Patents

Literature

1086 results about "Emulsion explosive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Emulsion explosive. An explosive material containing substantial amounts of oxidizer dissolved in water droplets surrounded by an immiscible fuel or droplets of an immiscible fuel surrounded by water containing substantial amounts of oxidizer.

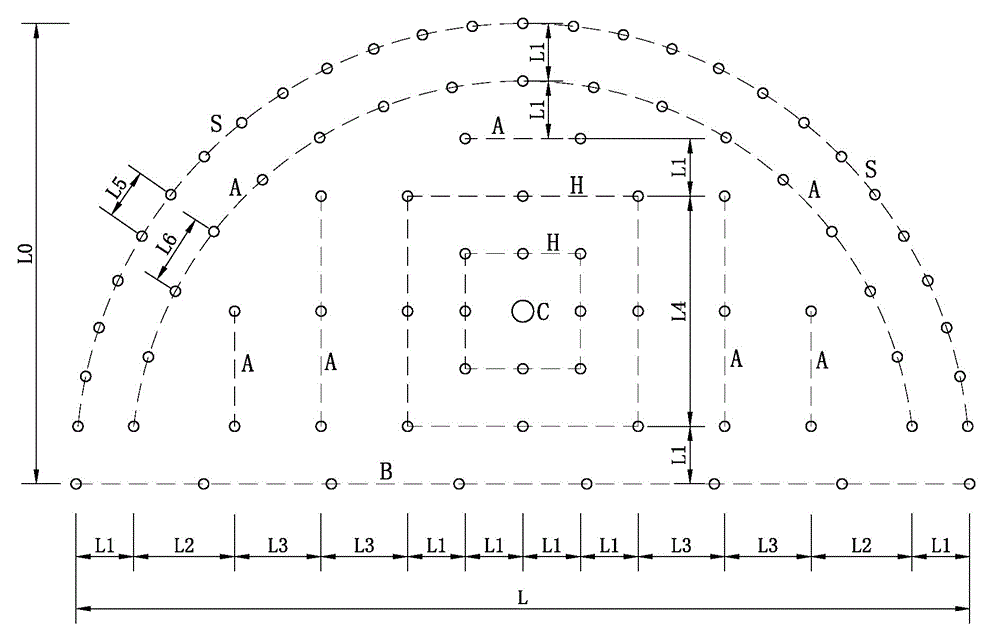

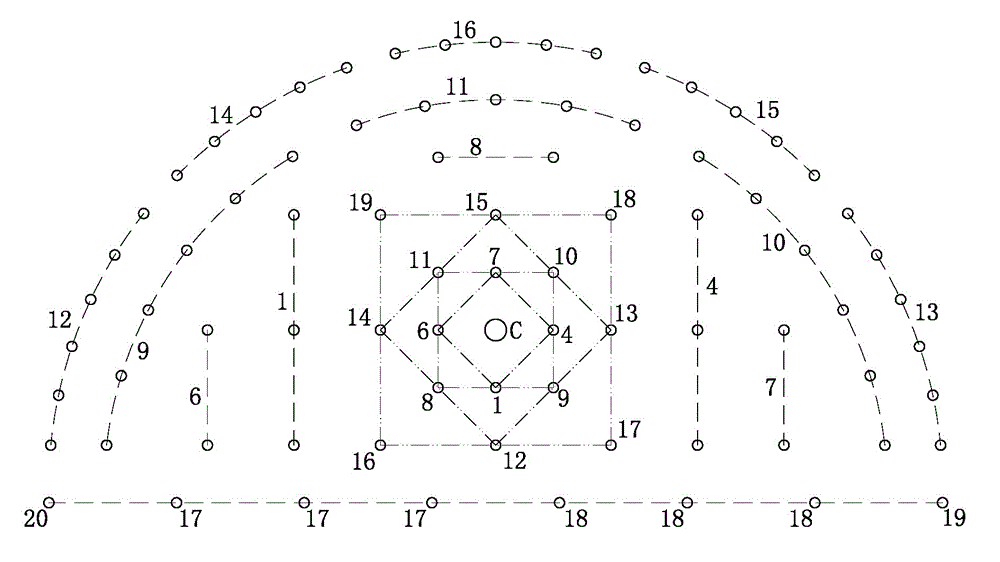

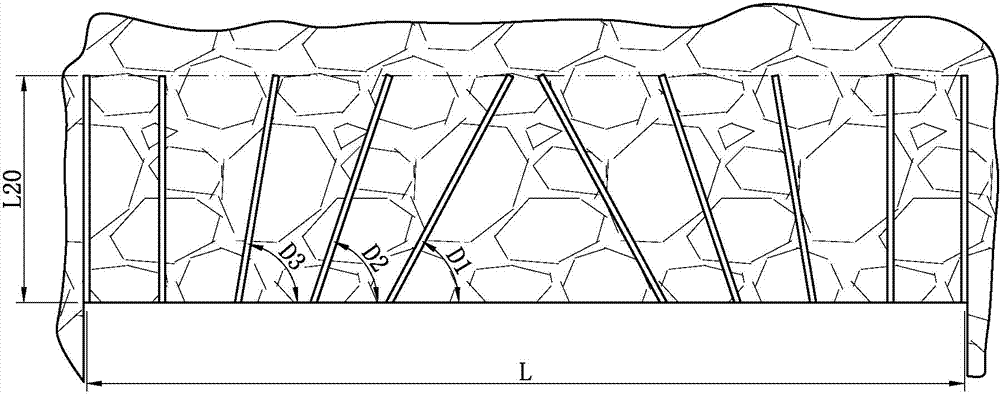

Hollow-hole rhombic parallel cut blasting damping method

InactiveCN102914226AReduce blasting vibration velocityReduce the impactBlastingDetonatorUnderground tunnel

The invention relates to a hollow-hole rhombic parallel cut blasting damping method. Blasting tunneling is performed on the tunnel face of an underground tunnel. The construction method comprises using a down-the-hole drill to drill a hollow hole with the diameter of 90mm to 180mm at the position of the middle of the tunnel face of the tunnel; using a hammerdrill to drill a plurality of blast holes, enabling the blast holes to comprise cut holes, auxiliary holes, periphery holes and base plate holes which are expanded around the hollow hole; filling explosives and detonators, using stemming to seal the blast holes, adopting rock emulsion explosives, and using ordinary millisecond nonel detonators or high-precison millisecond nonel detonators; and detonating the explosives according to blast hole arranging orders and detonator delay time. The hollow-hole rhombic parallel cut blasting damping method has the advantages that when an urban subway underneath passes buildings at a close range in a granite stratum and old resident houses, the blast vibration speed can be effectively controlled, influences of blast vibration on the buildings and life of residents are reduced, and compared with a traditional wedge cut blasting scheme, the hollow-hole rhombic parallel cut blasting damping method enables the maximum blasting vibration speed to be reduced by 50%.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

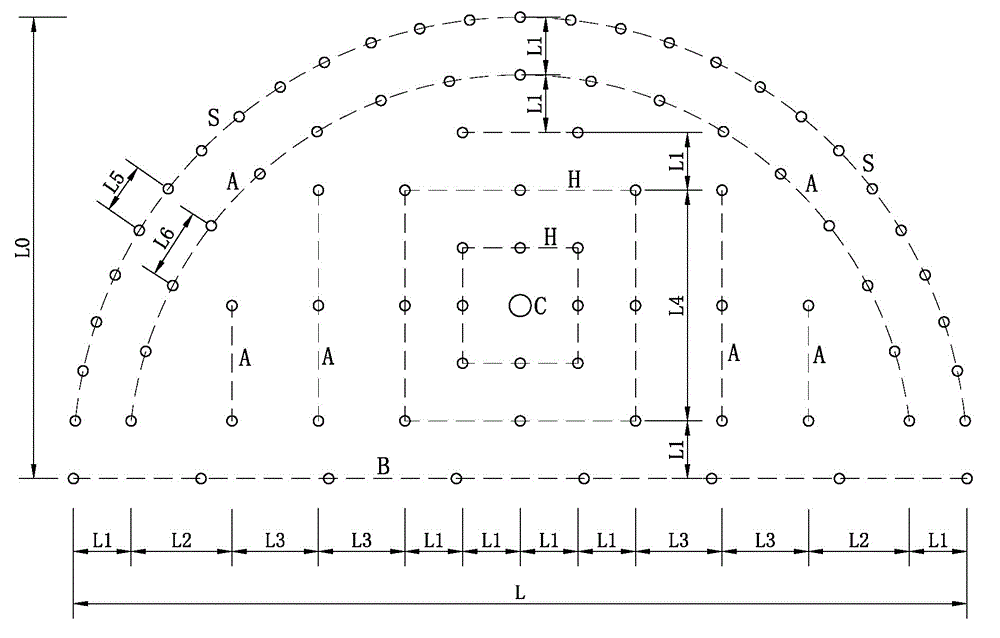

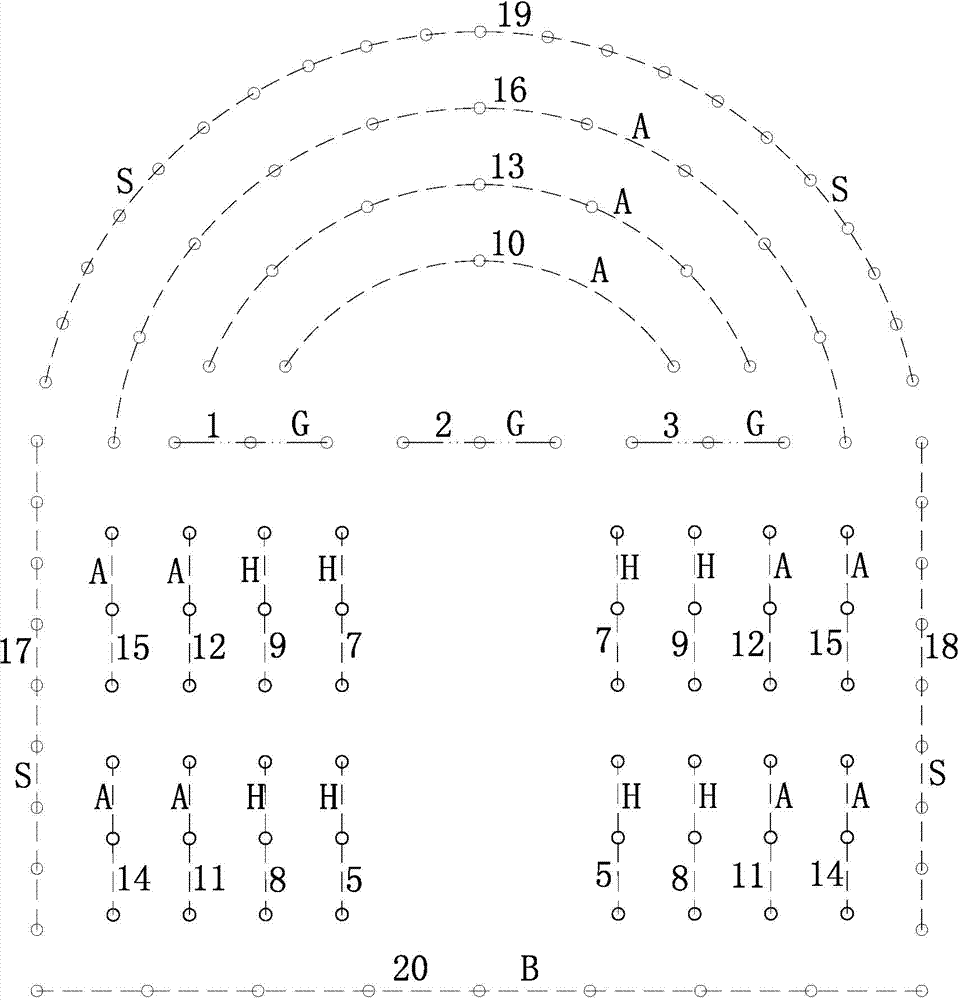

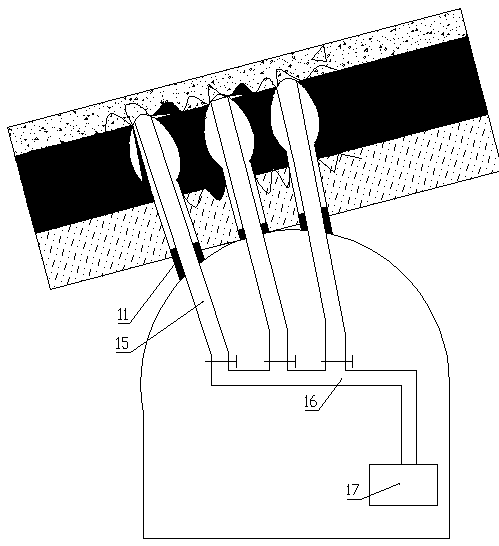

Vibration absorbing method for cut presplitting blasting

InactiveCN102927867AReduce vibration speedReduce the maximum blasting vibration velocityBlastingDetonatorEmulsion explosive

The invention relates to a vibration absorbing method for cut presplitting blasting, which comprises the steps that blasting tunneling is performed on a face of a subway tunnel; a gadder is used to drill blastholes including presplitting blastholes, cutholes, assistance holes, periphery holes and bottom plate holes; the presplitting blastholes are a group of transversely arranged blastholes that are located 500mm-600mm above the cutholes; the presplitting blastholes adopt mixed connected kerf cartridges for explosive loading; the cutholes, the assistance holes, the periphery holes and the bottom plate holes adopt common emulsion explosive loading, and adopt millisecond nonel detonators; and the presplitting blastholes, the cutholes, the assistance holes, the periphery holes and the bottom plate holes are initiated in sequence. The vibration absorbing method has the benefits that as a presplitting surface and a presplitting crushed zone are formed above the cutholes, the vibration is reduced and absorbed in transmission paths, the vibration velocity caused by the cut blasting is reduced obviously, and blasting vibration can be controlled effectively. Compared with the traditional smooth blasting, the maximum blasting vibration velocity can be reduced by 30%, and effects on protected heritages along a line are reduced.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

