Quenching and tempering type abrasion resistant steel and heat treating method thereof

A heat treatment method and wear-resistant steel technology, which is applied in the field of quenched and tempered wear-resistant steel, can solve the problems of not being able to improve the surface hardness and limit the scope of use, and achieve the effects of shortening the tempering time, easy operation, and reasonable matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

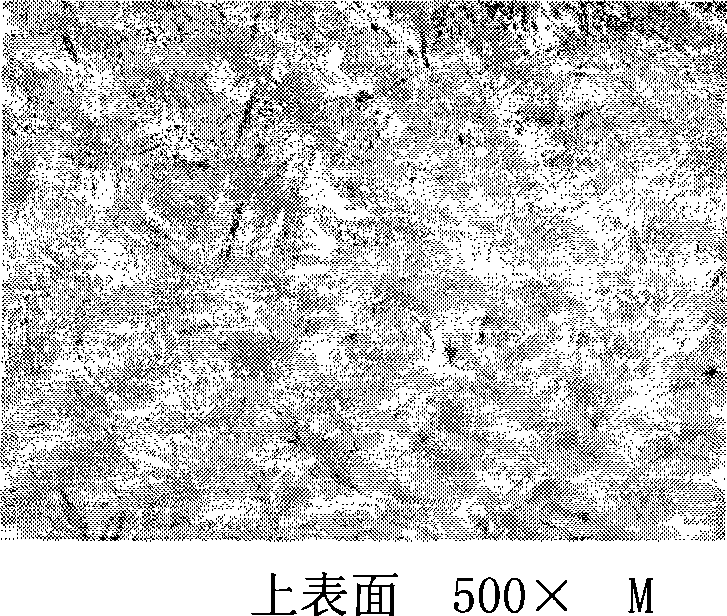

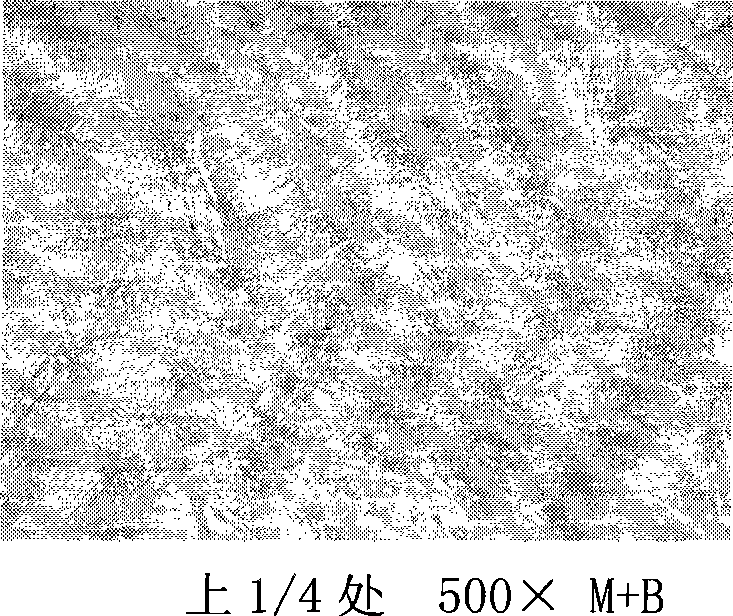

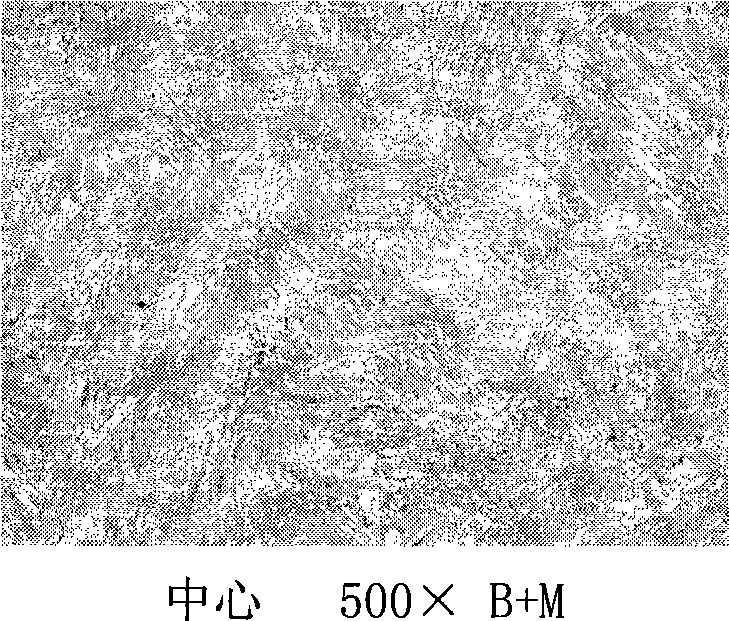

[0018] The quenched and tempered wear-resistant steel in this embodiment (take furnace number: 07102663N batch number: GZH73420480mm thick WNM360B as an example), comprises the chemical composition composition of following percentage by weight: C 0.17%, Si 0.31%, Mn 1.31%, P 0.014%, S 0.003%, Ni 0.46%, Cr 0.60%, Cu 0.07%, Mo 0.45%, Nb 0.025%, V 0.046%, Al 0.042%, Ti 0.022%, B 0.0028%, the rest is Fe and unavoidable Impurities. The smelting method of the wear-resistant steel of the present invention is: electric furnace + refining outside the furnace.

[0019] Heat treatment method of the present invention is:

[0020] Quenching temperature: 930°C; holding time: PLC+30min, where PLC means computer logic program control;

[0021] Cooling roll speed: 2m / min; cooling water volume: maximum water volume (total amount about 6200-6700 units)

[0022] Tempering temperature: 585°C, holding time PLC+60min.

[0023] Properties of quenched steel plate

[0024] Mechanical properties (s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com