Patents

Literature

61results about How to "Increase the flow channel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

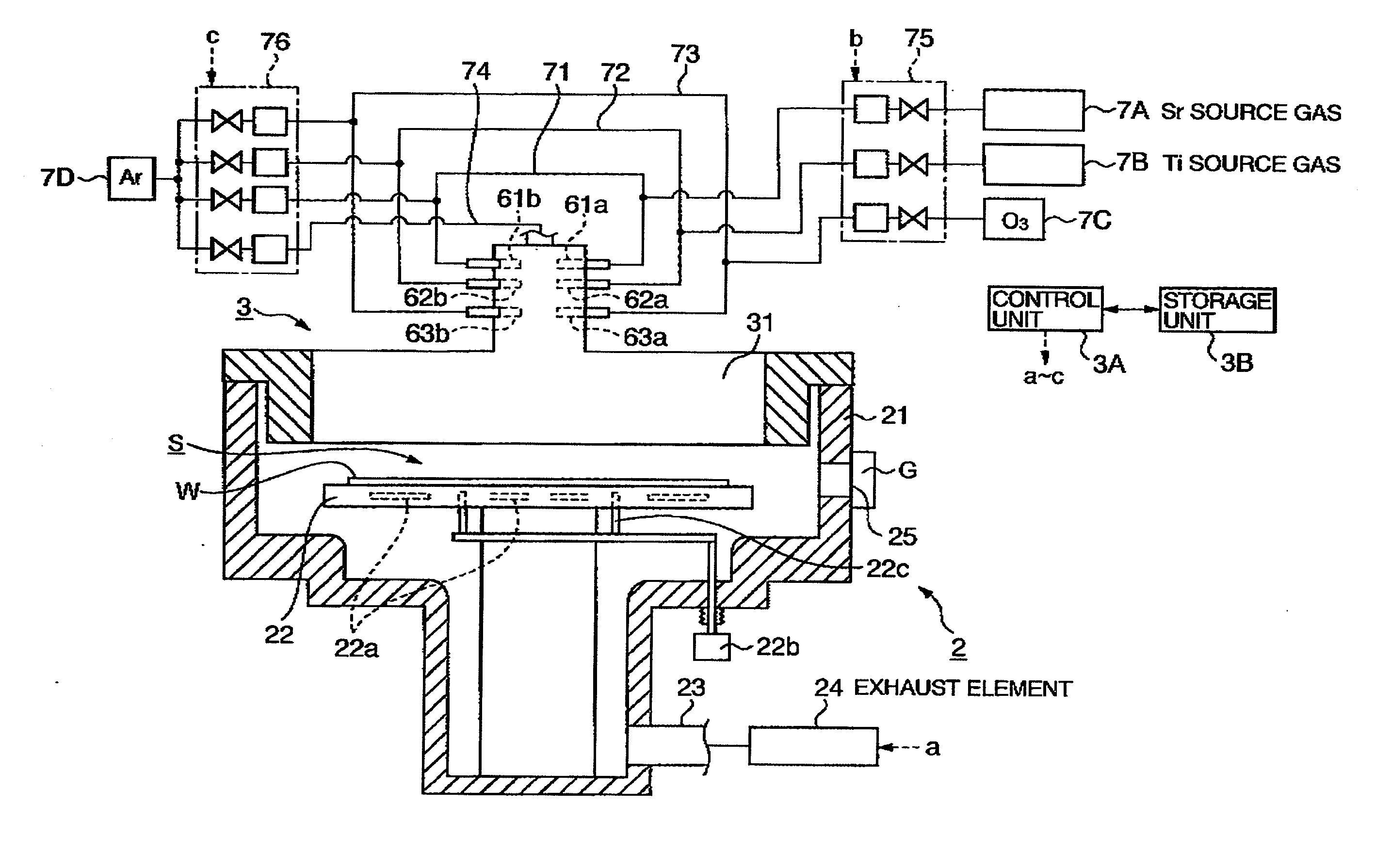

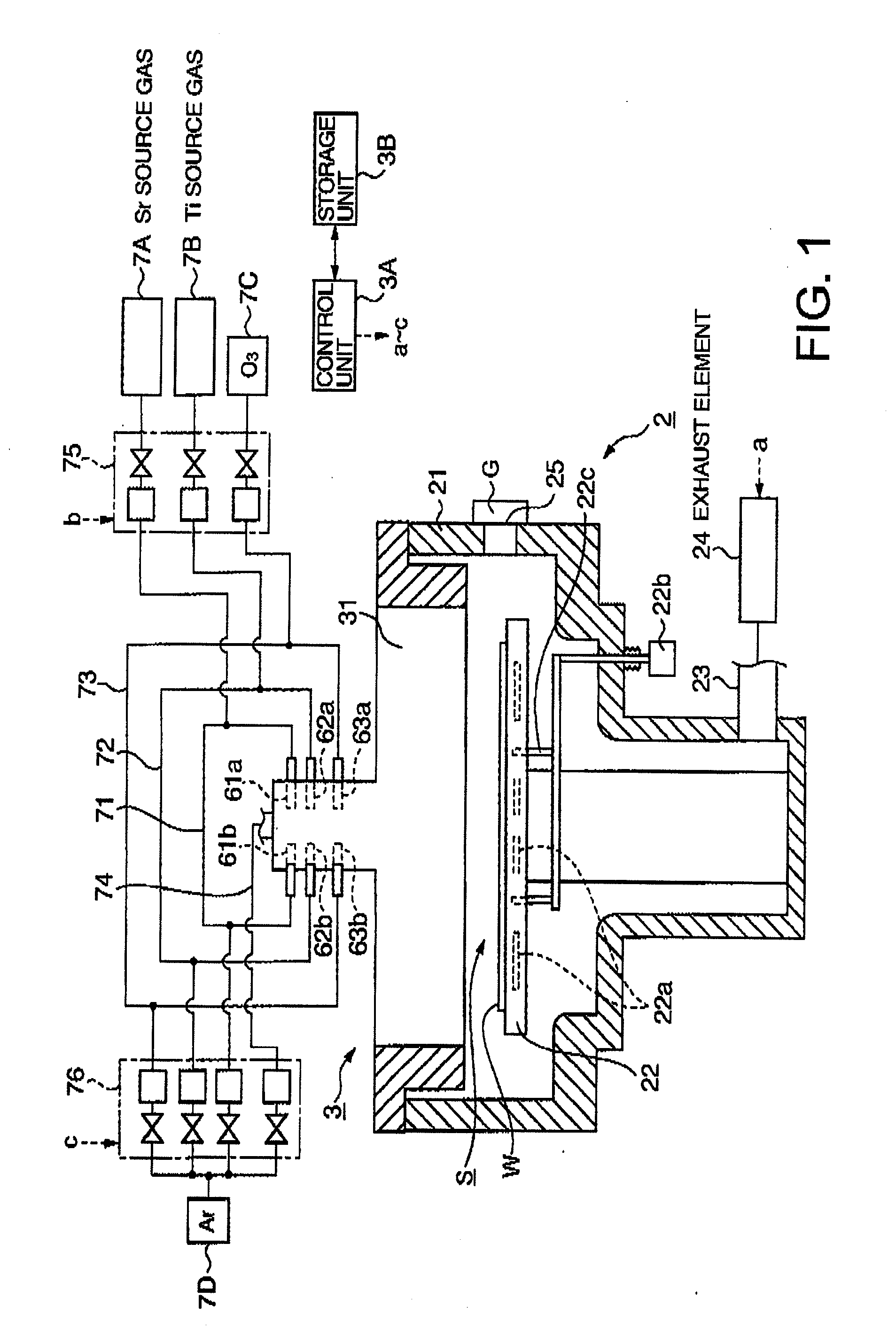

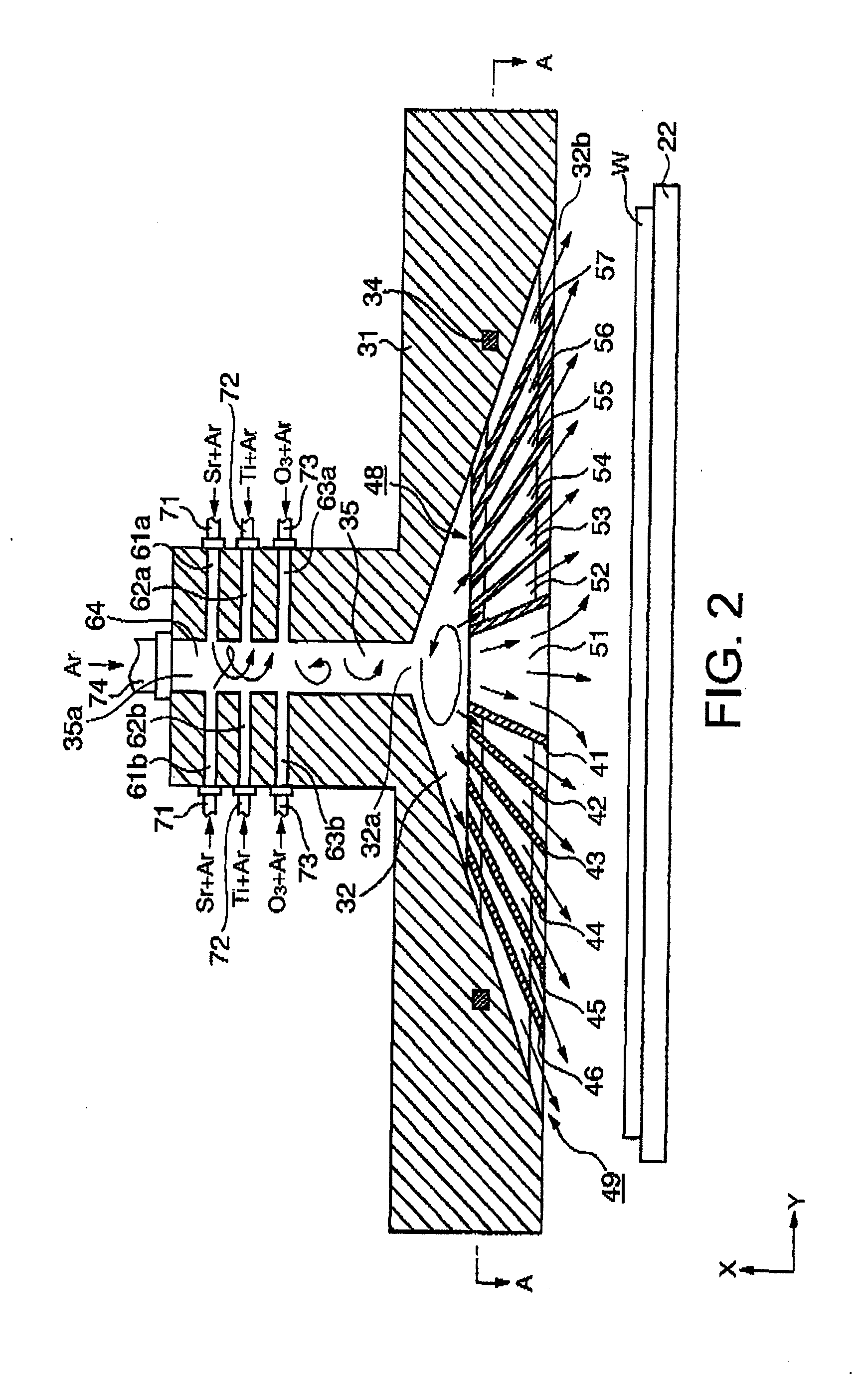

Gas supply device, processing apparatus, processing method, and storage medium

InactiveUS20110098841A1Easy to manufactureGood flexibilityDecorative surface effectsSemiconductor/solid-state device manufacturingEngineeringGas supply

A gas supply device 3 includes a device body 31 forming a substantially conical gas-conducting space 32 for conducting gases therethrough from a diametrally reduced end 32a of the space 32 to a diametrally enlarged end 32b thereof, gas introduction ports 61a to 63a, 61b to 63b, and 64, each provided near the diametrally reduced end 32a of the gas-conducting space 32 in the device body 31 to introduce the gases into the gas-conducting space 32, and a plurality of partitioning members 41 to 46 provided in the gas-conducting space 32 of the device body 31 to partition the gas-conducting space 32 concentrically. The partitioning members 42 to 46 arranged adjacently to each other at a radially outer side of the gas-conducting space 32 are greater than the adjacently arranged partitioning members 41 to 45 at a radially inner side in dimensionally diverging rate per partitioning member. Thus, internal gas flow channels of the gas supply device have high gas conductance and enhanced gas replaceability, compared with those of the conventional gas showerhead.

Owner:TOKYO ELECTRON LTD

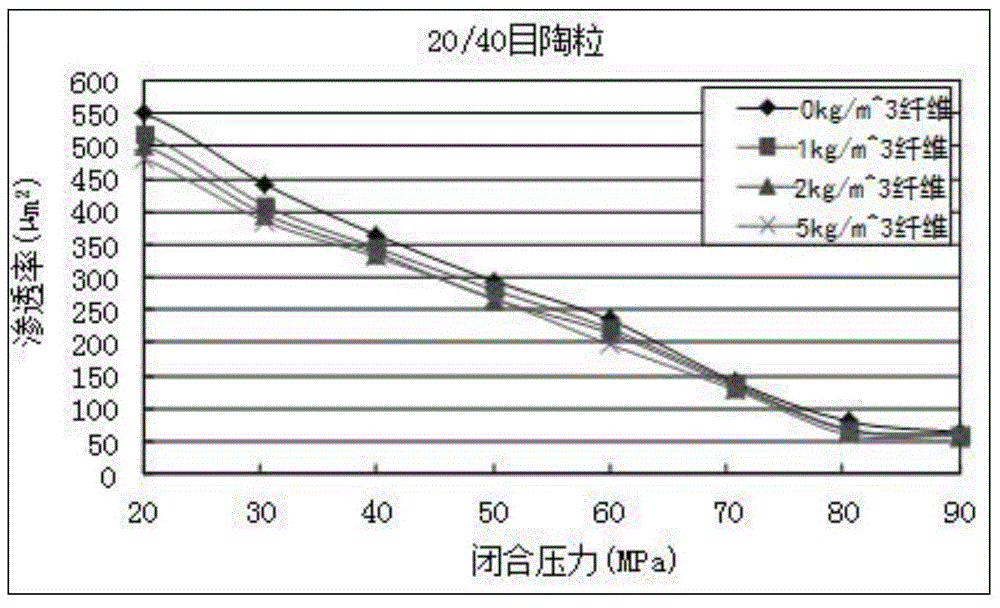

Fracturing method capable of improving sand-carrying performance of fracturing liquid

ActiveCN104405360AReduce sedimentation velocityImprove sand carrying capacityFluid removalFiberFracturing fluid

The invention provides a fracturing method capable of improving the sand-carrying performance of fracturing liquid. The method comprises the following steps: dispersing degradable fibers by virtue of a dispersion device, and uniformly dissolving the dispersed degradable fibers in a fracturing liquid base solution; pumping into a fracturing blender truck, and mixing with a propping agent for fracturing so as to form sand-carrying fluid; then pumping the sand-carrying fluid dissolved with the fibers into a strata so as to support a formed fracture geometry. When the degradable fibers added into the fracturing liquid are uniformly dispersed in the fracturing liquid, the fibers and a guanidine gum chain with a network structure form a tangled structure, so that the strength of the cross-linked network structure is enhanced, the sedimentation rate of the propping agent is reduced, the sand-carrying capacity of the fracturing liquid is improved, the propping agent is uniformly distributed in a whole crack, a supporting effect is fully realized, the crack is prevented from being closed and thus the fracturing period of validity is increased; furthermore, the added fibers are capable of effectively preventing the propping agent from flowing back and preventing formation sand flow; an oil gas flow passage is additionally increased, so that the fracturing yield-increasing effect is finally realized.

Owner:中石化胜利油田分公司采油工艺研究院 +1

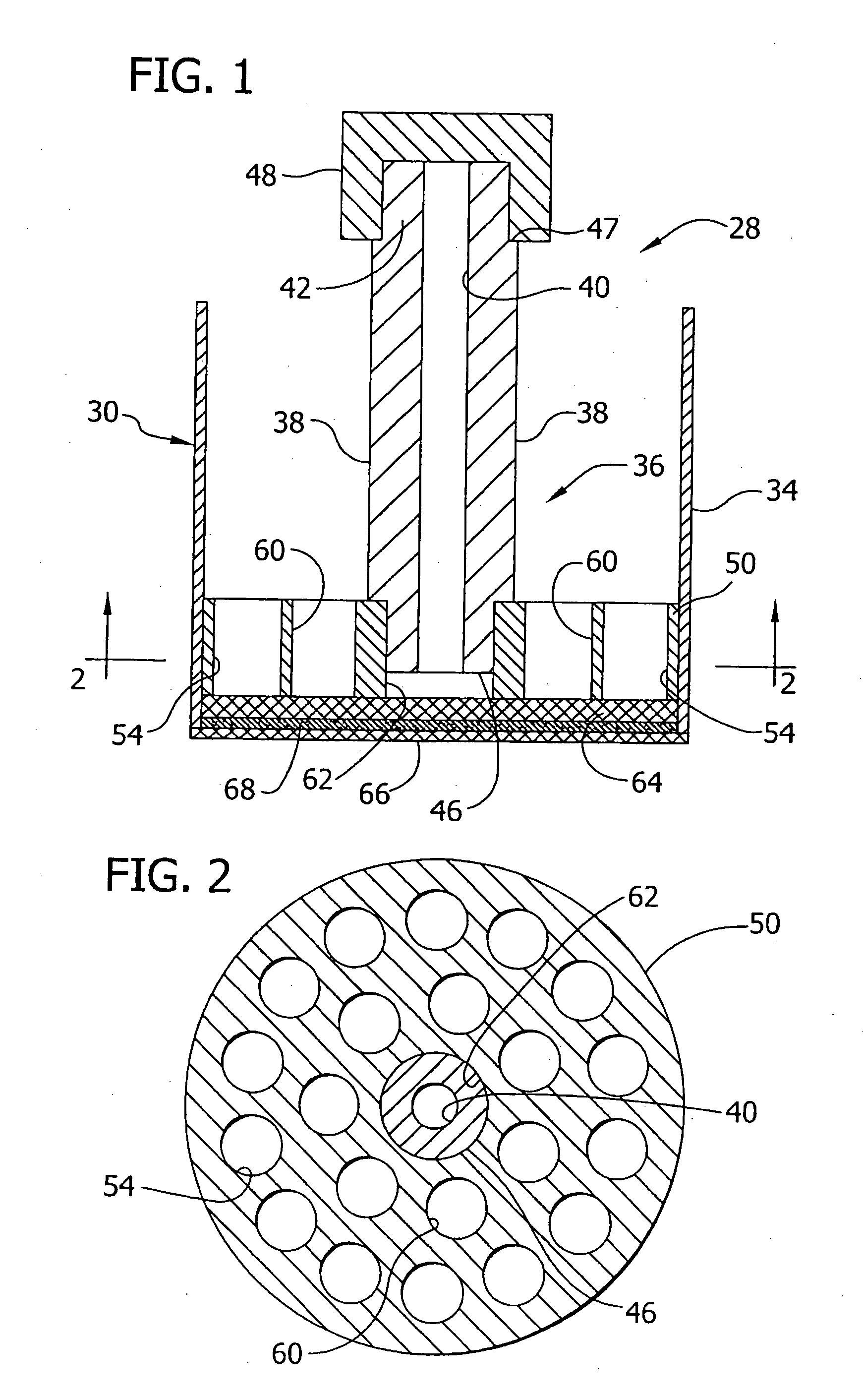

Surface charge manipulation for improved fluid intake rates of absorbent composites

InactiveUS20050142965A1Improving fluid intake rateIncrease ratingsSynthetic resin layered productsAbsorbent padsFluid intakeFiber

This invention describes a novel means for improving fluid intake rates in disposable absorbent composites by altering the surface charge on the components of such composites through utilization of surface charge treatments (i.e., charge modifiers). The composite components contemplated for the invention may include, but are not limited to, conventional superabsorbent particles (SAP) and fluff fibers (fluff). The surface charge modifiers of the present invention are specifically selected to achieve an ionically (i.e., electrically) generated repulsive force between the individual composite components in the presence of an insulting fluid. This active repulsion between composite components creates a condition in the composite conducive to superabsorbent swelling and generation of void volume and flow channels, thus improving the fluid intake rate.

