Patents

Literature

170results about How to "Reduce sedimentation velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

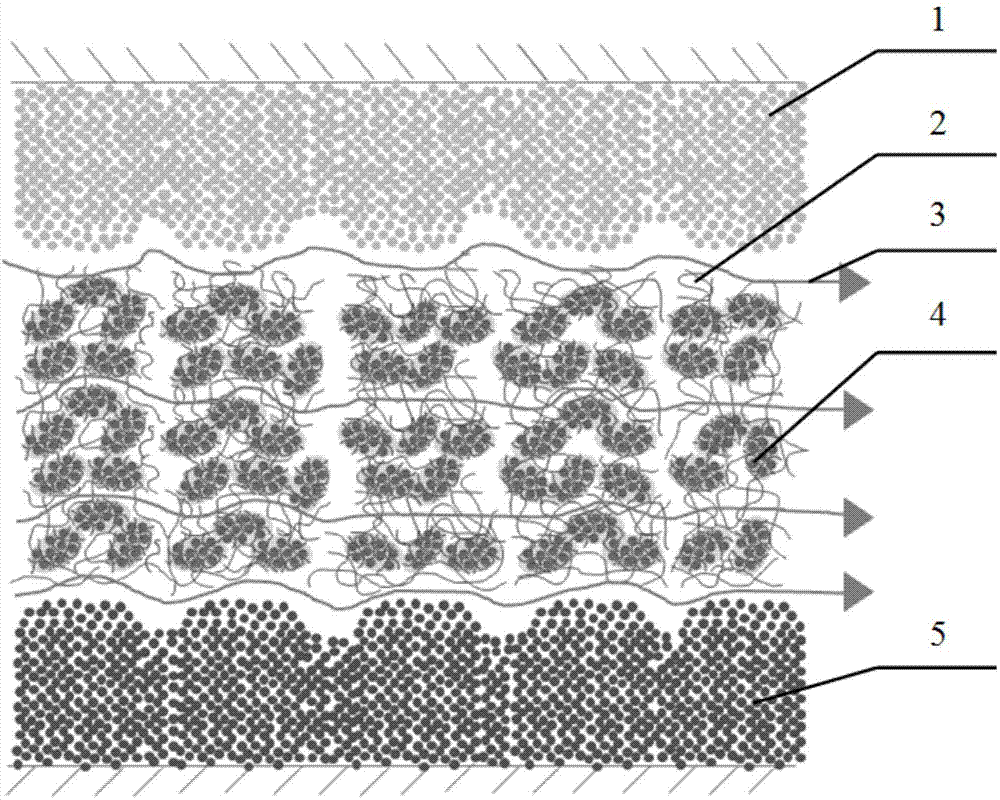

Fracturing method capable of improving sand-carrying performance of fracturing liquid

ActiveCN104405360AReduce sedimentation velocityImprove sand carrying capacityFluid removalFiberFracturing fluid

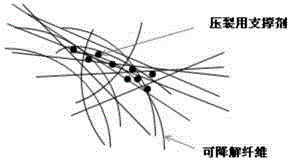

The invention provides a fracturing method capable of improving the sand-carrying performance of fracturing liquid. The method comprises the following steps: dispersing degradable fibers by virtue of a dispersion device, and uniformly dissolving the dispersed degradable fibers in a fracturing liquid base solution; pumping into a fracturing blender truck, and mixing with a propping agent for fracturing so as to form sand-carrying fluid; then pumping the sand-carrying fluid dissolved with the fibers into a strata so as to support a formed fracture geometry. When the degradable fibers added into the fracturing liquid are uniformly dispersed in the fracturing liquid, the fibers and a guanidine gum chain with a network structure form a tangled structure, so that the strength of the cross-linked network structure is enhanced, the sedimentation rate of the propping agent is reduced, the sand-carrying capacity of the fracturing liquid is improved, the propping agent is uniformly distributed in a whole crack, a supporting effect is fully realized, the crack is prevented from being closed and thus the fracturing period of validity is increased; furthermore, the added fibers are capable of effectively preventing the propping agent from flowing back and preventing formation sand flow; an oil gas flow passage is additionally increased, so that the fracturing yield-increasing effect is finally realized.

Owner:中石化胜利油田分公司采油工艺研究院 +1

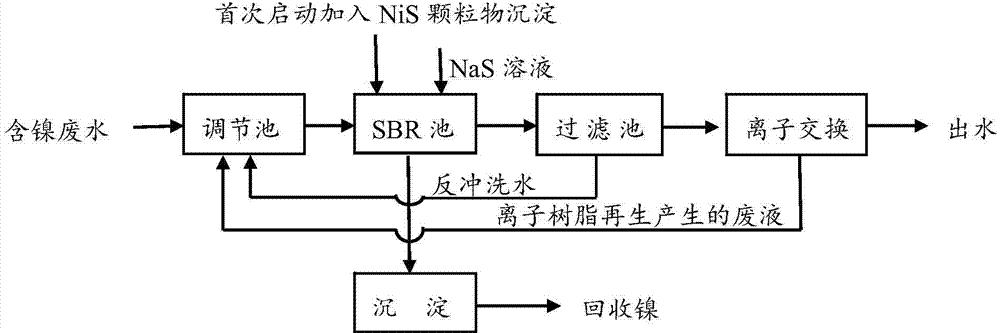

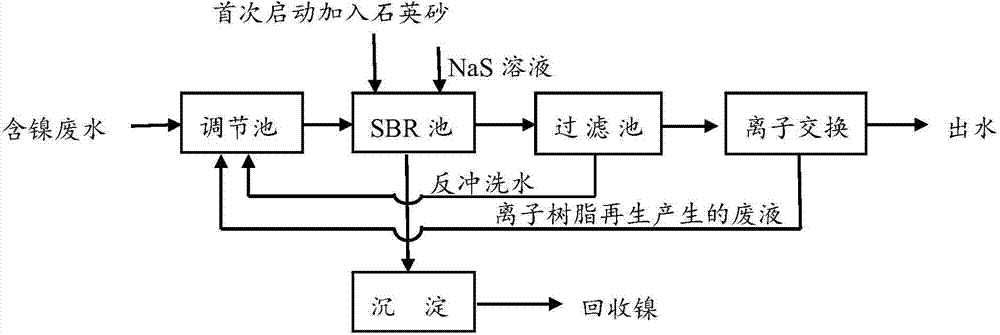

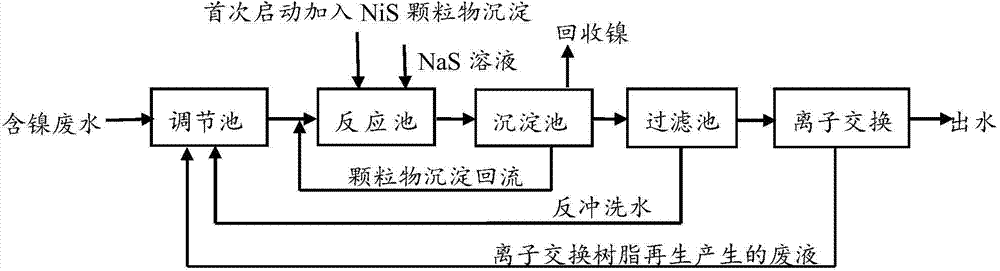

Treatment method of heavy metal wastewater

InactiveCN104261526ATo achieve the purpose of purifying wastewaterLarge particle sizeWater treatment compoundsWater contaminantsParticulatesFiltration

The invention provides a treatment method of heavy metal wastewater, and particularly relates to a method for treating heavy metal wastewater by virtue of a precipitation method. The method comprises the following steps: adding sodium sulfide in a heavy metal wastewater treatment process, reacting sulfur ions with heavy metal ions in the wastewater to generate particulate matters, further adding sulfide precipitates of heavy metal, stirring, standing, and accelerating the sedimentation of micro particulate matters and other substances by using generated particulate matter precipitates; further preferably adding quartz sand, and accelerating the rapid sedimentation of the particulate matters and other substances under the wrapping action of quartz sand; further performing subsequent process treatment including sand filtration and ion exchange on a supernatant liquor obtained after sedimentation to reach the emission standard; and periodically discharging and collecting part of the precipitates, and recycling heavy metals in the precipitates. Because the method provided by the invention is simple in working procedure, low in cost and high in efficiency, the method can be widely applied to the treatment of industrial wastewater particularly the heavy metal wastewater.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

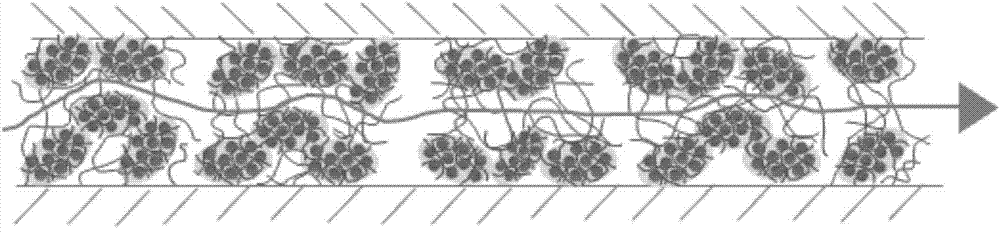

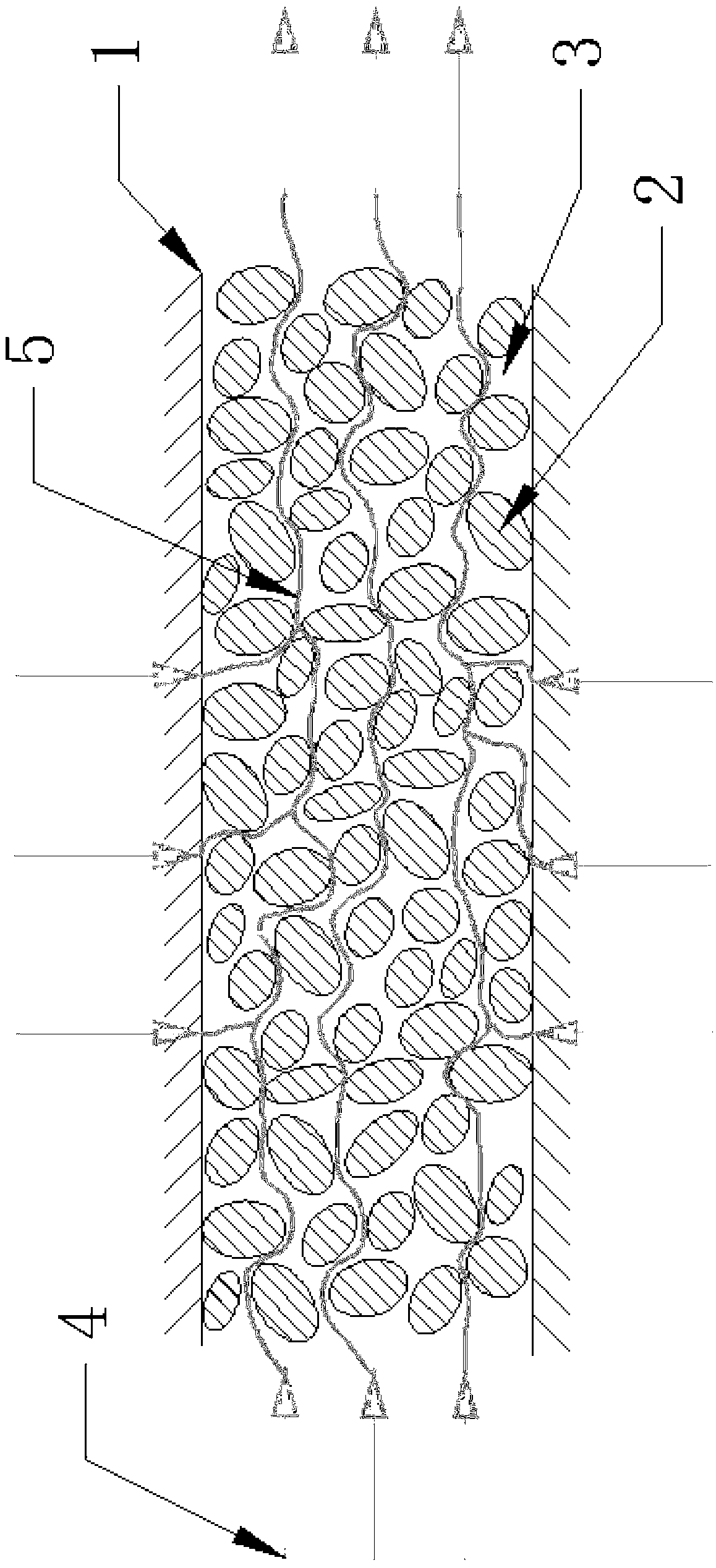

Fracturing technology using propping agent density variation for obtaining large channels

ActiveCN104727801AEasy to closeImprove diversion capacityFluid removalDrilling compositionFiberHigh density

The invention relates to a fracturing technology using propping agent density variation for obtaining large channels. The fracturing technology includes the following steps that propping agent fracturing fluid low in density, intermediate in density and high in density is prepared, and fibers are added into the propping agent fracturing fluid intermediate in density to form propping agent clusters serving as the premise of channel fracturing; at the beginning of fracturing, prepad fluid is pumped into the stratum so that the stratum can form a crack of a certain width and a certain length, and the propping agent fracturing fluid of the three densities is together pumped into the stratum; because no fibers are added into low-density propping agent particles and high-density propping agent particles, the low-density propping agent particles and the high-density propping agent particles can freely float and precipitate at the top and the upper portion of the crack; the propping agent fracturing fluid intermediate in density is injected in a pulse mode, and the channels of a certain size can be formed between the propping agent clusters. The large channels of larger sizes are formed between an intermediate-density propping agent zone and a low-density propping agent zone as well as between the intermediate-density propping agent zone and a high-density propping agent zone.

