Heat treatment method of 9Cr180Mo steel valve bush part

A heat treatment method and part technology, applied in the field of heat treatment, can solve the problems of large axial dimension change of parts and low product qualification rate, and achieve the effect of uniform hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

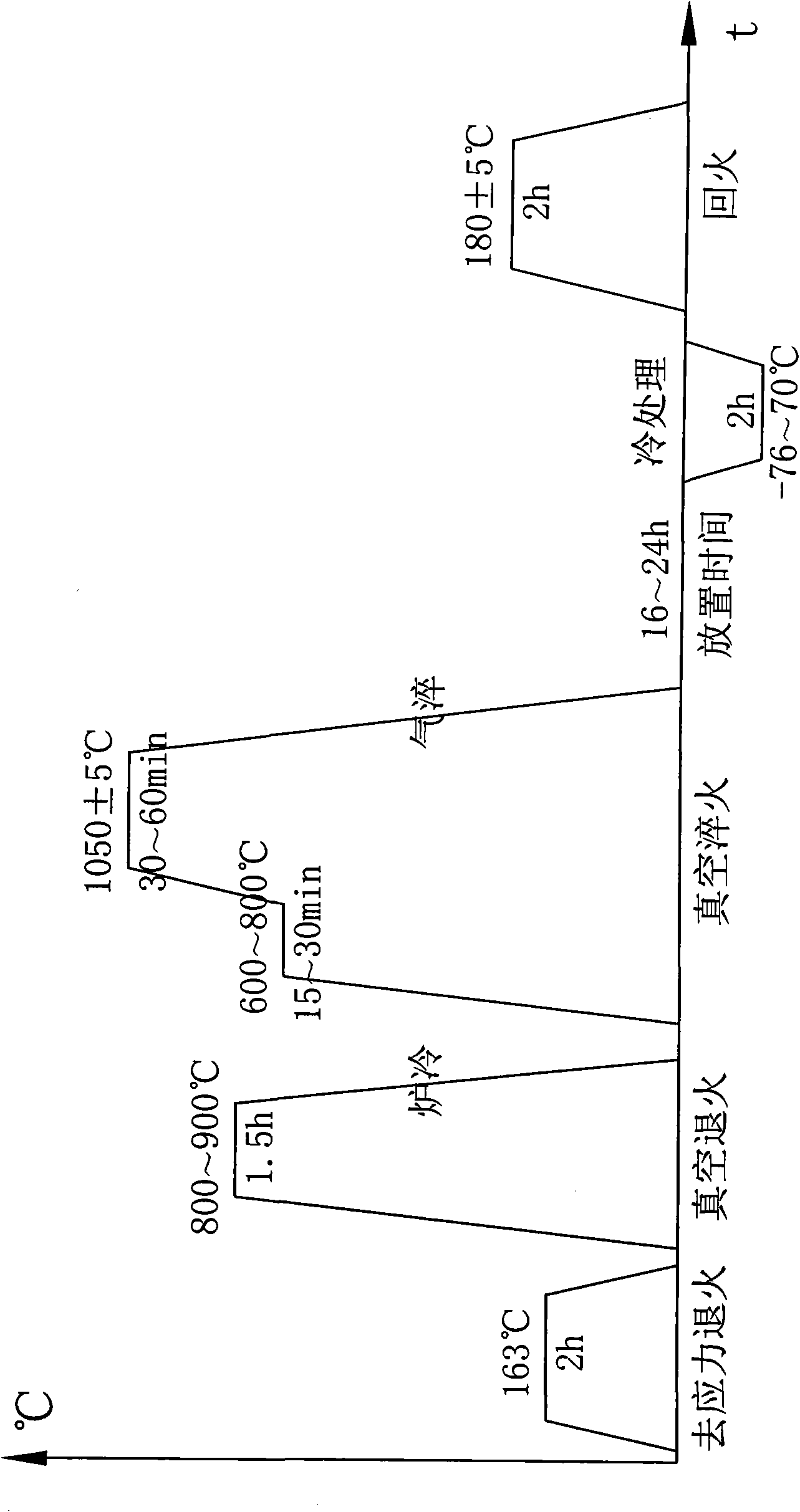

[0024] Specific implementation mode one: as figure 1 As shown, the heat treatment method steps of the 9Cr18Mo steel valve sleeve parts of the present embodiment are as follows:

[0025] Step 1. Stress relief annealing: heat the furnace to 163°C, then place the 9Cr18Mo steel valve sleeve parts in the heating furnace, keep the furnace temperature for 2 hours, take the 9Cr18Mo steel valve sleeve parts out of the heating furnace, and place them in the air Cool to room temperature;

