Hydraulic flushing and presplit blasting combined permeability-increasing extraction system in crossing holes

A technology of hydraulic punching and pre-splitting blasting, which is applied in the direction of earth drilling, mining fluid, mining equipment, etc., which can solve the problems of large amount of drilling construction, small effective range of influence, and complicated construction procedures, so as to reduce blank areas , improve air permeability and reduce blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

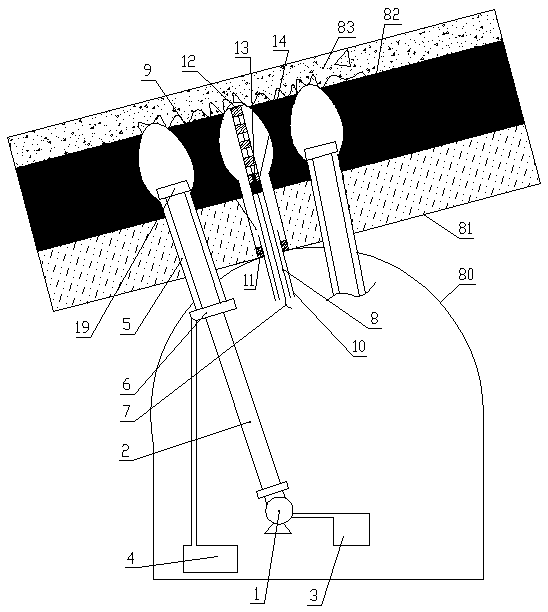

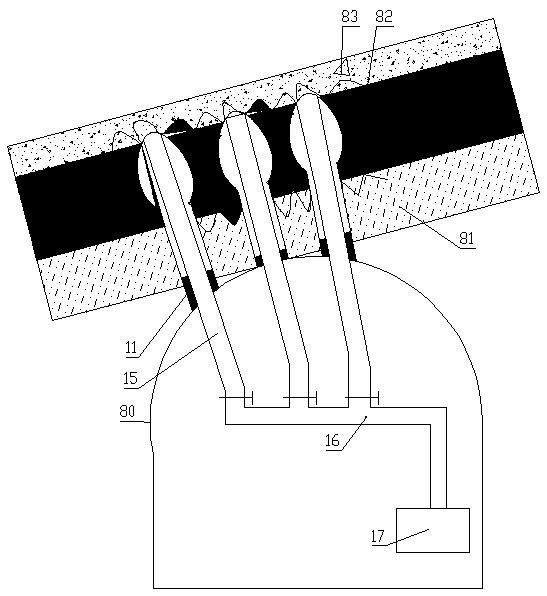

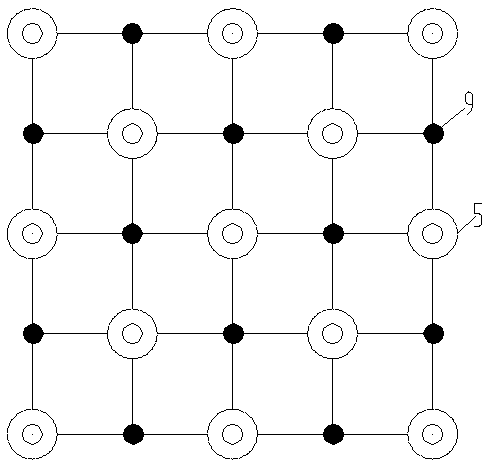

[0021] Such as Figure 1-5 As shown, the hydraulic punching and pre-splitting blasting combined anti-reflection drainage system in the interlayer drilling of the present invention includes a hydraulic punching device, a pre-splitting blasting device and a gas drainage device; the top of the drainage lane 80 is from bottom to top The coal seam floor 81, the coal reservoir 82 and the coal seam roof 83 are successively, and some blasting boreholes 9 and punching boreholes 5 are alternately arranged on the coal seam floor 81; the distance between the blasting boreholes 9 and the adjacent punching boreholes 5 is 3-6m, the working end of the hydraulic punching device extends into the punching hole 5, and the working end of the pre-splitting blasting device extends into the blasting hole 9; after the punching hole 5 is punched and the blasting hole 9 After blasting, the extraction end of the gas extraction device extends into the punching hole 5 and the blasting hole 9;

[0022] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com