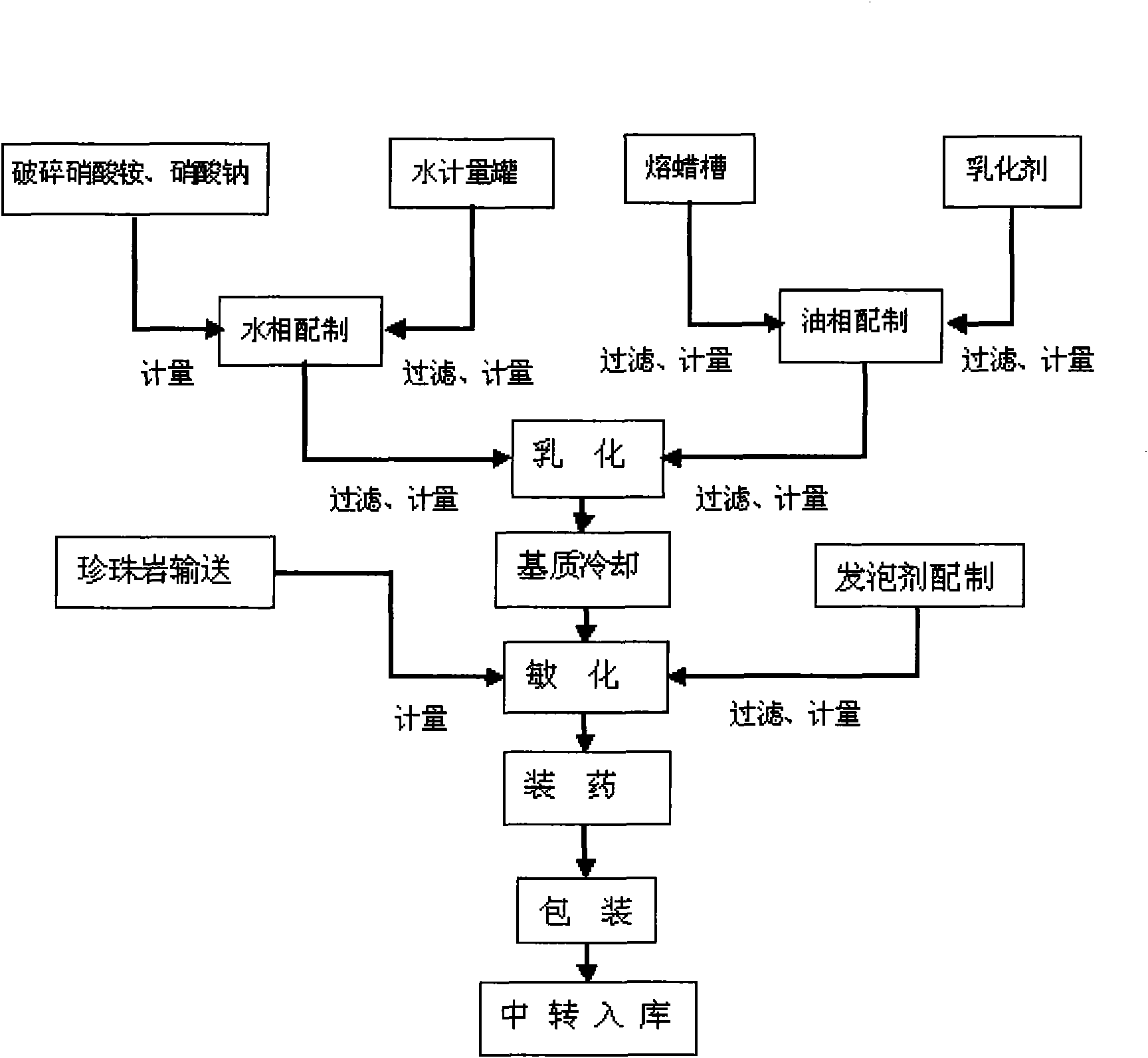

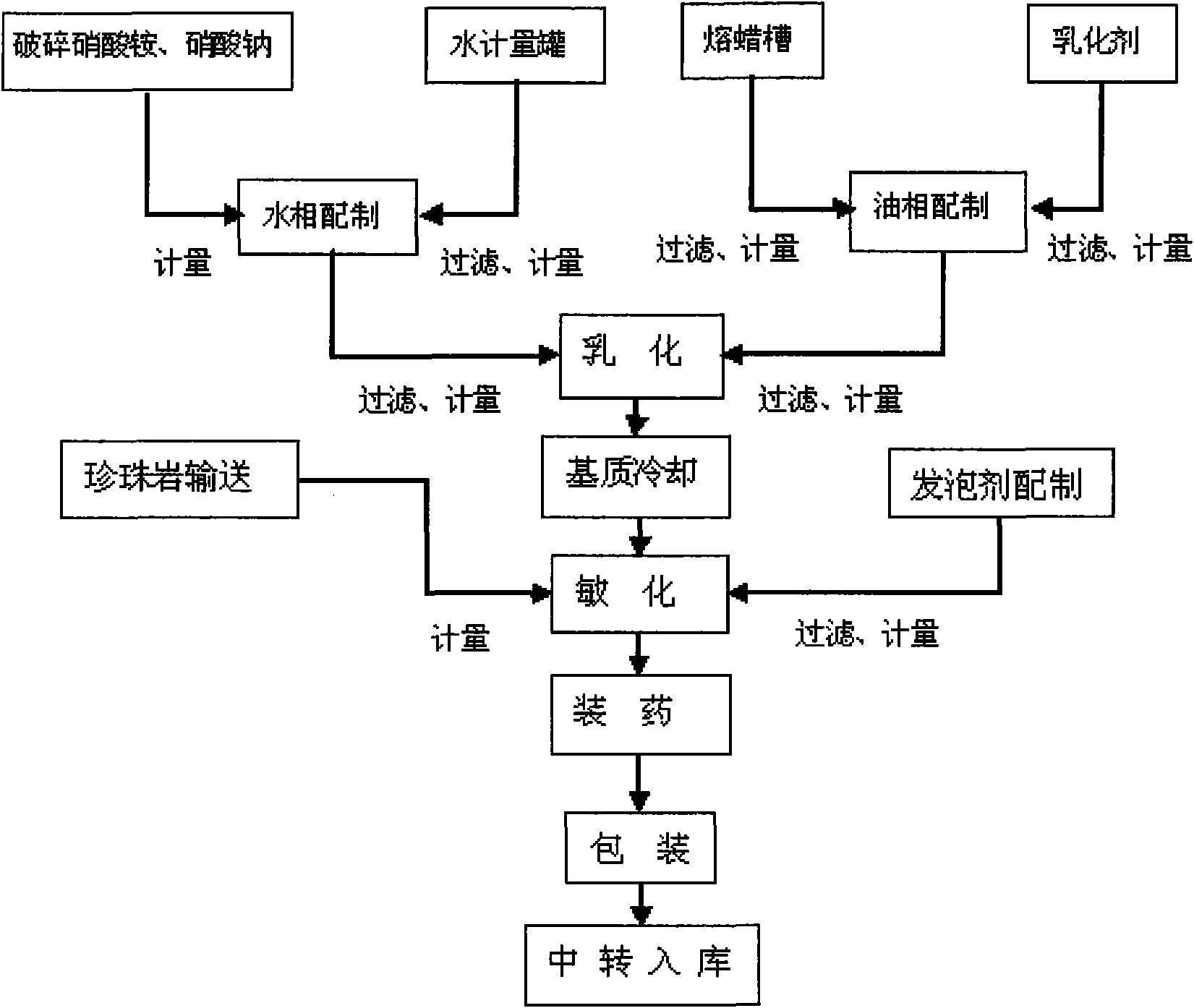

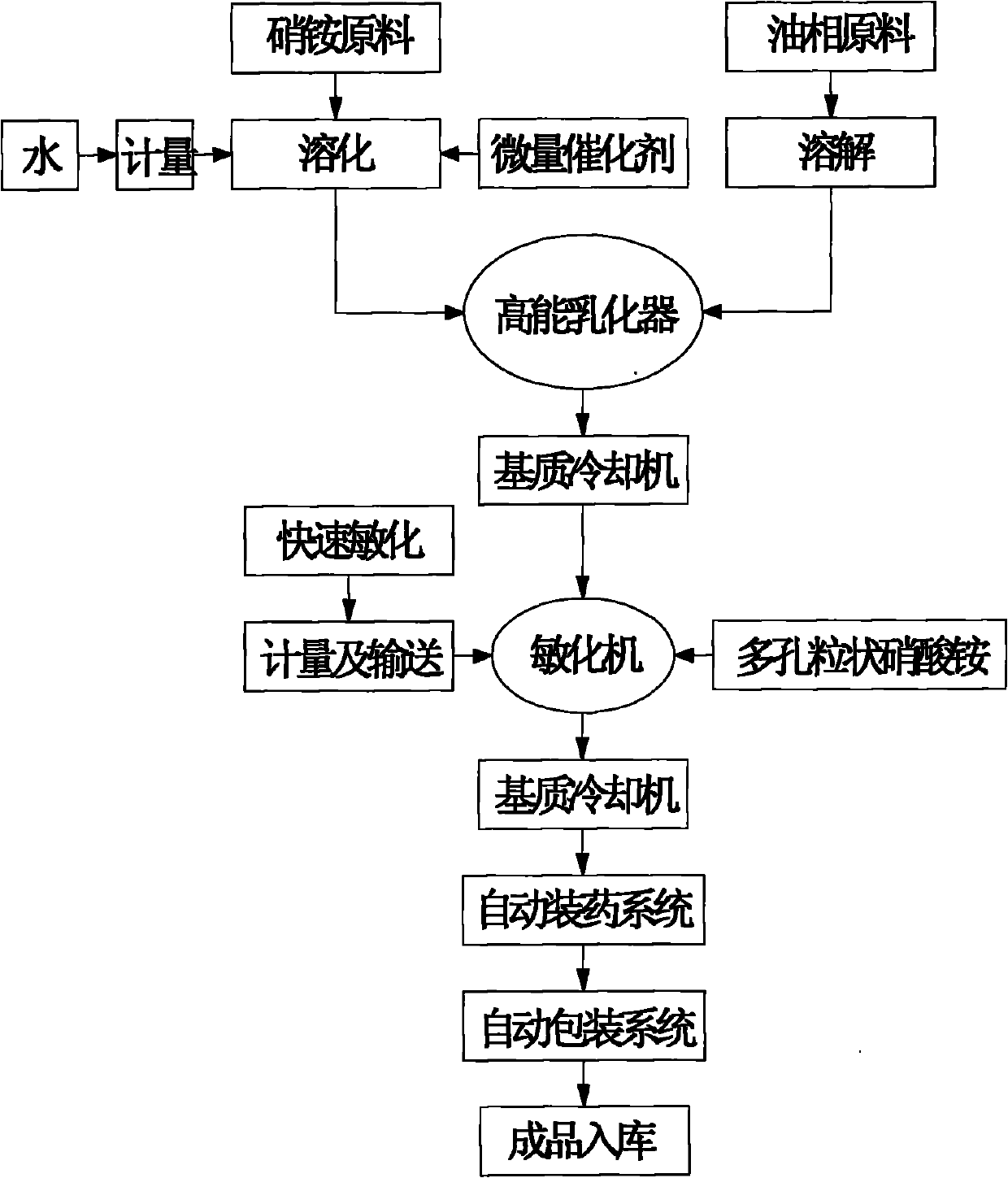

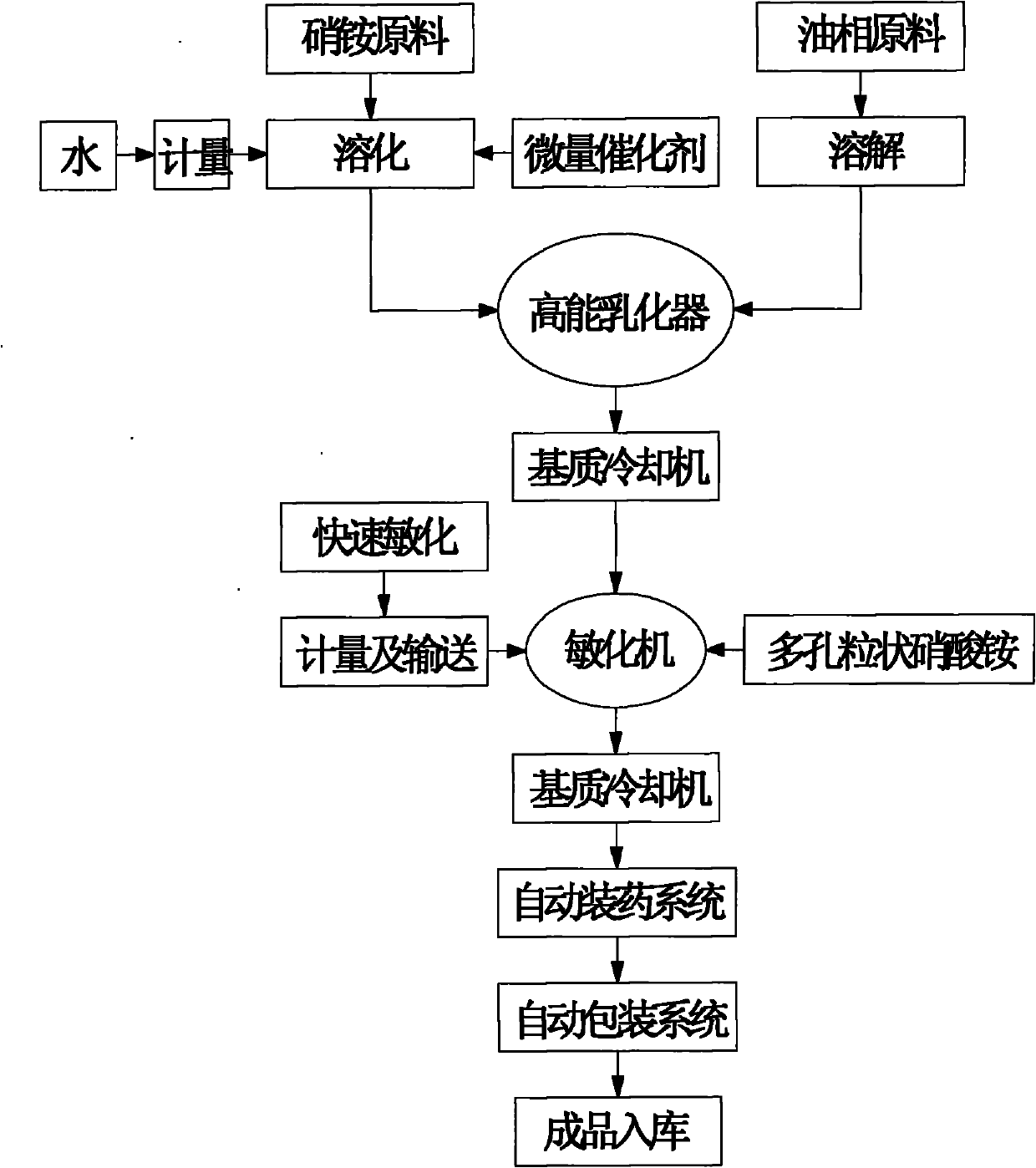

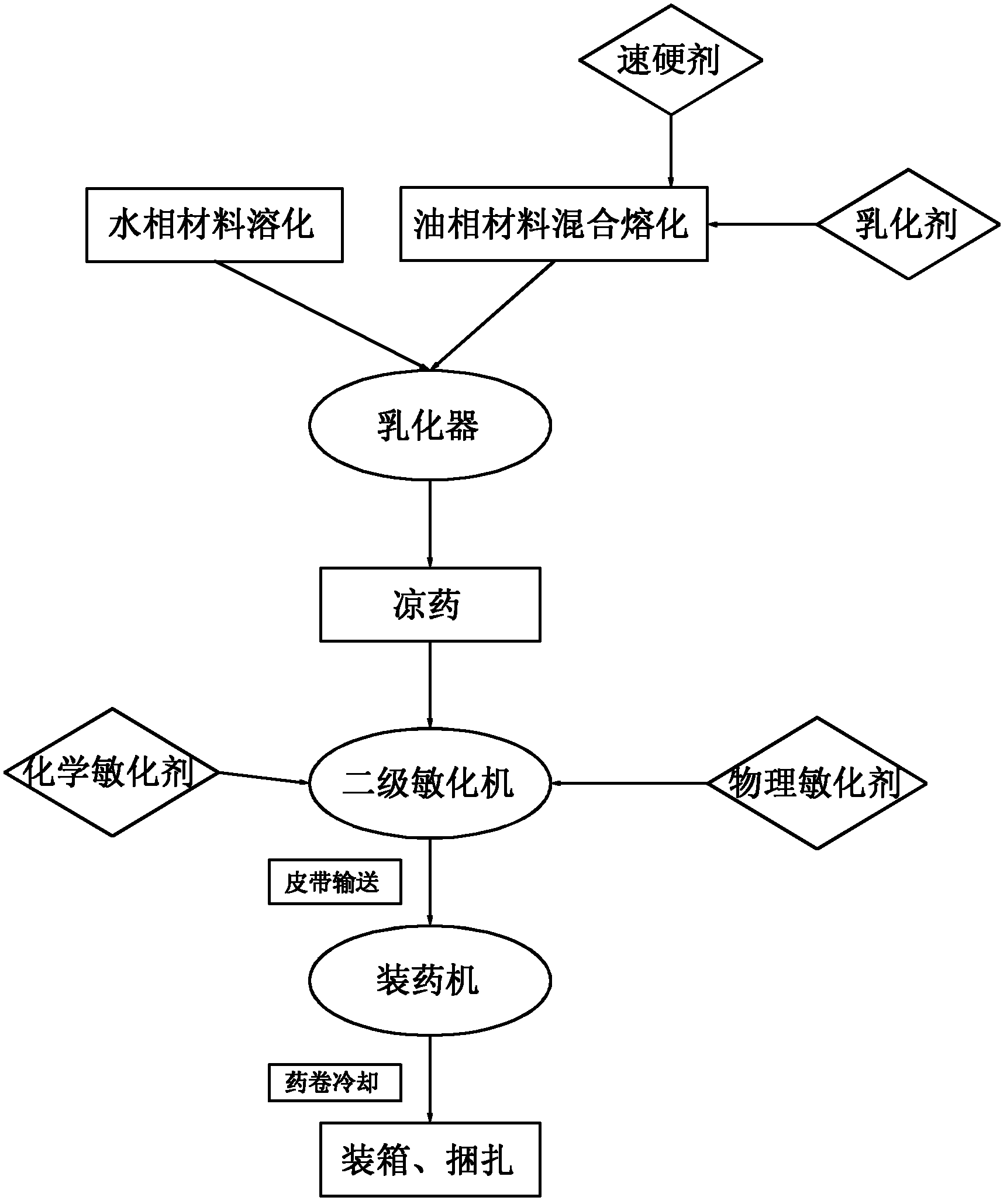

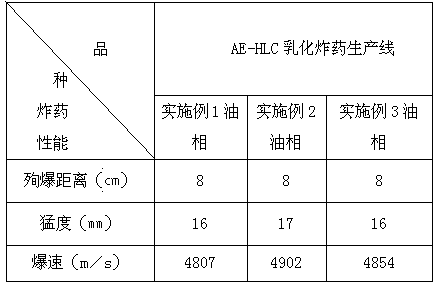

Production method of emulsified explosive

The invention discloses a production method of an emulsified explosive, which comprises the following steps that: water phase and oil phase are prepared, and then water phase solution is added into oil phase solution to be emulsified by an emulsifier to prepare a latex matrix, and simultaneously a cooling steel strip controls the temperature of the latex matrix to be 90 to 105DEG C; and the matrix is cooled, the cooled latex matrix is added into a sensitizing machine, and then one or two of perlite and chemical blowing agent is added in for sensitization; and then the explosive is charged, and finally the loaded explosive is packaged to prepare the emulsified explosive. The production method of the emulsified explosive has the advantages of reducing the production cost, having no waste explosive, waste material, waste gas, waste water and dust in production, realizing the free switching of a plurality of sensitization methods, such as physical sensitization, chemical sensitization and physical and chemical composite sensitization, so as to meet the needs of different consumers; perlite is adopted for physical sensitization, and can improve the explosion performance and the storage performance; and the production method of the emulsified explosive can adapt to the requirements of small-diameter explosive charging and full-automatic packaging automatic calandria.

Owner:宜兴市阳生化工有限公司

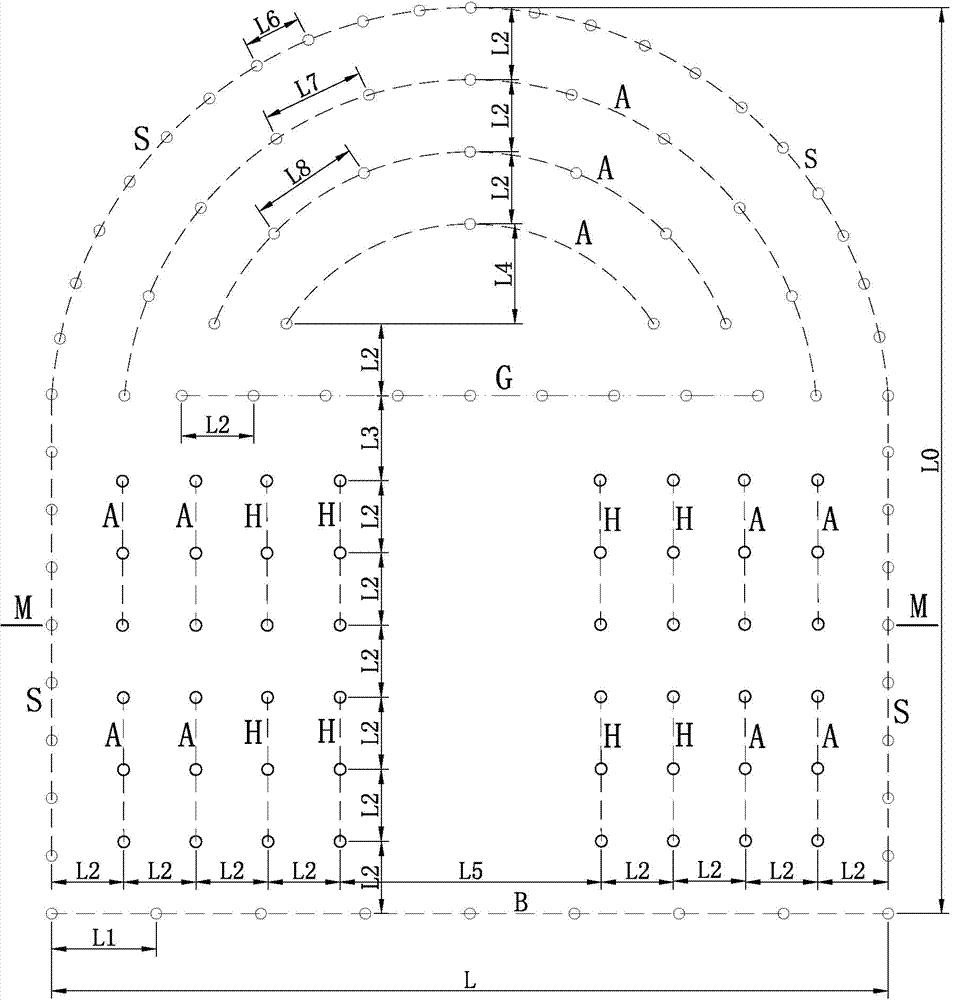

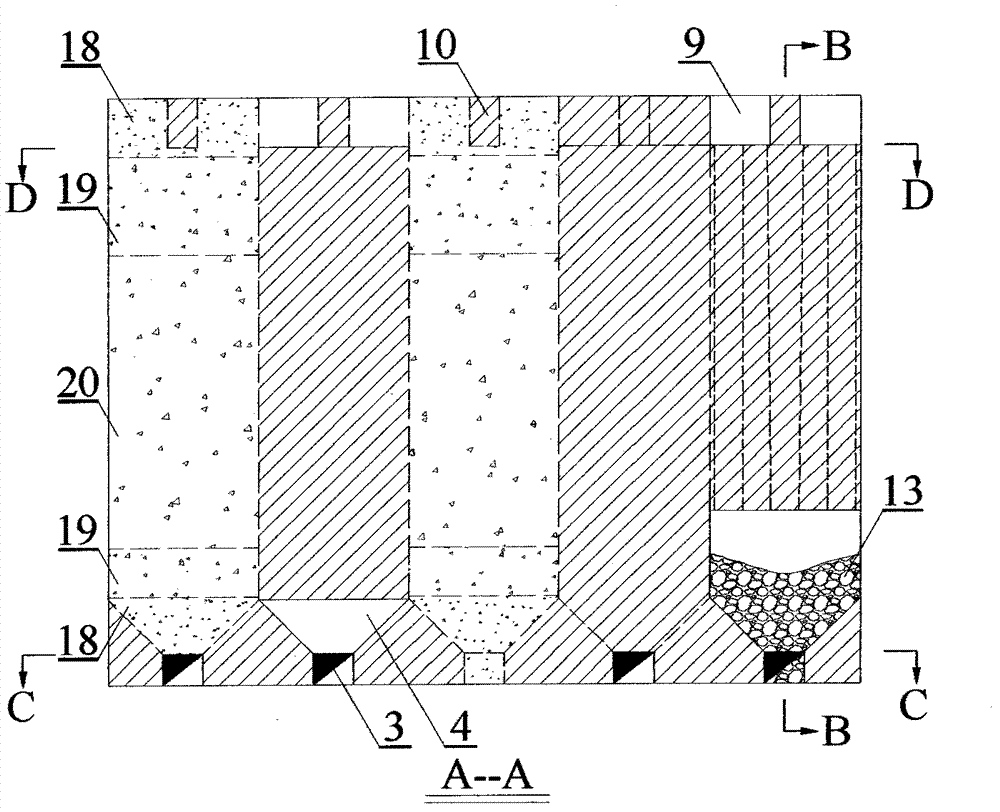

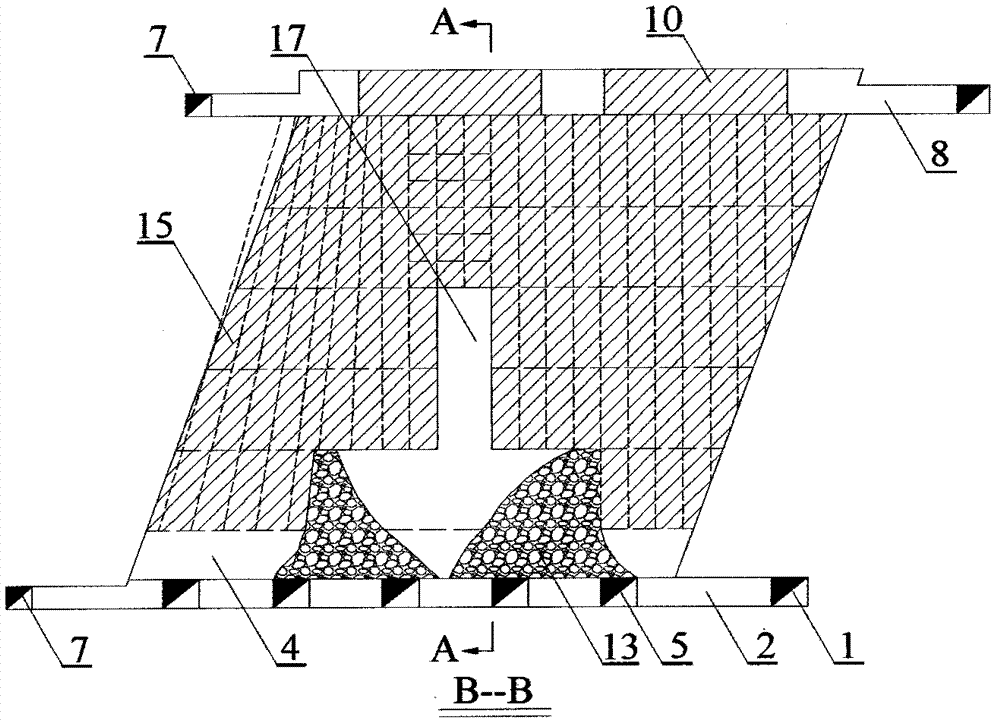

Room-and-pillar major-diameter longhole inverted-step-like segmented lateral caving subsequent filling mining method

InactiveCN102953732AImprove mining safetyGood for stope stabilityUnderground miningSurface miningRoom and pillar miningSingle stage

The invention discloses a room-and-pillar major-diameter longhole inverted-step-like segmented lateral caving subsequent filling mining method for a steeply-inclined medium-thick orebody and gently-inclined and inclined extremely-thick orebodies with steady surrounding rocks at upper and lower panels. The method is characterized in that: an orebody is divided into panels, then the panels are divided into continuous single-stage stoping units, and mining is carried out by using a stoping sequence of stoping one unit every other unit, i.e., mining a room at first and a pillar next; when mining a room, a V-shaped trench bottom structure is employed, a longhole drilling chamber is arranged at the upper part of stope, bar-shaped pillars are left to support the top plate of the chamber, a down-the-hole drill is used for drilling rocks, an explosion mode of light section VCR method underholing inverted-step-like lateral caving with a common emulsion explosive is employed, access roads towards the room for ore removal are arranged in the pillars, and cemented roof-contact filling is employed; and during stoping of the pillars, access roads for ore removal are dug towards the pillars in cemented bodies in the room, a stoping manner for the pillars is identical to that for the room, and non-cemented filling with tailings and waste is employed. The method provided by the invention has the advantages of high security, a low production cutting ratio, great production capacity, low operation cost and small loss and dilution of resources.