[0026] Step 2. Vacuum annealing: place the cooled 9Cr18Mo steel valve sleeve parts in a vacuum heating furnace, and vacuumize the vacuum heating furnace to a degree of 10 -3 Pa, heat the furnace temperature of the vacuum heating furnace to 800-900°C at a heating rate of 15°C / min, keep the furnace temperature for 1.5 hours, cool with the furnace, and cool the temperature to 300°C, and then heat the 9Cr18Mo steel valve sleeve parts from vacuum Take out from the furnace;

[0027] Step 3, vacuum quenchi...

specific Embodiment approach 2

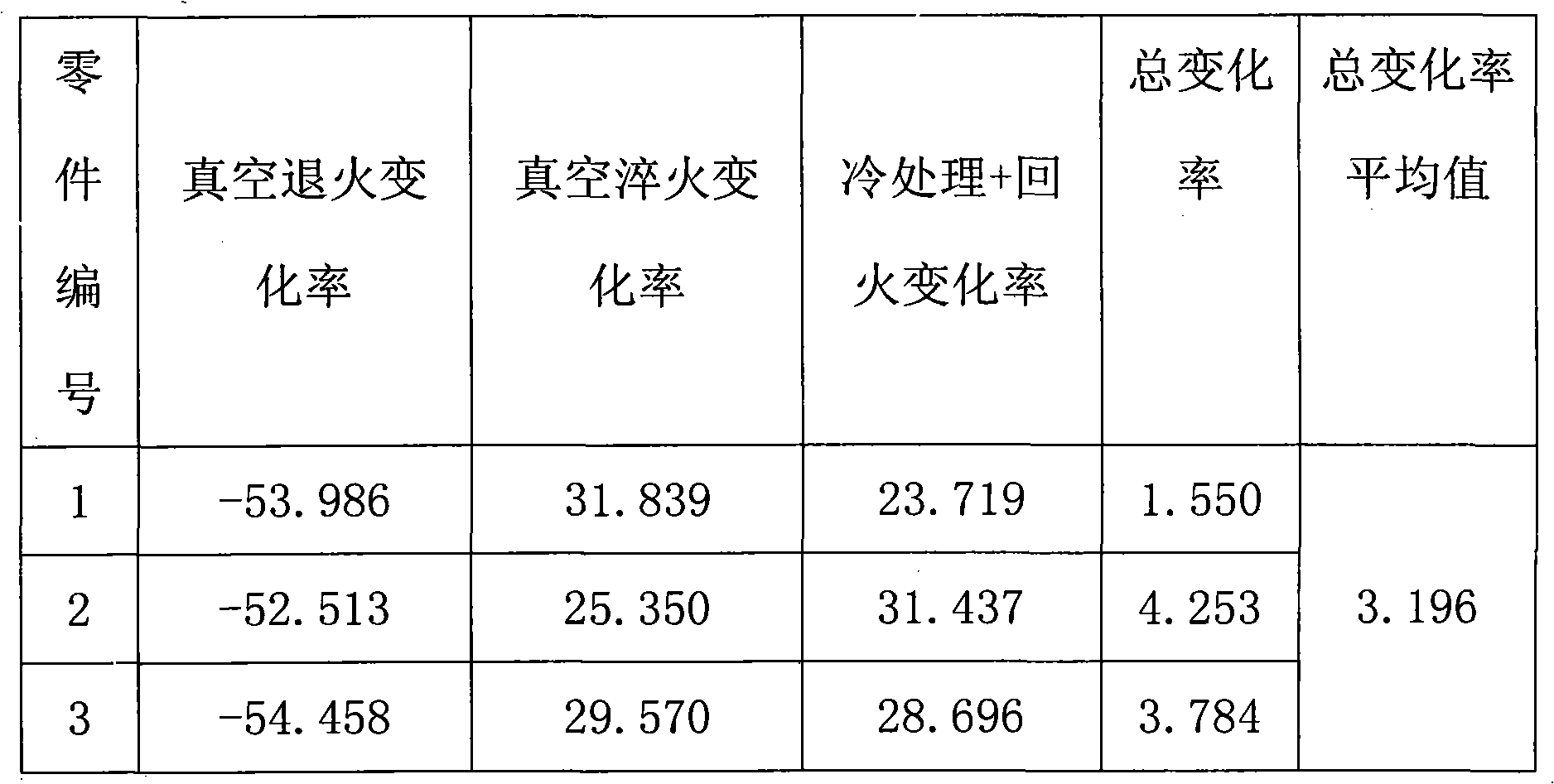

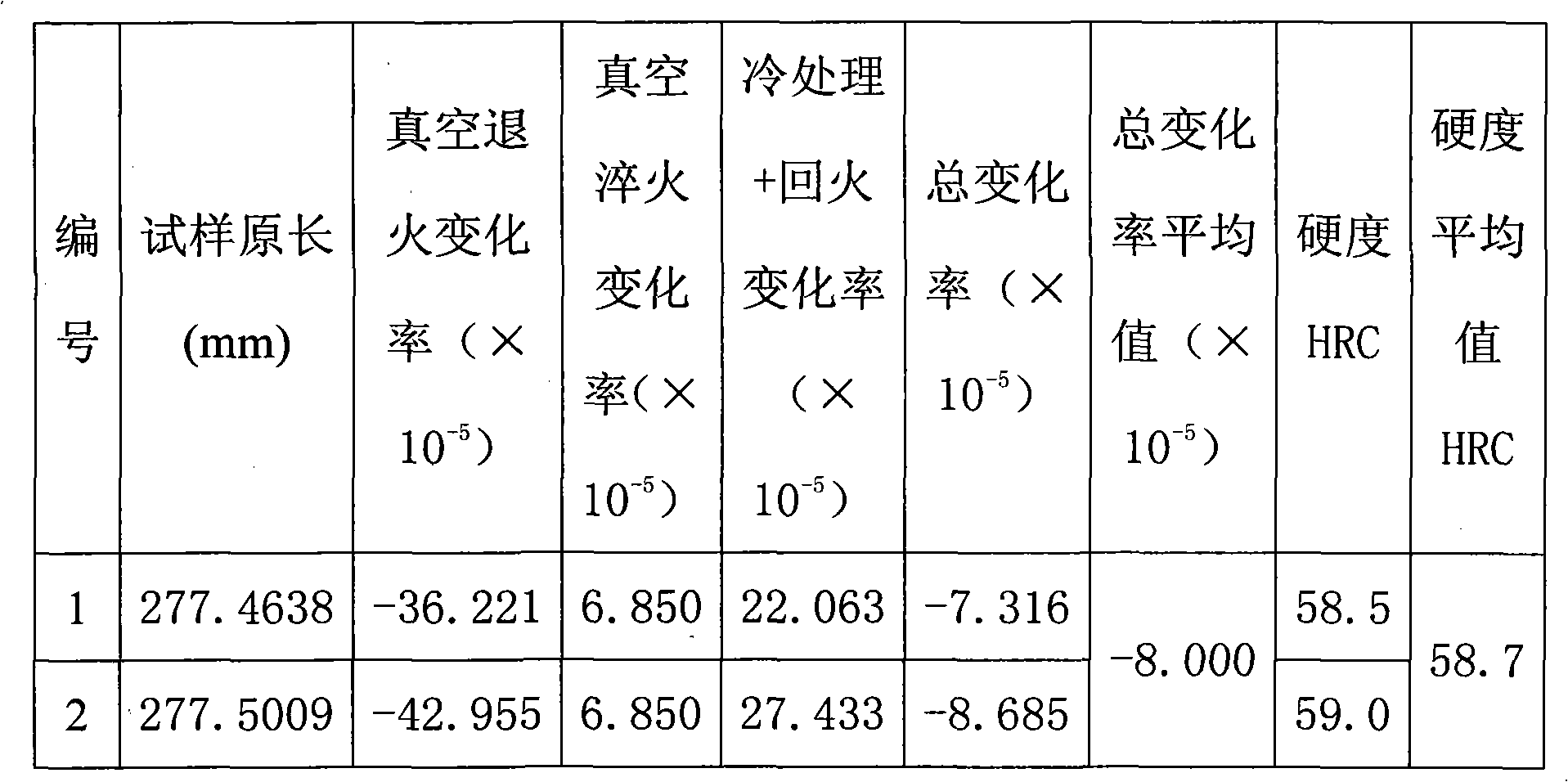

[0031] Embodiment 2: In step 2 of this embodiment, after the vacuum heating furnace is evacuated, the furnace temperature of the vacuum heating furnace is heated to 850° C. at a heating rate of 15° C. / min. In this way, the axial dimensional change rate of the obtained 9Cr18Mo steel valve sleeve parts is less than ±15×10 -5 , compared with the axial dimensional change rate of 9Cr18Mo steel valve sleeve parts obtained by the existing heat treatment method (±15×10 -5 ~±100×10 -5 ) has been greatly reduced. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: In step 3 of this embodiment, after the vacuum quenching furnace is evacuated, the furnace temperature of the vacuum heating furnace is heated to 750° C. at a heating rate of 15° C. / min. In this way, the axial dimensional change rate of the obtained 9Cr18Mo steel valve sleeve parts is less than ±15×10 -5 , compared with the axial dimensional change rate of 9Cr18Mo steel valve sleeve parts obtained by the existing heat treatment method (±15×10 -5 ~±100×10 -5 ) has been greatly reduced. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com