Fracturing method capable of improving sand-carrying performance of fracturing liquid

A fracturing fluid and fracturing technology, applied in the field of hydraulic fracturing, can solve the problems of not achieving the effect of increasing production, difficult to accurately control the amount of fiber, laborious and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

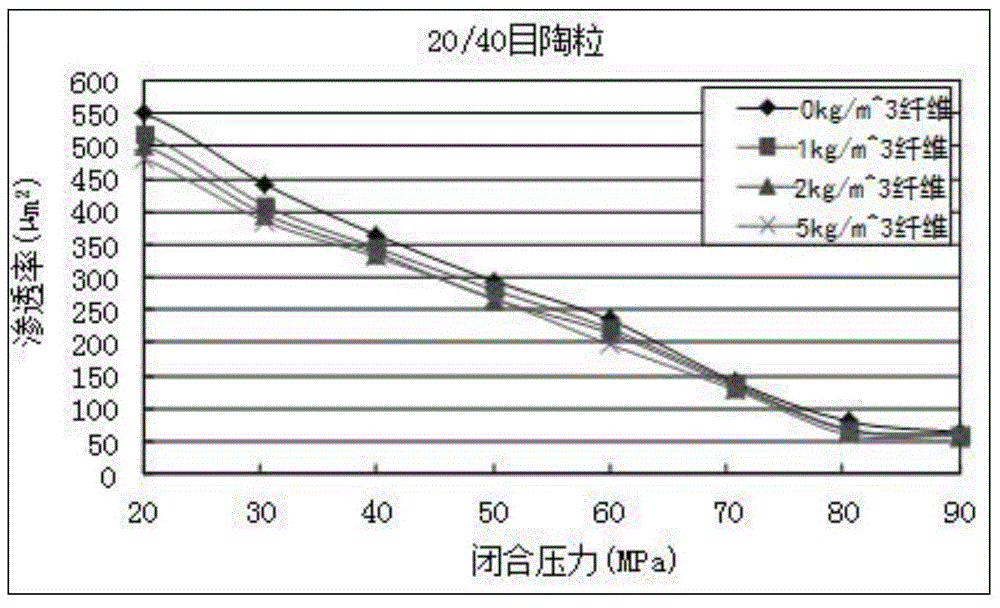

[0009] A fracturing method for improving the sand-carrying performance of fracturing fluid, comprising the following steps:

[0010] (1) pumping the front fluid into the formation to form a crack in the formation, the width of the crack is 0.1-1.0cm, and the length of the single-wing slit of the crack is 10-300m;

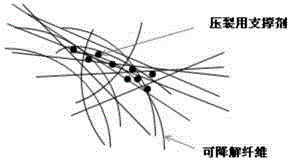

[0011] (2) Disperse the degradable fiber through the dispersing device, mix it evenly with the fracturing fluid base liquid, and then pump it to the sand mixer and stir it with the proppant for fracturing to form the sand-carrying fluid; the dispersing device is described in the patent CN102536188B A fiber conveying device used in the fiber-assisted fracturing process of oil and gas wells;

[0012] (3) The fracture formed by pumping the sand-carrying fluid into the formation: used to support the geometry of the fracture.

[0013] Preferably according to the present invention, the degradable fibers are polymer fibers.

[0014] Preferably according to the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com