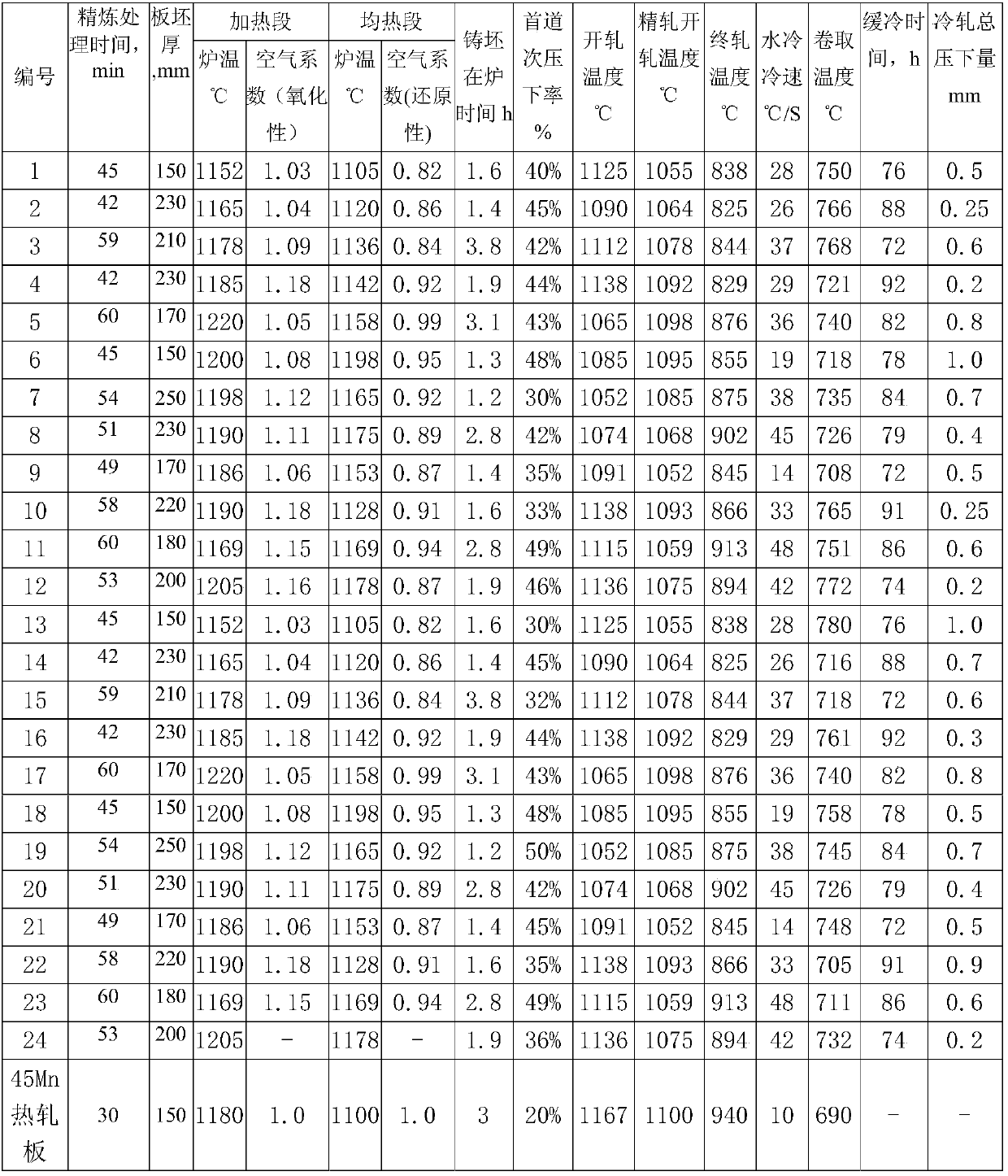

ActiveCN1904119AReduce the risk of continuous casting billet breakageReduce the technical problem of large deformation resistanceFurnace typesMetal rolling arrangementsChemical compositionImpurity

This invention relates to a type of steel used for saw blade for stone slotting. Account for weight the chemical composition is: C 0.45-0.60,Si 0.10- 0.60,Mn 1.30-1.80,P<=0.02,S<=0.01,V 0.05-0.20,Cr 0.15-0.30, N 0.005-0.020,Ca 0-0.0050,Al 0.005-0.040, and the rest is Fe and inevitable impurity. The process includes steps as follows: smelting, casting,; continuous casting billet use heat sending and heat packing , ensure the temperature keep above 300DEG C before it be send into plate body for heating; keep temperature for plate body heating above 1150DEG C,temperature for hot rolling above 900DEG C; cooling after rolling, then coiling, keep the coiling temperature above 700DEG C. This invention has higher hardenability then midst-carbon and low-alloy steel, especially refer to make large saw blade which diameter is above 1000mm.

