Coal water slurry dispersant and preparation method thereof

A technology of dispersant and coal-water slurry, which is applied in the field of coal-water slurry dispersant and its preparation, can solve the problems of rough flow pattern, high water absorption, reduced Zeta potential, etc. Viscosity, effect of slowing down the settling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

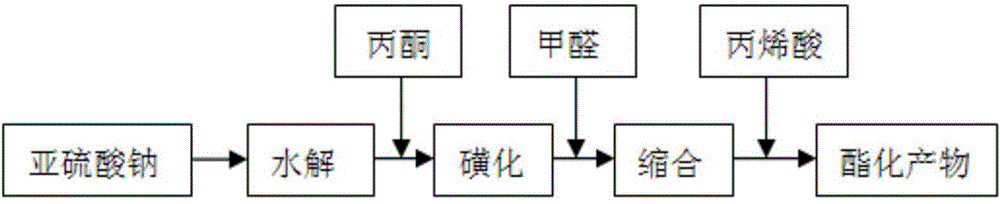

Method used

Image

Examples

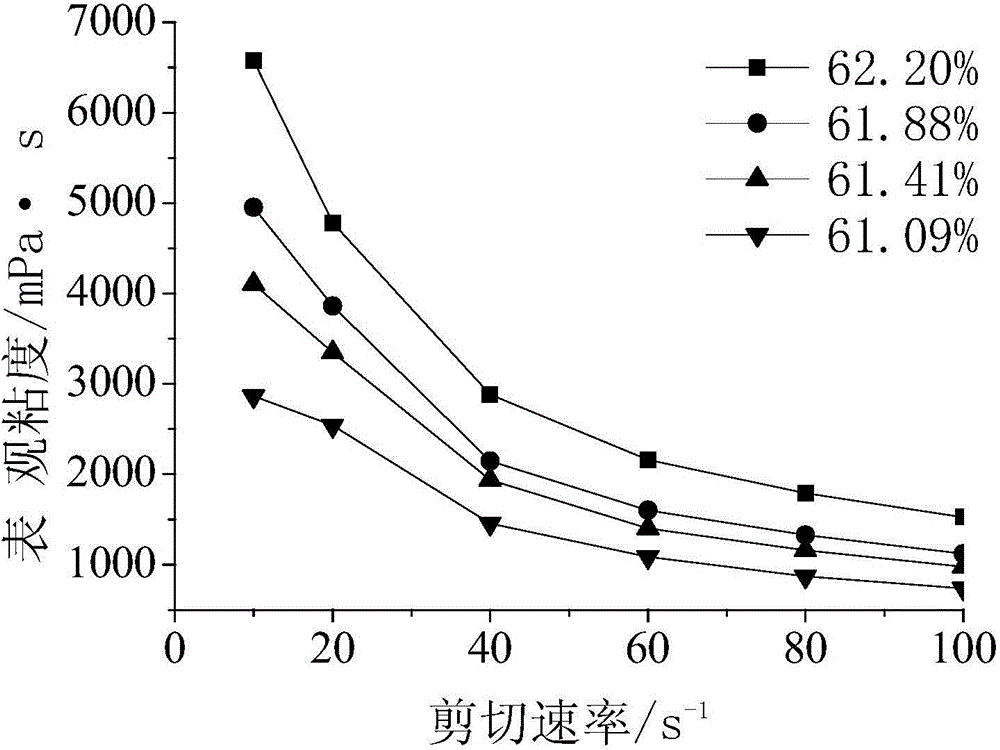

Embodiment 1

[0059] At a stirring rate of 120r / min and a temperature of 25°C, add 0.05mol of sodium sulfite powder into a three-necked flask filled with 50mL of water for dissolution. Then, the temperature was raised to 50°C, and 0.3mol formaldehyde was slowly added dropwise to the three-necked flask with a constant pressure funnel, the temperature was raised to 90°C, and the reaction was continued for 30 minutes to obtain a red liquid containing formaldehyde-acetone condensation polymer.

[0060] The red liquid decompression distillation that contains formaldehyde acetone condensation polymer is to remove remaining water, then in there-necked flask, continue to add p-toluenesulfonic acid (addition is 2% of the red liquid quality in the there-necked flask) and 0.1mol Acrylic acid was heated in a magnetic stirring heating mantle equipped with a reflux condenser, reacted at a temperature of 90°C for 6 hours, and the reaction was terminated to obtain a mixed solution containing monomers and ac...