Owner:彭康

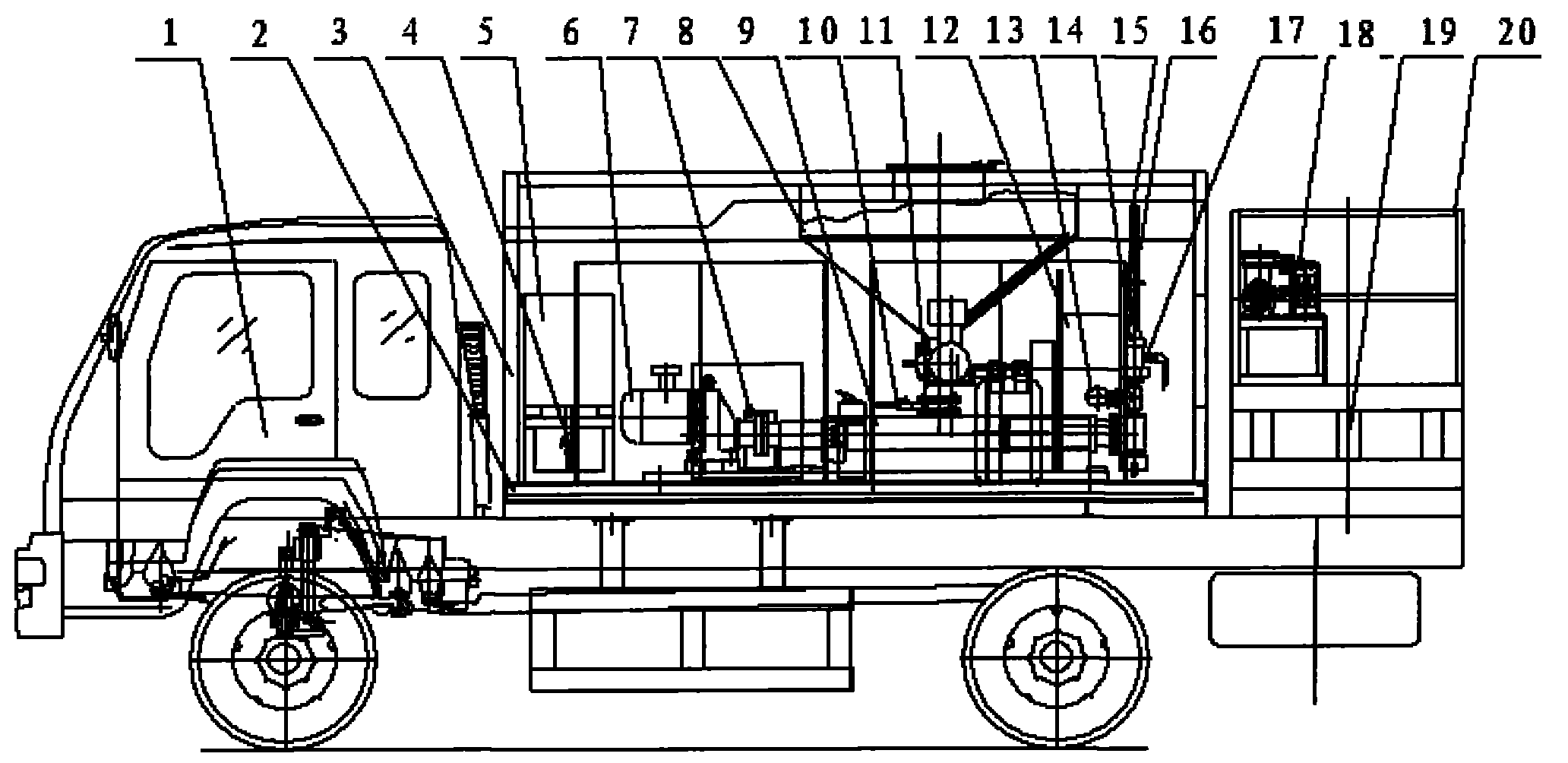

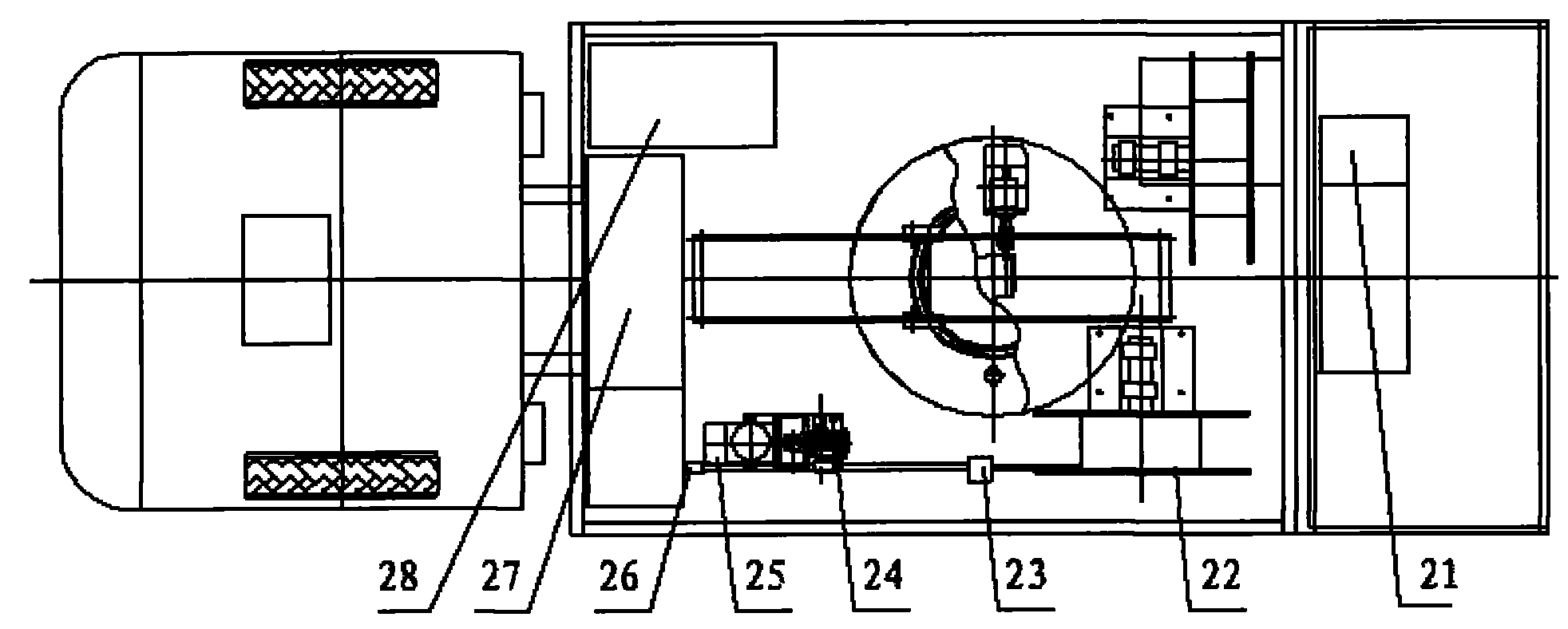

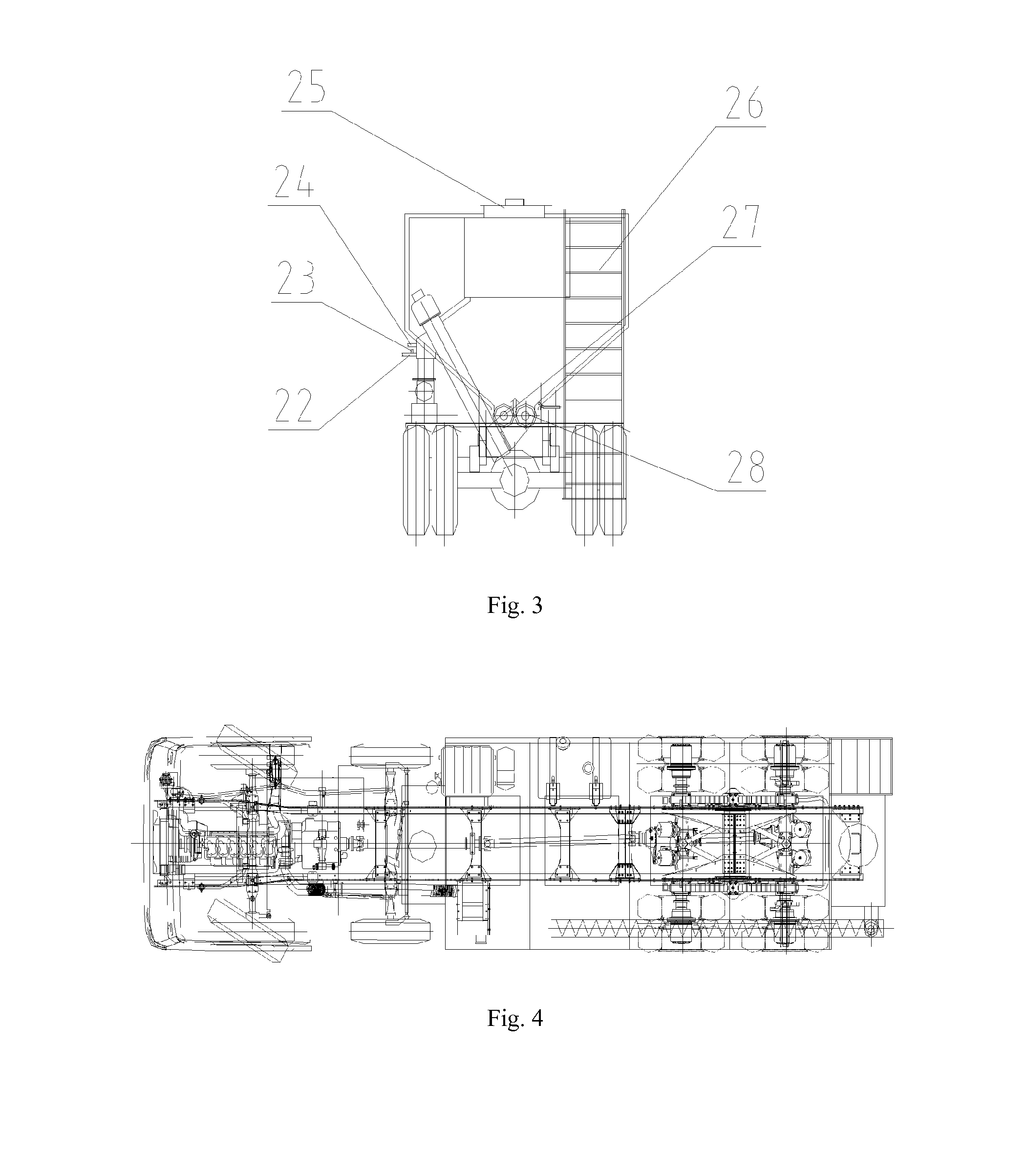

Underground in-situ emulsified explosive mixed charging vehicle

InactiveCN101968334AMeet the requirements of on-site mixingAccurate measurementBlastingVehicle frameEmulsion explosive

The invention discloses an underground in-situ emulsified explosive mixed charging vehicle, and relates to a device for underground tunneling and mining blast charging. The invention overcomes the problems that the manual charging has large labor intensity, low efficiency and poor operation safety, and a compressed explosive charger is easy to return powder and pollute the environment when charging granulose emulsion ammonium nitrate fuel oil explosive or powder ammonium nitrate explosive. The underground in-situ emulsified explosive mixed charging vehicle comprises an automobile chassis, and is characterized in that a secondary frame is installed on the front part of the automobile chassis, a lifting platform is installed on the rear part of the automobile chassis, an outer box assembly is installed on the secondary frame and internally provided with a sensitizing agent box, an emulsion matrix bin, a cleaning water tank, a screw pump, a power box and an electric cabinet. The underground in-situ emulsified explosive mixed charging vehicle is used for underground tunneling and mining blast charging, and has the advantages of simple structure, high efficiency, low cost, safety, reliability, free lifting and all-around charging.

Owner:SHANXI HUIFENG SPECIAL AUTOMOBILE

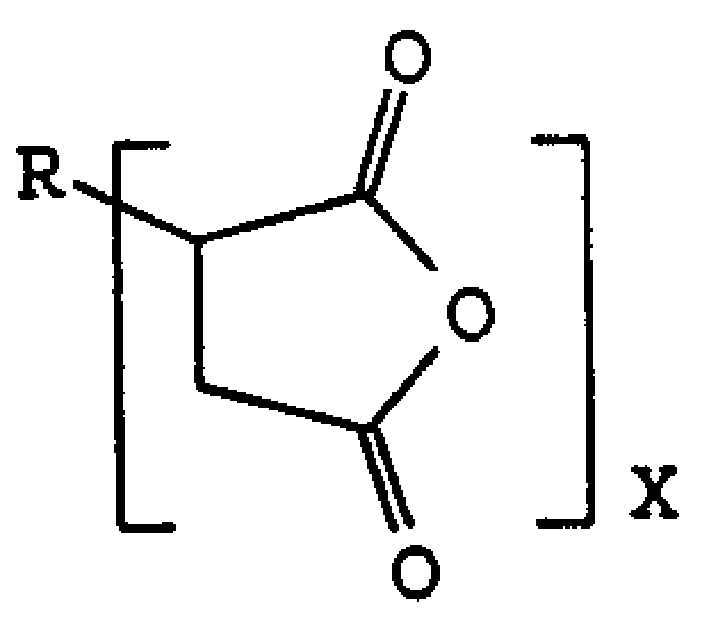

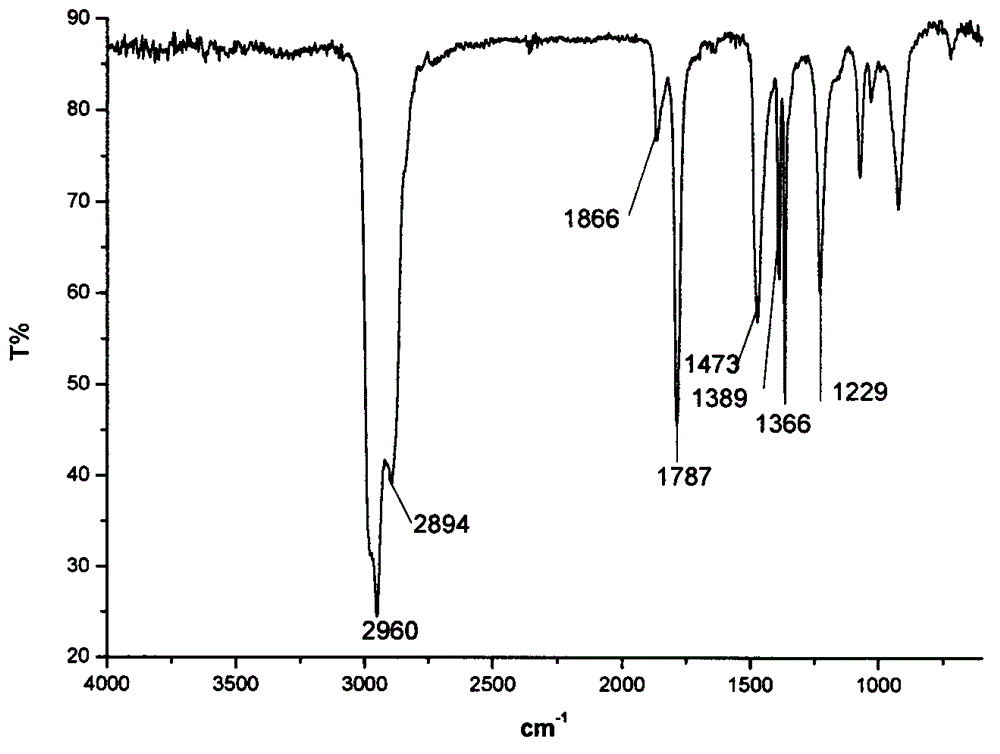

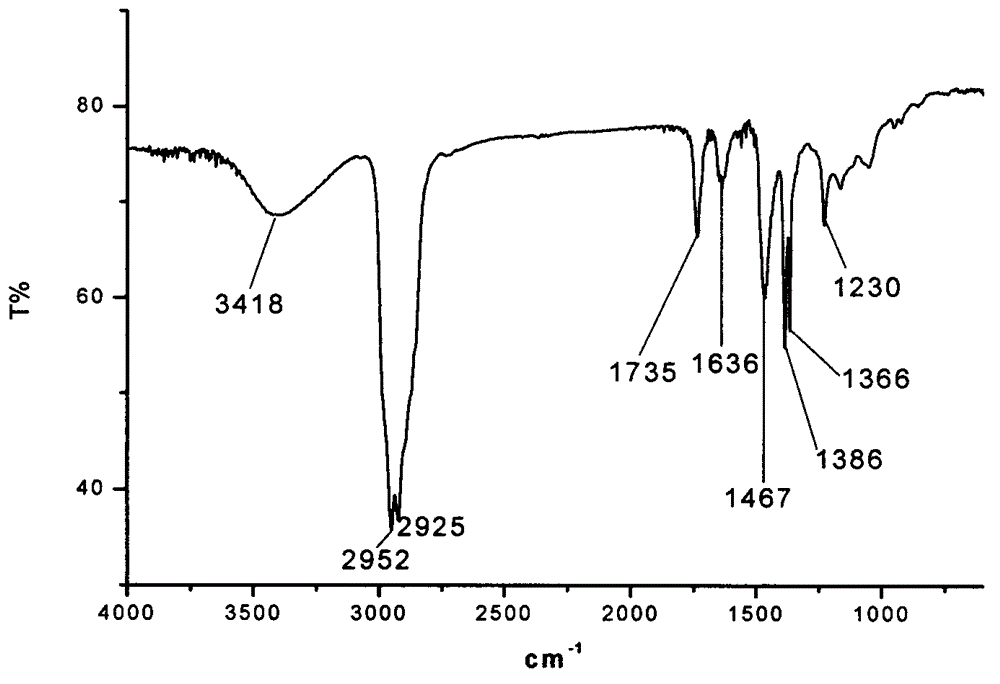

Emulsifier utilized for emulsion explosive and its preparation method

InactiveCN1415588AGood emulsificationEasy to emulsifyTransportation and packagingMixingEmulsion explosiveStructural formula

An emulsifier for preparing emusified explosive with long storage time is prepared by the reaction of acylating agent on alkylol amine. Its advantage is high emulsifying performance. Its structural formula is also disclosed.

Owner:CHINA PETROLEUM & CHEM CORP +1

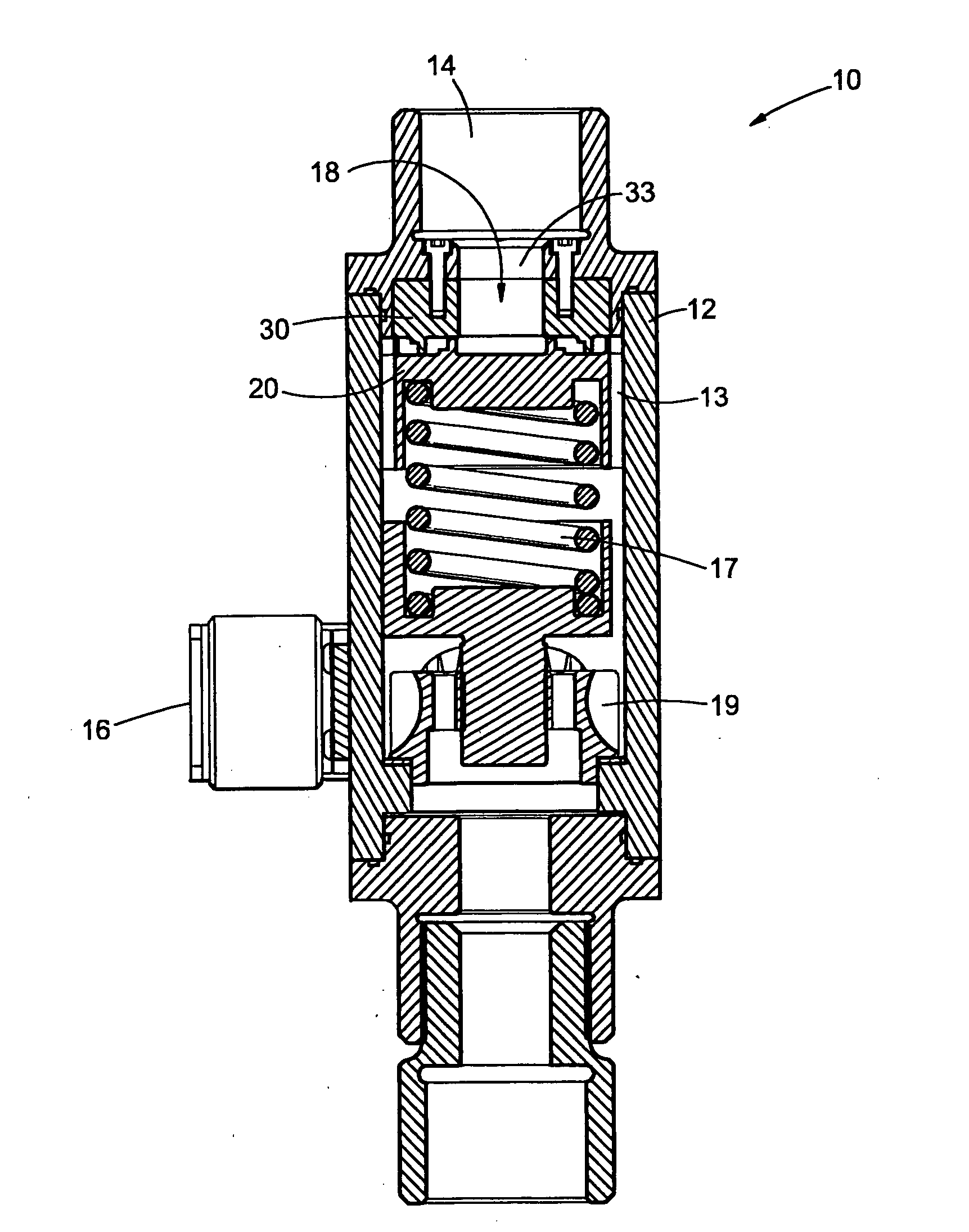

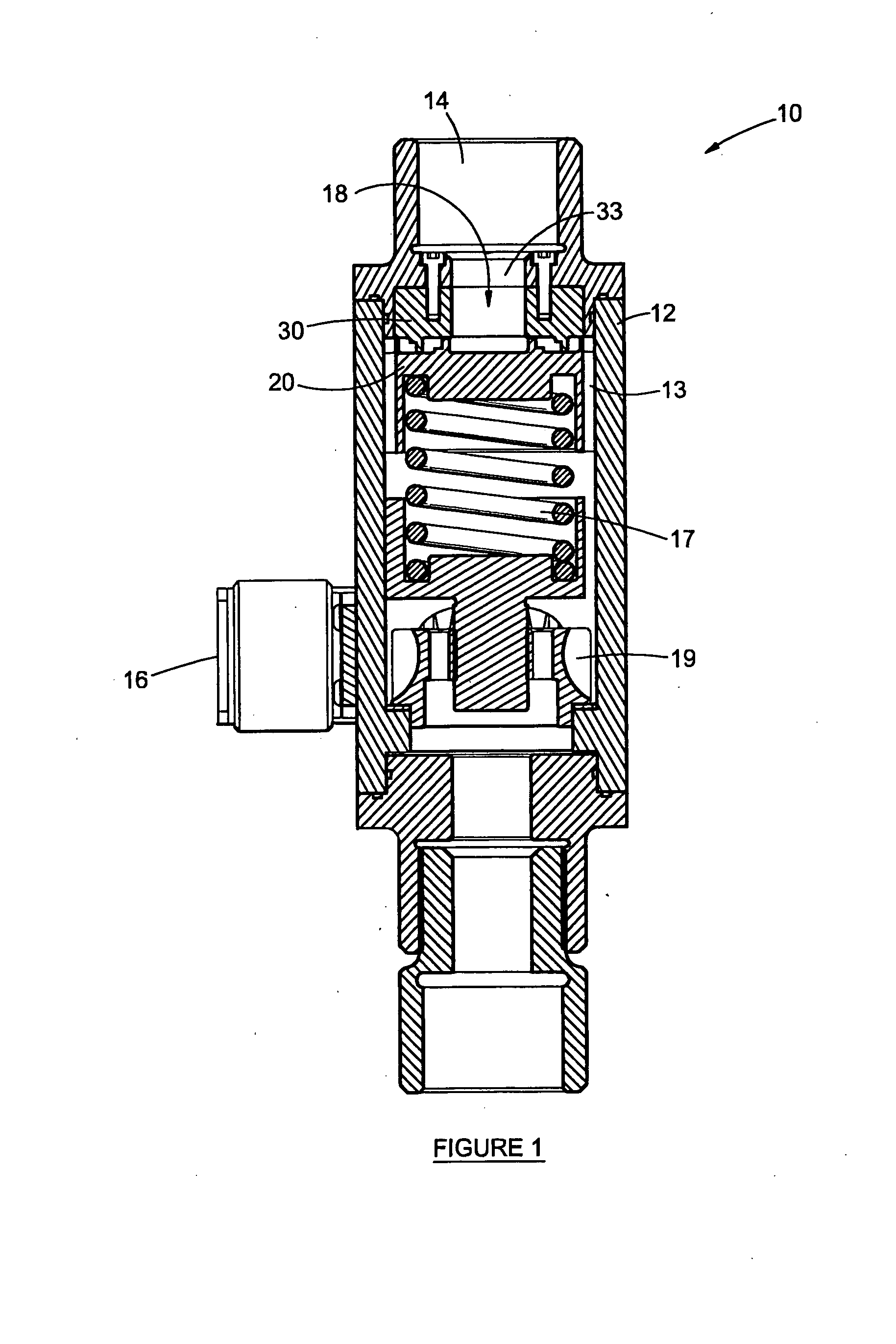

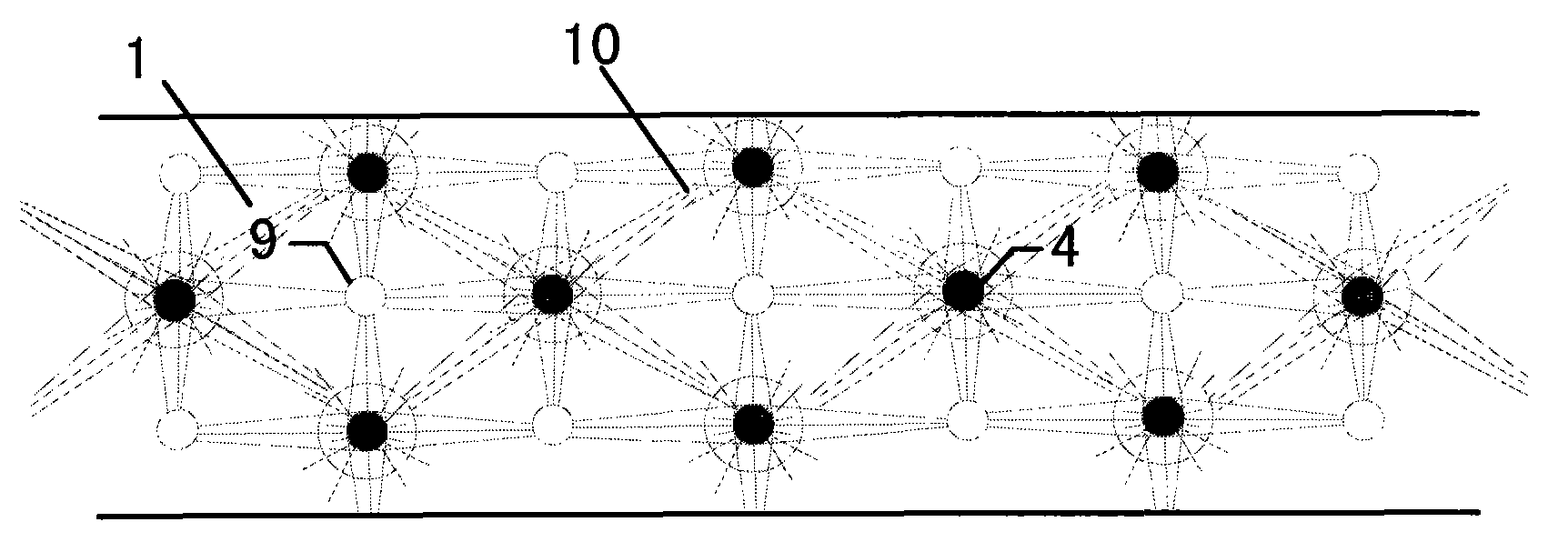

Homogenisation valve

ActiveUS20090141584A1Reduce disadvantagesFlow mixersTransportation and packagingEmulsion explosiveEngineering

The invention relates to an improved homogenization valve, and more particularly, but not exclusively, to a homogenization valve for use in homogenizing emulsion explosives. The homogenization device comprises a body having a flow passage therethrough, opposing first and second homogenization members located in the flow passage; the homogenization members having opposing homogenization surfaces that form a flow restriction of the flow passage therebetween. At least one of the homogenization surfaces has a flow resistance being suitable to cause at least part of the flow passing through the flow restriction to be diverged in a non-linear path across the homogenization surface.