Owner:BAOSHAN IRON & STEEL CO LTD

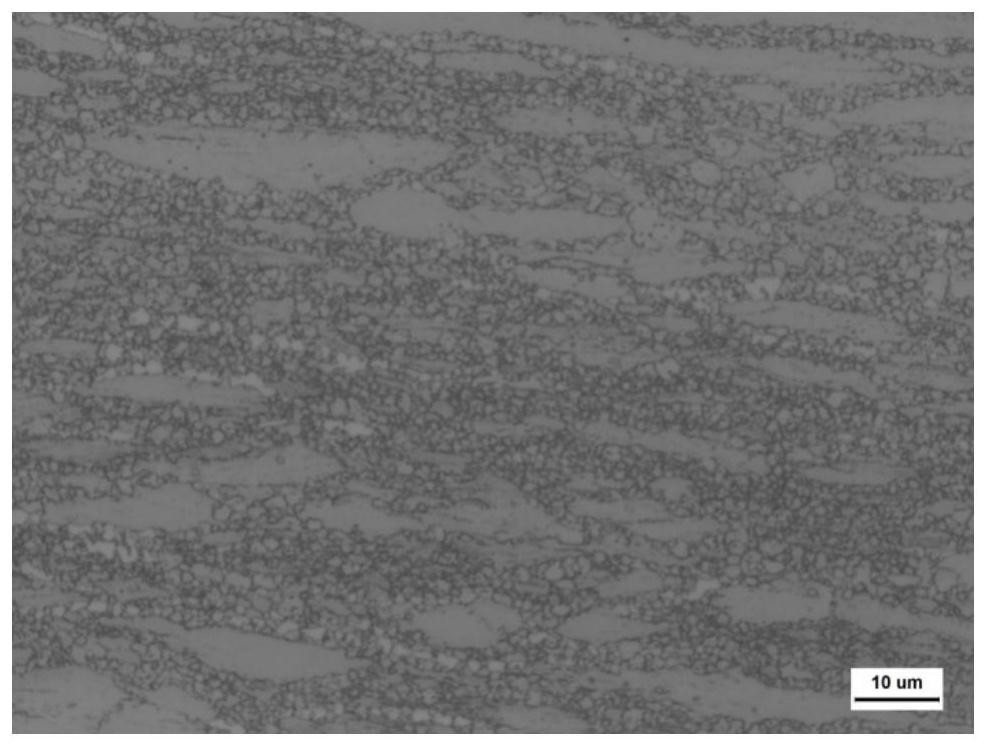

Laser bionic coupling guide rail and regeneration method thereof

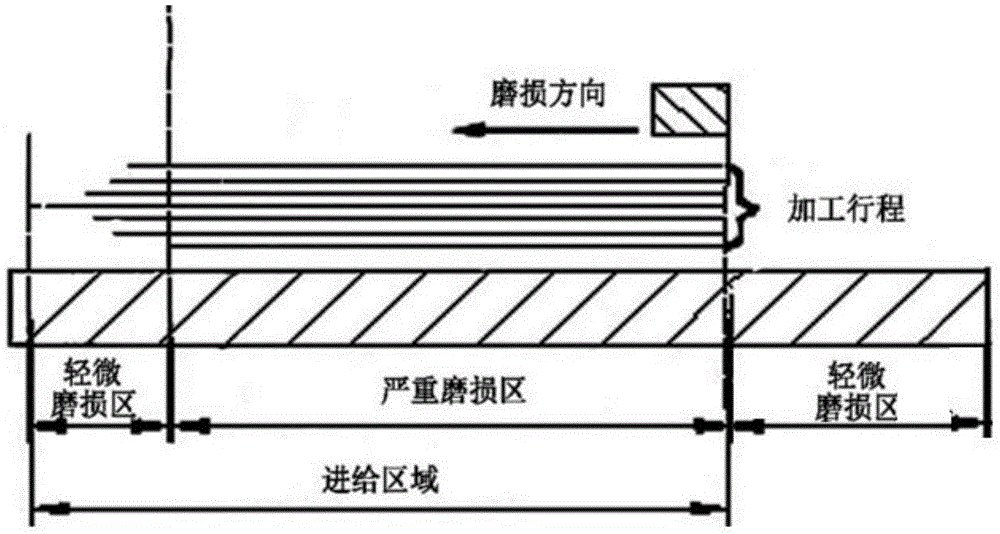

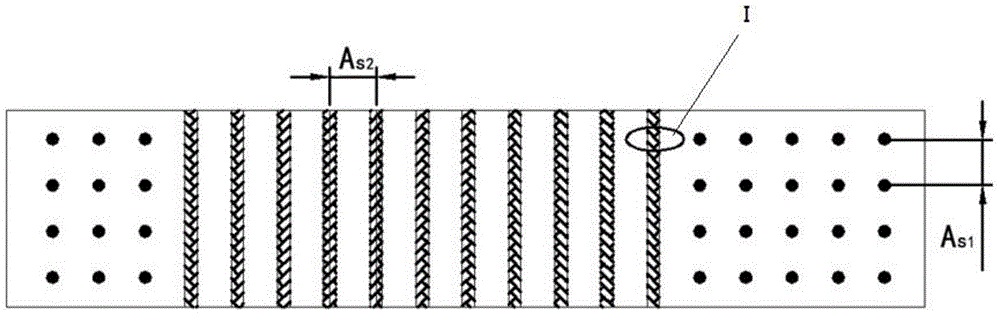

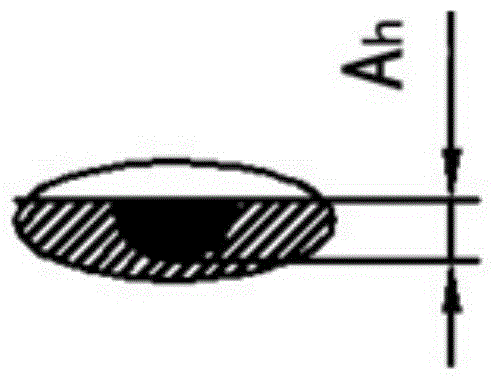

ActiveCN105081577ASolve the difficult regeneration problemUniform hardnessLarge fixed membersLaser beam welding apparatusCouplingEngineering

The invention relates to a laser bionic coupling guide rail and a regeneration method thereof. Bionic surfaces different in abrasion resistance are machined in a slight abrasion area and a serious abrasion area on the working face of the guide rail. A point and strip bionic surface combining form or a strip and net bionic surface combining form or a point and net bionic surface combining form is adopted according to the hardness gradient or the stress gradient of the serious abrasion area and the slight abrasion area of the working face of the guide rail. A bionic surface with the overall abrasion resistance being consistent for a long term is formed through the combination of the bionic surfaces different in abrasion resistance, the mechanical performance of the surface with the uneven mechanical performance distribution can be recovered to be evenly distributed, the phenomenon of serious local abrasion caused by large local stress is effectively avoided, and the bionic coupling guide rail is more suitable for the angle of the actual work of the bionic coupling guide rail. A multi-bionic coupling surface combined uneven regeneration repairing manner is directly implemented on the local abrasion surface of a cast iron guide rail on which high-frequency quenching is carried out, and the problem that due to the uneven abrasion of the surface of the scraped guide rail, the scraped guide rail is hard to regenerate is basically solved.

Owner:JILIN UNIV

Wear-resistant material workpiece quenching medium

The invention discloses a wear-resistant material workpiece quenching medium, relating to the technical field of heat treatment quenching. The wear-resistant material workpiece quenching medium comprises following raw materials based on weight percentage: 6-12% of sodium hydroxide, 6-8% of zinc chloride, 0.01-0.03% of sulfonated castor oil, 1-5% of polyamide polyethylene glycol, 2-5% of acrylic acid, 5-10% of acrylic ester, 0.1-2% of additive and the balance of water. In the wear-resistant material workpiece quenching medium, formula is reasonable, a quenching piece can achieve high and uniform hardness and can be directly subjected to quenching, residual forging heat quenching and induced spraying quenching, and the medium is particularly applicable for quenching of a large workpiece; the sodium hydroxide used in the invention can mutually react with oxide skin on the surface of the quenching piece to generate oxygen, so that the oxide skin is rapidly stripped off, and the surface of the quenching piece shows shiny silver ; the zinc chloride and the sodium hydroxide react to generate strong zinc oxide, the scabbing speed of a high-temperature region is faster than that of water, the cooling speed of a low-temperature region is slower than that of the water, the quenching piece is slightly deformed, is not easy to crack and has a shiny surface.

