Multipurpose all-austenite low-density steel and preparation method thereof

A technology of full austenitic, low-density steel, applied in the field of metal materials and their preparation, can solve the problems of poor plasticity, high cost, unsuitable for industrial production and popularization, and reduced density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

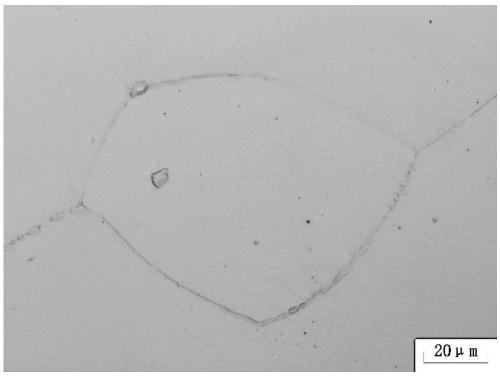

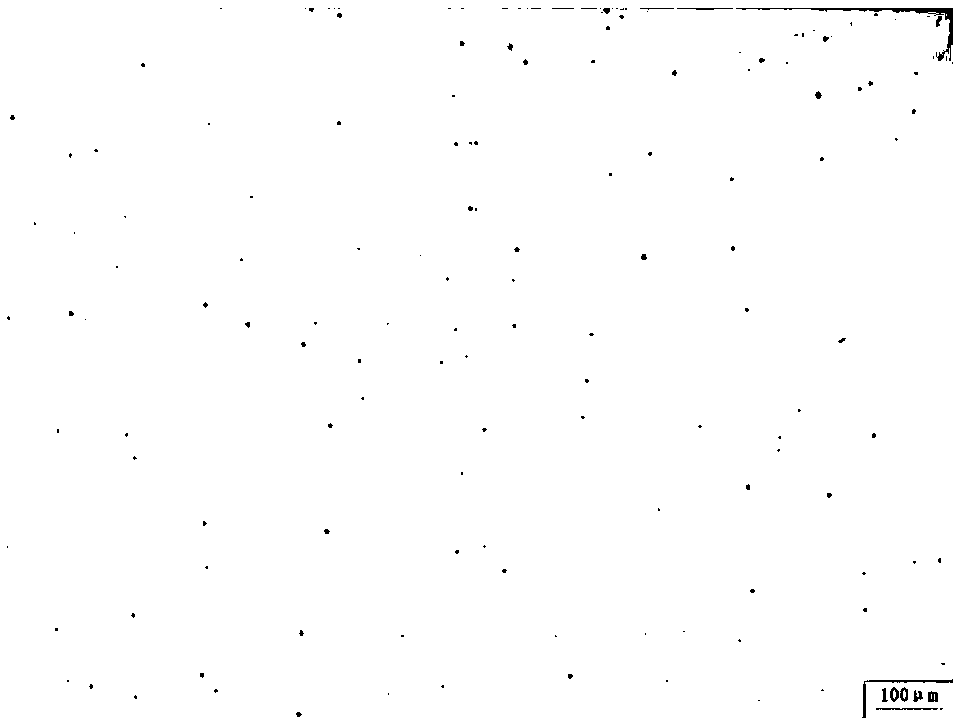

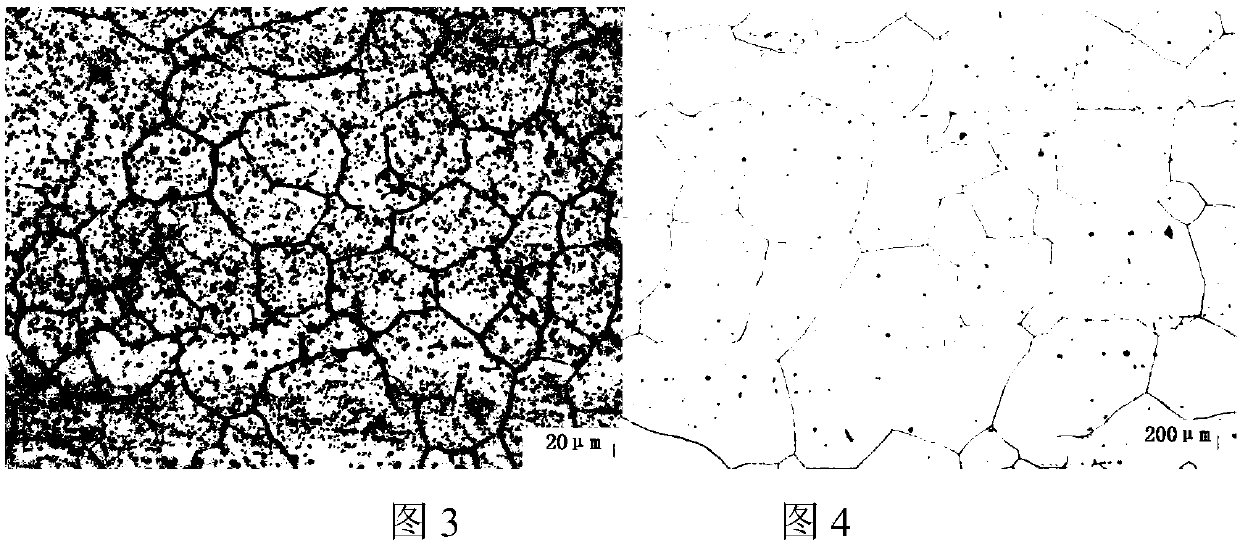

Image

Examples

Embodiment Construction

[0057] The following are examples of alloy steel produced with 10 chemical components under the same smelting, casting and rolling process conditions and their performance test results. The chemical composition and mechanical properties are shown in Table 1, and the actual production process parameters are shown in Table 2.

[0058] After hot rolling, direct water cooling and water cooling after warming were carried out respectively, followed by solid solution, cold rolling and annealing after cold rolling. The specific process parameters and material mechanical properties are shown in Table 3 and Table 4.

[0059] Table 1 embodiment chemical composition and hot-rolled performance (mass fraction %, balance is Fe)

[0060]

[0061] Table 2 actual production process parameters

[0062]

[0063] Table 3 Performance of hot rolling + water cooling + medium temperature aging process

[0064]

[0065] Table 4 Process and mechanical properties of hot rolling + water cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com