Quenching process and its quenching device for bearing internal and external rings

A technology for quenching equipment and inner ring of bearings, which is applied in the direction of quenching equipment, heat treatment equipment, manufacturing tools, etc., can solve the problems of low utilization rate of heating equipment, inability to process black leather, uneven deformation, etc. The effect of small area and uniform hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

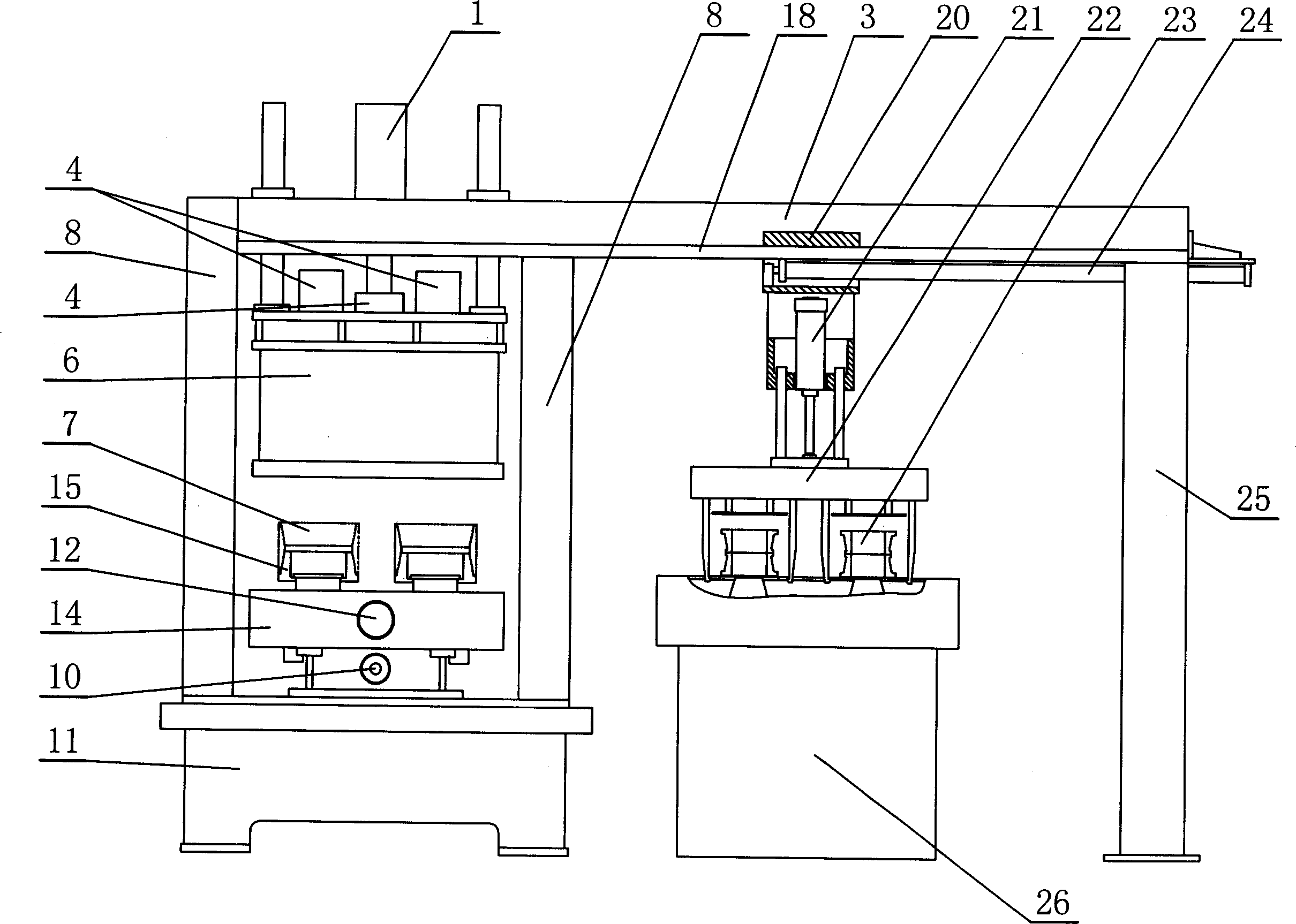

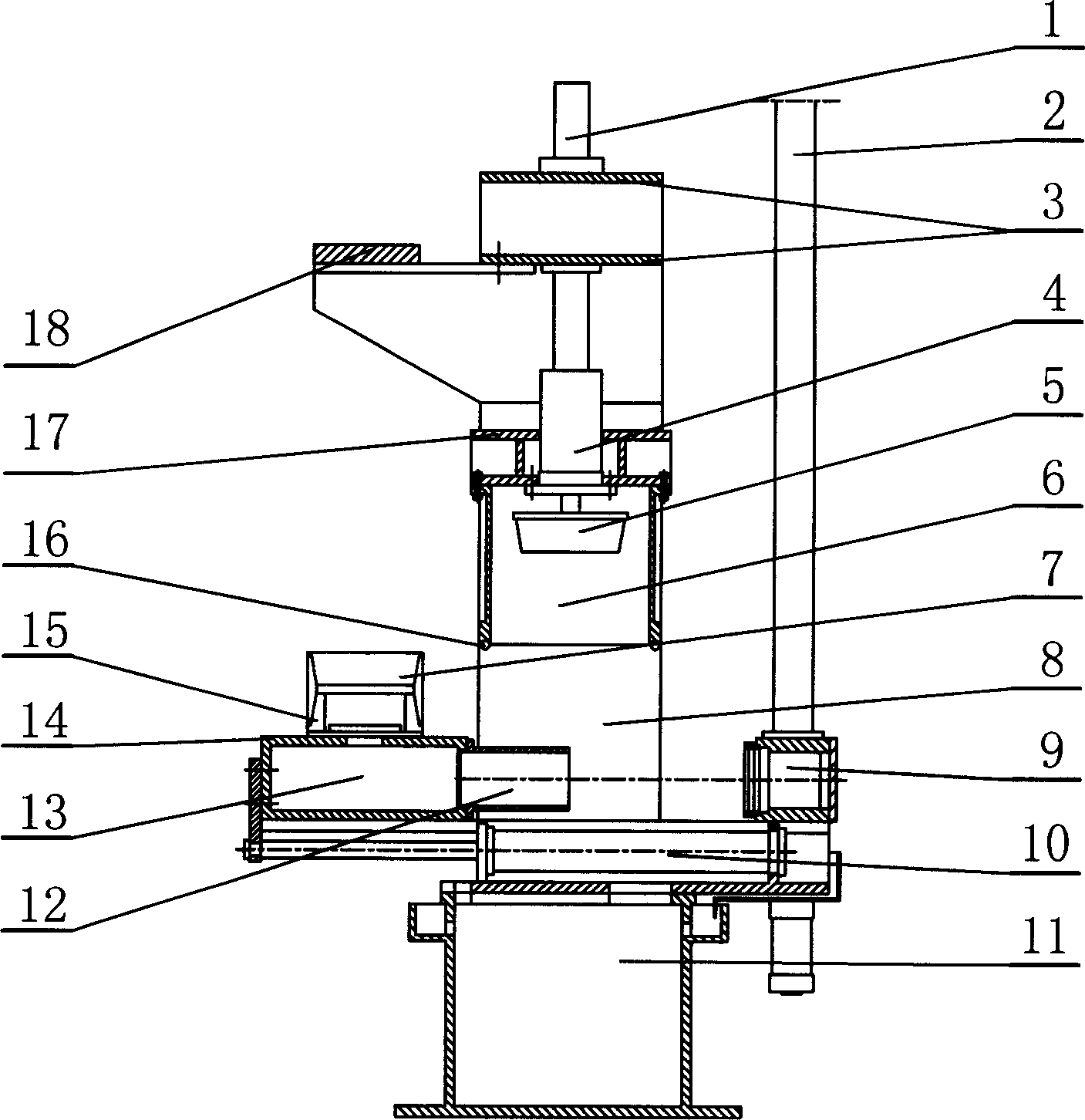