Owner:安徽新马铸造科技有限公司

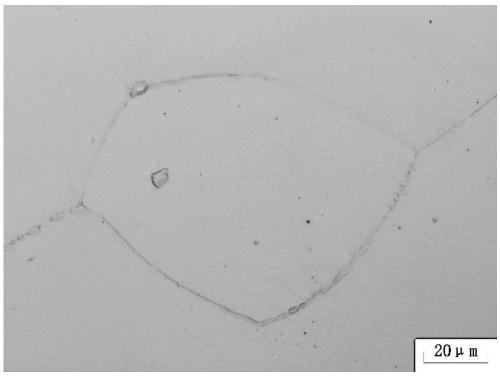

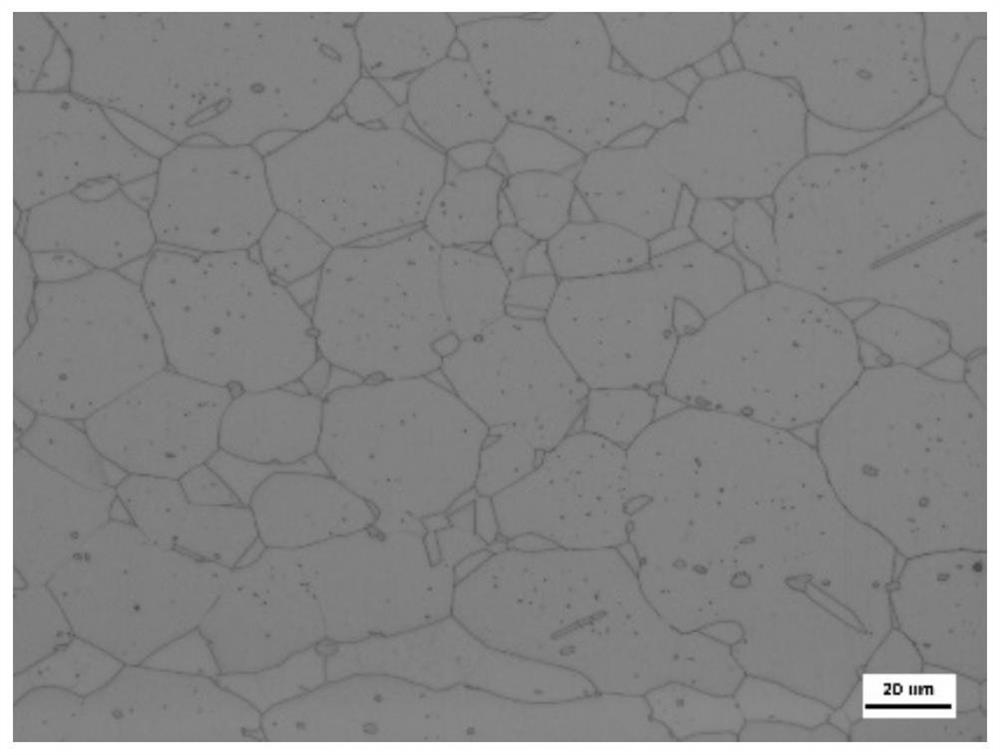

Pot-Shaped Copper Sputtering Target and Manufacturing Method Thereof

Provided is a pot-shaped copper sputtering target manufactured with die forging, wherein the Vickers hardness Hv at all locations of the inner surface of the pot-shaped target is 70 or greater. With this pot-shaped copper sputtering target, the average crystal grain size in the target structure is 65 μm or less. Further, the inner surface of the pot-shaped target comprises crystalline orientations of (220), (111), (200), (311) obtained by X-ray diffraction, and the crystalline orientation of the face subject to erosion of the pot-shaped target is of a (220) primary orientation. An object of the present invention is to obtain a manufacturing method of a high quality sputtering target by improving and devising the forging process and heat treatment process to make the crystal grain size refined and uniform, and to obtain a high-quality sputtering target.

Owner:JX NIPPON MINING& METALS CORP

Laser cladding repair process for cross shafts

InactiveCN102828181AImprove wettabilityImprove wear resistanceMetallic material coating processesOptoelectronicsHardness

The invention relates to a laser cladding repair process for cross shafts. The process comprises the following steps of: A. carrying out treatment on the surface of the cross shaft, and carrying out failure analysis; B. carrying out 80-150 DEG C overall preheating on the cross shaft; C. according to failure analysis results of the cross shaft, optimizing process parameters, and carrying out laser cladding, wherein adopted alloy powder comprises the following components in percentage by weight: less than or equal to 0.1% of C, 10-13% of Cr, 1.5-2.5% of B, 1-2% of Si, 0.5-1.2% of Mo, 8-12% of Mn, 6-12% of W, 5-15% of TiO2, and the balance of Fe; and D. carrying out detection. According to the laser cladding repair process for the cross shafts, disclosed by the invention, through carrying out the laser cladding on the surface of the cross shaft, the size of the cross shaft can meet the application requirements, and the hardness and the wear resistance of the cross shaft subjected to repair exceed the original hardness and the original wear resistance of the cross shaft.

