Temperature-resistant salt-resistant heterogeneous nano-composite oil displacement system as well as preparation method and application thereof

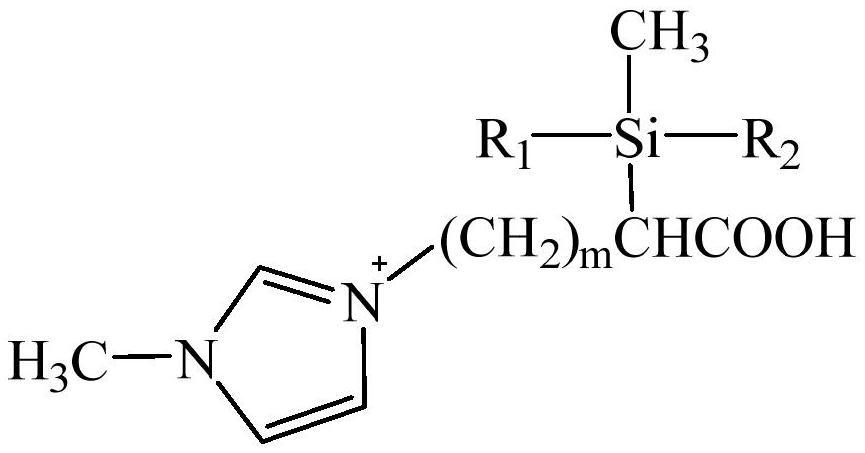

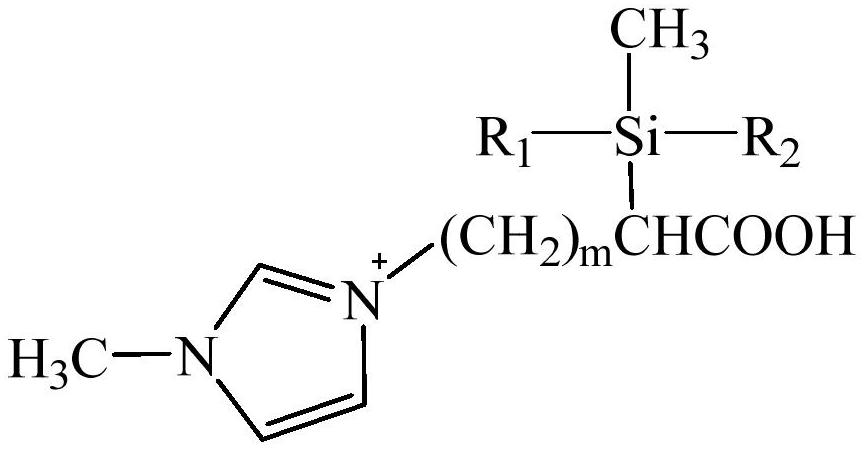

A nano-composite, temperature-resistant and salt-resistant technology, applied in chemical instruments and methods, silicon-organic compounds, drilling compositions, etc. The problems of poor salt tolerance and low permeability can achieve the effect of excellent imbibition oil recovery performance, improving suspension performance, and promoting the speed of particle settling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Weigh the required surfactant and nano-SiO 2 The aqueous dispersion is made into a nano-osmotic agent solution with a concentration of 1.2%;