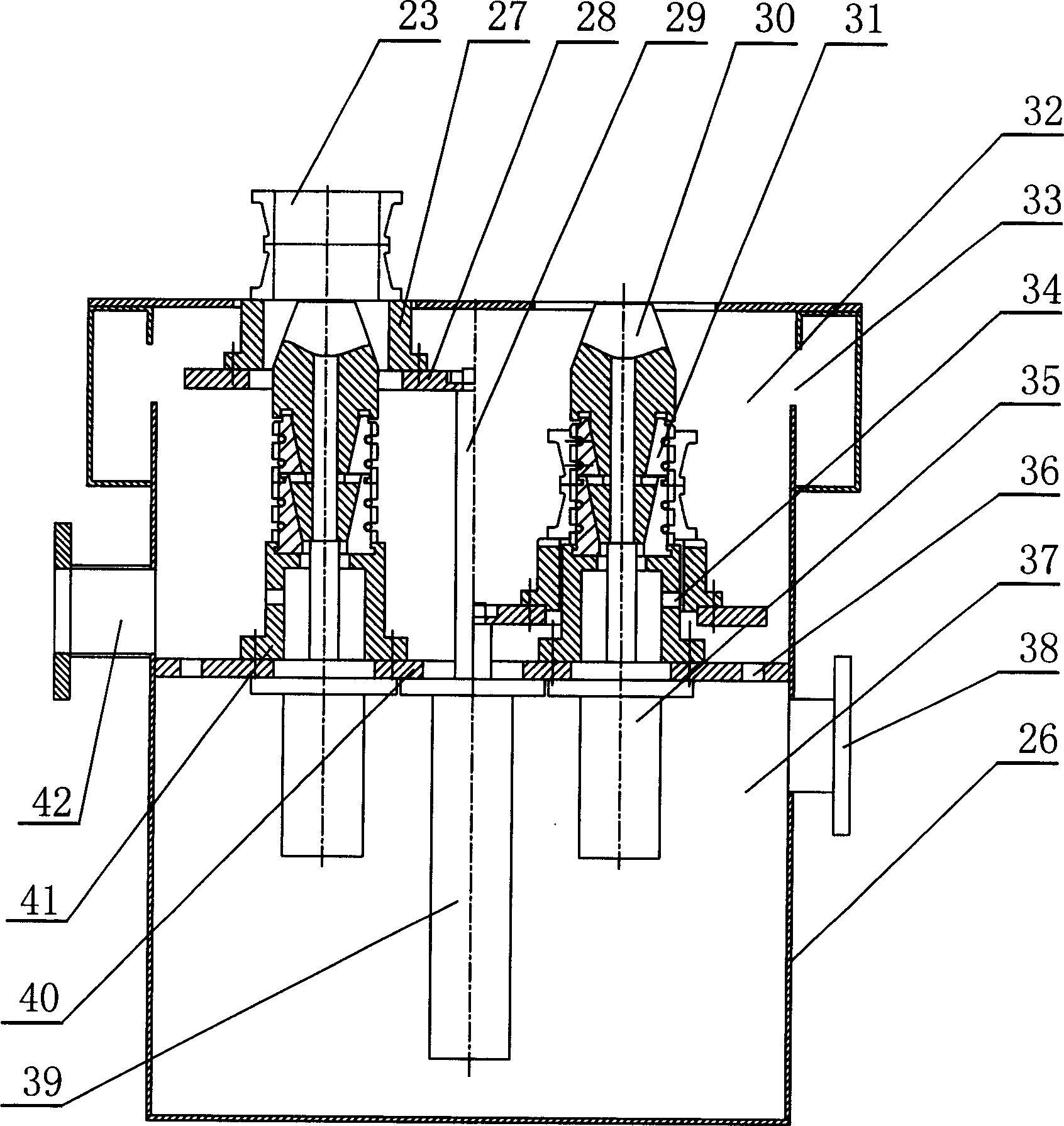

[0022] A set of railway bearings is composed of two inner sleeves and an outer sleeve. When quenching the inner and outer rings, the two bearing inner sleeves are stacked and installed in a bearing outer sleeve, and then sent to a continuous heating furnace for heating , the heated inner and outer rings of railway bearings are transported to such as figure 1 On the workbench 26 of the bearing inner sleeve quenching equipment shown, the manipulator 22 installed on the guide rail 18 of the protruding part of the beam 3 grabs the bearing outer sleeve 7, moves to the left along the guide rail, and puts it into the box-type The bearing jacket on the workbench 14 is quenched in the lower mold 15, and the two sets of bearing inner sleeves 23 are quenched by the bearing inner sleeve quenching equipment installed on the right side.

[0023] After the quenching is finished, after the bearing outer cover 7 is picked up by the manipulator 22, the material is discharged after being fitted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com