Owner:DANYANG HONGTU LASER TECH

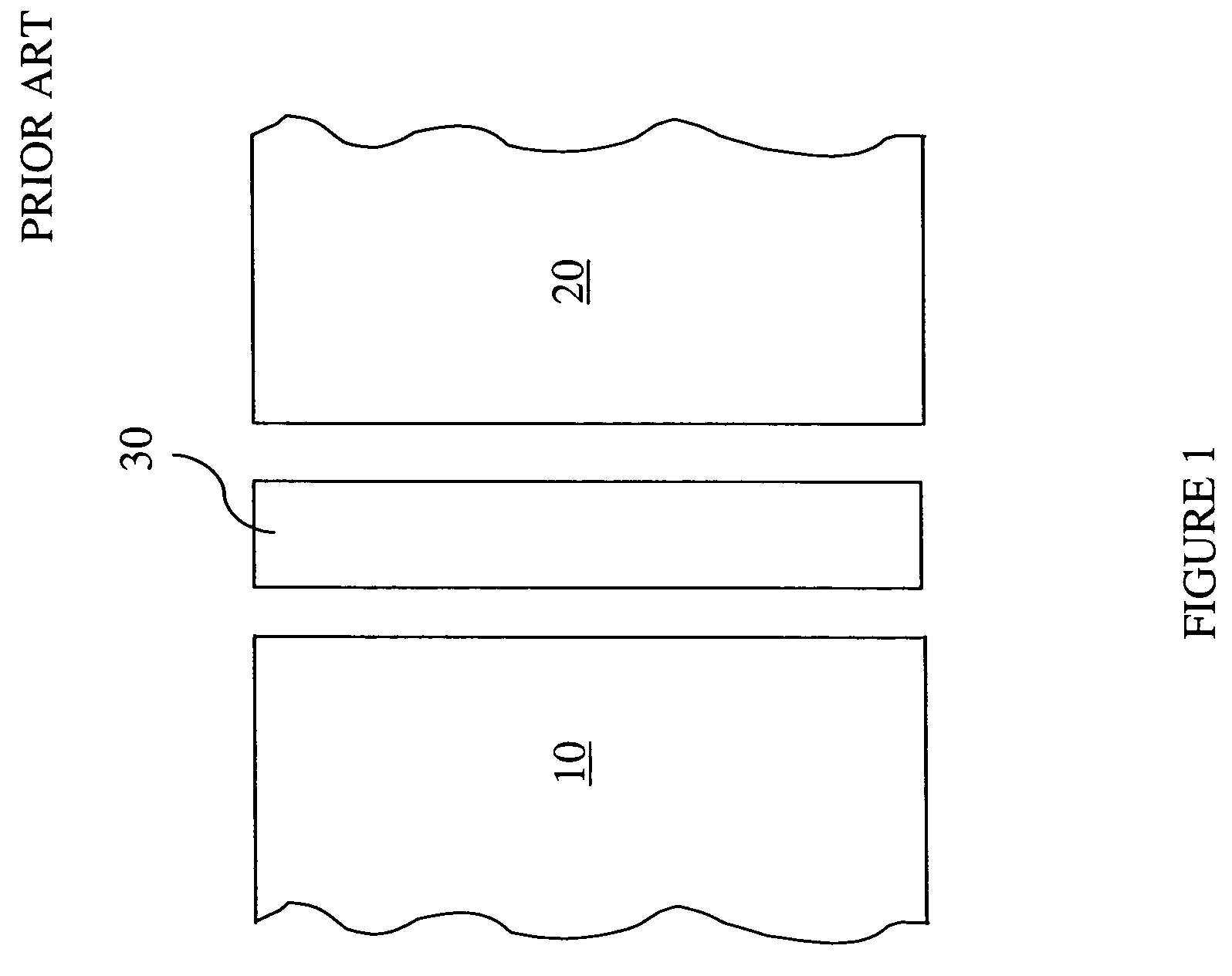

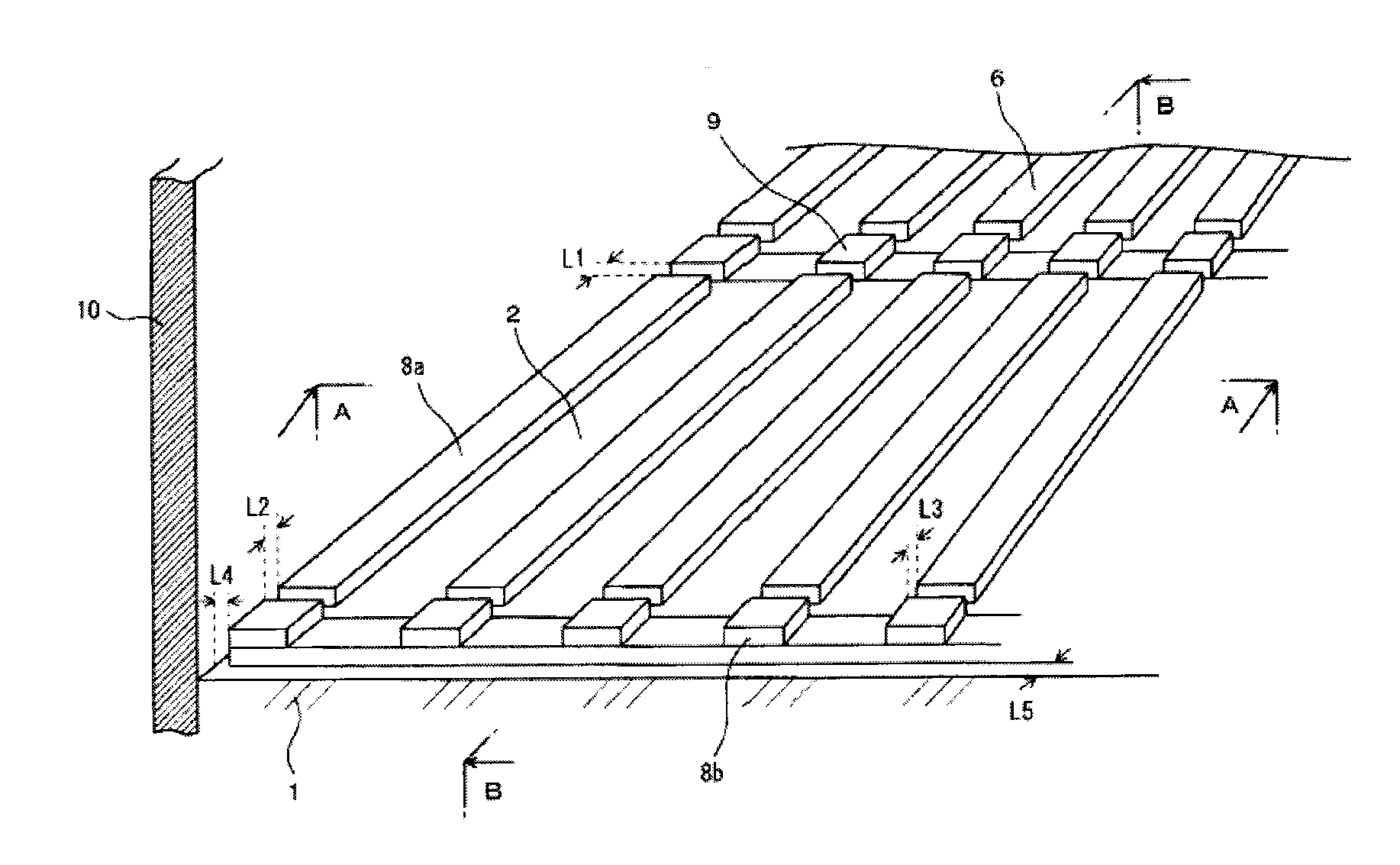

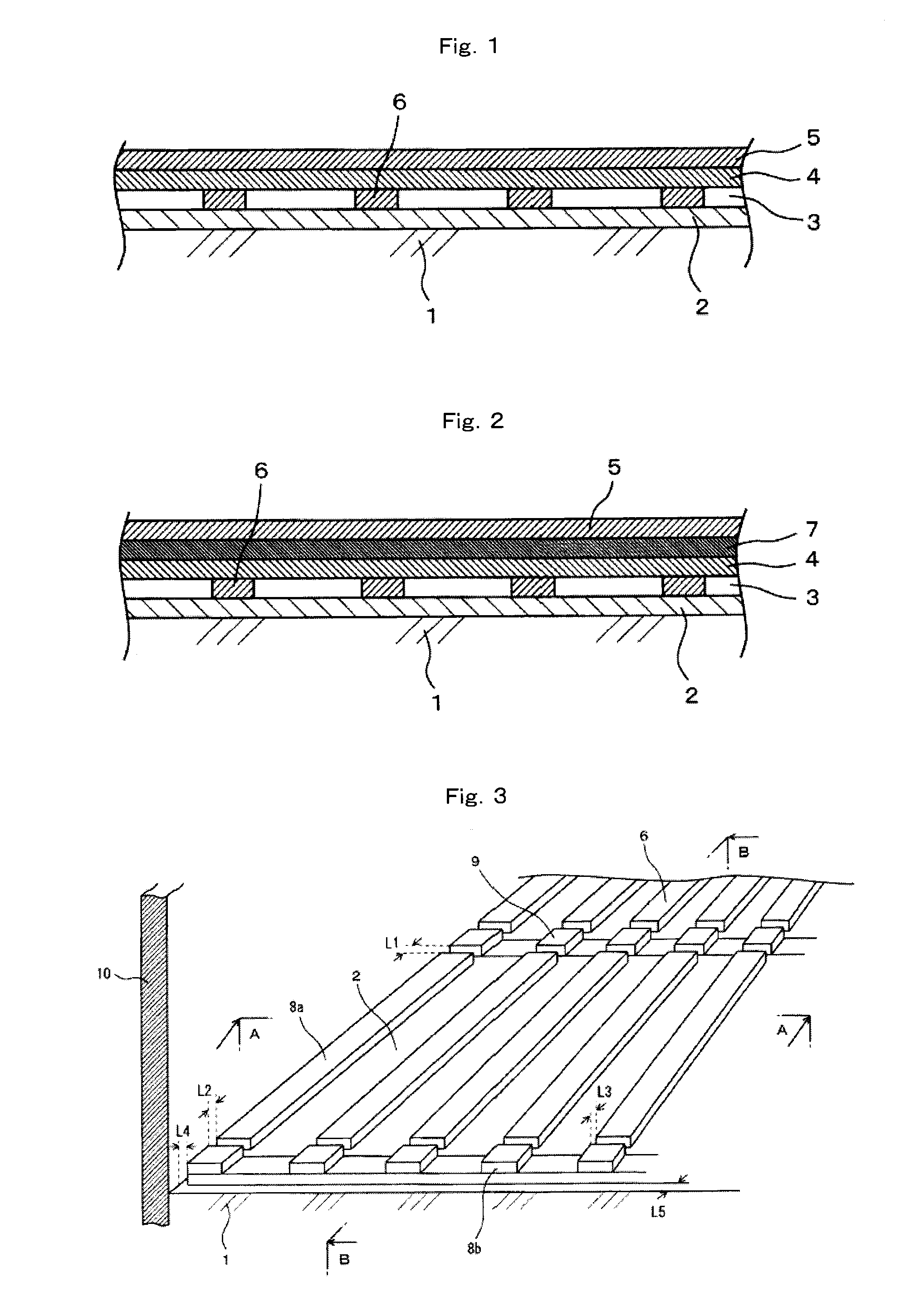

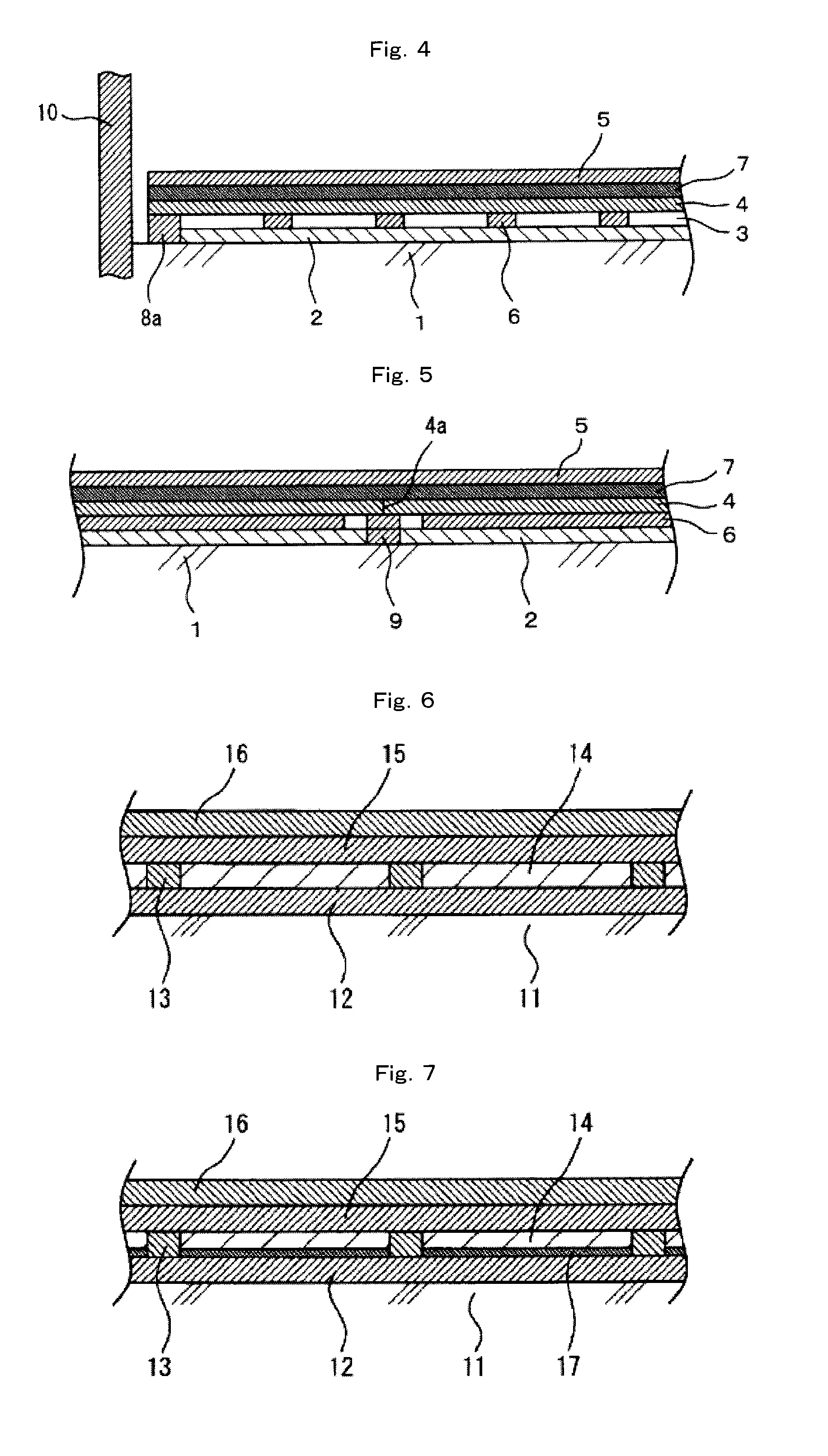

Sound insulation floor structure and sound insulation floor component as well as method for reducing floor impact sound

ActiveUS20130025965A1Avoid structureComfortableness to walkCovering/liningsWallsFiberThermal adhesive

A sound insulation floor structure comprises a floor backing member, a floor finishing layer, and an intermediate layer between the floor backing member and the floor finishing layer, the intermediate layer comprising a buffer member comprising a nonwoven structure. The nonwoven structure comprises a thermal adhesive fiber under moisture which is melt-bonded to a fiber of the nonwoven structure to fix the fibers. For example, the sound insulation floor structure may comprise, in sequence, a floor backing member 1, a buffer layer 2, an air layer 3, a hard layer 4, and a floor finishing layer 5. In the floor structure, a support member 6 is disposed between the buffer layer 2 and the hard layer 4. The support member may occupy 10 to 70% of a floor area. The sound insulation floor structure prevents subsidence of a floor member due to walking, achieves comfortableness to walk, and has improved floor impact sound insulation.

Owner:KURARAY CO LTD

Wear-resistant alloy cast iron modified material and method for manufacturing grinding plate blank casting thereby

The invention relates to a wear resistant alloy cast iron modified material and a method thereof of fabricating nog plate blank casting, pertaining to a sphere material fabrication technology. The problems of low grinding processing efficiency and short service life of present nog plate are solved. Wear resistant alloy cast iron materials are fabricated by cast iron and nano rare earth modified material. The