Owner:RES INST OF PETROLEUM ENG SHENGLI OIL FIELD SINOPEC +1

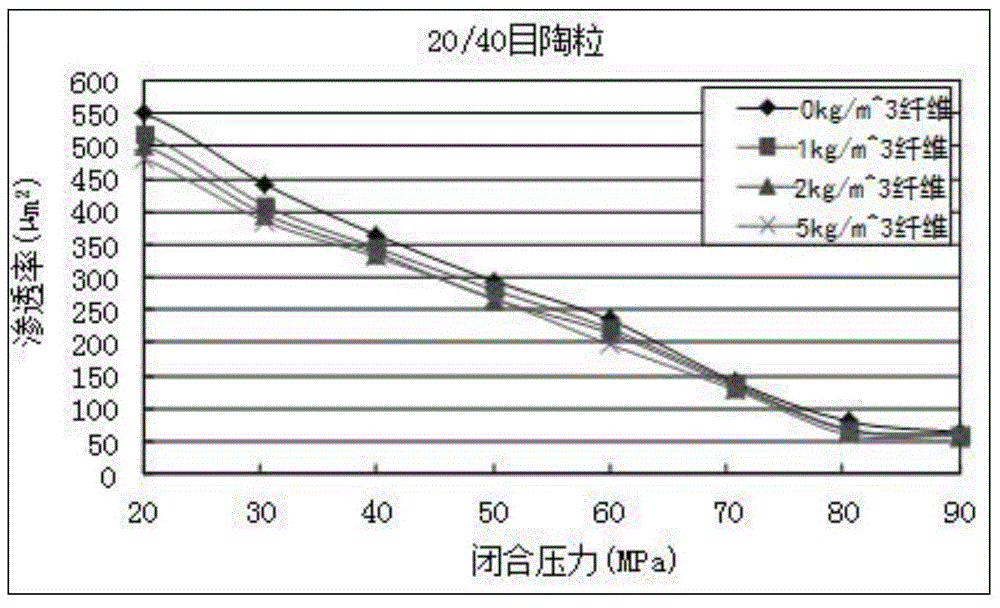

Fracturing technology for implementing ultrahigh flow conductivity

ActiveCN103306659ALow effective concentrationReduce the overall heightFluid removalMaterial PerforationOrder of magnitude

The invention relates to a fracturing technology for implementing the ultrahigh flow conductivity, which comprises the following steps: 1, judging whether geomechanics parameters of a target reservoir is suitable for the fracturing technology disclosed by the invention or not; 2, judging whether completion perforation of a target well is suitable for the fracturing technology disclosed by the invention or not, and if no, changing a perforating scheme of a well bottom; 3, before fracturing, selecting related fracturing materials; 4, carrying out fracturing on the target well by using a unique pumping program of the fracturing technology disclosed by the invention. According to the fracturing technology, proppant struts are formed in a stratum; flow conductivity of a stratum fracture is not improved by a filling layer of a proppant, but oil gas passes through by passages between the proppant struts; the flow conductivity is obviously improved by the open flowing passages; the flow conductivity of an existing conventional fracturing technology is not more than 200mum<2>*cm generally, but the flow conductivity of the fracturing technology for implementing the ultrahigh flow conductivity, which is disclosed by the invention, is higher than that of the conventional fracturing technology by 1 to 3 orders of magnitude; the fracturing technology reduces a pressure drop in the fracture, is helpful for improving drainage capacity and increases the effective fracture half-length and the production increase volume of the reservoir so as to improve yield.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

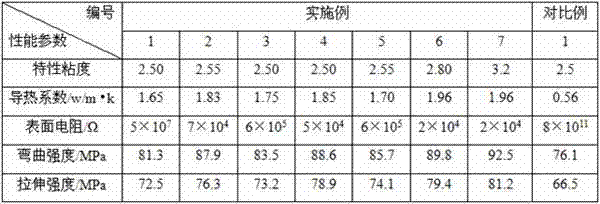

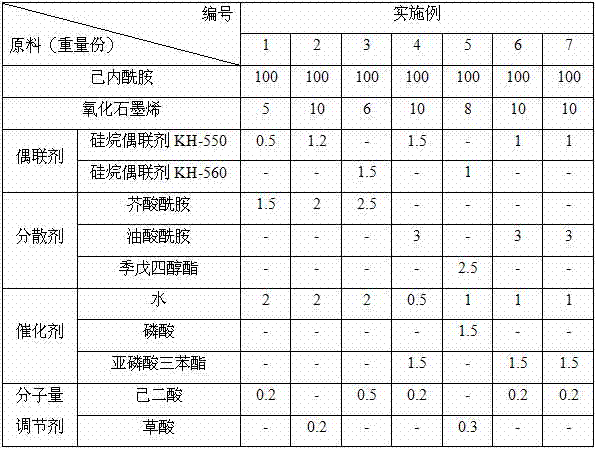

High-content graphene modified nylon 6 master batch as well as preparation method and application thereof

ActiveCN107459642AControl dispersion speedDispersion speed can be controlledElectroconductive/antistatic filament manufactureConjugated synthetic polymer artificial filamentsFiberFlexural strength

The invention provides a high-content graphene modified nylon 6 master batch as well as a preparation method and application thereof. The master batch is prepared from caprolactam, graphene oxide, coupling agents, dispersing agents, catalysts and molecular weight modifiers. The method comprises the following steps of (1) mixing the graphene oxide and the coupling agents; performing heating and ultrasonic agitation; then, adding dispersing agents; performing heat stirring; then, adding catalysts; performing heating stirring to obtain graphene slurry; (2) heating and stirring the caprolactam and the molecular weight modifiers; adding the graphene slurry; performing ring-opening reaction; performing vacuum pumping, polymerization, still standing, temperature reduction nitrogen filling, discharging, cooling pelletizing to obtain a semi-finished product; (3) performing hot water extraction and drying to obtain a finished product. The master batch has the advantages of high intrinsic viscosity and high graphene content; the prepared composite material has high heat conduction coefficient, low surface resistance, high bending intensity and high stretch intensity. The method provided by the invention has the advantages that the process is simple; the cost is low; the mass production can be realized.

Owner:长沙五犇新材料科技有限公司

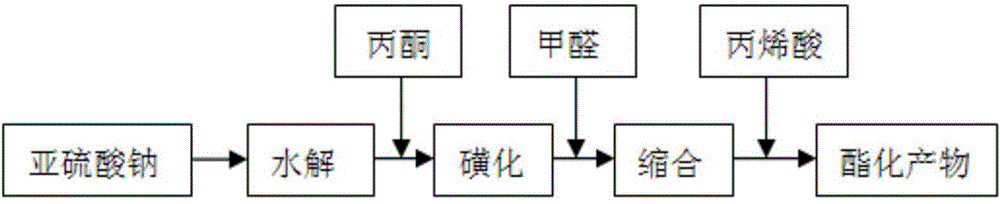

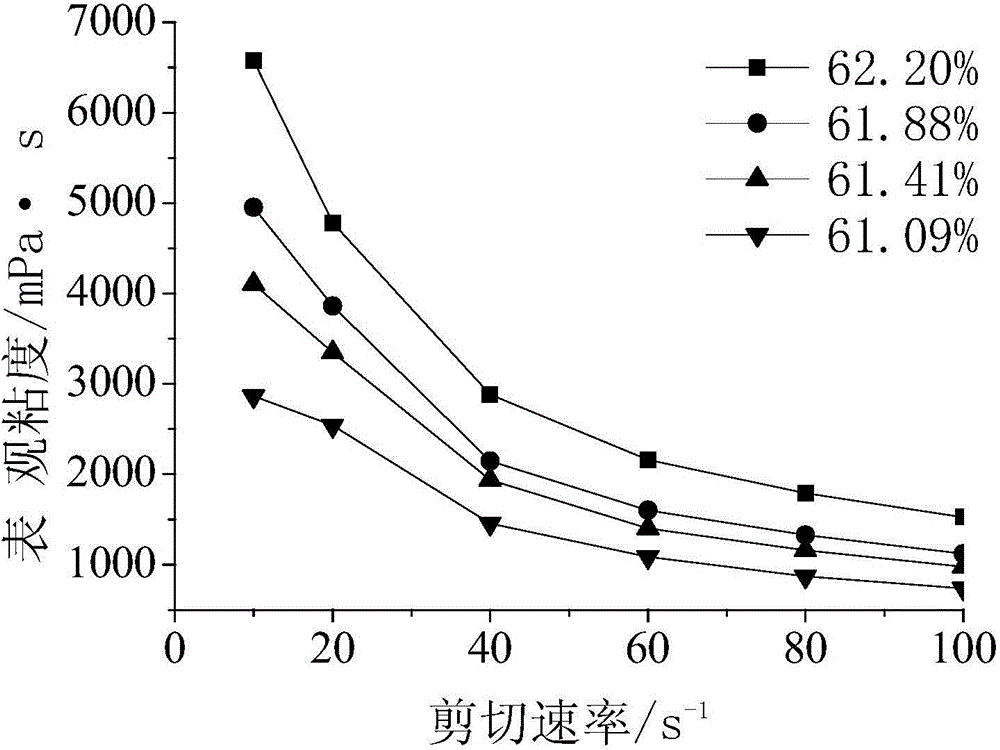

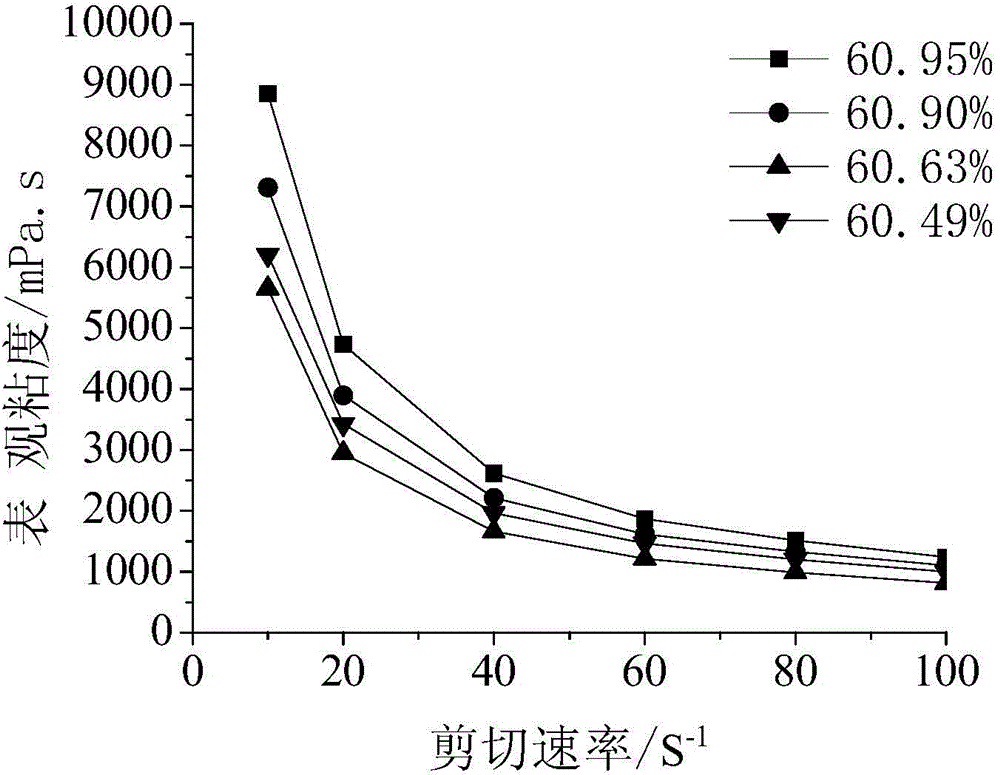

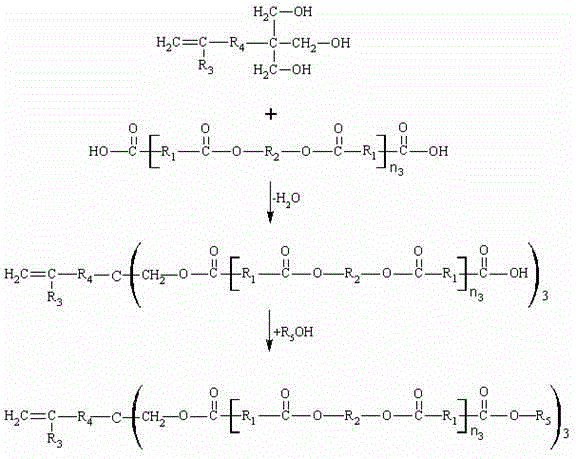

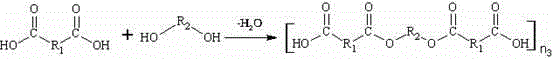

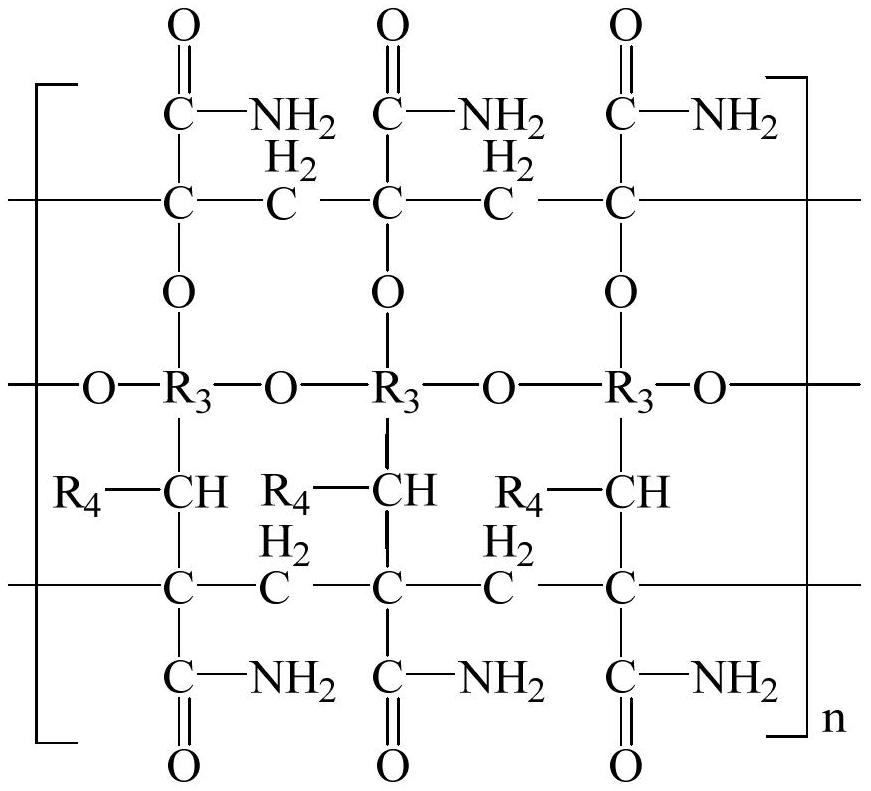

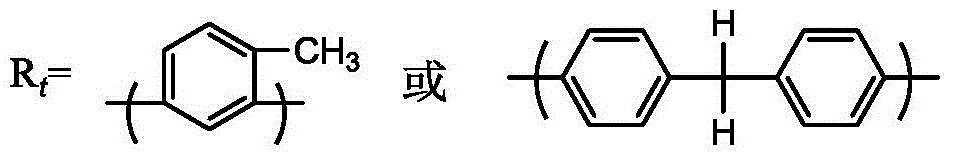

Coal water slurry dispersant and preparation method thereof

ActiveCN104448163AImprove stabilityImprove bindingLiquid carbonaceous fuelsPotassium persulfateDistillation