Owner:AECI LTD

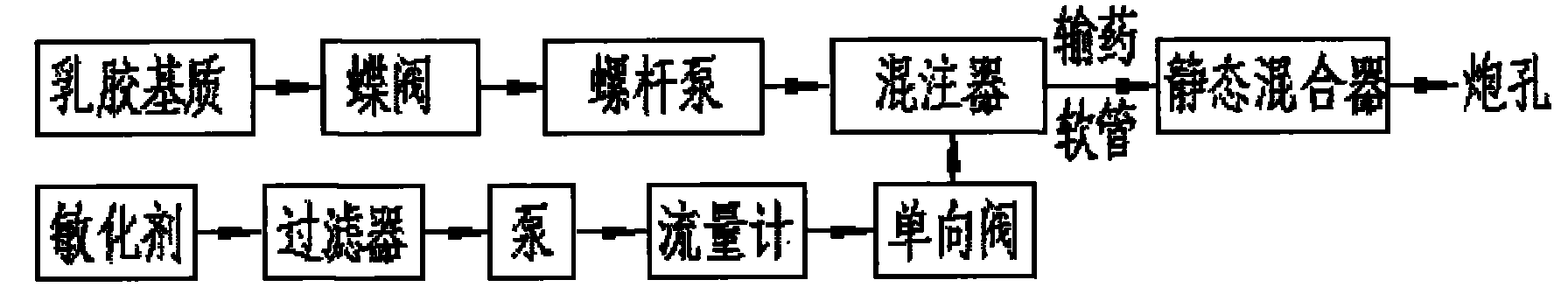

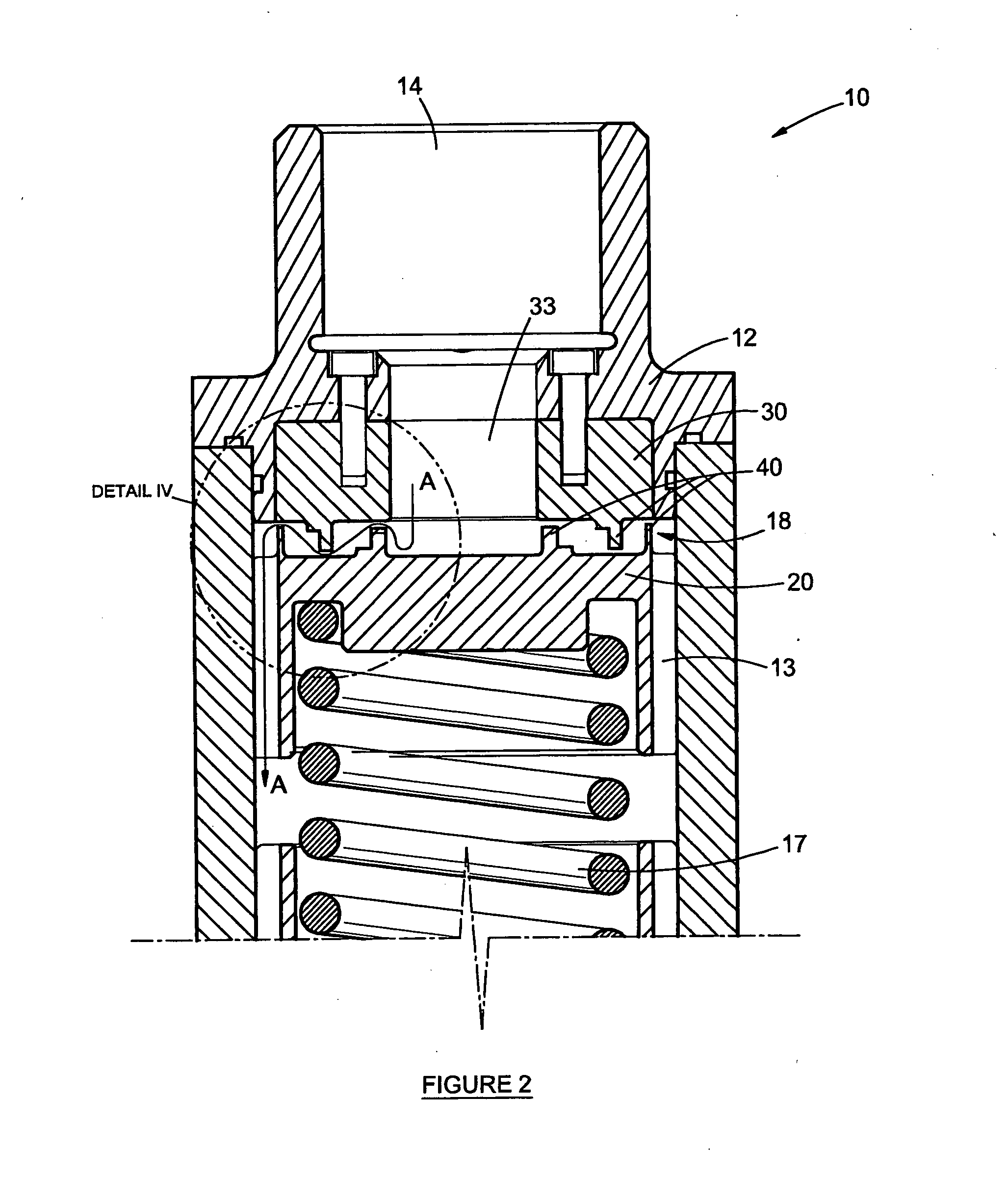

Method for preparing emulsion explosive

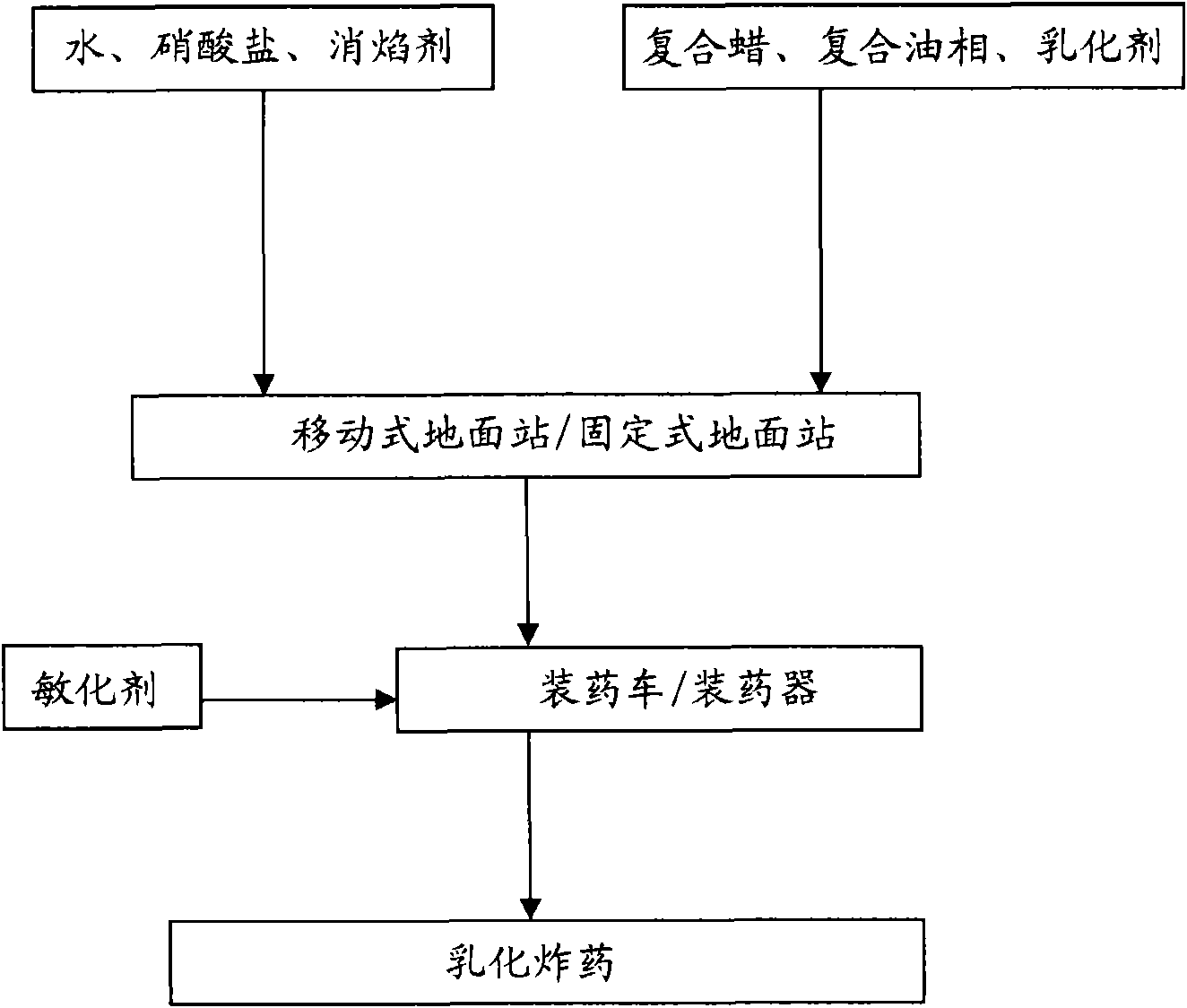

The invention discloses a method for preparing a coal mine-allowed emulsion explosive. The method comprises the following steps of: preparing an emulsion matrix on a ground station and conveying the prepared emulsion matrix with charge equipment to a blasting operation site; and mixing the emulsion matrix and a sensitizing agent and then filling into a blast hole to sensitize the emulsion matrix in the blast hole to obtain the emulsion explosive. According to the method of the invention, the process of preparing the emulsion explosive by sensitization and foaming in the blast hole is a complete coupling charging process, so that the blasting effect is good. As manual charging is replaced by mechanical charging, the charging efficiency is high. In addition, as the emulsion matrix is fully sensitized to form the emulsion explosive after the emulsion matrix and the sensitizing agent are filled into the blast hole, high safety is guaranteed in the conveying process.

Owner:BEIJING BGRIMM YIBO TECH +1

High-power emulsion explosive and preparation method thereof

ActiveCN101948362ASimple processWith energy saving and emission reductionExplosivesPotassium nitrateNitrate

The invention discloses a high-power emulsion explosive and a preparation method thereof, aiming to provide a novel explosive with strong explosive capacity, low energy consumption and stable quality. The high-power emulsion explosive is formed by mixing a component A and a component B, wherein the component A comprises the following raw materials in percentage by weight: 75-85 wt% of ammonium nitrate, 9-14 wt% of water, 3-5 wt% of nitrate, 0.3-2.0 wt% of urea, 0.3-3.5 wt% of modified Span-80 emulsifier, 0.3-3.5 wt% of compound oil phase, 1-1.5 wt% of paraffin and 0.8-3 wt% of quick foaming agent. The component B is one of porous granulous ammonium nitrate, or granulous ammonium nitrate or potassium nitrate. The weight ratio of the component A to the component B is 88-96:4-12. The processing method mainly comprises aqueous phase preparation, oil phase preparation, emulsification, sensitization and packaging, wherein porous granulous ammonium nitrate, or granulous ammonium nitrate or potassium nitrate is added during sensitization.

Owner:广东华威化工股份有限公司

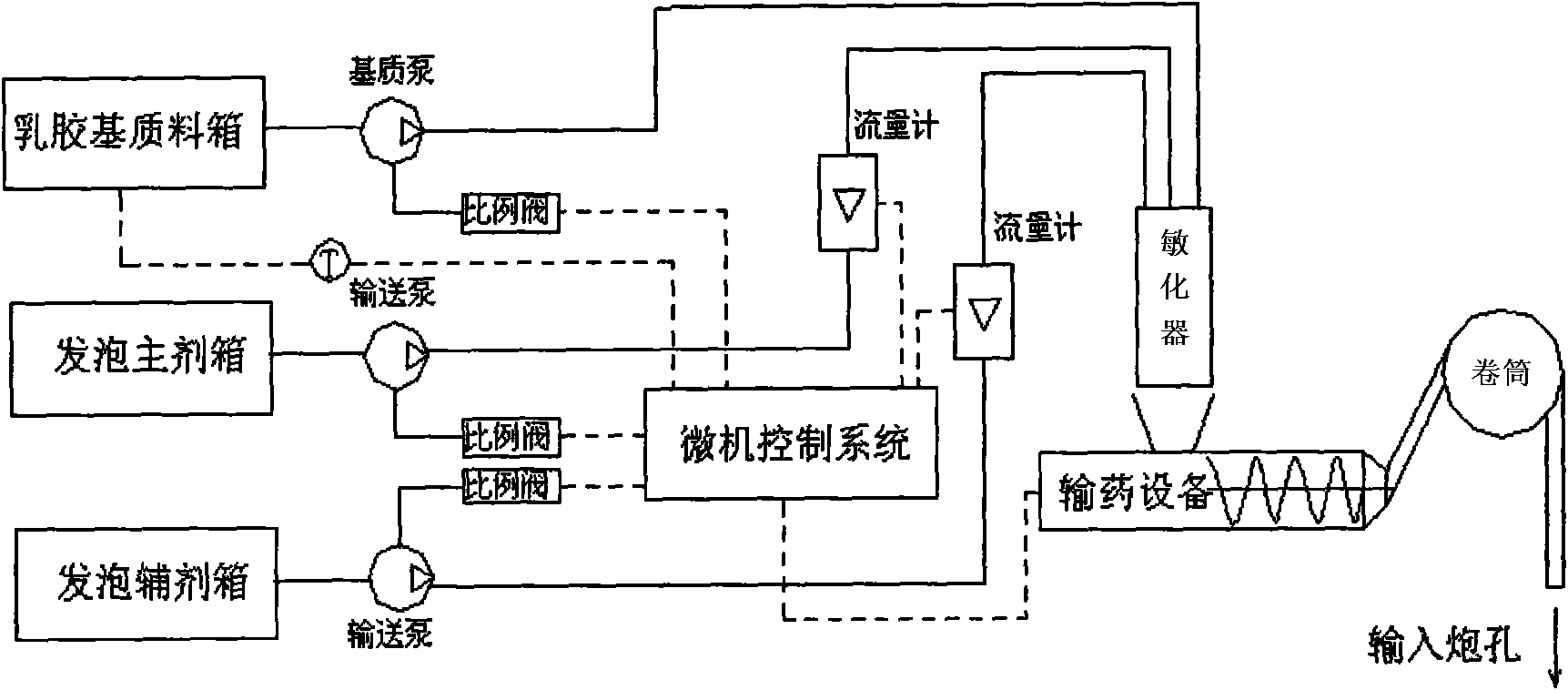

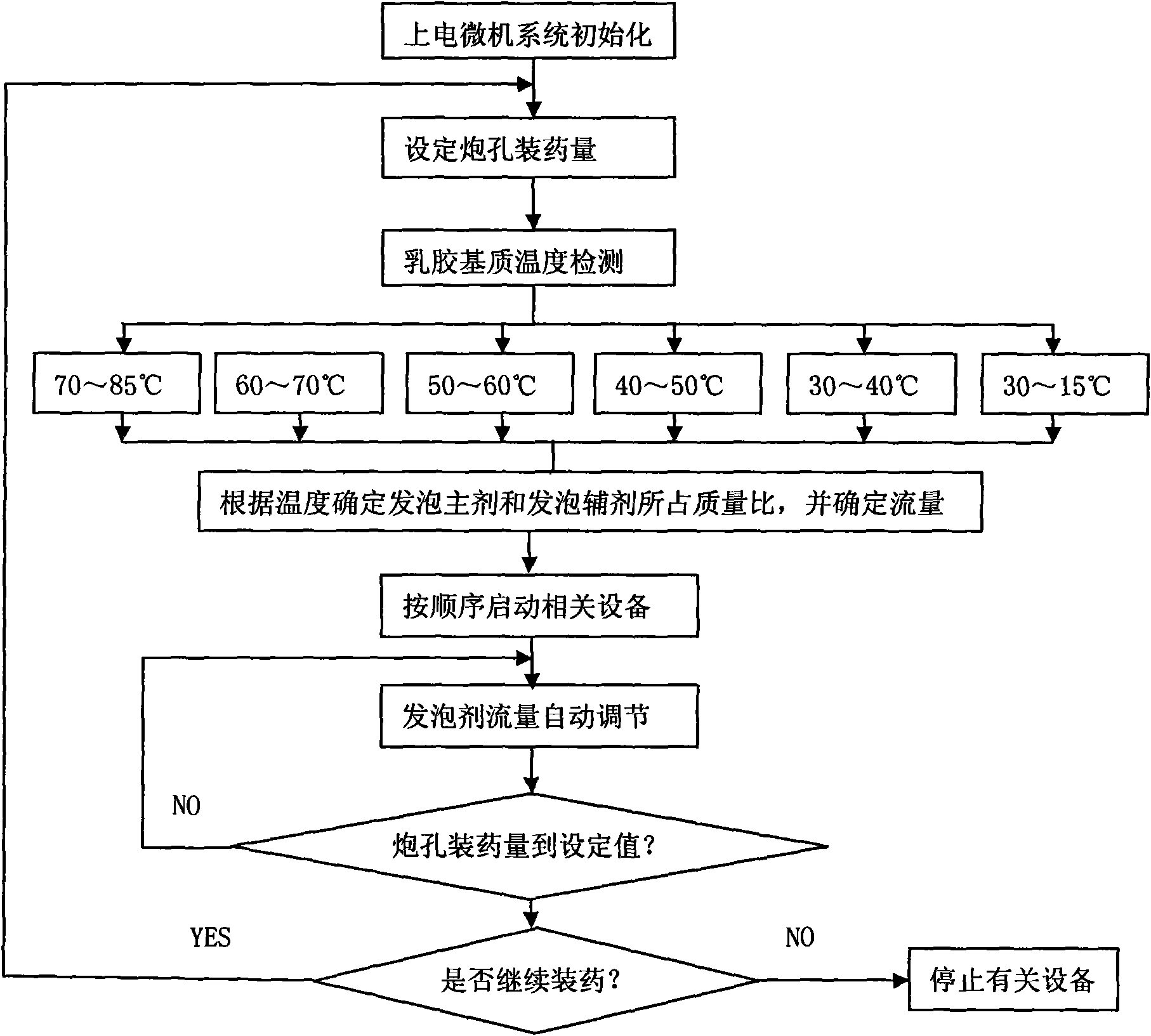

Chemical sensitizing method for emulsive explosive

InactiveCN101602637AGuaranteed stabilityAchieve normal chemosensitizationExplosive working-up apparatusAutomatic controlControl system

The invention discloses a chemical sensitizing method for emulsive explosive, which comprises the following steps: (1) preparing a foaming main agent and a foaming assistant agent, wherein the foaming main agent is prepared from sodium nitrite and water according to a weight ratio of 15-20:80-85 percent, and the foaming assistant agent is prepared from citric acid, ammonium nitrate and water according to a weight ratio of 1.5-2.5:12-18:80-85.5 percent; and (2) at different sensitizing temperatures of an emulsion matrix, adding the foaming main agent and the foaming assistant agent into the emulsion matrix respectively, and stirring the mixture evenly to form the explosive. Through an automatic control system for automatically adjusting the adding amount of a sensitizer at the different sensitizing temperatures, the method ensures the stability of explosive performance, realizes normal chemical sensitization in any colloid temperature range so as not to cool the emulsion matrix or preserve heat, simplifies the equipment process, saves the equipment investment, and reduces the cost and energy consumption.

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD

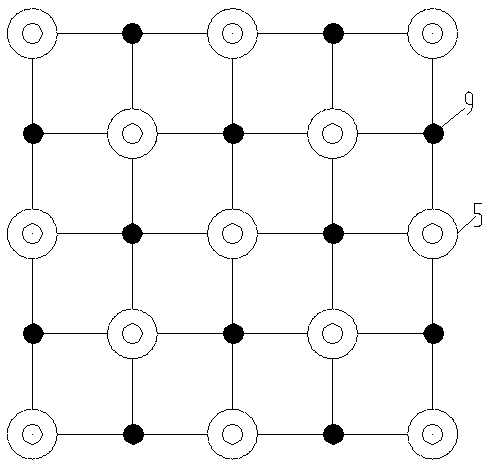

Drilling-explosion-pumping triadic pressure-relief outburst-prevention method

The invention provides a drilling-explosion-pumping triadic pressure-relief outburst-prevention method, which is most suitable for regional pressure-relief outburst-prevention of a high gas and low permeability outburst coal seam. The method comprises the following steps: alternately arranging hole positions of control holes and blast holes of an along bed or a cross seam on a coal seam in front of a coal mining or tunneling working surface; performing construction work on the control holes one by one which are arranged alternately, and performing gas drainage pressure-relief on the coal seam; and constructing the blast holes one by one which are arranged alternately, placing emulsion explosive, detonating a detonating cord for detonation until finishing all operation of the blast holes of the working surface, and performing cycle operation on the next working surface. The method can improve the air permeability of a coal body by 20 to 50 times, has full entire pressure relief and function of effectively preventing outburst, and provides excellent conditions for high work efficiency and safe mining; and the method has the advantages of simplicity, convenient operation and good using effect, and improving the labor efficiency and reducing the labor intensity.