Owner:KIMBERLY-CLARK WORLDWIDE INC

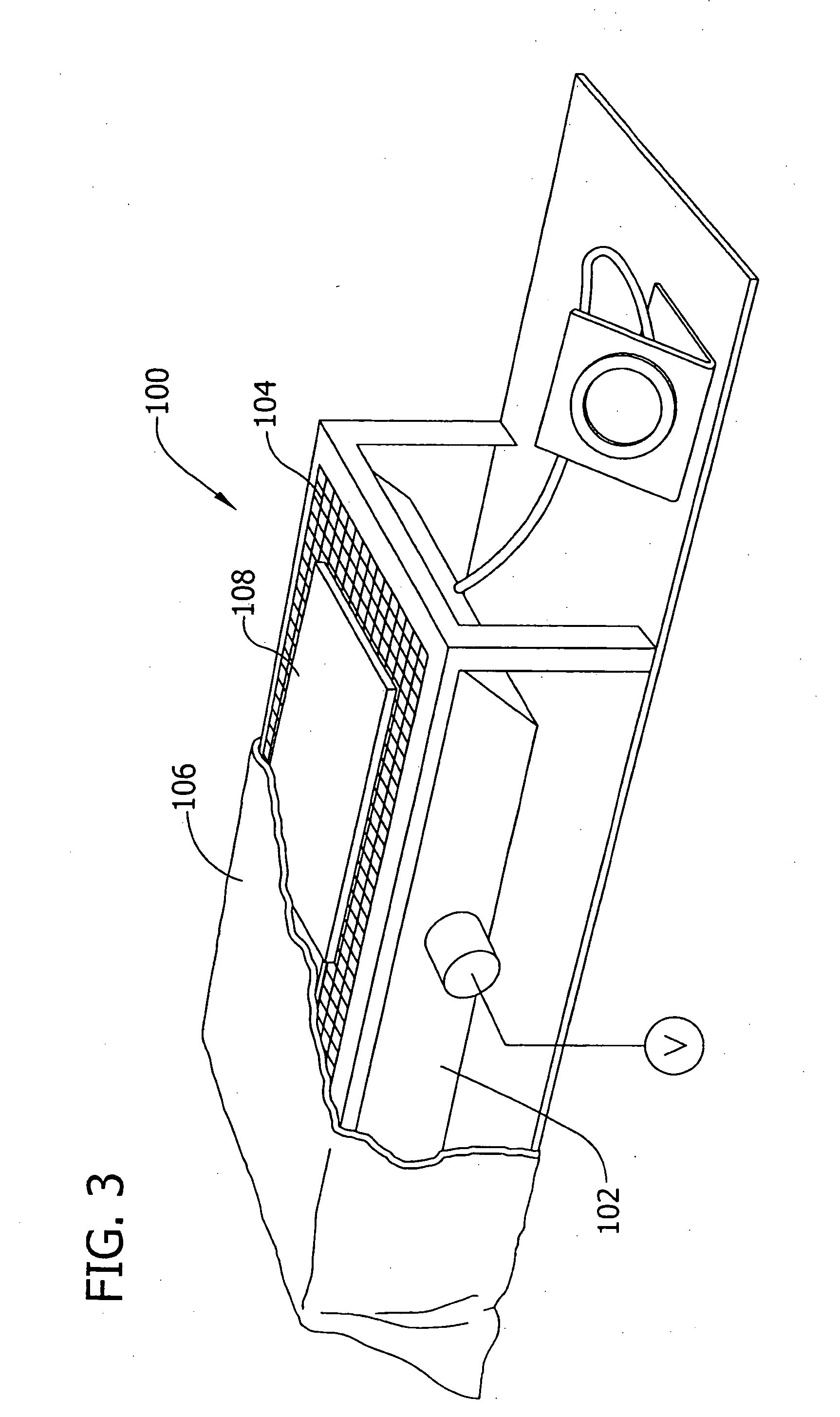

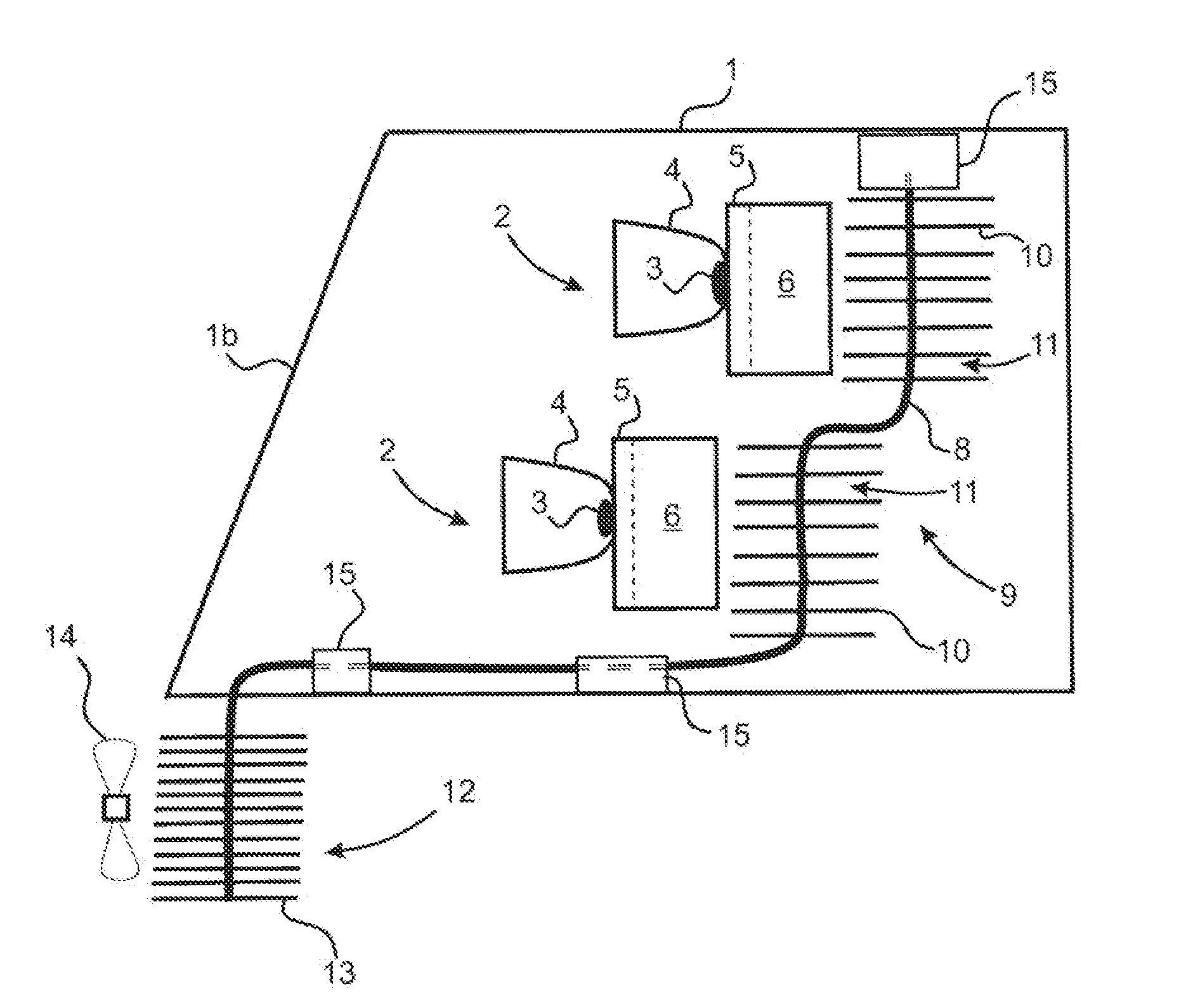

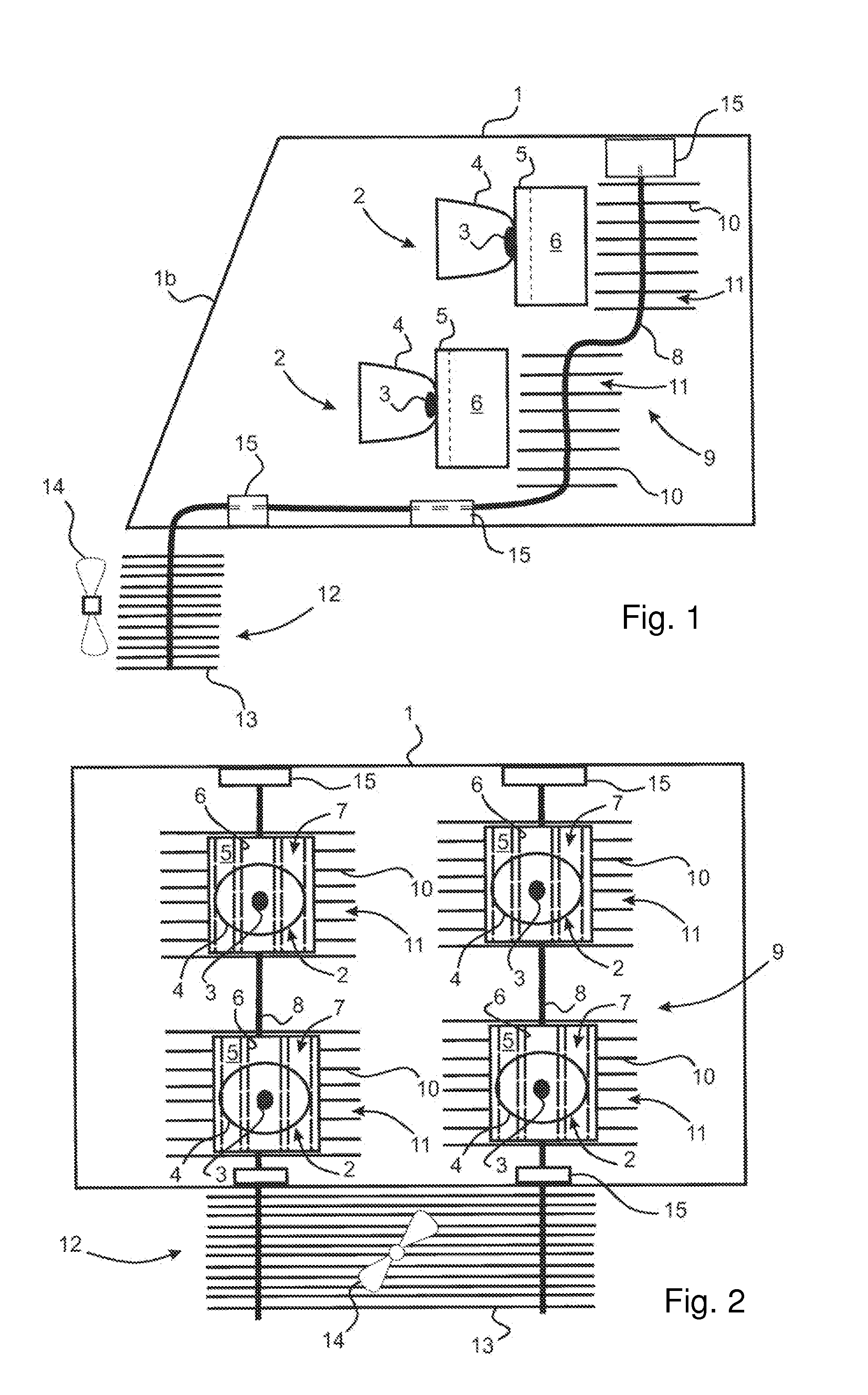

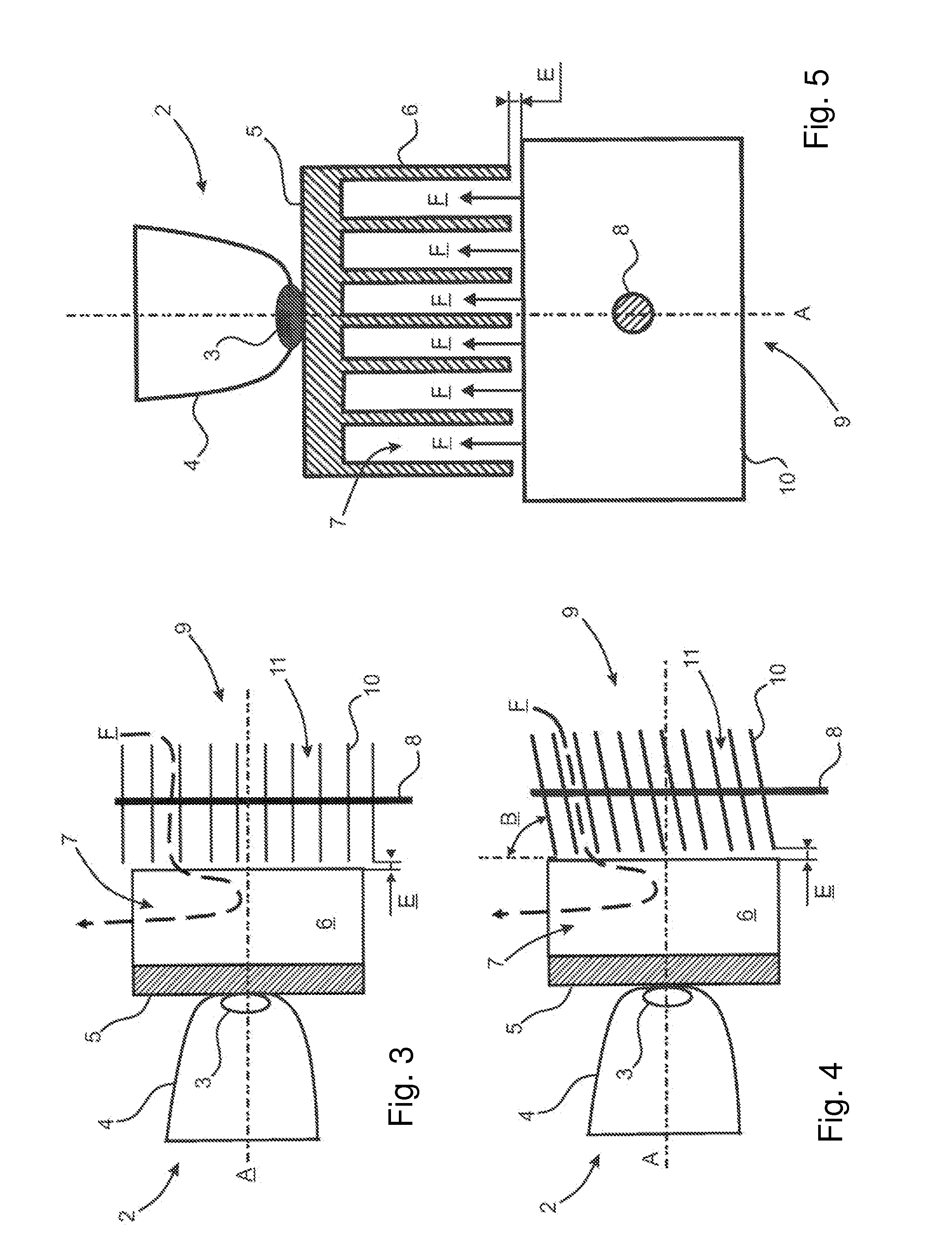

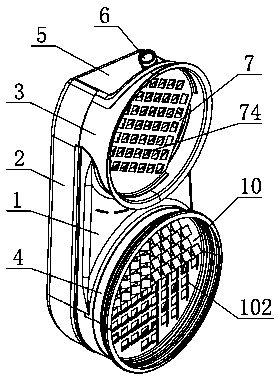

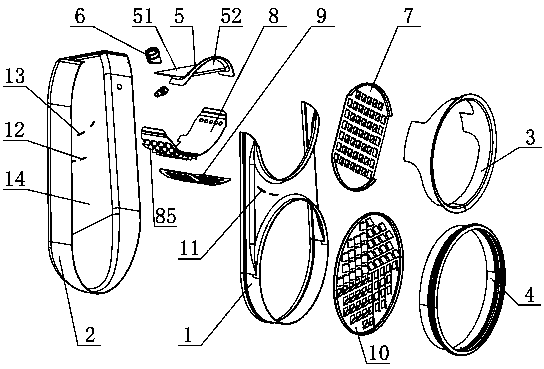

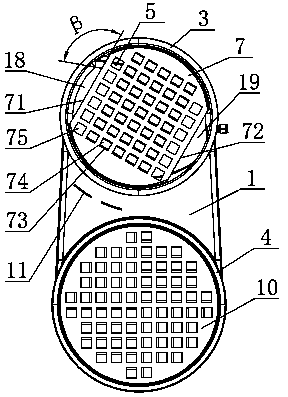

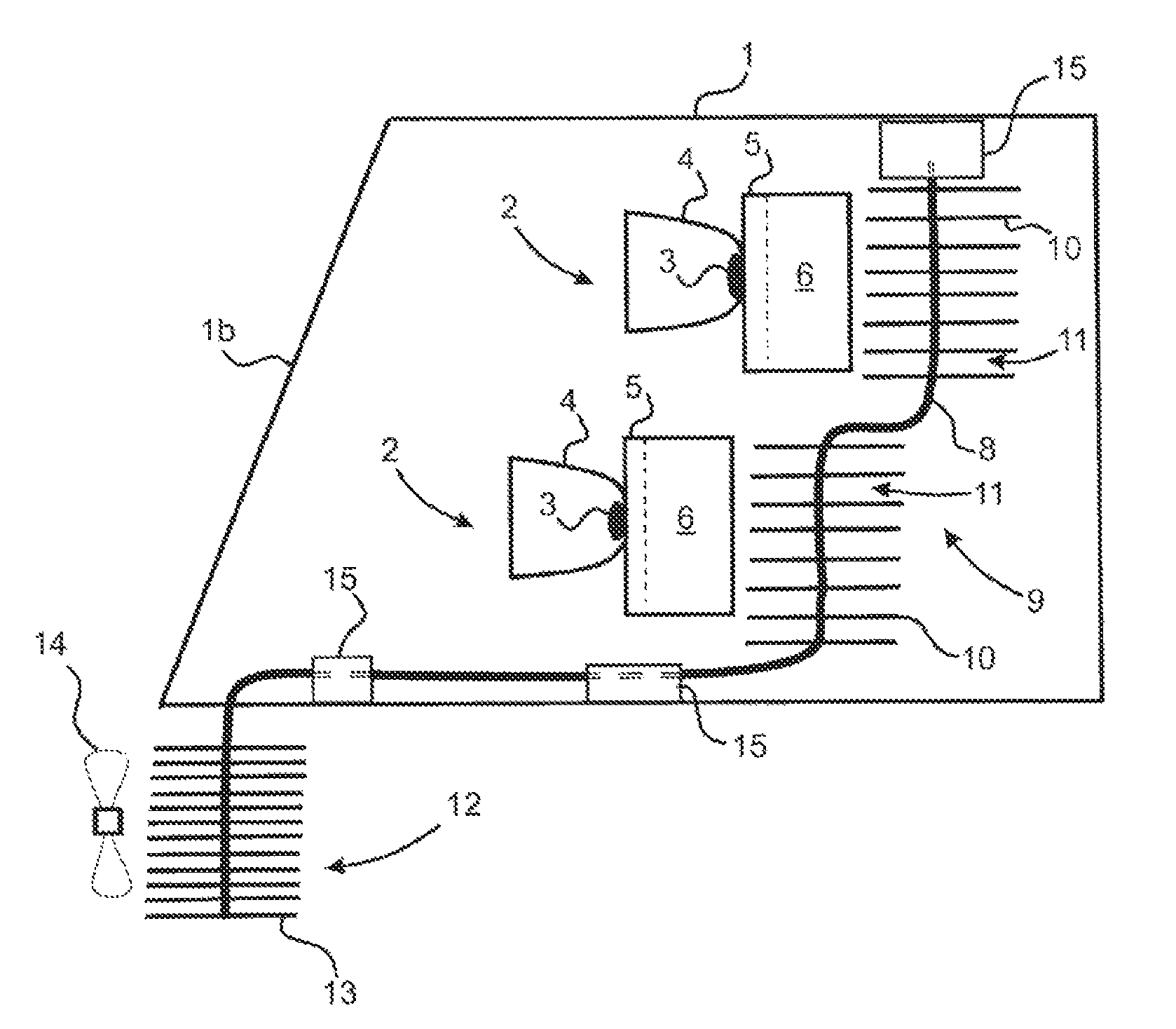

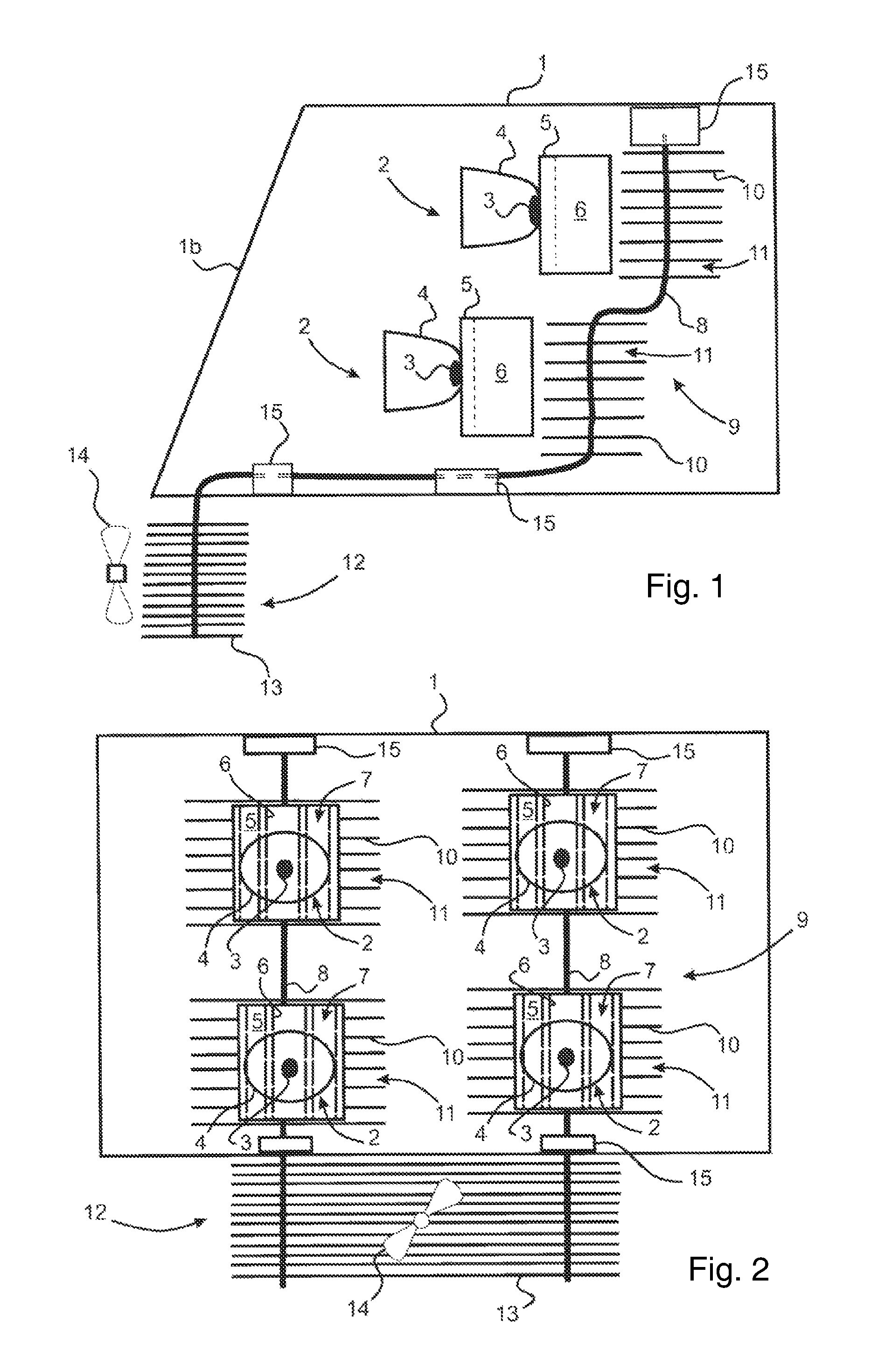

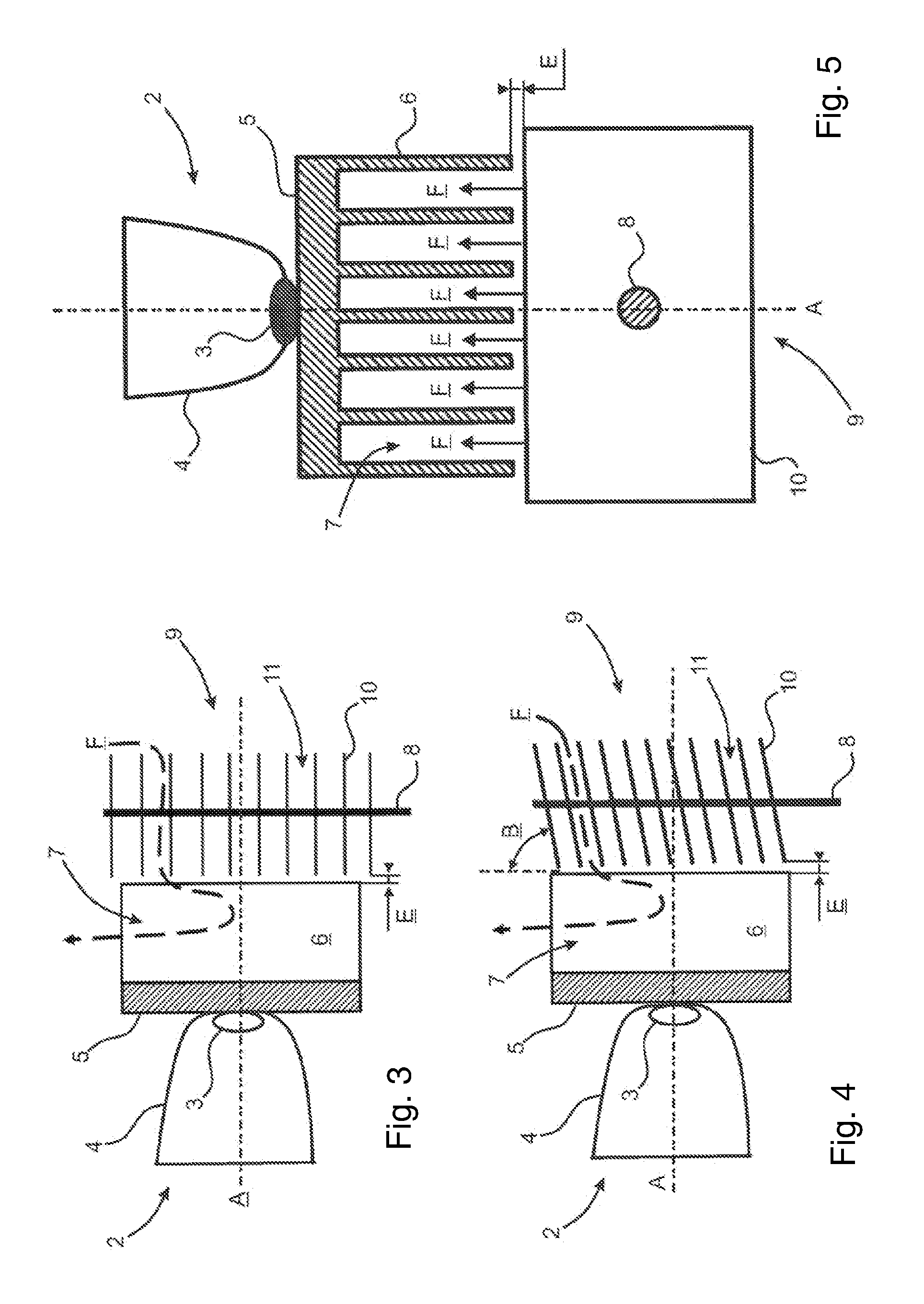

Device for cooling an optical module for a motor vehicle headlight

ActiveUS20100157606A1Improve the level ofImprove cooling effectVehicle headlampsPoint-like light sourceCold airMobile vehicle

A lighting and / or signaling device comprising at least one optical module equipped with a cooling unit, comprising at least one heat conductor, one end of which is placed spaced from the cooling unit, and is provided with a plurality of deflectors which channel a flow of cold air towards a heat-exchange surface of the cooling unit.

Owner:VALEO VISION SA

Outburst coal bed hydraulic phase change cracking cross-cut coal uncovering method

ActiveCN104213932AChange mechanical propertiesImprove breathabilityUnderground miningSurface miningLiquid stateFreezing thawing

The invention provides an outburst coal bed hydraulic phase change cracking cross-cut coal uncovering method, which is applicable to high-gas-outburst coal bed cross-cut coal uncovering operation. The minimum normal distance from the cross-cut coal uncovering working face to the coal bed is greater than or equal to 7m position, a plurality of holes are respectively drilled in the coal uncovering region, a conventional capsule hole sealing coal bed water injection technology is adopted for injecting water into the coal bed through the drilled holes, after the water injection completion, a conventional refrigeration freezing technology is adopted for freezing the coal bed around the water injection hole, in the freezing process, free water in the coal bed is gradually converted from the liquid state into the solid state, and the volume of the water expands for 9.1 percent in the phase change process; after the freezing completion, the freezing coal bed absorbs the underground environment head and gradually thaws. After the freezing thawing completion, the water injection hole and a gas extraction pipeline are connected for gas extraction, or the gas extraction drilling is implemented on the coal bed in the phase change cracking region for gas extraction. When the coal bed gas content is less than 8m<3> / t, the gas extraction is stopped, the water is injected into the water injection hole again, the secondary freezing of the coal bed is completed, and then, the coal bed is uncovered according to a conventional coal uncovering method.

Owner:CHINA UNIV OF MINING & TECH

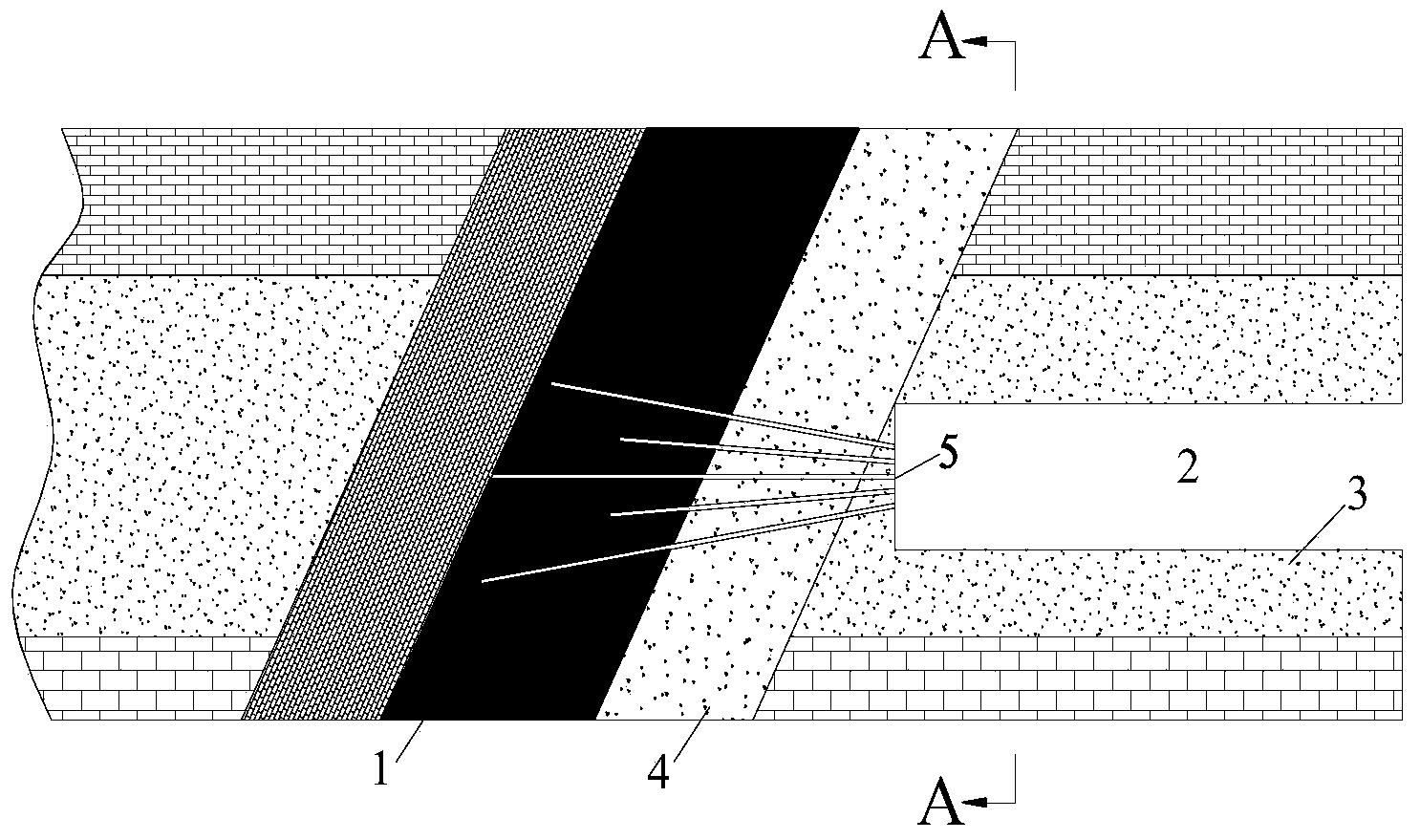

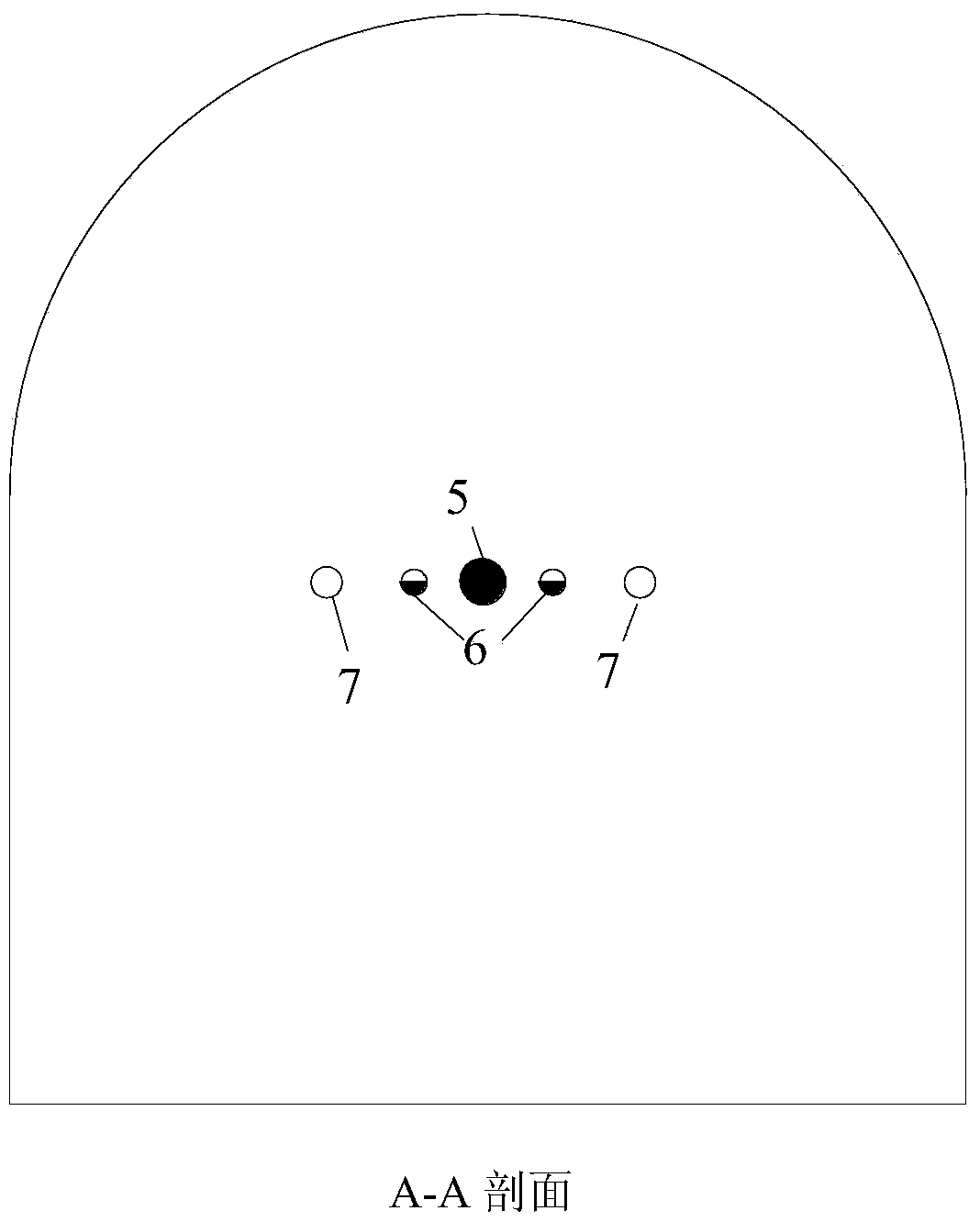

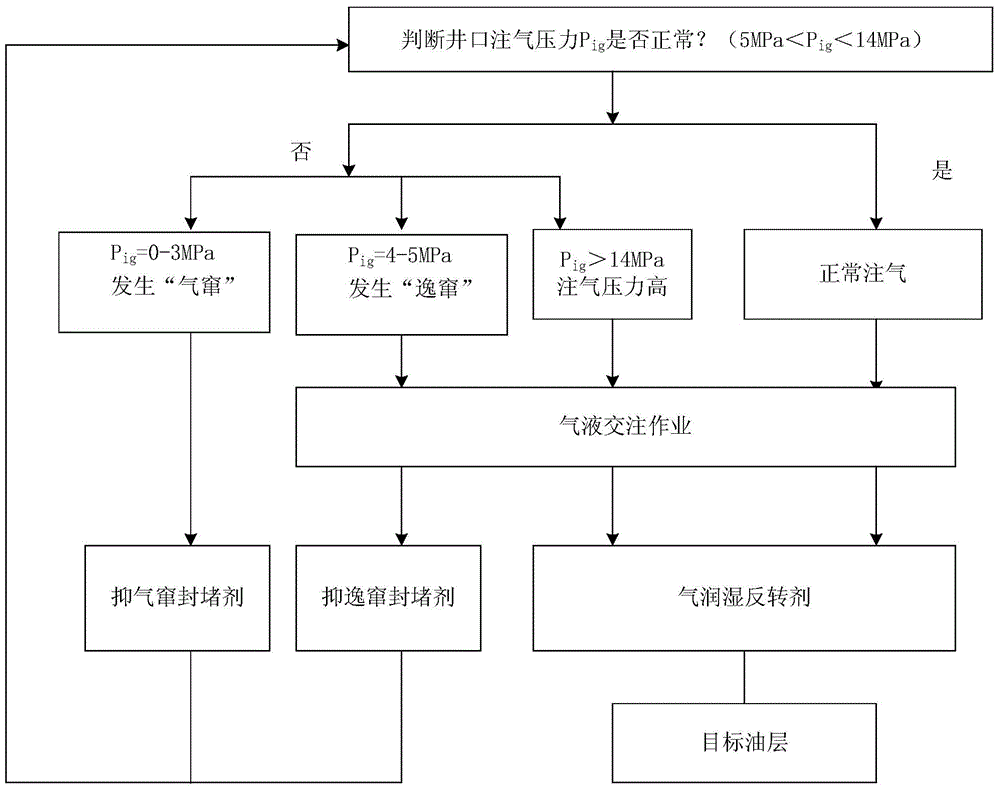

Blocking system and blocking method for channeling inhibition in carbon dioxide non-miscible flooding of low permeability reservoir

