Steel with excellent processing performance for gardening tool and production method thereof

A gardening tool and processing performance technology, which is applied in the field of hot-rolled coils and its manufacturing, can solve the problems of poor shape of hot-rolled plates, high resistance to thermal deformation of boron-containing steel, and large amount of grinding, etc., to achieve excellent processing and forming performance, The effect of high processing yield and improvement of hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

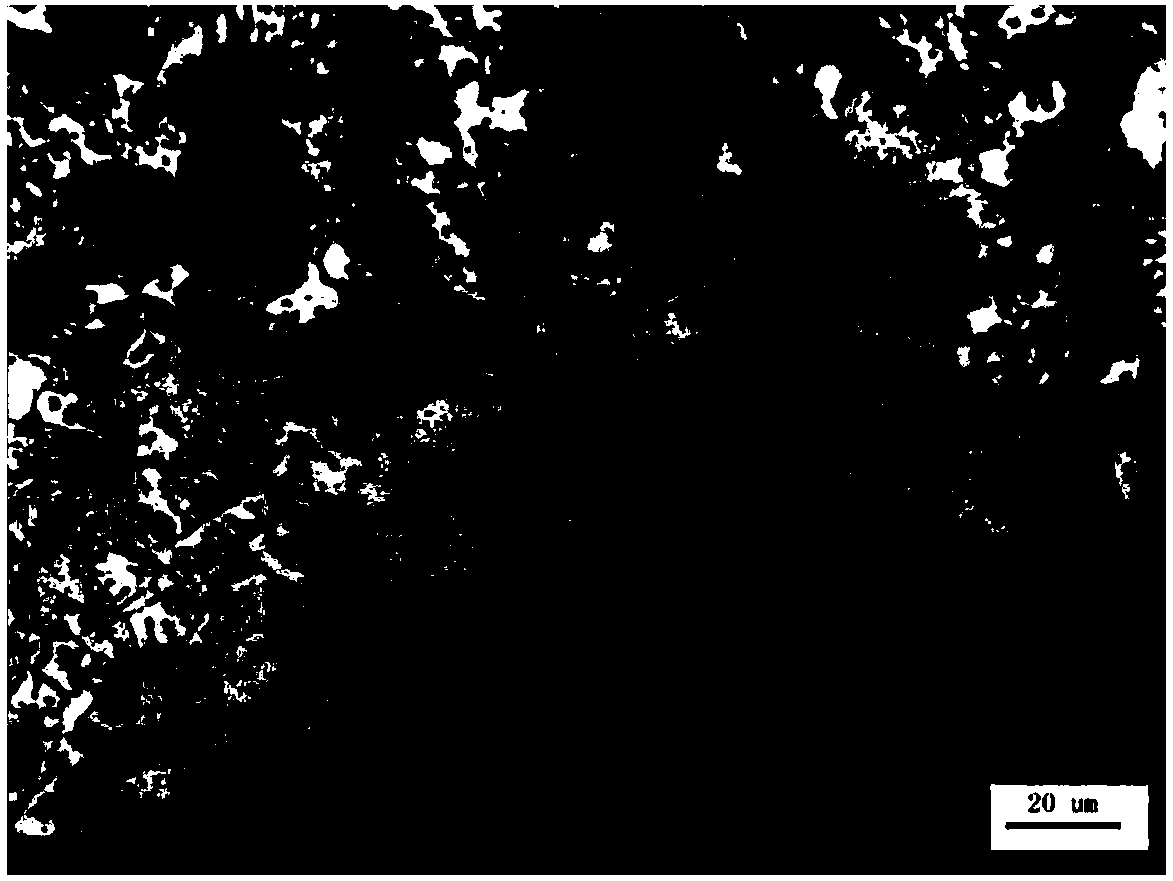