The invention discloses a coal water slurry dispersant and a preparation method thereof. The preparation method comprises the following steps: (1) dissolving sodium sulfite in water, adding acetone, reacting for 20-40 minutes at 30-40 DEG C, heating to 45-55 DEG C, adding formaldehyde, and reacting for 20-40 minutes at 80-100 DEG C to obtain red liquid; (2) performing reduced pressure distillation on the red liquid, adding p-methylbenzene sulfonic acid and acrylic acid, and reacting for 4-8 hours at 80-100 DEG C to obtain a mixed solution; (3) mixing the mixed solution with acrylamide and potassium persulfate, and reacting for 2.5-4 hours at 80-100 DEG C to obtain a reaction solution; and (4) after the reaction solution is cooled, adjusting the pH value to 6.5-7.5, and centrifuging, depositing and drying to obtain the coal water slurry dispersant. The coal water slurry dispersant has better binding capacity with particles and can achieve a better dispersion viscosity reduction effect, and the structure of the coal water slurry dispersant has better matching property with that of a type of coal.

Owner:CHINA UNIV OF MINING & TECH

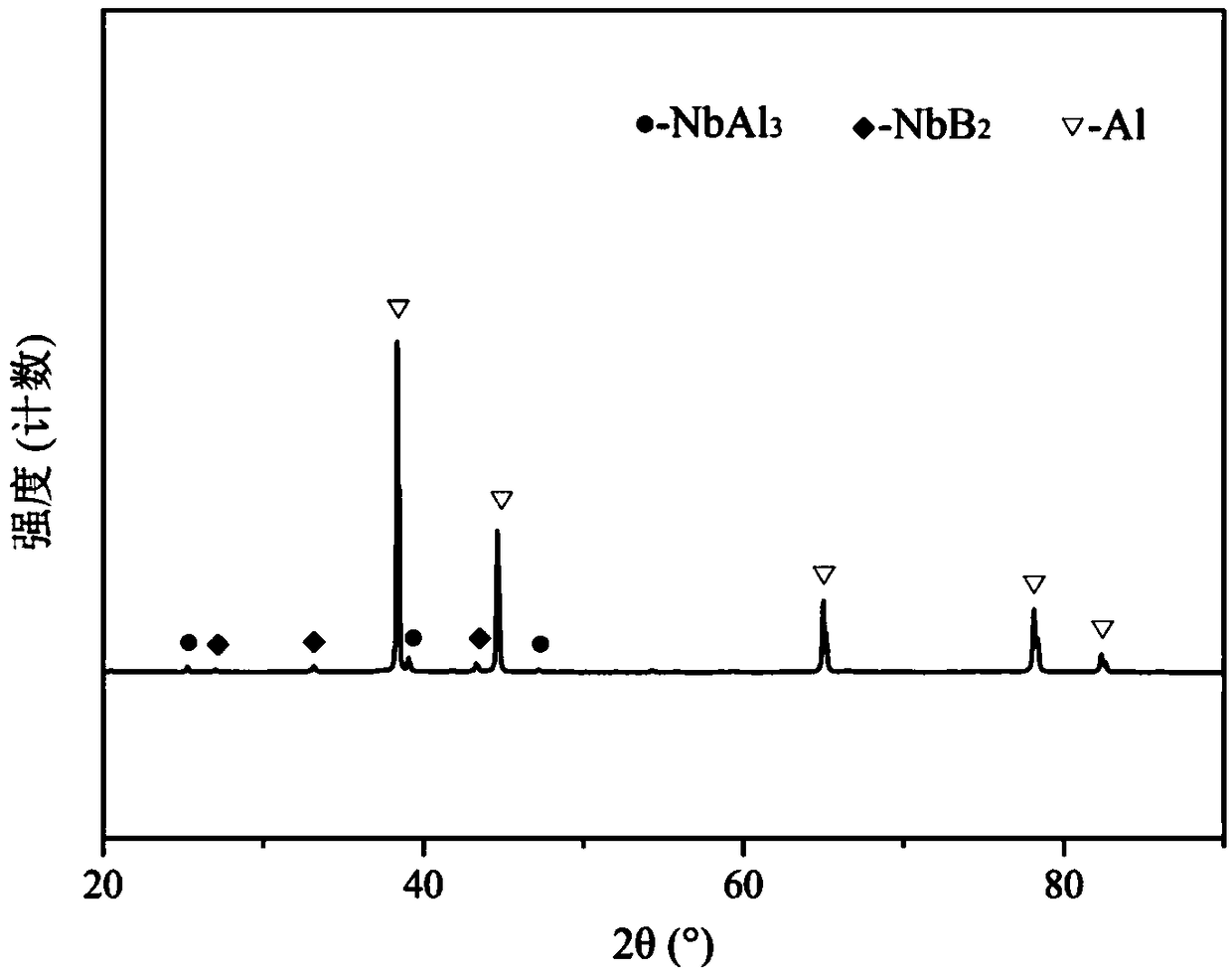

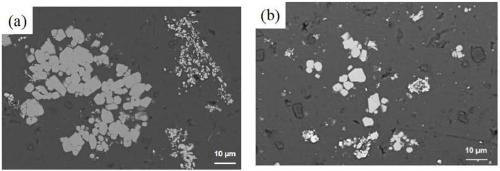

Preparation method of Al-Nb-B alloy rod for grain refinement

The invention provides a preparation method of an Al-Nb-B alloy rod for grain refinement, and belongs to the field of grain refiner material preparation. The alloy consists of the following componentsby the mass percentage: 2.5-3.5 wt.% of Nb, 0.2-0.5 wt.% of B and the balance Al. The Al-Nb-B alloy rod is characterized by being formed by hot extrusion of an Al-Nb-B alloy ingot; the preparation method mainly includes the following steps: preparing materials, preparing an Al-Nb-B alloy liquid, moulding the Al-Nb-B alloy liquid by casting, preheating the Al-Nb-B alloy ingot, and carrying out hotextrusion of the Al-Nb-B alloy ingot into the alloy rod. The problem that NbAl3 and NbB2 particles are easy to agglomerate in a traditional direct casting moulding process is overcome because the Al-Nb-B grain refiner is prepared by the hot extrusion method. The NbAl3 and NbB2 particles in the prepared Al-Nb-B alloy rod are uniformly distributed, and stronger anti-recession performance and higherrefining efficiency are achieved.

Owner:SHANGHAI UNIV

Asphalt pavement net-shaped crack treatment regeneration sealing layer material and preparation method thereof

The invention relates to an asphalt pavement net-shaped crack treatment regeneration sealing layer material and a preparation method thereof. The asphalt pavement net-shaped crack treatment regeneration sealing layer material is characterized by being composed of the raw materials in parts by weight: 70-100 parts of a composite emulsion and 200-400 parts of a fine aggregate; the composite emulsion is prepared by mixing the raw materials in pars by weight: 20-50 parts of an inorganic solution and 200-600 parts of an organic emulsion; the inorganic solution is an acidic silicon solution or a neutral silicon solution, the silica content is 10-30% (mass), the pH value is 3-7, the sodium oxide content is less than 0.5% (mass), and the average particle size is 10-20 nm; the organic emulsion comprises the raw materials by weight: 100 parts of a regeneration agent emulsion and 100-500 parts of modified emulsified asphalt. The asphalt pavement net-shaped crack treatment regeneration sealing layer material has strong permeability, plays good seam-sealing and waterproof roles in cracks, and has remarkable regeneration and reduction improvement effects on aged asphalt.

Owner:上海乐辛新材料科技有限公司

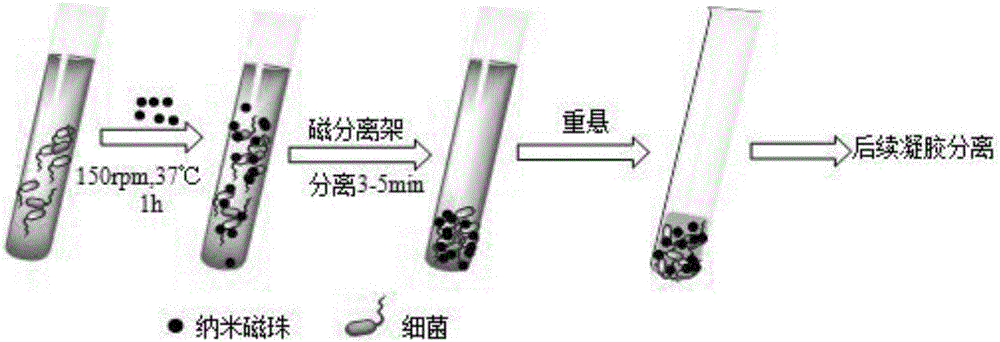

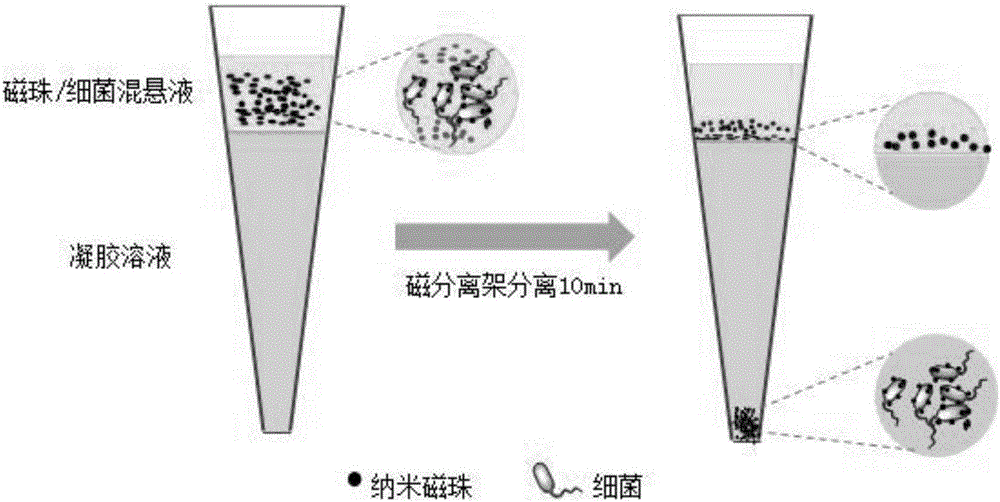

Method for quickly enriching, separating and detecting bacteria

ActiveCN106191199AAvoid dissociationAchieve non-specific adsorptionMicrobiological testing/measurementMicroorganism based processesPhosphateMagnetic bead

The invention discloses a method for quickly enriching, separating and detecting bacteria. The method comprises the following steps: (1) mixing a sample to be detected with magnetic beads, oscillation incubation, carrying out magnetic separation, and suspending the magnetic beads subjected to magnetic separation in a PBS (phosphate buffer solution) to obtain residual magnetic beads and a bacteria-adsorbed magnetic bead suspension; (2) adding prepared gel into a separator tube, putting the suspension obtained in the step (1) on the gel, and carrying out magnetic separation; and (3) after finishing the magnetic separation, visually inspecting the black precipitate on the bottom of the separator tube and carrying out qualitative analysis on the result, or establishing standard samples with different concentrations to obtain the corresponding relationship between the black precipitate quantity and standard sample concentration, comparing the quantity of black precipitate obtained by separating the sample to be detected with the corresponding relationship, and judging the quantity range of bacteria contained in the sample to be detected. The method can implement quick separation on bacteria in a complex sample, and can perform quick recognition and semiquantitative judgment on the sample with the bacteria content of 10<2> CFU / mL or above.