ActiveCN104087280AHigh mechanical strengthImprove plugging performanceFluid removalDrilling compositionWellheadChemistry

The invention discloses a blocking system and a blocking method for channeling inhibition in carbon dioxide non-miscible flooding of a low permeability reservoir. The system is mainly prepared from the following raw materials in percentage by weight: 1%-2% of fine mineral particles, 0.2%-0.3% of polymer, 0.01%-0.02% of compound crosslinking agent, 0.04%-0.1% of retarder, 0.01% of deoxidant, 0.1%-0.5% of surfactant and the balance of water. By virtue of monitoring the steam injection pressure of a wellhead in real time and adjusting the system, graded control of high-pressure steam injection, 'gas channeling' and 'escape channeling' processes in the carbon dioxide non-miscible flooding is realized and the development effect of the carbon dioxide non-miscible flooding of the low permeability reservoir is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Freezing-type stone door cross-measure coal uncovering method based on hydraulic seam cutting

ActiveCN104213921AImprove flow statusImprove breathabilityUnderground miningSurface miningUltimate tensile strengthCoal

A freezing-type rock cross-measure coal uncovering method based on hydraulic seam cutting is suitable for a rock cross-measure coal uncovering operation in a high-gas outburst coal seam. The method includes following steps: (1) constructing a plurality of water injection holes into a coal uncovering operation surface at a position of the coal uncovering operation surface, wherein a minimum normal distance from the coal seam to the position is not less than 7 m; (2) performing hydraulic seam cutting to the water injection holes through a conventional hydraulic seam cutting technology; (3) when the hydraulic seam cutting is finished, connecting the water injection holes to a gas extraction pipe network to perform gas extraction; (4) when the content of gas in the coal seam is less than 8 m<3> / t, stopping the gas extraction; (5) constructing a freezing holes and a temperature measuring hole respectively at the two sides of the water injection holes; (6) sealing the holes through a capsule hole-sealing device; (7) injecting water into the coal seam through the water injection holes and closing valves when the water injection process is finished to enable the water injected into the coal seam to gradually seep into micro cracks in coal; (8) freezing the coal seam around the water injection holes through a conventional freezing technology to enable free water in the micro cracks in the coal seams to gradually convert from liquid phase into solid phase during the freezing process, so that a strength and an anti-impact performance of the coal are increased and an effect of solidification of the coal seam is achieved; and (9) uncovering the coal seam through a conventional coal uncovering method.

Owner:CHINA UNIV OF MINING & TECH

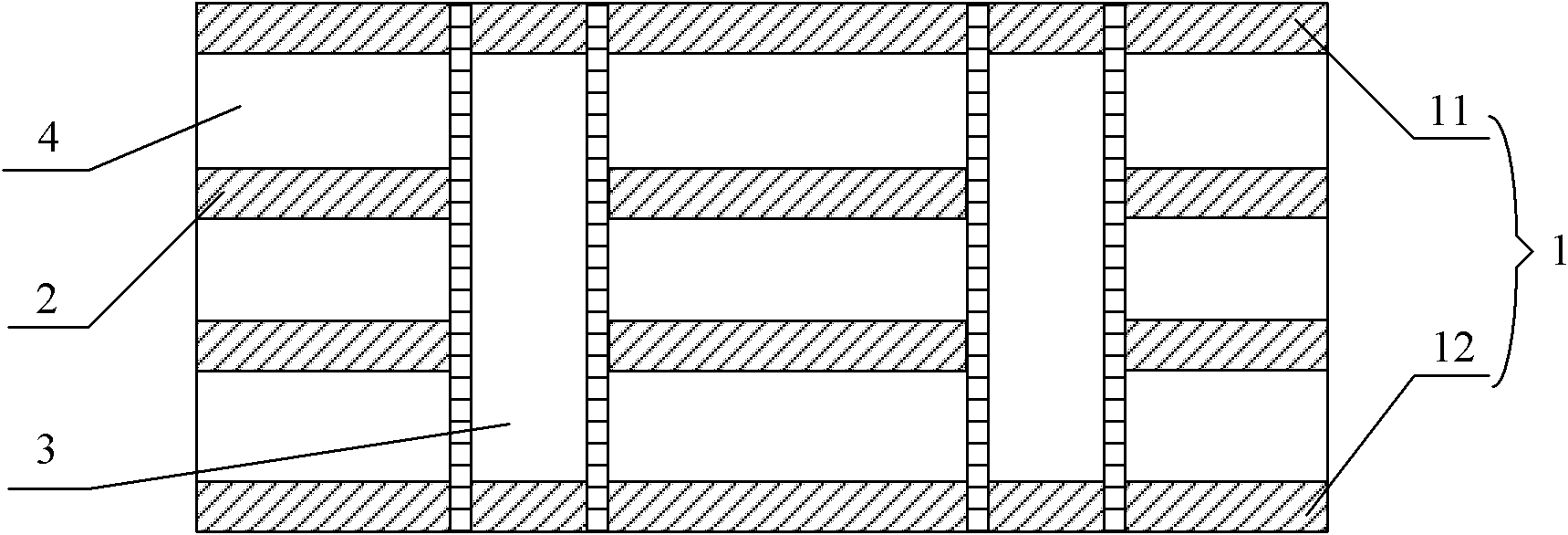

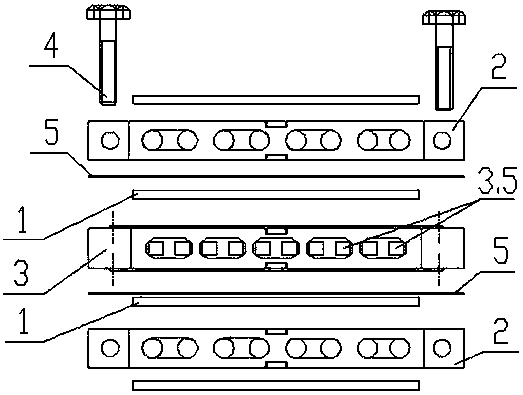

Golden finger and plate edge interconnection device

ActiveCN102548205AIncrease the flow channelImprove flow capacityPrinted circuit aspectsHigh current circuit adaptationsMetallic foilSurface layer

The embodiment of the invention provides a golden finger and a plate edge interconnection device. The golden finger comprises a PCB surface layer and at least one PCB inner layer, wherein the metallic foils of the PCB inner layer are communicated with the metallic foil on the PCB surface layer through a through flow structure; and the through flow channel of the golden finger comprises the PCB surface layer and the PCB inner layers. The plate edge interconnection device comprises the golden finger. According to the embodiment of the invention, under the premise that the size and thickness of the copper foil in the PCB in the golden finger are not increased, and the through flow channel of the PCB in the golden finger is increased, with greatly improved through flow ability.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

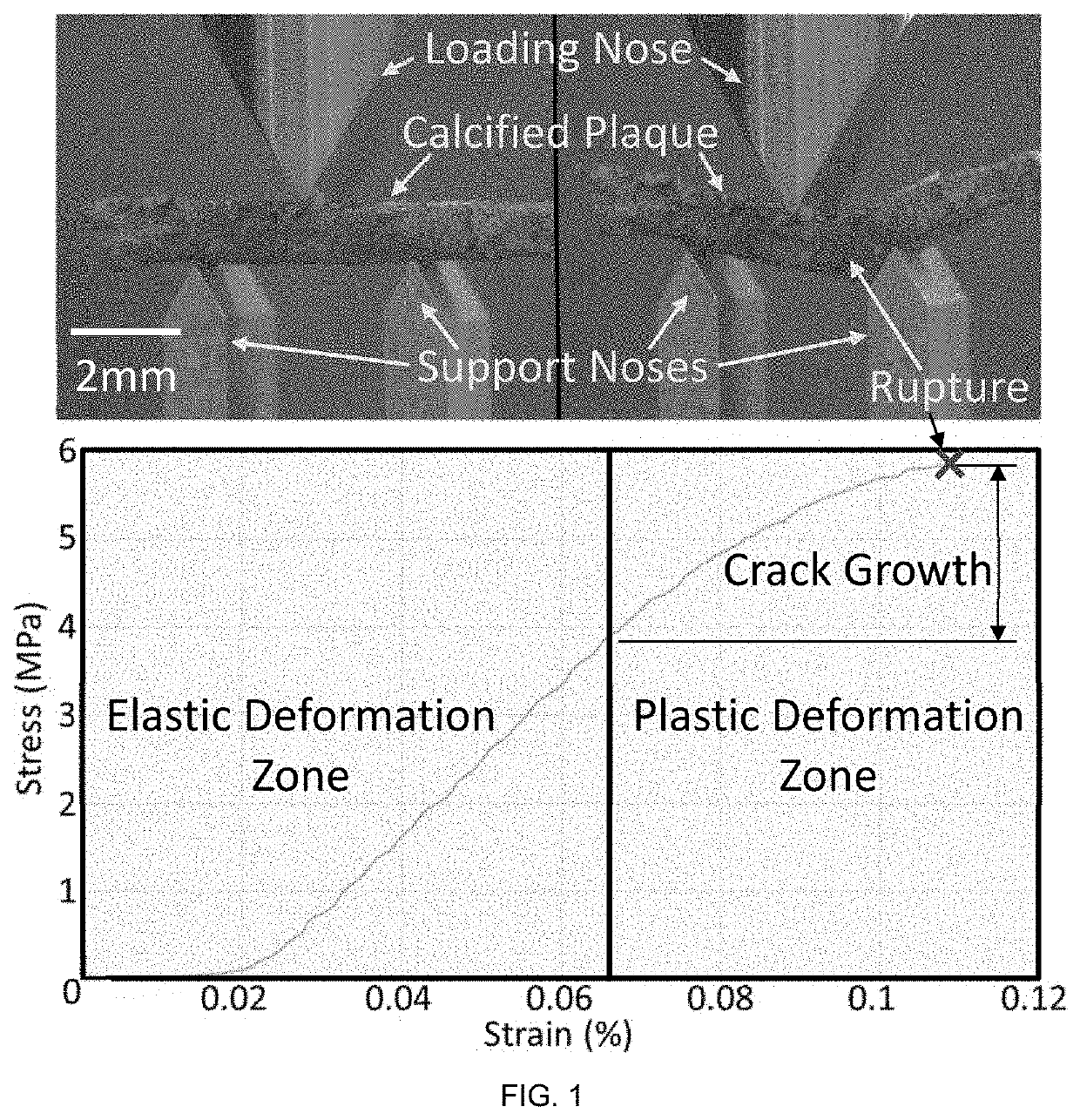

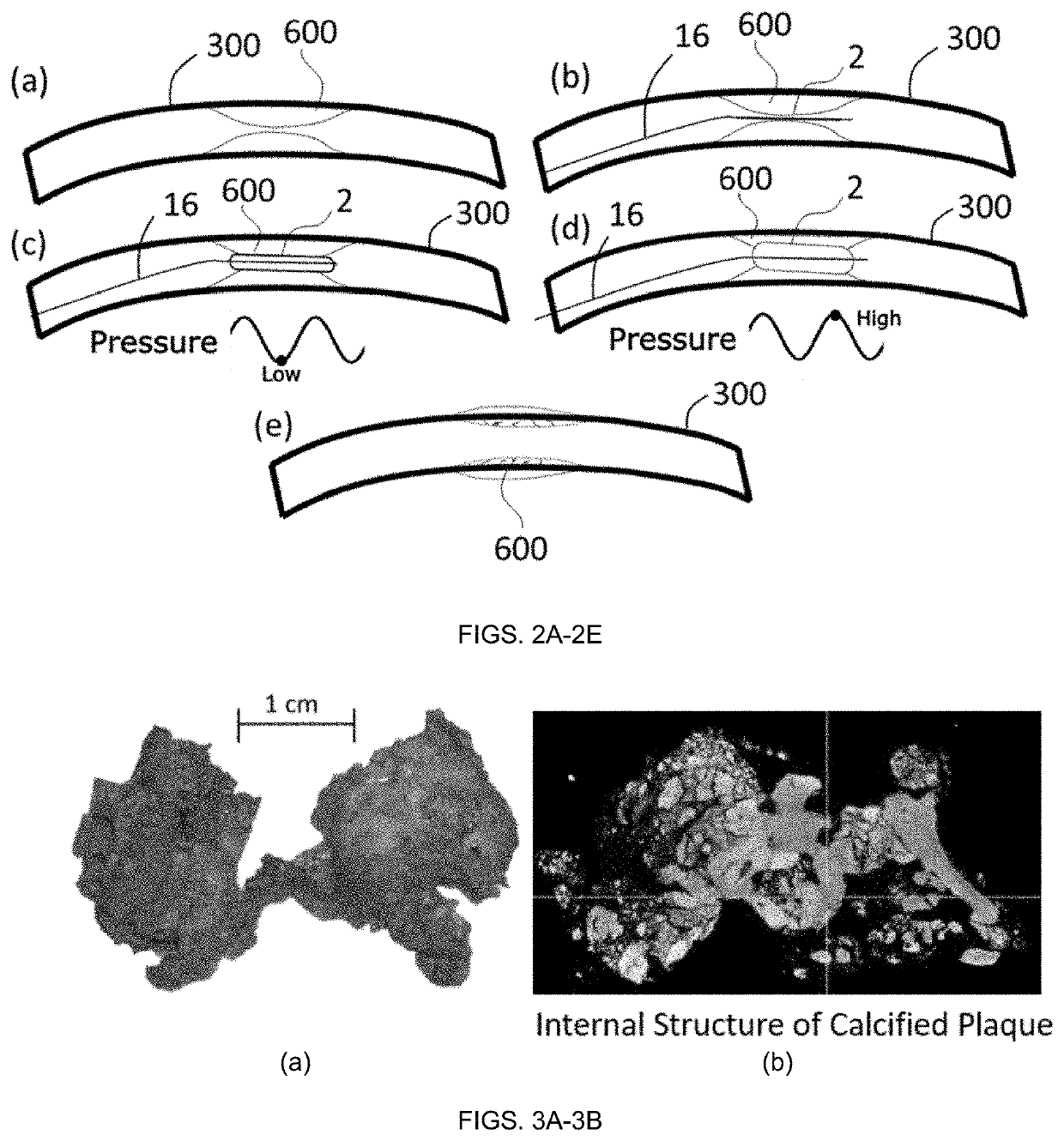

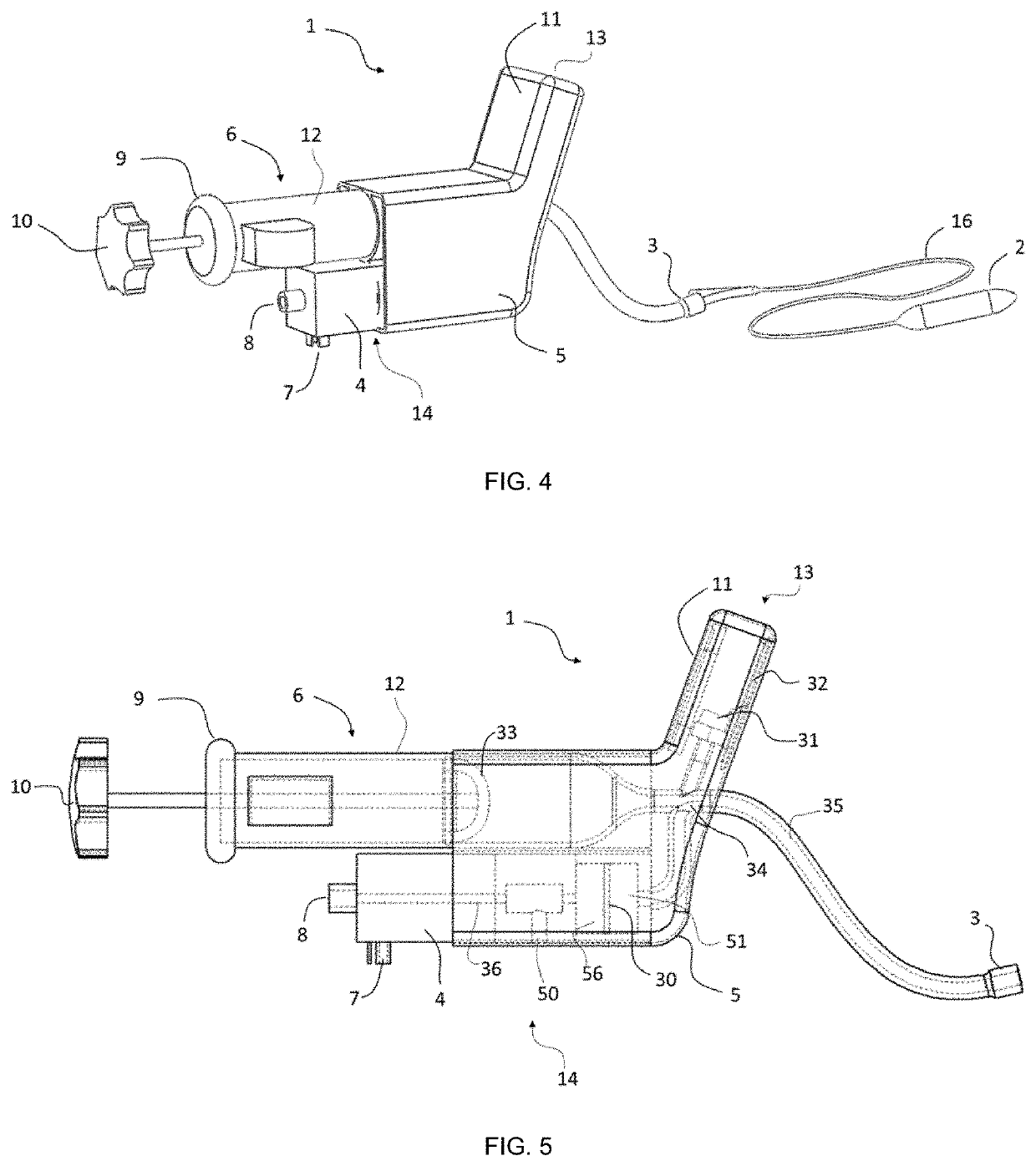

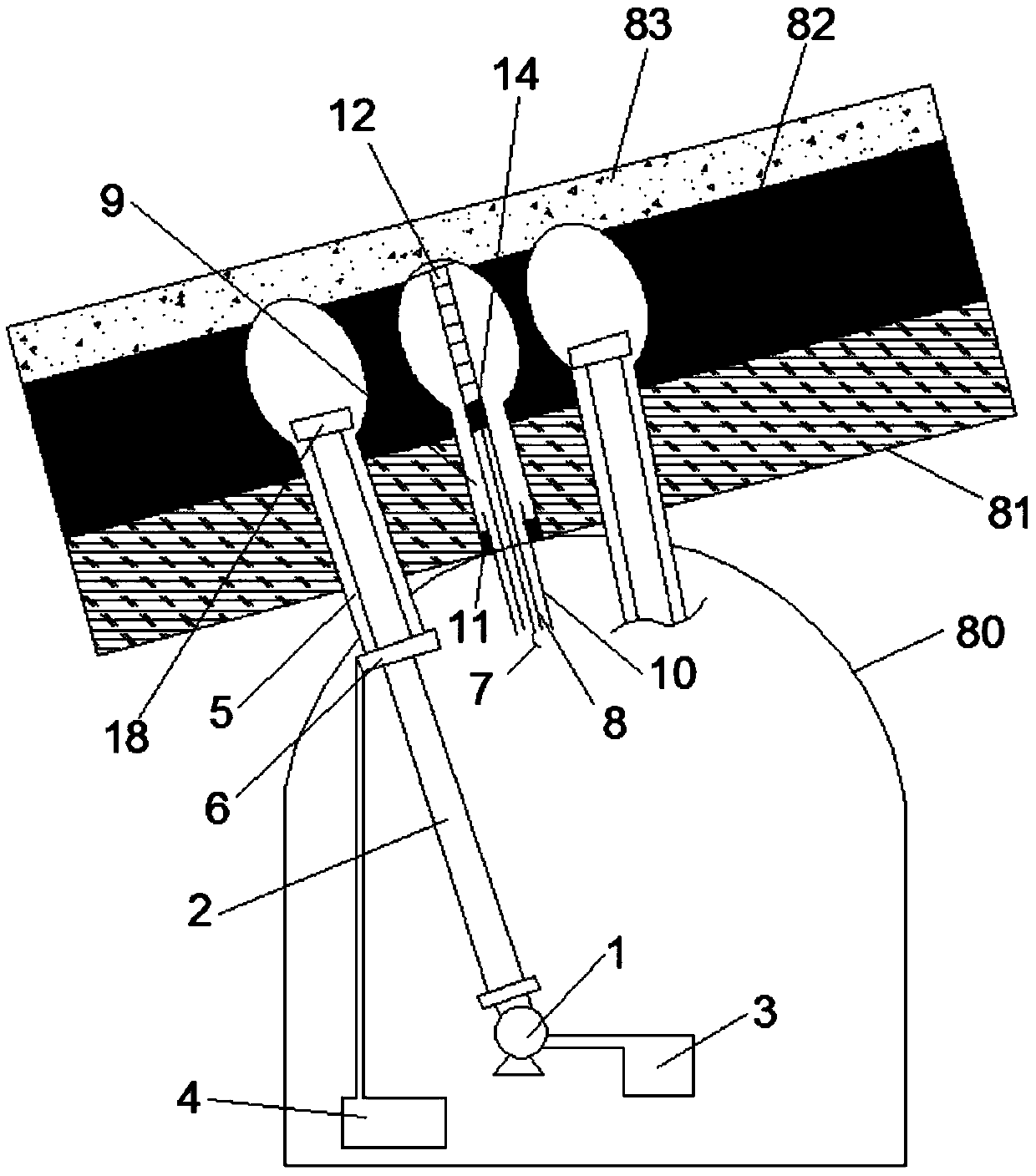

System for effecting and controlling oscillatory pressure within balloon catheters for fatigue fracture of calculi

ActiveUS20200046949A1Improve efficiencyLow pressureBalloon catheterSurgeryAngioplasty balloonControl signal

A dynamic balloon angioplasty system for applying a dynamic pressure to fracture hardened materials embedded within an elastic conduit. The system having a pressure source system outputting at least a first predetermined pressure from a pressure source outlet, and an angioplasty unit fluidly coupled to the pressure source outlet receiving at least the first predetermined pressure. The angioplasty unit having an angioplasty inflation device, an angioplasty balloon connector, and an oscillating mechanism selectively actuated to output a plurality of pressure pulses to the angioplasty balloon via a fluid communication path. A control system is configured to determine an optimal hydraulic pressure oscillation frequency and amplitude for a given procedure and output a control signal to the oscillating mechanism, and monitor a pressure signal to detect fracture of the hardened material within the elastic conduit or system failure or leakage.