Owner:CHINA UNIV OF MINING & TECH

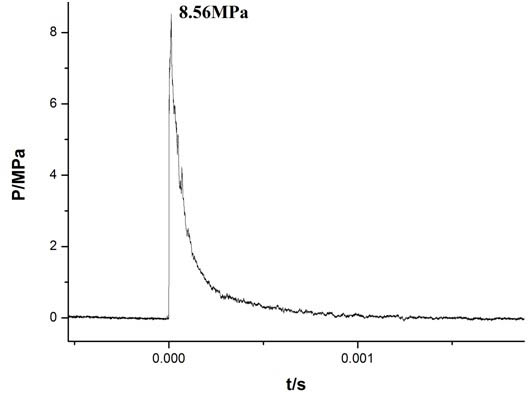

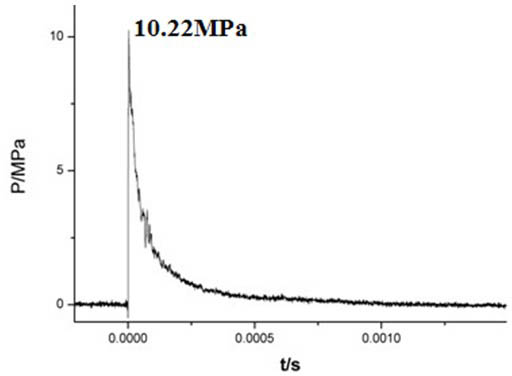

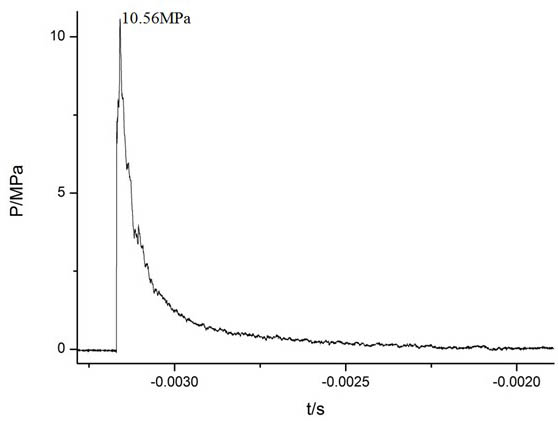

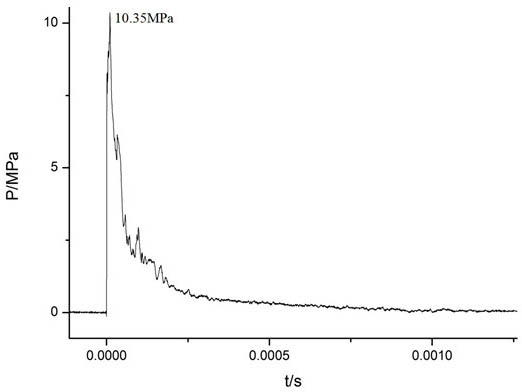

Titanium hydride hydrogen storage emulsion explosive

InactiveCN102432408AEvenly distributedPlay a foaming effectNon-explosive/non-thermic compositionsDetonationChemical reaction

The invention, belonging to the technical field of explosive preparation, particularly relates to an emulsion explosive prepared by using hydrogen storage materials. The explosive comprises an emulsion base and a sensitizing agent, wherein, the sensitizing agent is titanium hydride, the weight of the sensitizing agent accounts for 0.6-8 % of the total weight of the titanium hydride hydrogen storage emulsion explosive, and the purity of titanium hydride is no less than 95 %. During the detonation process, partial titanium hydride reacts with water in the emulsion base to release a little hydrogen, thus a certain foaming effect on the emulsion base is achieved, and the emulsion base is allowed to detonate, so that titanium hydride plays a role as the sensitizing agent. Simultaneously, the rest titanium hydride is subject to thermal decomposition under the effect of high temperature generated by the reaction between emulsion base and hydrogen bubbles to rapidly release hydrogen, and hydrogen continues participating the detonation reaction with the emulsion base to allow the output energy to contain the energy released by the emulsion base and titanium hydride together. The titanium hydride hydrogen storage emulsion explosive disclosed herein has the characteristics of low output explosion pressure, large impulse, long decay time, and high energy.

Owner:UNIV OF SCI & TECH OF CHINA

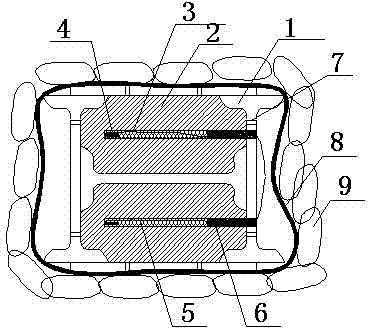

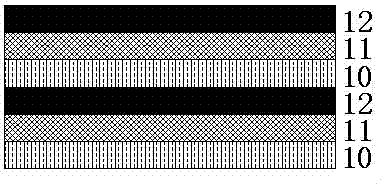

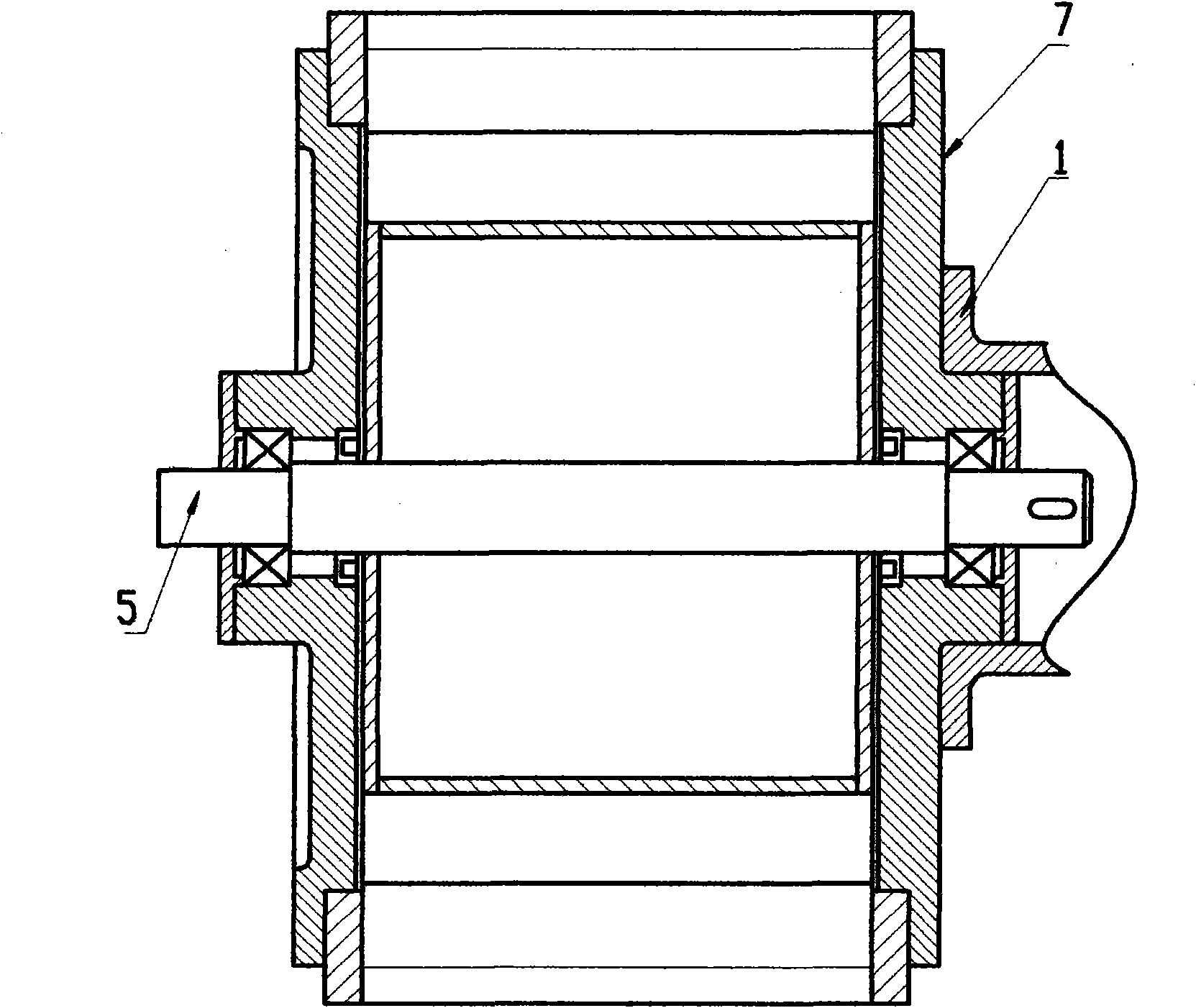

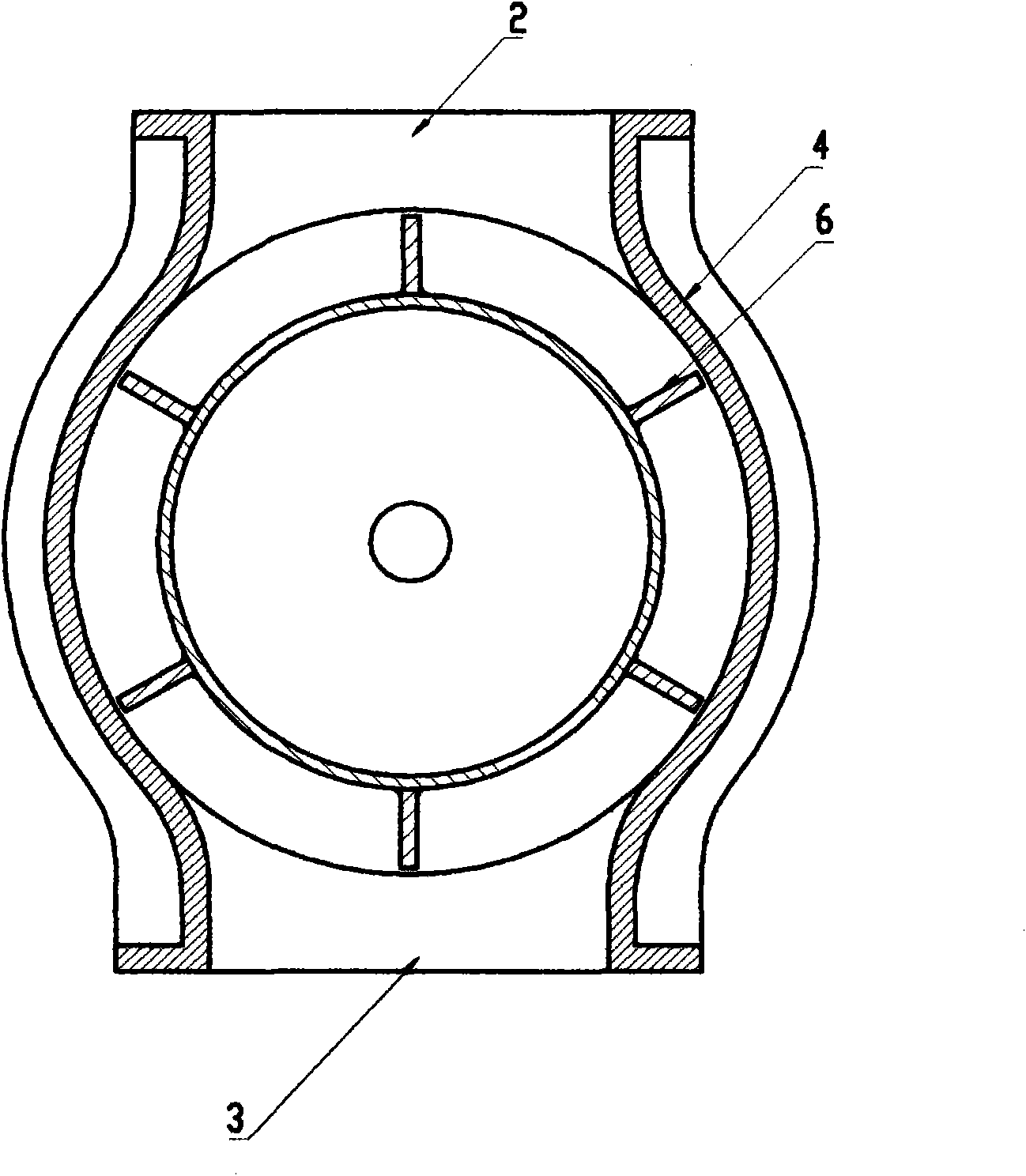

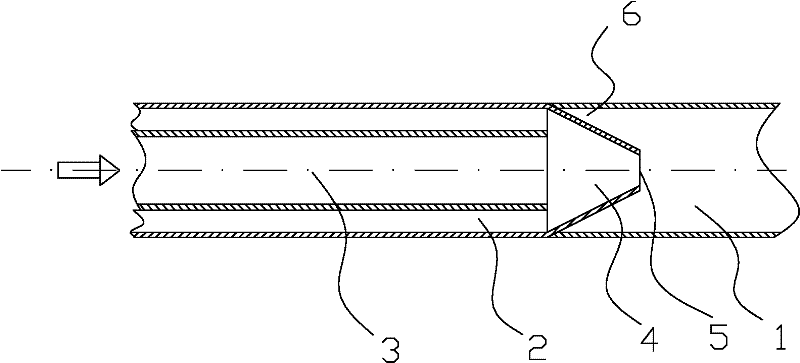

Blasting demolition method for cylindrical steel column structure buildings

The invention belongs to the technical field of engineering blasting and particularly relates to a blasting demolition method for various cylindrical steel column structure components and buildings, wherein the cross sections of the cylindrical steel column structure components and buildings are shaped like Chinese character 'tian' or 'ri' or are of a square shape. The blasting demolition method is characterized by comprising the steps of (a) pouring concrete 2 in a columnar steel structure 1 to be blasted, (b) maintaining the concrete 2, (c) conducting oxyacetylene metal-cutting and drilling a blast hole 3 in the obverse side of the columnar steel structure 1, (d) precutting a seam 7 in the columnar steel structure 1, (e) determining blasting parameters, charging powder and connecting lines, (f) conducting protection and (g) conducting blasting. By means of effective implementation of the blasting demolition method for the cylindrical steel column structure buildings, the purpose of blasting demolition of the cylindrical steel column structure components or buildings through industrial explosive materials (emulsion explosives) can be achieved, and the blasting demolition method has the technical advantages of being safe, efficient and low in cost compared with a traditional manual demolition means.

Owner:中铁二十三局集团(湖北)爆破有限公司

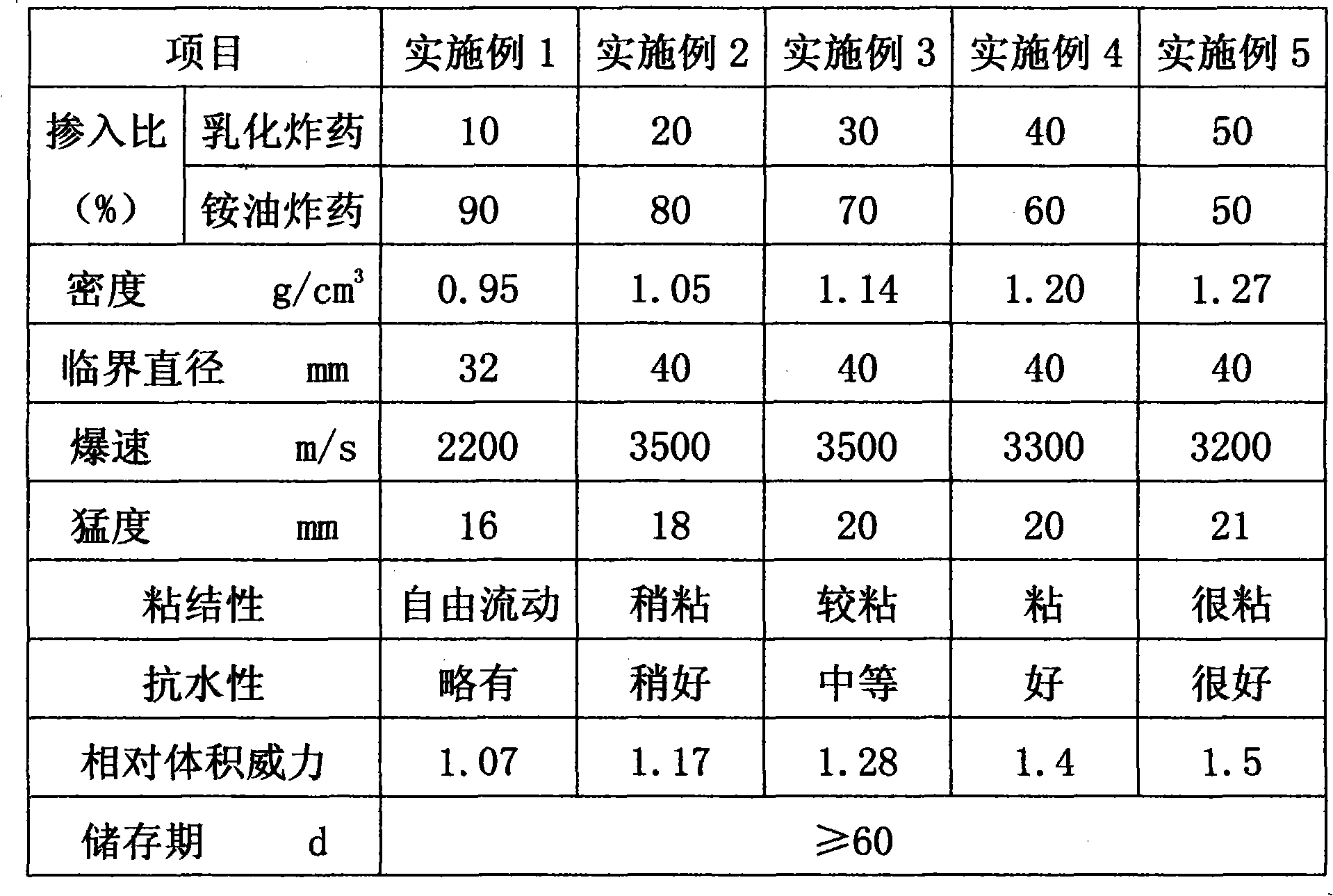

Heavy ammonium nitrate-fuel oil explosive with detonator sensitivity produced by using chemical sensitization

The invention relates to a heavy ammonium nitrate-fuel oil explosive with detonator sensitivity produced by using chemical sensitization and a preparation method thereof. The heavy ammonium nitrate-fuel oil explosive comprises the following components in percentage by mass: 5-55 percent of emulsion explosive and 45-95 percent of porous granular ammonium nitrate-fuel oil explosive. The preparation method comprises the following steps of: preparing the porous granular ammonium nitrate-fuel oil explosive; preparing a latex matrix; sensitizing the latex matrix; and mixing the emulsion explosive with the porous granular ammonium nitrate-fuel oil explosive. The heavy ammonium nitrate-fuel oil explosive with detonator sensitivity has small critical diameter, favorable detonator sensitivity and large capacity power without igniting an igniting primer, and can be used for various blasting engineering, such as medium-small blast hole, big hole diameter and upward fan-shaped medium-length hole, and the like. In the invention, the chemical sensitization is carried out by utilizing a brand new and quick chemical foaming agent at the same time. The novel quick chemical foaming agent has the characteristics of high foaming speed, thoroughly eliminated after-effect and fine and stable bubbles, and is a novel safe and effective chemical sensitization technique.

Owner:谢斌

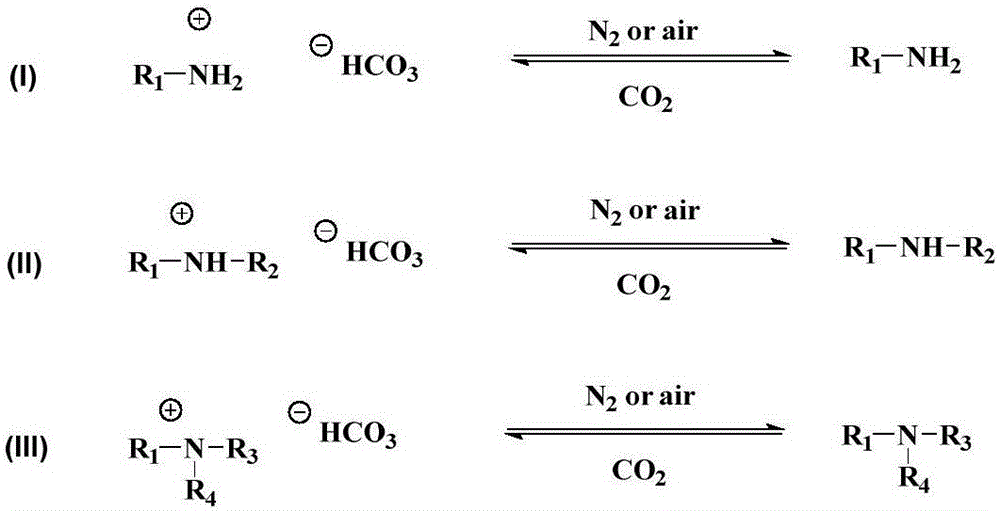

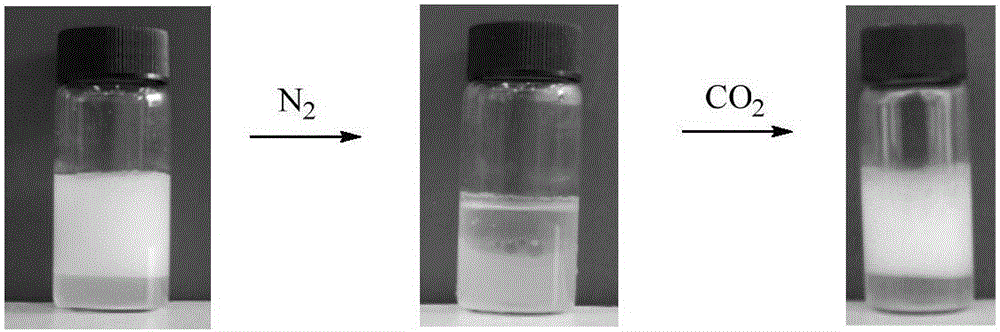

Room-temperature CO2 switch type compound emulsifier

InactiveCN106582431AImprove efficiencyTransportation and packagingMixingSilica particleEmulsion polymerization

The invention relates to a room-temperature CO2 switch type compound emulsifier and belongs to the field of colloid and interface chemistry. The emulsifier is prepared from unmodified commercial nano silica particles and a CO2 / N2 switch type surfactant, the primary particle size of nano silica particles is 20-200 nm, the use concentration is 0.1%-10% (based on the aqueous phase), an emulsifier stabilized emulsion belongs to Pickering emulsion, inactivation of the emulsification and demulsification of the emulsion are caused after introducing N2 or air into the emulsion at the room temperature (subzero 5-35 DEG C), CO2 is introduced into the emulsion at the room temperature (subzero 5-35 DEG C), the activity of the emulsion can be recovered, and a Pickering emulsion can be obtained again. The emulsifier and the emulsion have important application value in chemistry and chemical engineering related fields of oil delivery and processing, emulsion polymerization, wastewater treatment, emulsion explosives and the like as well as multiple fields of food, textile dyeing and finishing, leather and the like.