Owner:CHONGQING UNIV

Novel green grouting superfine cement

InactiveCN102838332AConducive to turning waste into treasureReduce pollutionAluminateMicrofine cement

The invention discloses novel green grouting superfine cement. The superfine cement comprises the following minerals of superfine silicate cement, superfine aluminate cement, superfine mineral powder, superfine coal ash, a swelling agent, a water reducing agent, a retarding agent and a diluting agent. The temperature range of the superfine cement when in use is 5-60 DEG C; the compression strength of cement stone is more than 20 MPa within 24 hours, the compression strength within 3 days is more than 42 MPa, the compression strength within 7 days is more than 55 MPa, and the compression strength within 28 days is more than 65 MPa; the initial setting time of the cement is 23-208min, the final setting time is 45-223min, time is adjustable and controllable, and the cement is high in penetrating power and can penetrate through a narrow gap with a width of 15 mum; a cement slurry body with controllable setting time and controllable strength can be formed on the premise of a water-to-cement ratio ranging from (1 to 1) to (3 to 1); and the superfine cement can be applied to seepage prevention, leaking stoppage and reinforcement in excavation of projects such as water dams, mine roadways, tunnels and the like, and is a novel green blocking material.

Owner:SHANDONG JIANZHU UNIV

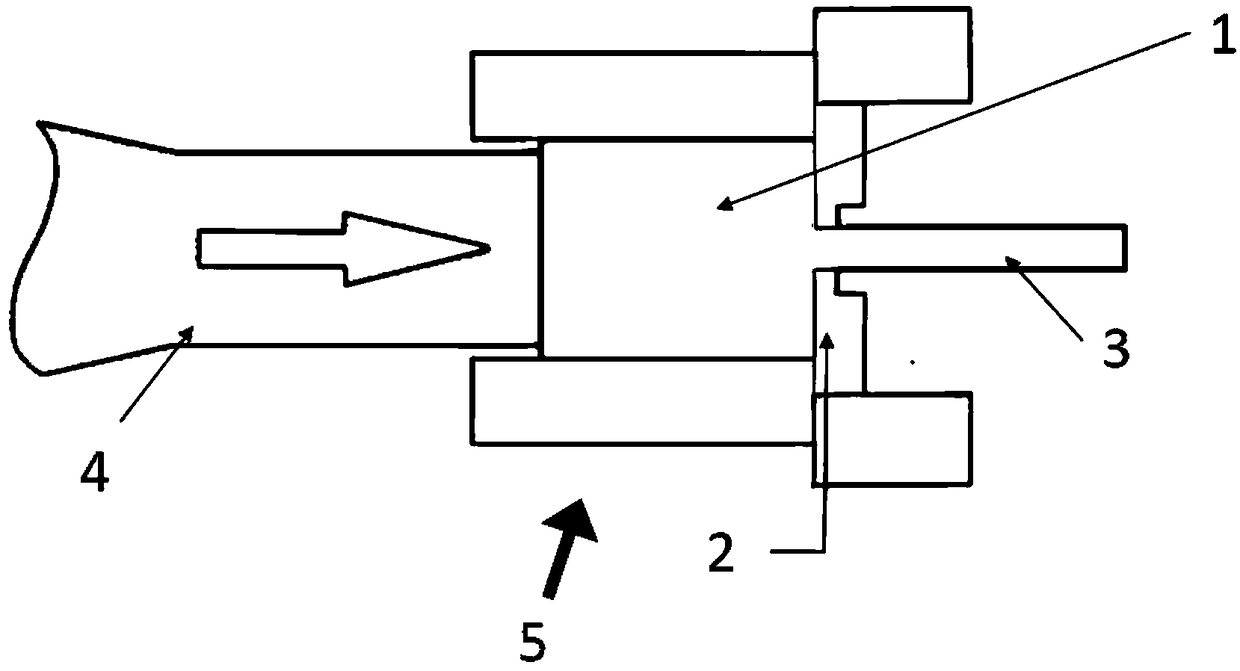

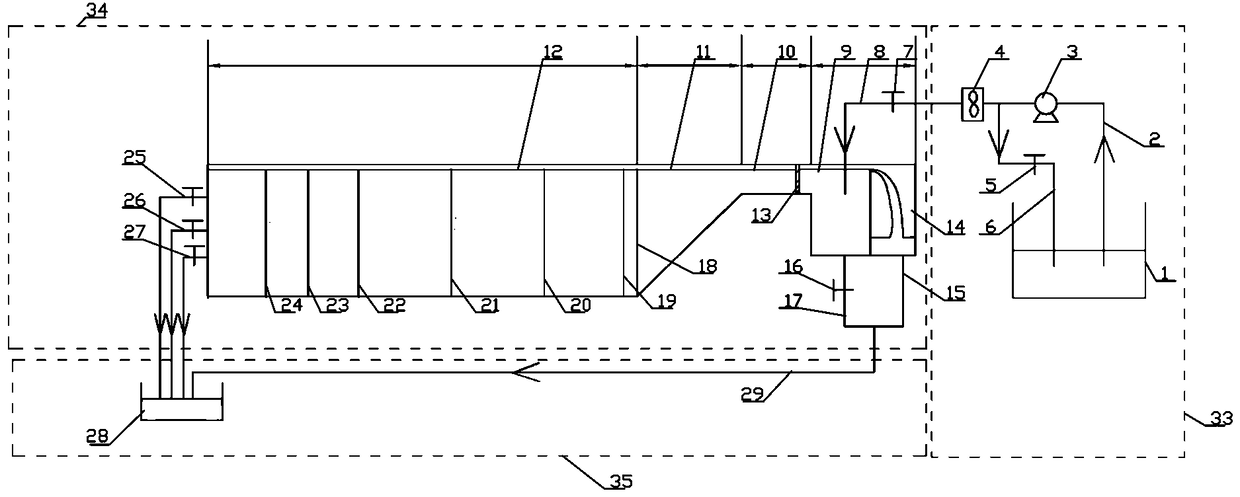

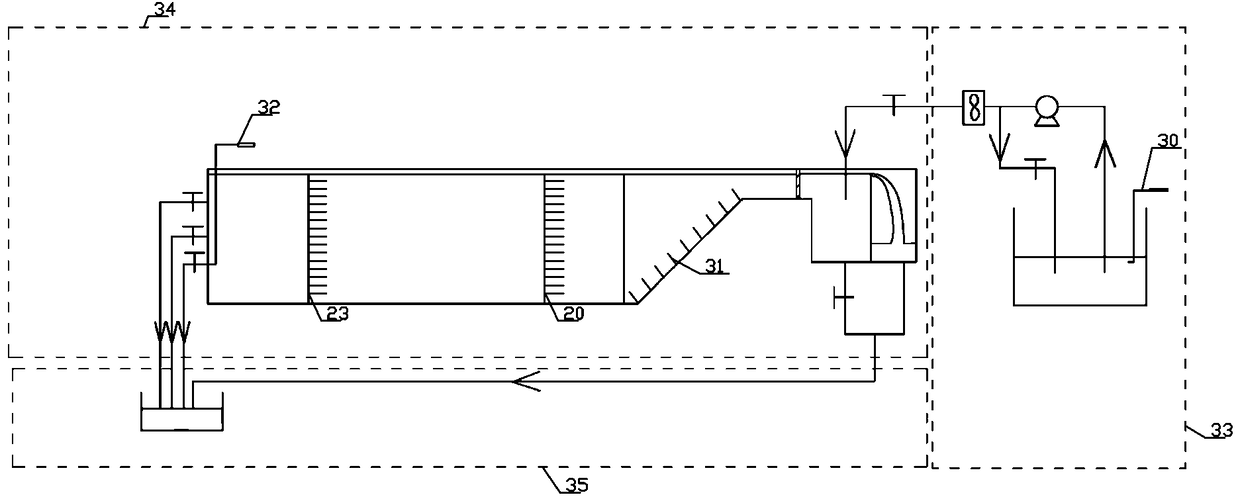

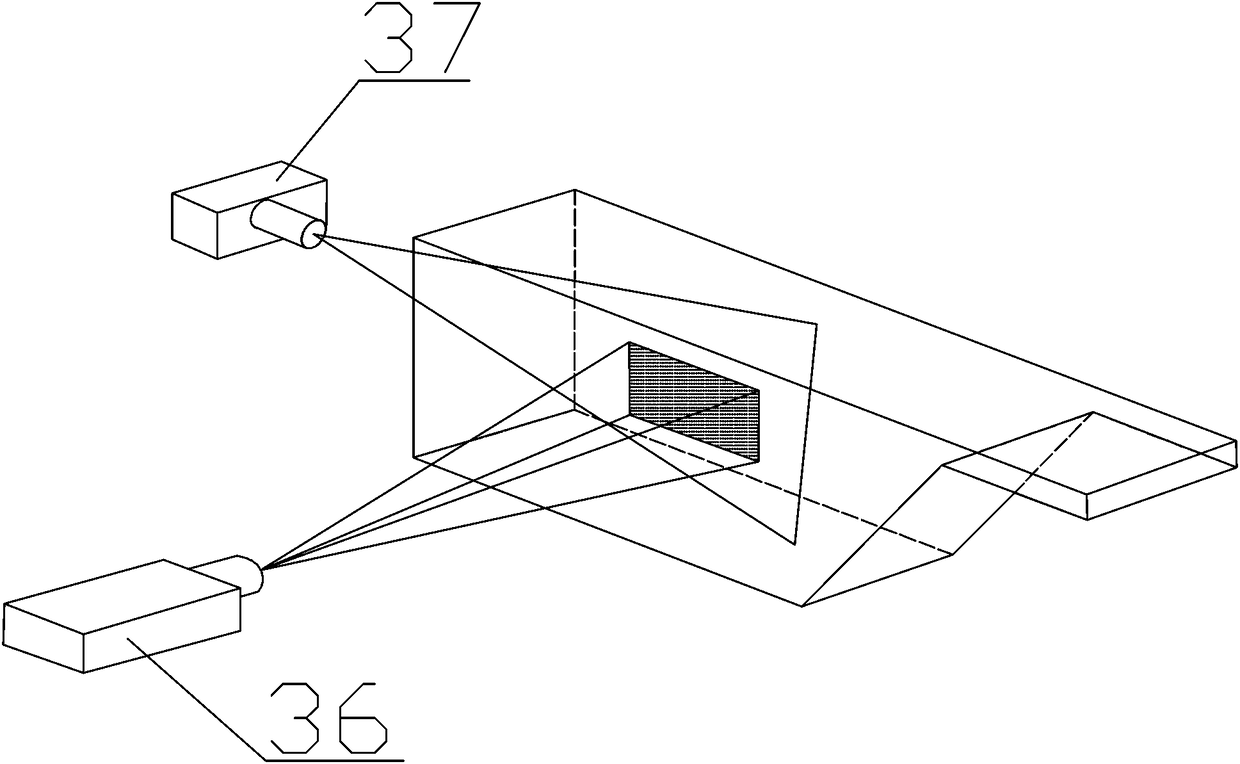

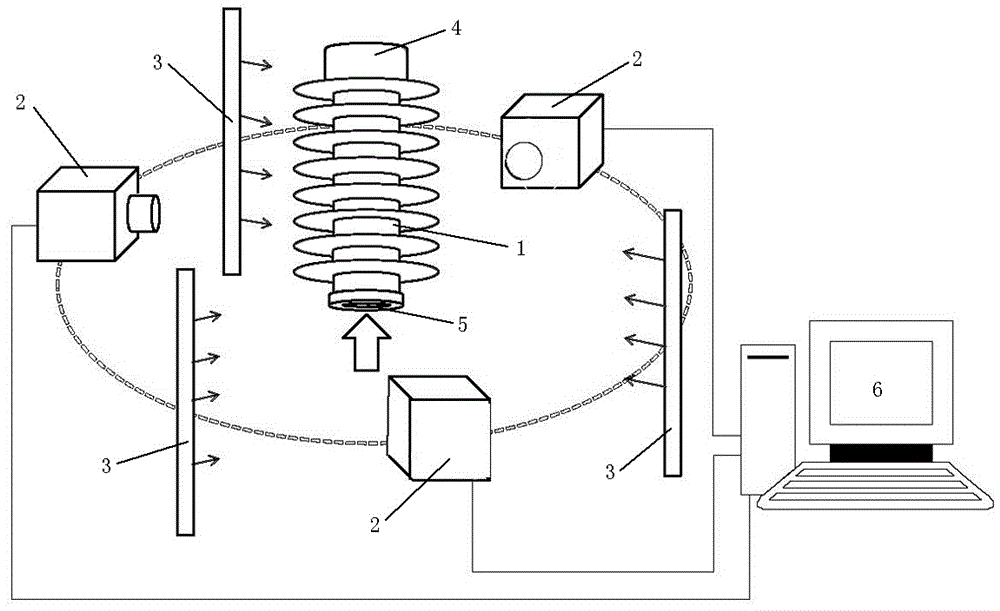

Physical model for affecting layered reservoir water temperature structure by silt carrying flow and experimental method

ActiveCN108286237AEasy to controlMix wellClimate change adaptationHydraulic modelsPhysical modelWater reservoir

The invention relates to a physical model for affecting a layered reservoir water temperature structure by silt carrying flow and an experimental method, and belongs to the technical field of water environment research in water resource and hydropower engineering. According to the method, the influence on the vertical water temperature of a reservoir by the silt carrying flow can be simulated in alaboratory by controlling the inflow sand content, water temperature and initial vertical water temperature distribution of environmental water. A PIV two-dimensional flow field measuring device is adopted to effectively capture the silt carrying flow, density current forward flow field distribution is formed, and important flow field verifying data are provided for model verification of numerical simulation. Quartz sand is adopted to simulate suspended sediments in the silt carrying flow in testing, and the phenomenon that the silt carrying flow forms bottom density currents and inter-layerdensity currents to influence the water temperature structure is successfully simulated. An electrical heating bar is adopted in a heating device for heating at a water temperature thermocline position, the heating speed is higher compared with that of an existing lamplight heating mode, the thermocline position can be controlled conveniently, and the initial temperature field can be controlled more accurately.

