Ultrahigh-strength all-austenite low-density steel and preparation method

A low-density steel and austenitic technology, which is applied in the field of ultra-high-strength low-density steel and its preparation, can solve the problems of reduced density, limited Al addition for lightweight, complicated process, etc., and achieve uniform hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

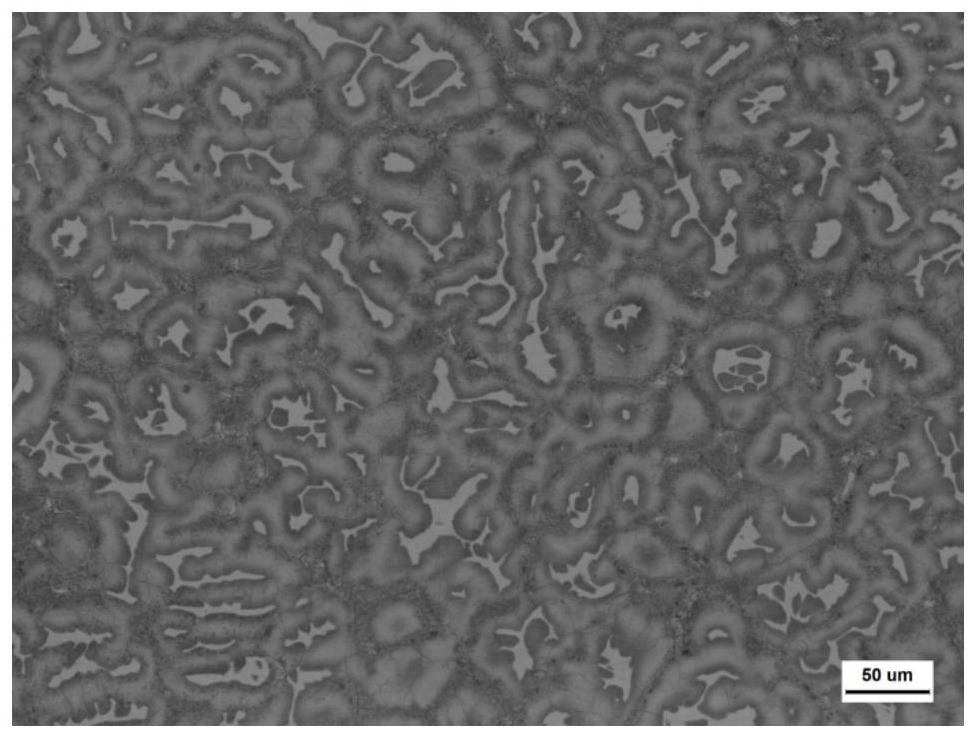

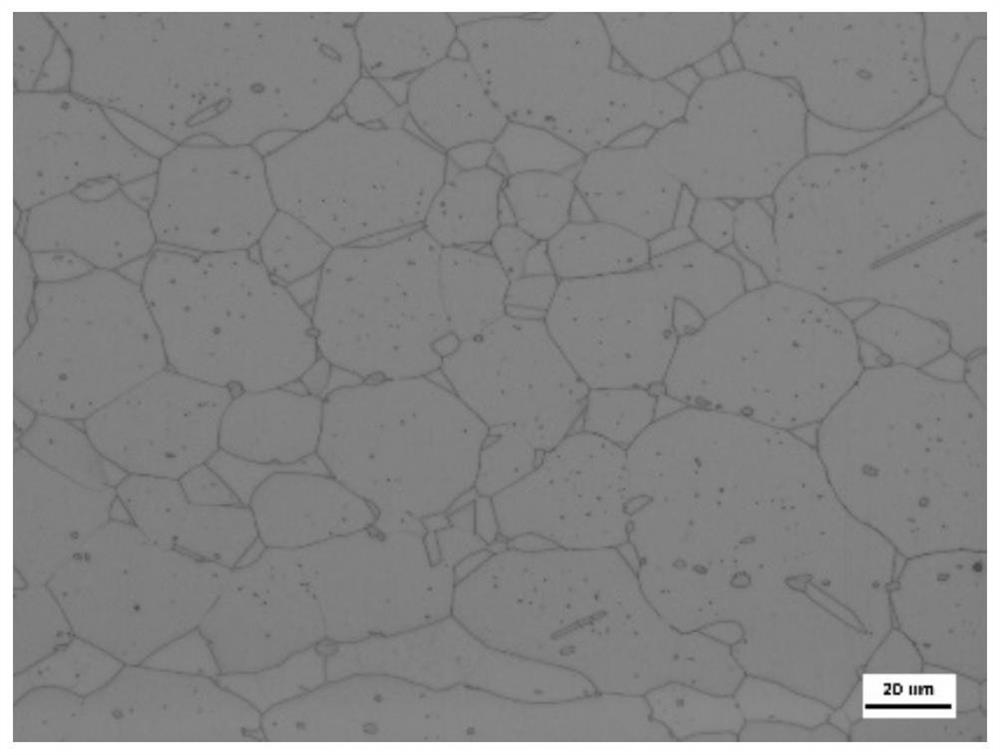

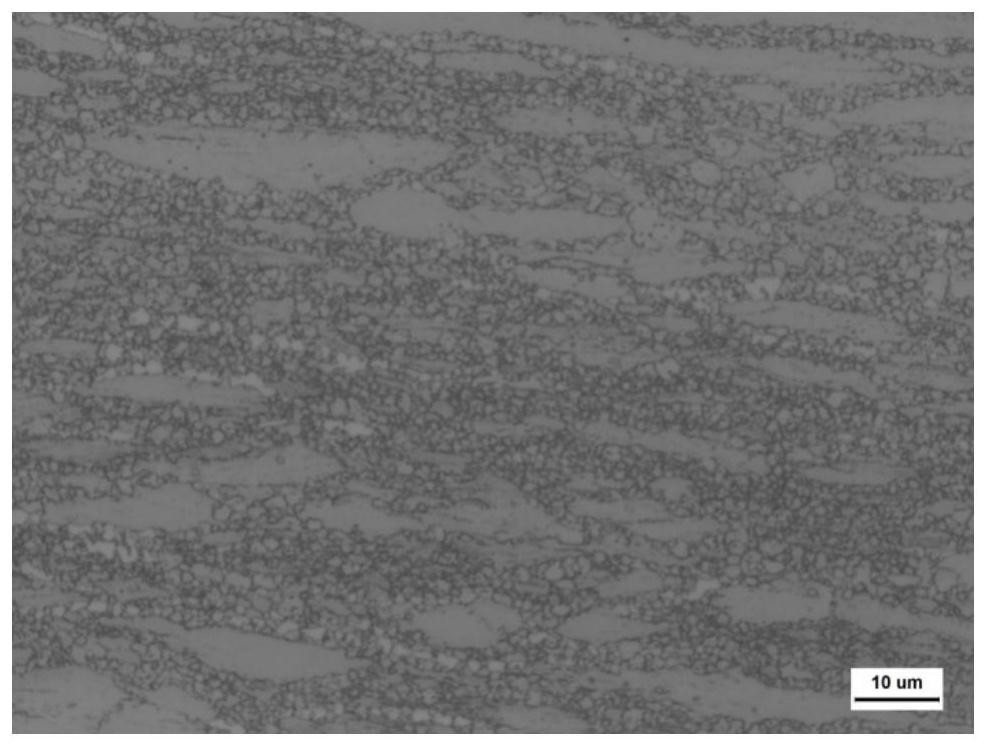

Image

Examples

Embodiment Construction

[0045] The following are examples of alloy steel produced with 8 chemical components under the same smelting, casting and rolling process conditions and their performance test results. The chemical composition is shown in Table 1, and the actual production process parameters are shown in Table 2 and Table 3.

[0046] After hot rolling, it was directly water-cooled, and the aging process was also tested later. The comprehensive mechanical properties of the specific materials are shown in Table 4.

[0047] Table 1 embodiment chemical composition (mass fraction %, balance is Fe)

[0048]

[0049]

[0050] Table 2 Smelting and forging blank production process parameter range

[0051]

[0052] Table 3 Hot rolling and aging process parameter range

[0053]

[0054] Table 4 comprehensive mechanical properties

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com