Epoxy resin used for cathode electrophoretic coating and independent of circulation and preparation method of epoxy resin

A cathodic electrophoretic coating and epoxy resin technology, which is applied in the preparation of electrophoretic coatings, epoxy resin coatings, organic compounds, etc., can solve the problems of low solid content, achieve the effect of reducing the sedimentation speed and improving the wrapping ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

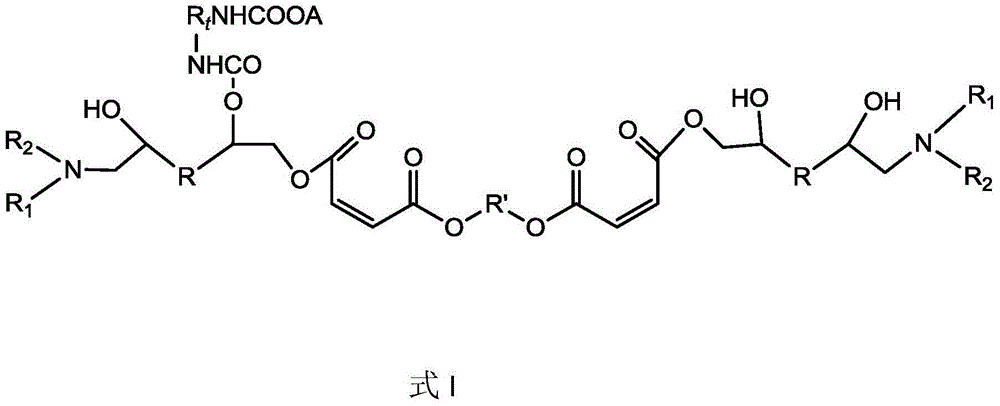

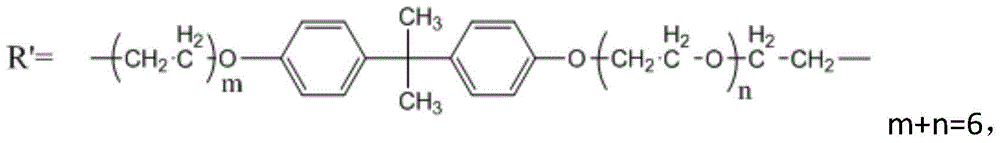

Method used

Image

Examples

Embodiment 1

[0037] Preparation of carboxylated bisphenol A polyoxyethylene ether

[0038] The specific formula is as follows:

[0039] Substance name

Servings (g)

Bisphenol A polyoxyethylene ether

560

200

2

30

[0040] Add bisphenol A polyoxyethyl ether, succinic anhydride, triethylamine and xylene into a four-necked flask equipped with a thermometer, a stirring paddle and a condenser tube, raise the temperature to 85°C, keep the temperature for 5 hours, and then cool down and discharge the material, namely Get carboxylated bisphenol A polyoxyethylene ether. Store in a dry airtight container for later use. The reaction formula is as follows:

[0041]

Embodiment 2

[0043] The specific formula is as follows:

[0044] Substance name

Servings (g)

Example 1 Resin

90

128 epoxy resin

200

1

[0045] In a four-neck flask equipped with a thermometer, a stirring paddle, and a condenser, add 128 epoxy resin (produced by Nanya Company, epoxy equivalent 186) and then add the resin of Example 1. Add triethylamine as a catalyst, raise the temperature to 130°C, keep the temperature for 3 hours, then cool down and discharge the material to obtain an epoxy resin with an epoxy equivalent of about 1100, and put it in a clean and sealed container for later use. The reaction formula is as follows:

[0046]

Embodiment 3

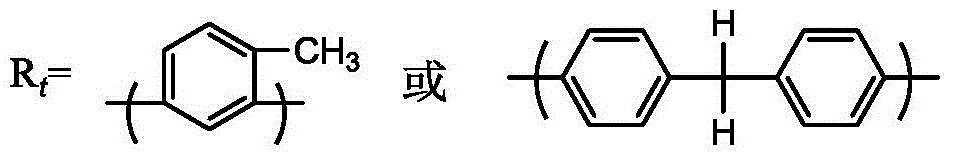

[0048] Preparation of semi-blocked isocyanates.

[0049] The specific formula is as follows:

[0050] Substance name

Servings (g)

Toluene diisocyanate

200

100

Diethylene glycol monobutyl ether

185

[0051] In a four-necked flask equipped with a thermometer, a stirring paddle, and a condenser tube, add toluene diisocyanate and methyl isobutyl ketone, and heat up to 50°C. Add diethylene glycol ethylene glycol monobutyl ether dropwise into it. About two hours after the completion of the dropwise addition, the insulation was continued for two hours to obtain a semi-blocked isocyanate. Put it in a dry and sealed container for later use, the reaction formula is as follows:

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com