Owner:CHINA THREE GORGES CORPORATION +2

Lignin modified asphalt composition with steady heat storage and preparation method thereof

The invention discloses a lignin modified asphalt composition and a preparation method thereof. The asphalt composition comprises 65 to 98 percent of residue oil and / or asphalt, 1 to 20 percent of lignin, and 0.5 to 15.0 percent of stabilizer. The method utilizes glycol ether and / or phenol with a boiling point over 110 DEG C as the stabilizer, adopts an emulsifier further to disperse the lignin so as to promote the lignin to be uniformly and steadily dispersed into the asphalt, can obviously reduce the settling velocity of the lignin in the asphalt, and improve the stability of lignin modified asphalt, thereby contributing to the mass production of the lignin modified asphalt.

Owner:CHINA PETROLEUM & CHEM CORP +1

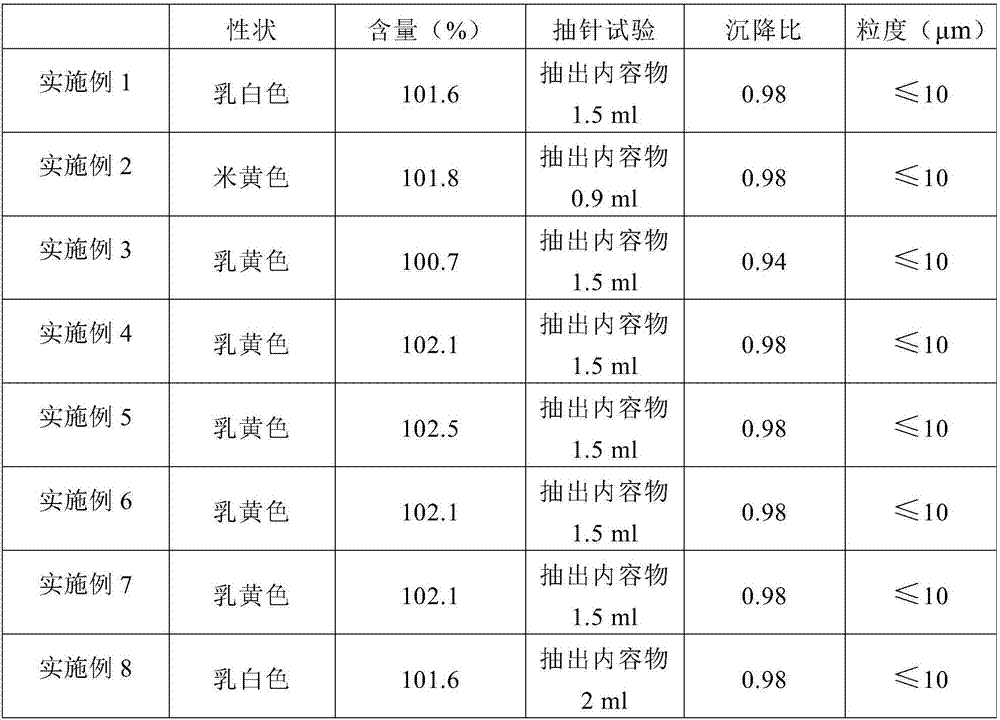

A compound suspension of molluscicidal drug niclosamide ethanolamine salt and its preparation method

ActiveCN101006778AGrind evenlyReduce interfacial tensionBiocideMolluscicidesNiclosamideSuspending Agents

The invention discloses a snail control insecticide of compound niclosamide ethanolamine salt suspending agent which comprises the constituents (by weight portion) of niclosamide ethanolamine salt 1-50 parts, methaldehyde 0.01-5 parts, dispersing agent 1-20 parts, wetting agent 0.5-20 parts, and thickening agent 0.05-10 parts, and balancing water. The invention also discloses the process for preparing the suspending agent.

Owner:JIANGSU ESSENCE AGROCHEM

Natural Suspending Agent Including a Synergistic Blend of Xanthan Gum and Konjac Powder for Oral Pharmaceutical Suspensions

ActiveUS20160051684A1Improve stabilityRapid redispersionBiocideDispersion deliveryFlocculationPreservative

The present disclosure refers to a synergistic blend of Konjac powder and Xanthan gum that is included, as a natural suspending agent, in oral pharmaceutical suspensions. Oral pharmaceutical suspensions comprising the synergistic blend are aqueous solutions. The synergistic blend, used as a suspension agent to suspend suitable active pharmaceutical ingredients (APIs), improves the stability of oral pharmaceutical suspensions, and helps in the formation of a thermo-reversible gel and shear thinning necessary to keep APIs suspended within oral pharmaceutical suspensions. The synergistic blend of Konjac powder and Xanthan gum has unique anti-flocculation properties, which improve the homogeneity of the oral pharmaceutical suspensions. Additionally, the blend provides a better texture and mouth feel. Oral pharmaceutical suspensions, comprising the synergistic blend, include a vehicle, such as water, as well as different components, such as, for example APIs, preservatives, sweeteners, flavoring agents, and pH regulators or buffers, among others.

Owner:PROFESSIONAL COMPOUNDING CENTS OF AMERICA PCCA

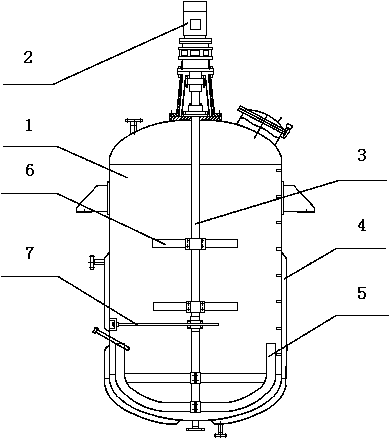

Scraper evaporator

InactiveCN103861305AConcentration effect is goodReduce shakingOrganic chemistryTransportation and packagingConcentration effectEvaporator

The invention discloses a scraper evaporator, and relates to a concentrating and solvent recovering apparatus. The apparatus comprises a hollow tank, the top of the tank is provided with a motor, a rotating shaft is vertically arranged in the tank, the output end of the motor is connected with the rotating shaft, one end of the rotating shaft far from the motor is provided with a scraper plate, a jacket is arranged outside the tank, a plurality of reinforcing ribs are arranged on the surface of the inner sidewall of the tank, the rotating shaft between the motor and the scraper plate is provided with a plurality of stirring blades, and the stirring blades are vertically arranged in a parallel interval manner; and the lower end of the tank is provided with a fixing seat. The apparatus has the advantages of good concentration effect, unlikely shaking of the rotating shaft driving the scraper plate to rotate, use safety, convenience and practicality.

Owner:酉阳县荞丰农产品开发有限公司

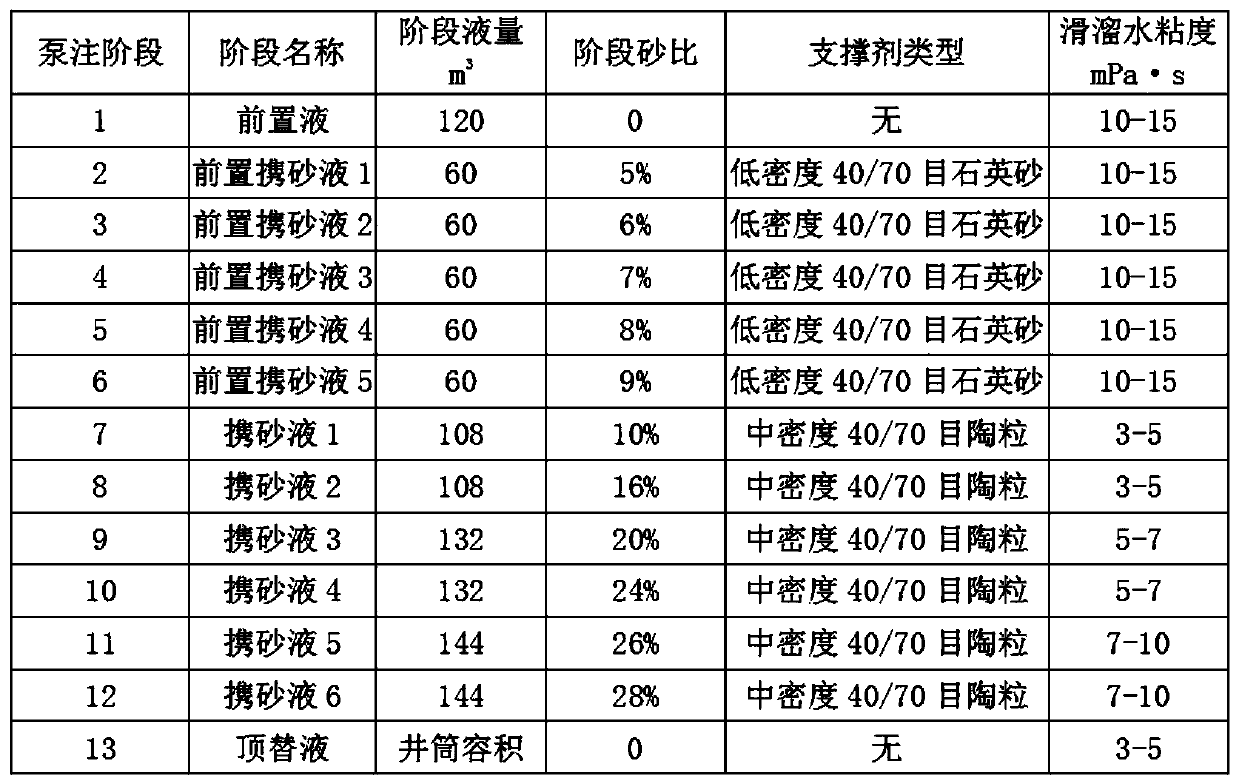

Fracturing method for improving laying effect of heterogeneous reservoir proppant

ActiveCN111396018AReduce construction frictionGuaranteed effective supportFluid removalDesign optimisation/simulationFracture controlGeotechnical engineering

The invention discloses a fracturing method for improving a laying effect of a heterogeneous reservoir proppant, and relates to the technical field of oil and gas field sand fracturing processes. According to the method, geological data of a target well are collected and evaluated; according to the target well reservoir permeability and the single artificial fracture control radius, the segment length, the cluster spacing and the cluster number are designed; the artificial fracture length, the flow conductivity, the fracturing fluid scale and the fracturing proppant scale are designed on the basis of achieving the optimal yield; testing fracturing is conducted on the target well, and the reservoir fracturing fluid efficiency of the target well is determined; the usage amounts of prepad fluid, prepad sand-carrying fluid and sand-carrying fluid are calculated according to the determined fracturing fluid scale and the determined fracturing fluid efficiency correspondingly; the use amountof displacing fluid is determined according to the volume of a target well shaft; and a pump injection program is generated according to the determined proppant scale as well as the determined amountsof the prepad fluid, the prepad sand-carrying fluid, the sand-carrying fluid and the displacing fluid, and fracturing operation is implemented. The method solves the technical problem that unsupported and invalid seams are formed in the fracturing process due to the fact that the proportion of the prepad fluid cannot be completely matched with a reservoir stratum in traditional fracturing design.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Glass etching solution, preparation method of glass etching solution and method for preparing anti-glare glass with glass etching solution

The invention discloses a glass etching solution. The glass etching solution is prepared from raw materials in percentage by weight as follows: 5%-15% of citric acid, 5%-15% of acetic acid, 20%-30% ofNH4F, 5%-10% of (NH4)2SiF6, 1%-5% of K2SiF6, 5%-15% of (NH4)2HPO4, 0.5%-1.5% of a viscosity regulator, 0.5%-1.5% of a surfactant and the balance of water. Meanwhile, the invention provides a corresponding preparation method of the glass etching solution and a method for preparing anti-glare glass with the glass etching solution. The glass etching solution has good stability and durability, and the prepared anti-glare glass is in the gloss 100-130 range required by vehicle mounting display, has the haze up to 6%-17% and the roughness of 0.040-0.065 mu m and has the performance superior to existing anti-glare glass.

