Fabrication process of hexagonal flange toothed bolt

A manufacturing process and flange surface technology, applied in the field of hexagonal flange surface toothed bolt manufacturing process, can solve the problems of raw material waste, unstable quality, difficult processing, etc., and achieve reasonable metal volume deformation, reasonable metal flow, and hardness. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described below in conjunction with accompanying drawing.

[0025] as attached figure 1 Shown is a hexagonal flange surface toothed bolt manufacturing process according to the present invention, which adopts medium carbon cold heading steel wire rod, and it mainly includes the following steps:

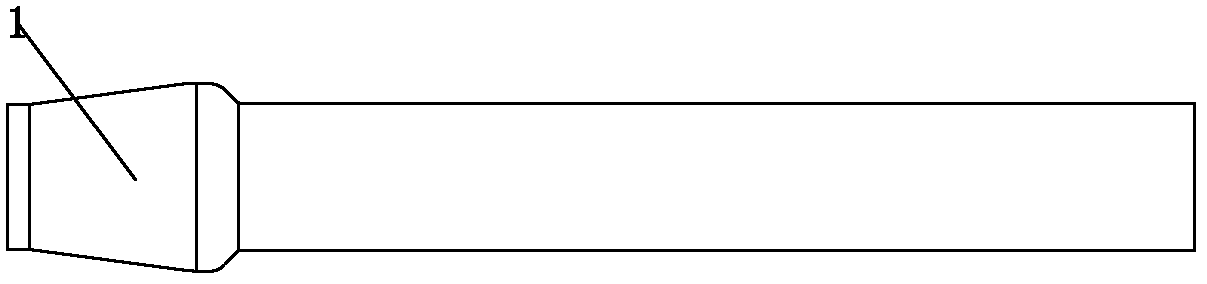

[0026] (1) Shearing and blanking: At the cutting station of the multi-station cold forging machine, cut the round material to the workpiece A with the same length, see figure 1 ;

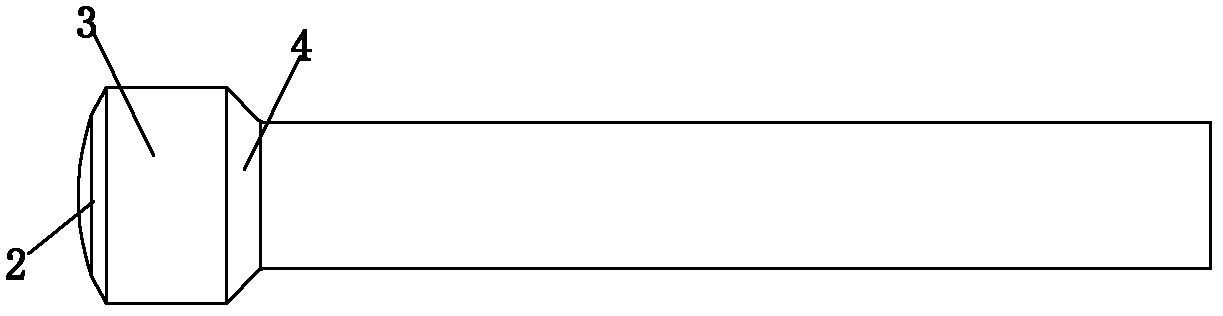

[0027] (2) Pre-upsetting workpiece B: send the workpiece A obtained in step (1) to the first station of the cold forging machine to pre-upset the conical head 1, the height of the conical head 1 is controlled to 17mm, The included angle of the cone is controlled to be 15°, and the workpiece B is obtained, see figure 2 ;

[0028] (3) After pressing the dome, the workpiece C is obtained: send the workpiece B obtained in step (2) to the second station of the cold forging mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com