nano rare earth modified material accounts for 0.01 to 5.00 percent of total weight of wear resistant alloy cast iron modified materials; alloy cast iron comprises Cr-Mo-Cu alloy cast iron, W-Cr-Cu alloy cast iron, W-Cr-Cu-Mn alloy cast iron, Cr-Mo-Cu-Ni alloy cast iron, Mo-Ni alloy cast iron, gray cast iron, white cast iron or ductile cast iron; the grain diameter of the nano rare earth modified material is 1 to 500nm of lanthanon and / or rare earth compounds; the nog plate blank casting fabricating method employs a melting casting method. The grinding processing efficiency of the nog plate fabricated by the wear resistant alloy cast iron modified material of the invention is higher than existing nog plate by more than 50 percent and the service life is twice or more as that of the existing nog plate and the application range is wide. The fabrication technic of the invention is characterized by simple technique and easy operation.

Owner:施伟晶 +1

Ultrahigh-strength all-austenite low-density steel and preparation method

The invention discloses ultrahigh-strength all-austenite low-density steel and a preparation method, and belongs to the technical field of metal materials and preparation thereof. The ultrahigh-strength all-austenite low-density steel comprises, by weight, 1.0%-1.6% of C, 25.0%-30.0% of Mn, 9.0%-13.0% of Al, 0.6%-1.0% of Mo, 1.0%-1.2% of V, 0.01%-0.04% of Ti, 0.02%-0.04% of Nb, less than or equal to 0.03% of P, less than or equal to 0.002% of S and less than or equal to 0.006% (60ppm) of N. And the balance of Fe and inevitable impurities are used for preparing raw materials. A uniform and stable all-austenite steady-state structure is obtained through casting, controlled rolling and controlled cooling technologies, and VC and MoC precipitated phases of 1-10 nanometers and a k phase of 10-50 nanometers are obtained on the basis of the stable all-austenite steady-state structure through the aging precipitation technology. The ultrahigh-strength all-austenite low-density steel and the preparation method are suitable for various fields of automobiles, buildings, engineering machinery and the like.