Owner:ZHENGZHOU HIHO OPTICAL TECH CO LTD

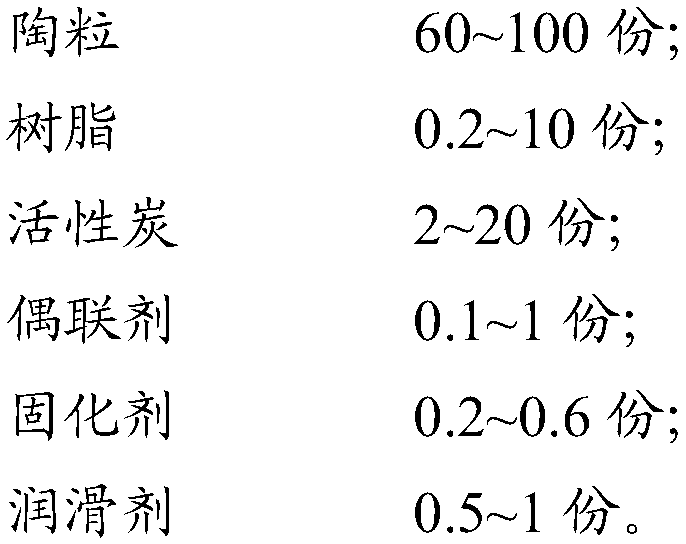

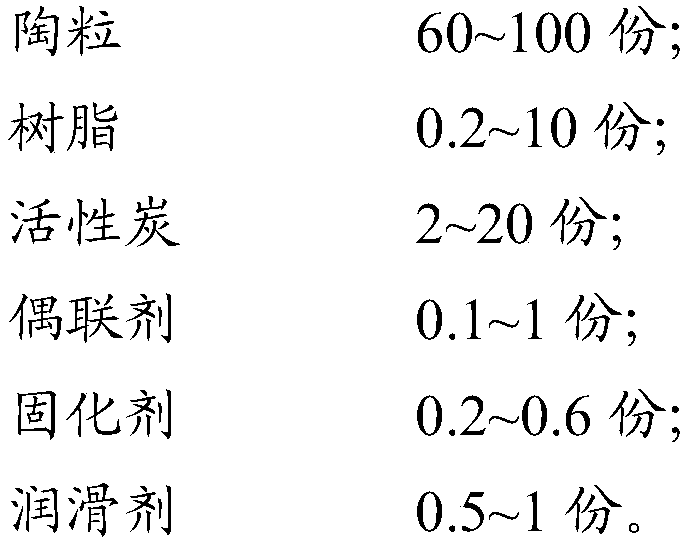

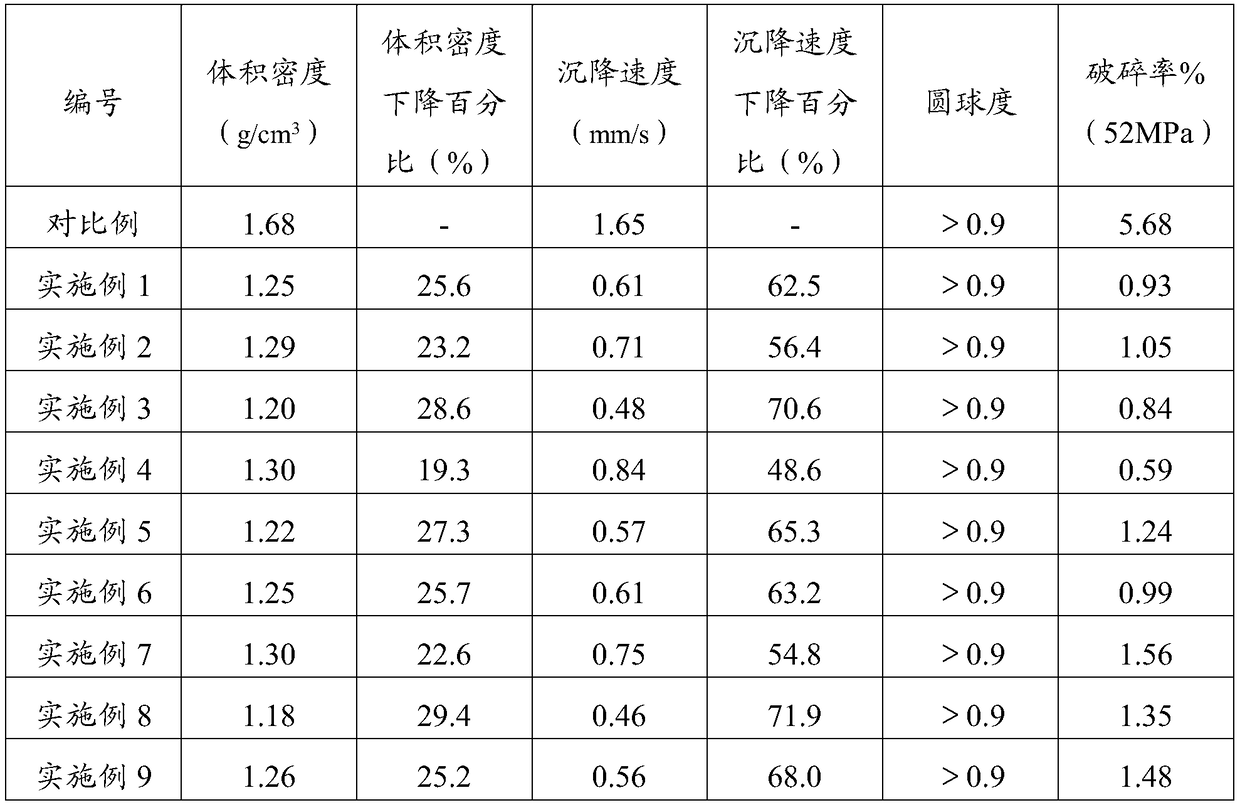

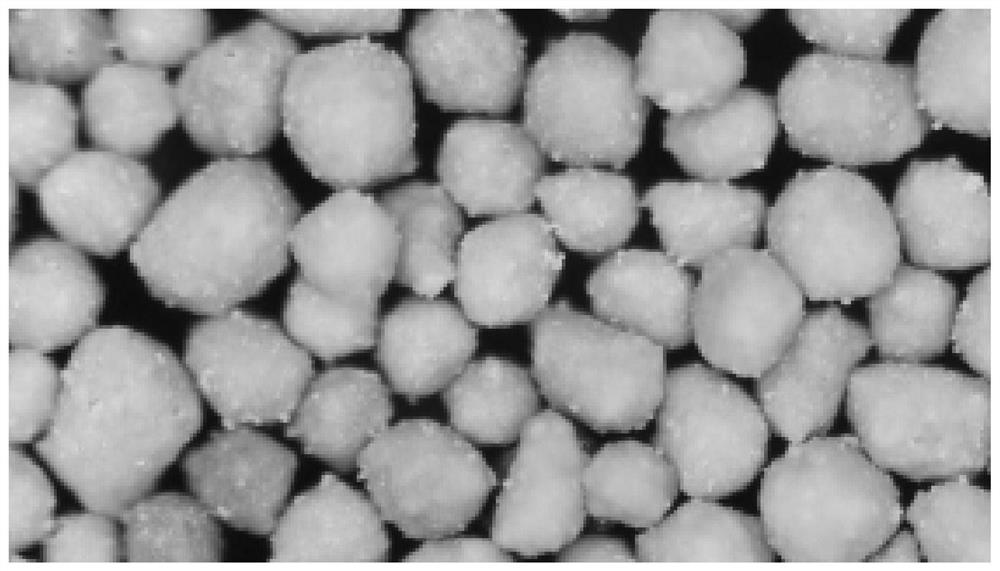

Low-density coated ceramsite proppant and preparation method thereof

InactiveCN109385263ARich in microporesCoated evenlyFluid removalDrilling compositionActivated carbonExpanded clay aggregate

The invention provides a low-density coated ceramsite proppant, and belongs to the technical field of hydraulic fracturing proppants. The low-density coated ceramsite proppant is prepared from the following raw materials in parts by weight: 60-100 parts of ceramsite, 0.2-10 parts of resin, 2-20 parts of activated carbon, 0.1-1 part of a coupling agent, 0.2-0.6 parts of a curing agent and 0.5-1 part of a lubricant. The activated carbon and resin are used as a film material and are applied to the surface of ceramsite under the action of the coupling agent by coating, and uniform coating and curing of the film material are achieved by cooperating with the curing agent and the lubricant; the activated carbon has rich micropores, and orifices of the activated carbon are closed by the resin material through mixing and curing with the resin. Thus, strength of the prepared coated ceramsite proppant can be ensured, certain gaps can be contained in the film material, and density is reduced; besides, the activated carbon has hydrophobic characteristic, and the hydrophobic surface of the activated carbon can reduce settling velocity of the activated carbon in fracturing fluid.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Ultrathin weather-resistant fire retardant coating for steel structure and preparation technology of ultrathin weather-resistant fire retardant coating

InactiveCN104673022AImprove mechanical propertiesImprove adhesionFireproof paintsAnti-corrosive paintsPtru catalystFoaming agent

The invention discloses an ultrathin weather-resistant fire retardant coating for a steel structure. The fire retardant coating comprises the following components: 24-30 parts of base resin, 17-23 parts of an intumescent flame retardant system, 8-15 parts of filler and pigment, 6-11 parts of auxiliaries, 17-22 parts of a solvent, 4-8 parts of modified nano-aluminum hydroxide and 1-3 parts of a plasticizer, wherein the intumescent system comprises components in parts by mass as follows: 8-10 parts of a dehydration catalyst, 5-7 parts of a charring agent and 2-4 parts of a foaming agent. The invention further designs a preparation technology of the ultrathin weather-resistant fire retardant coating for the steel structure. The preparation technology is simple, dense smoke and poison gas are not produced in the preparation process, and the prepared fire retardant coating has the advantages of environmental protection, ultrathin performance, weather resistance, fire retardance, durability, good fire retardant effect, low cost and good decoration performance.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

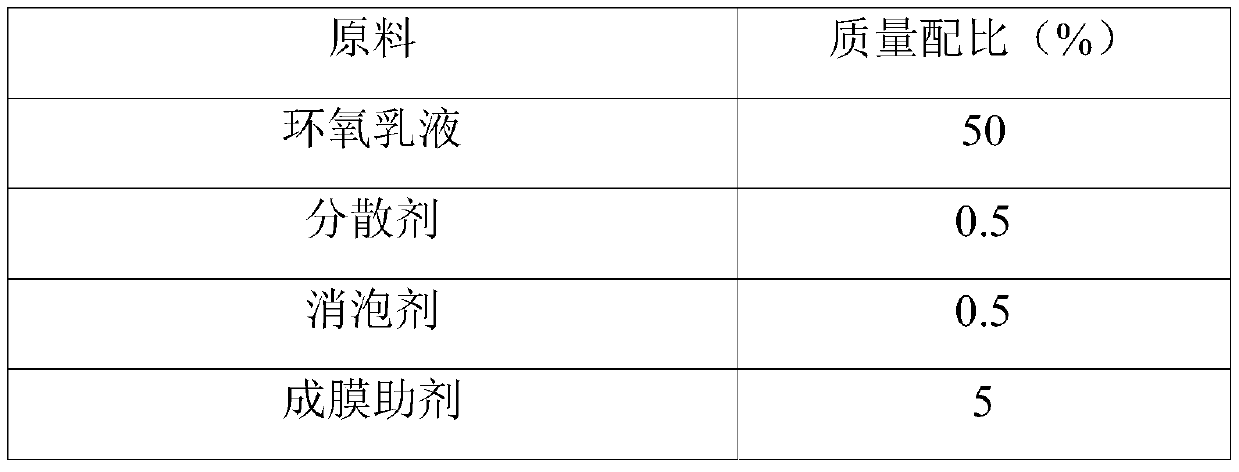

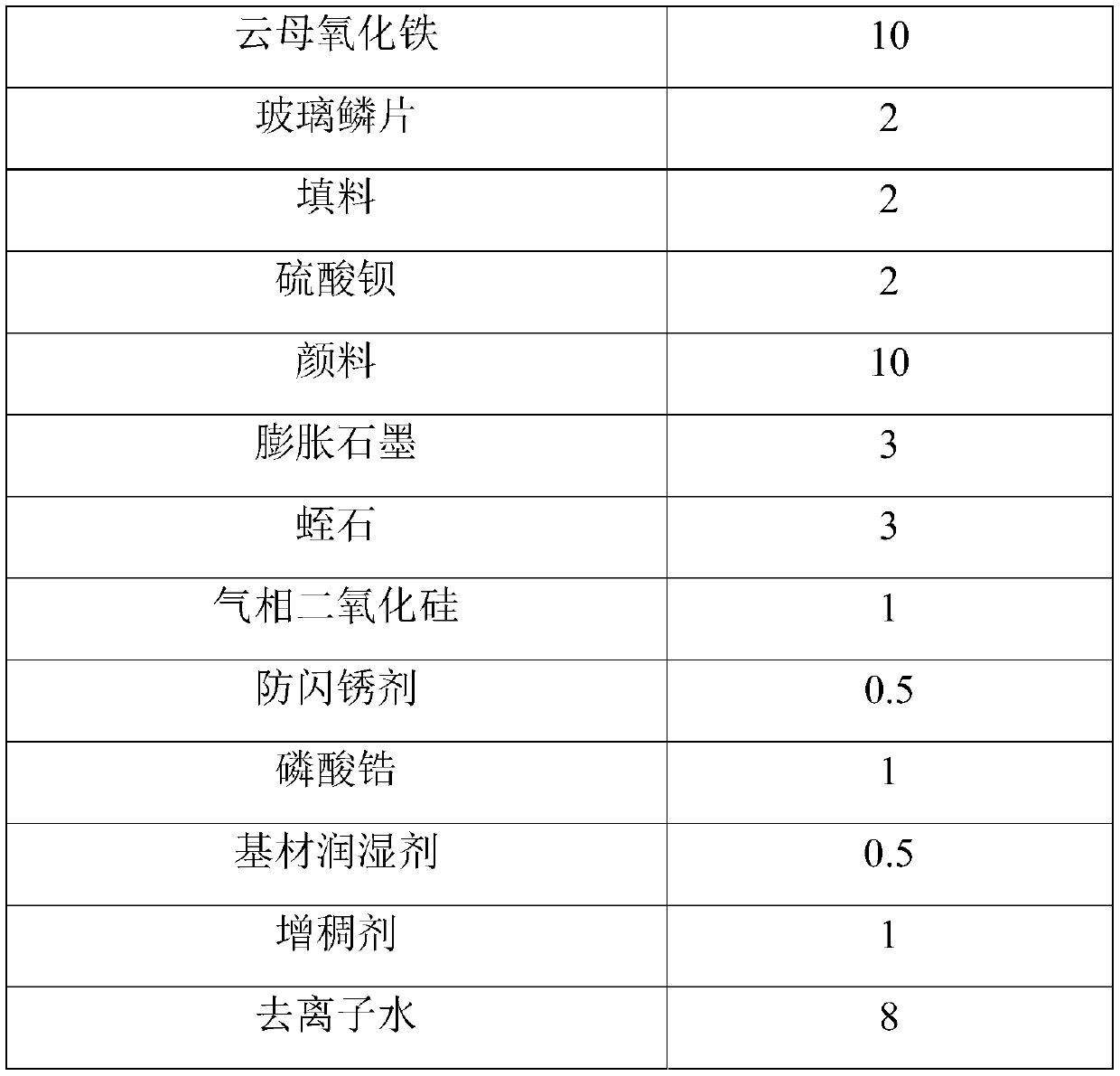

Waterborne intermediate paint coating and preparation method thereof

InactiveCN110373086AGood storage stabilityImprove sag resistanceFireproof paintsAnti-corrosive paintsEpoxySilicon dioxide