Owner:JIANGNAN UNIV

Emulsion explosive and preparation method thereof

InactiveCN102173967ALow viscosityThickenNon-explosive/non-thermic compositionsEmulsion explosiveOil phase

The invention relates to an emulsion explosive which is formed by mixing a latex substrate and a sensitizing agent in a weight ratio of (95-97): (3-5) and sensitizing, wherein the latex substrate is formed by emulsifying 90-95 wt% of oil phase and 5-10 wt% of water phase; and the oil phase is prepared from 28-40 wt% of emulsifier and 60-72 wt% of oil phase material, wherein the emulsifier consists of 40-60 wt% of surfactant and 40-60 wt% of wetting and stabilizing agent, and the surfactant contains high hydroxyl S-80 which is prepared by a method comprising the following steps of: mixing oleic acid with sorbierite in an equivalent molar ratio, adding KOH the weight of which accounts for 0.1-0.15% of the total weight of reaction mixture, and effectively reacting for 3-7 hours at the temperature of 200-250 DEG C and the negative pressure of 0.05-0.1MPa. The emulsion explosive disclosed by the invention has a sensitization effect superior to emulsion explosive obtained by using the prior art. The invention further provides a preparation method of the emulsion explosive.

Owner:GUANGDONG HONGDA BLASTING

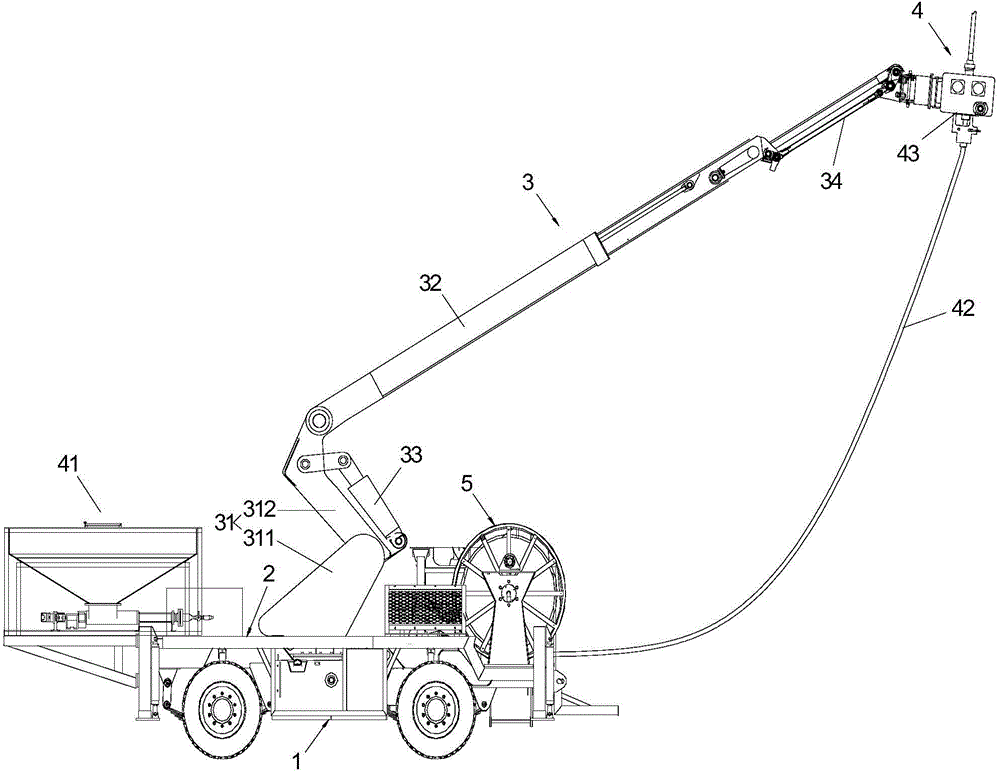

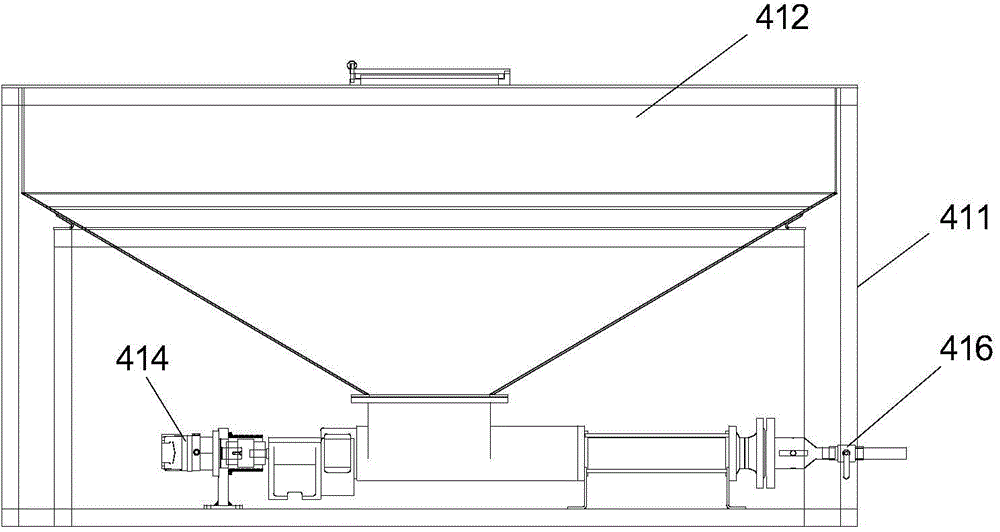

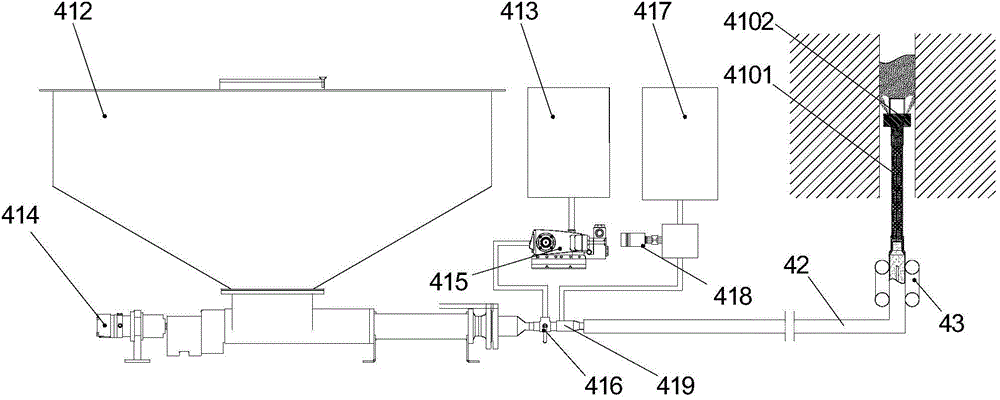

Underground on-site explosive dosing and charging truck

ActiveCN104949593AReduce labor intensityImprove safety conditionsBlastingControl systemEmulsion explosive

The invention relates to the technical field of underground explosive trucks and discloses an underground on-site explosive dosing and charging truck. The underground on-site explosive dosing and charging truck comprises a truck body, a chassis disposed on the truck body, a mechanical arm automatic hole finding mechanism and a charging conveying mixing mechanism which are disposed on the chassis, and a hydraulic system and an electric control system which are matched with the mechanical arm automatic hole finding mechanism and the charging conveying mixing mechanism, wherein the charging conveying mixing mechanism comprises an automatic charging module used for mixing and charging emulsion matrix to form emulsion explosives, a charging tube which is connected with the automatic charging module and used for conveying the emulsion explosives, and an automatic tube conveyor for automatically conveying the charging tube; the mechanical arm automatic hole finding mechanism is matched with the automatic tube conveyor and used for performing blast hole position alignment on the head end of the charging tube. The underground on-site explosive dosing and charging truck has the advantages that mechanical hole finding, automatic tube collecting and conveying and automatic blast hole filling are achieved, charging efficiency is increased, operator labor intensity is lowered, and operator safety conditions are improved effectively.

Owner:SHENZHEN KING EXPLORER SCI & TECH CORP

High-temperature acceleratingly-hardened emulsion explosive and preparation method for same

ActiveCN102633580AIncrease the hardness of the outer phaseMolecular chain lengthNon-explosive/non-thermic compositionsEmulsion explosiveHardness

The invention relates to a high-temperature acceleratingly-hardened emulsion explosive, which comprises water-phase materials, oil-phase materials, emulsifier, sensitizer and hardening accelerator, wherein the water-phase materials include wax and / or fatty acid; the sensitizer includes physical sensitizer and chemical sensitizer simultaneously; and the hardening accelerator is selected from silicate and / or alkaline matter. The temperature of the emulsion explosive is higher than 35 DEG C, and the emulsion explosive has a certain hardness and is non-sticky, thereby being applicable to open-air filling operation in hot summer, and being high in explosion performance.

Owner:ANHUI JIANGNAN CHEM IND CO LTD

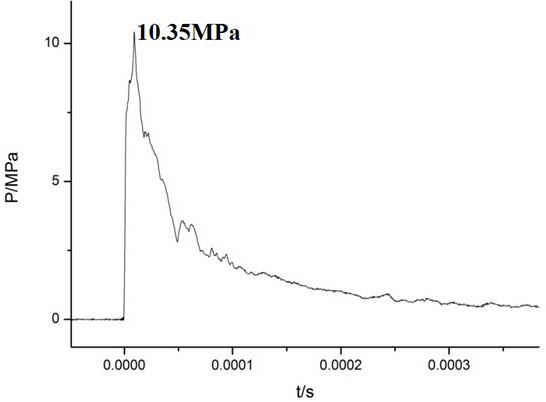

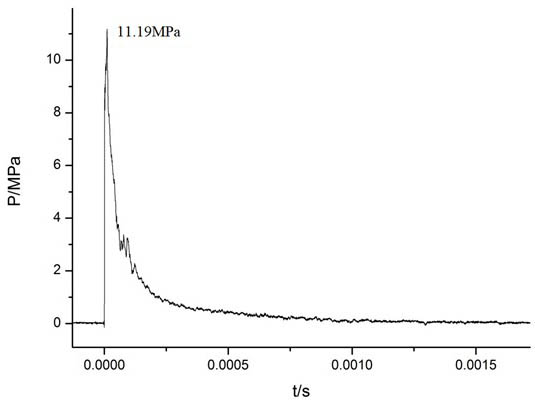

Magnesium hydride type hydrogen-stored emulsion explosive

The invention belongs to the technical field of explosive preparation, in particular to a magnesium hydride type hydrogen-stored emulsion explosive. The components comprise an emulsion base and a sensitized material, wherein the sensitized material is magnesium hydride; the mass of the magnesium hydride takes up 0.2-6% of the total mass of the emulsion explosive; the magnesium hydride is powders with purity not smaller than 95%. The added magnesium hydride is uniformly distributed in the emulsion base such that a part of magnesium hydride has a chemical reaction with water in the emulsion base, and a little amount of hydrogen is released, and foaming effect is performed on the emulsion base, and the detonator sensitivity is improved. When the emulsion base of the mixed magnesium hydride is initiated, the hydrogen bubbles under the function of shock waves produced in emulsion base detonation generate detonation reaction, and at the same time, the rest magnesium hydride quickly releaseshydrogen under the denotation waves of the emulsion base, and the hydrogen joins the detonation reaction of the emulsion base such that the emulsion explosive has characteristics of a high output shock wave peak value, a high impulse and a high energy. The detonation energy of the emulsion explosive is better than that of the common emulsion explosive.

Owner:UNIV OF SCI & TECH OF CHINA

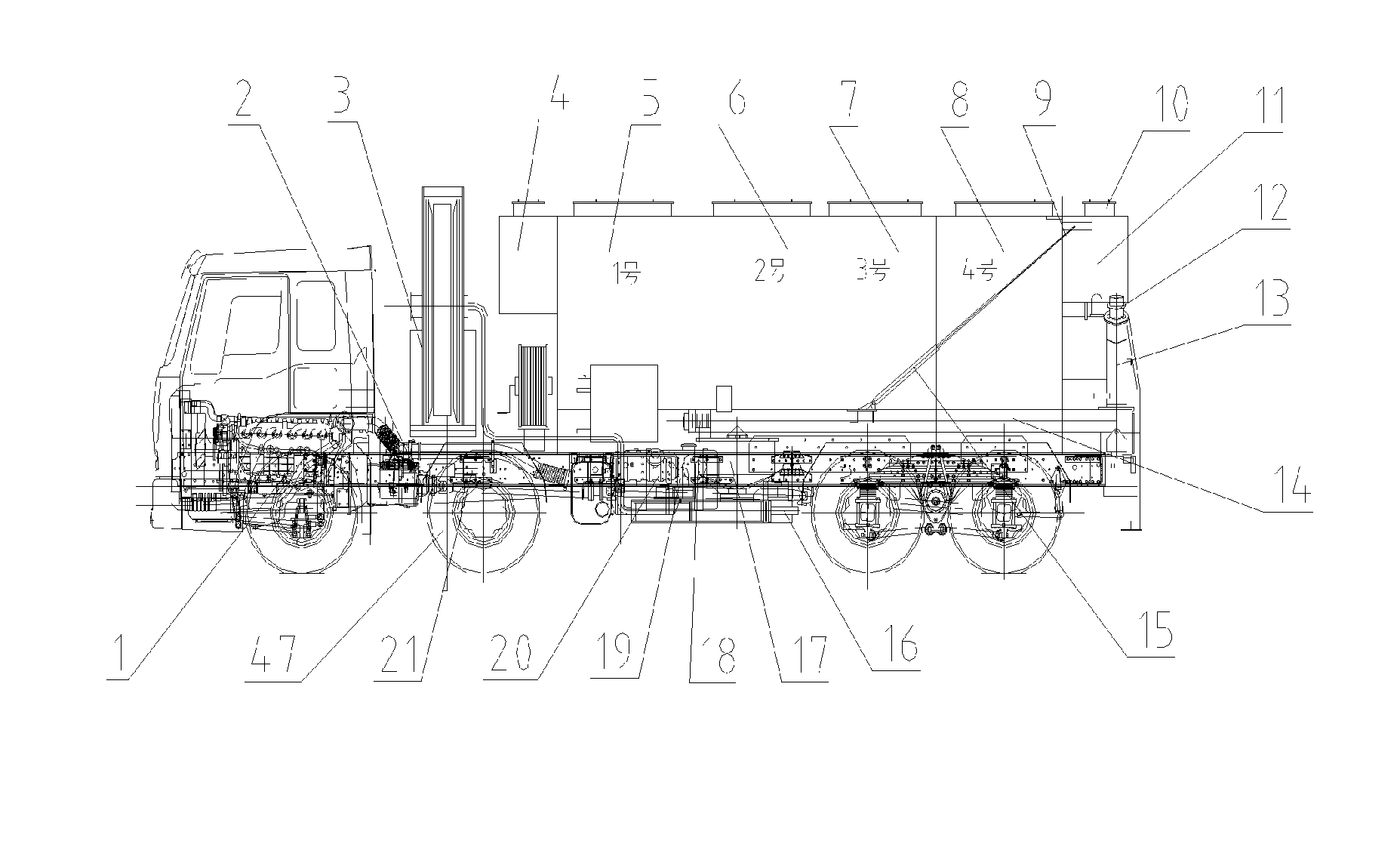

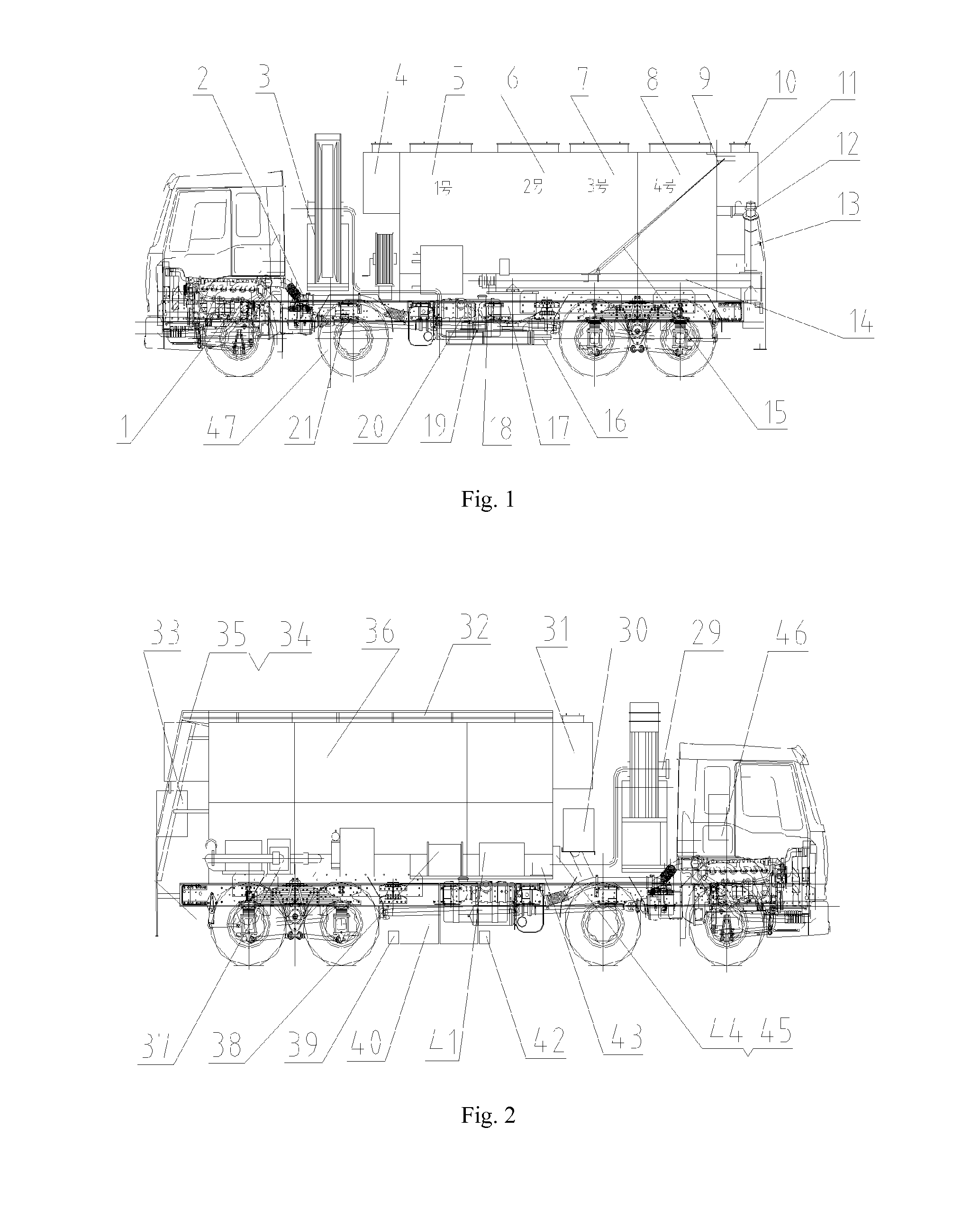

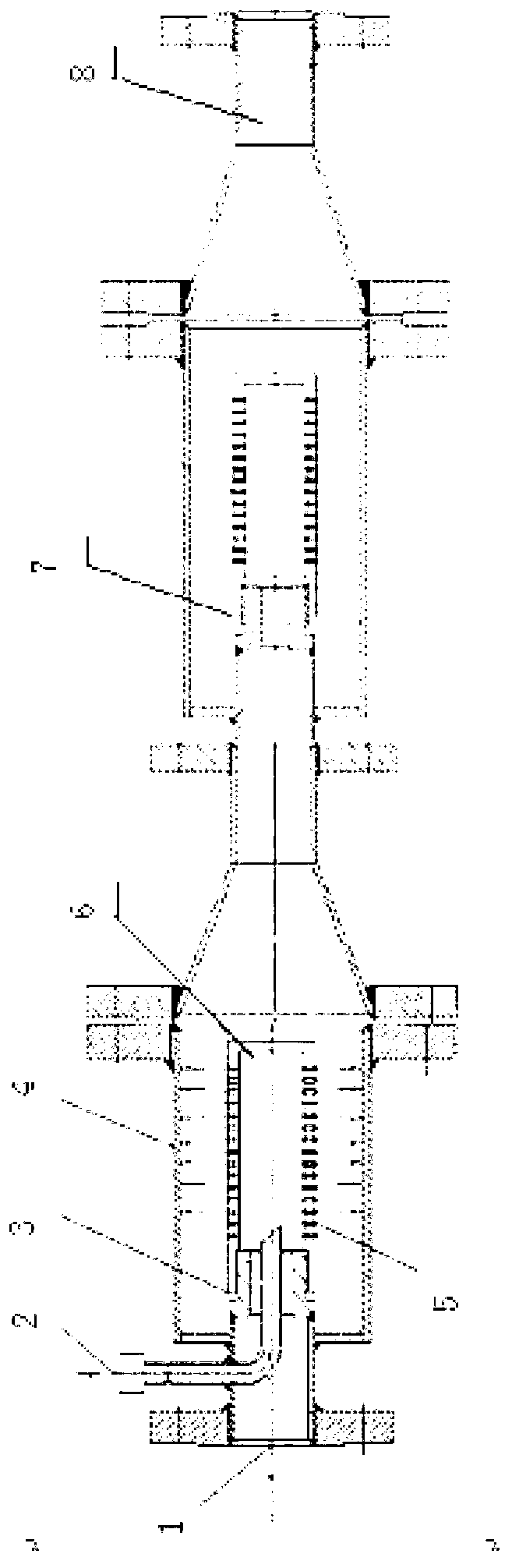

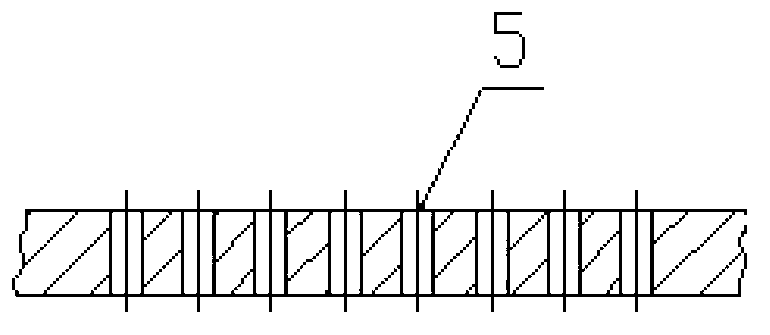

Site vehicle for mixing and loading multiple kinds of explosives with different detonation velocities

ActiveUS20150003186A1Low densityOvercomes shortcomingControlling ratio of multiple fluid flowsTank vehiclesEmulsion explosiveFuel oil

Provided is a site vehicle for mixing and loading multiple kinds of explosives with different detonation velocities. The vehicle contains a double-helix conveying system, a plurality of storage bins (5-8) and multiple sets of pipelines. Emulsified bases, porous granular ammonium nitrate and physical density modifier are stored in the main material storage bins, an adjuvant storage bin is provided with a diesel tank (4, 31), a sensitizing solution tank (40) and a washing water tank (11), and the technical effect that multiple kinds of explosives with different detonation velocities are mixed and loaded can be realized by using the different combinations of the different raw materials of the storage bins and various output pipelines and some baffle plates. The vehicle has the advantages of multiple purposes, capability of producing heavy emulsion explosive, density-modifiable heavy emulsion explosive, low density emulsion explosive, ultra-low density emulsion explosive, heavy ammonium nitrate fuel oil explosive, density-modifiable ammonium nitrate fuel oil explosive, porous granular ammonium nitrate fuel oil explosive, density-modifiable porous granular ammonium nitrate fuel oil explosive, and minor-diameter and long-distance conveying emulsion explosive, and applicability to the needs of various blasting operation environments and loading different kinds of explosives in the same blast hole.