Owner:RGT UNIV OF MICHIGAN

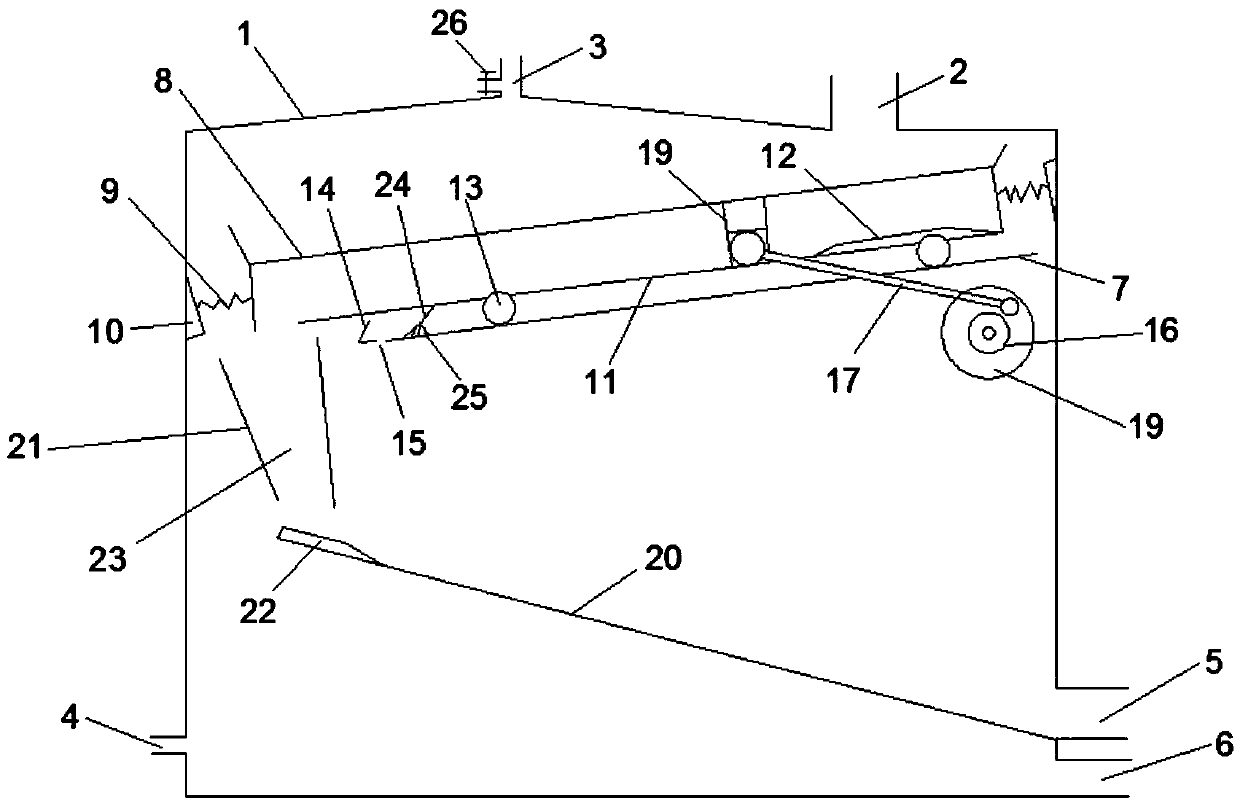

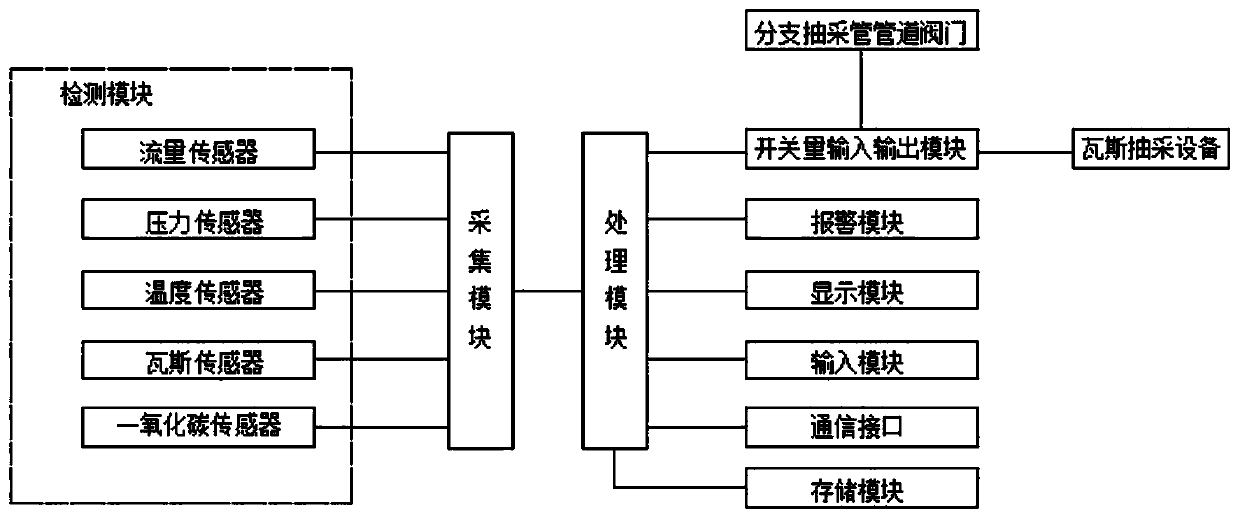

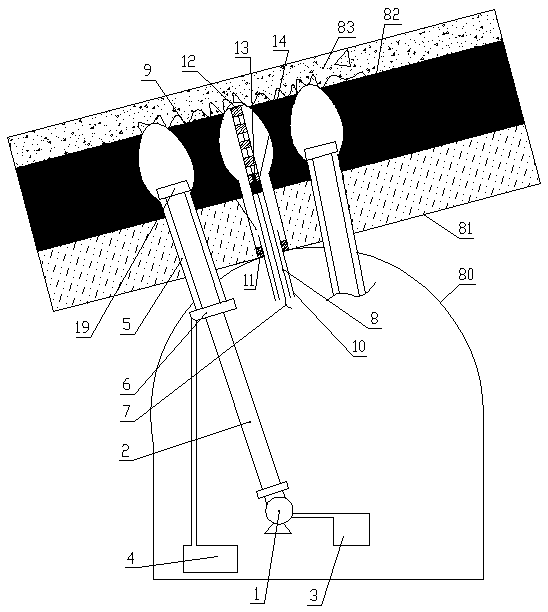

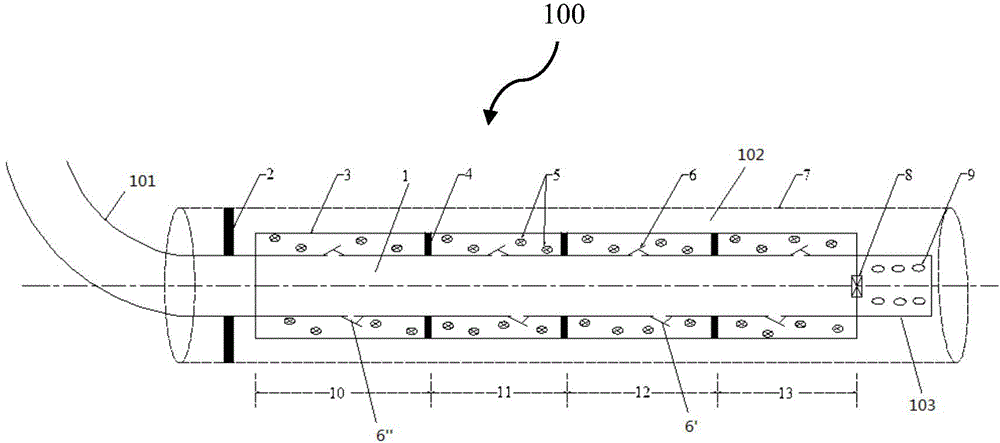

Permeability-improving extraction system of coal seam in borehole

InactiveCN109578054AIncrease the flow channelImprove breathabilityMining devicesLiquid/gas jet drillingDetonatorHigh pressure water

The invention discloses a permeability-improving extraction system of a coal seam in a borehole. The system comprises a hydraulic flushing device, a pre-split blasting device, a gas extraction deviceand a safety monitoring system which are all arranged in a coal mine underground extraction roadway, a coal seam bottom plate, a coal reservoir and a coal seam top plate are arranged at the top of theextraction roadway sequentially from bottom to top, the hydraulic flushing device comprises a boring machine, a drill stem, a drill bit, a high-pressure water injection pump and a water gas separator, the pre-split blasting device comprises a detonator, a lead and a PVC tube, the gas extraction device comprises a branched extraction pipe, a main extraction pipe and gas extraction equipment, and the safety monitoring system comprises a detection module, a processing module, a collection module, an on-off input-output module and a pipeline valve arranged on the branched extraction pipe. By thesystem, safety of gas extraction control is improved, gas accidents can be prevented effectively, coal seam permeability is improved effectively, gas extraction effect is improved, extraction time isreduced effectively, and gas potential safety hazards are lowered to greatest extent.

Owner:SICHUAN UNIV +1

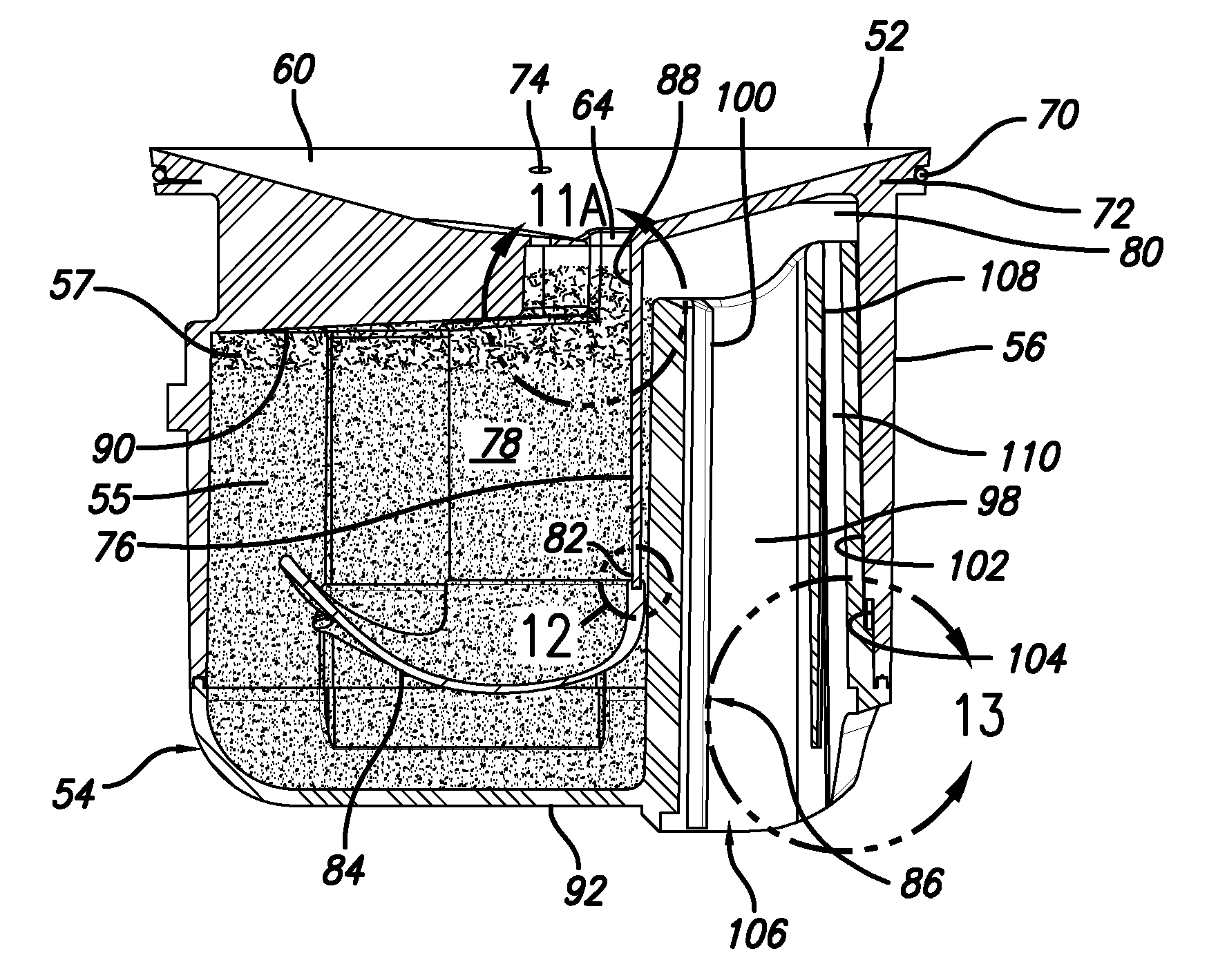

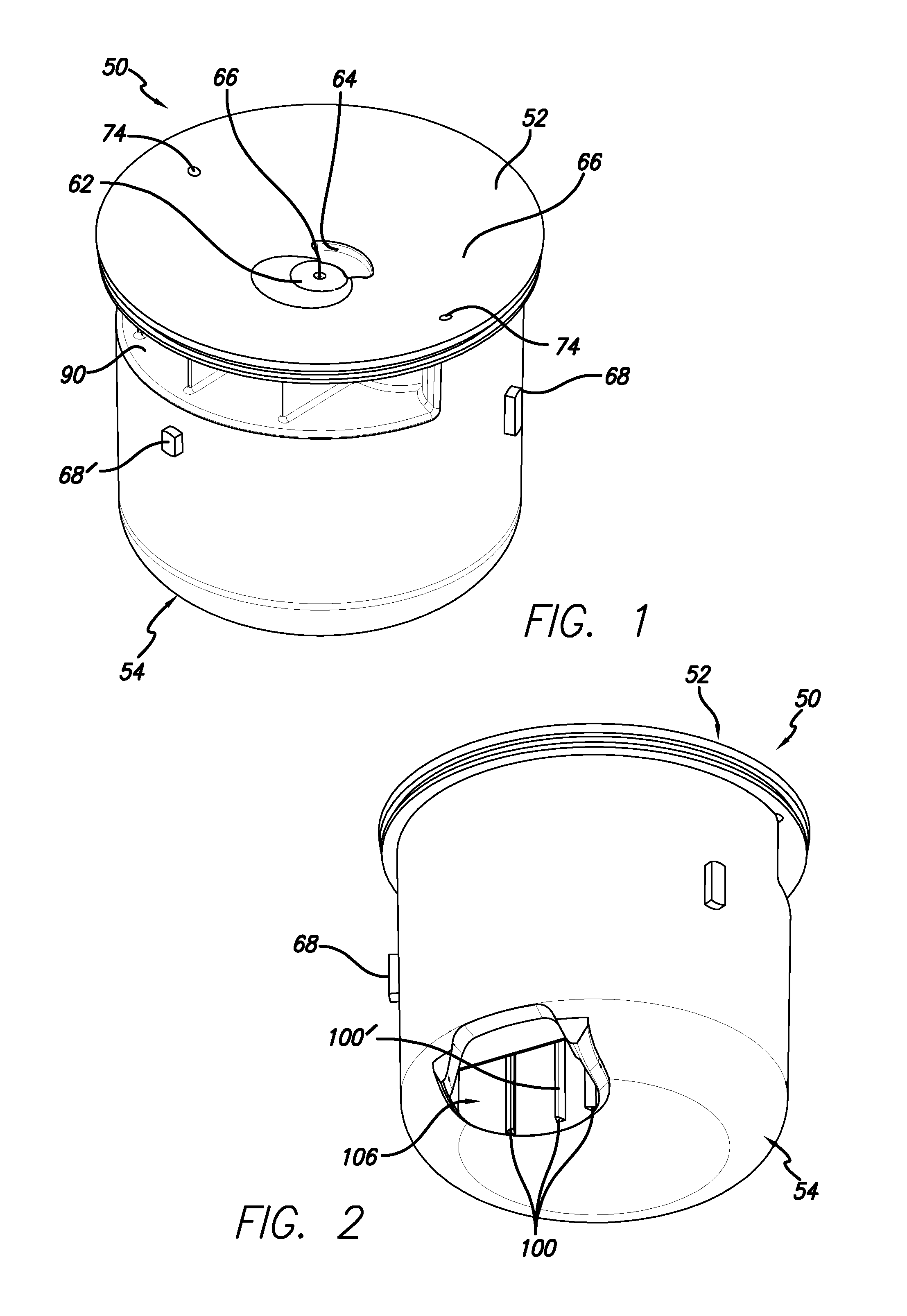

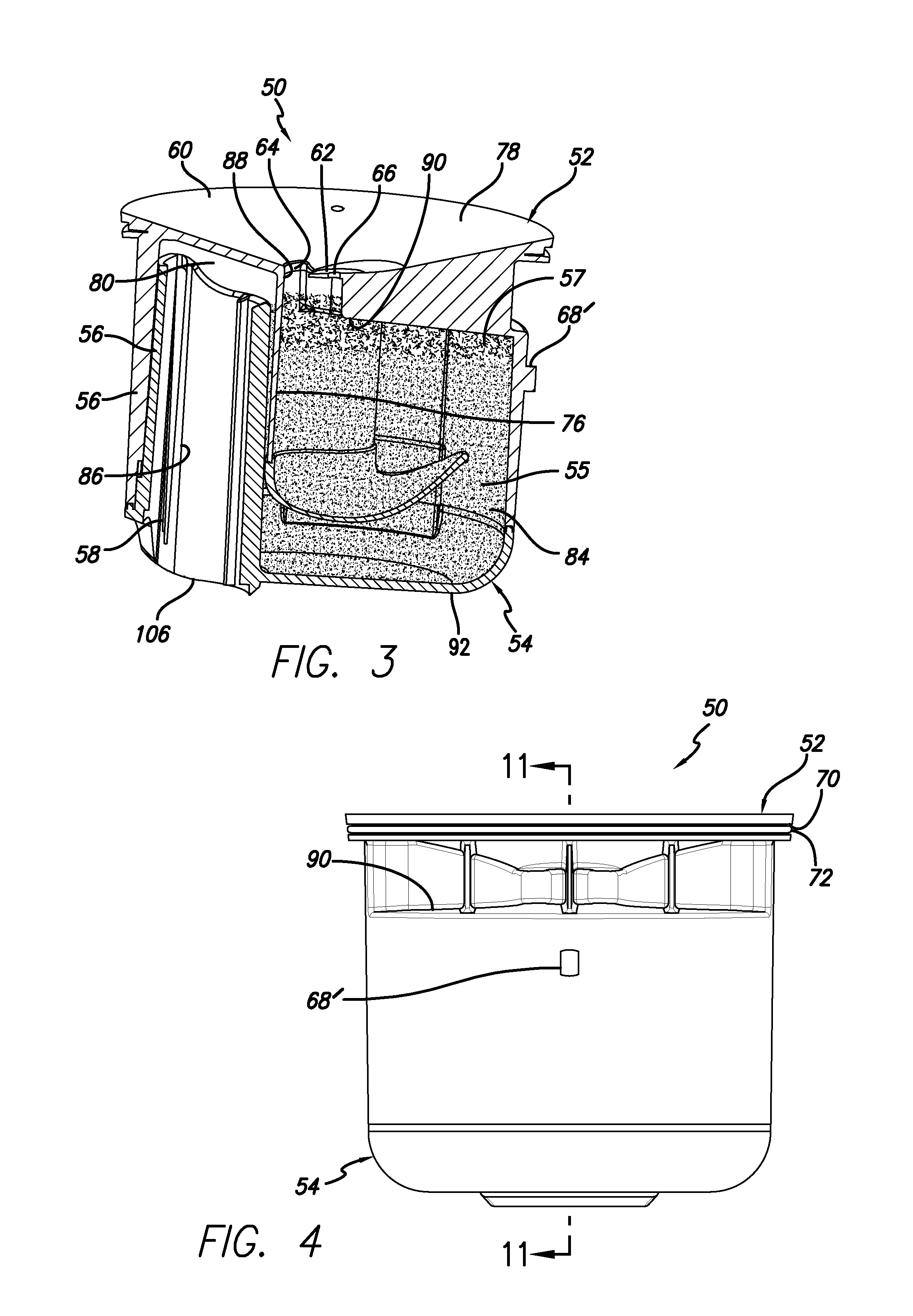

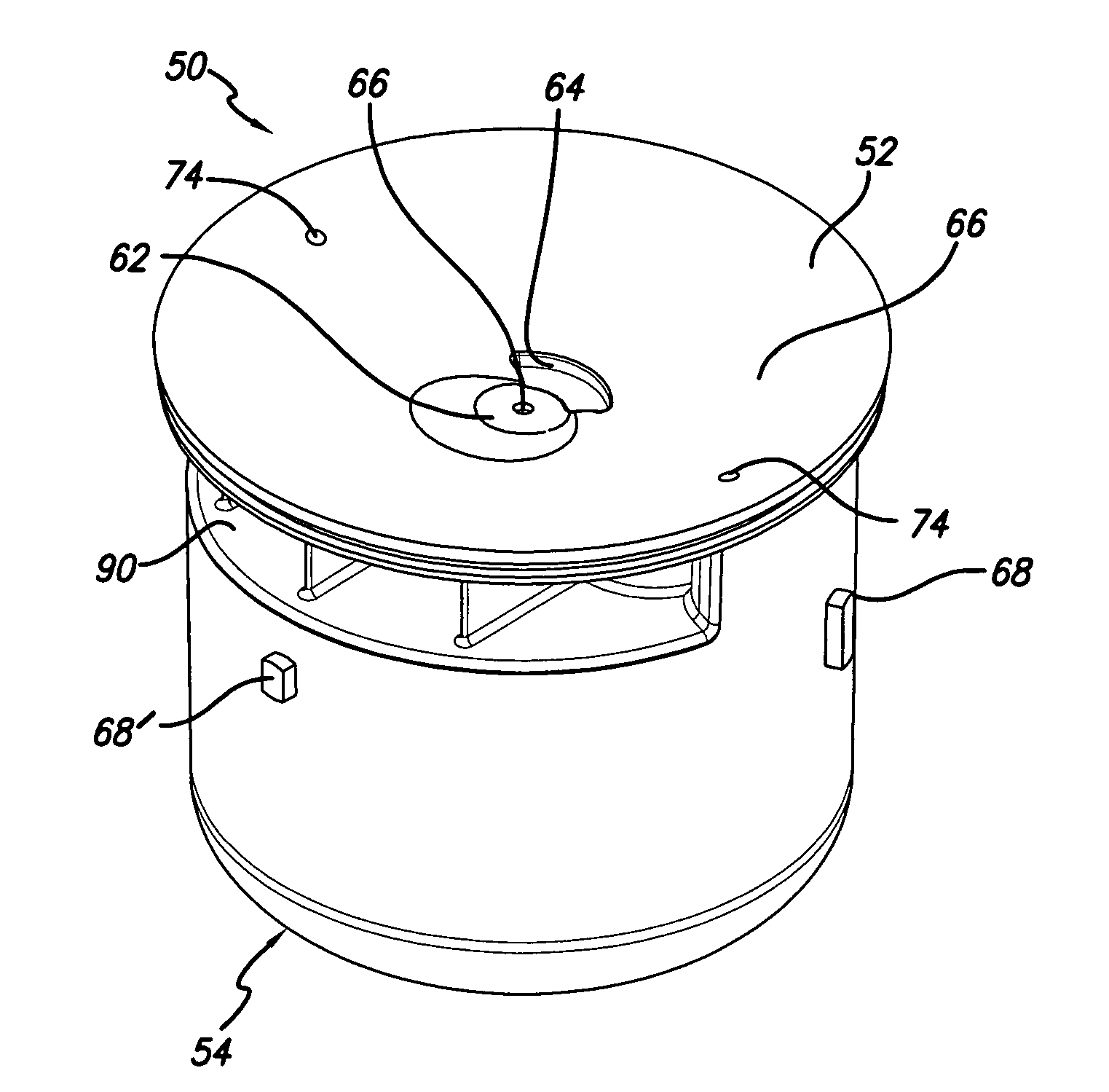

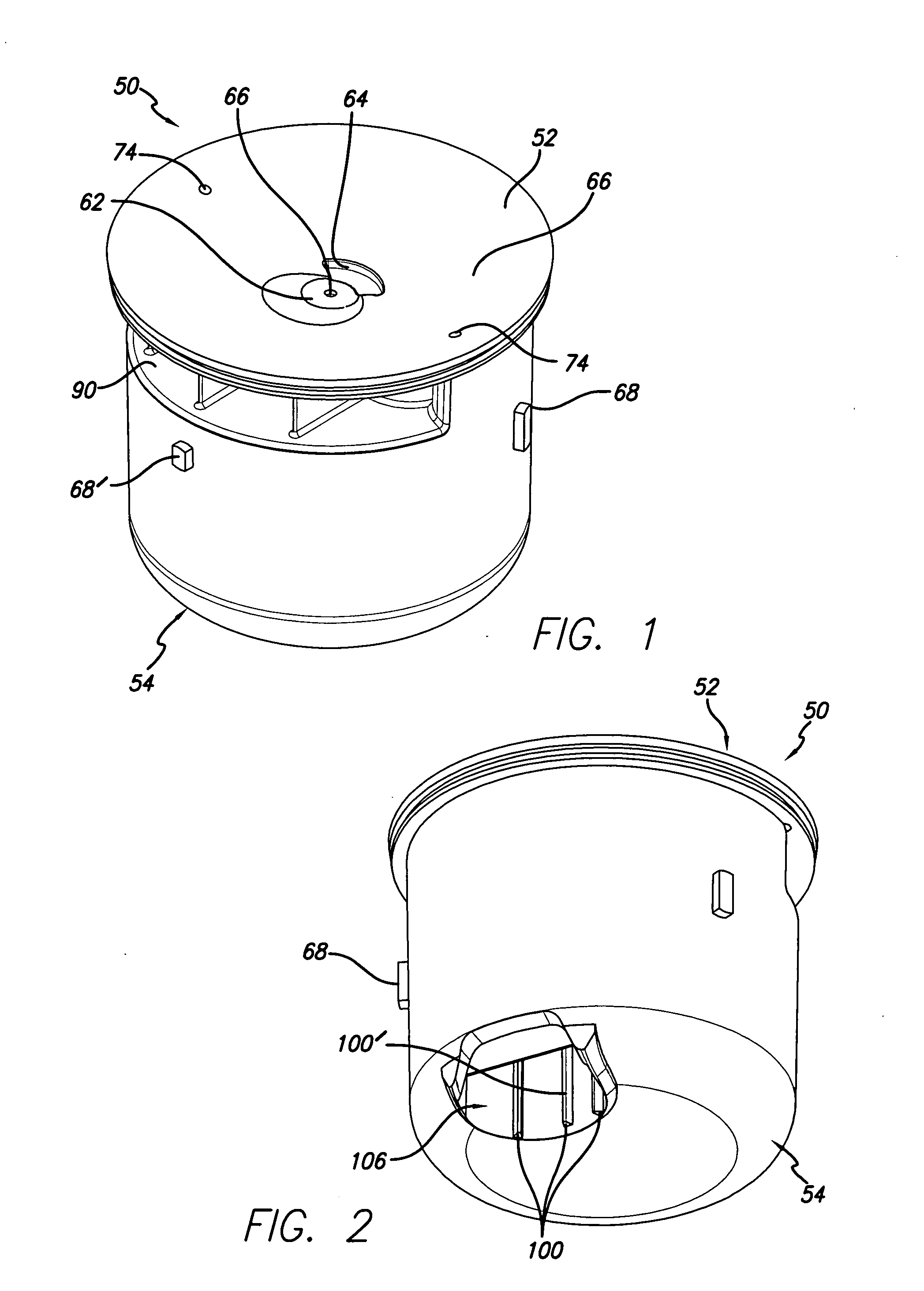

Anti-siphon trap with snorkel

To reduce the barrier sealant amount, the area of a throat (88), communicating an inlet compartment (78) to an outlet opening (64), is made small. Should sealant not be in the throat, wastewater in the throat would be correspondingly small. A snorkel (110) in a discharge section drain tube (98) extends downwards to above the level of the horizontal drain, and allows any air from the external drain to pass to the outlet compartment generally below the ceiling (90) so that, should wastewater cover the opening of the drain tube, such air is permitted to enter into the cartridge and to prevent any syphoning. A three rib channel guide mechanism (100) within the tube guides wastewater flow towards the drain tube center, and away from the drain tube walls to avoid deposit of any sediment contained in the wastewater.