Owner:CENT IRON & STEEL RES INST

Hot rolled strip steel for automobile clutch diaphragm spring and manufacturing method thereof

The invention relates to hot rolled strip steel for an automobile clutch diaphragm spring and a manufacturing method thereof. The strip steel consists of the following components in percentage by mass: 0.45-0.57 percent of C, 0.12-0.43 percent of Si, 0.62-1.18 percent of Mn, 0.015-0.06 percent of Al, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, 0.85-1.30 percent of Cr, 0.08-0.30 percent of V and less than or equal to 0.005ppm of N. The manufacturing method is characterized by comprising the following steps: I, external refining: LF deep desulfuration+RH vacuum degasification and Ca treatment of balling inclusion; II, slab continuous casting, wherein the casting speed is 0.6-2.0m / min; III, red charging of a slab, wherein the red charging temperature is higher than or equal to 150 DEG C; IV, slab heating, wherein the heating temperature is 1,210-1,280 DEG C; V, rough rolling unit rolling, wherein the rough rolling final temperature is 1,030-1,150 DEG C; VI, fine rolling unit rolling, wherein the fine rolling final temperature is 810-920 DEG C; and VII, strip steel coiling, wherein the coiling temperature is 600-800 DEG C. The tensile strength Rm of the hot rolled strip steel manufactured by using the method is less than or equal to 1,150MPa, the yield strength is less than or equal to 850MPa, the elongation percentage is more than or equal to 18 percent, and the thickness of a decarbonized layer is not larger than 1.1 percent of the thickness of strip belt.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