Owner:QINGDAO TARGET MINING SERVICES

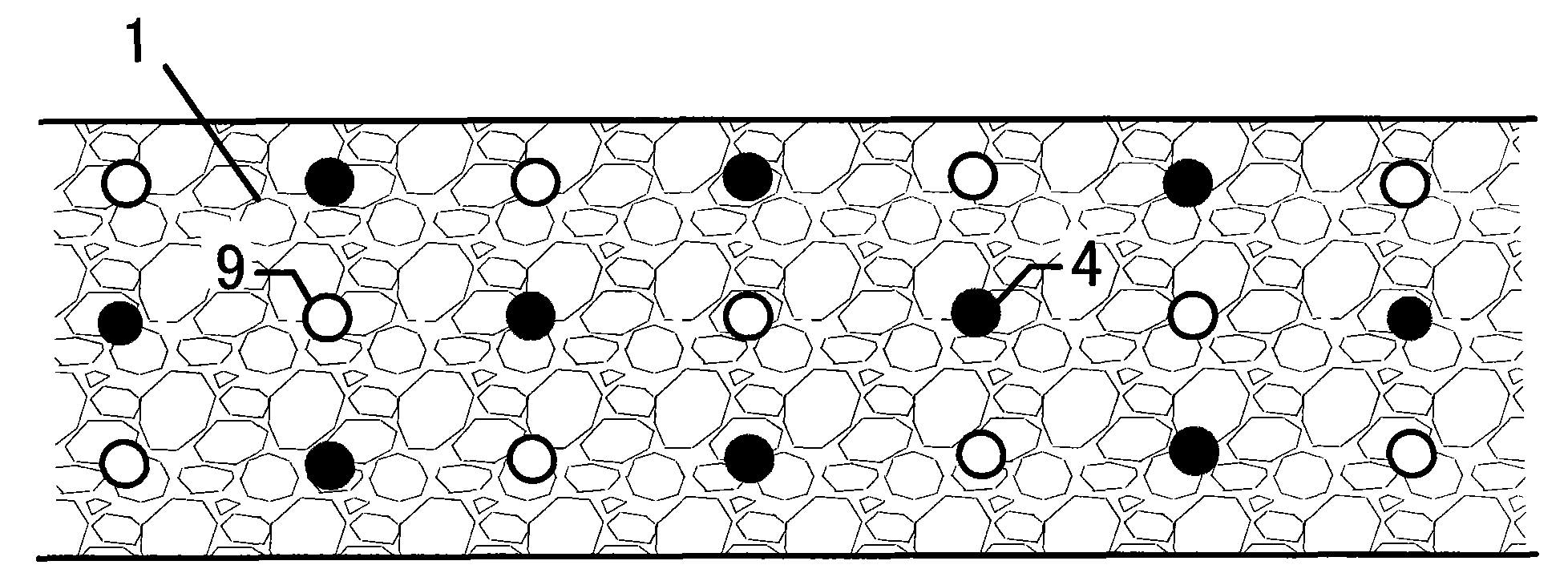

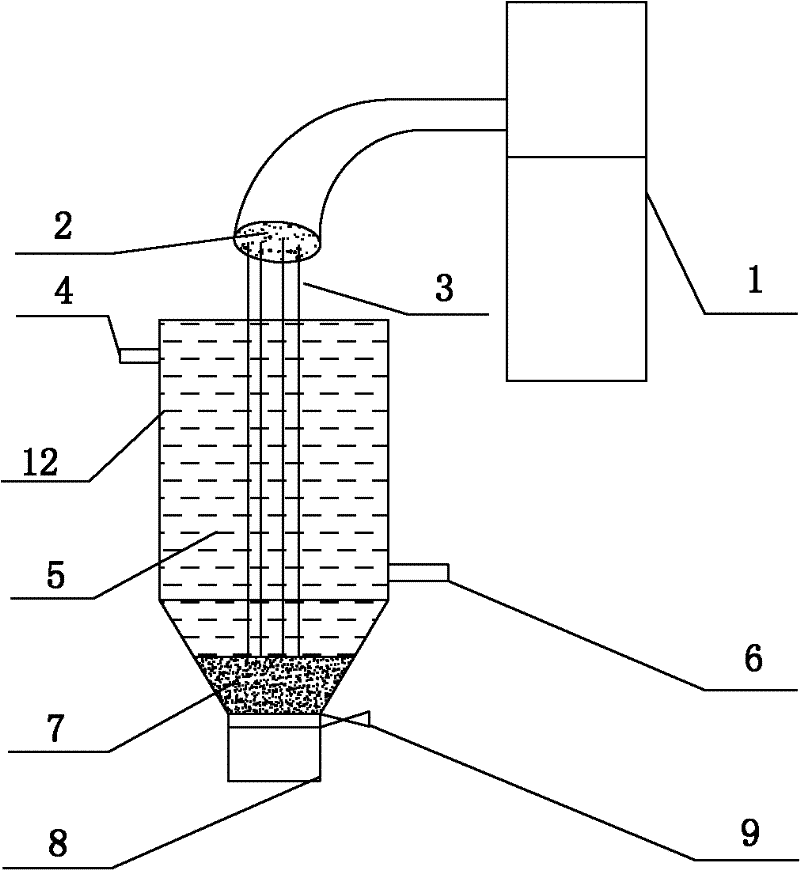

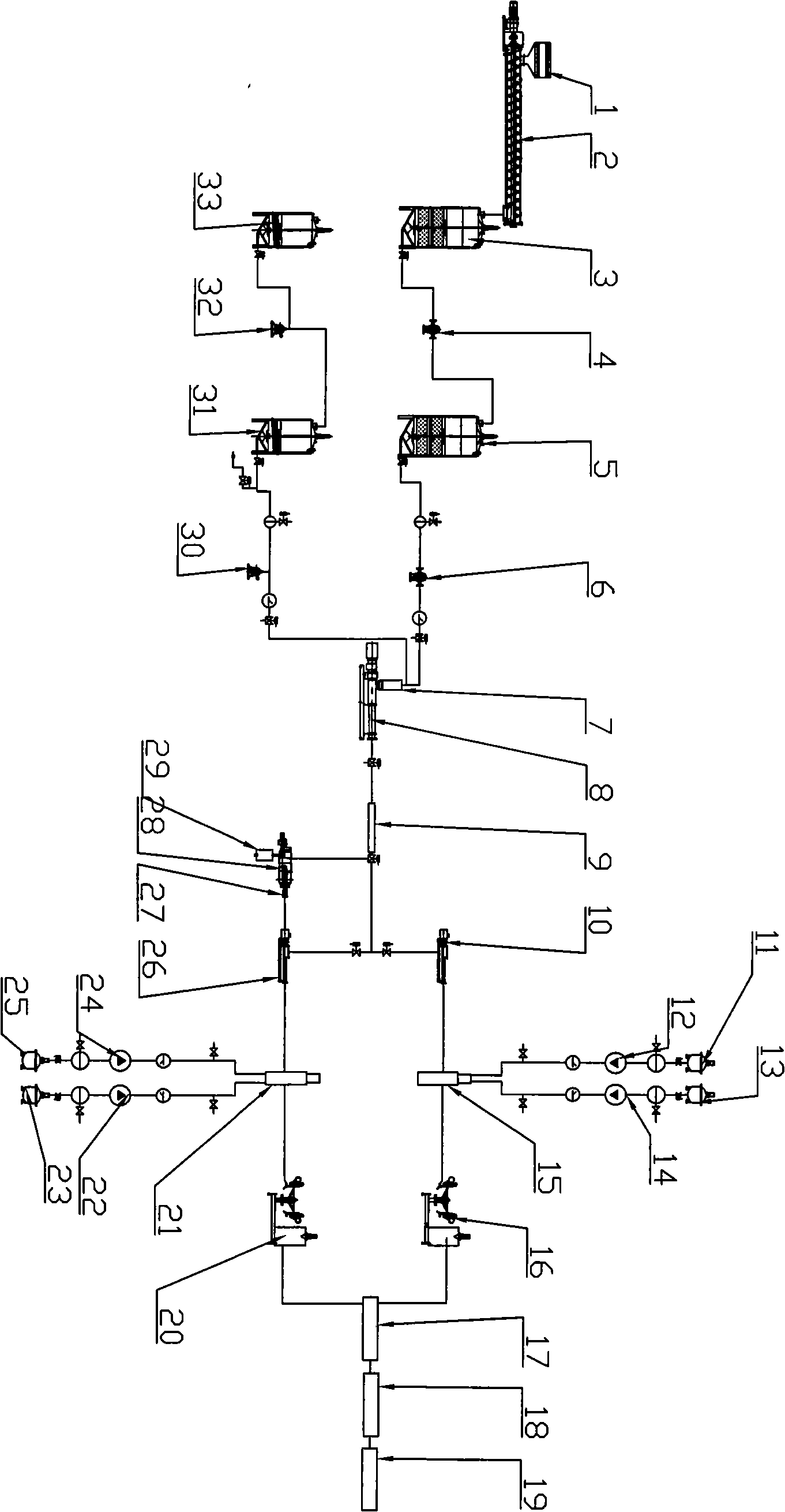

Static sensitization method and static sensitization equipment for packaging emulsion explosives

InactiveCN103304348ASimplify cooling equipmentImprove securityExplosive working-up apparatusExplosive AgentsEmulsion explosive

The invention relates to static sensitization equipment for packaging emulsion explosives. The static sensitization equipment comprises a static sensitizer (3), a colloid feeding hole (1) connected with the static sensitizer, a sensitizer feeding hole (2), an injection outer cavity (4), and a blocking chamber (6), wherein multiple rows of injection holes (5) are formed in the side wall; the sensitizer is mixed with an emulsion matrix, is ejected from the injection holes (5) under the action of the external pressure and is injected to the inner wall of the outer cavity (4), so that the emulsion matrix and the sensitizer form the first collision mixing; along with continuous entrance of the materials, repeated collision mixing is formed between the materials, the materials are pressed in the second-stage and third-stage sensitizers for repeating the collision mixing process, and finally, the emulsion matrix and the sensitizer are uniformly mixed. According to the equipment, the emulsion matrix and the sensitizer can be uniformly mixed under the condition that mechanical stirring is avoided, and a good sensitization effect can be achieved under the high / medium / low temperature conditions.

Owner:SHIJIAZHUANG SUCCESS MACHINERY ELECTRICAL

Novel emulsifier for emulsion explosive and preparation method of novel emulsifier

ActiveCN102976877ASolve the slightly soft problemMeet the requirements of hydrophilicityNon-explosive/non-thermic compositionsEmulsion explosiveEsterification reaction

The invention relates to a novel emulsifier mainly used for an emulsion explosive and a preparation method of the novel emulsifier. The emulsifier is the novel emulsifier obtained by carrying out esterification reaction on polyisobutylene succinic anhydride and polyglycerol, and then carrying out amination reaction on the obtained exterification product and alkylol amine. The emulsifier has good emulsifying property and can be used for preparing the emulsion explosive.

Owner:山东金奥银雅化工有限公司

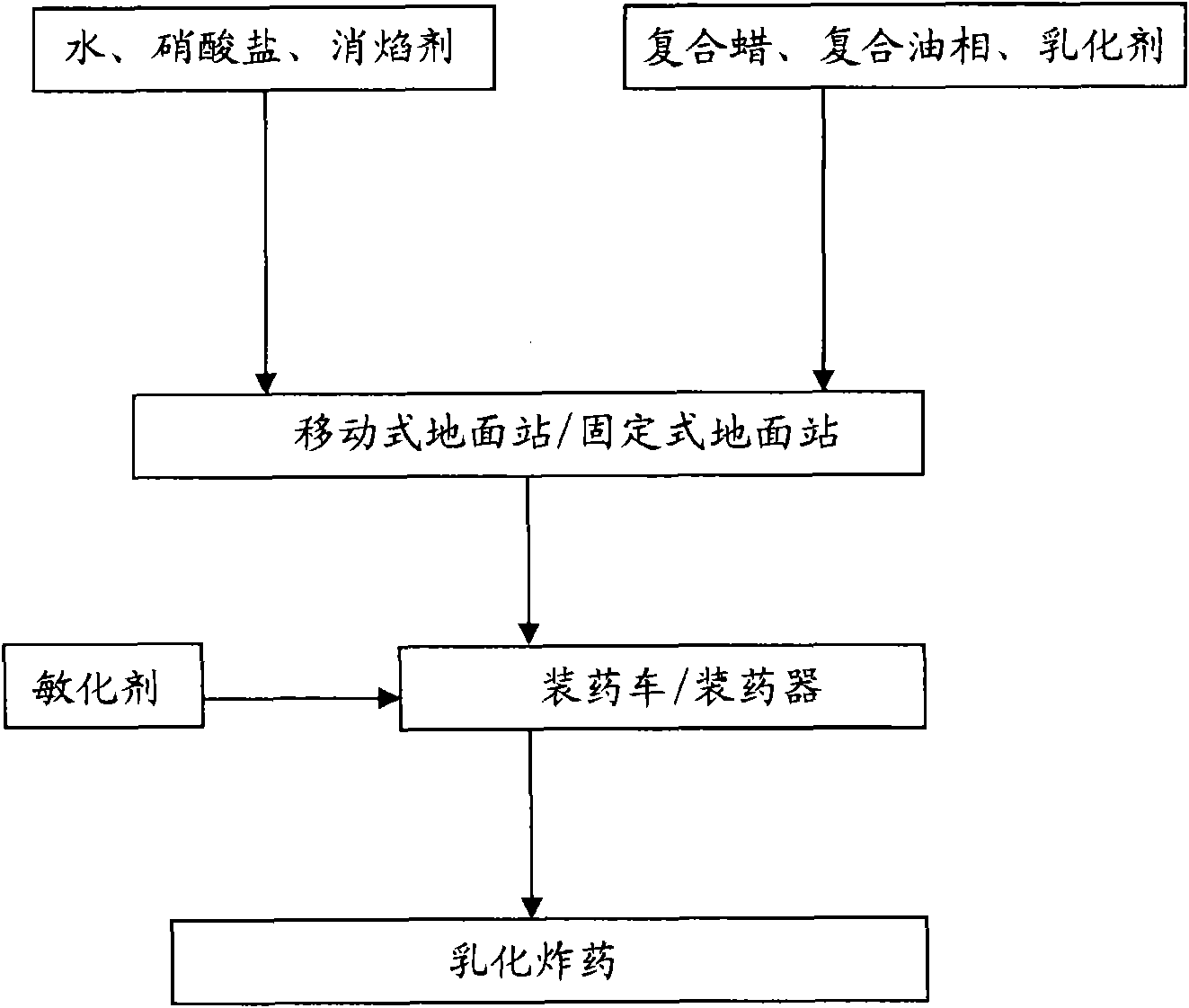

Continuous technique for preparing emulsifying explosive and charging

ActiveCN101357873AAvoid direct immersion in waterAvoid damageExplosive working-up apparatusEmulsion explosiveOil phase

The invention provides a continuous producing process for pharmacy and charging of emulsion explosive, which comprises the following steps: (1) aqueous phase solution and oil phase solution are respectively prepared; (2) the aqueous phase solution and the oil phase solution are delivered into a colostrum device for mixing, and after the process of colostrum, the aqueous phase solution and the oil phase solution are delivered into a static mixer for refining colostrum; (3) after the refined colostrum latex are delivered into a sensitized charging system for sensitized treatment, charging is carried out and after being cooled by a cooling system, the products are delivered to a packaging system for packaging. The technique proposal of the process is characterized by no warming after the process of the colostrum, high safety, and little damage of latex.

Owner:SHENZHEN KING EXPLORER SCI & TECH CORP

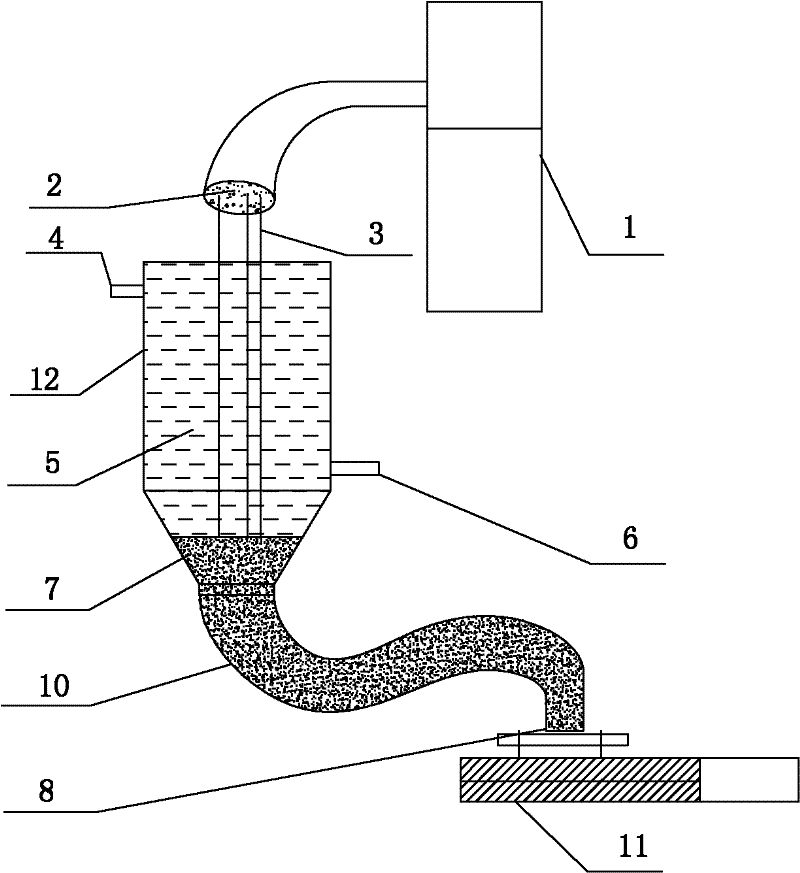

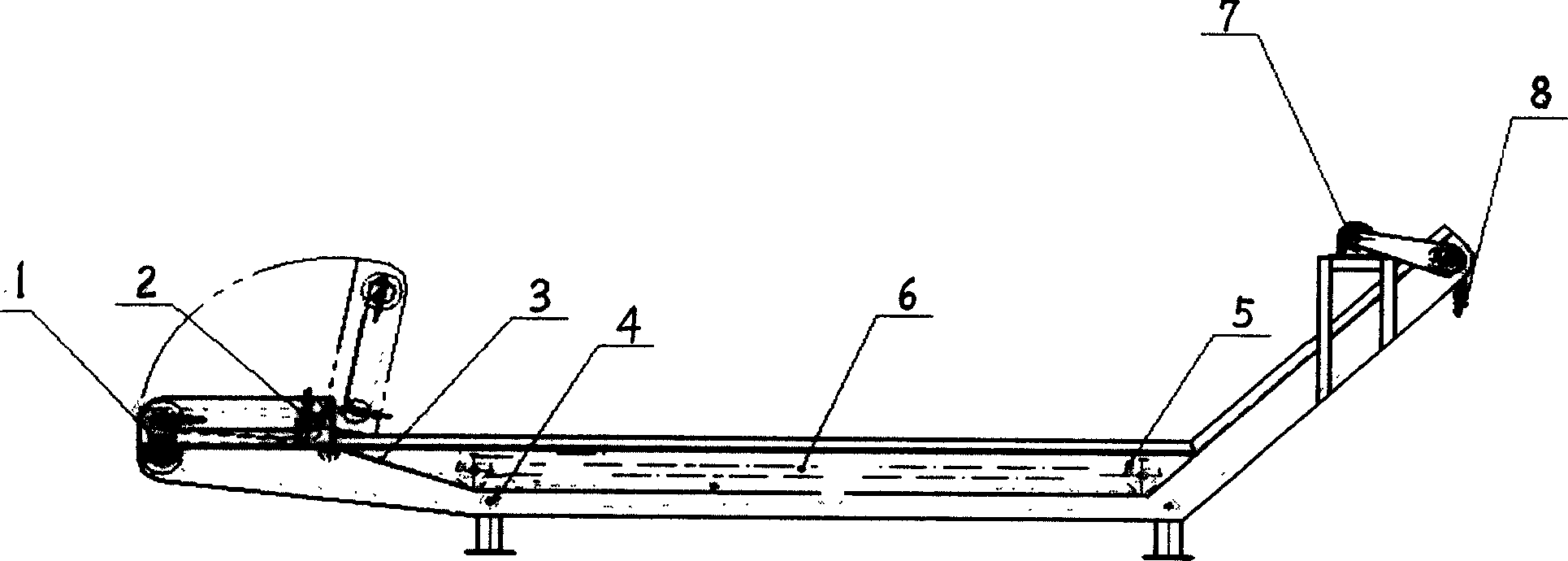

Process and device for immersion direct-cooling continuous production of latex matrix of emulsion explosive

InactiveCN1569775AConsistent detonation velocityExplosive working-up apparatusEmulsion explosiveColloid

The invention discloses a method and apparatus for cooling down the emulsion substrate for emulsified explosive which is characterized in that, the emulsion substrate is distributed on the conveyor belt, the conveyor belt traverses the cooling-water in the cooling-water tank so as to cool the colloid directly, the colloid is cooled down and passes the upward slope with an inclination angle of 15-85 degree to remove the moisture, then is loaded into next operation through a discharging mechanism.

Owner:SHIJIAZHUANG SUCCESS MACHINERY ELECTRICAL

Composite oil phase for emulsion explosive

InactiveCN101560128AImprove detonation sensitivityHigh detonation velocityNon-explosive/non-thermic compositionsDetonationMicrocrystalline wax

The invention provides a composite oil phase for an emulsion explosive for solving the drawbacks of oil phases, which has the advantages of stable quality, simple production and low cost. The emulsion explosive has the advantages of high detonation sensitivity, stable explosion velocity, easy charging and few cartridge igniters. The invention adopts a technical proposal that the oil phase is mixed by using the following raw materials by weight percentage: 29 to 32 percent of span-80, 3.2 to 3.4 percent of polymer emulsifier, 58 to 61 percent of compound wax, 3.1 to 3.5 percent of polyethylene wax and 3.1 to 3.5 percent of No.70 microcrystalline wax.