Owner:FALCON WATERLESS TECH INC

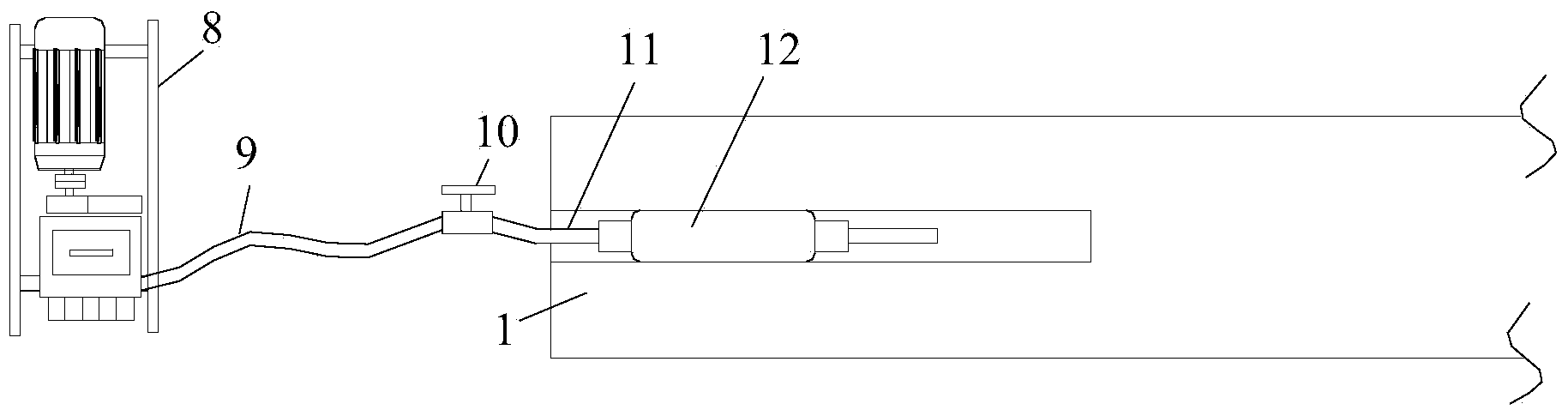

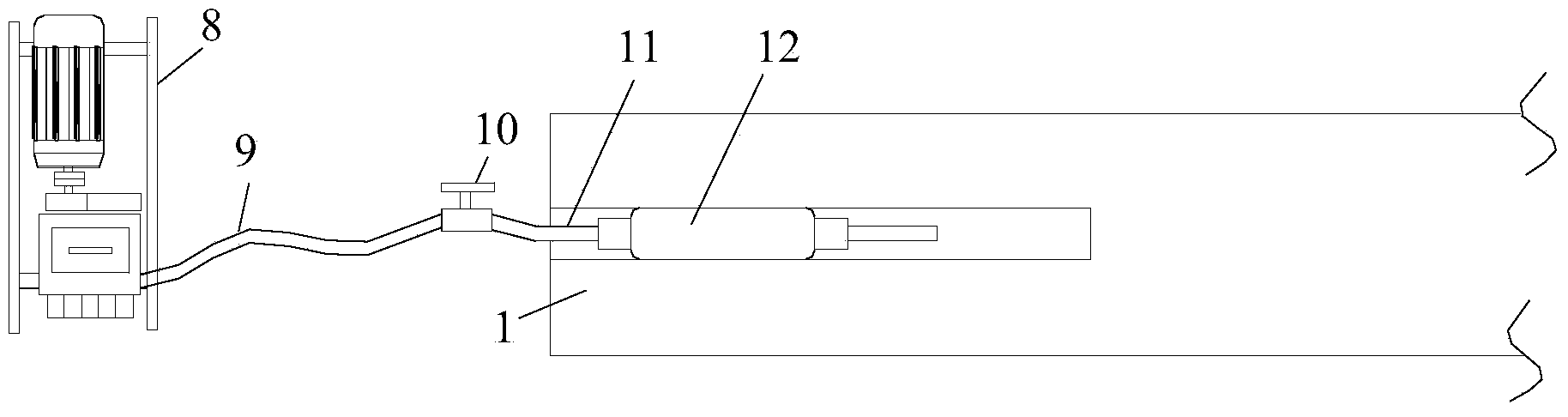

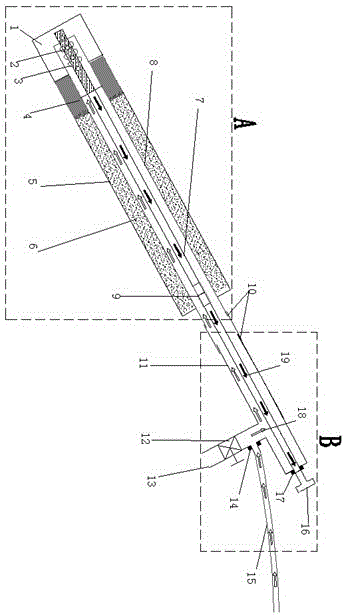

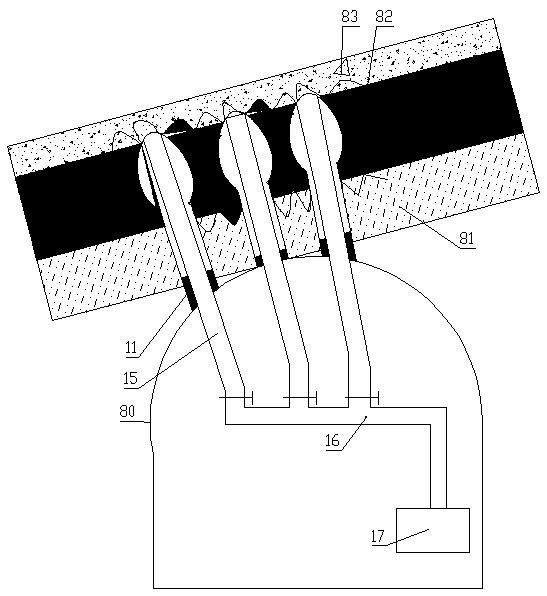

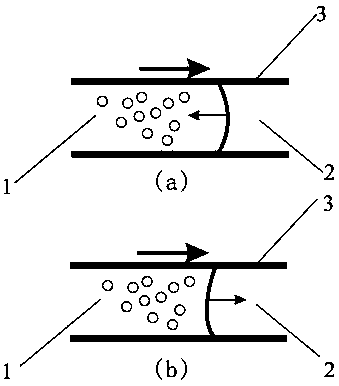

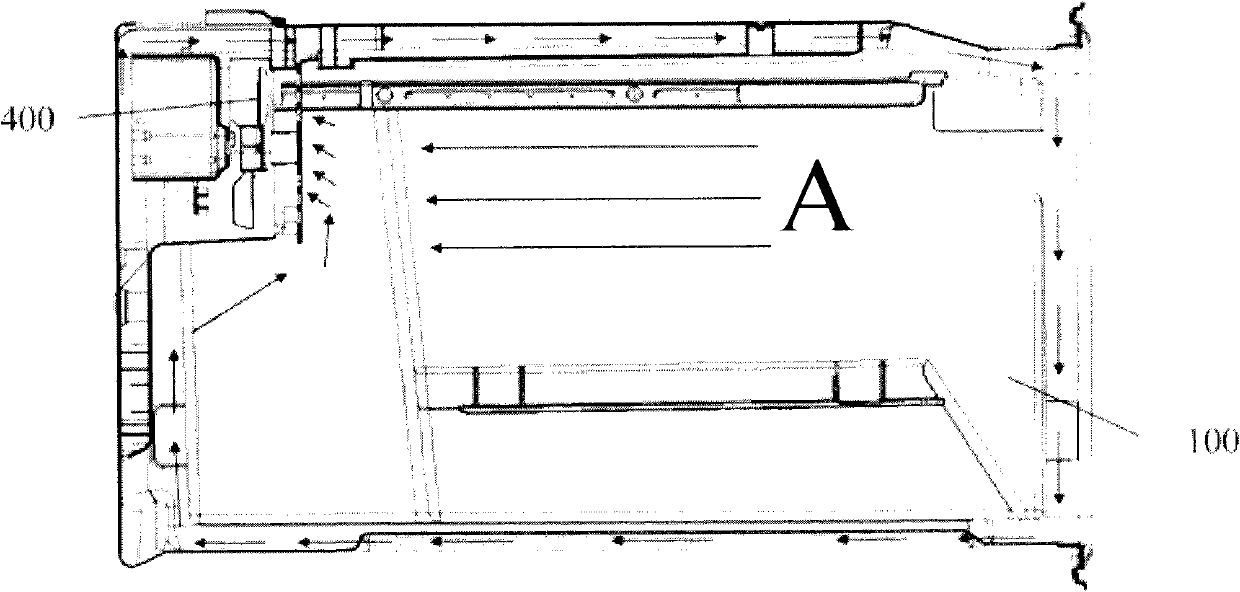

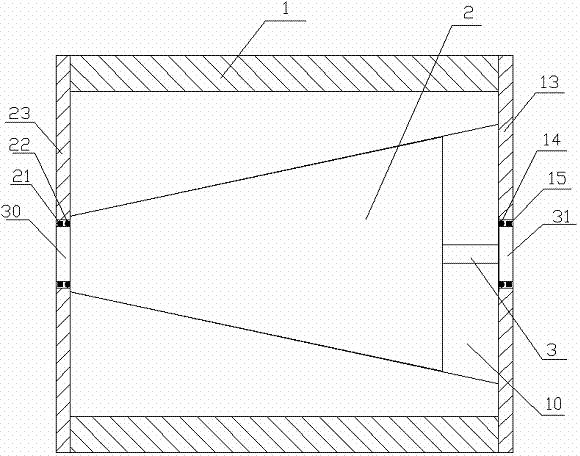

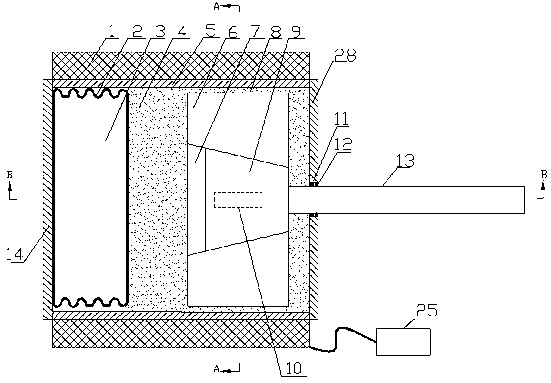

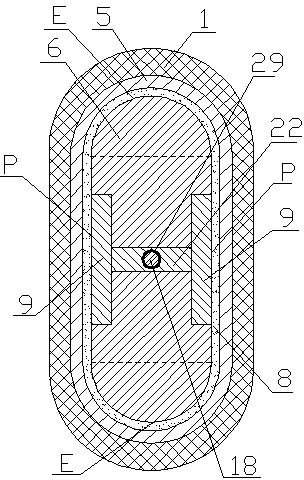

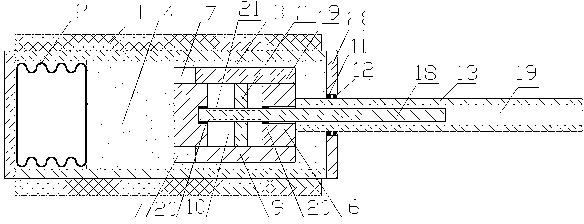

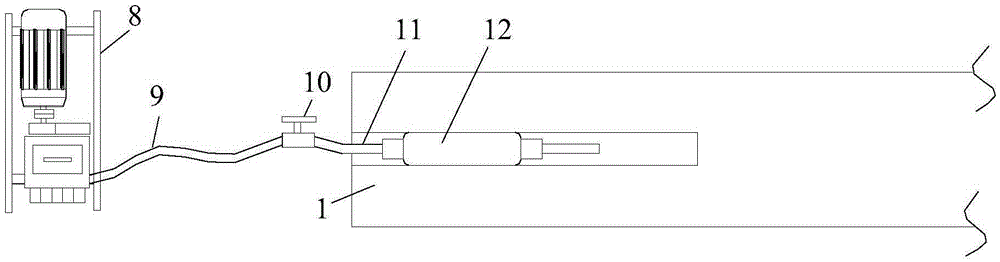

Improved gas extraction structure adopting downward hole drainage and implementation method thereof

InactiveCN105114119AIncrease the flow channelLow flow resistanceDrainageGas removalYarnPoint of entry

The invention discloses an improved gas extraction structure adopting downward hole drainage and an implementation method thereof. The improved gas extraction structure comprises a hole-inside structure (A); the hole-inside structure (A) is communicated with a hole-outside drainage device (B) through hole-inside and hole-outside connecting parts (10); the improved gas extraction structure is characterized in that the hole-inside structure (A) comprises a gas collection chamber (1) and an extraction pipe (8) which are communicated with each other; the gas collection chamber (1) is positioned at the front end of the hole-inside structure (A); the extraction pipe (8) sequentially passes through a Marithan cotton yarn blocking section (4) and a grouting blocking section (6) from one end of the gas collection chamber (1) to be fixed; a drainage pipe (7) is arranged in the extraction pipe (8); the hole-outside drainage device (B) comprises an extraction pipe connection pipe (11) communicated with the extraction pipe (8); the hole-outside length of the drainage pipe (7) is the same as the length of the extraction pipe connection pipe (11); a drainage outlet screw (16) and a drainage outlet nut (17) are arranged at the outer end opening of the drainage pipe (7); and a side surface opening of the extraction pipe connection pipe (11) is communicated with a gas extraction outlet (13) and a compressed air inlet as well as a side flowing hole (14).

Owner:GUIZHOU UNIV

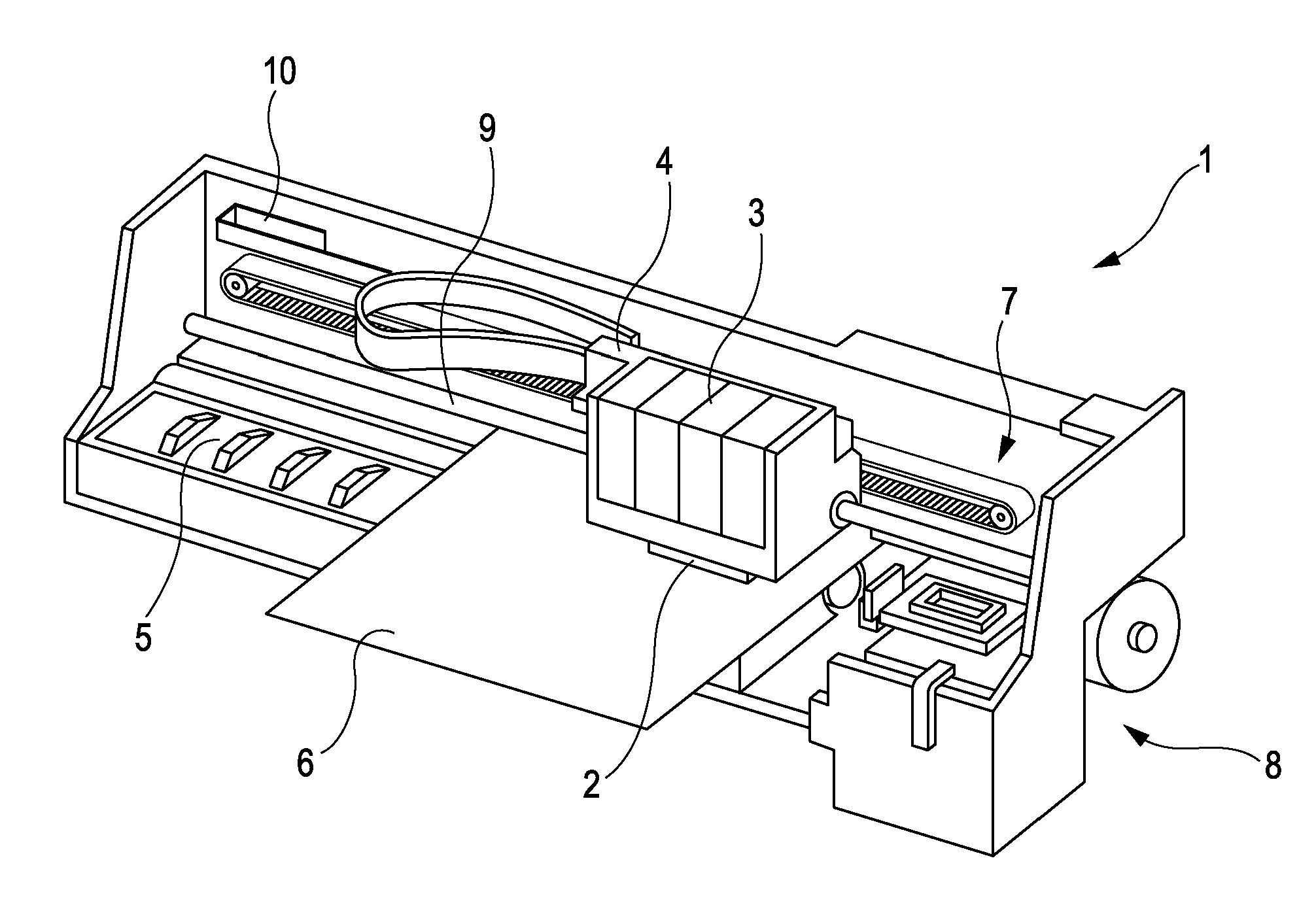

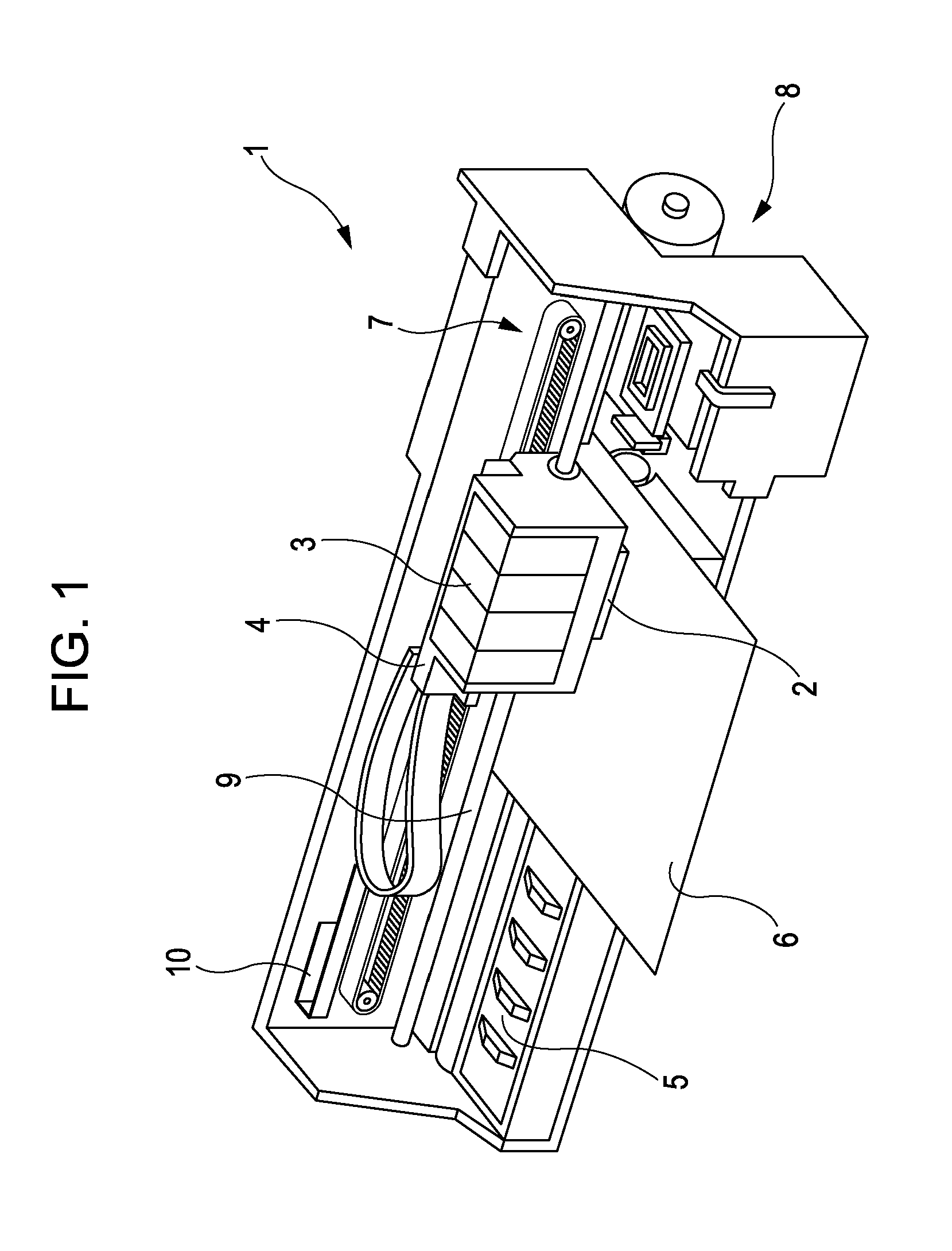

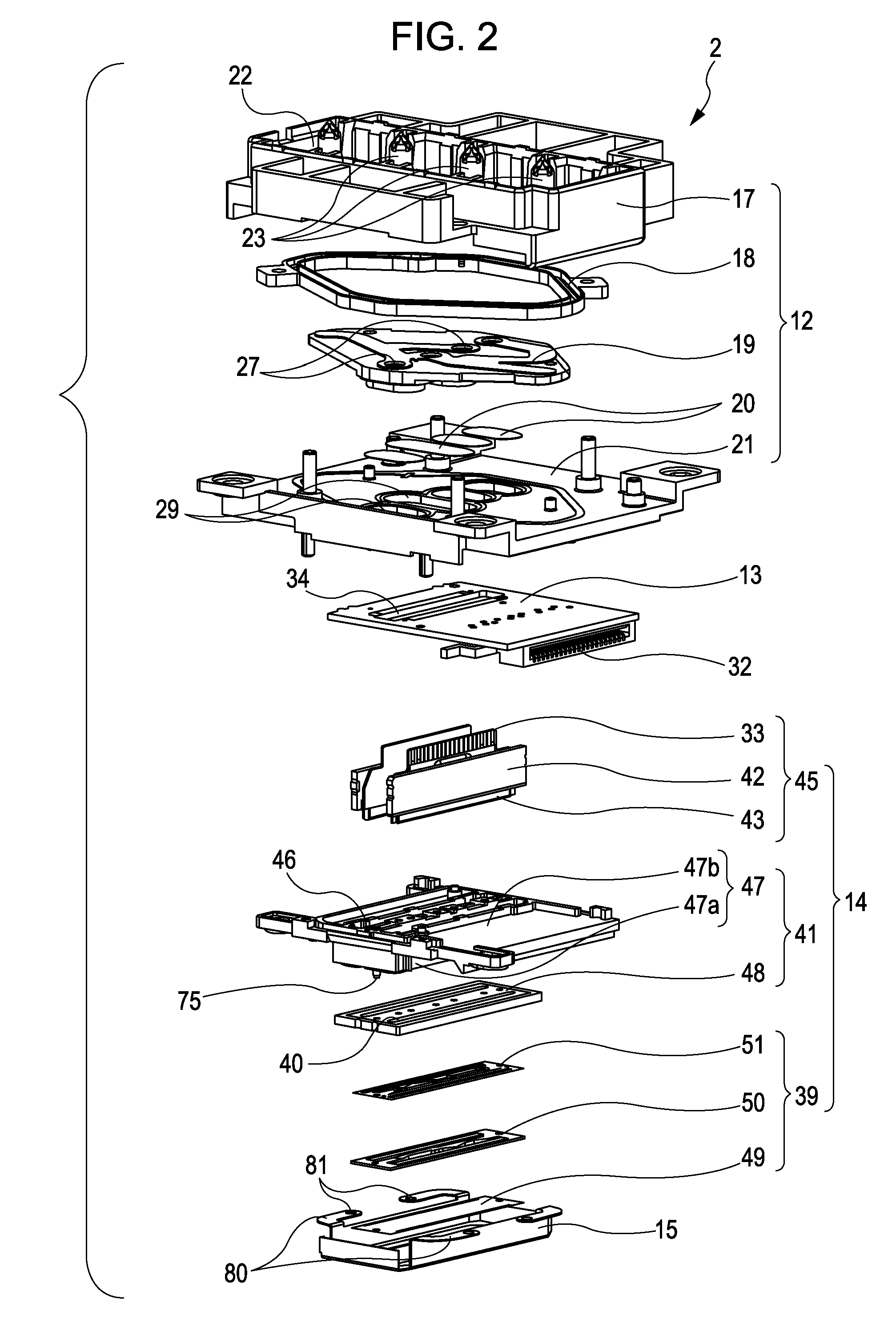

Liquid ejecting head and liquid ejecting apparatus

A liquid ejecting head includes: a main head unit that ejects ink; a first flow channel member and a second flow channel member that include first and second flow channels, respectively, through which ink to be supplied to the main head unit flows; and a ring-shaped sealing member pinched by the first flow channel member and the second flow channel member. The first flow channel and the second flow channel communicate with the interior of a space area defined by the first flow channel member, the second flow channel member, and the sealing member, and an atmosphere exposure channel that connects the space area with the exterior is formed in a joining surface between the sealing member and the first flow channel member.

Owner:SEIKO EPSON CORP

Anti-siphon trap with snorkel

The amount of sealant needed as an odor barrier in a wastewater cartridge is reduced. The cartridge inlet compartment (78) has a ceiling (90) of given area. The ceiling is spaced from the cartridge upper wall (60) and from the wastewater-receiving opening (64) therein. A throat (88), which communicates the inlet compartment with the wastewater-receiving opening, has an area which is less than the area of the ceiling, so that the amount of the sealant acting as the barrier, as contained within the throat, is less than any further amount of the sealant (under the ceiling) which floats on the wastewater in the inlet compartment. Also, should sealant not be present within the throat to act as an odor barrier, only a small area of wastewater present within the throat would be exposed to the air external to the cartridge and, thus, present a lesser opportunity of odor to emanate to the outside environment. Further, a discharge section (86) is coupled between an outlet compartment (80) and the external drain and includes a drain tube (98) having walls surrounding a center and communicating with the outlet compartment and opens at an exit port area (106) for discharge of the wastewater fluid from the outlet compartment to the drain. A three rib channel guide mechanism (100) is formed within the tube to guide flow of the wastewater towards the drain tube center, and away from the drain tube walls to avoid deposit of any sediment contained in the wastewater. In addition, the discharge section drain tube (98) includes a snorkel (110) which extends downwards to above the level of the horizontal drain, to allow any air from the external drain to pass to the outlet compartment generally below the ceiling (90) so that, should wastewater cover the opening of the drain tube, such air is permitted to enter into the cartridge and to prevent any syphoning.