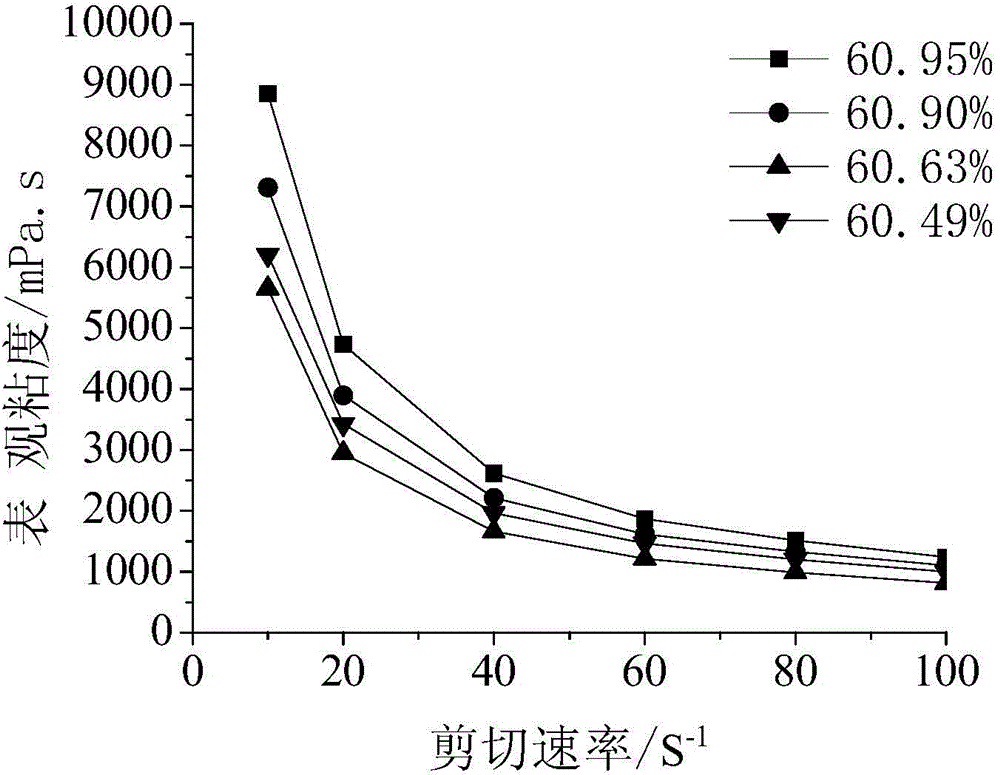

Embodiment 2

[0065] At a stirring rate of 100r / min and a temperature of 26°C, add 0.1mol of sodium sulfite powder into a three-necked flask filled with 55mL of water for dissolution. Then, the temperature was raised to 48°C, and 0.5 mol of formaldehyde was slowly added dropwise to the three-necked flask with a constant pressure funnel, the temperature was raised to 88°C, and the reaction was continued for 35 minutes to obtain a red liquid containing formaldehyde-acetone condensation polymer.

[0066] The red liquid decompression distillation that contains formaldehyde acetone polycondensate is to remove remaining water, then in there-necked flask, continue to add p-toluenesulfonic acid (the addition is 2.5% of the red liquid quality in the there-necked flask) and 0.15mol Acrylic acid was heated in a magnetic stirring heating mantle equipped with a reflux condenser, reacted at a temperature of 90°C for 5 hours, and the reaction was terminated to obtain a mixed solution containing monomers an...

Embodiment 3

[0071] At a stirring rate of 100r / min and a temperature of 28°C, add 0.07mol of sodium sulfite powder into a three-necked flask filled with 50mL of water for dissolution. Then, the temperature was raised to 55°C, and 0.26 mol of formaldehyde was slowly added dropwise to the three-necked flask with a constant pressure funnel, the temperature was raised to 92°C, and the reaction was continued for 38 minutes to obtain a red liquid containing formaldehyde-acetone condensation polymer.

[0072] The red liquid decompression distillation that contains formaldehyde acetone polycondensate is to remove remaining water, then in the there-necked flask, continue to add p-toluenesulfonic acid (addition is 3% of the red liquid quality in the there-necked flask) and 0.2mol Acrylic acid was heated in a magnetic stirring heating mantle equipped with a reflux condenser, reacted at a temperature of 100°C for 5.5 hours, and the reaction was terminated to obtain a mixed solution containing monomers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com