Owner:HUBEI TIANSHEN INDAL

Construction method of hydraulic flushing and presplit blasting combined permeability-increasing extraction system in drill holes

ActiveCN105507938AIncrease the flow channelImprove breathabilityConstructionsLiquid/gas jet drillingDetonatorEmulsion explosive

A construction method of a hydraulic flushing and presplit blasting combined permeability-increasing extraction system in drill holes includes the steps of (1), forming the drill holes, namely forming a plurality of blasting drill holes and a plurality of flushing drill holes in an extraction roadway of a coal seam floor towards a coal seam direction in a staggered manner, wherein a distance between each blasting drill hole and the adjacent flushing drill hole ranges from 3 meters to 6 meters; (2), blasting, namely mounting a steel pipe at an orifice of each blasting drill hole, filling a gap between the steel pipe and the corresponding blasting drill hole with cement mortar hermetically, filling one end of a PVC (polyvinyl chloride) pipe with emulsion explosive after the cement mortar is solidified, mounting a primer detonator closely to the emulsion explosive, filling a position, close to the primer detonator, with emulsion explosive, filling circularly sequentially and filling a position, close to the last primer detonator, with stemming, wherein a distance between each two adjacent primer detonators is one meter. According to the construction method, coal seam gas permeability is improved effectively, gas extraction effects are enhanced, extraction time is shortened effectively and potential safety hazards of gas are reduced maximally.

Owner:HENAN POLYTECHNIC UNIV

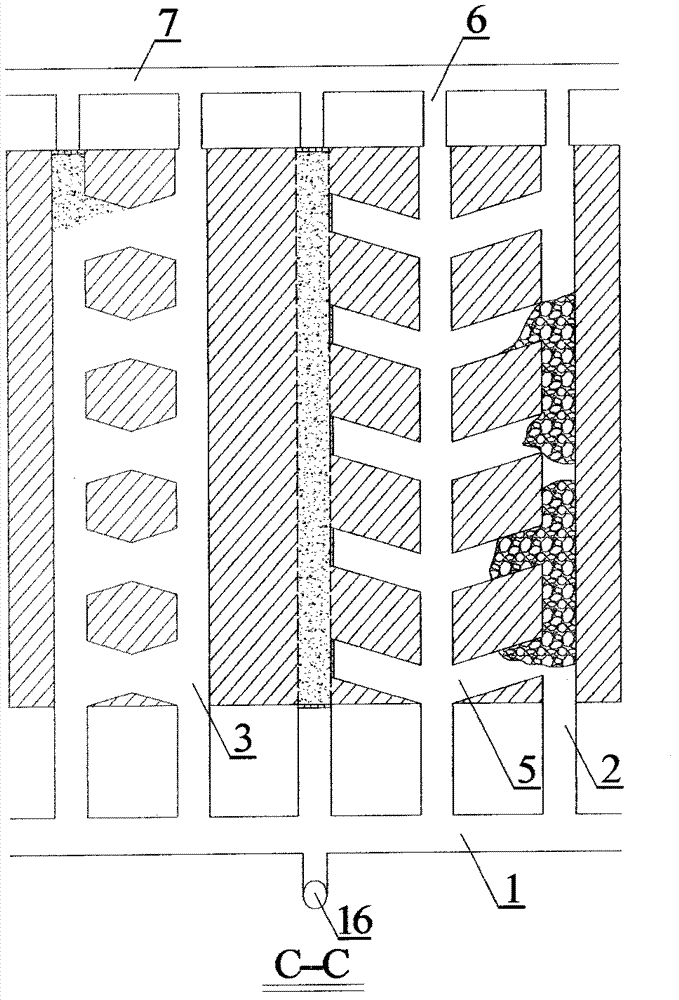

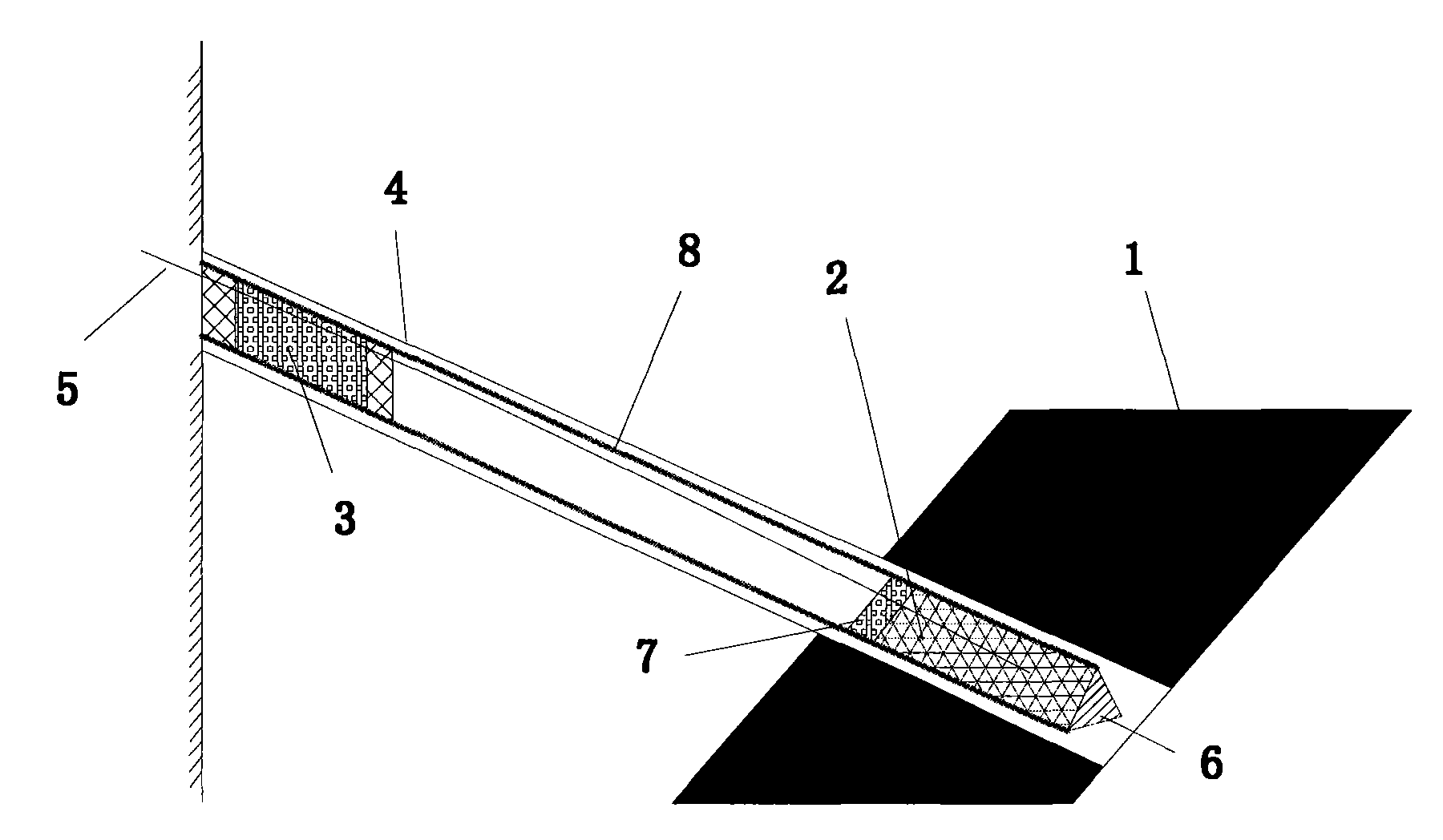

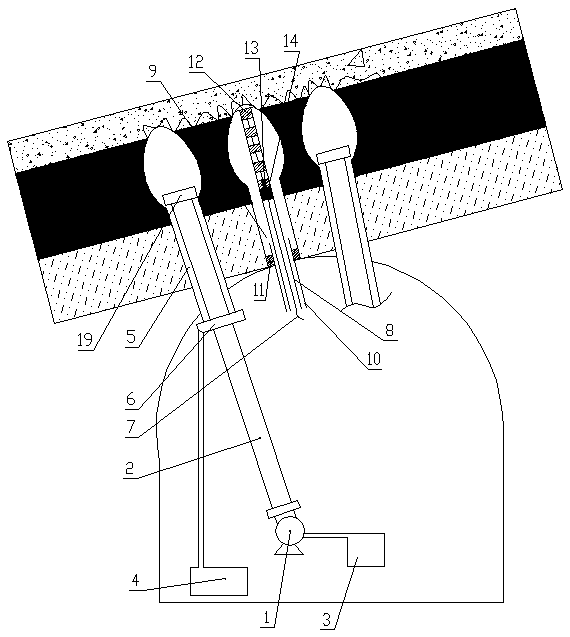

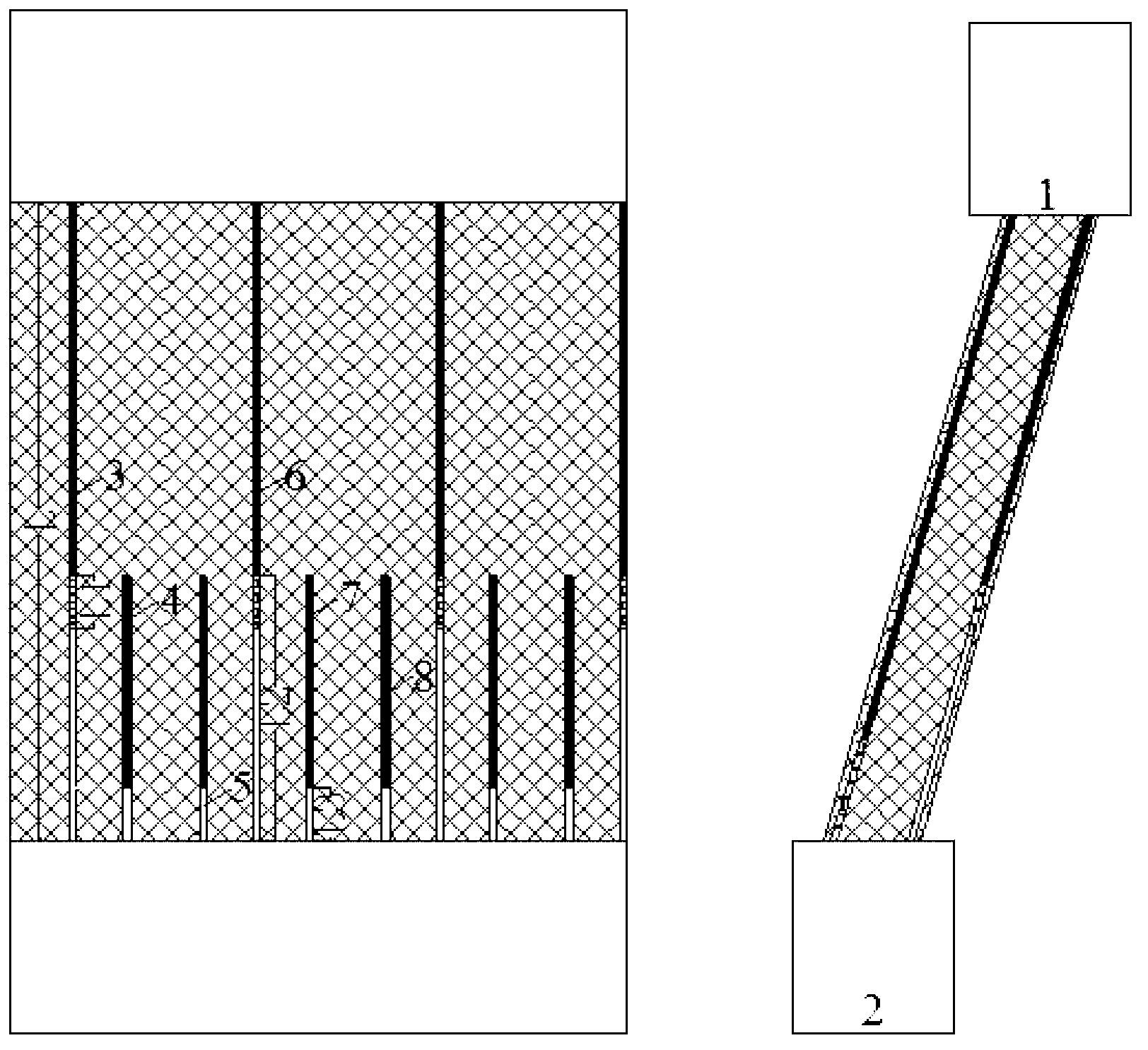

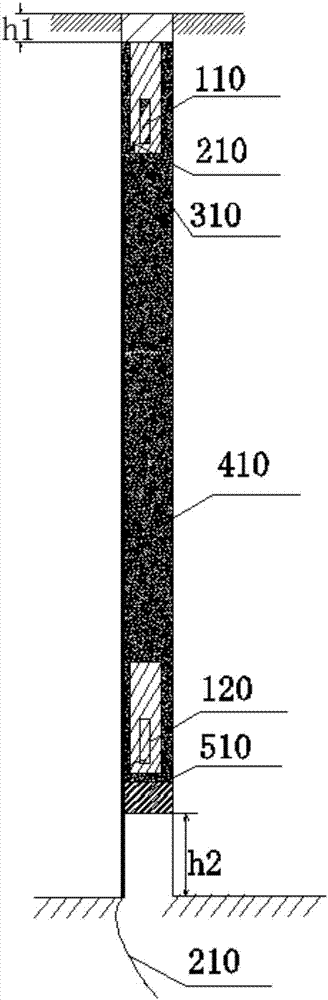

Blasting method for reducing depletion in steeply inclined thin ore body recovery

The invention provides a blasting method for reducing depletion in steeply inclined thin ore body recovery and belongs to the field of blasting engineering. The design process comprises the following steps: (1) actually detecting and locating a hole arrangement point in a lower subsection ore drift roadway (2) by using a total station; (2) drilling a recovery explosive-filled hole (3) and a presplitting hole (4) by using a middle-deep hole drill jumbo K41X and checking whether blast holes are in a good condition; (3) respectively filling the recovery explosive-filled hole (3) and the presplitting hole (4) by using a big cartridge rock water-gel explosive (6) and a small cartridge rock emulsion explosive (7) and stuffing the big cartridge rock water-gel explosive (6) and the small cartridge rock emulsion explosive (7) by using a nonmetal stuffing (5); and (4) after line connection is finished, detonating blast holes in a footwall, gradually carrying out microsecond detonating on the rest holes in a zigzag shape, detonating the blast holes by using a detonating tube (8) and igniting the blast holes by using an electric detonator. The blasting method for reducing the depletion in the steeply inclined thin ore body recovery, provided by the invention, has the advantages as follows: surrounding rock spallation of the footwall can be reduced, ore depletion is reduced, damages caused by the blasting impact to the surrounding rocks of the footwall can be reduced to a maximum extent, and the safety of follow-up ore removal is enhanced.

Owner:QINGHAI SHANJIN MINING

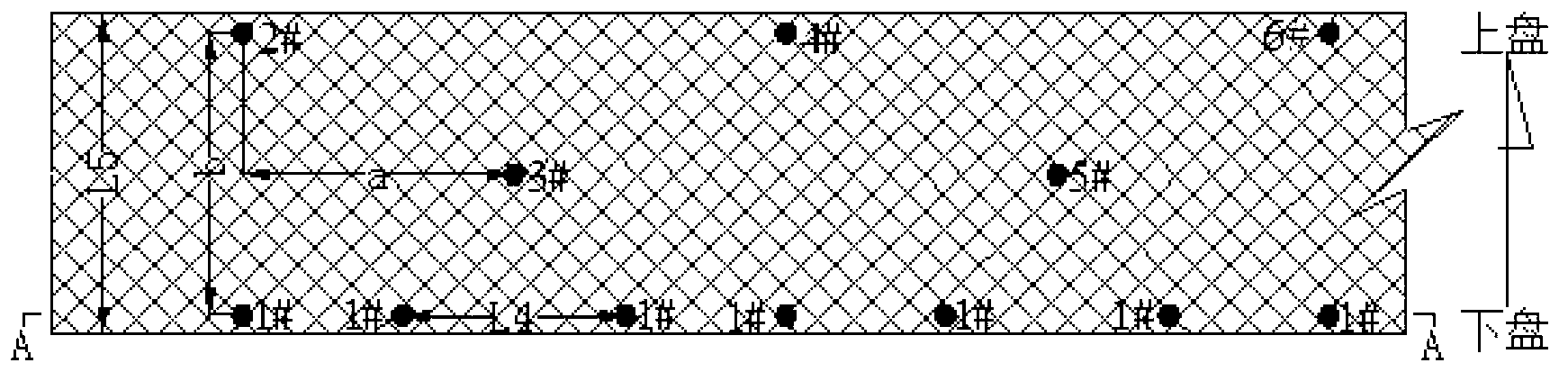

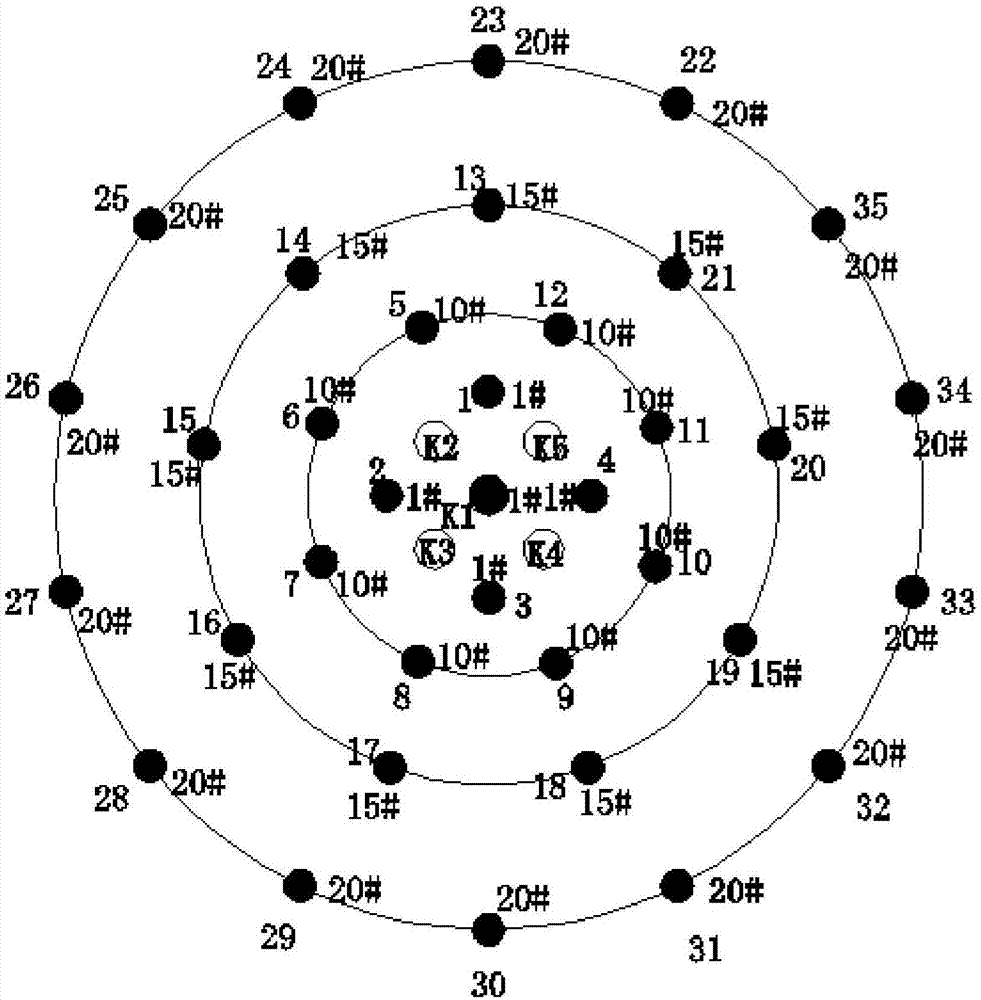

One-time well completion blasting method of measure well

ActiveCN107131806AGuarantee the blasting effect of well completion onceAchieve smooth expectationsBlastingDetonatorEmulsion explosive

The invention discloses a one-time well completion blasting method of a measure well. The method comprises following steps: firstly, trolley drilling, wherein a center hole and four empty holes are sequentially drilled in a lower chamber of the measure well upwards, four rings of charging holes are drilled from inside to outside, the center hole is located in the center position of the measure well, the empty holes are formed in the periphery of the center hole and are arranged in a square manner, the four empty holes are formed in the four top points of the square, the four rings of charging holes are sequentially provided with four, eight, nine, and fourteen charging holes from inside to outside, and each ring of charging holes are arranged on the circumference with the center hole as the round center at equal distances; secondly, charging, wherein emulsion explosives and detonators are loaded in the center hole and all the charging holes, and after charging, stemming is used for plugging hole openings; thirdly, blasting, wherein blasting is carried outside electronic detonator holes, and blasthole millisecond blasting is carried out. According to the one-time well completion blasting method of the measure well, the construction efficiency of the measure well is effectively improved, and the one-time well completion blasting effect and the wall face smoothness of the measure well are improved.

Owner:SHENZHEN ZHONGJIN LINGNAN NONFEMET COMPANY +1

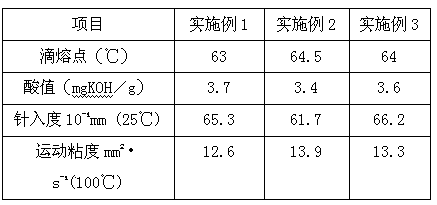

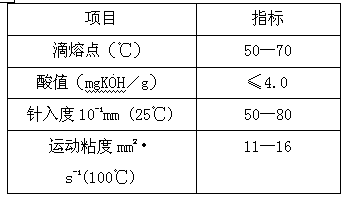

Plant type compound oil phase for emulsion explosive

ActiveCN103694068ASimple production processProduct quality is easy to controlNon-explosive/non-thermic compositionsWaxVegetable oil

The invention discloses a plant type compound oil phase for an emulsion explosive. The compound oil phase comprises main components of plant wax and plant oil, and is characterized by comprising the following materials by mass: 20%-50% of the plant wax, 10%-25% of the plant oil, 10%-25% of light dewaxing paste, 20%-35% of an emulsifier and 5%-15% of additives, wherein the total mass percentage of the materials is 100%. The compound oil phase prepared from the plant wax and the plant oil is applied to the industrial explosive production, so that a production process is simplified, and the production process quality is conveniently controlled; the compound oil phase is proper in drop melting point, acid value, needle penetration degree and kinematic viscosity, and is an ideal emulsion explosive oil phase material; the produced emulsion explosive is good in explosion performance; the plant oil phase material is clean, environment-friendly, low in price and highly available, and can effectively reduce the production cost; the compound oil phase used for producing the emulsion explosive has good economic and social benefits and is convenient for industrialization production and application.

Owner:FUZHOU GUOTAI COMPOSITE MATERIAL CO LTD

Method for preparation of emulsion explosive by using waste explosives

The invention relates to a method for preparation of an emulsion explosive by using waste explosives. The method comprises the following process steps: preparation of water phase liquid, preparation of a compound oil phase, emulsification, cooling, sensitization and charging. A key point of the invention lies in that waste emulsion explosives are utilized; and the waste emulsion explosives refer to chemical bubble-sensitive emulsion explosives which suffer demulsification, crystallization, hardening and the like and lose detonator sensitivity and detonation capacity. In the method, the waste emulsion explosives are used in the preparation of the water phase liquid. According to the invention, low temperature, environmental protection and no pollution of three wastes (waste gas, waste water and industrial residue) are realized, according with developmental requirements; and except packages of explosive cartridges, the explosives are totally recovered, and a high recovery rate is obtained.

Owner:CHINA COAL TECH & ENG GRP HUAIBEIBLASTING TECHN RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com