Owner:FALCON WATERLESS TECH INC

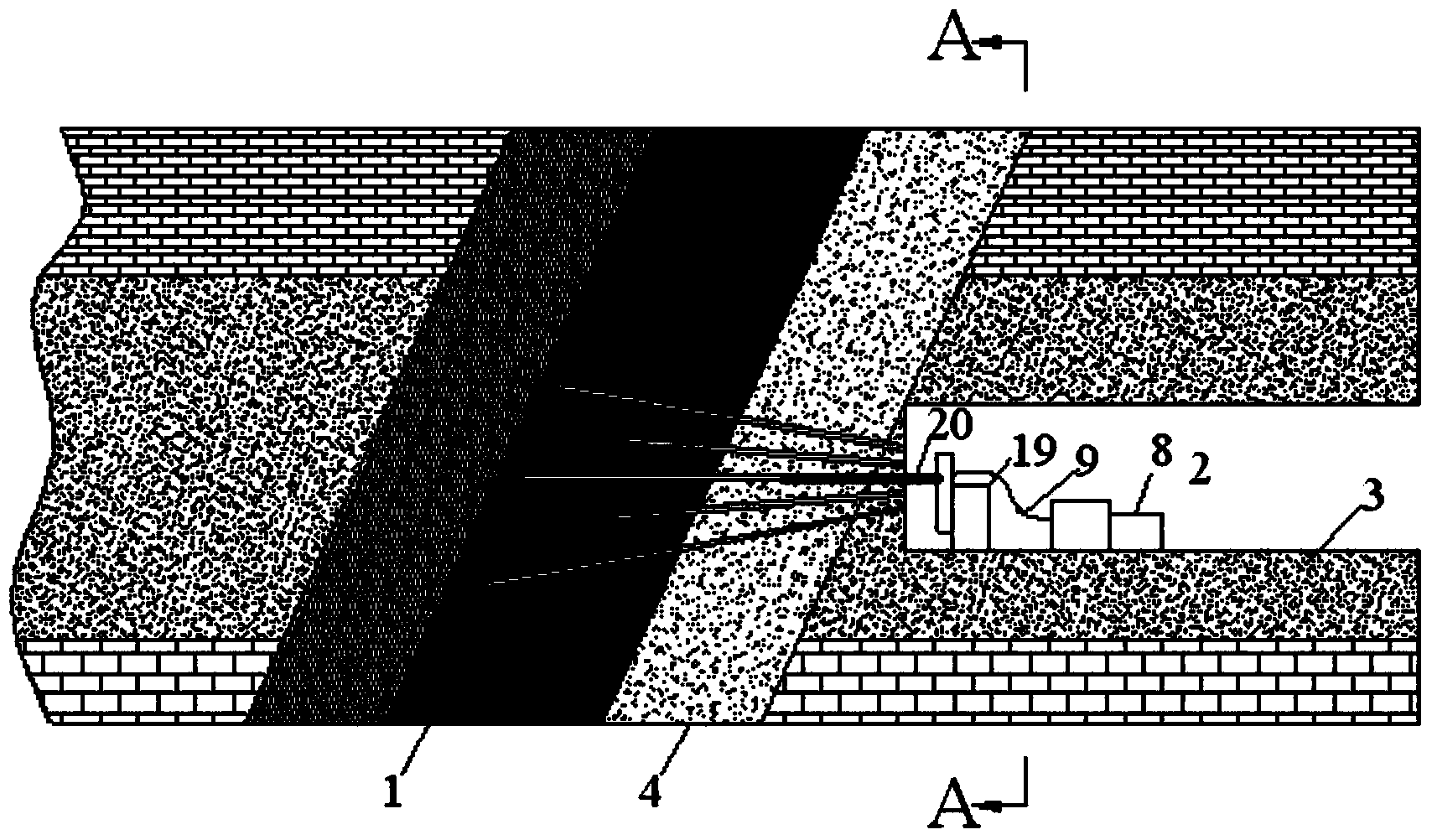

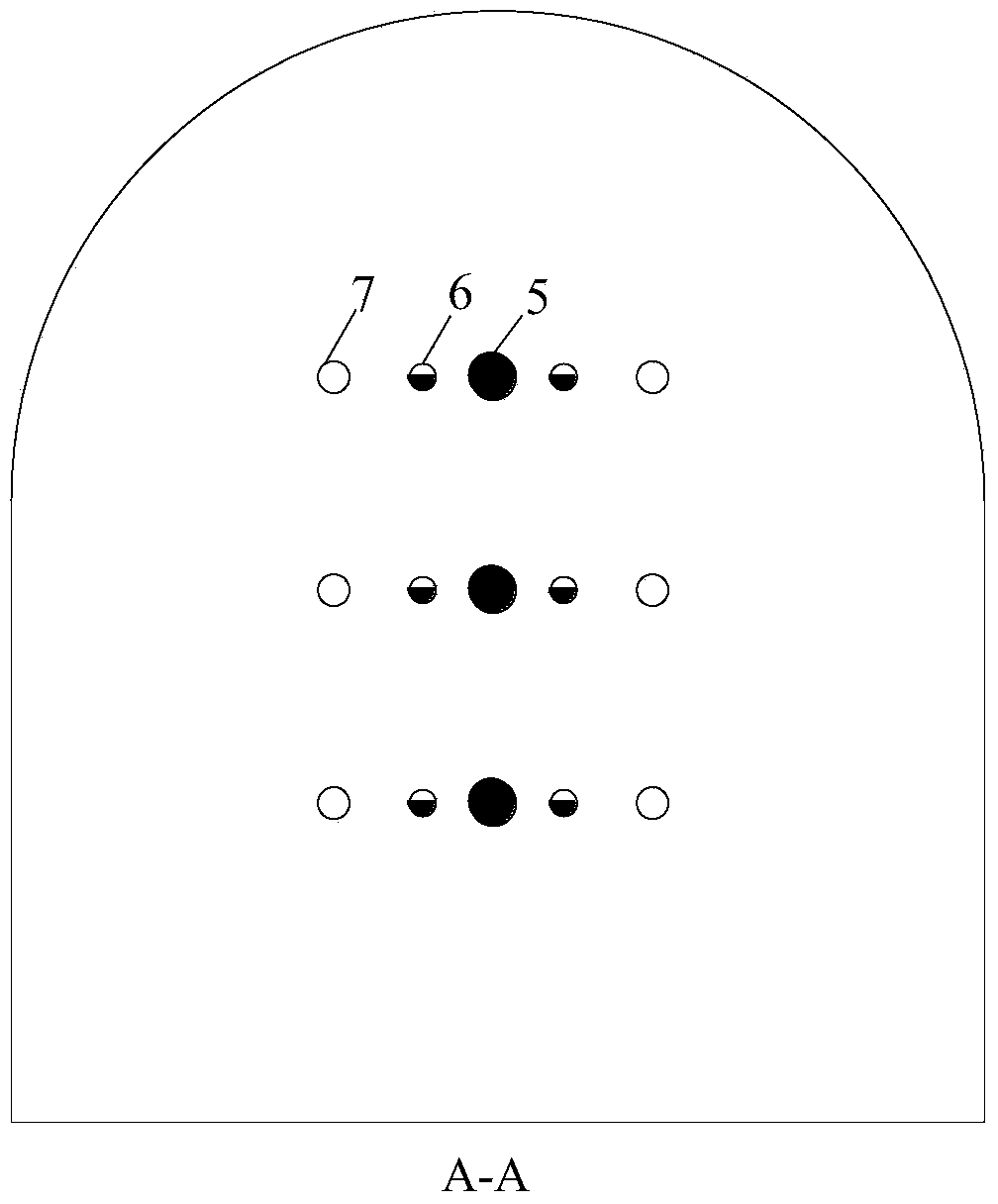

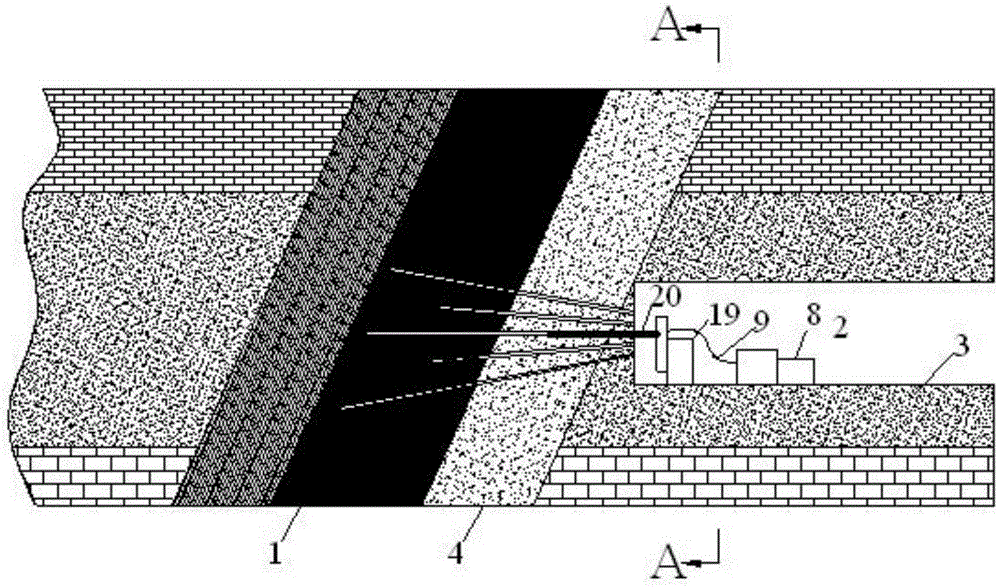

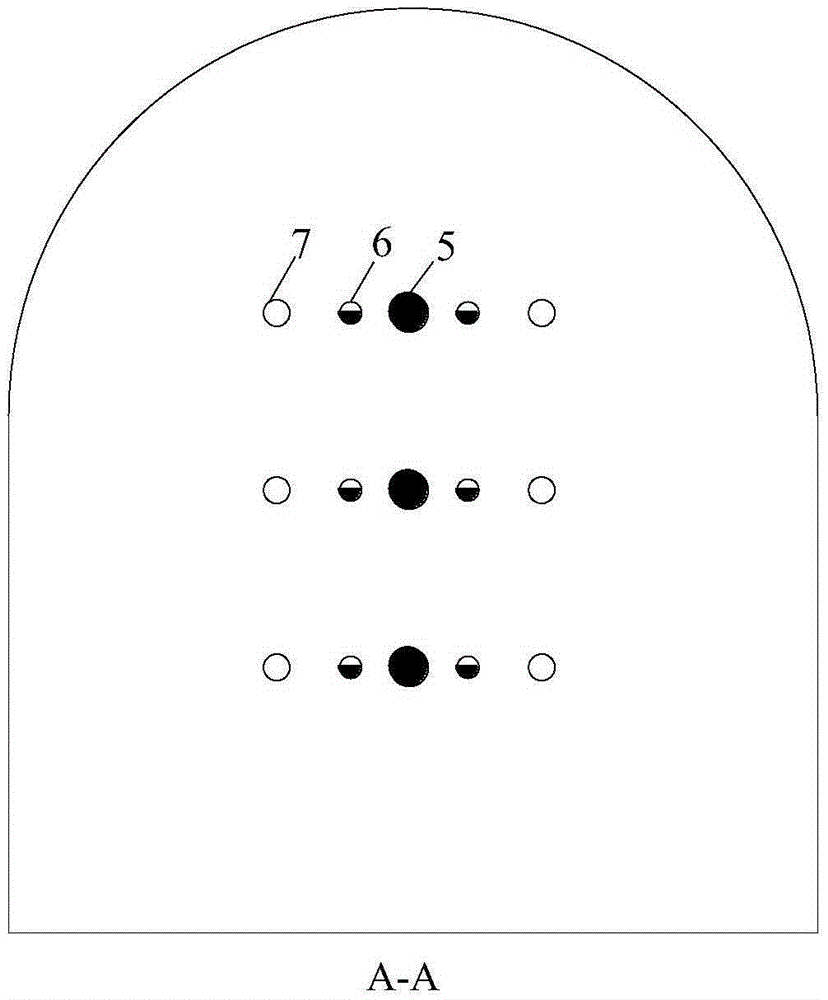

Hydraulic flushing and presplit blasting combined permeability-increasing extraction system in crossing holes

ActiveCN105507872AReduce impactReduce cloggingLiquid/gas jet drillingFluid removalEngineeringHigh pressure water

A hydraulic flushing and presplit blasting combined permeability-increasing extraction system in crossing holes comprises a hydraulic flushing device, a presplit blasting device, a gas extraction device and extraction pipelines. The hydraulic flushing device comprises a sounding borer, a drill rod, a high-pressure water-injection pump and a water gas separator, the upper end of the drill rod serves as a water outlet, the lower end of the drill rod serves as a water inlet, a water outlet of the high-pressure water-injection pump is connected with the water inlet of the drill rod, the lower end of the drill rod is connected with the power output end of the sounding borer, the upper end of the drill rod extends into a flushing drill hole, and a gas dust collecting device is arranged at the flushing drill hole position and is connected with an inlet of the water gas separator through a pipeline. The hydraulic flushing and presplit blasting combined permeability-increasing extraction system in the crossing holes has the advantages that coal seam gas permeability is improved effectively, gas extraction effects are enhanced, extraction time is shortened effectively and potential safety hazards of gas are reduced maximally.

Owner:HENAN POLYTECHNIC UNIV

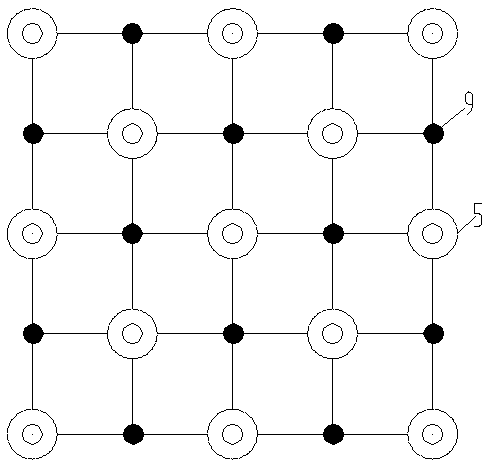

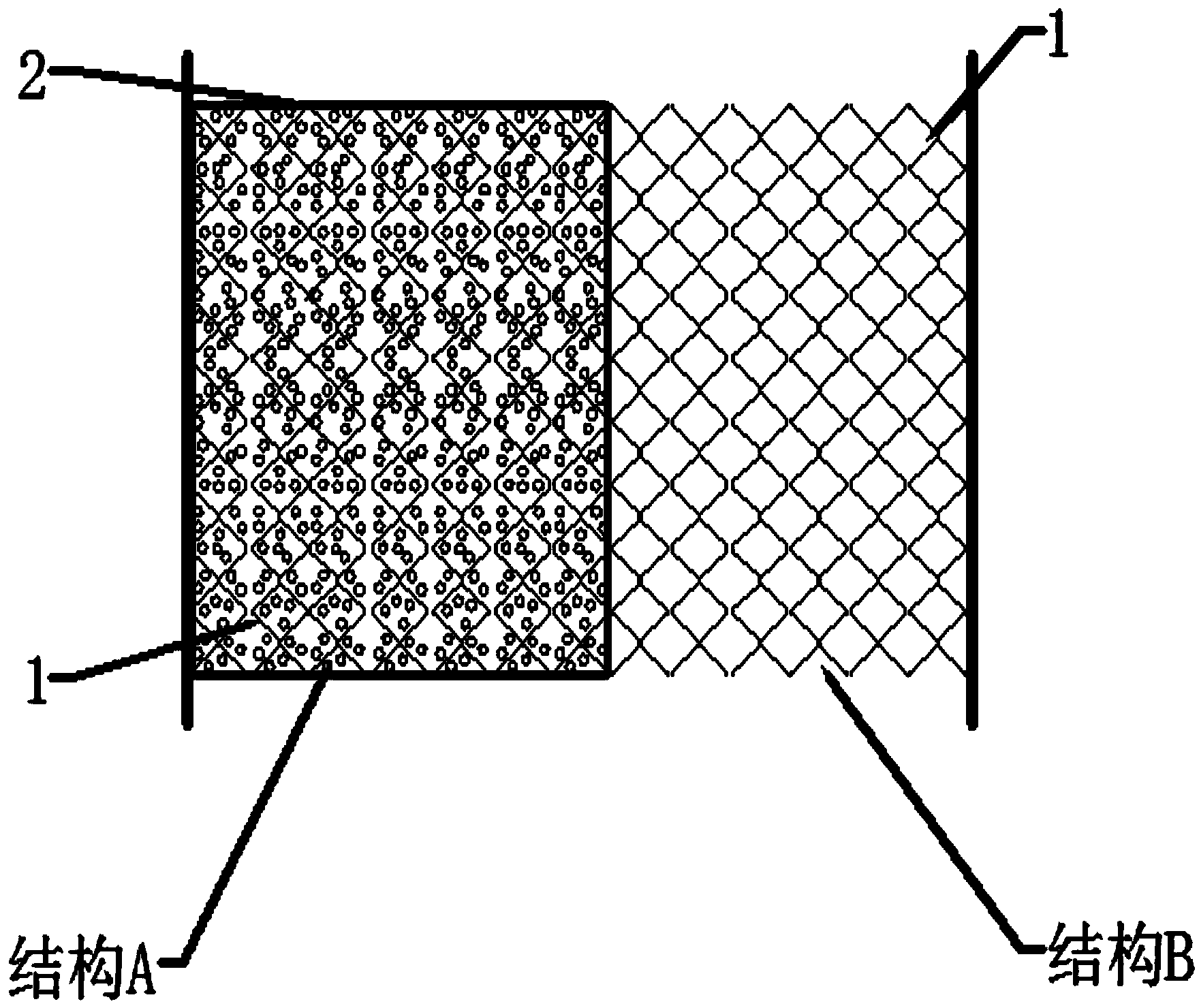

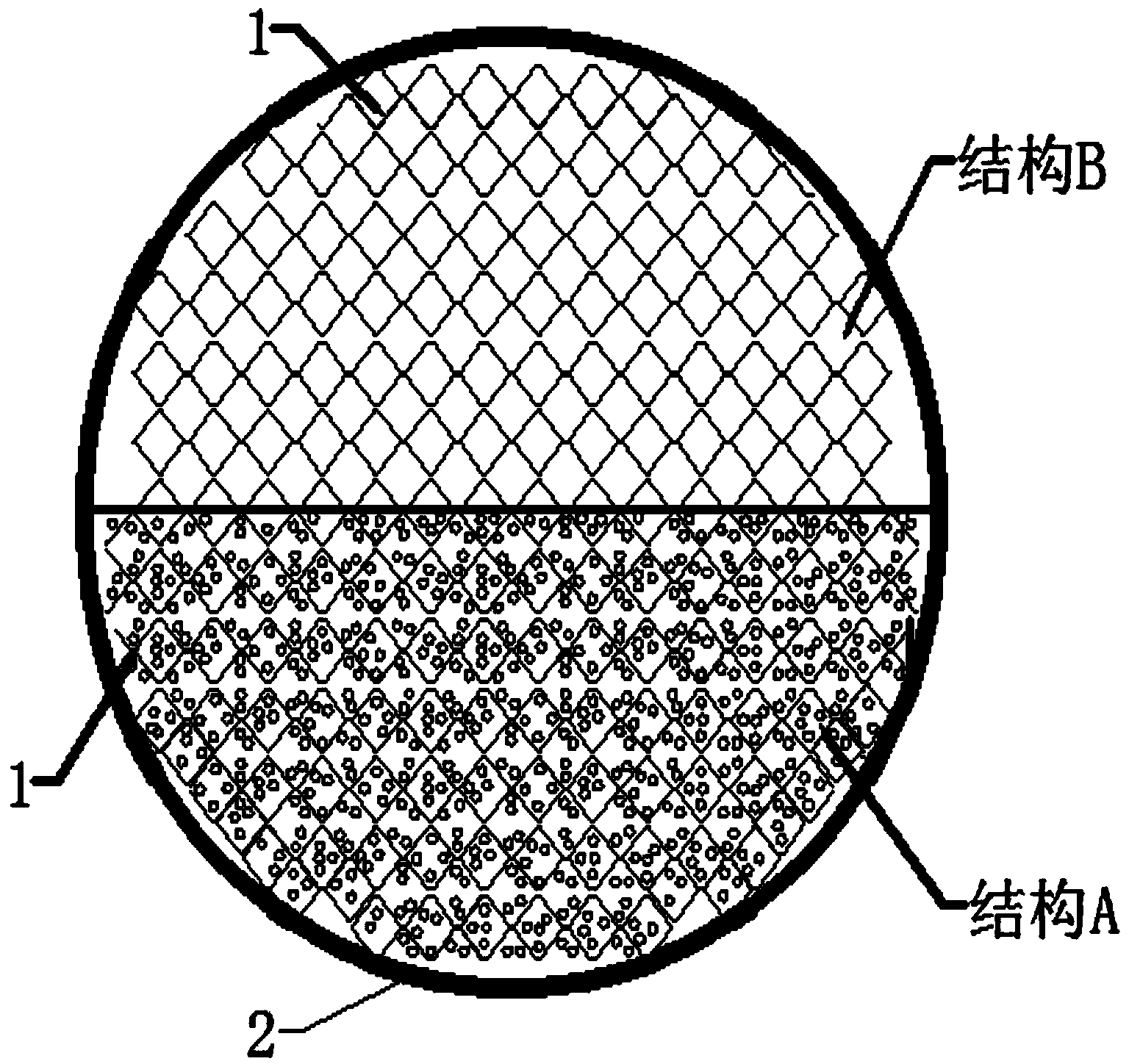

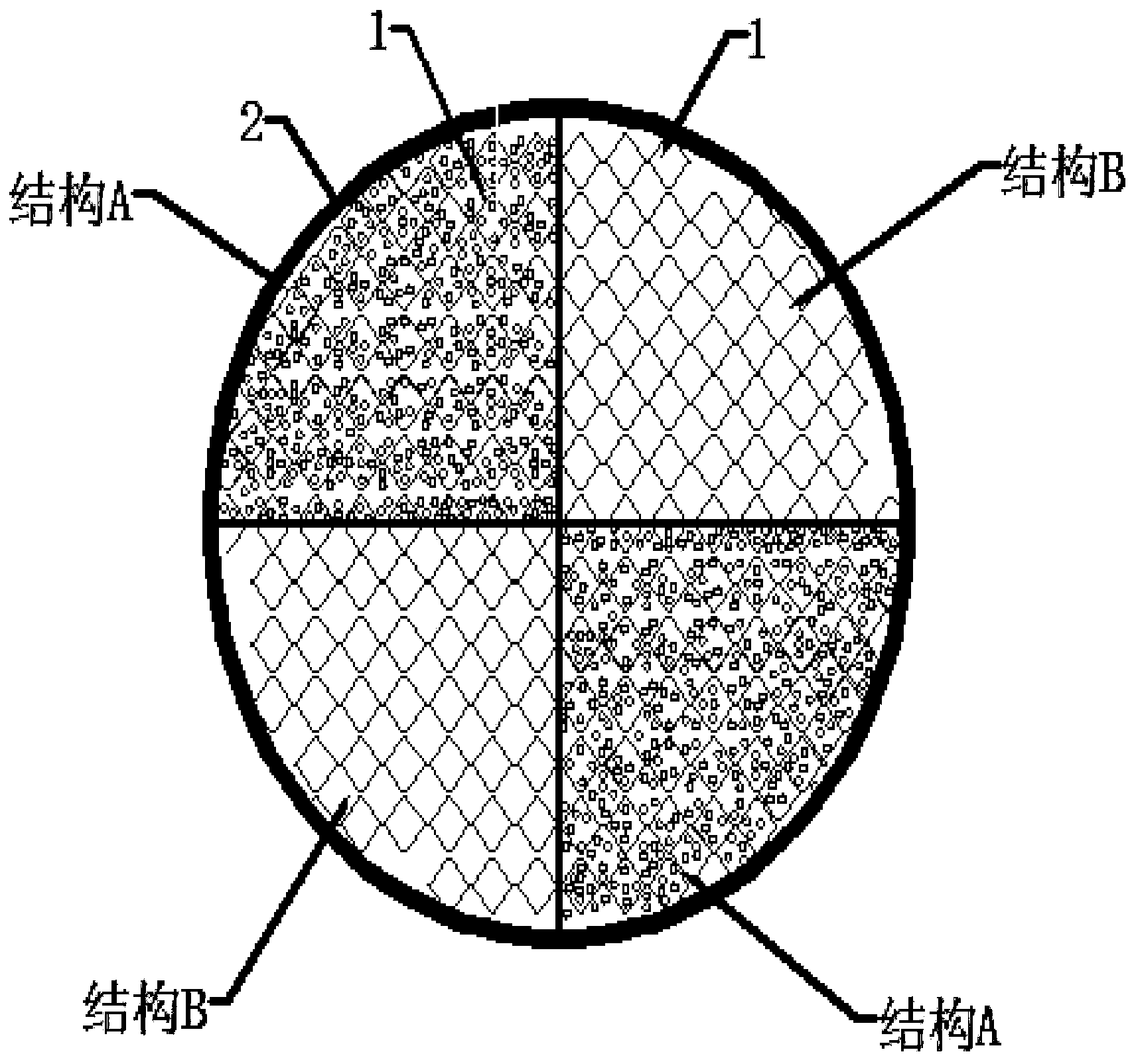

Catalytic rectification packing with radial distribution capacity

ActiveCN103752253AImprove Radial Distribution EffectImprove reaction efficiencyChemical/physical/physico-chemical processesFractional distillationVapor liquidEngineering

The invention relates to catalytic rectification packing with radial distribution capacity. The interior of a structure A consists of packing sheets; catalysts are filled in the packing, and the exterior is coated by a screen; a structure B refers to regular packing sheets and can be windowing guide packing, plate ripple packing, screen ripple packing, pore plate ripple packing, rolled pore plate ripple packing, cellular packing and other regular packing. The two structures are alternately and circumferentially distributed in a packing disc. The structure A and the structure B are circumferentially arranged in a staggered mode, so that the number of vapor-liquid multi-phase flow channels are increased, the mass transfer process of vapor-liquid multi-phase flow is facilitated, the phenomena of channeling and short circuit of vapor-liquid multi-phase flow are effectively avoided, small bed pressure drop is realized, a multi-phase flow radial diffusion effect is effectively enhanced, the reaction products are timely separated, and forward reaction is promoted, so that the amount of catalysts can be reduced.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD +1

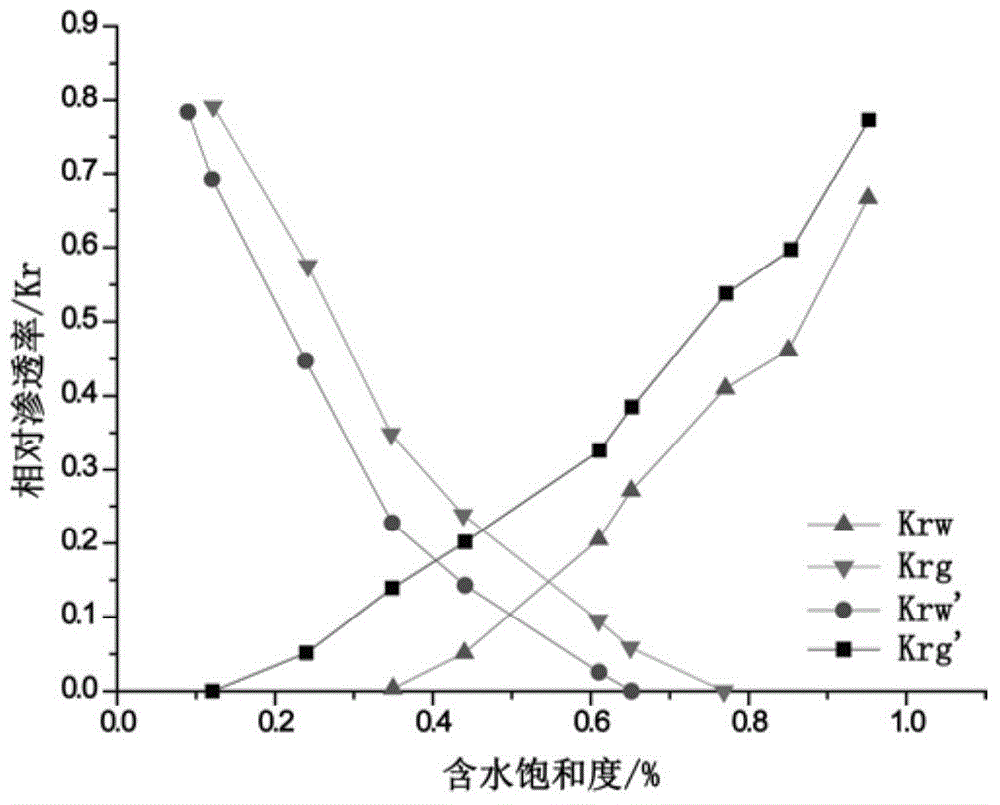

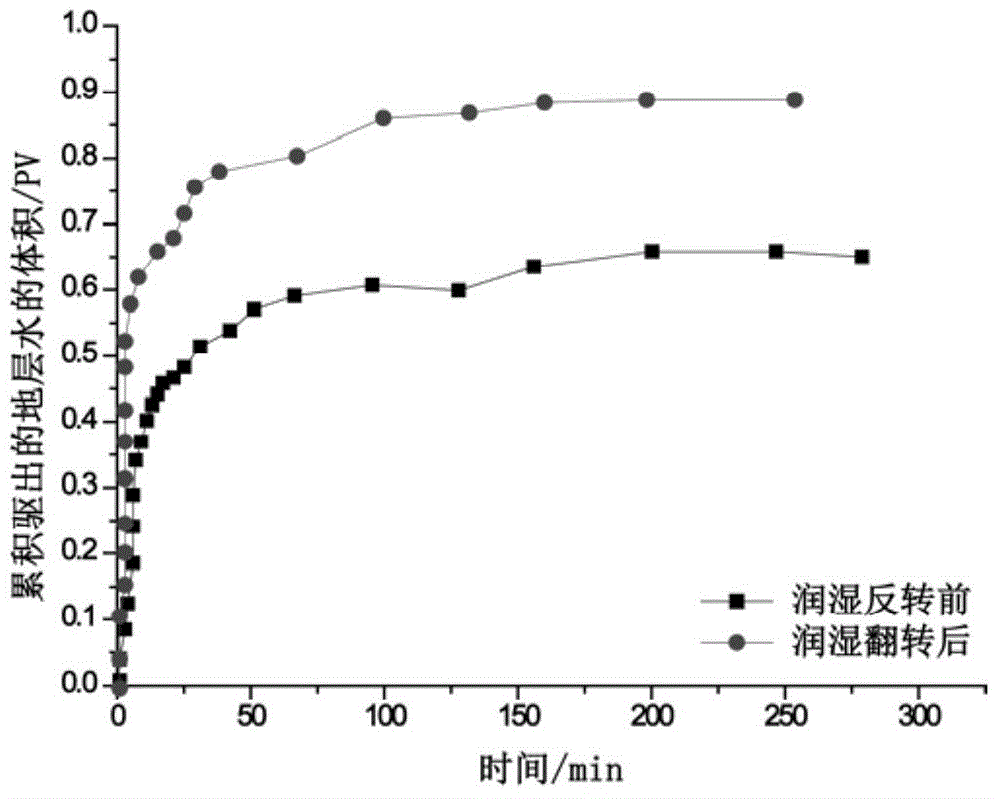

Fracturing method for reservoirs based on schistose propping agents and gas wetting reversal agents