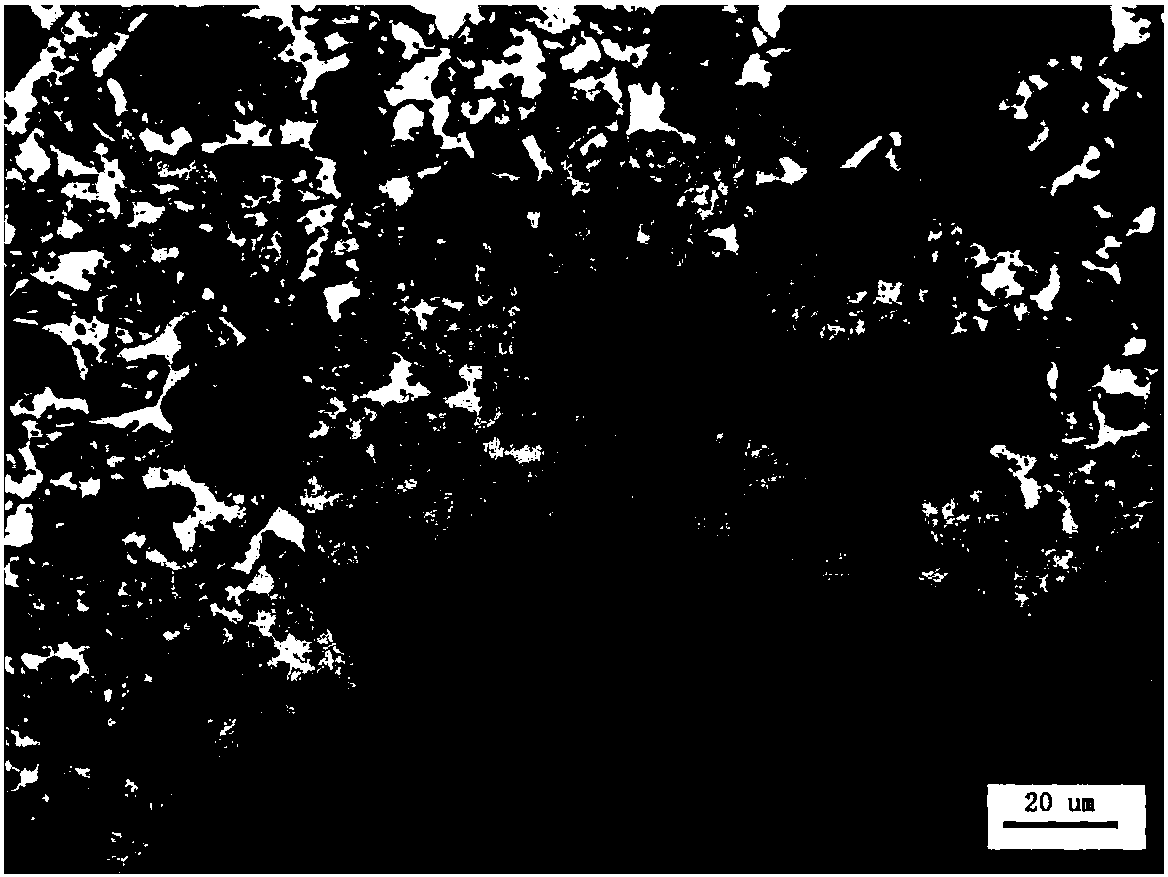

Image

Examples

Embodiment Construction

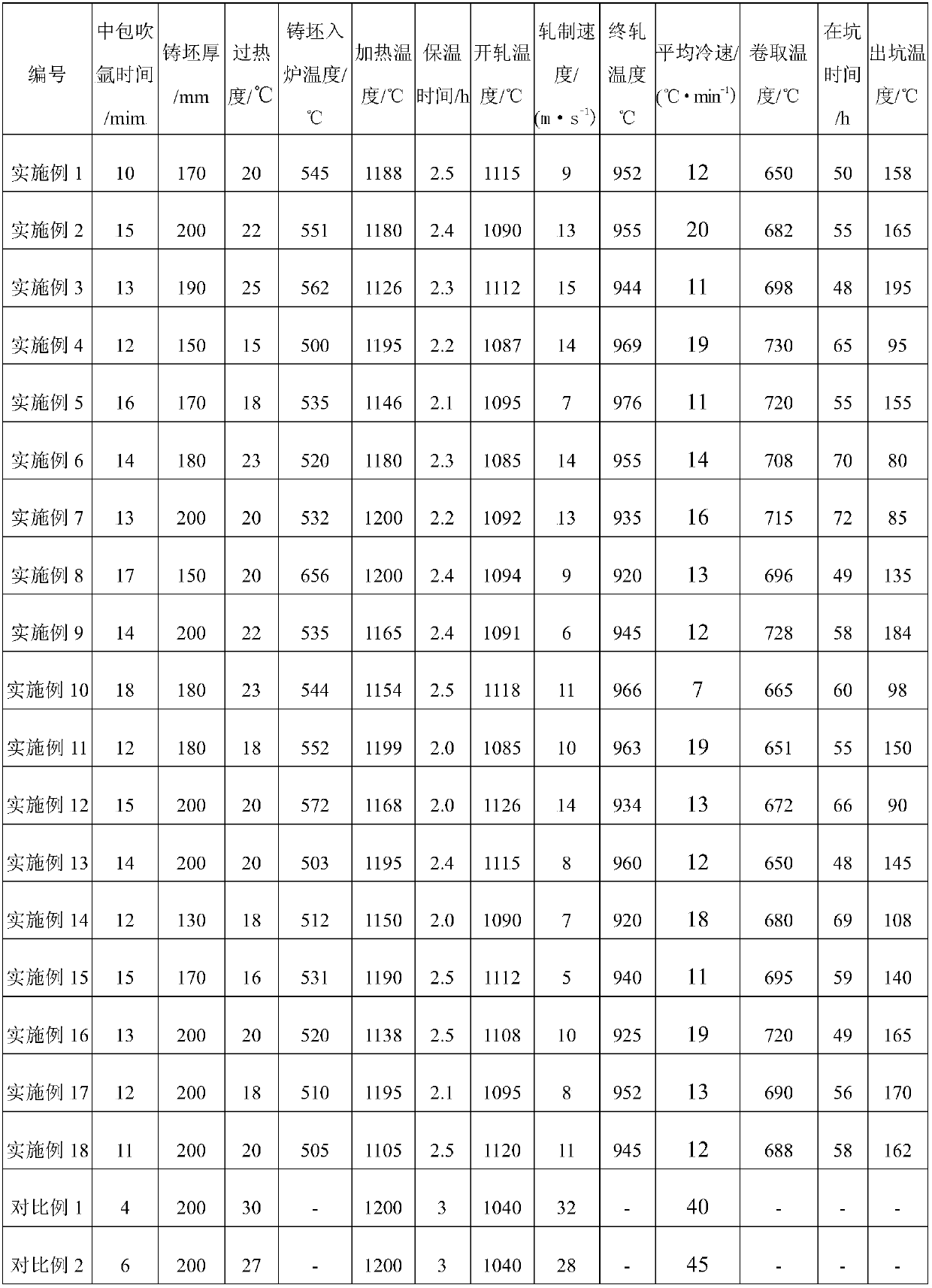

[0042] The technical problems involved in the present invention are solved by the following technical solutions: a garden tool steel with excellent processing performance and its production method, the mass percentage of its chemical composition is: C: 0.45% to 0.65%, Si: 0.1% to 0.40% , Mn: 0.5%~1.5%, Cr: 0.1%~0.5%, Al: 0.02%~0.05%, Ni≤0.4%, Cu≤0.5%, impurity elements P≤0.020% and S≤0.010%, the rest is Fe and unavoidable impurities. The hot-rolled coil plate of the present invention is rolled by continuous casting slabs smelted in a converter, refined outside a furnace, and poured. The thickness of the continuous casting slab is 130-200mm. Refining uses Al deoxidizer to deoxidize. The argon blowing time in the tundish is not less than 10 minutes, and the pouring superheat is ≤25°C. The continuous casting process adopts soft reduction technology. The continuous casting slab hot charging production process is adopted. After continuous casting and sawing, the casting slab is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com