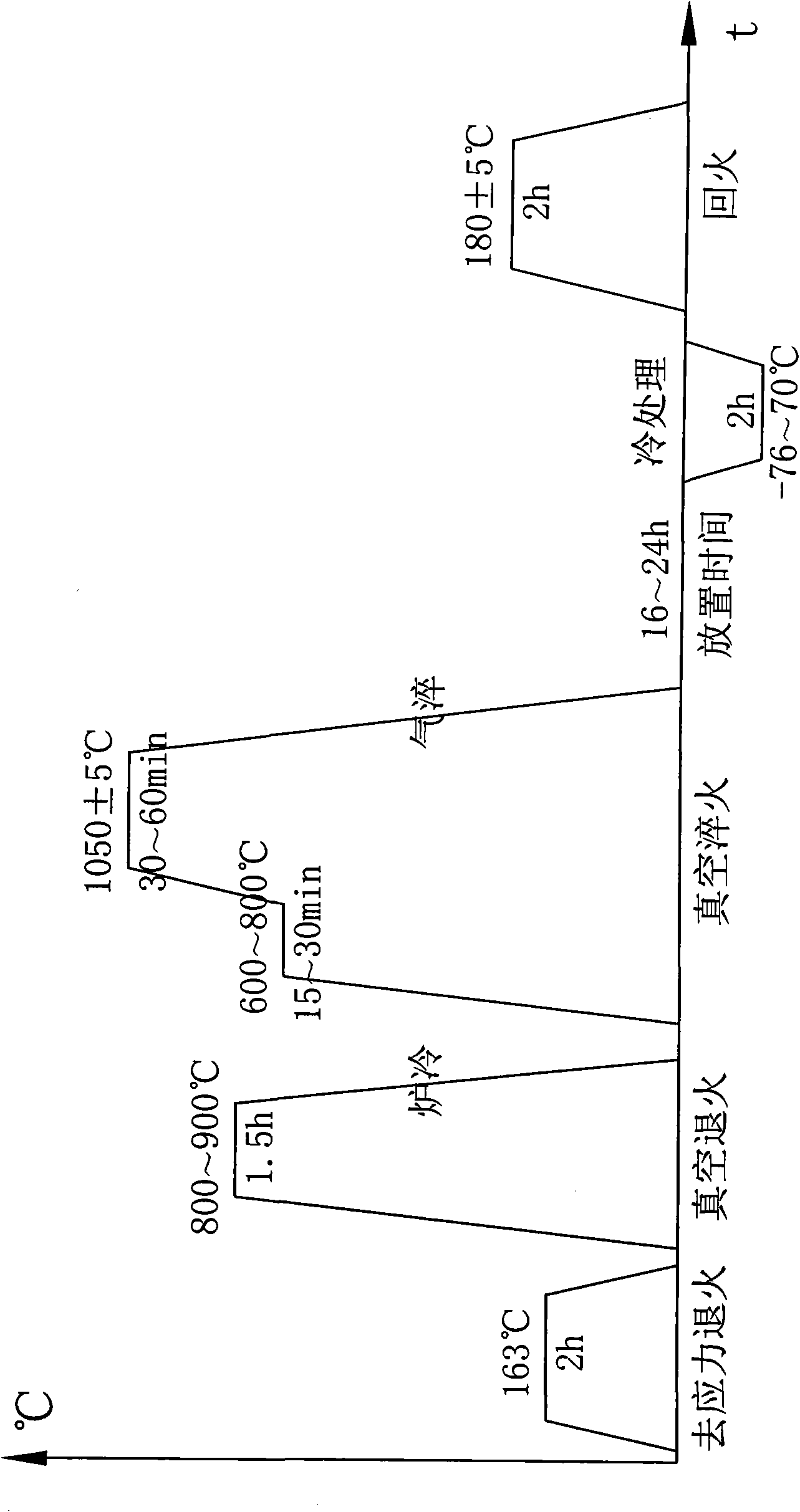

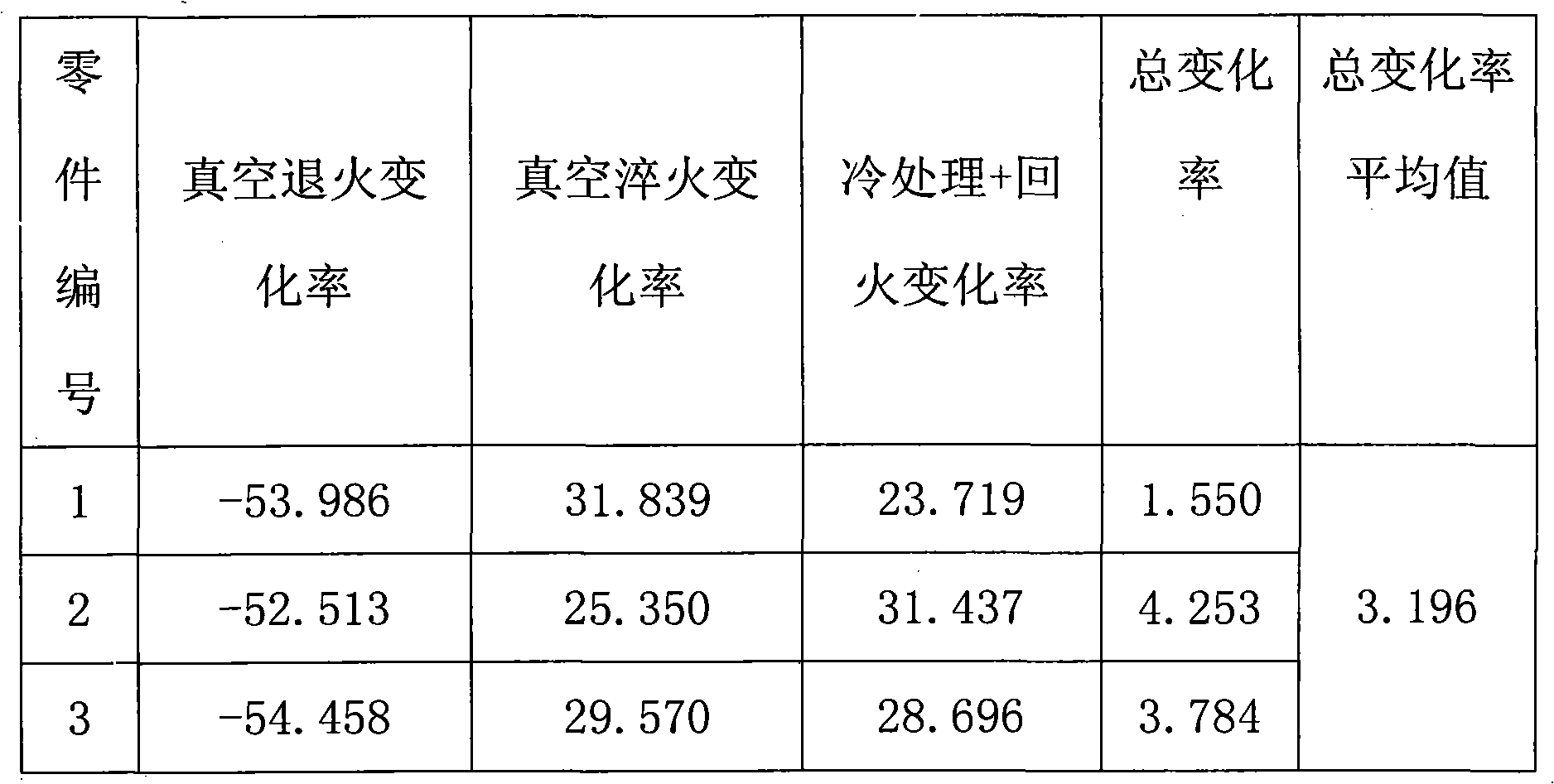

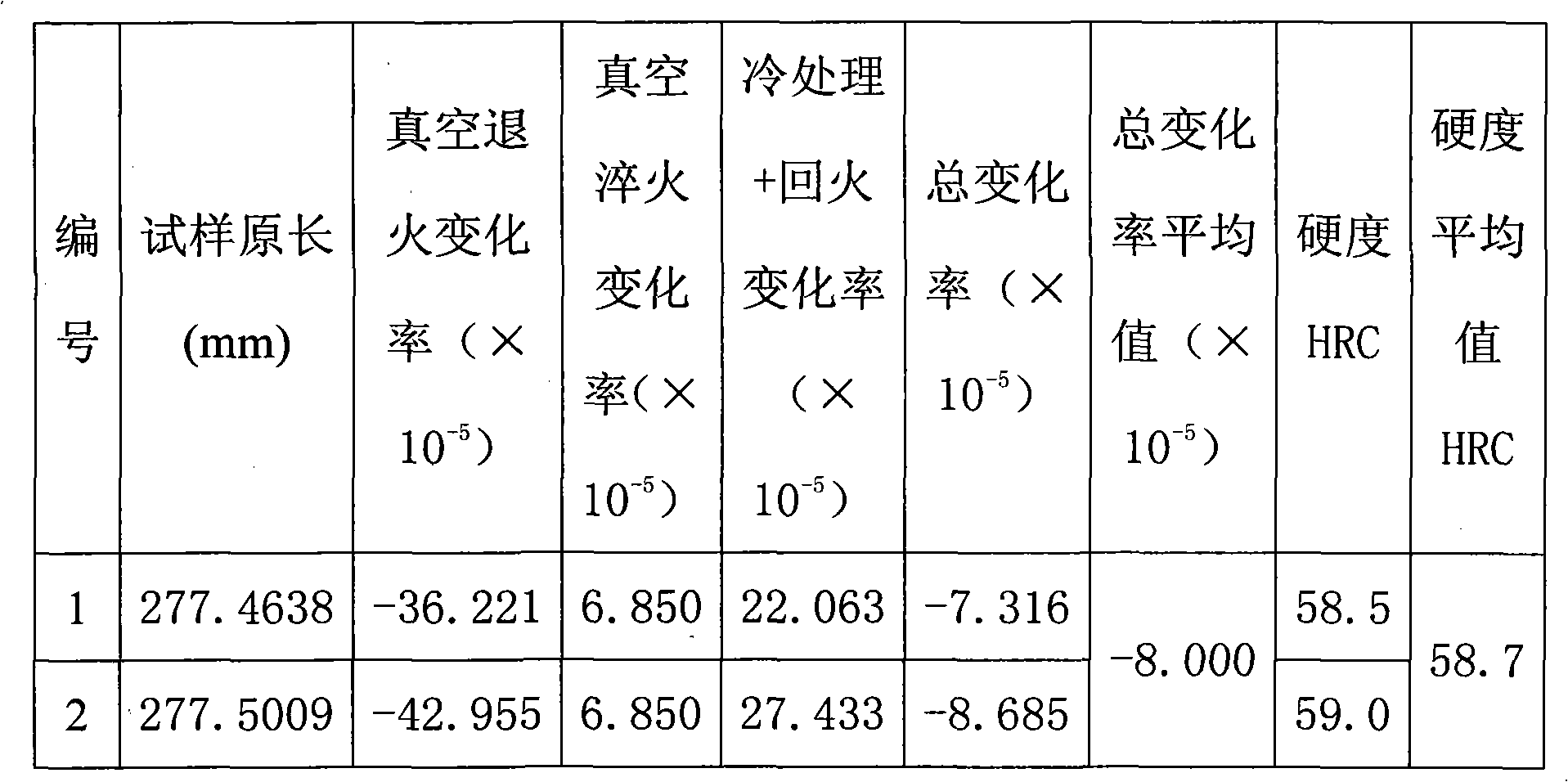

Heat treatment method of 9Cr180Mo steel valve bush part

InactiveCN101845546AUniform hardnessFurnace typesHeat treatment furnacesCold treatmentStress relieving

The invention discloses a heat treatment method of a 9Cr180Mo steel valve bush part, relates to a heat treatment method and solves the problems that the 9Cr180Mo steel valve bush part obtained by the heat treatment method has large axial size change and the product subjected to the heat treatment has low qualified rate. The heat treatment method comprises the following steps of stress relieving annealing, vacuum annealing, vacuum quenching, austenite stabilization, cold treatment and drawing temper. The axial size change rate of the 9Cr180Mo steel valve bush part is less than + / -15*10<-5> which is greatly reduced in comparison with the axial size change rate (+ / -15*10<-5>+ / -100*10<-5>) of the 9Cr180Mo steel valve bush part obtained by the traditional heat treatment method.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com