InactiveCN108194072AIncrease the flow channelImprove diversion capacityFluid removalCoalCeramic particle

The invention discloses a fracturing method for reservoirs (including hydrocarbon reservoirs, coal seams and so on) based on schistose propping agents and gas wetting reversal agents. When the fracturing method for the reservoirs is applied, schistose (including gangues, walnut shells and so on) propping agents with the total weight of the propping agents being 1.0%-99.0% are added to sand-carrying fluid, and others are traditional spherical (including quartz sand, ceramic particles, and so on) propping agents; gas wetting reversal agents which accounts for 0.0%-10.0% of the total weight of fracturing prepad fluid are added to the fracturing prepad fluid; and the wettability of the surfaces of the propping agents are changed into aerophily by adopting the gas wetting reversal agents, namely, gas wetting. According to the fracturing method for the reservoirs (including the hydrocarbon reservoirs, the coal seams and so on) based on the schistose propping agents and the gas wetting reversal agents, the gas extraction effect such as coal-bed methane wells or downhole hydraulic fracturing is improved through the fracturing method, fracturing fluid adding the gas wetting reversal agents,and the schistose propping agents, so that the flow conductivity of coal-bed methane is improved, and then the production of the coal-bed methane is increased effectively.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

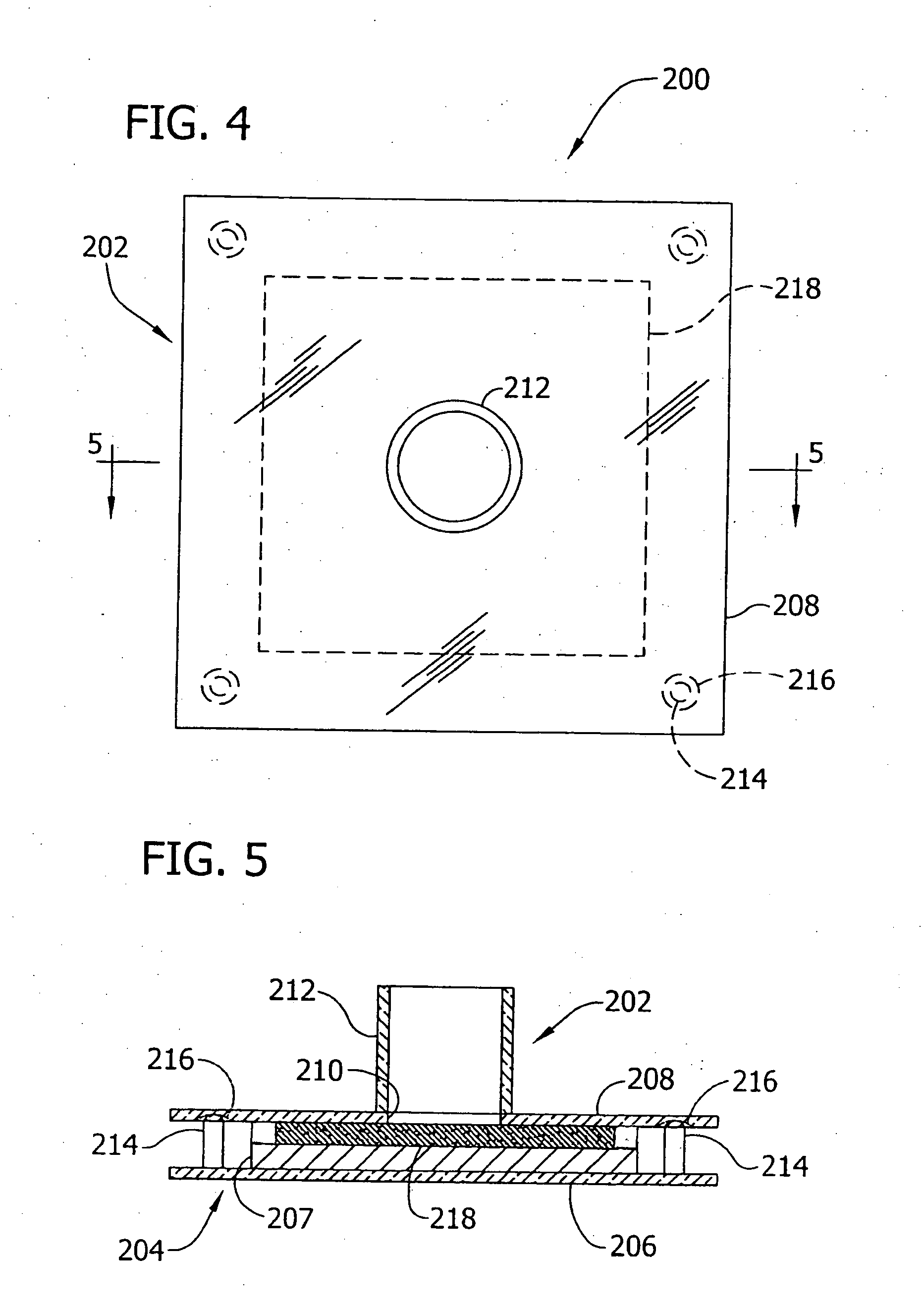

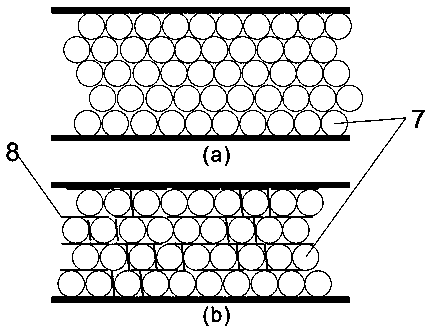

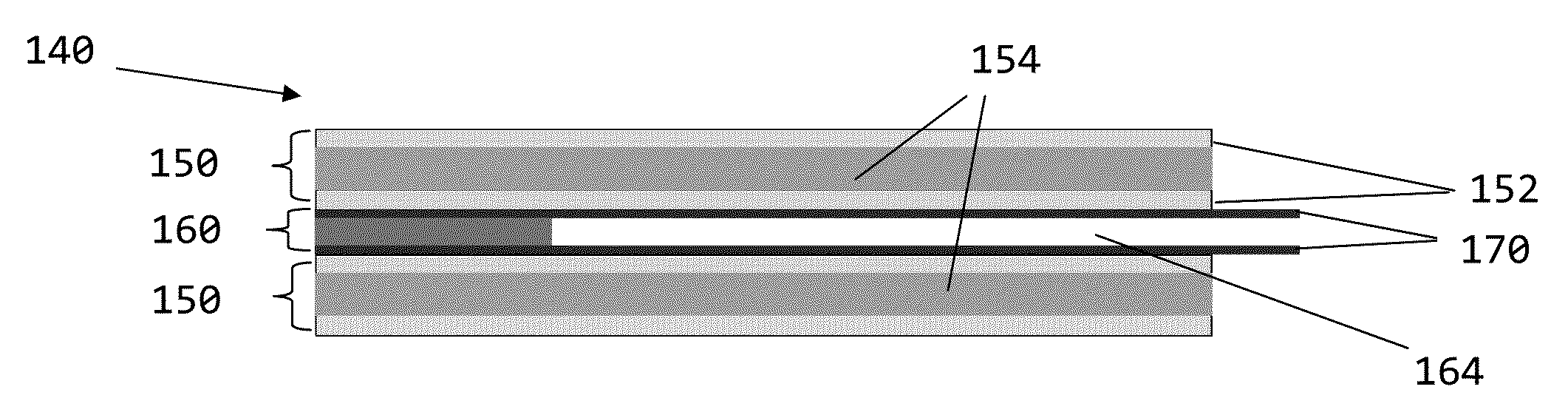

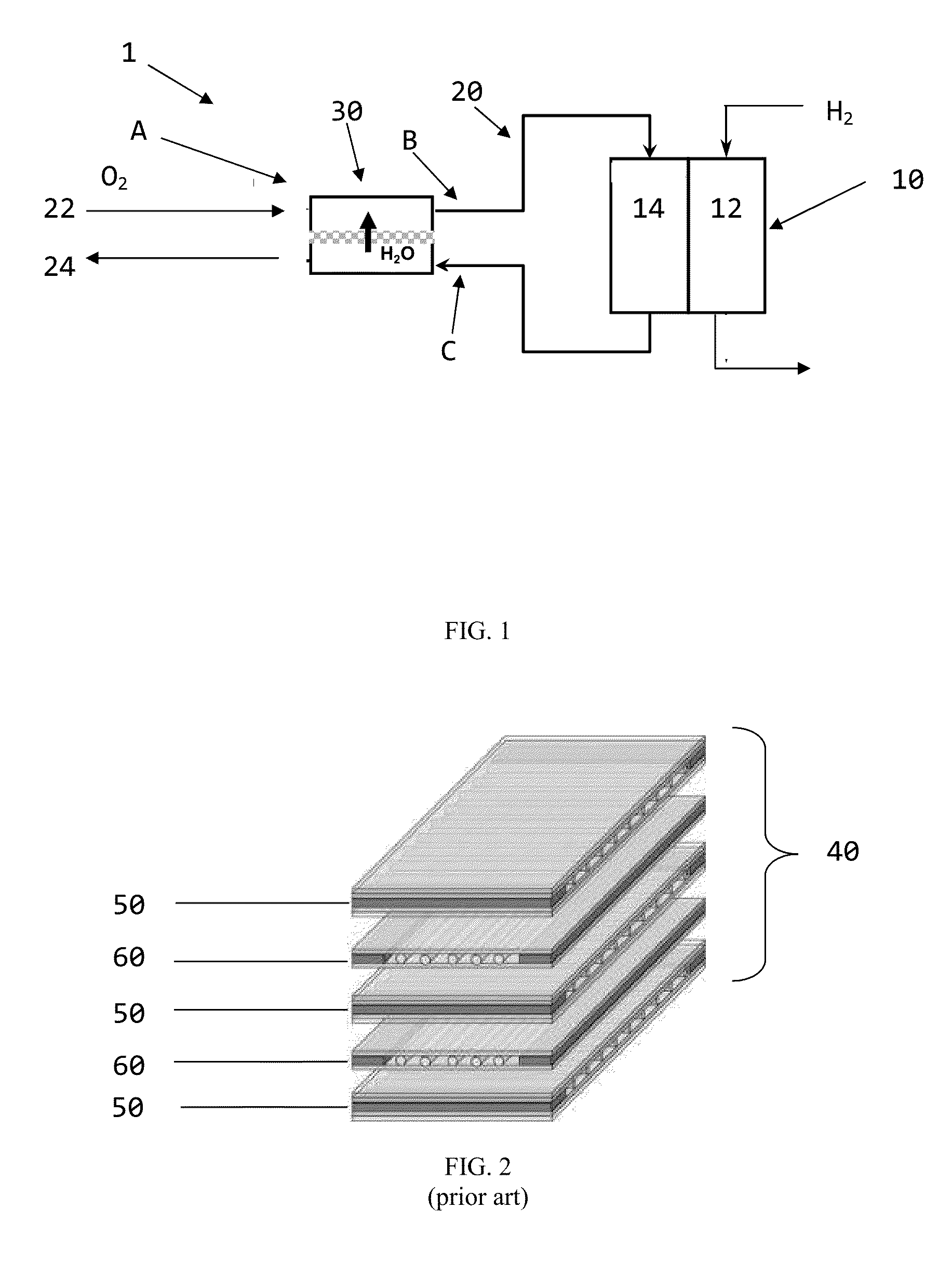

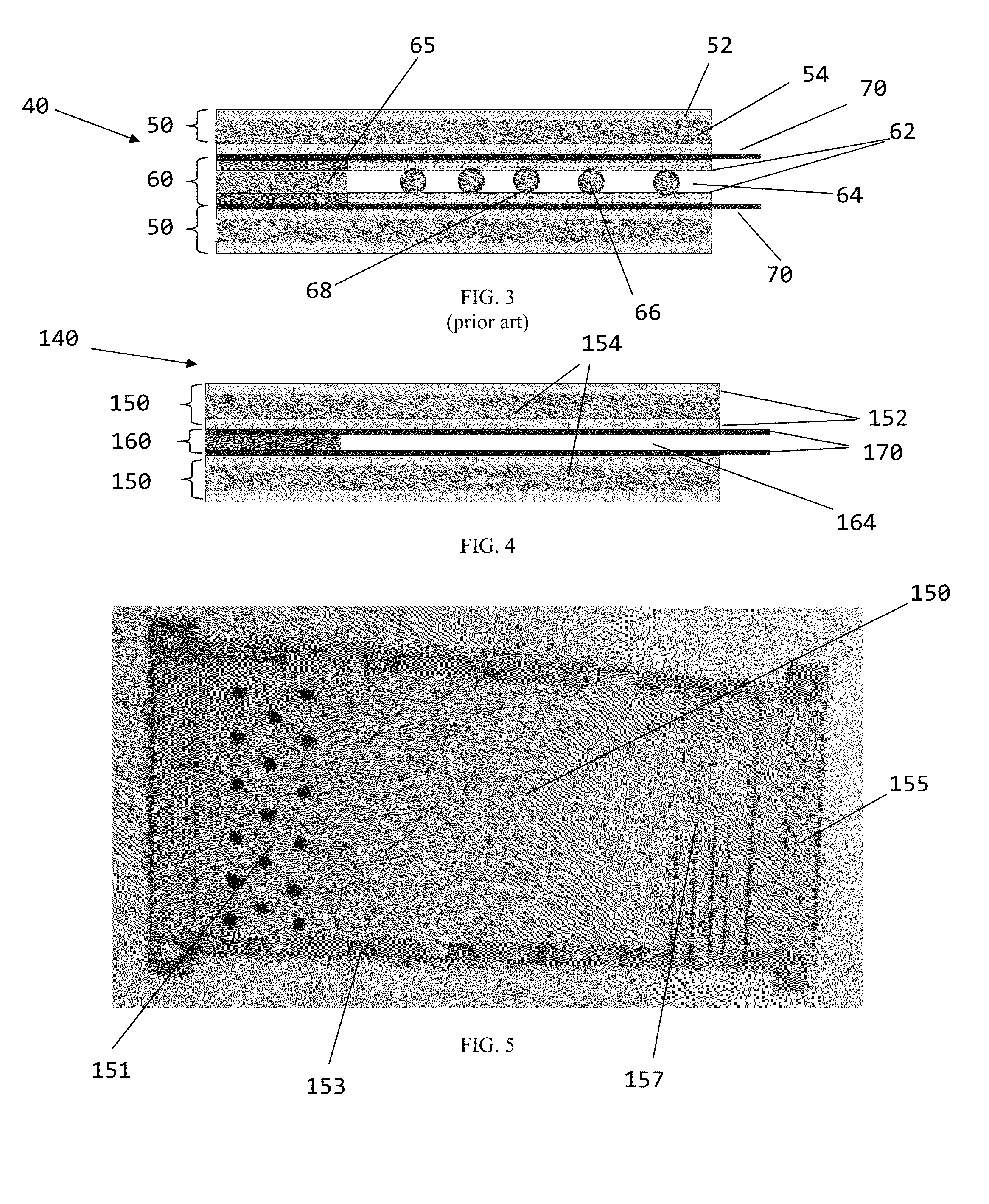

Discretely supported wet side plates

ActiveUS20130022897A1Guaranteed normal transmissionIncrease the flow channelMechanical working/deformationLamination ancillary operationsFuel cellsWater vapor

A water vapor transfer separator plate assembly and a method of making the same. In such an assembly made up of a stack of alternating wet side plates and dry side plates with a membrane disposed between them, a humid fluid such as that found in a fuel cell cathode exhaust flows against one side of each membrane such that at least some of its moisture content travels across the membrane to a lower humidity fluid on the opposite side of the membrane. The lower humidity fluid, such as that found in a fuel cell cathode entrance, experiences an increase in its humidity by the operation of the moisture flow across the membrane. At least a portion of the assembly may be made thinner by removing diffusion media and reinforcing structure of the dry side plates such that the overall assembly is simplified.

Owner:GM GLOBAL TECH OPERATIONS LLC

Aqueous urea solution decomposing mixing device

PendingCN110821615AReduce hindranceReduce lossesInternal combustion piston enginesExhaust apparatusVertical planeEngineering

The invention discloses an aqueous urea solution decomposing mixing device. A spoiler and a pore plate are arranged between a front shell and a rear shell. The spoiler and the pore plate divide an inner cavity into an upper spraying cavity, a middle flow guide cavity and a lower rotational flow cavity. A top cover is arranged at the top of the rear shell. An inclined plane is arranged in the spraying cavity, and an included angle is formed between the vertical plane and the inclined plane. A flow guide plate is provided with a flow guide vane. The spoiler is provided with a turbulent flow vane. A rotational flow plate is provided with a rotational flow vane outwards through a third vane hole. The inner cavity of the aqueous urea solution decomposing mixing device is divided into the spraying cavity, the flow guide cavity and the rotational flow cavity only through the spoiler and the pore plate. Little blocking occurs in an airflow channel, the airflow channel is smoother, mixed airflow passes through few turning points in the airflow channel, energy loss is small, and the airflow pressure drop is low. The top cover is provided with an inclined lower plane, and the spraying cavityforms a cavity which is asymmetric along the vertical plane. A nozzle seat is located in a low position of the lower plane, and thus the urea spraying line is toward the direction directly facing thedirection of the turbulent flow vane of the spoiler.

Owner:无锡亿利环保科技有限公司

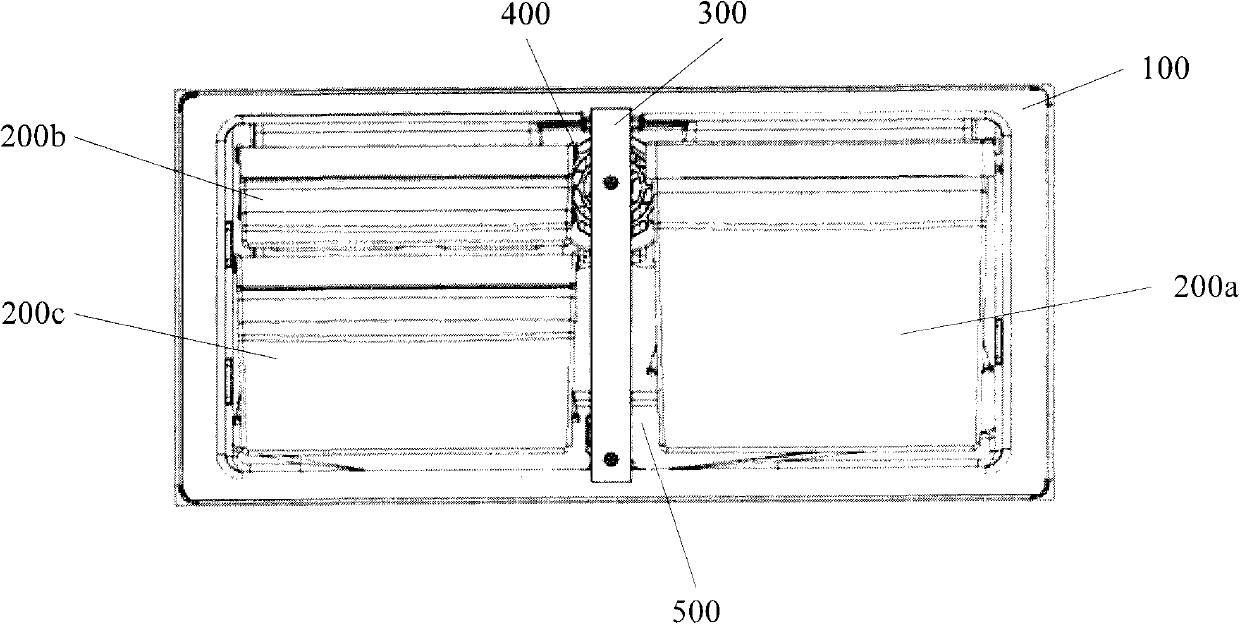

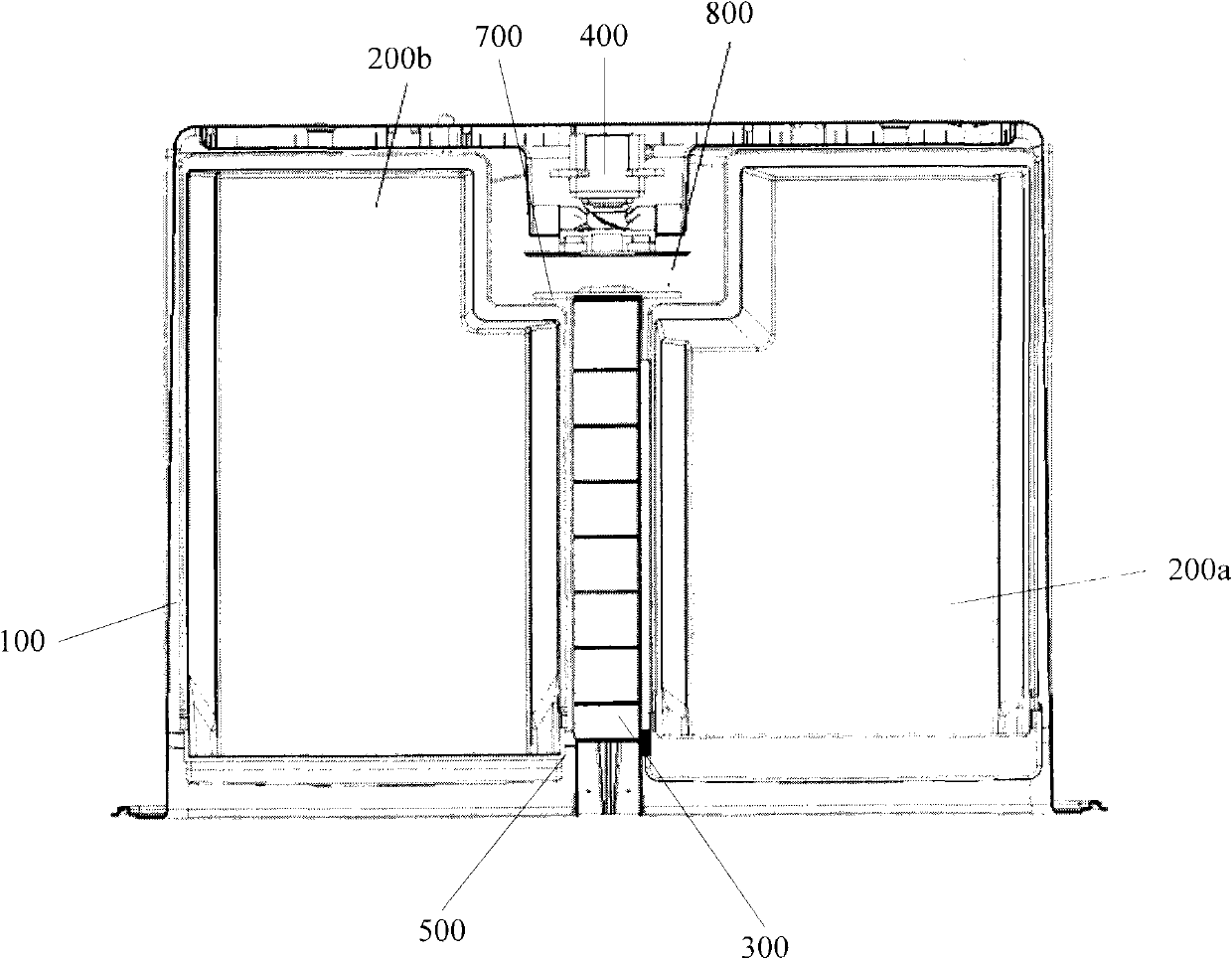

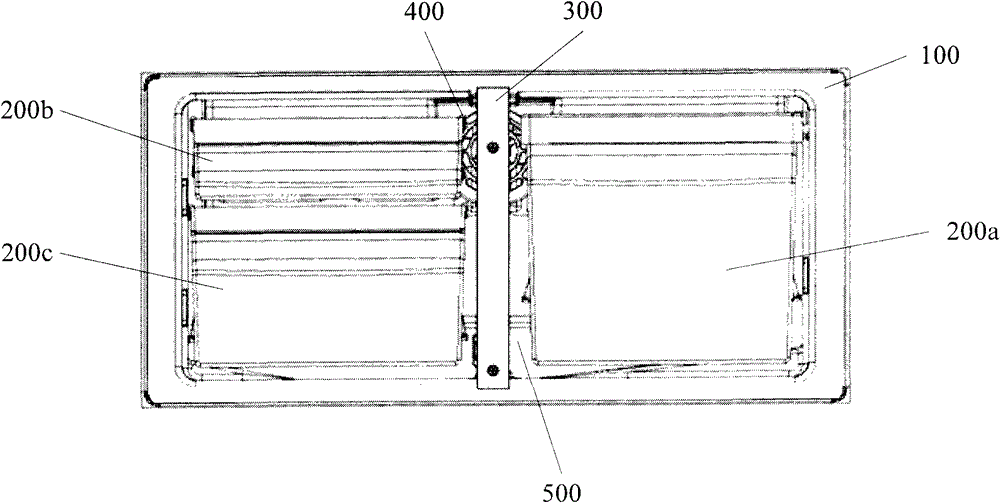

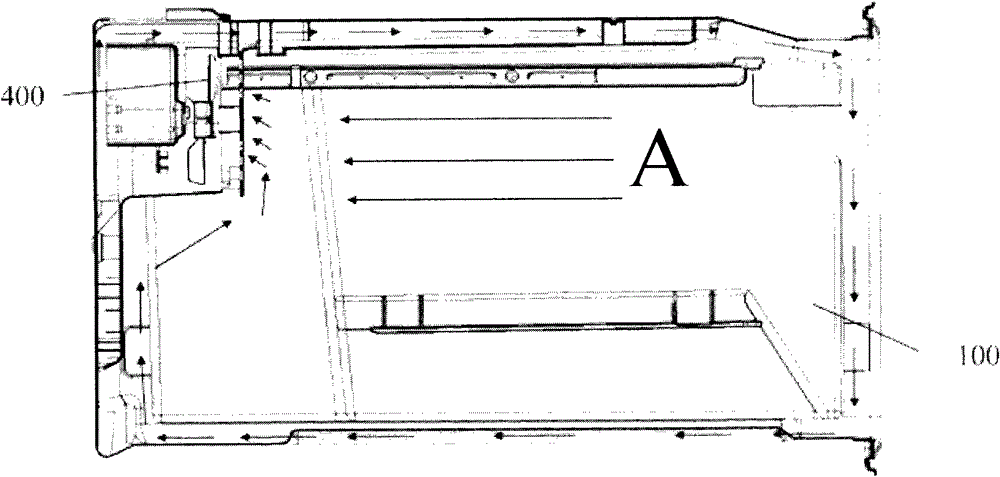

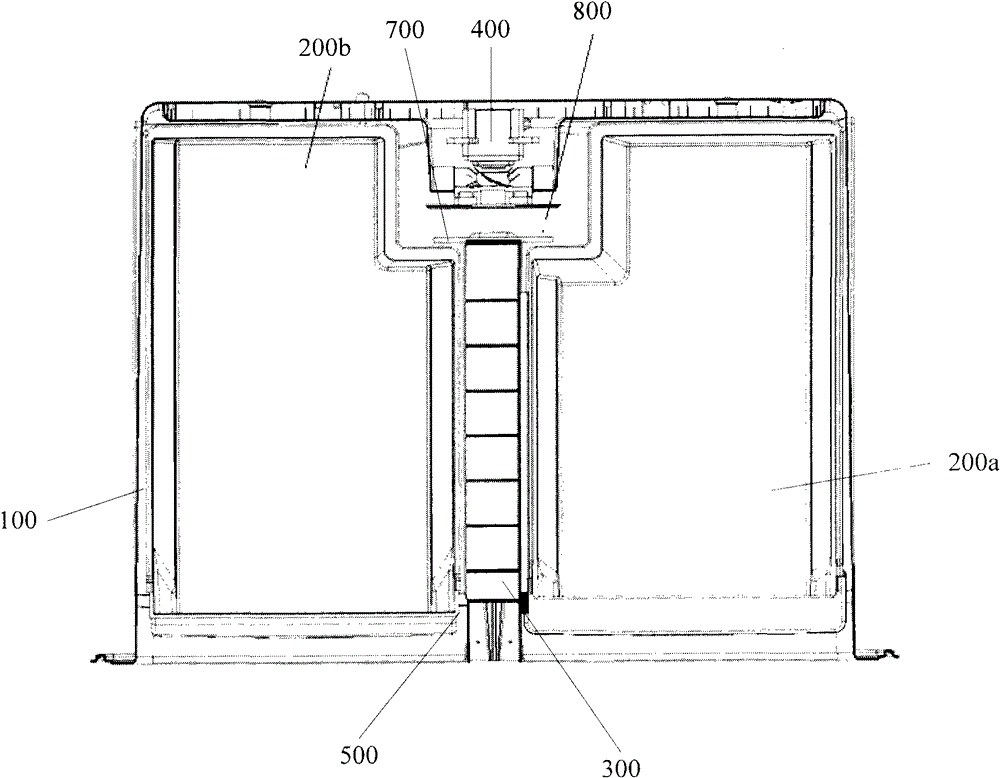

Refrigerator and air supply system of chamber of refrigerator

ActiveCN102564011AGuaranteed freshnessAvoid short circuitLighting and heating apparatusDomestic refrigeratorsCold airTemperature difference

An air supply system of a chamber of a refrigerator comprises a fan and a baffle plate, wherein the fan is arranged on a rear wall of an inner cavity of the chamber and provided with an air inlet and an air outlet, the air inlet faces to an opening surface of the chamber, and the air outlet is communicated with the air inlet; and the baffle plate is disposed at the front of the air inlet, and a gap is formed between the baffle plate and the air inlet. The baffle plate prevents eddy caused by backflow of cold air in the gap, short circuit of an air field is avoided, air circulates smoothly, and a refrigerating effect of the chamber of the refrigerator is improved. The invention further provides a refrigerator, which comprises the chamber and the air supply system, and the air supply system is mounted in the chamber. The air supply system and the refrigerator have the advantages that refrigerating efficiency of the chamber of the large-volume refrigerator is improved, air is supplied uniformly, the short circuit of the air field is avoided, and temperature difference is reduced.