The invention relates to the technical field of coatings, and discloses a waterborne intermediate paint coating and a preparation method thereof. The waterborne intermediate paint coating is preparedfrom the component A and the component B; the component A is prepared from the following components in percentage by mass: epoxy emulsion, a dispersant, a defoamer, a coalescing agent, mica iron oxide, glass flake, fillers, barium sulfate, pigments, expanded graphite, vermiculite, silicon dioxide, an anti flash rust agent, zirconium phosphate, a base material wetting agent, a thickener and the balance of deionized water; the component B is prepared from the following components in percentage by mass: a curing agent and the balance of a coalescing agent; the mass ratio of the component A to thecomponent B is (4-8) to 1. The waterborne intermediate paint coating is good in flow resistance, stable in storage performance and anticorrosion performance, and good in adhesion, impact resistance,flame retardancy and flexibility performance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

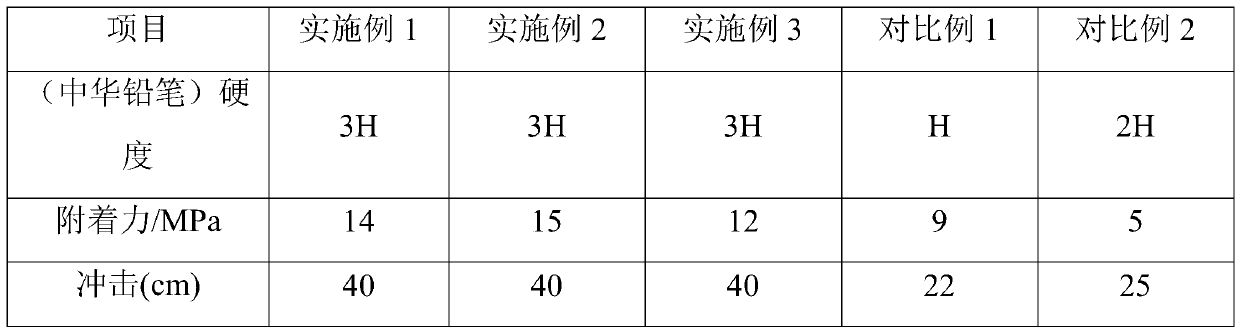

Emulsifying, stabilizing, water-retaining and thickening agent for food

The invention relates to the technical field of food, especially to a food additive. The invention provides an emulsifying, stabilizing, water-retaining and thickening agent for food to overcome the problems that conventional food additives have single function and do not have emulsifying, stabilizing, water-retaining and thickening functions at the same time. The emulsifying, stabilizing, water-retaining and thickening agent comprises, by weight, 55 to 60% of carrageenan, 20 to 25% of konjac glucomannan, 5 to 15% of xanthan gum, 0 to 10% of dextrin, 0 to 5% of potassium chloride and 0 to 5% of guar gum. The emulsifying, stabilizing, water-retaining and thickening agent employs a plurality of additives permitted to be used in food according to prescriptions in GB2760-2011 standard; raw materials are mixed together by using a physical method and applied to food; and the comprehensive effect of emulsification, stabilization, water retention and thickening is achieved.

Owner:何凯

Modified vinyl silicon resin and preparation method thereof, and paint composition containing resin and preparation method thereof

ActiveCN103059307AIncrease storage capacityIncrease elasticityCoatingsSolid contentUltimate tensile strength

The invention provides a modified vinyl silicon resin. The invention also provides a preparation method of the modified vinyl silicon resin and a paint containing the modified vinyl silicon resin. The paint composition prepared from the modified vinyl silicon resin has the advantages of low viscosity, high construction solid content and high VOC (volatile organic compound) content. The paint provided by the invention has the advantages of high settling grade, high storage stability, favorable percentage of elongation and favorable tearing strength.

Owner:BYD CO LTD

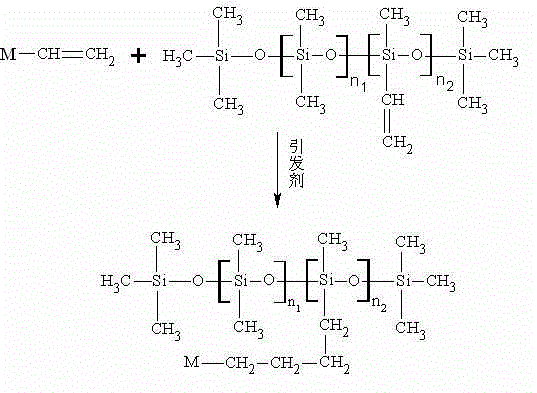

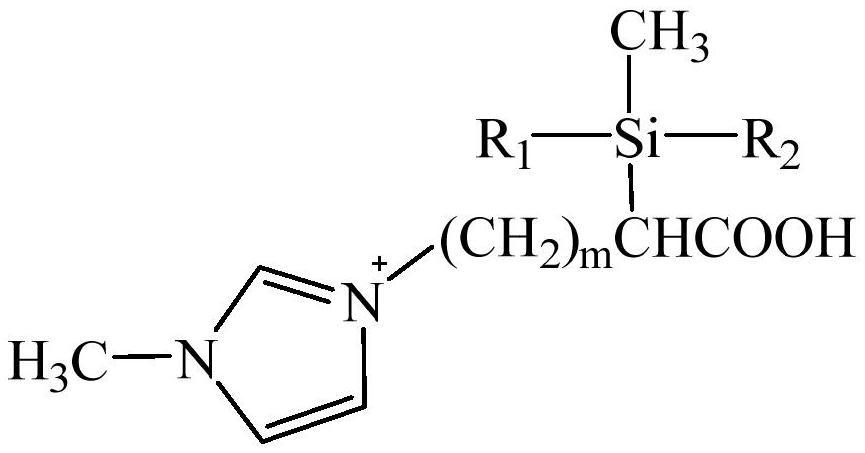

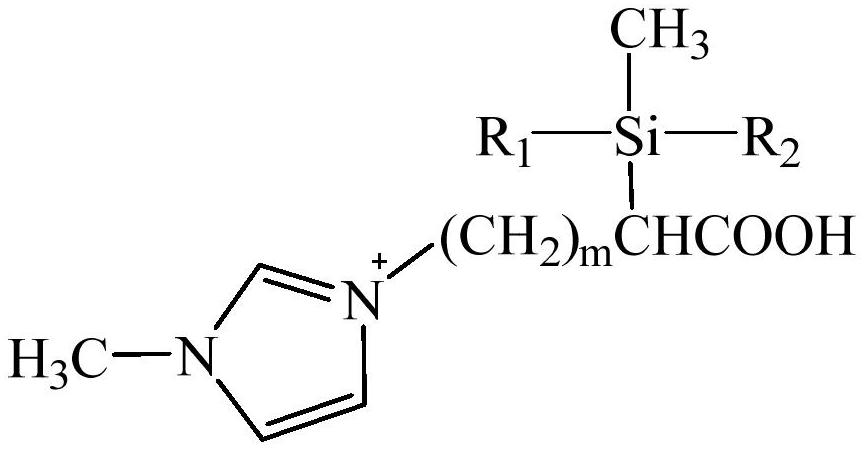

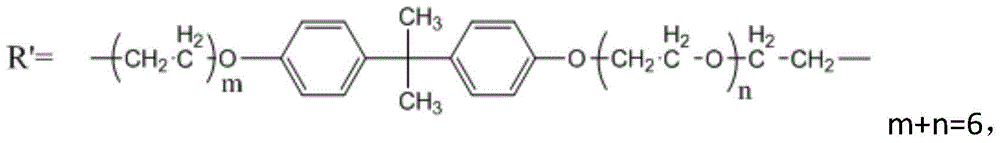

Temperature-resistant salt-resistant heterogeneous nano-composite oil displacement system as well as preparation method and application thereof

ActiveCN113292981AImprove stabilityNo decompositionSilicon organic compoundsDrilling compositionViscosityPetroleum engineering

Owner:山东聚星石油科技有限公司

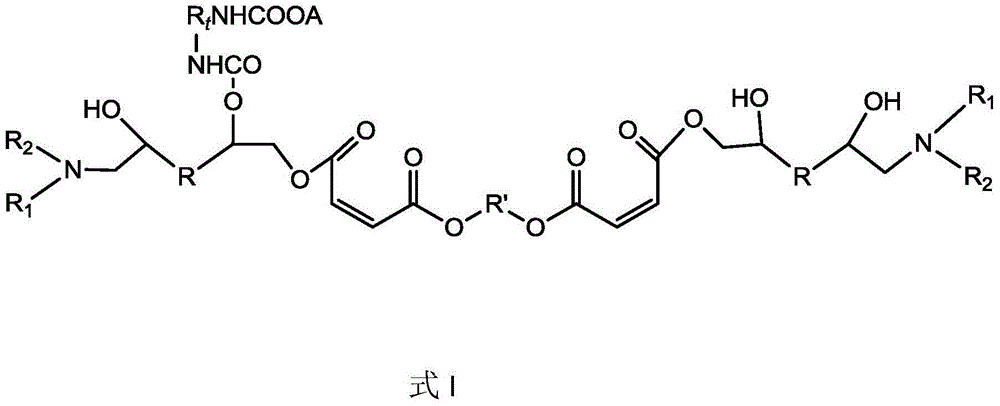

Epoxy resin used for cathode electrophoretic coating and independent of circulation and preparation method of epoxy resin

ActiveCN104803885AEasy to wrapReduce sedimentation velocityCarbamic acid derivatives preparationOrganic compound preparationLeveling effectSide chain

The invention relates to the technical field of cathode electrophoretic coatings, in particular to epoxy resin used for a cathode electrophoretic coating and capable of guaranteeing normal use without dependence of circulation as well as a preparation method of the epoxy resin. According to the epoxy resin, bisphenol A polyoxyethylene ether resin participates in chain extension and is modified by amine, meanwhile, semi-closed isocyanate is introduced on a side chain, and a side group comprises inclusion and a highly toughening main chain. The epoxy resin has a good appearance leveling effect and throwing power; the filler and pigment settling speed is greatly decreased when the coating stops circulating, and the coating after the circulation is stopped can be used normally when the circulation is performed again.

Owner:HAOLISEN COATING SHANGHAI

Adhesive for louver grinding disc and preparation method of adhesive

InactiveCN107118730AImprove mechanical propertiesImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyPolymer science

The invention discloses an adhesive for a louver grinding disc. The adhesive is prepared by mixing a component A and a component B, wherein the component A is prepared from the following components: titanium hydroxide emulsion, sulfuric acid, compound rare earth, an organic solvent, a flame retardant, a foaming agent, pigment and filler, a rheological auxiliary agent and a dehydration catalyst; the component B is prepared from the following components: polypropylene carbonate dihydric alcohol, diisocyanate, acrylic resin, epoxy resin, a thickener, a de-foaming agent, a flatting agent, an anti-skinning agent, a curing agent and a coupling agent. The invention further designs a preparation method of the adhesive for the louver grinding disc; the preparation method provided by the invention is simple and feasible; the prepared adhesive has good flame-retarding and heat-resisting properties and has long service life.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