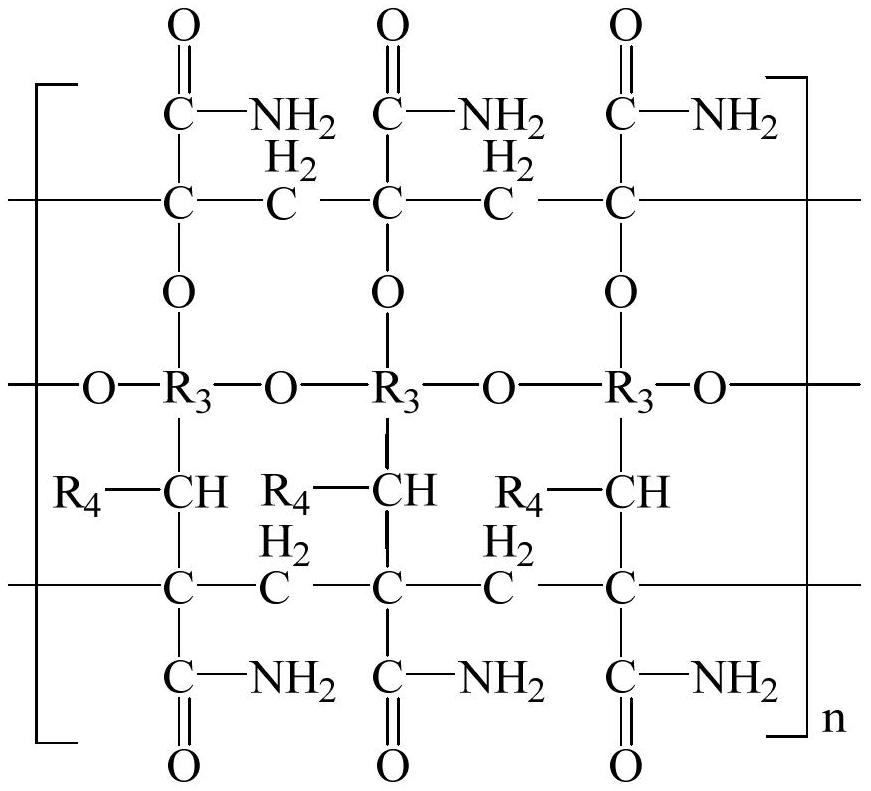

[0092] Accurately weigh 1.1071g instant polymer sample (R 3 = Re, R 4 =-CH 3 , n=35000), weighed 198.8929g of simulated brine in a 500mL beaker, started the constant speed stirrer and slowly added the sample along the vortex wall at (400±20)r / min for 30s, then stirred at a rate of (700 After stirring for 1 h at ±20) r / min, the concentration of the resulting solution was 5000 mg / L. After standing for 24 hours, stir slightly with a glass rod and then dilute the solution to a concentration of 2000mg / L;

[0093] Accurately weigh 5.5036g of pre-crosslinked gel particle samples, weigh 994.4964g of simulated saline in a 1000mL jar, turn on the constant speed stirrer and slowly add the sample along the vortex wall at (400±20)r / min for 30s. Sample, then stirred at a stirring rate of (500±20) r / min for 2 hours, the concentration of th...

Embodiment 2

[0097] Weigh the required surfactant and nano-SiO 2 The aqueous dispersion is made into a nano-osmotic agent solution with a concentration of 1.25%;

[0098] Accurately weigh 1.1049g instant polymer sample (R 3 = Mo, R 4 =-CH 2 CH 2 CH 2 CH 3 , n=43000), weighed 198.8951g simulated brine in a 500mL beaker, started the constant speed stirrer and slowly added the sample along the vortex wall at (400±20)r / min for 30s, then stirred at a rate of (700 After stirring for 1 hour at ±20) r / min, the concentration of the resulting solution is 5000 mg / L;

[0099] Accurately weigh 5.4867g of pre-crosslinked gel particle samples, weigh 994.5133g of simulated saline into a 1000mL jar, turn on the constant speed stirrer and slowly add the sample along the vortex wall at (400±20)r / min within 30s. Sample, then stirred at a stirring rate of (500±20) r / min for 2h, the concentration of the resulting solution was 5000mg / L, slightly stirred with a glass rod and then diluted to a concentration...

Embodiment 3

[0103] Weigh the required surfactant and nano-SiO 2 The aqueous dispersion is made into a nano-osmotic agent solution with a concentration of 3.0%;

[0104] Accurately weigh 1.1029g instant polymer sample (R 3 = Re, R 4 =-CH 2 CH 3 , n=40000), weighed 198.8971g of simulated brine in a 500mL beaker, started the constant speed stirrer and slowly added the sample along the vortex wall at (400±20)r / min for 30s, then stirred at a rate of (700 After stirring for 1 h at ±20) r / min, the concentration of the obtained solution was 5000 mg / L, and after stirring slightly with a glass rod, the concentration of the solution was diluted to 4000 mg / L.

[0105] Accurately weigh 5.4831g of pre-crosslinked gel particle samples, weigh 994.5169g of simulated saline into a 1000mL jar, turn on the constant speed stirrer and slowly add the sample along the vortex wall at (400±20)r / min within 30s. Sample, then stirred at a stirring rate of (500±20) r / min for 2 hours, the concentration of the obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com