Owner:博西华家用电器有限公司

Device for cooling an optical module for a motor vehicle headlight

ActiveUS8297805B2Increase the flow channelAssure continuityVehicle headlampsPoint-like light sourceCold airOptical Module

A lighting and / or signaling device comprising at least one optical module equipped with a cooling unit, comprising at least one heat conductor, one end of which is placed spaced from the cooling unit, and is provided with a plurality of deflectors which channel a flow of cold air towards a heat-exchange surface of the cooling unit.

Owner:VALEO VISION SA

Heavy oil thermal recovery steam injection device and heavy oil thermal recovery method

ActiveCN105626021AImprove heating efficiencyReduce injection volumeFluid removalEngineeringThermal recovery

The invention relates to a heavy oil thermal recovery steam injection device and a heavy oil thermal recovery method. The heavy oil thermal recovery steam injection device comprises an inner steam injection pipe and an outer steam injection pipe which is provided with a gas outlet and arranged outside the inner steam injection pipe in a sleeving mode. The two ends of the outer steam injection pipe are in seal connection with the outer surface of the inner steam injection pipe. A plurality of packers are arranged between the inner steam injection pipe and the outer steam injection pipe at intervals to divide a space between the inner steam injection pipe and the outer steam injection pipe into a plurality of noncommunicating steam injection sections. Pressure valves with different opening pressures are arranged in the zones, located in all the steam injection sections, of the inner steam injection pipe correspondingly. By using the heavy oil thermal recovery steam injection device, a horizontal shaft can be heated evenly, and the recovery efficiency of heavy oil is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

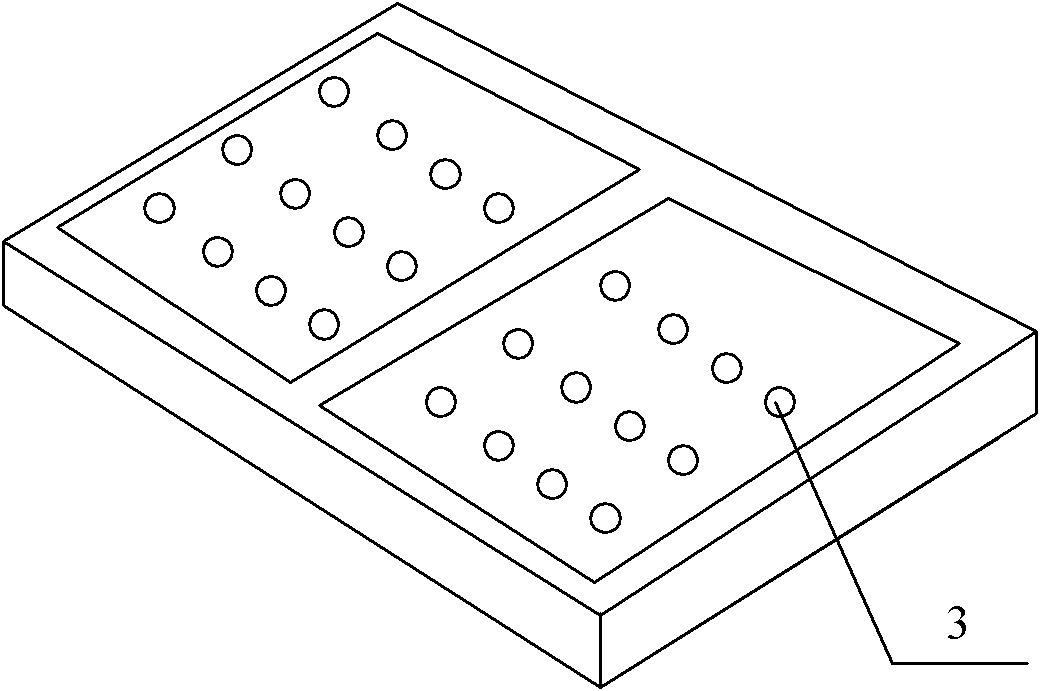

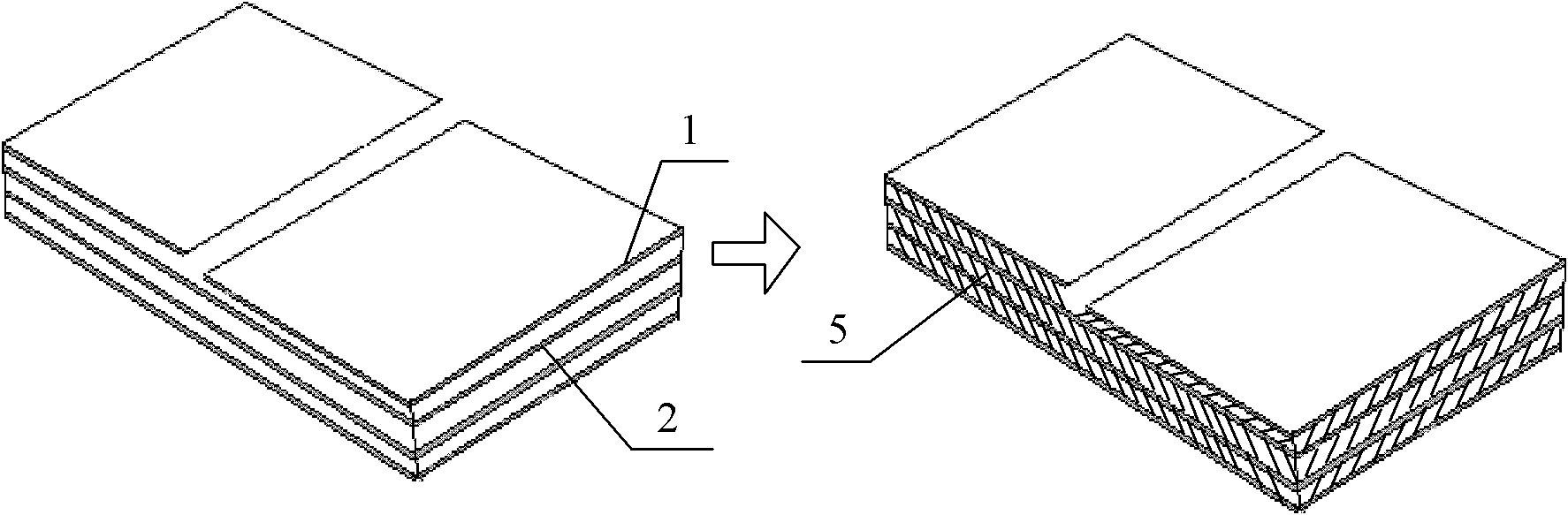

Preparation method of Balsa wood core material of wind driven generator blade web

ActiveCN111958711AMass does not increaseLow moisture absorptionFinal product manufactureWood veneer joiningWind drivenEngineering

The invention relates to the technical field of wind driven generator blades, and particularly relates to a preparation method of a Balsa wood core material of a wind driven generator blade web. The preparation method comprises the steps of slicing, accurate grinding, dehumidification, double-end sawing treatment and gluing, and after pretreatment, shallow groove forming, punching, cloth pasting,deep groove forming, finished product inspection, template manufacturing, line drawing, edge cutting, mark writing, chamfering, IPQC process inspection, plate separation, dehumidification, laying inspection and packaging and warehousing are sequentially conducted. According to shallow groove forming, a plurality of shallow grooves are formed in at least one surface of the core material and are staggered on the surface of the core material to be arranged in a rectangular grid shape, and through holes penetrating through the upper surface and the lower surface of the core material are punched inthe intersection points of the multiple shallow grooves. According to the preparation method, three times of humidity detection are set, the moisture absorption possibility of the core material in the preparation process is further reduced, the risk of corrosion of bacteria and the like sealed in the core material in the operation process is reduced, and therefore the defects of the Balsa wood core material are effectively overcome.

Owner:常州兆庚新材料有限公司

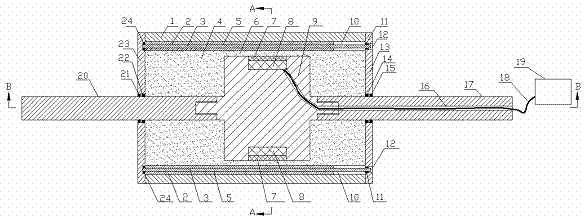

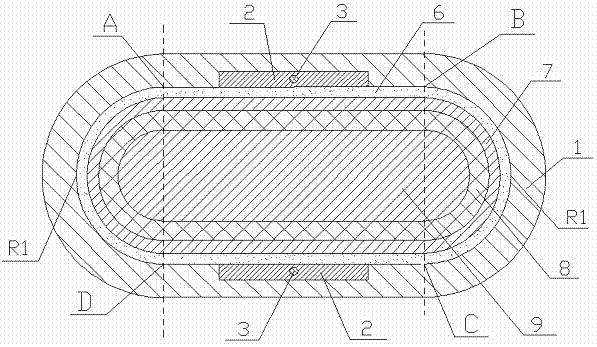

Crack cylinder double-out rod magneto-rheological damper

InactiveCN103089905ALarge adjustment rangeHigh strengthSpringsNon-rotating vibration suppressionEngineeringMagneto rheological damper

The invention discloses a crack cylinder double-out rod magneto-rheological damper which comprises a working cylinder, a piston and two piston rods. The working cylinder is composed of a working cylinder body, two identical sliding damping blocks, an adjusting screw and two end covers. The longitudinal section of an inner cavity of the working cylinder body is formed by externally adding a semicircle to each of the two symmetrical short sides of a rectangle, wherein the diameter of the semicircle is equal to the length of each short side of the rectangle. Two grooves are formed in two long sides of the longitudinal section of the working cylinder body in the axial direction, wherein the two grooves are symmetrical and penetrate through the working cylinder body. The two sliding damping blocks are arranged in the two grooves. One end of the adjusting screw penetrates through threaded through holes in the sliding damping blocks and is installed on one end cover in the working cylinder and the other end of the adjusting screw extends out of the working cylinder by penetrating through an adjusting hole in the other end cover. The shape of the longitudinal section of the piston is identical with the shape of the longitudinal section of the inner cavity of the working cylinder. A magneto-rheological fluid flowing gap is reserved between the outer peripheral wall of the piston and the inner peripheral wall of the working cylinder. A magnet exciting coil is wound in the middle portion of the piston.

Owner:谭晓婧

Air supply system for a refrigerator and its compartment

ActiveCN102564011BGuaranteed freshnessAvoid short circuitLighting and heating apparatusDomestic refrigeratorsRefrigerator carEngineering

The present invention discloses an air supply system for a compartment of a refrigerator, comprising: a fan provided on a rear wall of an inner chamber of the compartment, said fan is provided with an air inlet and an air outlet, said air inlet faces an open side of said compartment, and said air outlet and said air inlet are in communication with each other; and a barrier, which is provided in front of said air inlet, and there is a gap between said barrier and said air inlet. By providing the barrier, vortex caused by backflow of cool air in the clearance can be prevented, short circuit of air field can be avoided, smooth flowing of air flow can be achieved and refrigeration effect of the compartment of the refrigerator can be enhanced. The present invention further provides a refrigerator further comprising the air supply system, said air supply system is fitted in said compartment. This enhances refrigeration efficiency of the compartment of the large-capacity refrigerator, achieves even air supply, avoids short circuit of air field and reduces temperature difference in the large-capacity refrigerator.

Owner:博西华家用电器有限公司

Gapped magneto-rheological damper with single piston rod out

InactiveCN103062275AHigh strengthIncrease the flow channelSpringsNon-rotating vibration suppressionControl theoryMagneto rheological

The invention discloses a gapped magneto-rheological damper with single piston rod out. The magneto-rheological damper comprises a piston, a piston rod, a working cylinder, a compensating air bag and an external electromagnet, the piston comprises a rectangular piston body, two slide damping blocks and a slide damping block position adjuster, two short sides of the vertical section of the piston body are arc-shaped, two long sides of the vertical section of the piston body are axially provided with two symmetrical grooves through the piston body, the two slide damping blocks are mounted in the two grooves respectively and are fixed on the slide damping block position adjuster, the piston rod is provided with a central through hole, one end of the piston rod is fixed with the piston body, the other end of the piston rod extends out from the working cylinder through a sealing device and a sliding bearing which are at one end of the working cylinder, the compensating air bag is fixed at the inner bottom of the working cylinder, the external electromagnet is fixed on a shell of the working cylinder, and the piston is mounted in the working cylinder filled with magneto-rheological fluid.

Owner:谢宁

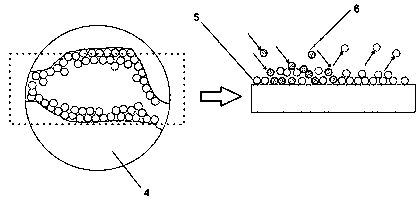

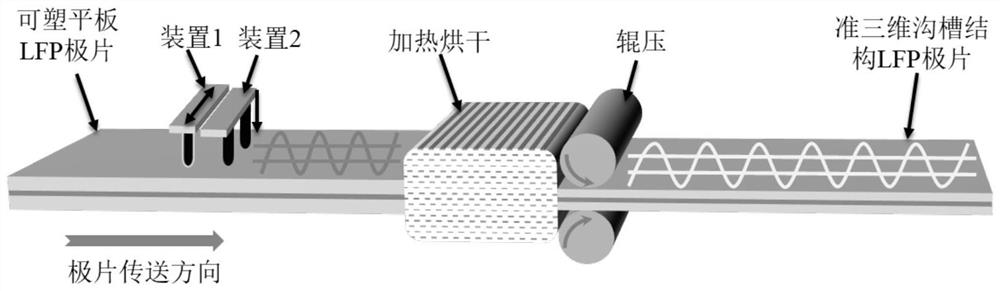

Electrode plate for improving wettability of lithium battery electrolyte and preparation method of electrode plate

PendingCN114203970AIncrease the flow channelIncrease the transmission interface areaElectrode manufacturing processesSecondary cellsElectrolytic agentLithium-ion battery

The invention belongs to the field of lithium ion batteries, and particularly relates to an electrode plate for improving wettability of a lithium battery electrolyte and a preparation method of the electrode plate. The preparation method comprises the following steps that when the electrode plate is horizontally moved, a groove is carved in the surface of the first face of the electrode plate in a plastic state through a horizontal needle head and a corrugated needle head, the horizontal needle head is fixedly carved to obtain a linear stripe groove, and the corrugated needle head scans and carves back and forth to obtain a corrugated stripe groove; and heating, curing and forming to obtain the first surface groove structure electrode plate. And processing the second surface to obtain a second surface groove structure electrode pole piece, and rolling the electrode pole piece to obtain the groove structure electrode pole piece. The quasi-three-dimensional groove pattern is constructed, an electrolyte flowing channel is increased, the electrolyte transmission interface area is increased, meanwhile, the flowing distance of an electrolyte in the electrode plate is shortened, the interior of the electrode plate can be rapidly and completely infiltrated, and the electrode plate has very high application value.

Owner:HUAZHONG UNIV OF SCI & TECH

Freezing Shimen Uncovering Coal Method Based on Hydraulic Slit

ActiveCN104213921BImprove flow statusImprove breathabilityUnderground miningSurface miningLiquid stateCross cut

Owner:CHINA UNIV OF MINING & TECH

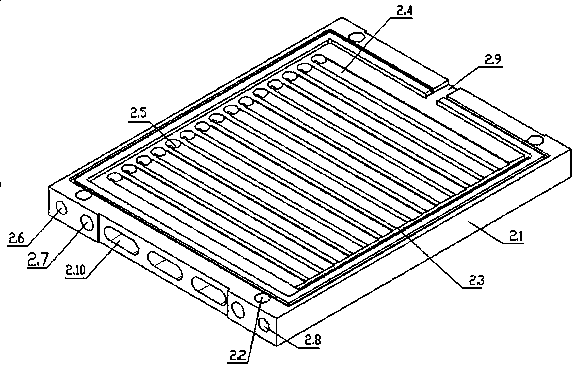

Novel ozone generator module unit

PendingCN108529565AIncreased cooling capacityReduce plumbing connectionsElectrical discharge ozone preparationOzone generatorsGrounding electrodes

The invention discloses a modularized plate type ozone generator water cooling unit and belongs to the field of ozone generator equipment. The modularized plate type ozone generator water cooling unitcomprises heat-conducting plates, a ground electrode, ceramic dielectric bodies and bolts, wherein the ceramic dielectric bodies are fixed on the ground electrode, and the bolts compress the heat-conducting plates and the ground electrode. The modularized plate type ozone generator water cooling unit has the advantages that the heat-conducting plates are assembled to two sides of the ground electrode, so that the ozone discharge area proportion of each water cooling unit is increased greatly, the flow of cooling water channels is increased at the same time by thickening the ground electrode,and accordingly ozone concentration and ozone quantity are increased greatly.

Owner:JIANGSU WATER ENVIRONMENTAL PROTECTION

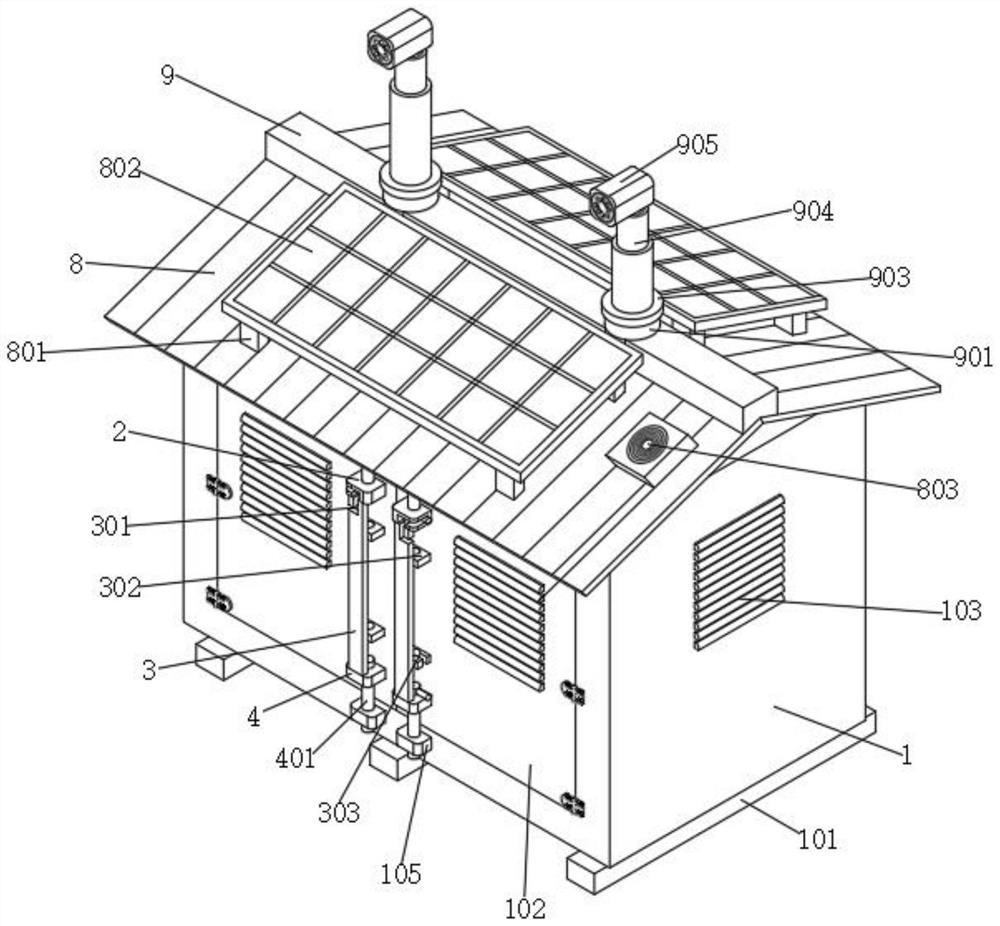

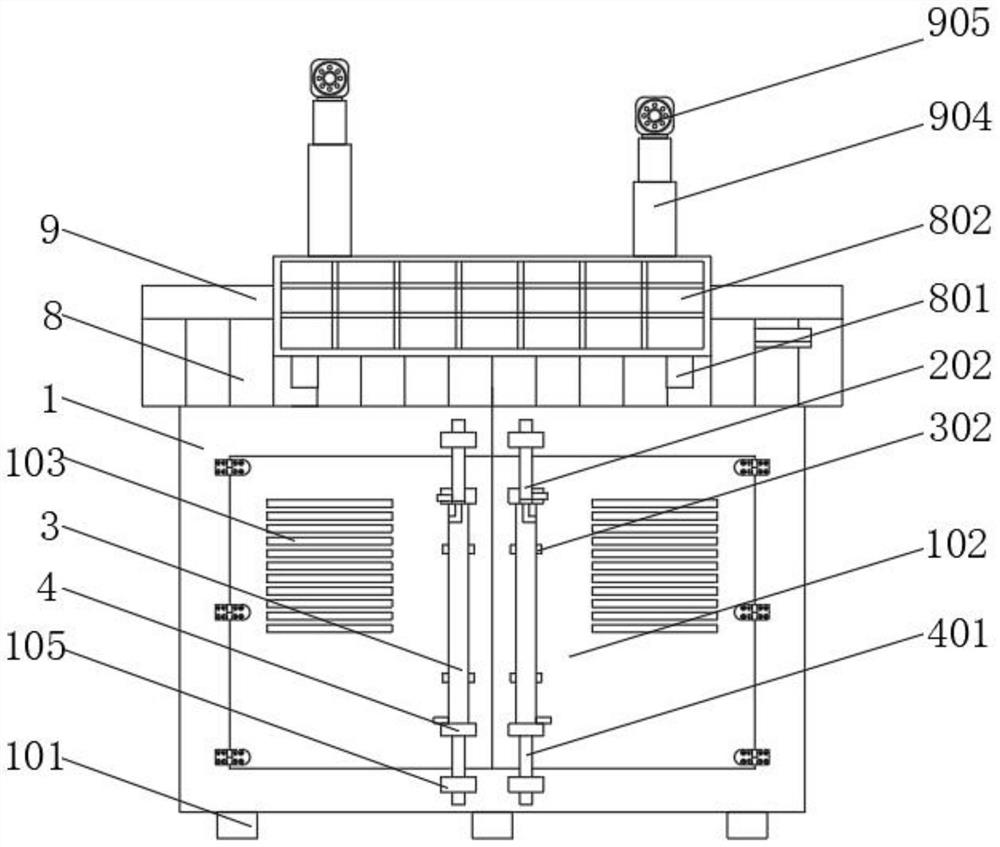

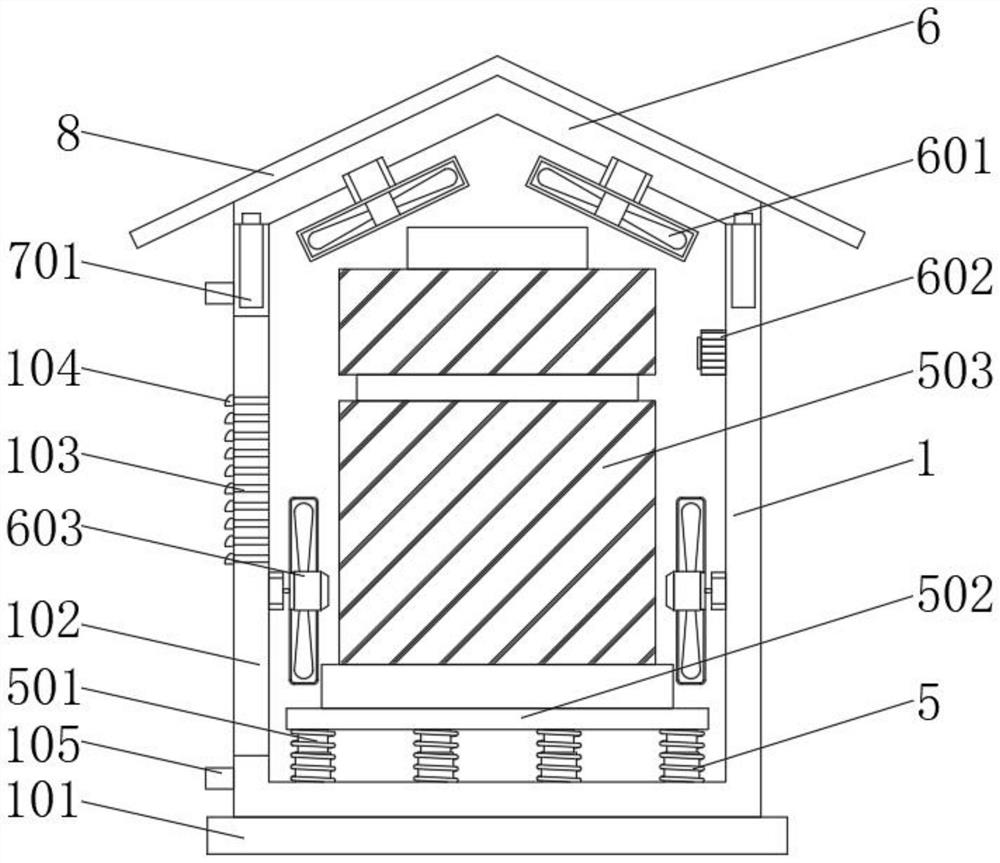

Box-type substation with remote monitoring function

InactiveCN113451889AThe height difference increases or decreasesReduce height differenceBatteries circuit arrangementsSubstation/switching arrangement cooling/ventilationSurveillance cameraStructural engineering

The invention discloses a box-type substation with a remote monitoring function, and the substation comprises a frame body, a fixed block and a pull rod; a plurality of groups of telescopic springs are uniformly mounted on the bottom wall of the frame body, a top cover is mounted at the top of the frame body, an annular embedding groove is formed in the top of the frame body, and a rain baffle is mounted at the top of the top cover; a ridge is installed at the top of the rain baffle, two sets of groove holes arranged side by side are formed in the top of the ridge, and cylinders are installed on the bottom walls of the groove holes. The two groups of monitoring cameras are arranged in a high-low manner, so high-low monitoring can be realized, and far and near area monitoring is facilitated; moreover, the two groups of monitoring cameras can perform rotary monitoring, so the monitoring range is increased; the internal temperature condition of the frame body can be monitored in real time through a temperature sensor, and when the internal temperature exceeds a set value, a channel can be extended to increase the heat dissipation efficiency; when the door plate in the device is closed, the door plate can be reinforced by adopting a top rod and an insertion rod, so the door plate is prevented from being influenced by larger wind power.

Owner:NANTONG XINGYU ELECTRICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com