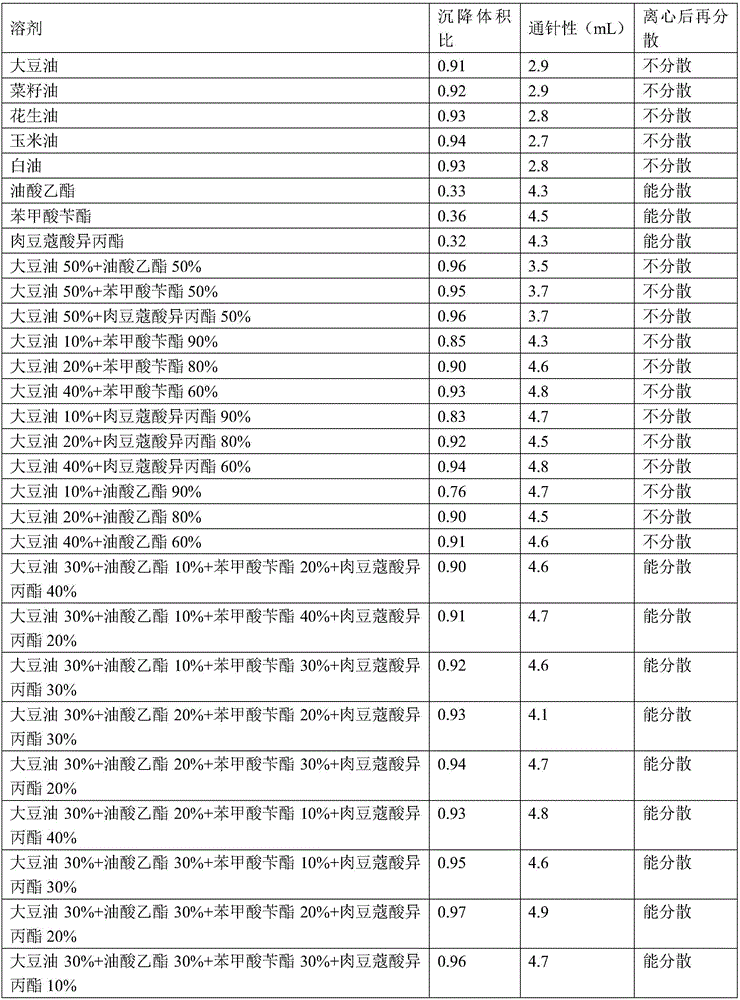

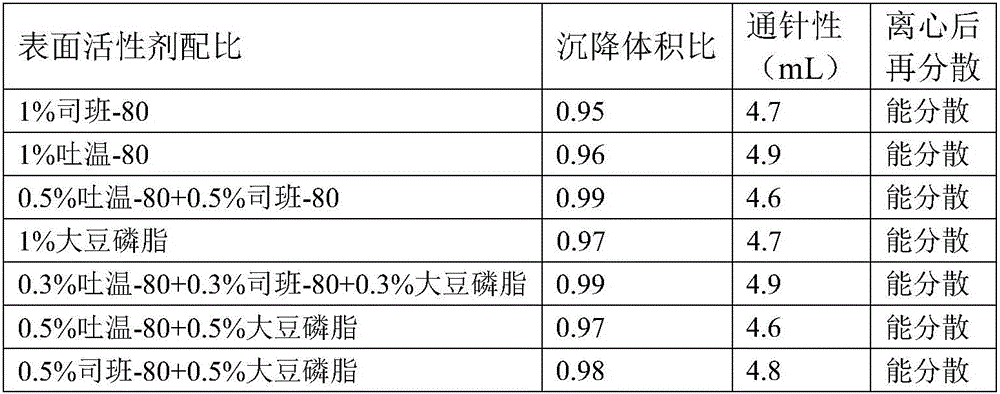

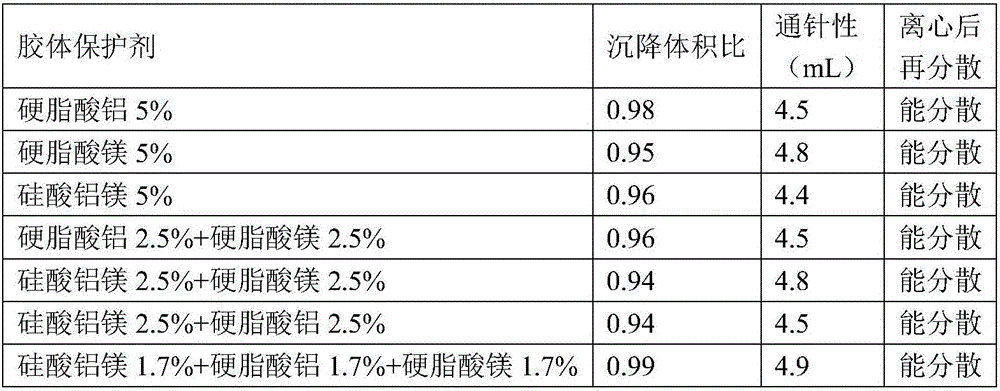

Cefquinome sulfate oil suspension and preparation method thereof

ActiveCN106344509AImprove qualityReduce volumeAntibacterial agentsOrganic active ingredientsDispersityDrug content

The invention discloses a cefquinome sulfate oil suspension. Every 100mL of the suspension contains the following raw and auxiliary materials: 2-15g of cefquinome sulfate, 0.9-1.0g of surfactant, 5.0-5.1g of colloid protective agent, 2.0-8.0g of suspending agent, 0-0.1g of antioxidant and the balance of oil phase. The high-quality cefquinome sulfate oil suspension with the main drug content of 2-15% is obtained by screening the formula. The used auxiliary materials lower the drug sedimentation volume and sedimentation rate. The product has the advantages of low flowability, low sedimentation rate, high sedimentation volume, high needle penetration property and favorable dispersity after centrifugation. In addition, the inspection on the stability under different temperature conditions further proves the high quality of the suspension.

Owner:CHENGDU QIANKUN VETERINARY PHARMA

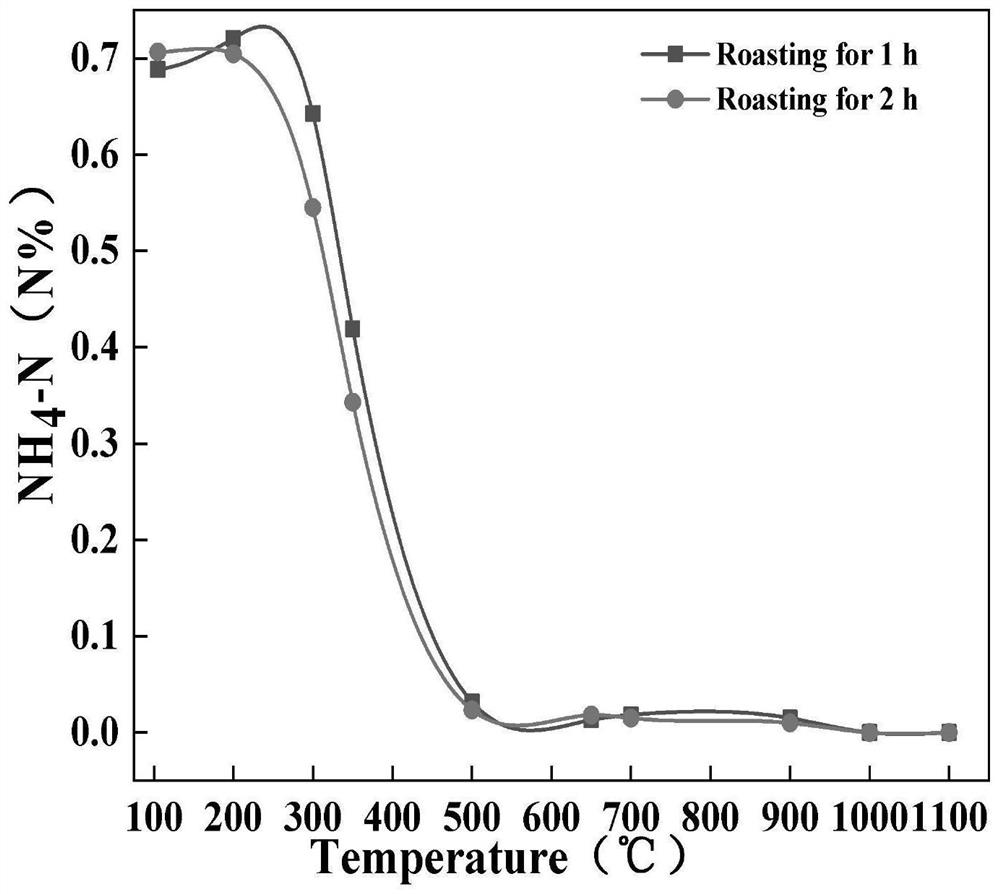

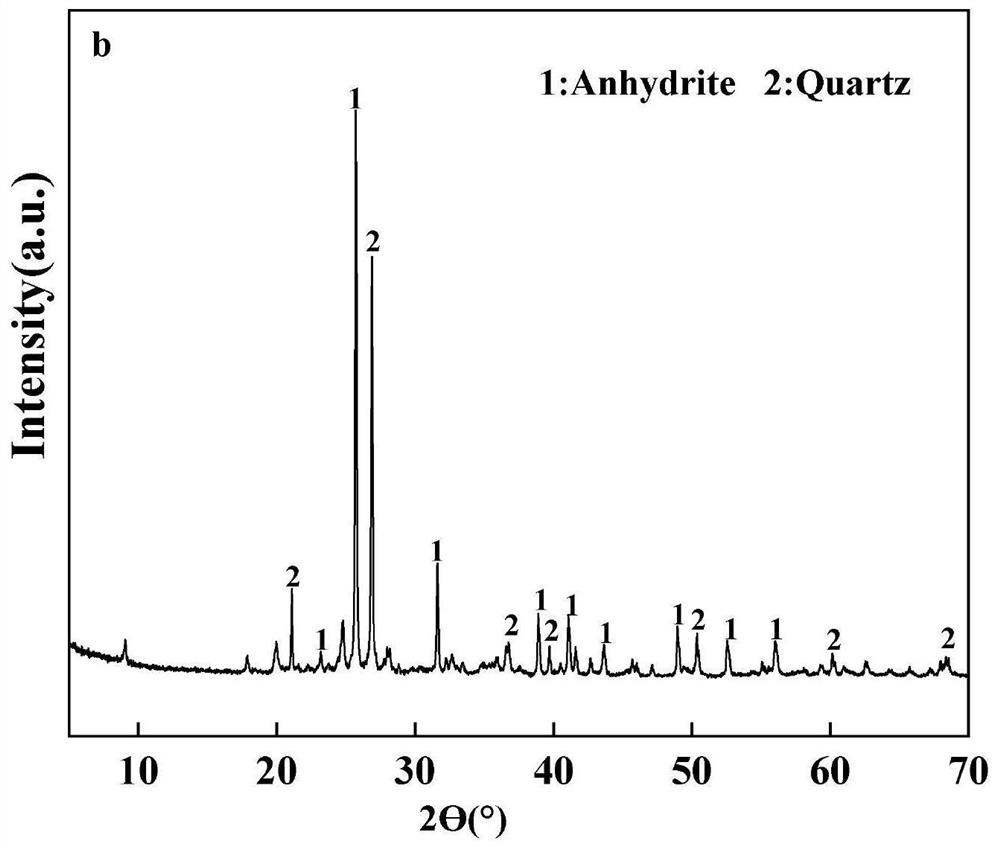

Preparation method and application of low-density ceramsite proppant added with pretreated electrolytic manganese residues

ActiveCN112919889AReduce bulk densitySimple peak shapeFluid removalDrilling compositionElectrolysisPhysical chemistry

The invention discloses a preparation method and application of a low-density ceramsite proppant added with pretreated electrolytic manganese residues. The low-density ceramsite proppant is mainly prepared from the following raw materials: pretreated electrolytic manganese residues and bauxite, wherein the mass fraction of the pretreated electrolytic manganese residues is 15-20%; the pretreated electrolytic manganese residues are obtained by calcining waste residues obtained after a process of extracting manganese metal through wet electrolysis for 2-3 hours at the temperature of 650-750 DEG C. The performance of the prepared low-density ceramsite proppant meets the SY / T5108-2014 industrial standard, the low-density ceramsite proppant can be used for replacing natural quartz sand to be used for fracturing operation under the closing pressure of 52 MPa, and the low-density ceramsite proppant is particularly used for hydraulic fracturing exploitation of shallow petroleum and natural gas. According to the prepared low-density ceramsite proppant, the pretreated electrolytic manganese residues can be added in a large proportion, and the adding proportion can reach 15-20%. In the preparation method, the sintering temperature is further reduced after the ball blank is obtained through treatment, and only the temperature of 1150-1250 DEG C is needed.

Owner:GUIZHOU UNIV

Processing process and formula of finished natural asphalt cementing agent

The invention provides a processing process and a formula of a finished natural asphalt cementing agent, which finishes the history that natural asphalt can only be used as asphalt or an asphalt admixture. The finished natural asphalt cementing agent for asphalt admixture is prepared and can be stored for a long time and transported, and the problem of ductility loss in the natural asphalt application process is solved. Natural asphalt is crushed to be in the granularity of 300 meshes and added to an organic dispersant containing a surfactant in proportion to be dispersed into a flowable mixture, the mixture is ground into a micro-nano mixture in the granularity of 6,000 meshes or above, the micro-nano mixture is mixed with pavement petroleum asphalt in the proportion of (1:100)-(10:1), 1%-10% of a plasticizer and 1 per mill to 10 per mill of a stabilizer are added to the mixture, the mixture is stirred and reacts for 2-6 h, and the asphalt cementing agent for roads or buildings is obtained.

Owner:西咸新区众力沥青有限公司 +1

Insulator airtightness detection system and method

InactiveCN105043683AGood dispersionIncrease profitDetection of fluid at leakage pointFluorescenceUltraviolet lights

The invention relates to an insulator airtightness detection system and method. The detection system comprises an insulator and ultraviolet light sources. A cavity of the insulator is provided with air with fluorescent powder micro particles. The fluorescent powder micro particles are uniformly distributed in the air. The particle diameter of each fluorescent powder particle is 0.2-2.0 mum. The ultraviolet light sources are distributed around the insulator. One end of the insulator is enclosed and the other end thereof is provided with an air inlet. The ultraviolet fluorescent powders have very good floating performance, and can be distributed to each corner uniformly with the air, so that leak detection can be carried out on narrow and small spaces and concealed areas; the smaller the diameter of each ultraviolet fluorescent powder is, the smaller the dimension of each detectable leak point is; and the leak detection method can carry out accurate positioning on the leak points, and visual and obvious effects are achieved. The method can realize the purpose of detecting whether leakage exists through the fluorescence effect, and has the advantages of being simple to operate, small in workload, safe and reliable, good in detection effect and low in cost and the like.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Ceftiofur hydrochloride injection for dairy cattle and preparation method thereof

ActiveCN107049943AImprove dispersion stabilityGood acupunctureAntibacterial agentsOrganic active ingredientsDispersion stabilityAntioxidant

The invention provides ceftiofur hydrochloride injection for dairy cattle, comprising, by weight, 5-10 parts of ceftiofur hydrochloride, 0.5-3 parts of a suspending agent, 0.05-5 parts of a flocculant, 0.01-2 parts of an emulsifier, 0.1-2 parts of an antioxidant, and 55-100 parts of a lipid solvent. The ceftiofur hydrochloride injection has good dispersion stability and good needle passage, milk withdrawal period of dairy cattle injected with the ceftiofur hydrochloride injection is short, and the ceftiofur hydrochloride injection has a promising application prospect. A preparation method of the ceftiofur hydrochloride injection for dairy cattle is also provided; the preparation method is simple to perform and applicable to industrial application.

Owner:ZHENGZHOU BARY ANIMAL PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com